Piezoelectric sensor and method for simulating dam slope collapse self-powered monitoring through vibration table by usingpiezoelectric sensor

A piezoelectric sensor and vibrating table technology, used in the field of monitoring slope accidents and piezoelectric sensors, can solve the problems of impact, difficulty in guaranteeing the safety of workers, and high human and material resources, and achieve cost reduction, high efficiency, real-time performance, and excellent high temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

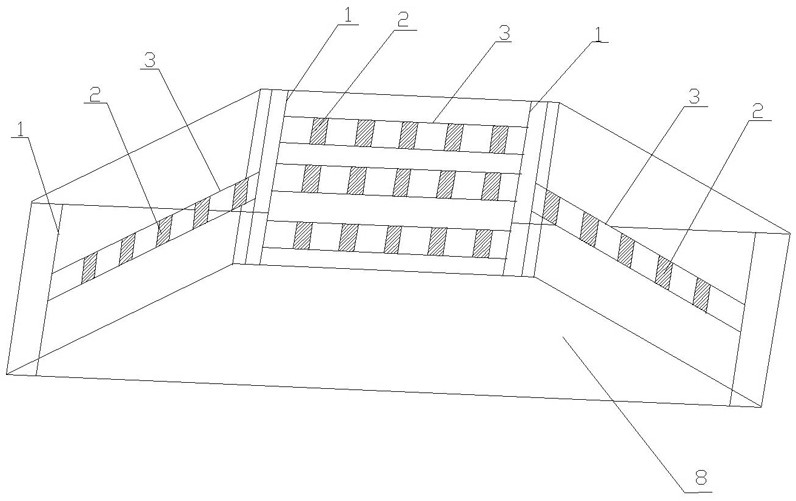

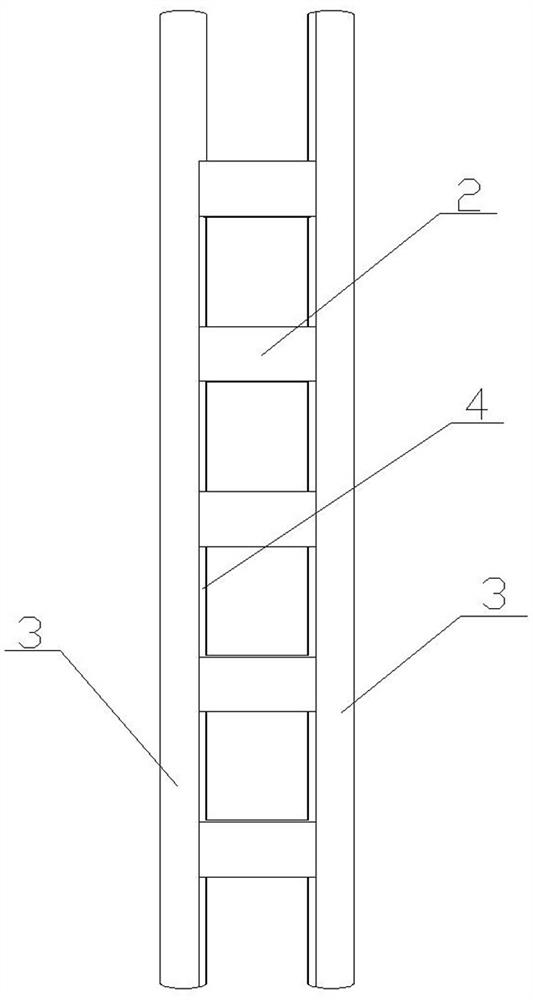

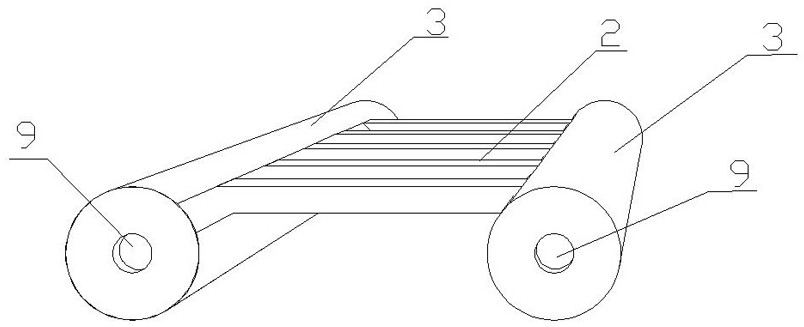

[0017] refer to Figure 1-Figure 6 As shown, the present invention provides a piezoelectric sensor, which includes a piezoelectric assembly and a fixed steel frame 1 for fixing the piezoelectric assembly. The piezoelectric assembly includes a plurality of piezoelectric rulers 2 and two steel rails 3 . The rail 3 is a circular tubular hollow rail, and the two rails 3 are arranged opposite to each other. There is a groove 4 on one side of the rail 3, and the grooves 4 of the two rails are placed opposite to each other. There are multiple fixed joints 13 in the groove 4, and the two ends of the piezoelectric ruler are respectively inserted into the fixed joints 13 of the steel rails on both sides and fixed by epoxy resin glue. The epoxy resin adhesive uses 3M-DP460 epoxy resin adhesive to prevent it from falling off due to vibration during use. The distance between adjacent fixed joints 13 is 50MM. A plurality of piezoelectric rulers 2 are respectively fixed between two steel r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com