Precision instrument guide rail system based on circular rolling element array arrangement and cambered surface clamping and positioning

A technology for clamping and positioning precision instruments, applied in the directions of instruments, measuring instrument components, bearings for linear motion, etc., it can solve the problems of inability to adjust the supporting force of the supporting surface, complex locking mechanism, low stiffness of the guide rail, etc., and achieve high motion accuracy. and stability, avoiding guide rail motion guide errors, and good bearing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

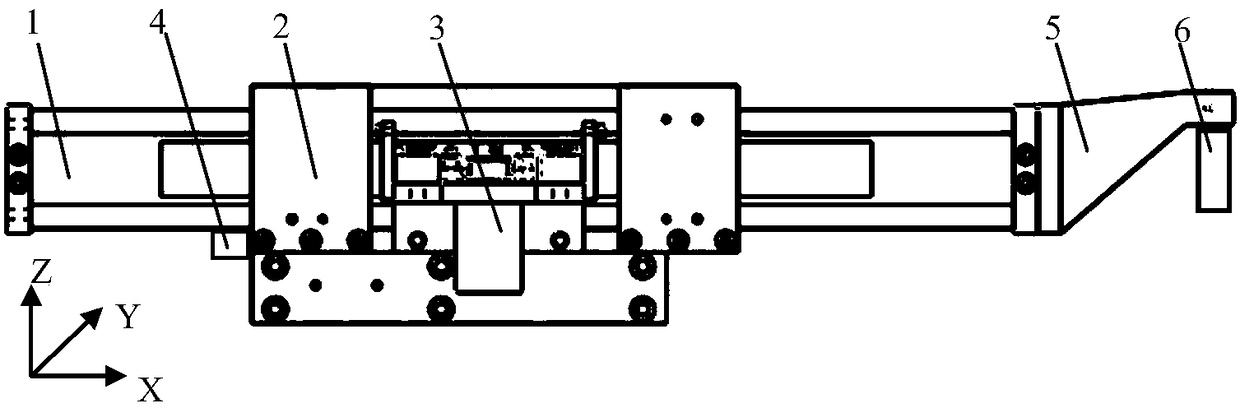

[0032] Depend on figure 1 As shown, the precision instrument rail system based on the array arrangement of circulating rolling elements and the clamping and positioning of the arc surface includes a rail component 1, a rail frame component 2, a driving component 3, a position detection component 4 and a sensor clamping and locking component 5; the driving component 3 Drive the guide rail part 1 to move back and forth along the X-axis direction in the guide rail frame part 2, and the sensor clamps the locking part 5 to lock the positioning sensor 6; the friction form between the guide rail part 1 and the guide rail frame part 2 is rolling friction .

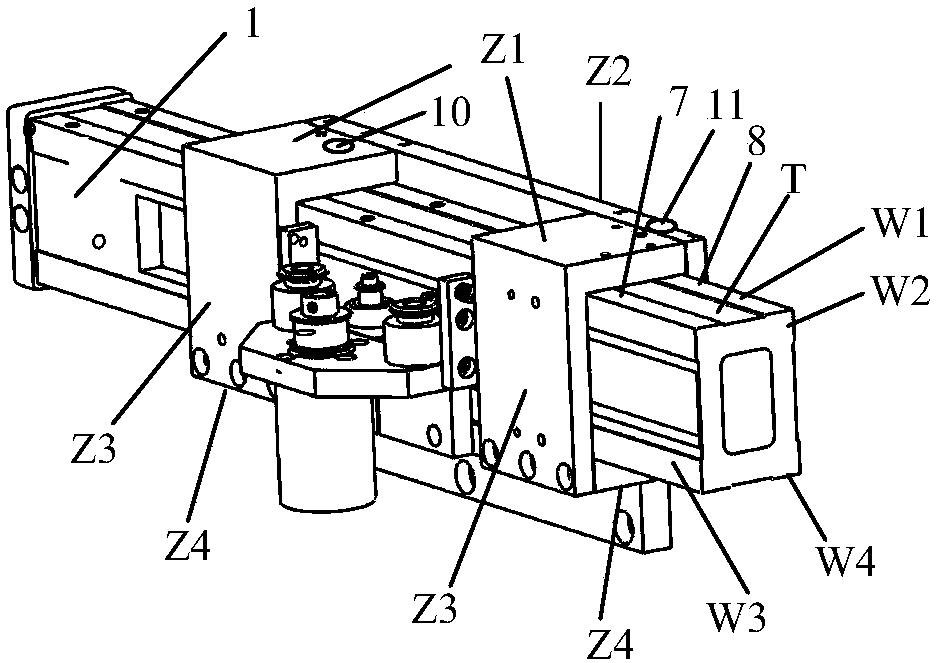

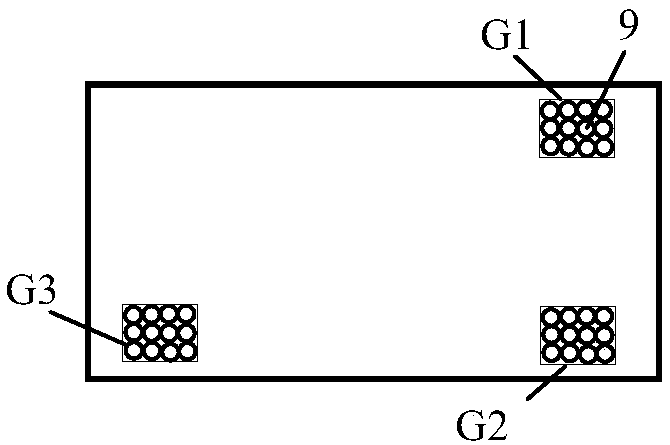

[0033] The guide rail component 1 is a cuboid structure with a rectangular cross section and four working surfaces, such as figure 2 As shown, it includes the first working surface W1, the second workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com