Single (double) wing type gas/ liquid two-phase composite gyration basic method and device

A datum device and wing-type technology, applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve the problem of insignificant vibration suppression effect of the rotating body, and overcome the stability of single-cycle motion and poor repeatability of multi-cycle motion trajectories. The effect of improving smoothness and improving motion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

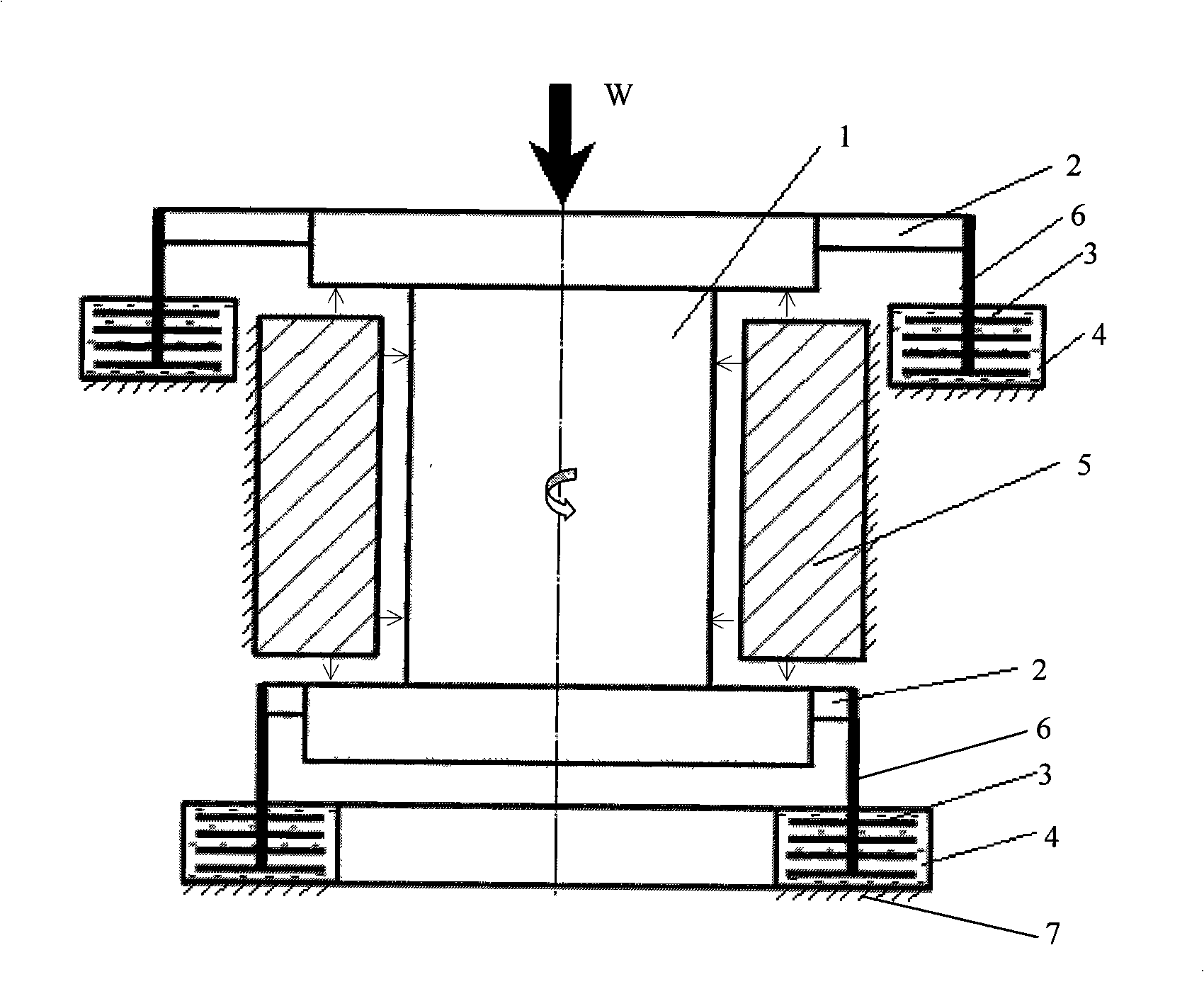

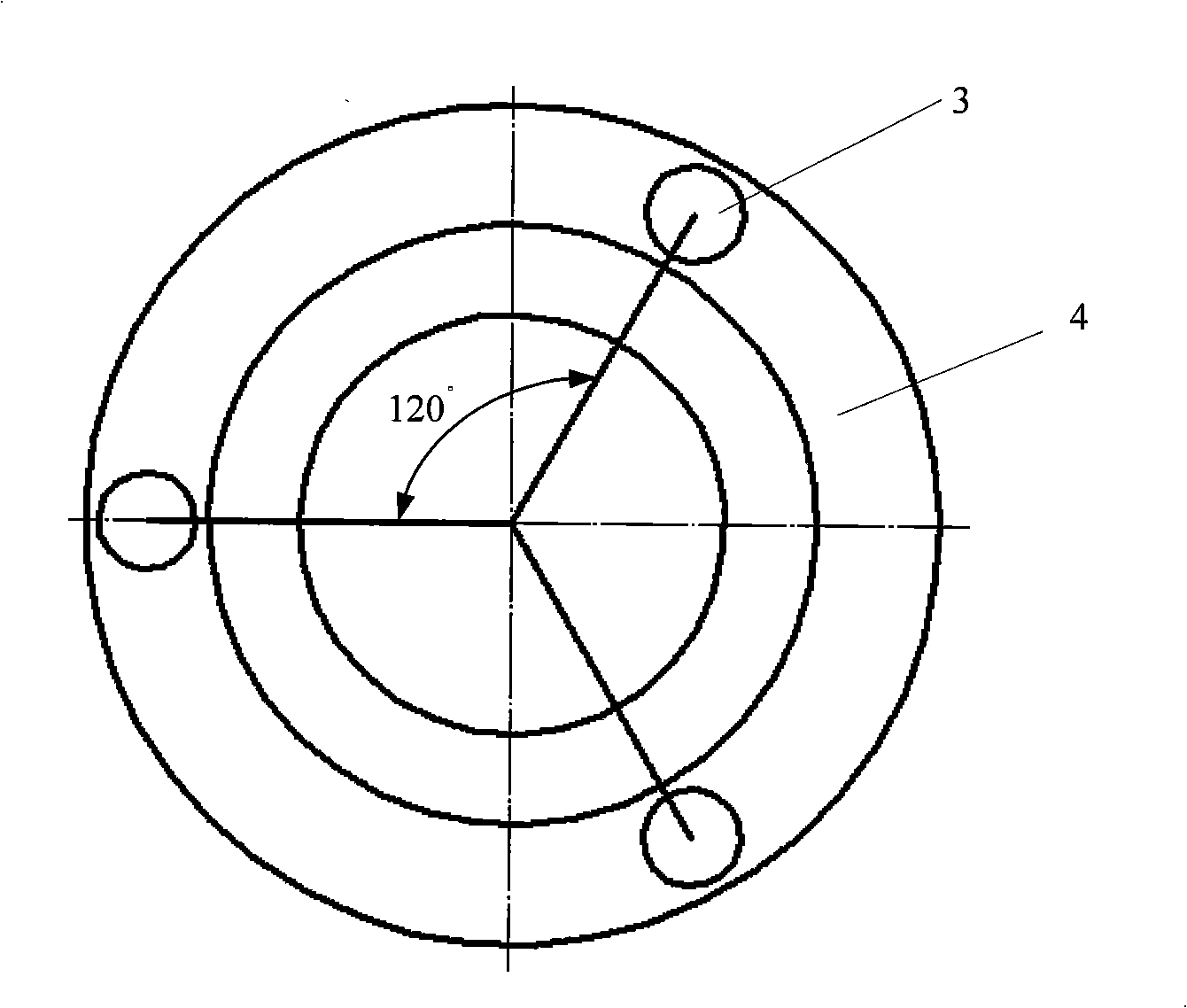

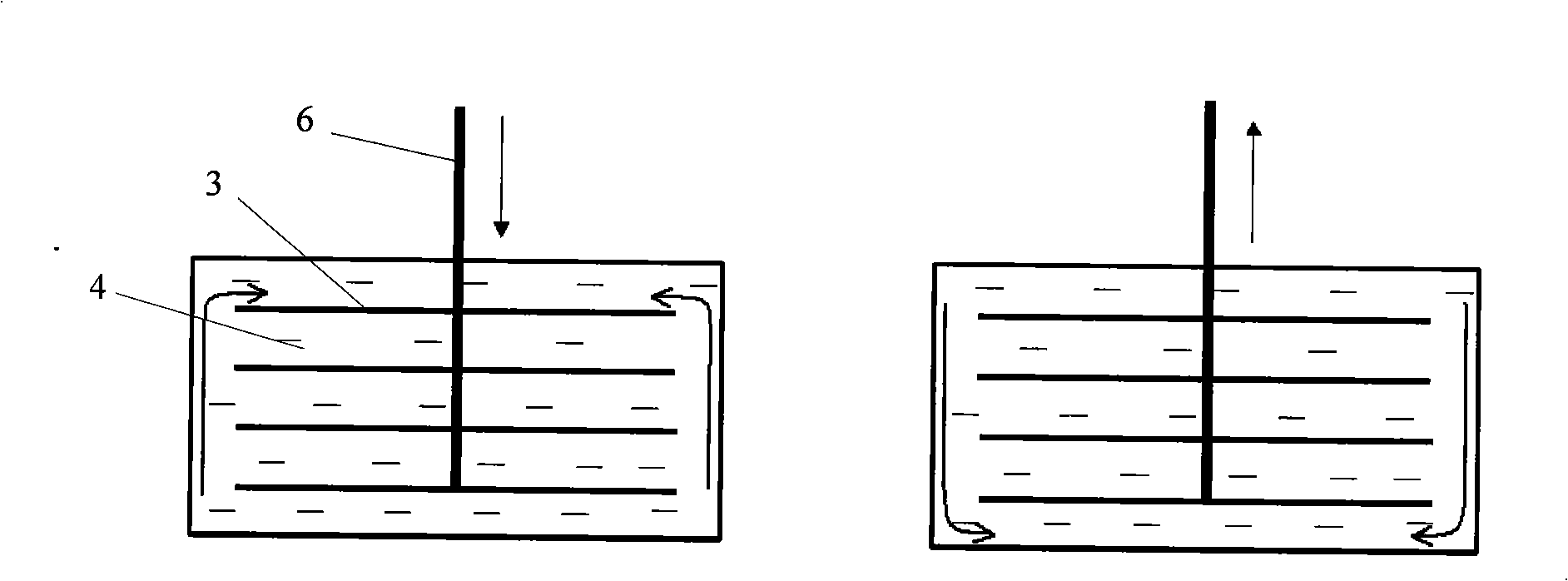

[0026] Such as figure 1 As shown, it is a structural configuration diagram of the gas / liquid two-phase composite rotary reference device equipped with an "I"-shaped air-floating spindle. The air-floating bushing 5 is fixed on a stable substrate such as the instrument base 7. The shaft sleeve 5 constitutes the basic structure of the air bearing shaft system. An axial and radial air film gap is formed between the air bearing main shaft 1 and the air bearing sleeve 5. When the air film gap is filled with pressurized gas, a gas bearing and Lubricated, the air-floating main shaft 1 can drive the load W to rotate in the air-floating bushing 5 . Utilizing the self-lubricating properties of the gas, the rotary motion has extremely small friction, which can ensure high displacement sensitivity of the rotary motion; the average effect of the gas film can ensure high rotary motion accuracy.

[0027] In order to overcome the axial and radial medium and high-frequency micro-vibrations of ...

Embodiment 2

[0031] Figure 4 It is a structural configuration diagram of a liquid damping system arranged at the upper end of the "T"-shaped air-floating main shaft, and its working principle and damping effect are similar to those of Embodiment 1.

Embodiment 3

[0033] Figure 5 It is a structural configuration diagram of a liquid damping system arranged at the lower end of the "T"-shaped air-floating main shaft, and its working principle and damping effect are similar to those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com