Pipe bending and ring sleeving integrated machine for pipe fitting

An all-in-one machine and collar technology, used in pipe cutting devices, manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as affecting product quality, increasing device energy consumption, and thinning pipe walls, reducing handling links, Improve quality and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

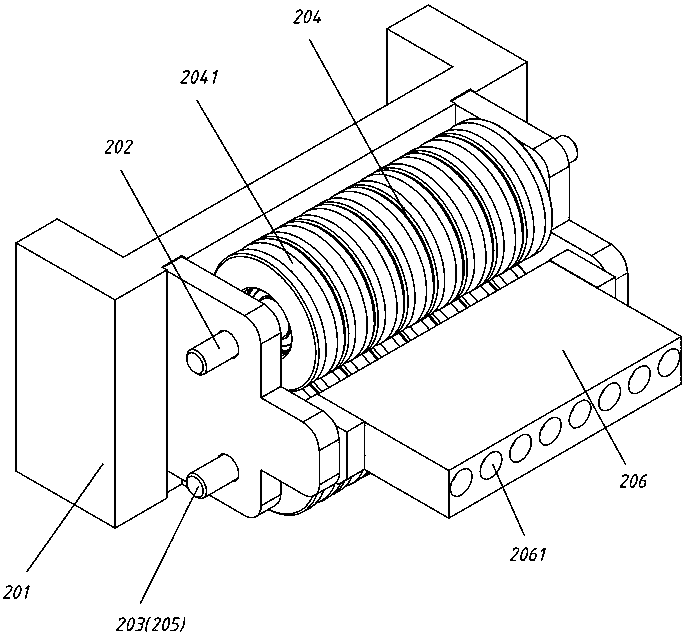

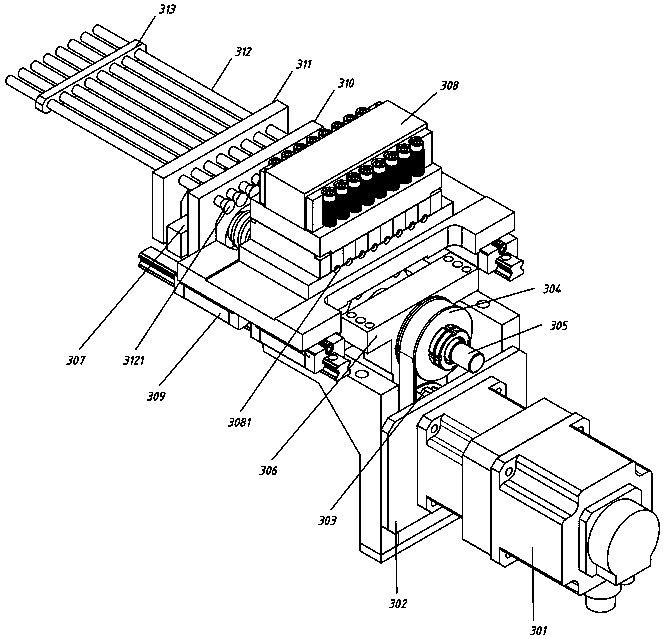

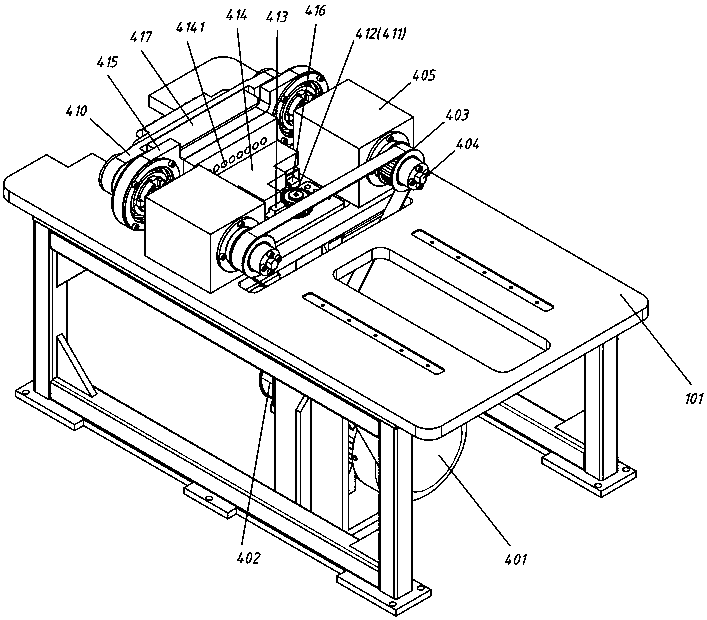

[0043] like figure 1 As shown in the figure, an all-in-one machine for pipe bending and collar for pipe fittings includes a fuselage 1, on which from right to left is sequentially provided a full-circle part 2 capable of aligning metal pipe fittings into a circle, and capable of sending pipe fittings of a specified length. 3, the cutting part 4 for cutting the metal pipe to a fixed length, the flaring part 5 for double-sided flaring of the metal pipe, the ejecting part for pushing the cut fixed-length pipe into the bending part 6. The bending part 7 used to clamp and bend the metal pipe into a U shape, the mandrel entry and exit part 8, the follower part 9 to push the mold to follow, and the unloading part 10 to unload the bent pipe. The elbow degreasing mechanism 11 for cleaning and degreasing the elbow, and the collar mechanism 12 for wrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com