Vegetable oil-based environment-friendly ink and preparation method thereof

A technology based on vegetable oil and vegetable oil, which is applied in the field of ink to achieve the effect of speeding up the fixing time and drying time of conjunctiva

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

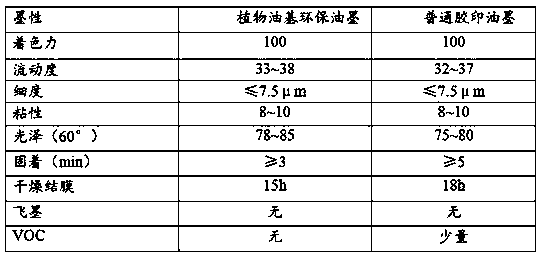

Image

Examples

Embodiment 1

[0022] A kind of vegetable oil-based environmental protection printing ink, calculated by 100kg, comprises following composition and is prepared from:

[0023] Rosin modified phenolic resin 28kg, using high structure, medium and low solubility, low viscosity, high softening point rosin modified phenolic resin, increasing the solid resin content to improve the fixing speed of ink, the softening point of the resin is 180 ~ 200 ℃;

[0024] Vegetable oil 27kg, the vegetable oil is a dry vegetable oil, using black mountain grass seed oil with high iodine value, which can give the ink a very fast drying speed, and its solubility is better than that of linseed oil, soybean oil, tung oil, etc.;

[0025] Solvent 12kg, selects black mountain grass seed oil derivatives for use, such as black mountain grass seed oil methyl ester;

[0026] Pigment and filler 25kg, wherein, the mass ratio of pigment and filler is 4:1; Described pigment can select magenta, phthalocyanine blue B, benzidine ye...

Embodiment 2

[0029] A kind of vegetable oil-based environmental protection printing ink, calculated by 100kg, comprises following composition and is prepared from:

[0030] Rosin-modified phenolic resin 30kg, using high-structure, medium-low solubility, low viscosity, high softening point rosin-modified phenolic resin, increasing the solid resin content to improve the fixing speed of the ink, the softening point of the resin is 180-200°C;

[0031] Vegetable oil 30kg, the vegetable oil is a dry vegetable oil, using black mountain grass seed oil with high iodine value, which can give the ink a very fast drying speed, and its solubility is better than that of linseed oil, soybean oil, tung oil, etc.;

[0032] Solvent 15kg, selects black mountain grass seed oil derivative for use, such as black mountain grass seed oil ethyl ester,

[0033] Pigment and filler 20kg, wherein, the mass ratio of pigment and filler is 5:2; Said pigment can select magenta, phthalocyanine blue B, benzidine yellow or p...

Embodiment 3

[0037] The difference from Example 1 is that the solvent is selected from black lily seed oil butyl ester.

[0038] The preparation method of the vegetable oil-based environmental protection ink in any of the above-mentioned embodiments comprises the following preparation steps:

[0039] (1) Put the rosin-modified phenolic resin, black mountain grass seed oil, solvent, and gel into the reaction kettle, and protect the liquid surface with an inert gas. The inert gas is argon, and the gas pressure is controlled at 0-5MPa. Exclude the air in the reaction kettle, then raise the temperature to 180~200°C, start stirring, and the stirring time is 30min;

[0040] (2) Then cool down to 80°C, put in fillers and pigments, stir for 10 minutes, add additives, and stir for another 30 minutes;

[0041] (3) Put the material obtained in step (2) into a three-roll mill for grinding, pass through a 10 μm filter membrane, check the ink index, adjust to pass, and finally pack and seal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com