Patents

Literature

31results about How to "Reduce handling links" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

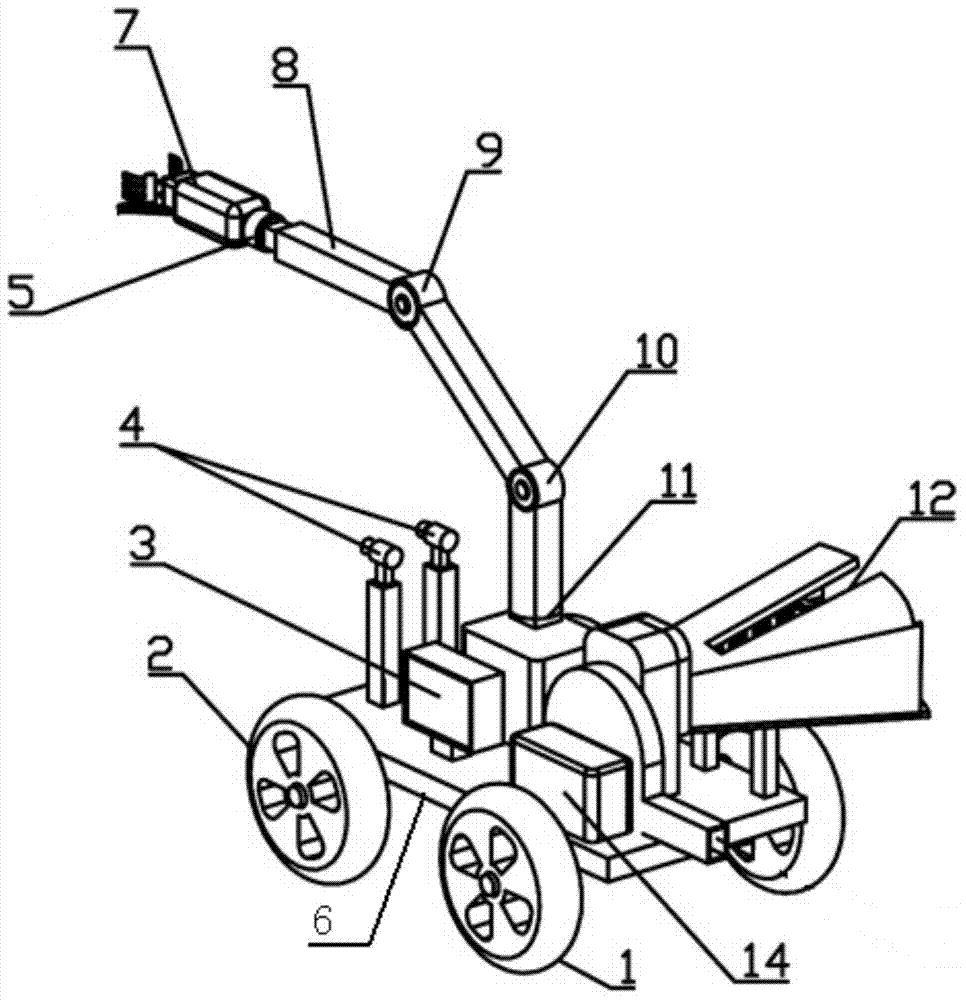

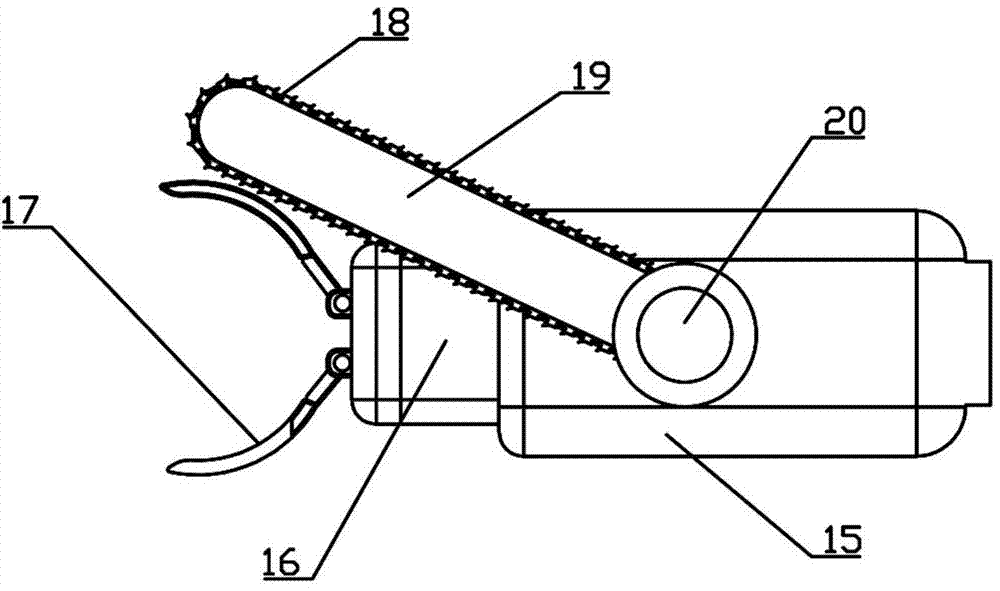

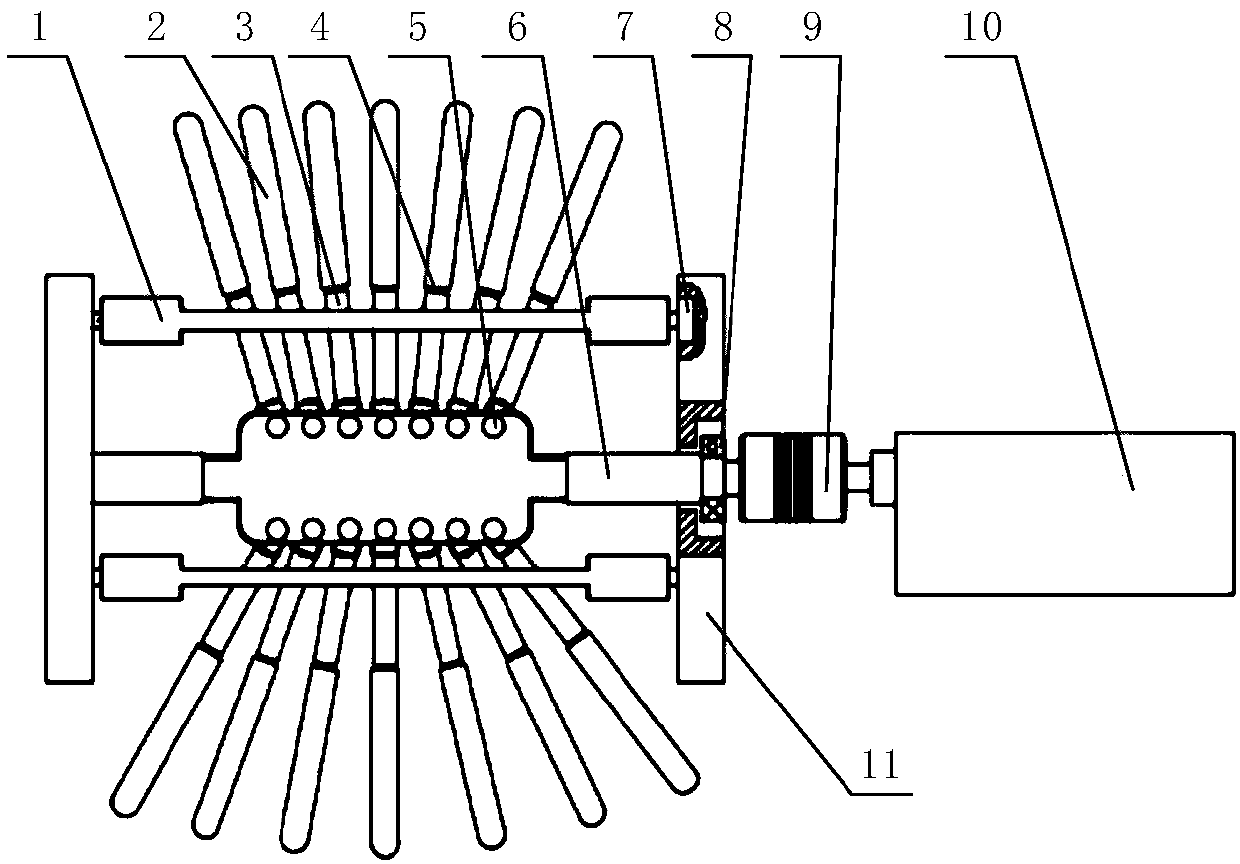

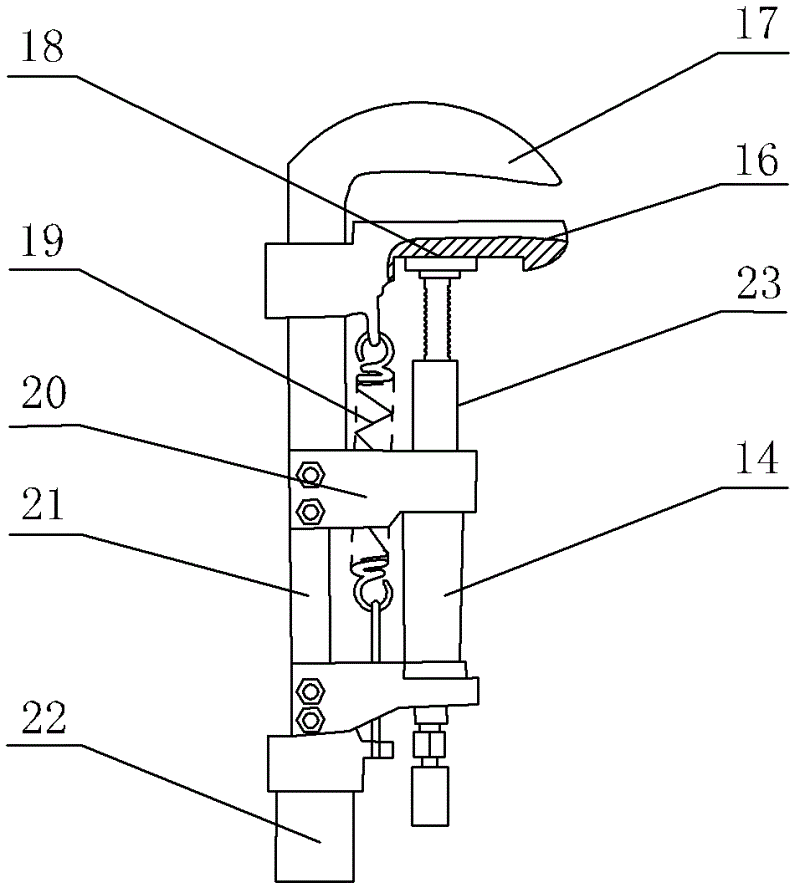

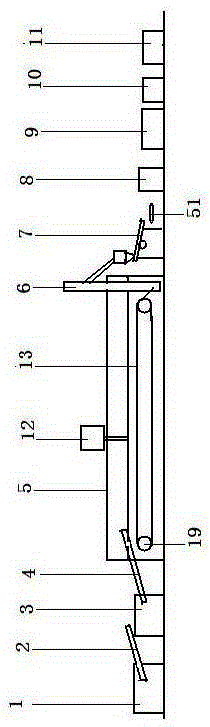

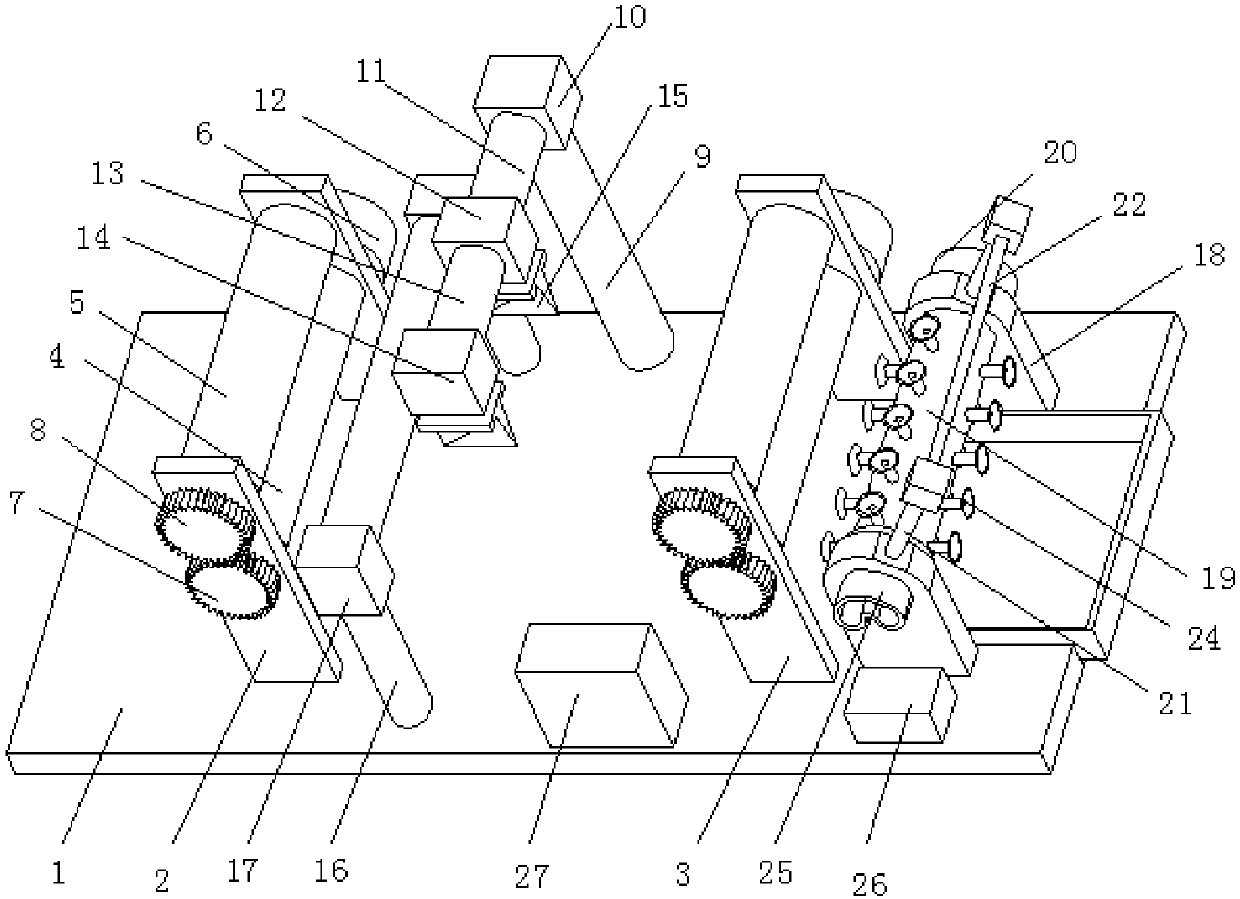

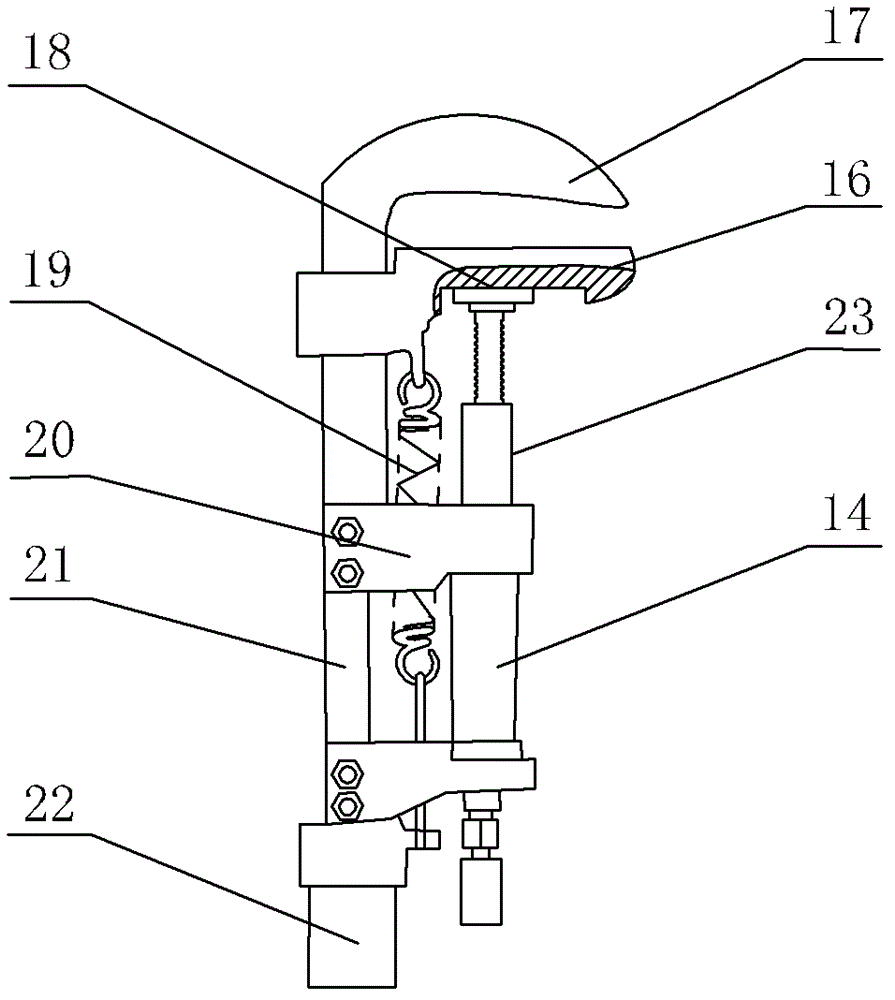

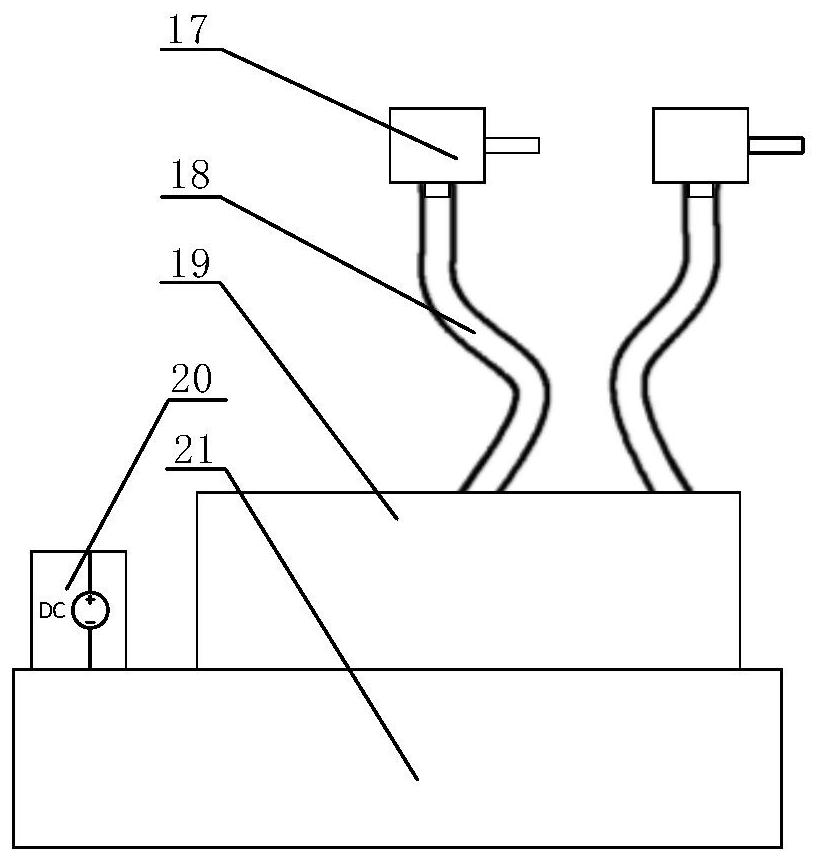

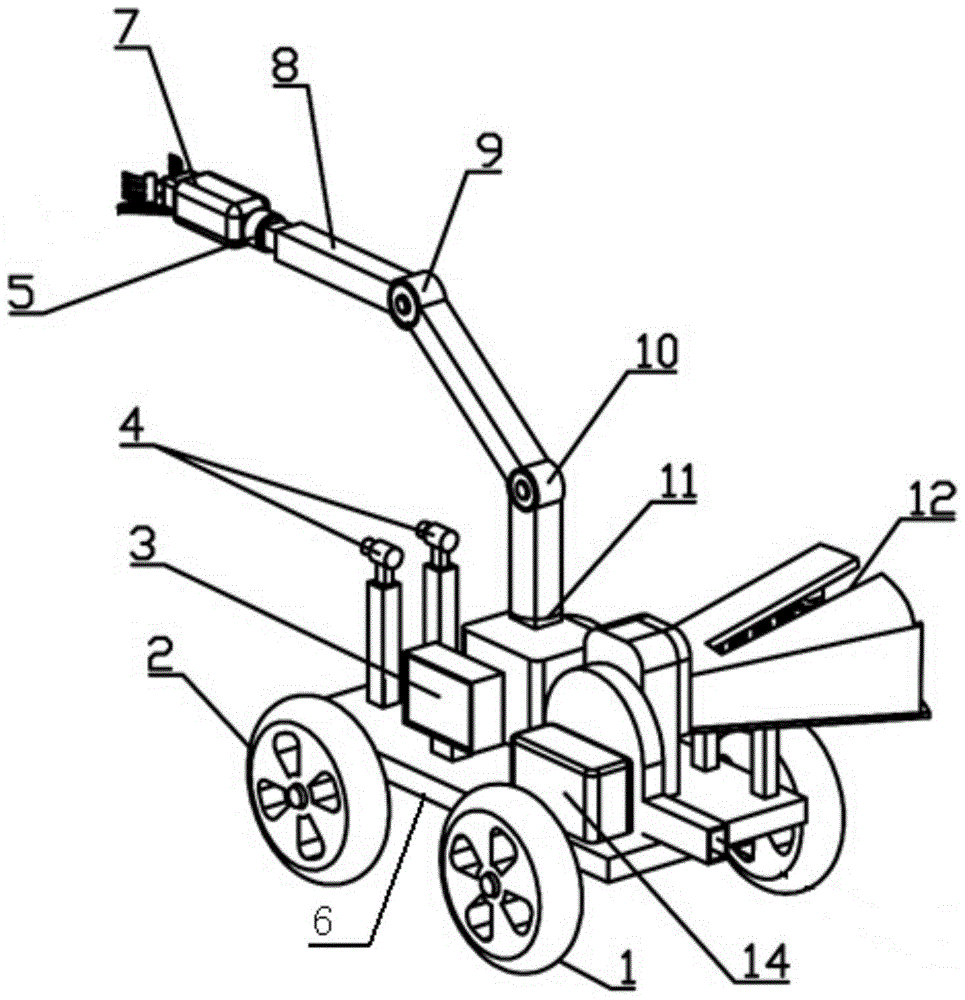

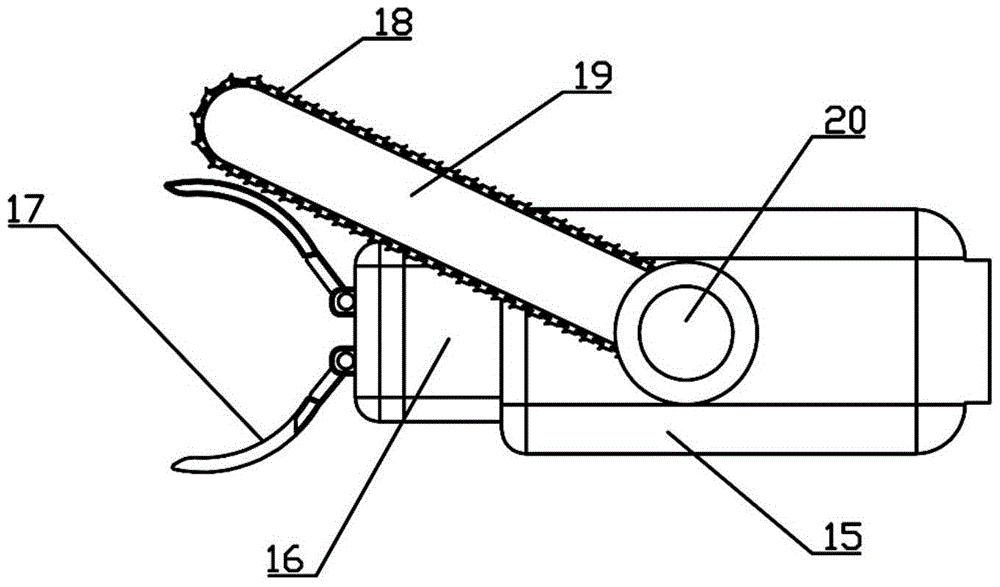

Robot and method for pruning and crushing twigs

InactiveCN104221732AReduce handling linksSmash real timeCuttersCutting implementsMotor driveRobotic arm

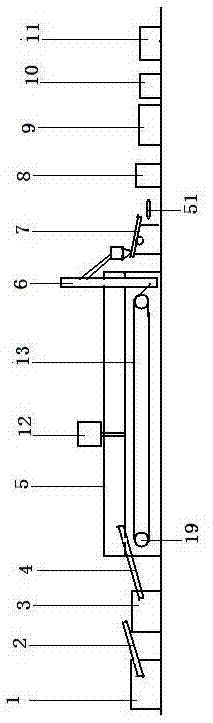

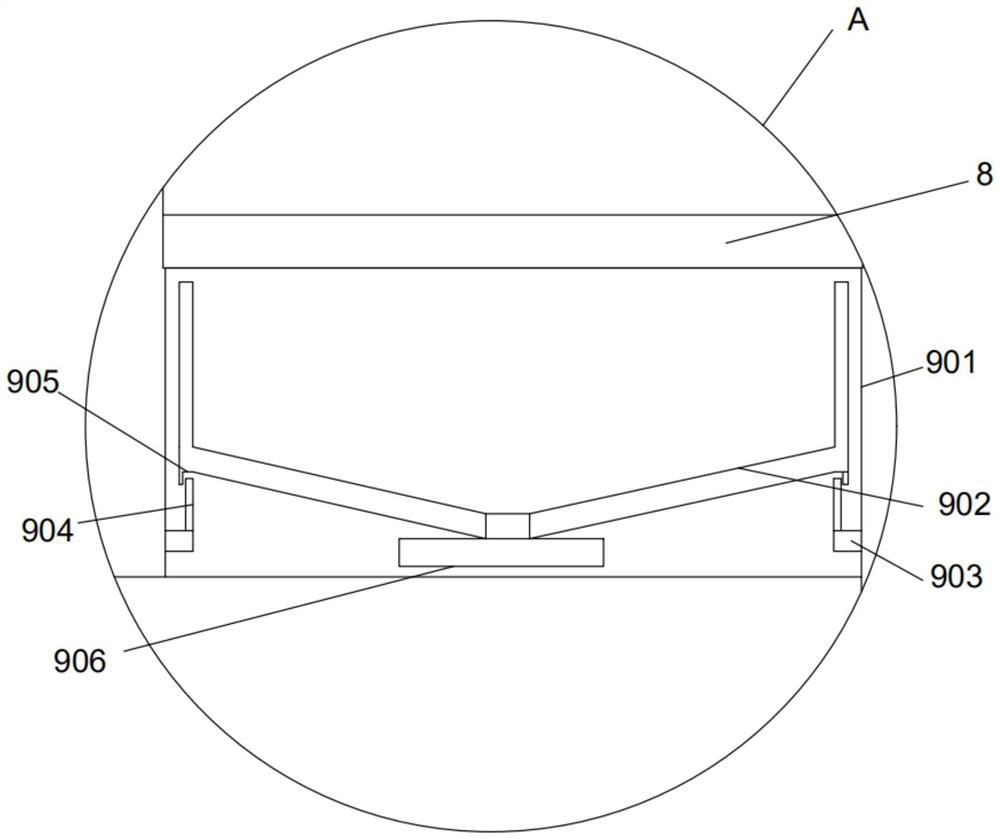

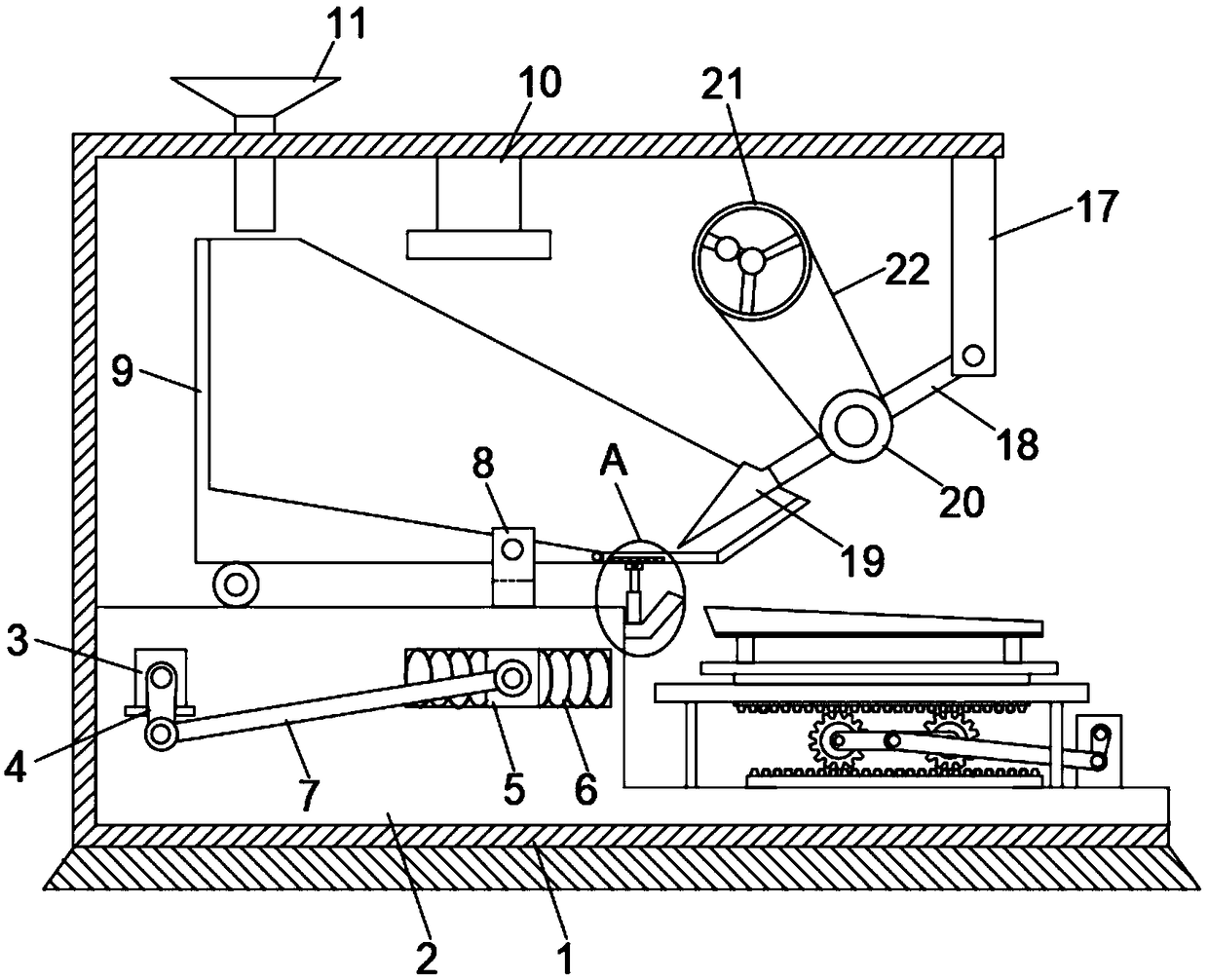

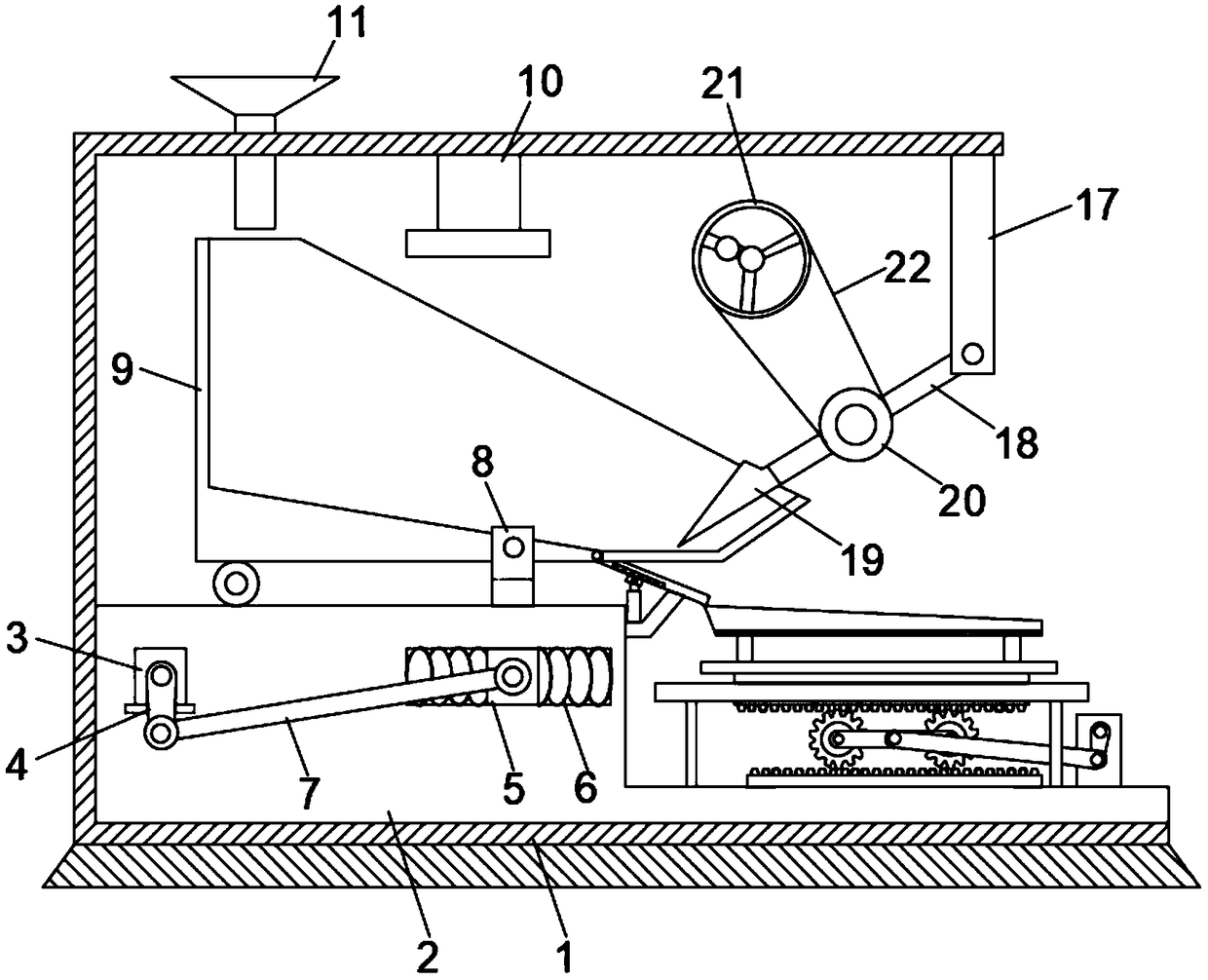

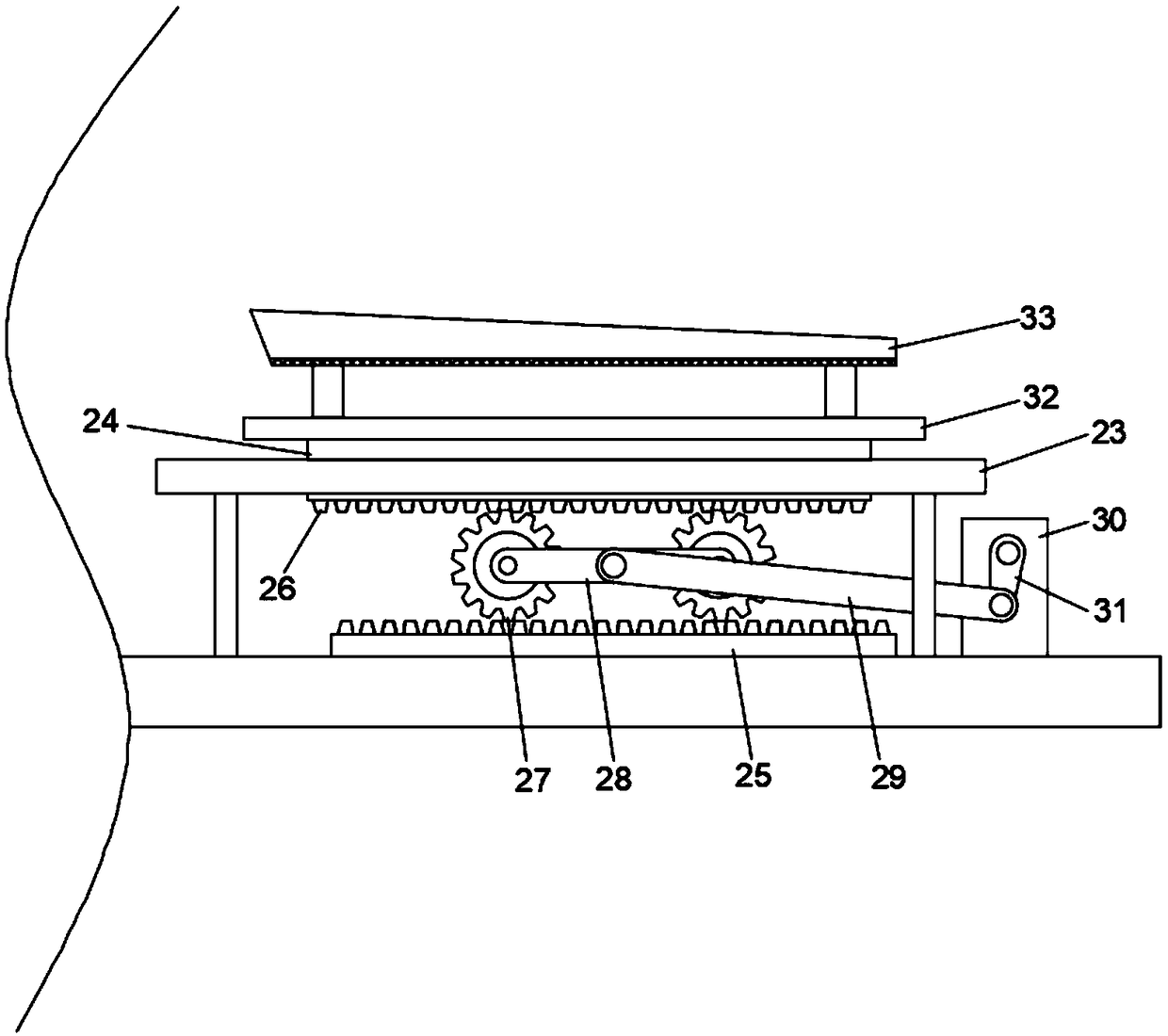

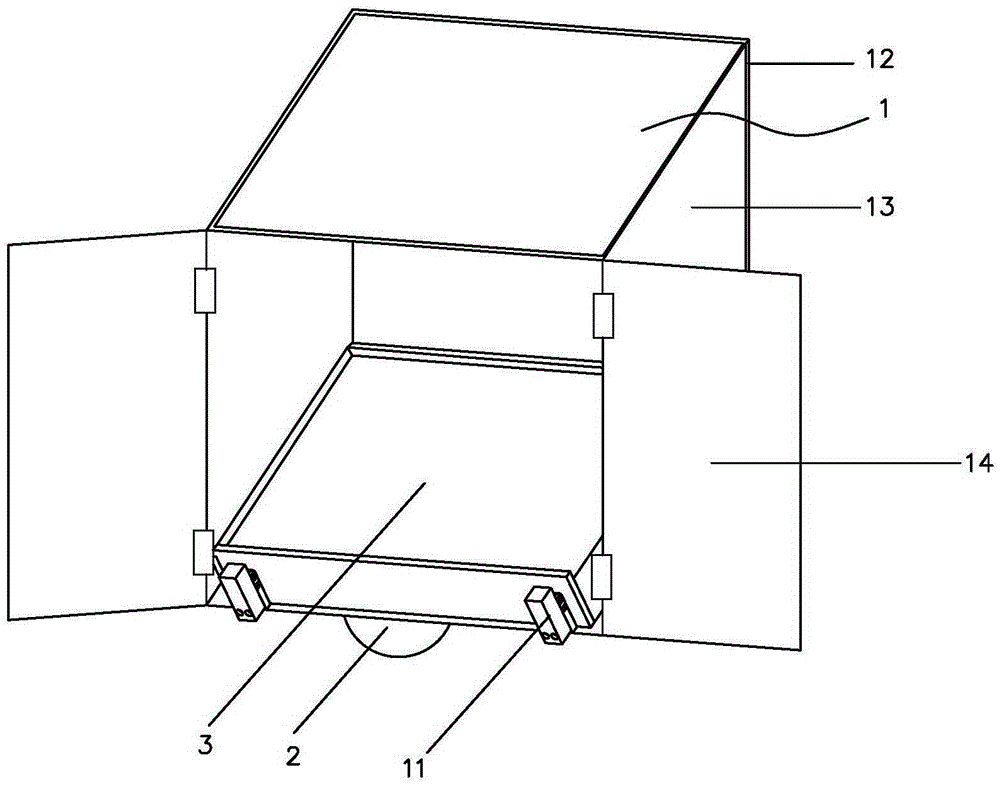

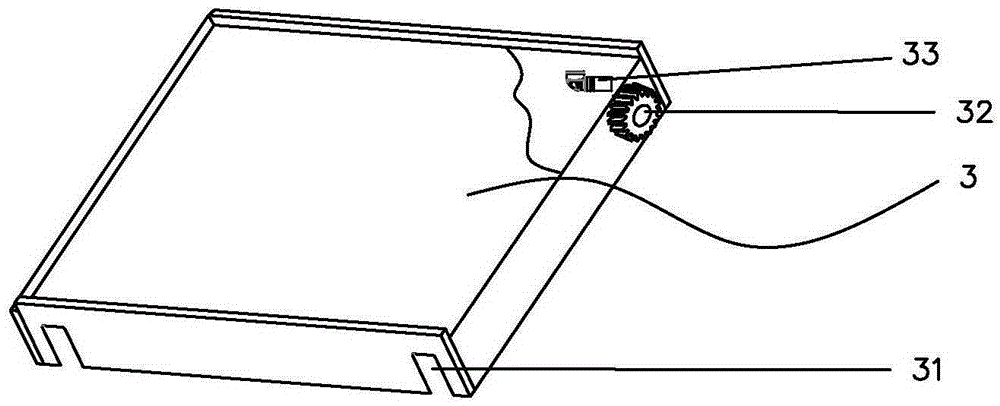

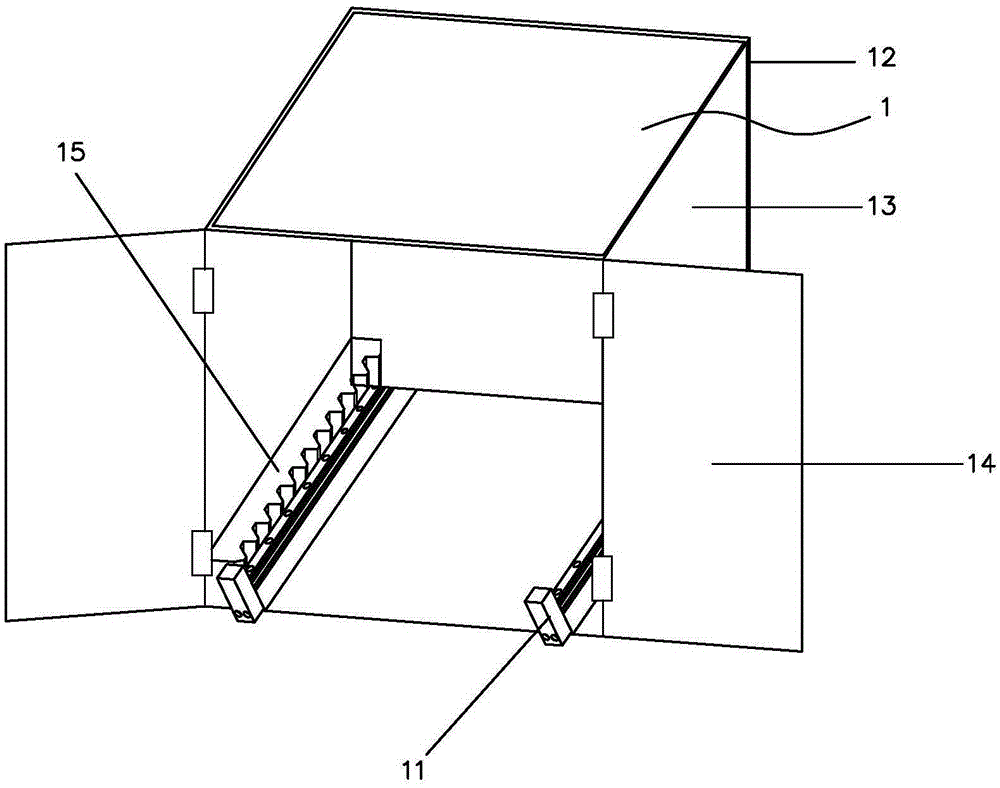

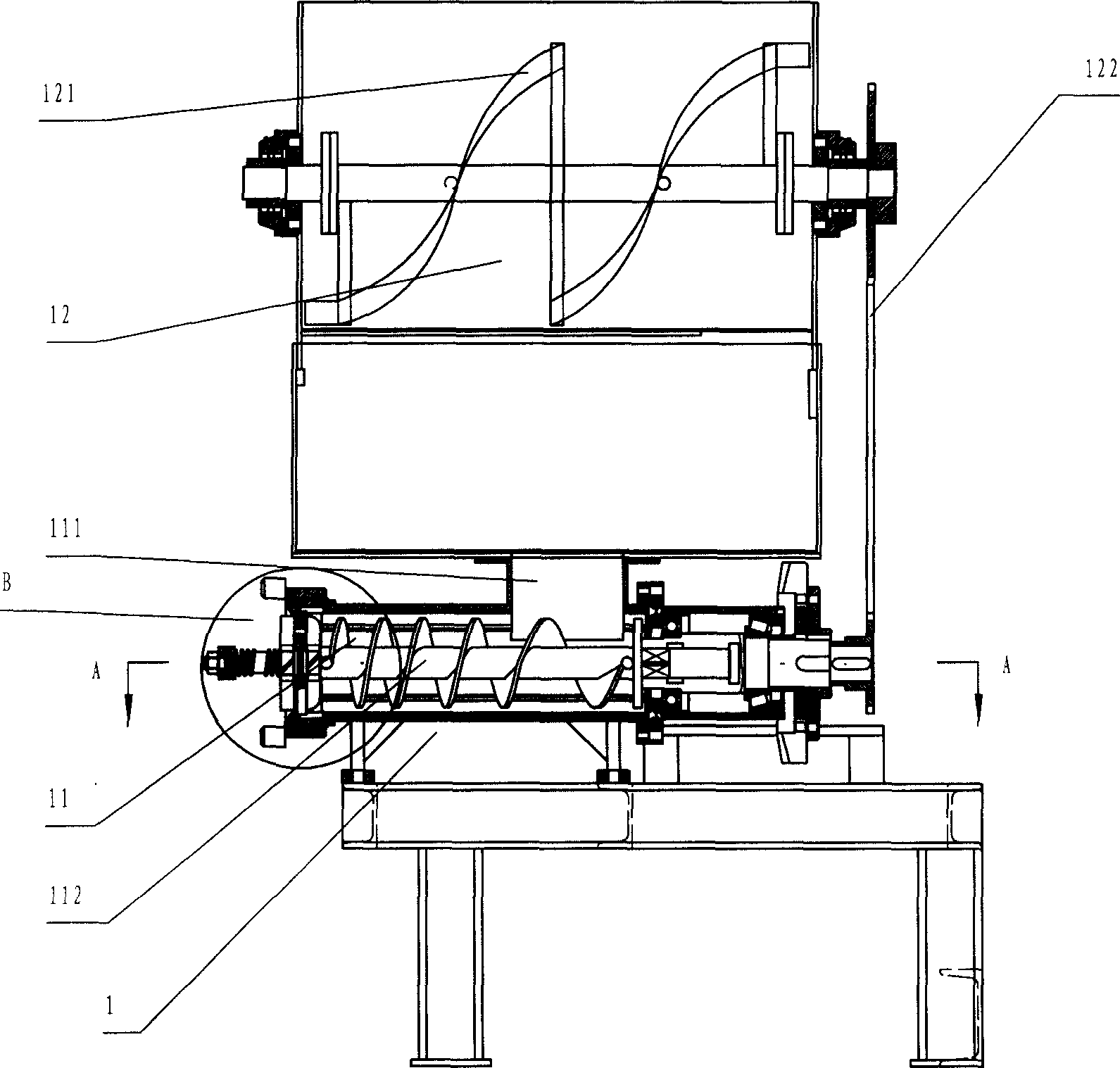

The invention discloses a robot and a method for pruning and crushing twigs. The robot comprises mechanical arms, pruning tail end actuators, a control unit and a camera, wherein the pruning tail end actuators are arranged at the front ends of the mechanical arms; actions of components such as the pruning tail end actuators and the camera are controlled by the control unit; each mechanical arm comprises a motor, a finger drive device, a forked finger, a saw web, a saw web shaft and a saw web shaft drive device; the motor drives the finger drive device and the saw web shaft drive device to act; the saw web is arranged at the periphery of the saw web shaft; the saw web shaft is connected with the saw web shaft drive device; the forked finger is connected with the finger drive device. The robot integrates selective pruning and crushing of the twigs, the twig transport link for crushing the twigs is reduced, and real-time crushing can be carried out; flakes which are crushed from twigs and leaves in situ are utilized as an organic fertilizer and are returned to the soil, so that the production cost is reduced, the usage amount of chemical synthetic fertilizers on the crops is reduced, and development of the organic fruit industry is promoted.

Owner:SOUTH CHINA UNIV OF TECH

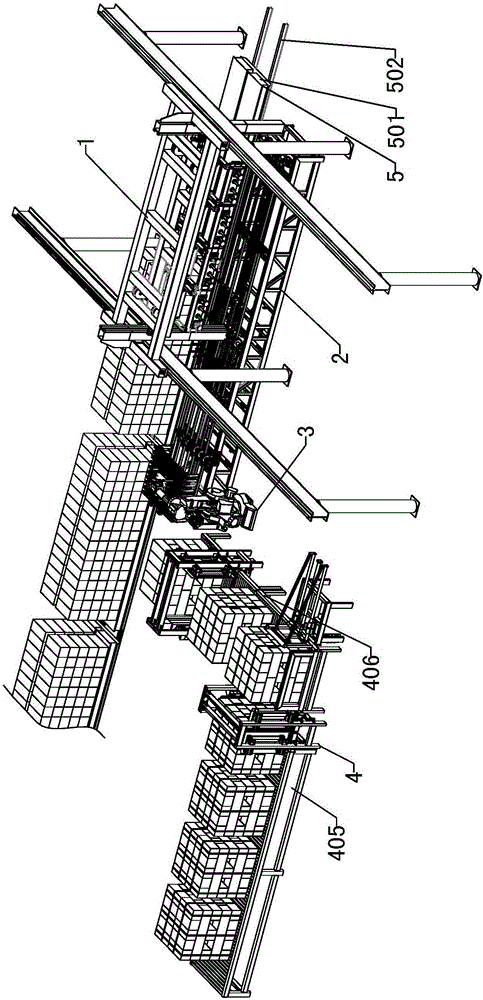

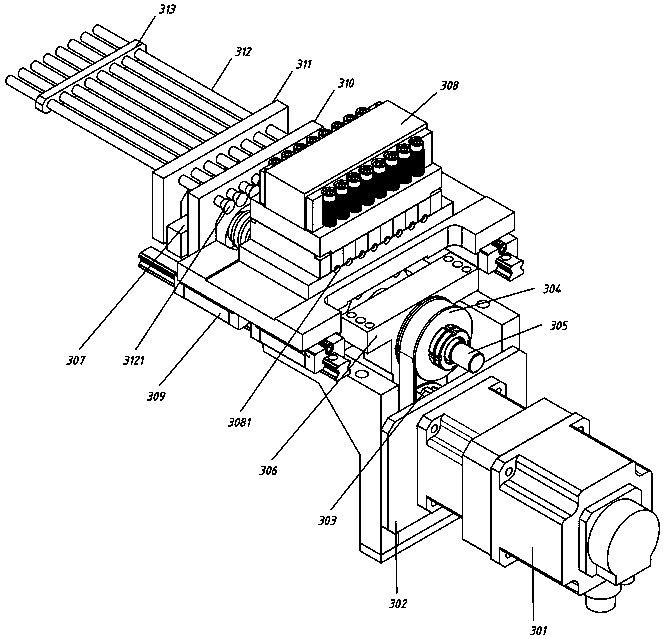

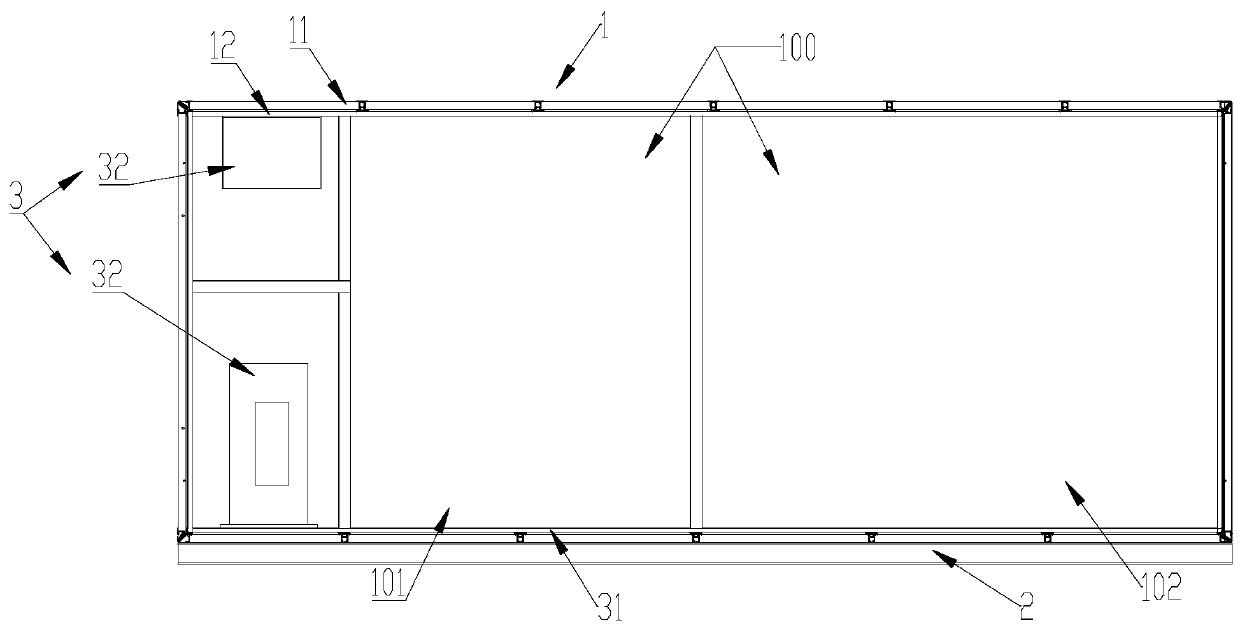

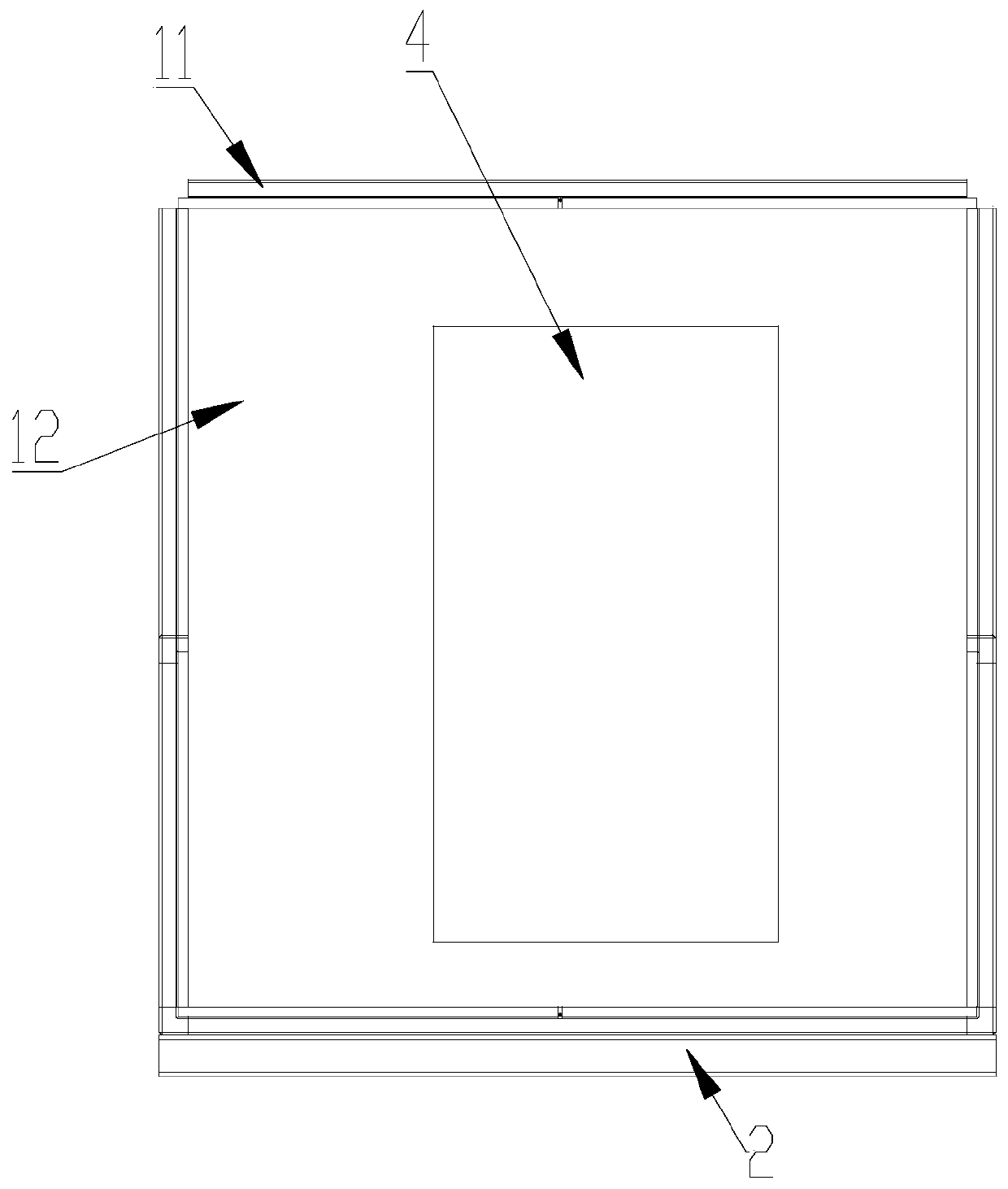

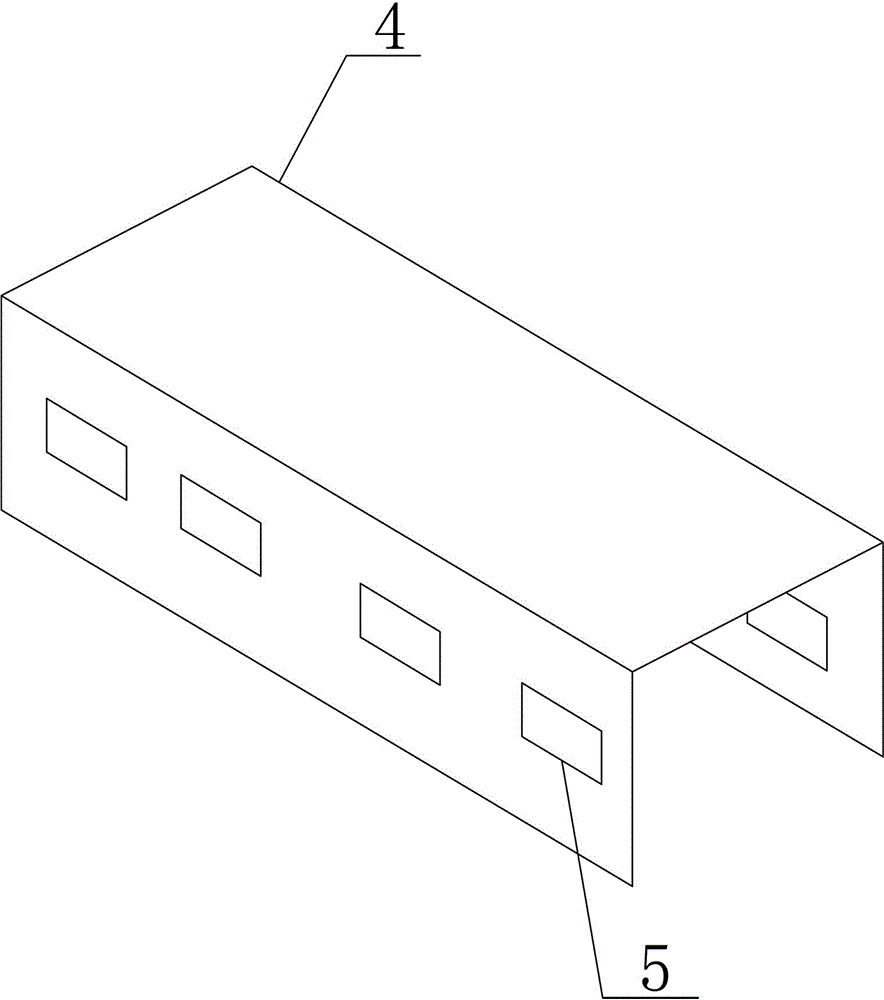

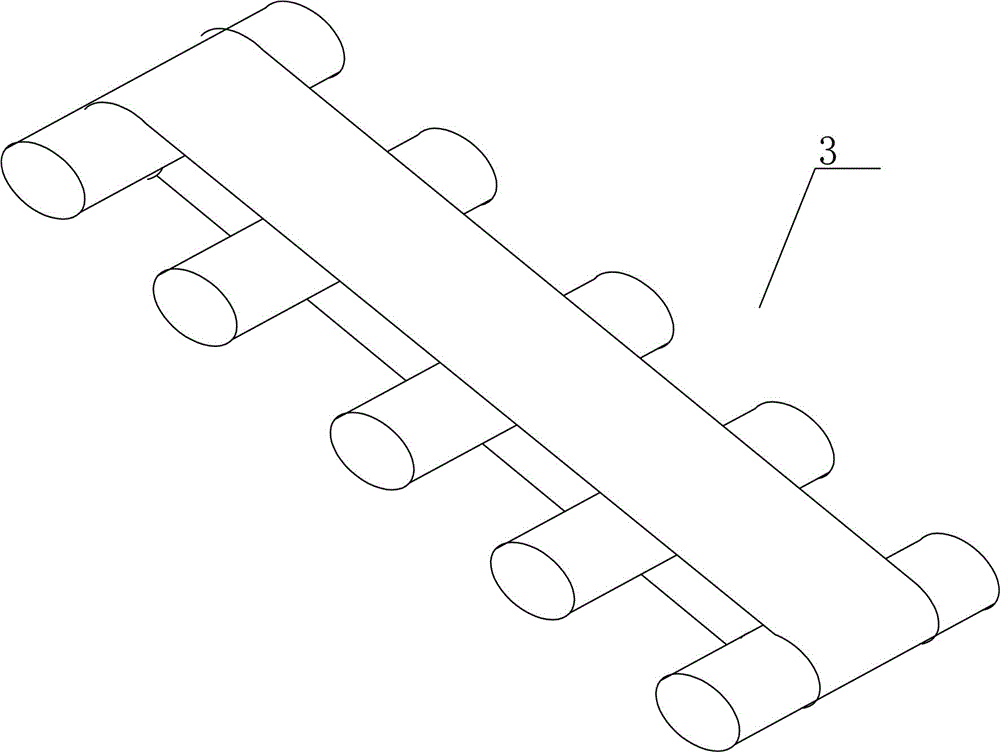

Tray-free stacking process for autoclaved lightweight concrete building blocks

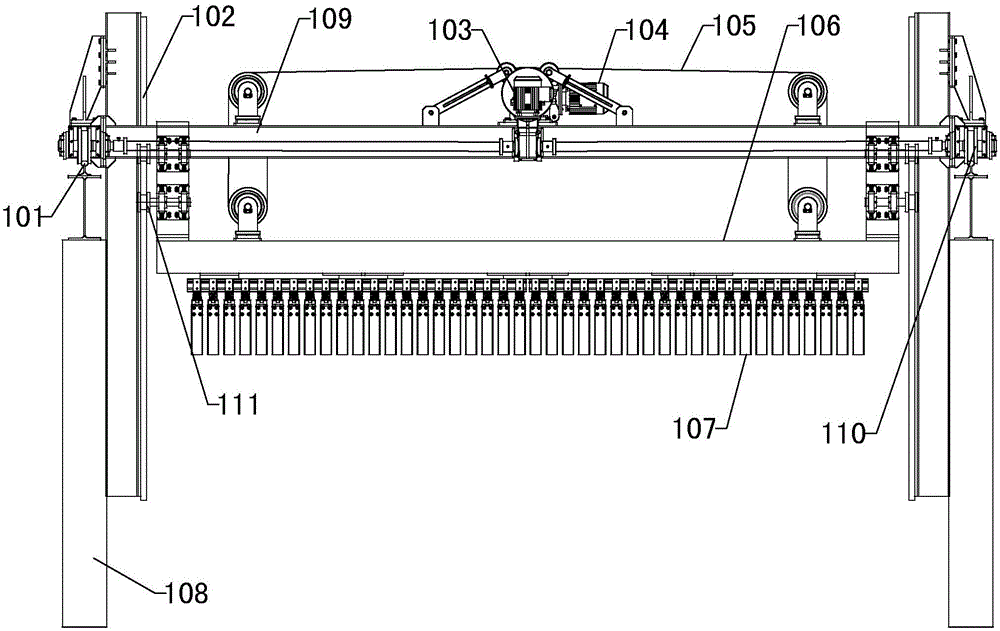

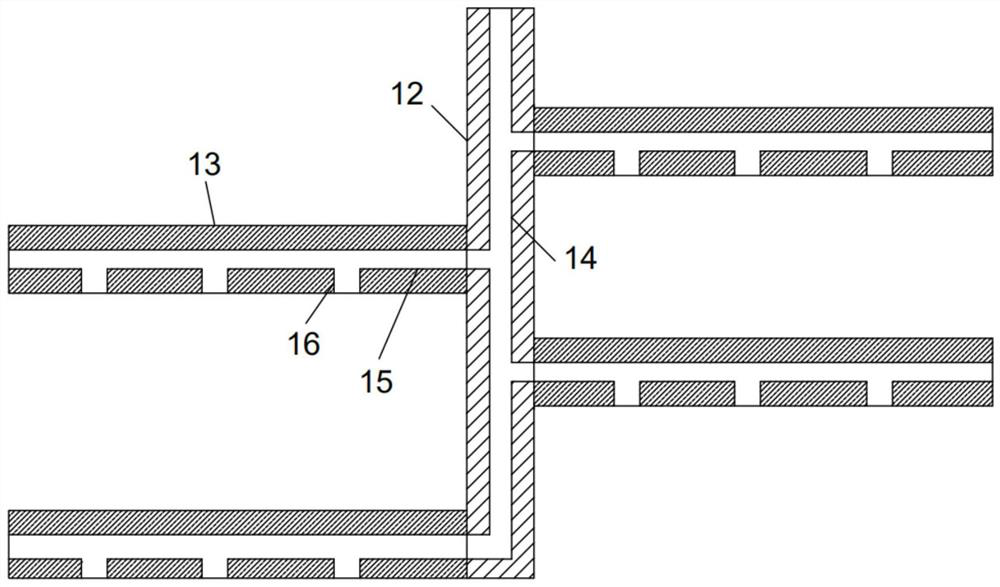

The invention discloses a tray-free stacking process for autoclaved lightweight concrete building blocks, and belongs to the field of concrete building block packaging processes. The tray-free stacking process is characterized by being implemented by a full-automatic packaging system, and each stacking clamp (302) is independently controlled to be opened and closed through a line; the tray-free stacking process comprises the following stacking steps: (1) setting the arrangement direction and the quantity of the building blocks on each layer in building block stack, and sizes of loading and unloading holes; (2) performing green brick rolling over: continuously rolling over a plurality of rows of building blocks row by row; (3) performing grounding: grouping the building blocks row by row until the quantity of building blocks for each layer is met; (4) performing layer-by-layer stacking: stacking the subsequent building blocks on the lower layer of the building block stack in sequence through a mechanical arm stacking mechanism (3); (5) reserving and setting loading and unloading holes; and (6) performing packaging. According to the tray-free stacking process for the autoclaved lightweight concrete building blocks, no tray is used in the whole conveying process, so that a large number of trays are saved; the building blocks can be directly carried by a forklift truck without the tray, so that the effect of the tray is thoroughly eliminated; and therefore, a lot of production cost is saved.

Owner:淄博捷达机械有限公司

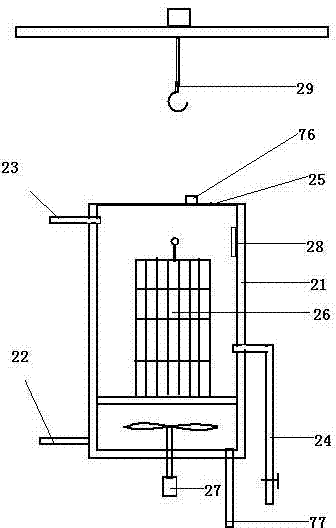

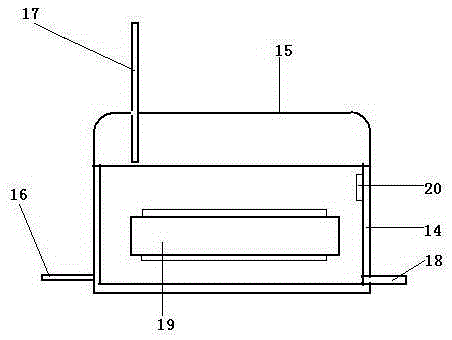

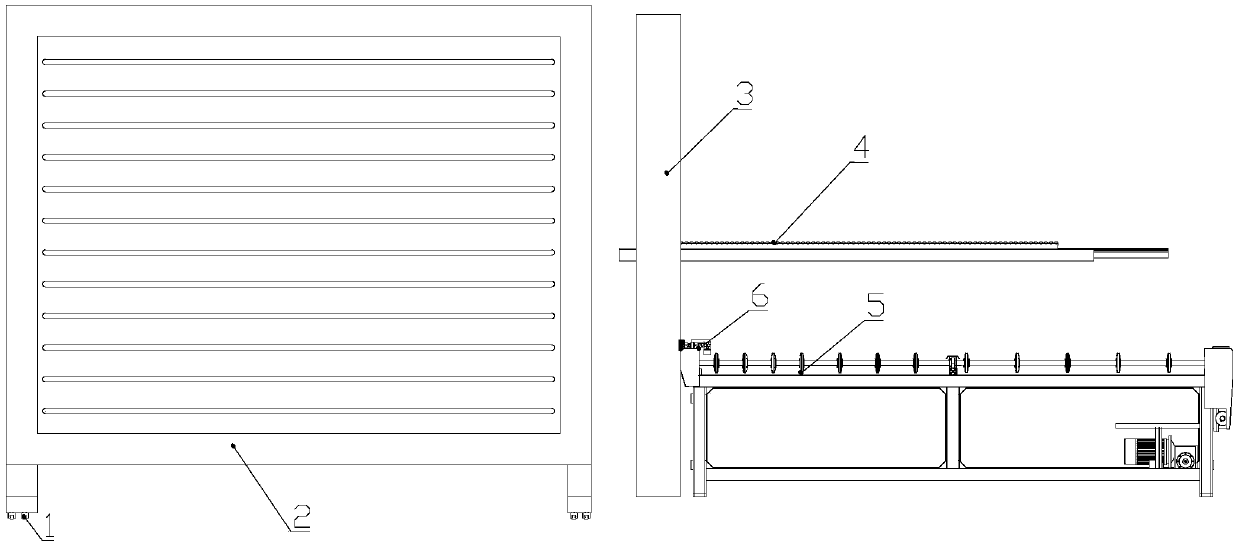

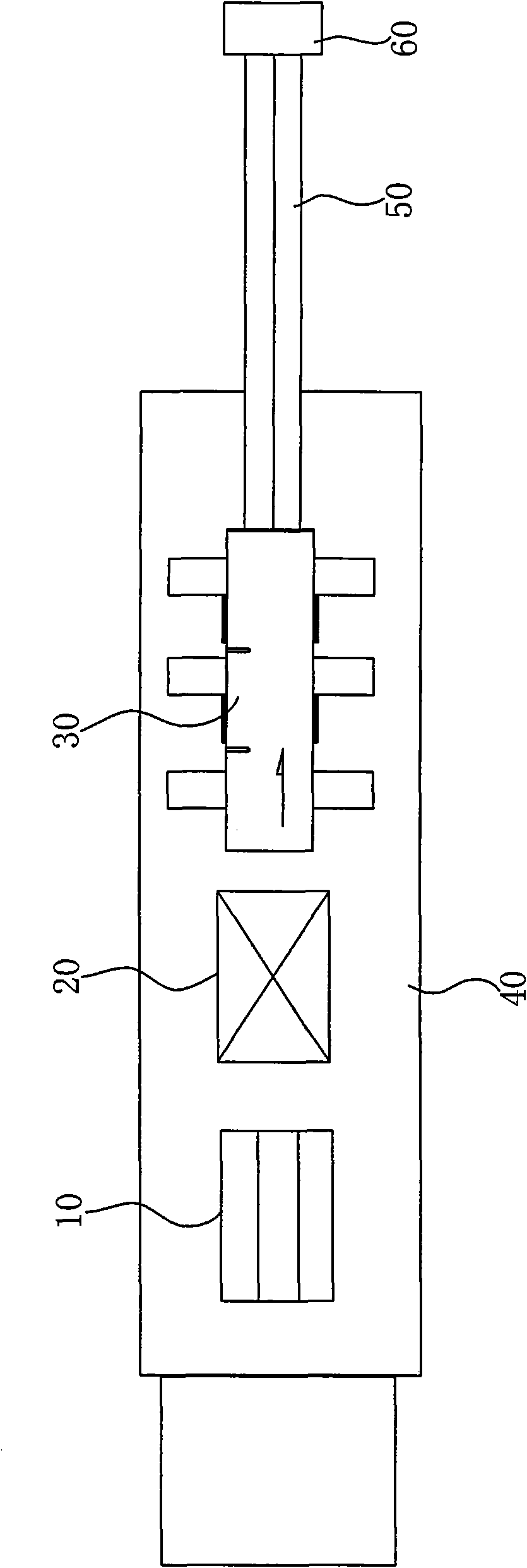

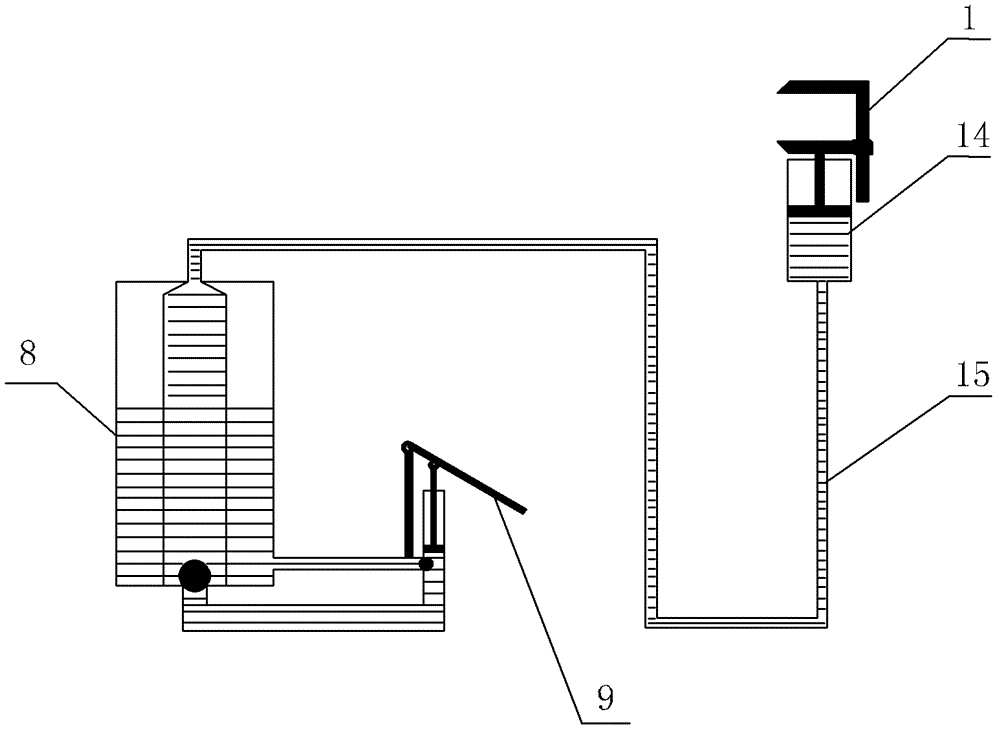

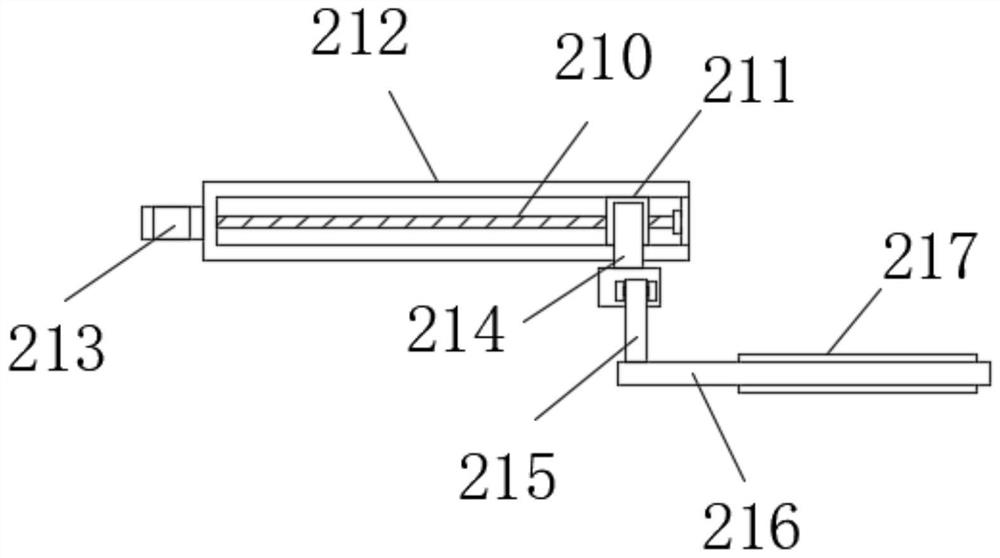

Method and equipment for continuously producing marinated food

ActiveCN103610223ARealize continuous operationHigh degree of mechanizationFood shapingOperation modeConveyor belt

The invention provides a method and equipment for continuously producing a marinated food. The method sequentially comprises the following steps: thawing, pickling, marinating, spreading for cooling, packing in small packages, sterilizing, washing, drying, packing in a large package and storing. The marinating step is continuously carried out in a marinating groove by a stainless steel silk screen conveyor belt. The equipment sequentially comprises a thawing tank, a first conveyor belt, a pickling tank, a second conveyor belt, the marinating groove, a bucket elevator, a spreading vibration sieve, an air pressure packaging machine, sterilization equipment, a spiral washing machine and a drying machine; a marinating liquid pot is arranged beside the marinating groove and the marinating groove is internally provided with the stainless steel silk screen conveyor belt. According to the method and the equipment for continuously producing the marinated food, a traditional manual operation mode is changed, the mechanization degree is high, the continuous work of a production line is realized, and the yield is great; the labor intensity in the production process is reduced, and a link of carrying in each working procedure is omitted; the quality, the appearance and the color and luster of the food are guaranteed; from the perspective of environmental sanitation, safety and heat loss, the equipment is easy to clean and convenient to operate, energy sources are saved and the total cost is reduced.

Owner:湖南桃花鸭食品科技有限公司

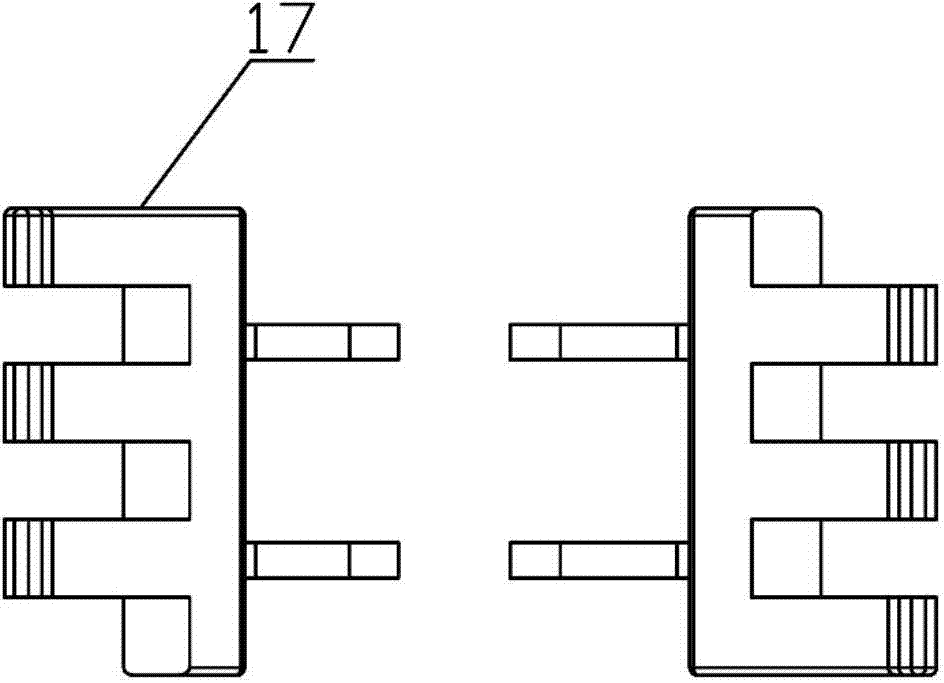

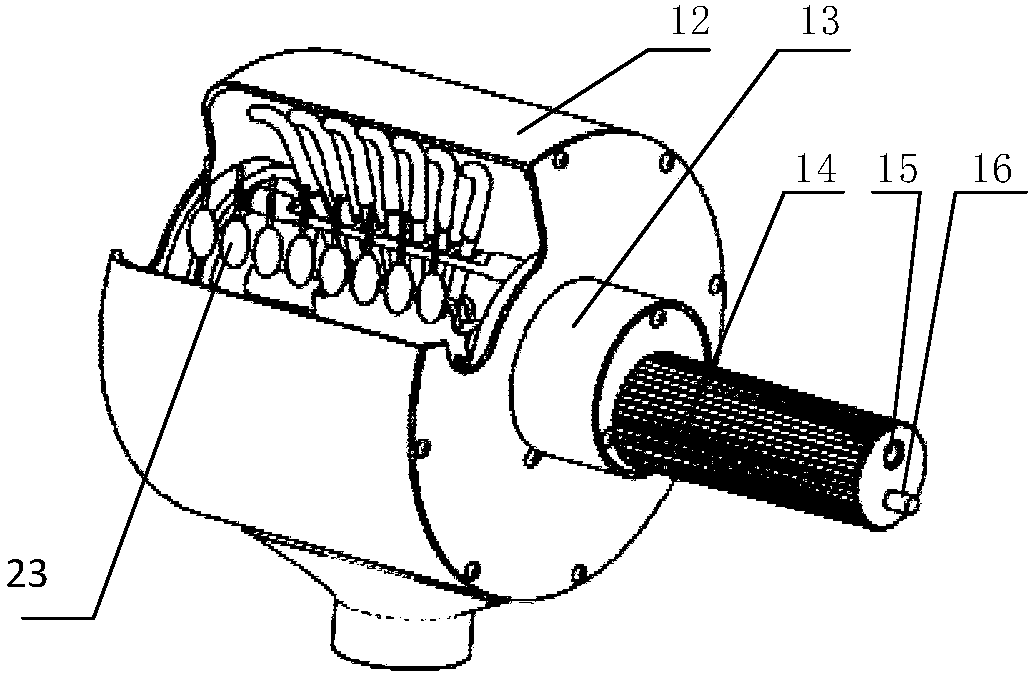

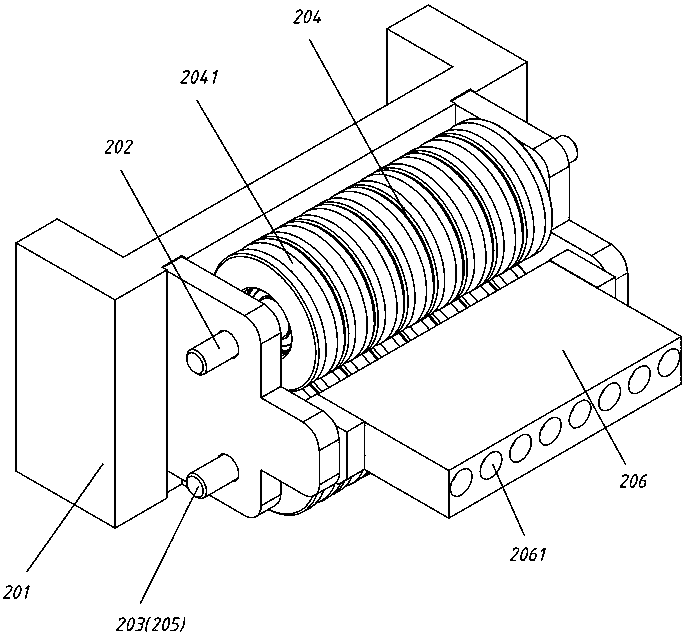

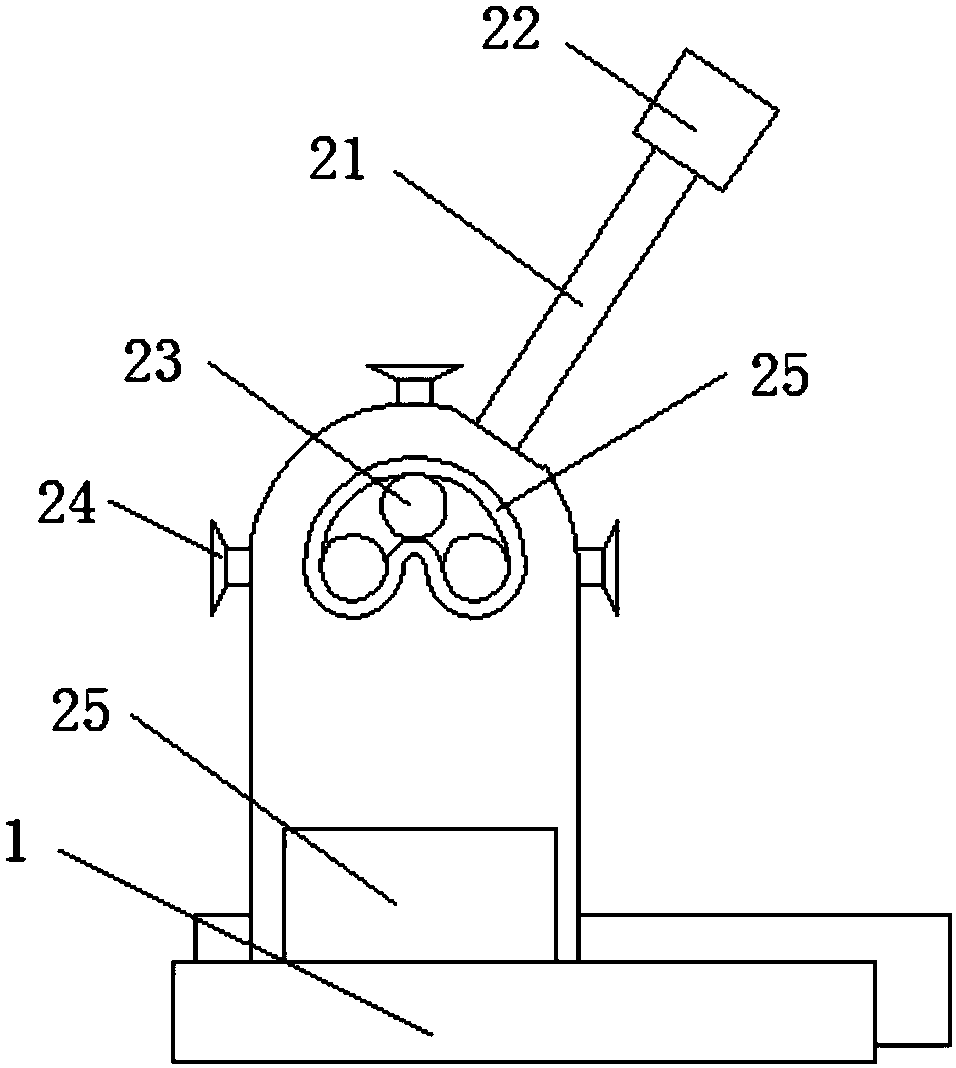

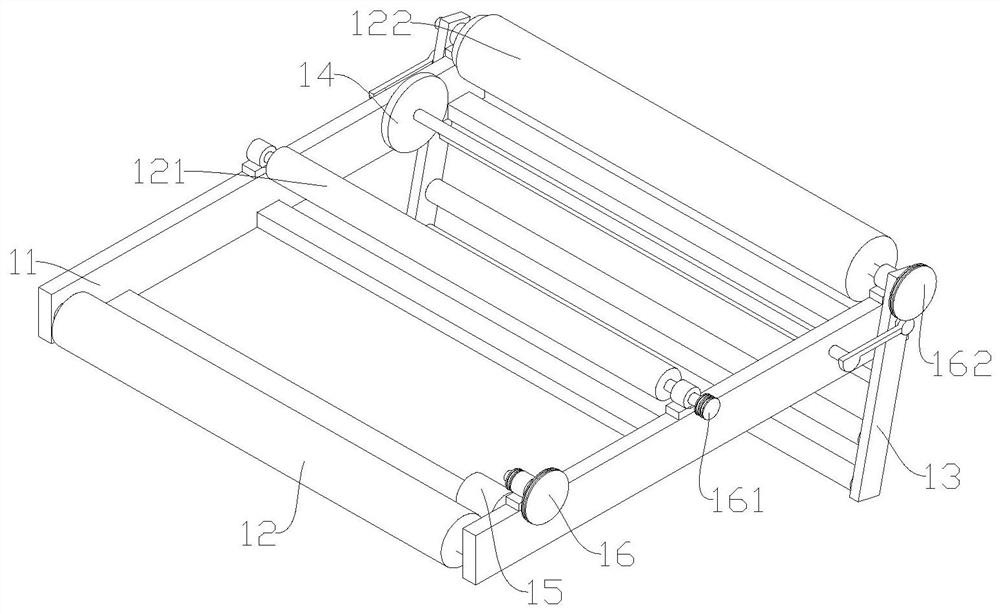

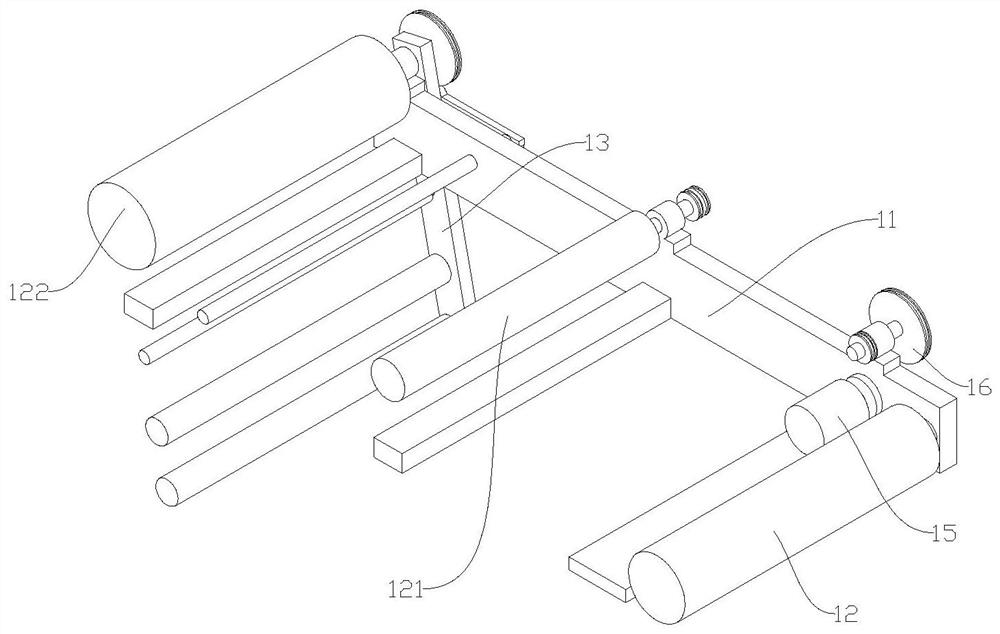

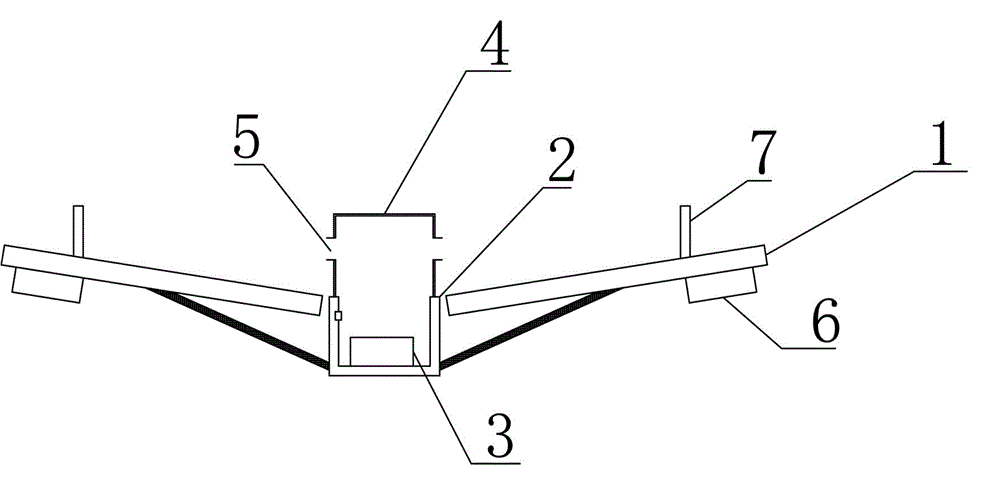

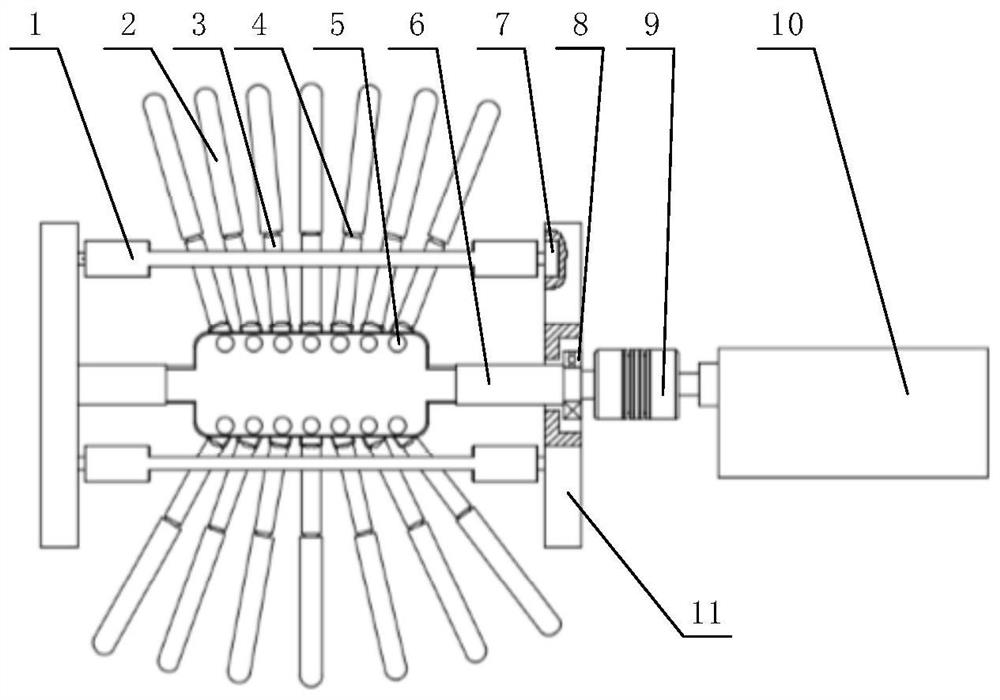

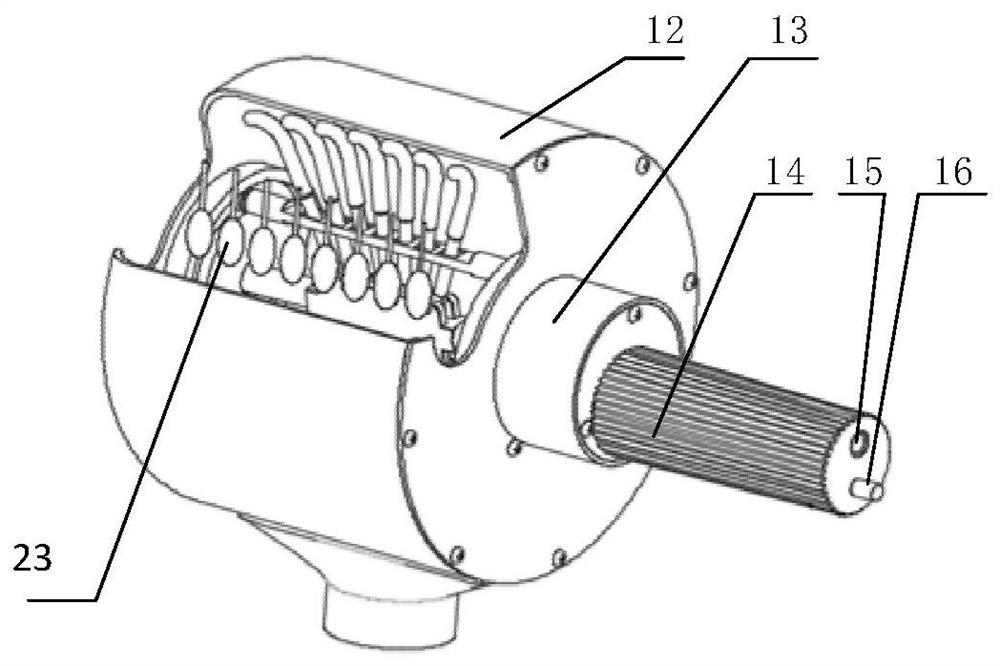

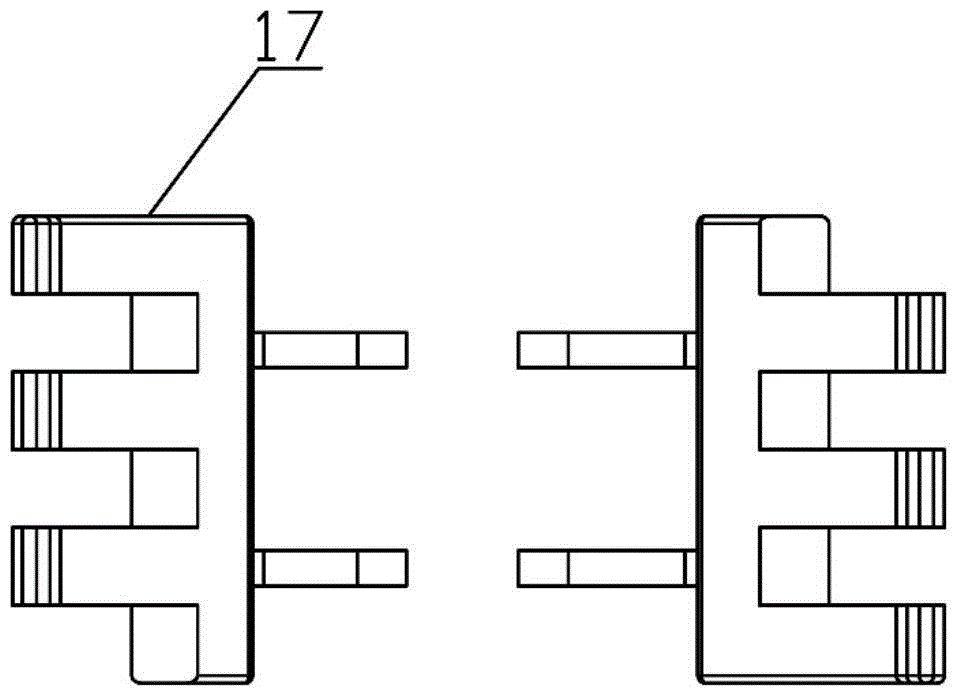

Combing-brush profile-modeling fructus-lycii picking tail-end executor

The invention belongs to the technical field of agricultural machines, and particularly relates to a combing-brush profile-modeling fructus-lycii picking tail-end executor. The combing-brush profile-modeling fructus-lycii picking tail-end executor comprises a main shaft and groove cams connected to the two ends of the main shaft. A plurality of picking fingers are hinged to the middle of the mainshaft, and are combined together to be in emission shapes from inside to outside, a ring of cam groove is formed in the inner side of the each groove cam in a milled mode, and cam driven bearings arearranged in the cam grooves and can freely roll along the cam groove; pressing plates are installed between the corresponding cam driven bearings on the two groove cams, a plurality of holes are formed in the pressing plates, each picking finger penetrates through the middle of each hole, the picking fingers are driven to rotate when the main shaft rotates, and drive the pressing plates to rotate,the holes in the pressing plates slide up and down at the lower ends of the picking fingers, and therefore gap changes between the picking fingers are oppressed. The structure is simple, the cost islow, and mature fruits can be effectively screened and picked; the breakage rate of fructus lycii is greatly reduced; meanwhile, friction force between the picking fingers and the fructus lycii is enlarged, and the net picking rate is guaranteed.

Owner:CHINA AGRI UNIV

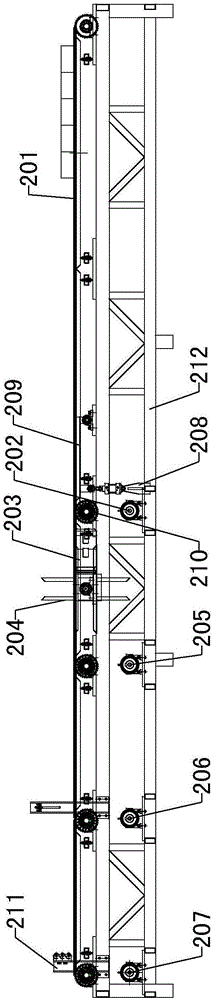

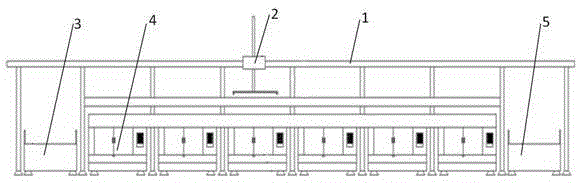

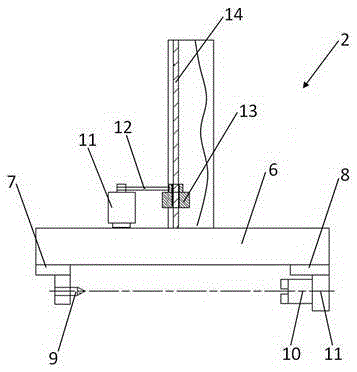

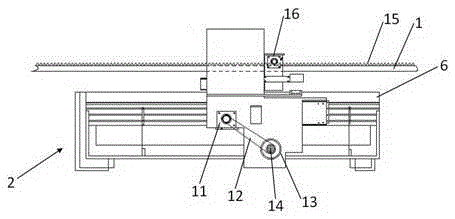

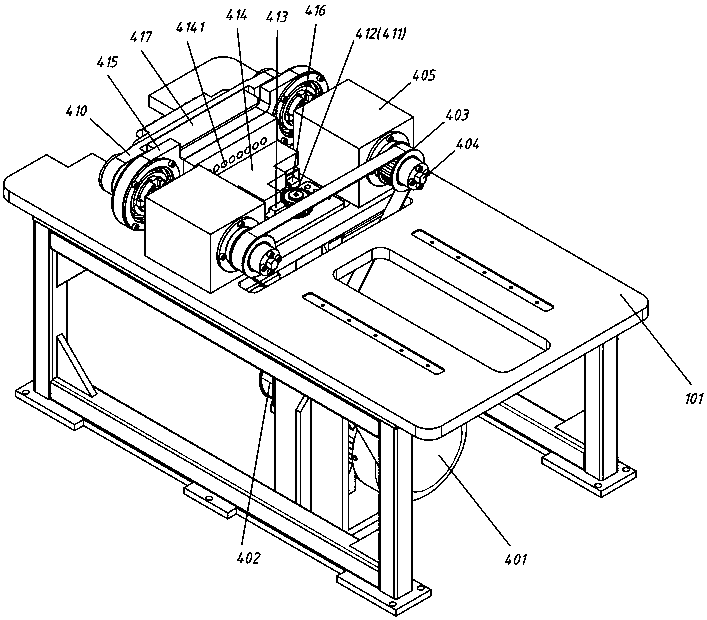

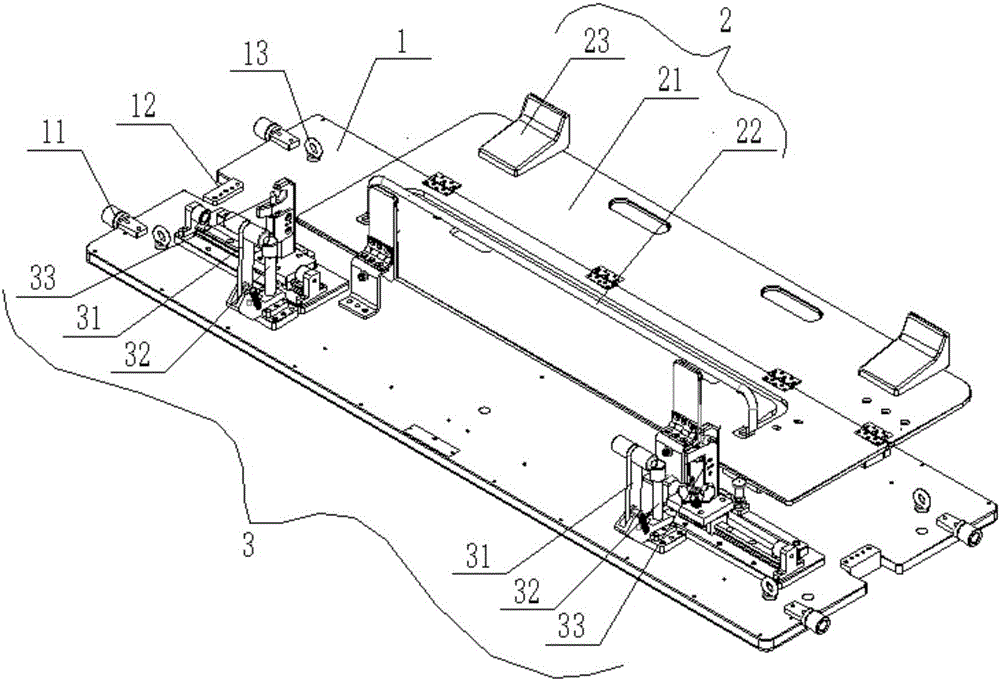

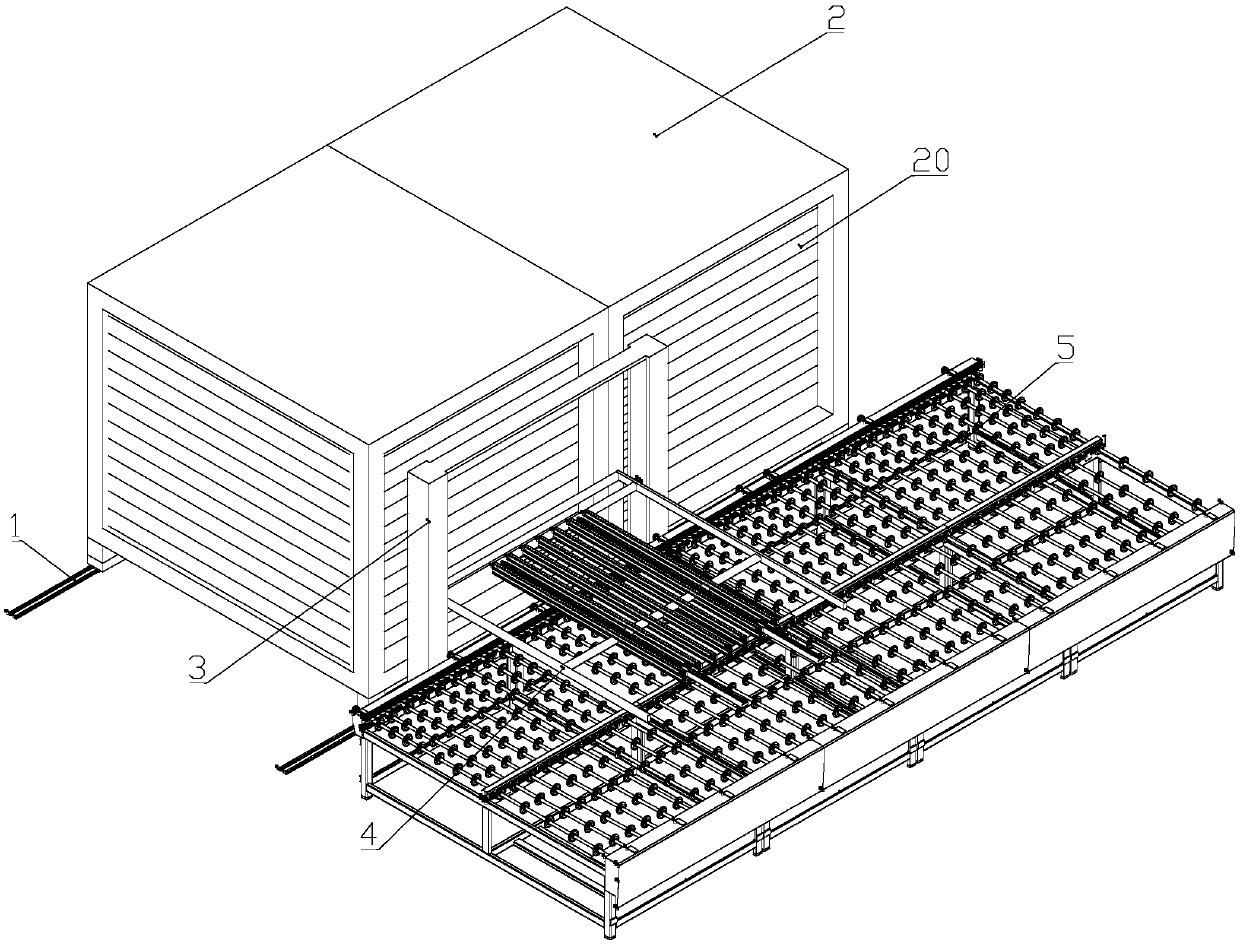

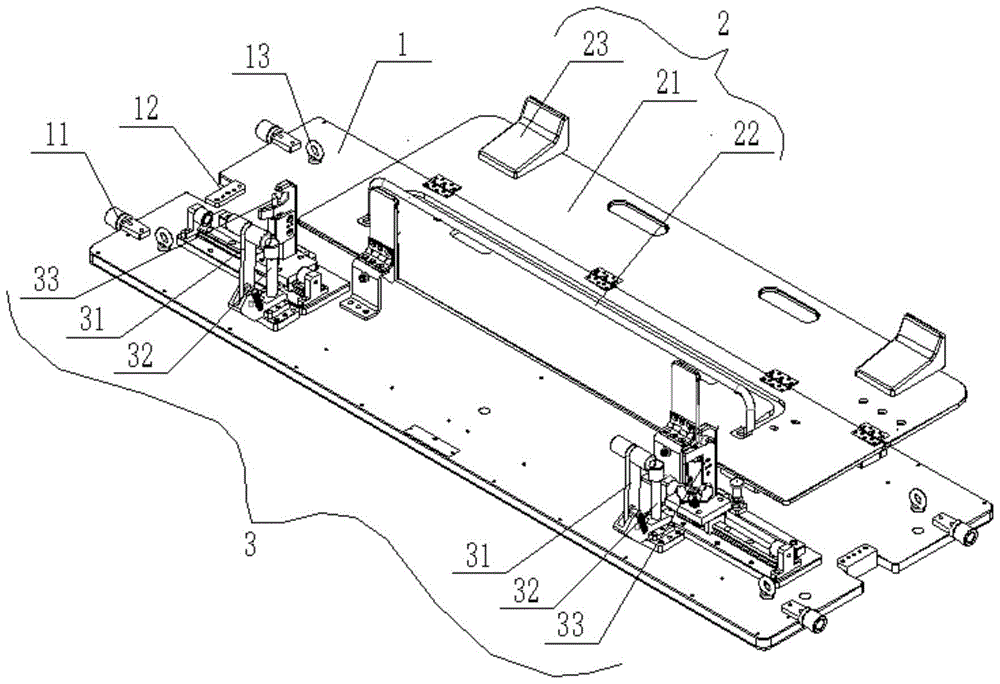

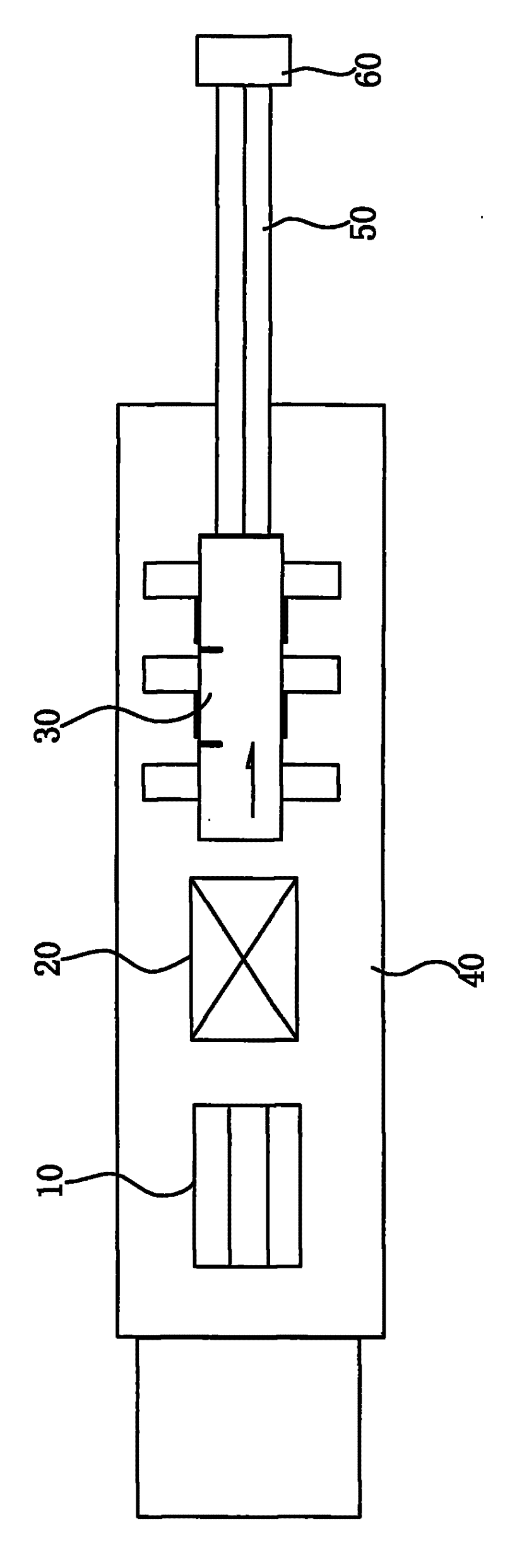

Automatic production line of slender special-shaped pipes

InactiveCN105345579AAvoid wear and tearReduce handling linksAutomatic workpiece supply/removalMetal working apparatusProduction lineEngineering

The invention discloses an automatic production line of slender special-shaped pipes. The automatic production line comprises a truss, a loading bin, processing centers and an unloading bin, wherein the loading bin, multiple processing centers and the unloading bin are linearly arranged along a cross beam of the truss; the truss is provided with a truss manipulator; and the truss manipulator comprises a clamping mechanism, an overturning mechanism, a transverse moving mechanism and a longitudinal moving mechanism. The automatic production line can realize multi-station and multi-procedure complex automatic processing of workpieces, so that the carrying link among the procedures is reduced, the workpiece wear possibly generated in the carrying link is prevented, and errors generated in the manual positioning and processing process are reduced; and the automatic production line is high in processing precision and high in yield, shortens the processing period, and improves the production benefit.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

Pipe bending and ring sleeving integrated machine for pipe fitting

PendingCN109317972ARealize zero rowAchieve wearOther manufacturing equipments/toolsTube shearing machinesPipe fittingEngineering

A pipe bending and ring sleeving integrated machine for a pipe fitting comprises a pipe cutting part, a bending part, a discharging part and a ring sleeving mechanism which are sequentially arranged,wherein the pipe cutting part is used for cutting the pipe fitting into pipes with specified length; the cut pipes are fed into the bending part for bending; the pipes are bent into U shapes and thenare discharged to the ring sleeving mechanism for sleeving with rings through the discharging part. With the adoption of the machine, the U-shaped pipe bending and ring sleeving processes can be finished by one machine, so that the carrying ring is reduced, the production efficiency is high, and the occupied area is small; a mode of rotatably cutting without scraps through an inner cutting tool iscarried out, so that cutting scraps cannot be produced; a bent U-shaped elbow workpiece can be directly degreased without being washed, thus zero emission of washing liquid is realized, and the environmental protection is realized; and moreover, the workpiece is uniformly stressed during being cut, and an inclined notch is avoided; a following part is additionally arranged during bending, so thatthe abrasion of the outer sidewall of a metal pipe fitting is decreased, and the quality of the bent metal pipe fitting can be effectively improved.

Owner:JDM JINGDA MASCH (NINGBO) CO LTD

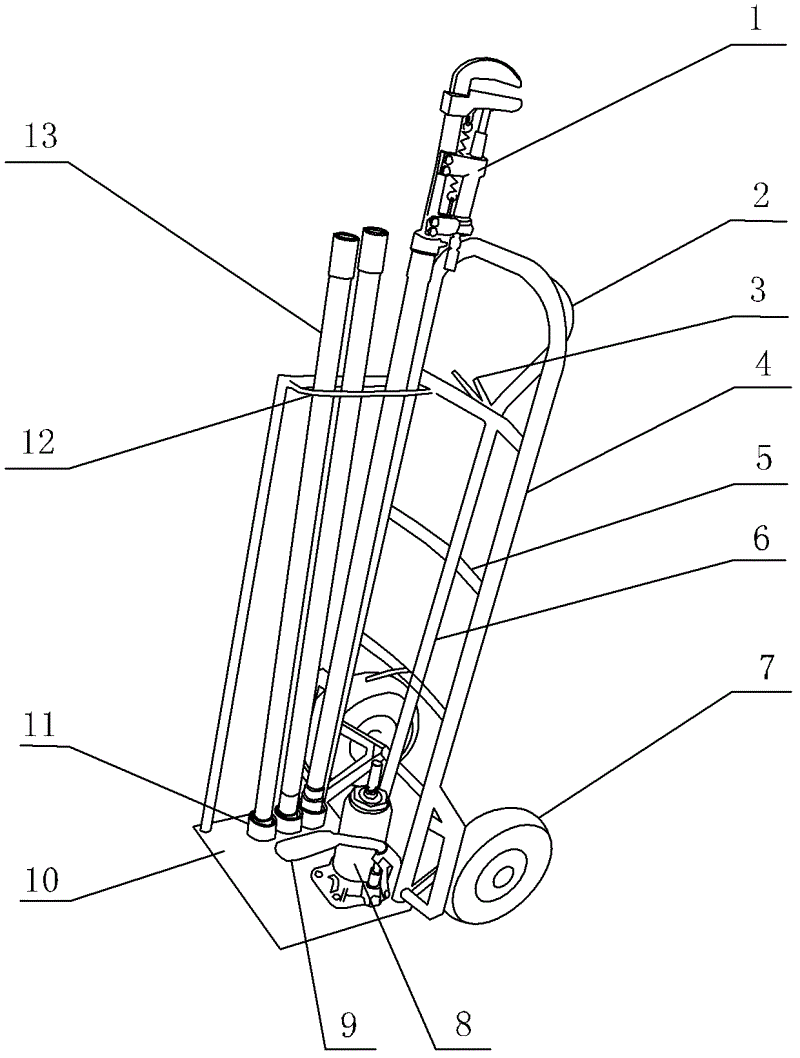

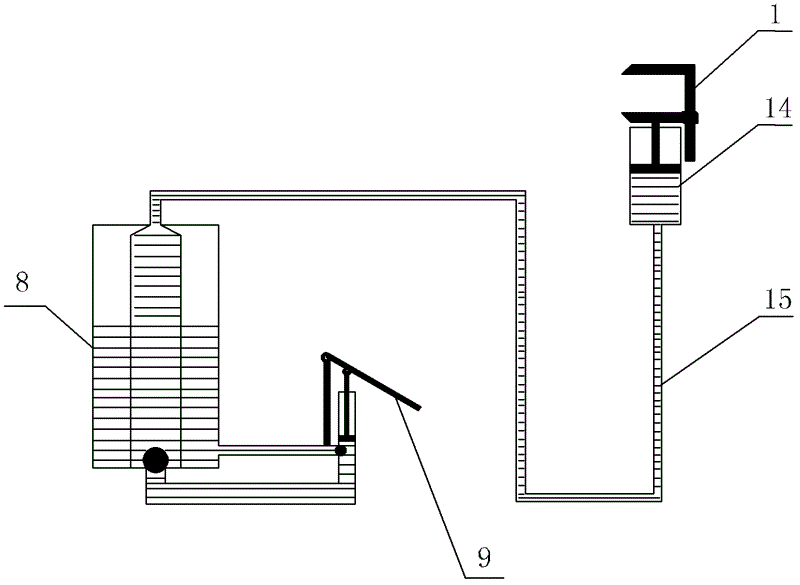

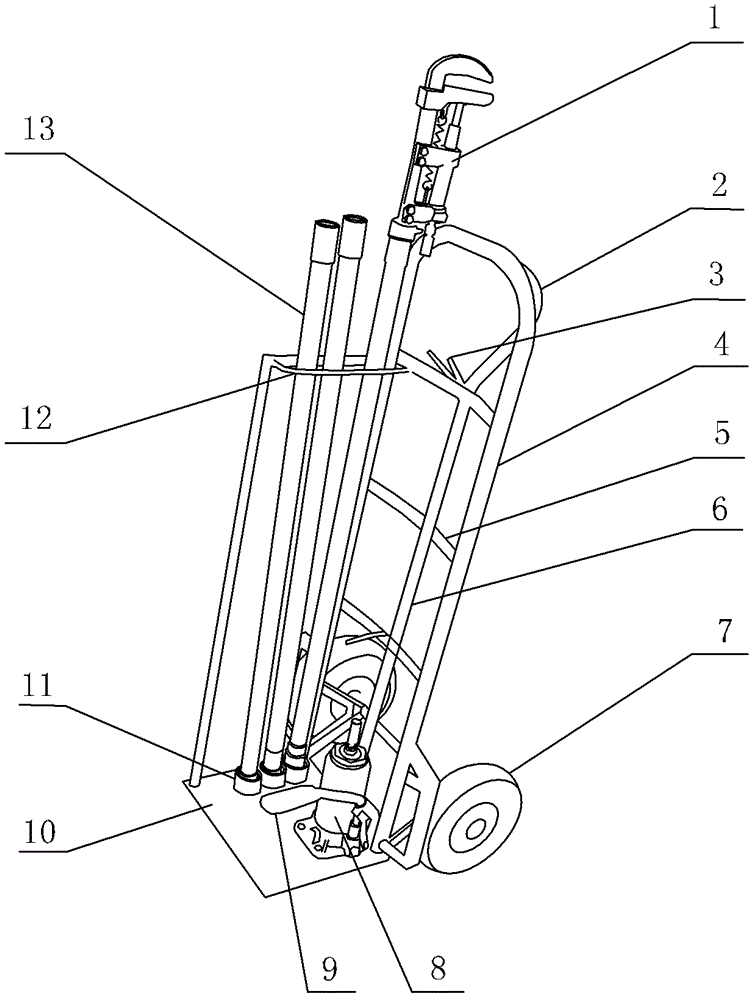

Tree pruning tool for line protective area

The invention relates to a tree pruning tool for a line protective area, which belongs to the tree pruning tool field. The tree pruning tool for the line protective area comprises a pair of hydraulic scissors, a hydraulic system and a movable trolley, and is characterized in that the hydraulic system consisting of a hydraulic jack and a pedal is fixed on the movable trolley, the hydraulic jack is connected with an oil cylinder of the hydraulic scissors through an oil pipe, and a fixed bracket of the hydraulic scissors is provided with one to four sections of handheld insulation rods. By adopting the movable trolley, the tree pruning tool is convenient to transport to a work site, so that the handling procedure can be reduced, and the time and labor can be saved; the tool can prune big tree branches, so that a maintainable range of the line protective area is larger, and trees are pruned to be more tidy; and by adopting a plurality of handheld insulation rods, high voltage can be isolated, an electric shock can be prevented, the handheld insulation rods can be assembled or disassembled according to a working condition, so that the tree pruning tool is applicable to different trees in different heights. Through further improvement, and by utilizing the tree pruning tool, the workload and the labor intensity of workers can be alleviated, the tree pruning tool is applicable to different trees in different heights, and the safety running of a power line can be guaranteed.

Owner:STATE GRID CORP OF CHINA +1

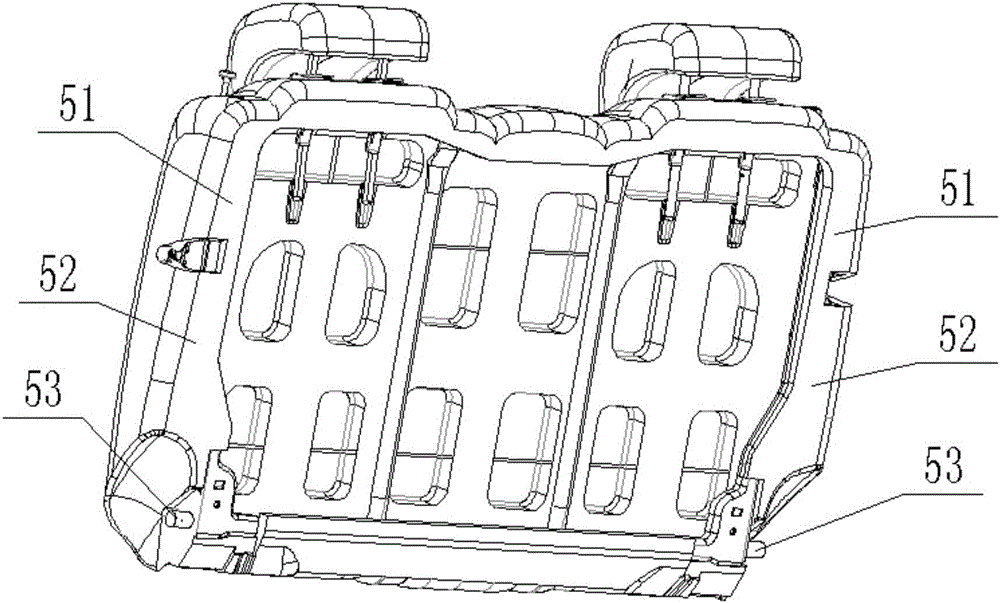

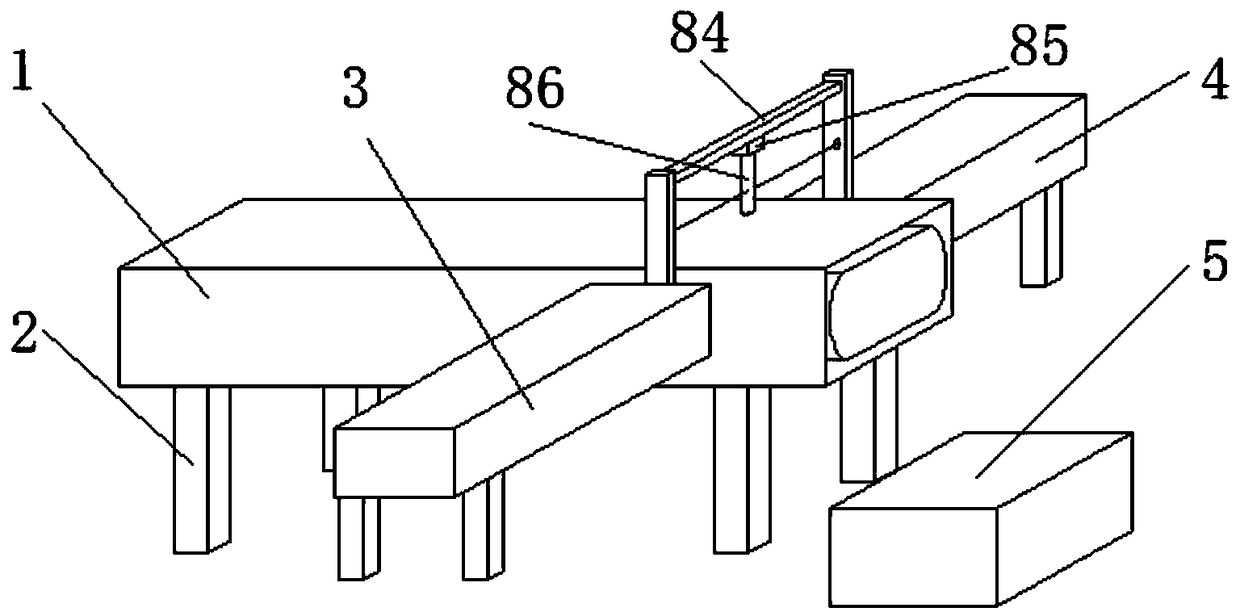

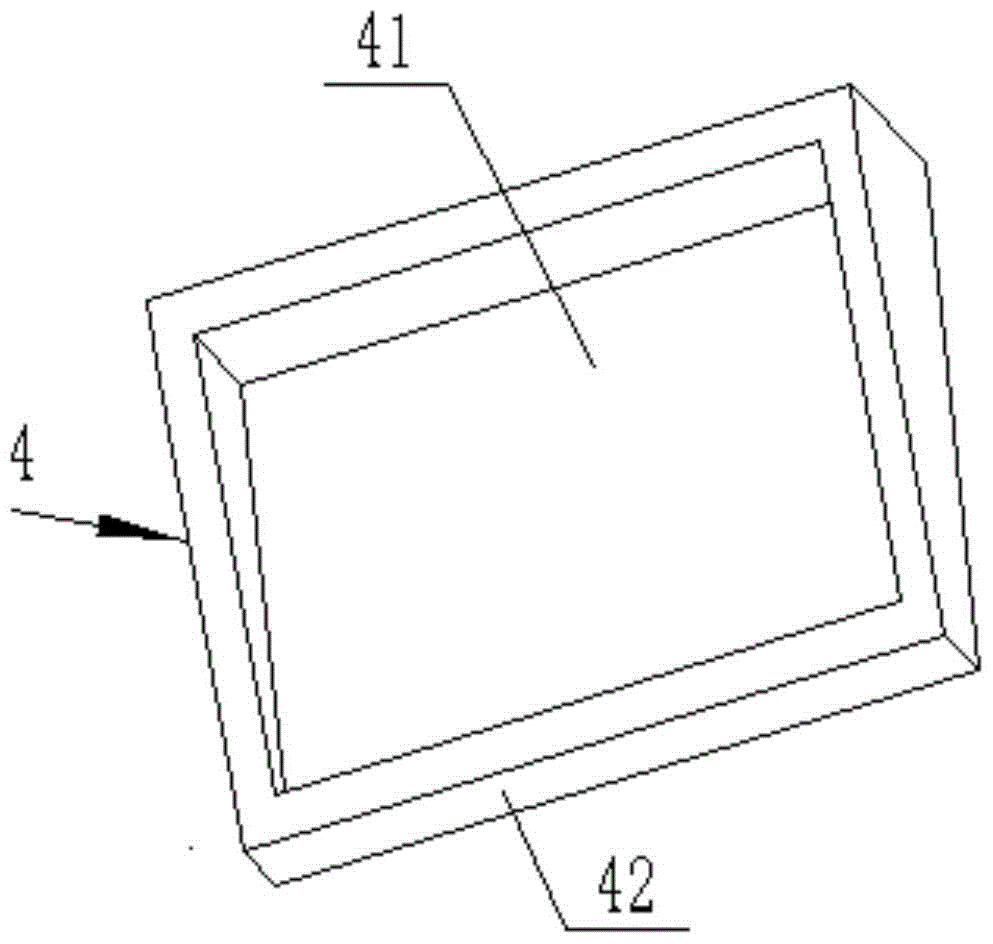

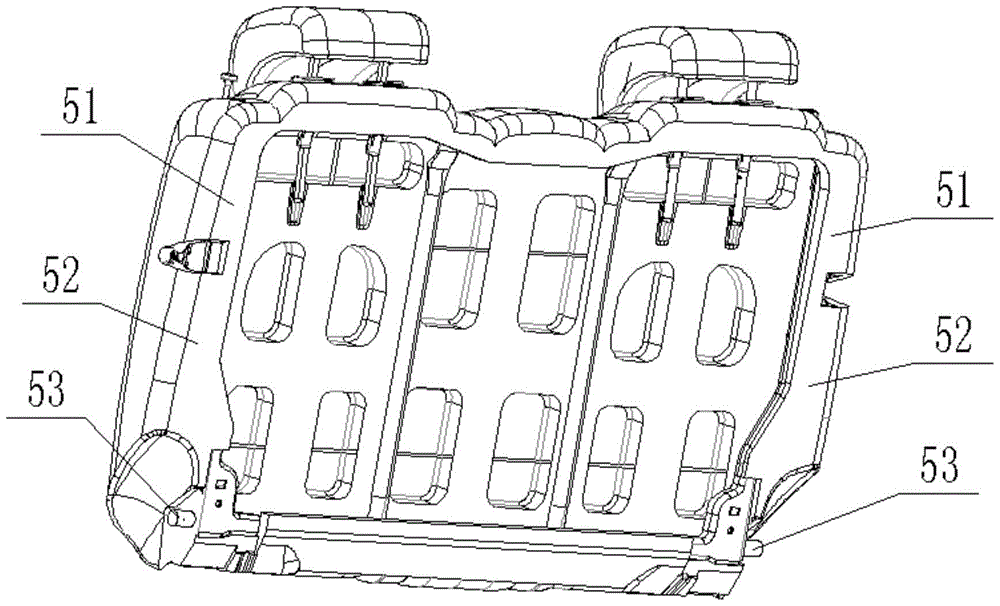

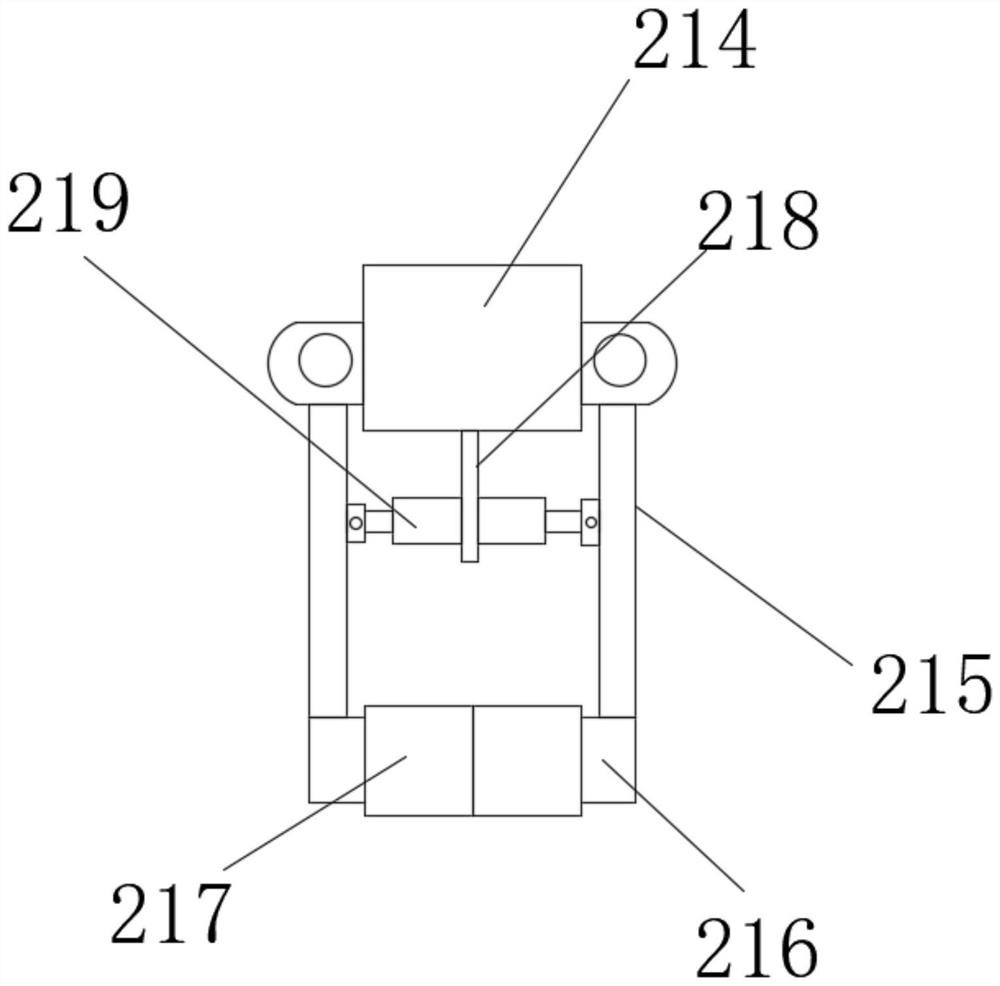

Synchronous assembly tool used for seat backrest and seat foam

InactiveCN105034907ASimple structureReduce storage and handling linksVehicle seatsElectricityProduction line

The invention discloses a synchronous assembly tool used for a seat backrest and seat foam. The synchronous assembly tool is characterized by comprising a station plate, a foam tool and a backrest tool, and the foam tool and the backrest tools are installed on two stream line operation sides of the station plate respectively; the foam tool comprises a bottom plate, a support capable of extending into an upper concave part of the seat foam is arranged on the bottom plate, and at least one limiting plate is arranged on the bottom plate and used for limiting the upper edge of the seat foam. The backrest tool comprises a pair of upper portion supporting mechanisms arranged symmetrically on the station plate, a pair of middle supporting mechanisms arranged symmetrically on the station plate and a pair of positioning mechanisms arranged symmetrically on the station plate. The seat foam and the seat backrest can be synchronously assembled, and one production line can be saved; after the seat foam and the seat backrest are assembled, the seat foam and the seat backrest are convenient to assemble in pairs, storing and carrying steps are omitted, production efficiency can be improved, and the costs of equipment, electricity and labor are lowered.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

Method and equipment for continuous production of stewed food

ActiveCN103610223BRealize continuous operationHigh degree of mechanizationFood shapingOperation modeBucket elevator

The invention provides a method and equipment for continuously producing a marinated food. The method sequentially comprises the following steps: thawing, pickling, marinating, spreading for cooling, packing in small packages, sterilizing, washing, drying, packing in a large package and storing. The marinating step is continuously carried out in a marinating groove by a stainless steel silk screen conveyor belt. The equipment sequentially comprises a thawing tank, a first conveyor belt, a pickling tank, a second conveyor belt, the marinating groove, a bucket elevator, a spreading vibration sieve, an air pressure packaging machine, sterilization equipment, a spiral washing machine and a drying machine; a marinating liquid pot is arranged beside the marinating groove and the marinating groove is internally provided with the stainless steel silk screen conveyor belt. According to the method and the equipment for continuously producing the marinated food, a traditional manual operation mode is changed, the mechanization degree is high, the continuous work of a production line is realized, and the yield is great; the labor intensity in the production process is reduced, and a link of carrying in each working procedure is omitted; the quality, the appearance and the color and luster of the food are guaranteed; from the perspective of environmental sanitation, safety and heat loss, the equipment is easy to clean and convenient to operate, energy sources are saved and the total cost is reduced.

Owner:湖南桃花鸭食品科技有限公司

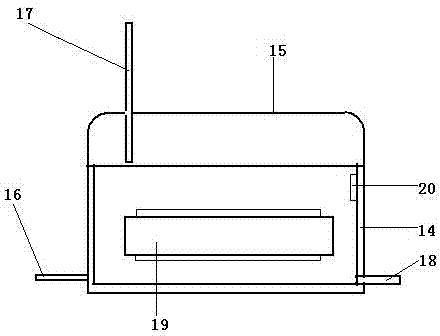

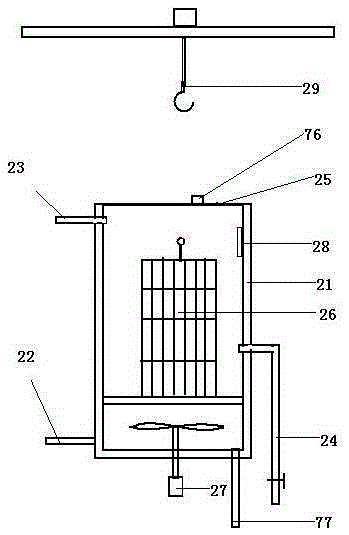

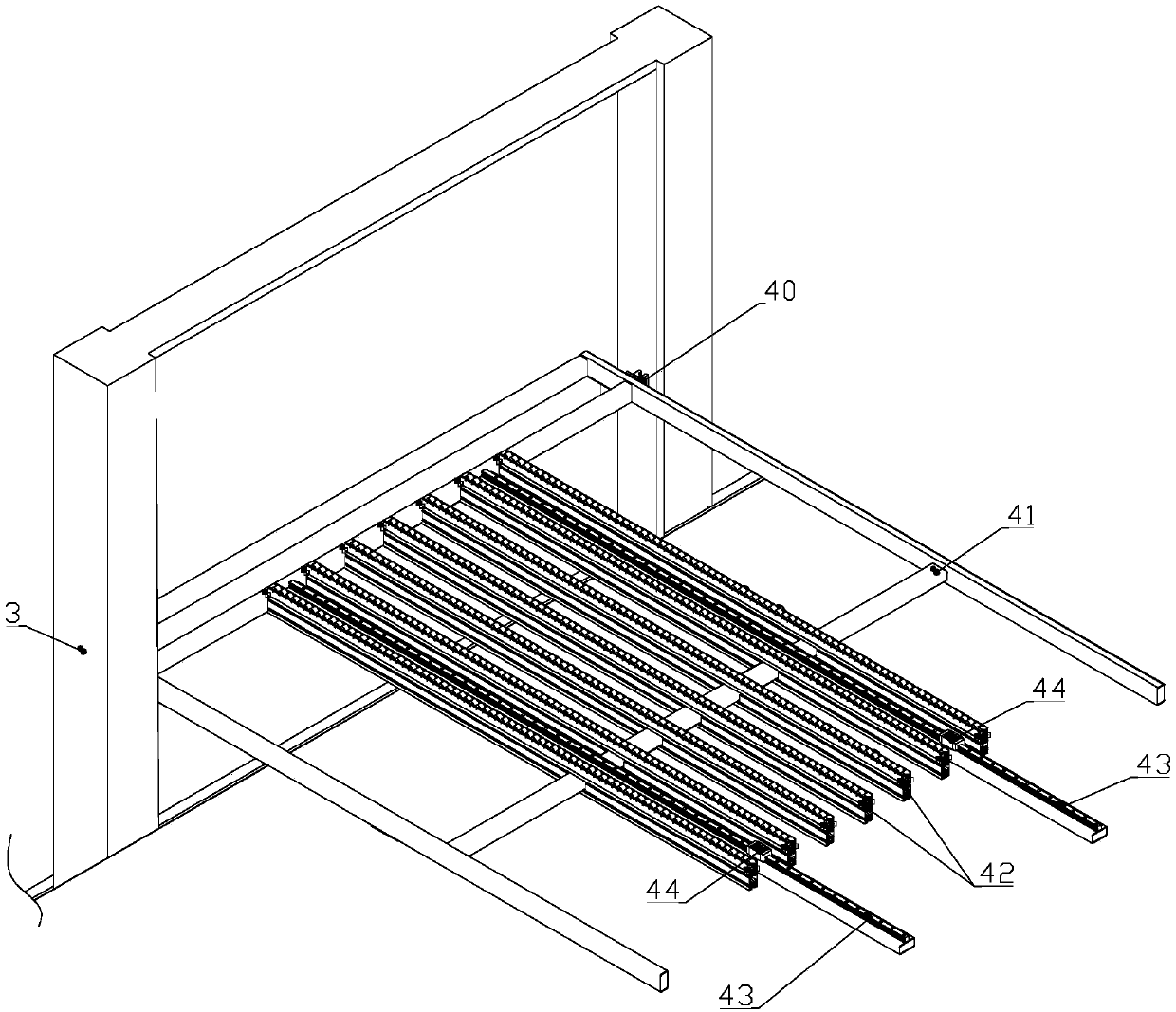

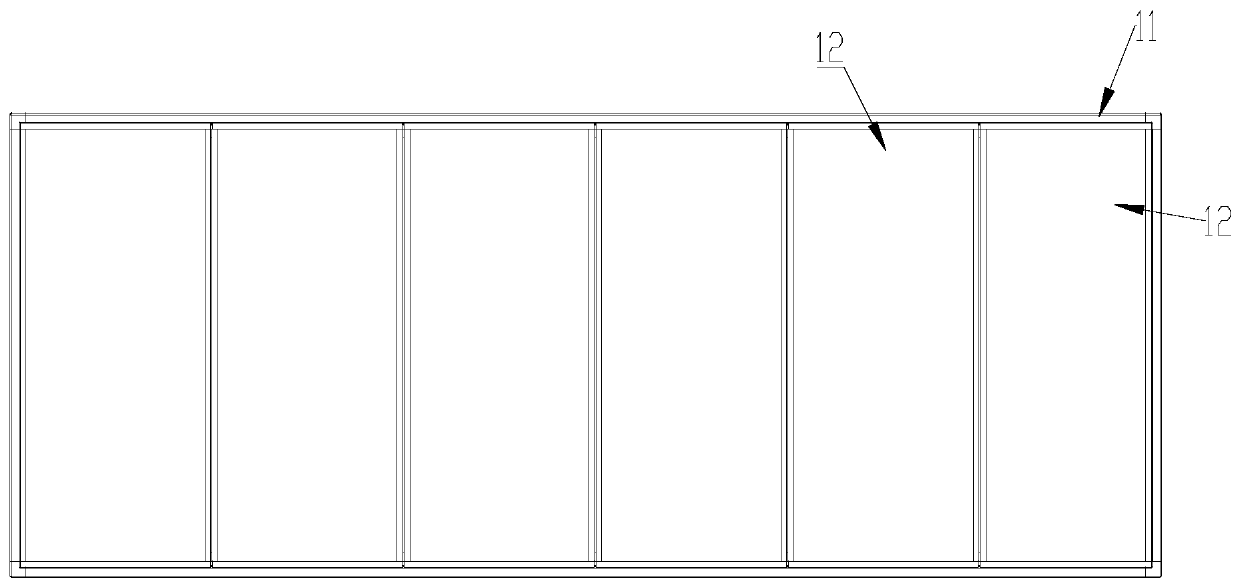

Glass warehousing system and control method

InactiveCN109625744ASimple structureAvoid wear and tearCharge manipulationStorage devicesProduction linePortal frame

The invention discloses a glass warehousing system and a control method thereof. The glass warehousing system comprises a warehousing cabinet, a portal frame, a glass taking and sending mechanism anda conveying platform. The warehousing cabinet is arranged on ground guide rails and moves relative to the ground guide rails. The ground guide rails are arranged parallel to the conveying platform. The portal frame is fixed to the position, between the ground guide rails and the conveying platform, on the ground. Lifting guide rails are arranged on the two sides of the interior of the portal frame, and a containing cavity used for being matched with the glass taking and sending mechanism is formed in the conveying platform. The two sides of one end of the glass taking and sending mechanism areconnected with the lifting guide rails, and the other end of the glass taking and conveying mechanism is suspended above the conveying platform or descends into the containing cavity along the lifting guide rails. By means of the glass warehousing system and the control method thereof, the occupied space of a glass edge polishing production line can be definitely reduced, the glass edge polishingefficiency is optimized, meanwhile, the labor proportion occupied by people in the edge polishing process is reduced, the labor cost is saved, and meanwhile the equipment service life is prolonged.

Owner:广东新泓达智能科技有限公司

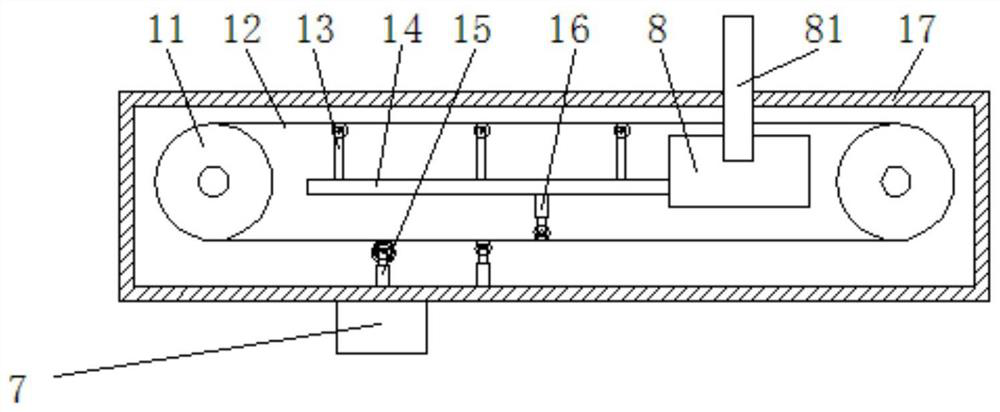

Automatic paper cutting machine for papermaking

PendingCN108044690AReduce handling linksProcessing speedMetal working apparatusPapermakingKnife holder

The invention discloses an automatic paper cutting machine for papermaking. The automatic paper cutting machine comprises a bottom plate. The surface of the bottom plate is provided with a first guideframe and a second guide frame. A first cutter frame is arranged between the first guide frame and the second guide frame. An adjusting device is arranged between the first guide frame and the firstcutter frame. An installation frame is arranged on the surface of the portion, on the side face of the second guide frame, of the bottom plate. An adsorption device is connected to the interior of theinstallation frame. A second cutter frame is arranged on the side face of the installation frame. According to the automatic paper cutting machine for papermaking, the work of a first electric telescopic rod, a second telescopic rod and a third electric telescopic rod is adjusted, and therefore paper is longitudinally cut through a first cutter; and the work of a fifth electric telescopic rod iscontrolled, accordingly, paper is transversely cut through a second cutter, the carrying process of paper in the cutting process is omitted, the paper processing speed is improved, working efficiencyis improved, and convenience is brought to people for using the machine.

Owner:何佳俊

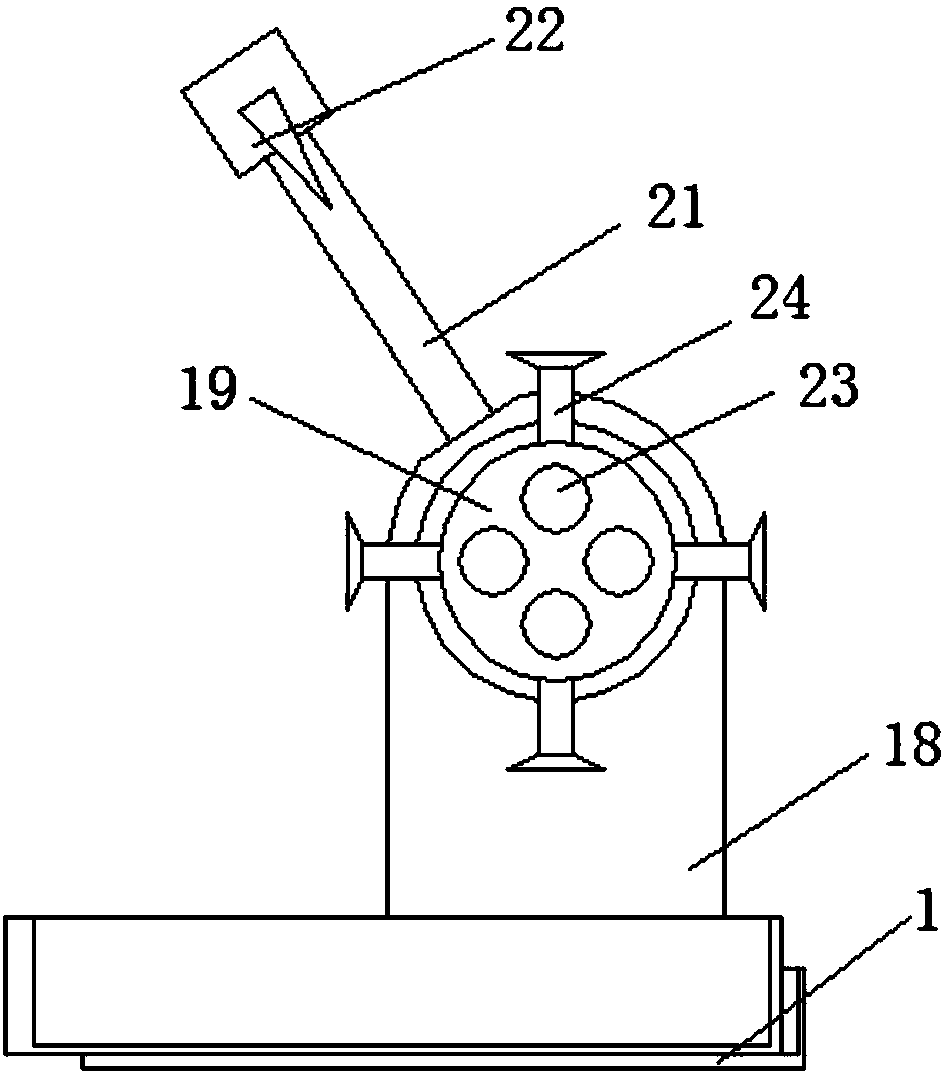

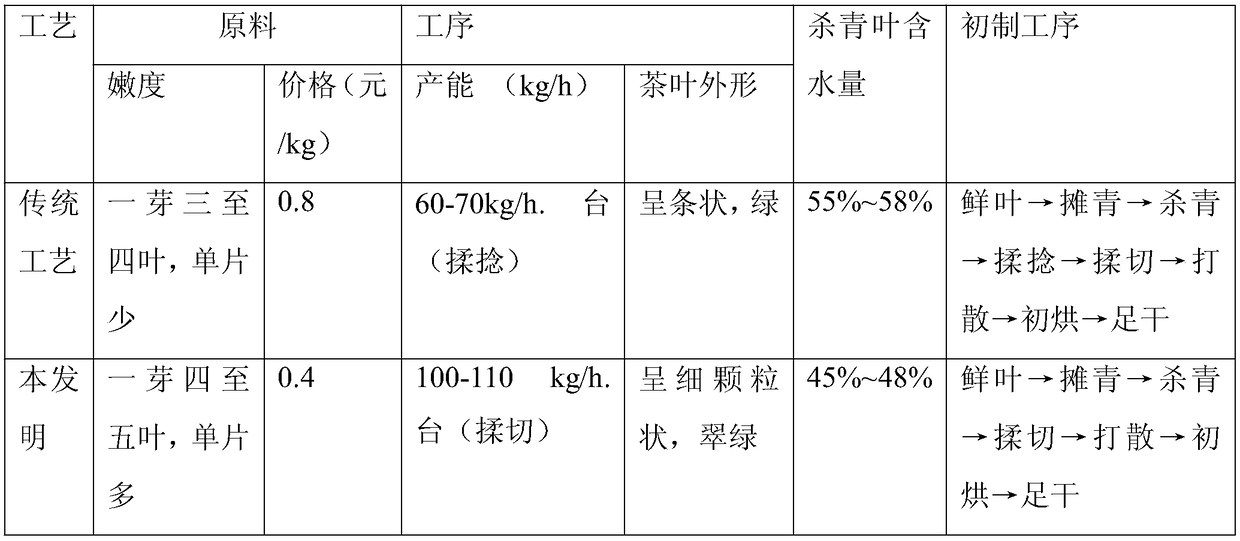

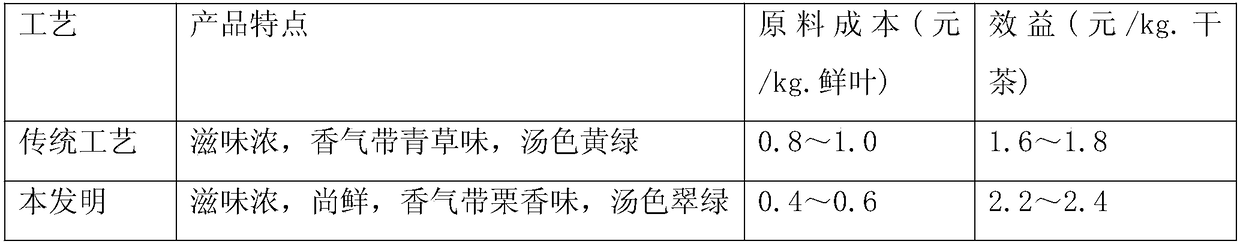

Primary refining integrated processing method of broken green tea from fresh leaves picked by machine

InactiveCN108378144AFixed shape qualityLow costPre-extraction tea treatmentEmeraldIntegrated processing

The invention relates to a primary refining integrated processing method of broken green tea from fresh leaves picked by a machine. The primary refining integrated processing method comprises the following steps of step I, selecting fresh leaves from tea trees on which the tea leaves have one bud and four to five leaves for natural spreading: step II, performing fixation, wherein the moderate standard lies in that the leaves are soft in texture, and green grass smell disappears; step III, performing rolling and cutting, wherein the moderate standard lies in that after rolling and cutting, theleaves are emerald green in color, and the tea stems and leaves are finely-crushed; step IV, performing deblocking, and then performing primary drying; step V, performing sufficient drying, wherein the temperature for sufficient drying is set to 135-145 DEG C, so that the water content of tea semi-finished products is 7% or below; step VI, performing classifying: sieving the broken tea leaves intotea of different grades from four outlets being smaller than 12 meshes, being 12-40 meshes, being 40-60 meshes, and being greater than 60 meshes, wherein the broken tea being smaller than 12 meshes and the broken tea being greater than 60 meshes are used as byproducts for storage; and step VII, performing stem sorting: separately obtaining a quality product 1, a quality product 2, a correspondingbyproduct 1 and a corresponding byproduct 2, and separately storing the quality products and the byproducts. The primary refining integrated processing is realized, so that quality products of the broken green tea of 2 different grades are obtained, and stable products are obtained.

Owner:INST OF FRUIT & TEA HUBEI ACAD OF AGRI SCI

Belt conveyor with allocation function

ActiveCN109018956ALarge distribution qualityFacilitate transmissionConveyorsCleaningEngineeringBelt conveyor

The invention discloses a belt conveyor with an allocation function. The belt conveyor comprises a conveyor body, supporting legs, a second conveying mechanism, a third conveying mechanism, a collecting device and an allocation device, and the number of the supporting legs is at least four. The supporting legs are fixed at the bottom of the conveyor body, the two sides of the conveyor body are connected with the second conveying mechanism and the third conveying mechanism, and the collecting device is arranged below the tail end of the conveyor body. The allocation device is arranged in the conveyor body, and the allocation device is located on the connecting line of the center of the second conveying mechanism and the center of the third conveying mechanism. The allocation device is arranged so that required articles can be allocated according to requirements. Due to the arrangement of the allocation device, the belt conveyor is more automatic, and the application efficiency of the belt conveyor is improved. The second conveying mechanism and the third conveying mechanism can directly transfer unnecessary articles, so that manual screening and carrying links are omitted, and the efficiency is improved.

Owner:安徽智崎环保设备有限责任公司

Large section pulling and extruding type production process and set thereof

A large section pulling and extruding type production process and a set thereof. The production process includes: adopting a pulling and extruding drawing tool provided with a fixed section extruding production device; when the section extruding production device working, the pulling and extruding drawing tool moving along the direction opposite to the section extruding direction. The invention eliminates the defect that the elongated large section is hard to move. The production process and the set realize the large section production on site and stable quality control in a way that the extruding device extends. The production is fast and convenient; the transportation is smooth and the waste due to improper cutting of large section is avoided.

Owner:BEIJING HAIBO SIQIANG BRIDGE NEW TECH

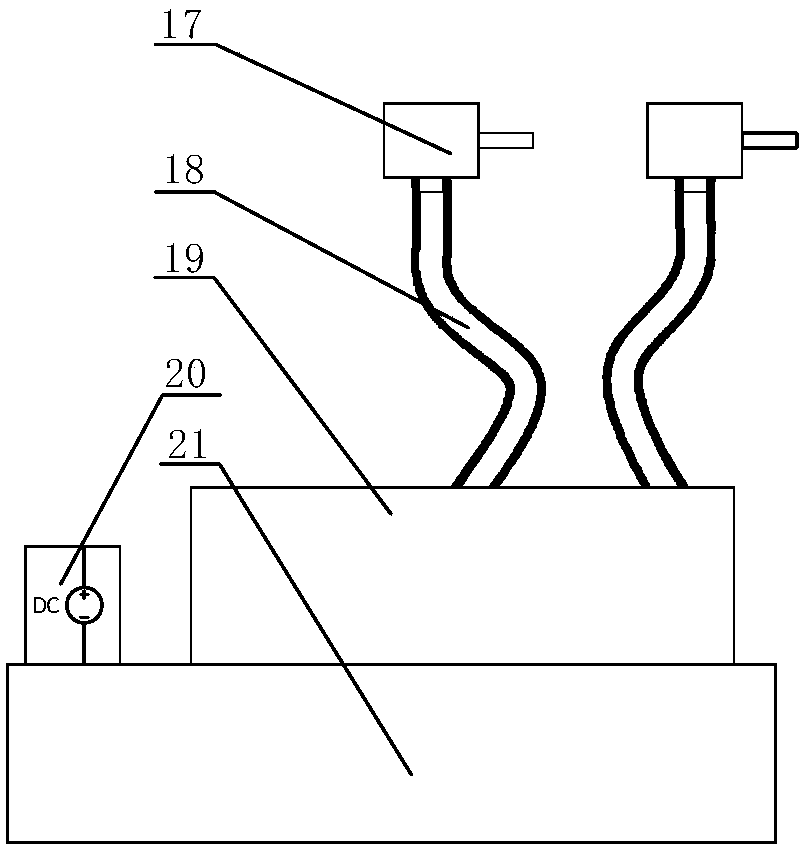

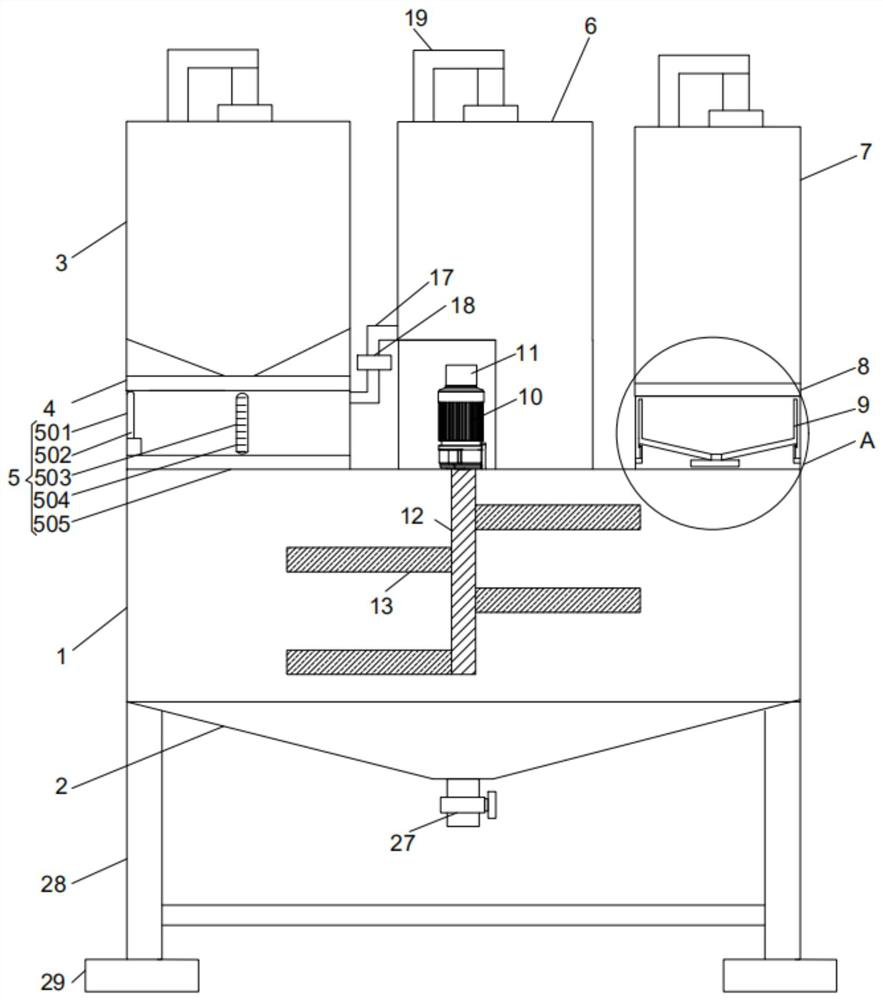

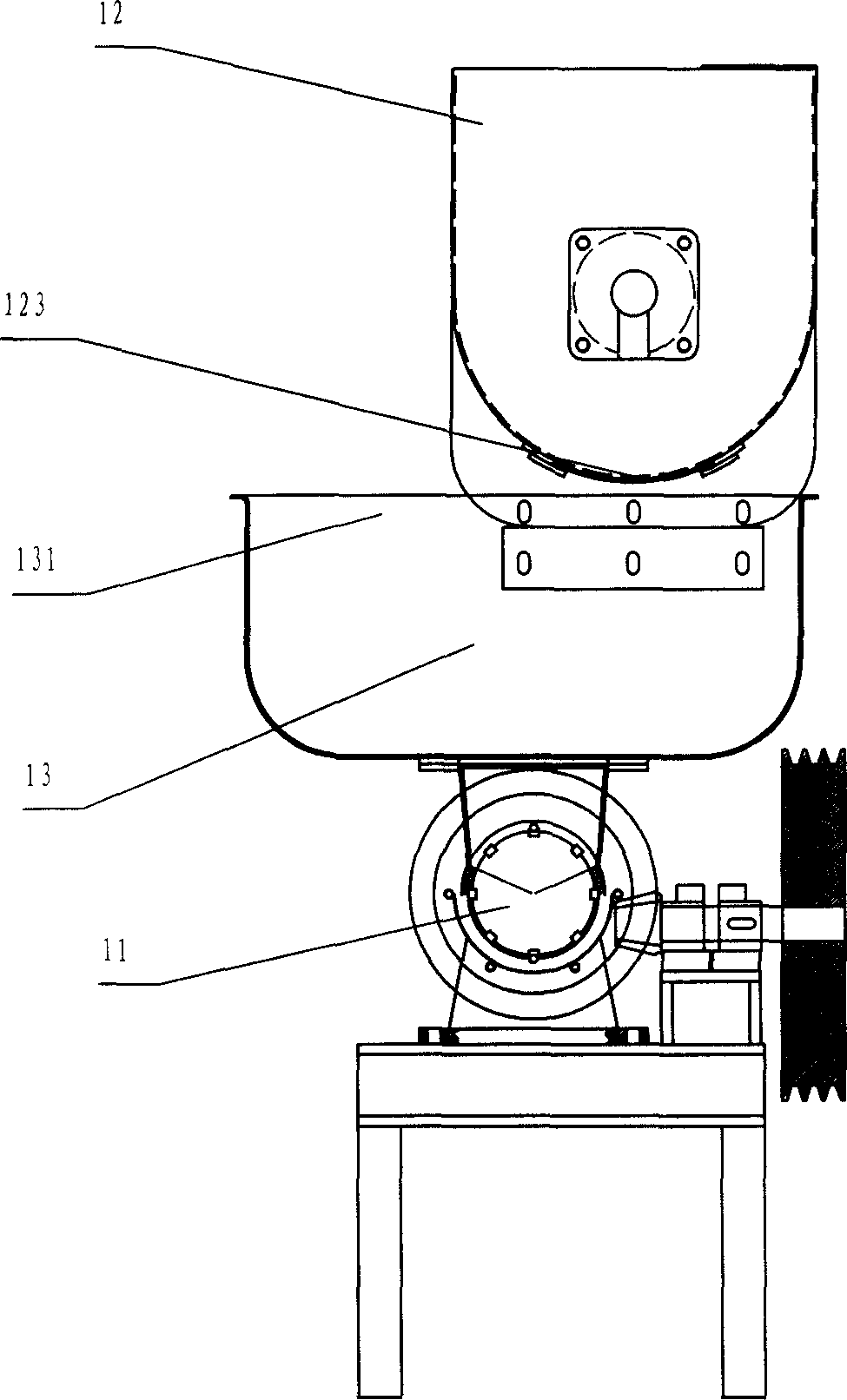

Cigarette adhesive mixing equipment

InactiveCN112023795AReduce handling linksReduce measurement errorTransportation and packagingMixer accessoriesAir pumpProcess engineering

The invention discloses cigarette adhesive mixing equipment, which belongs to the field of cigarette adhesive production and processing, and comprises a mixing tank, the bottom of the mixing tank is integrally connected with a blanking hopper, the left side of the top of the mixing tank is fixedly provided with a raw material tank, the bottom of the raw material tank is fixedly provided with a first electric control valve, a metering device is fixedly installed at the bottom of the first electric control valve, a water tank is fixedly installed in the middle of the top of the mixing tank, a chemical tank is fixedly installed on the right side of the top of the mixing tank, liquid raw materials in the raw material tank and water in the water tank are directly metered by arranging the metering device, the chemical raw materials in the chemical tank are metered through the weighing device, the carrying link in the metering process is omitted, metering errors are greatly reduced, and the production efficiency is improved. High-pressure gas is introduced into the first through hole and the second through hole through a high-pressure gas pump, and the high-pressure gas bursts through thecheck plate through the gas holes to be exhausted.

Owner:CHUZHOU GUANGWEI CHEM

Tea leaf drying and screening device for tea leaf processing plants

InactiveCN108812949AQuality improvementEasy to dryPre-extraction tea treatmentAgricultural engineeringMoisture

The invention discloses a tea leaf drying and screening device for tea leaf processing plants. The tea leaf drying and screening device comprises a tank body, wherein an opening is formed in the rightend of the tank body; a platform body is fixedly mounted at the bottom of the inner part of the tank body; a supporting frame is connected to the side wall of the platform body; a first motor is fixedly mounted at the upper end of the supporting frame; a first rotating handle is connected to an output rod of the first motor in a sleeving manner; a mounting cavity is also formed in the platform body; a sliding seat is in sliding connection to the inner part of the mounting cavity; springs are respectively and fixedly connected to the sliding seat, the left side wall of the mounting cavity andthe right side wall of the mounting cavity; and a first connecting rod is rotatably connected to the side wall of the sliding seat. Through the adoption of the tea leaf drying and screening device disclosed by the invention, time and energy of labor sources for performing continuous stir-frying can be saved, pollution which is possibly generated by manual operation is avoided, and moisture of tealeaves can be quickly dried; and tea residues and tea dust can be screened away, so that the quality of the tea leaves is higher; and a carrying link between drying and screening can also be saved, sothat the production efficiency is higher.

Owner:葛永琴

Material transporting vehicle for oral liquid workshop

ActiveCN106184305AAvoid handlingLabor savingLoading/unloading vehicle arrangmentTransportation itemsMaterial transportCar door

The invention provides a material transporting vehicle for an oral liquid workshop. The material transporting vehicle for the oral liquid workshop comprises a compartment body, a universal wheel arranged at the bottom of the compartment body, and a refrigerating system, a lighting device and a material platform which are arranged in the compartment body, wherein a guide rail is arranged at the bottom in the compartment body, and the material platform can slide on the guide rail; and the compartment body consists of a compartment body frame as well as compartment boards and vehicle doors, which are embedded in the compartment body frame. The transporting vehicle disclosed by the invention can transport oral liquid in a free-flexible manner, so that time and labor are saved. The transporting vehicle is equivalent to a trolley, and the oral liquid can be directly unloaded and put into a stock tank, so that labor force is saved greatly.

Owner:哈尔滨圣泰生物制药有限公司

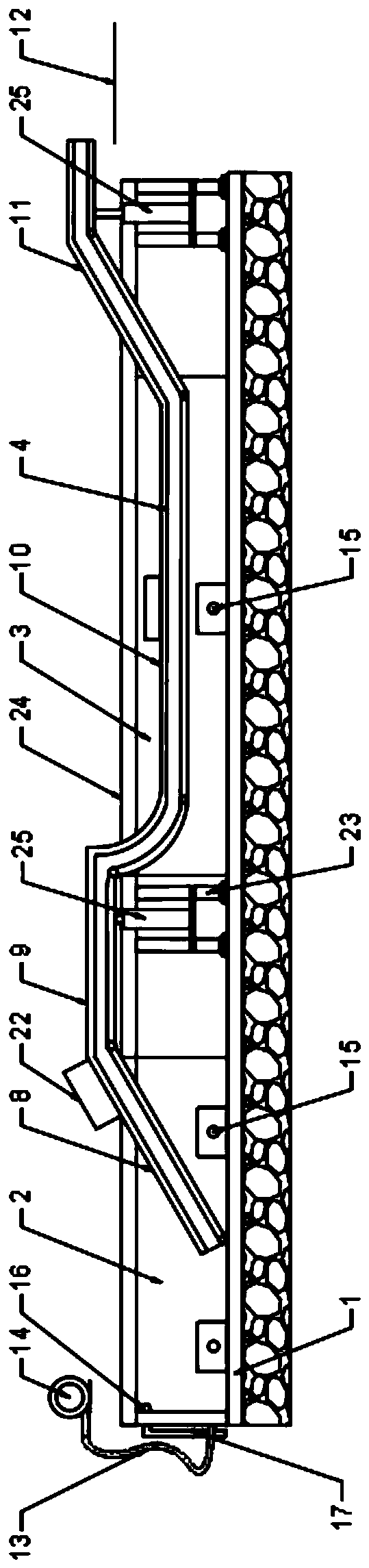

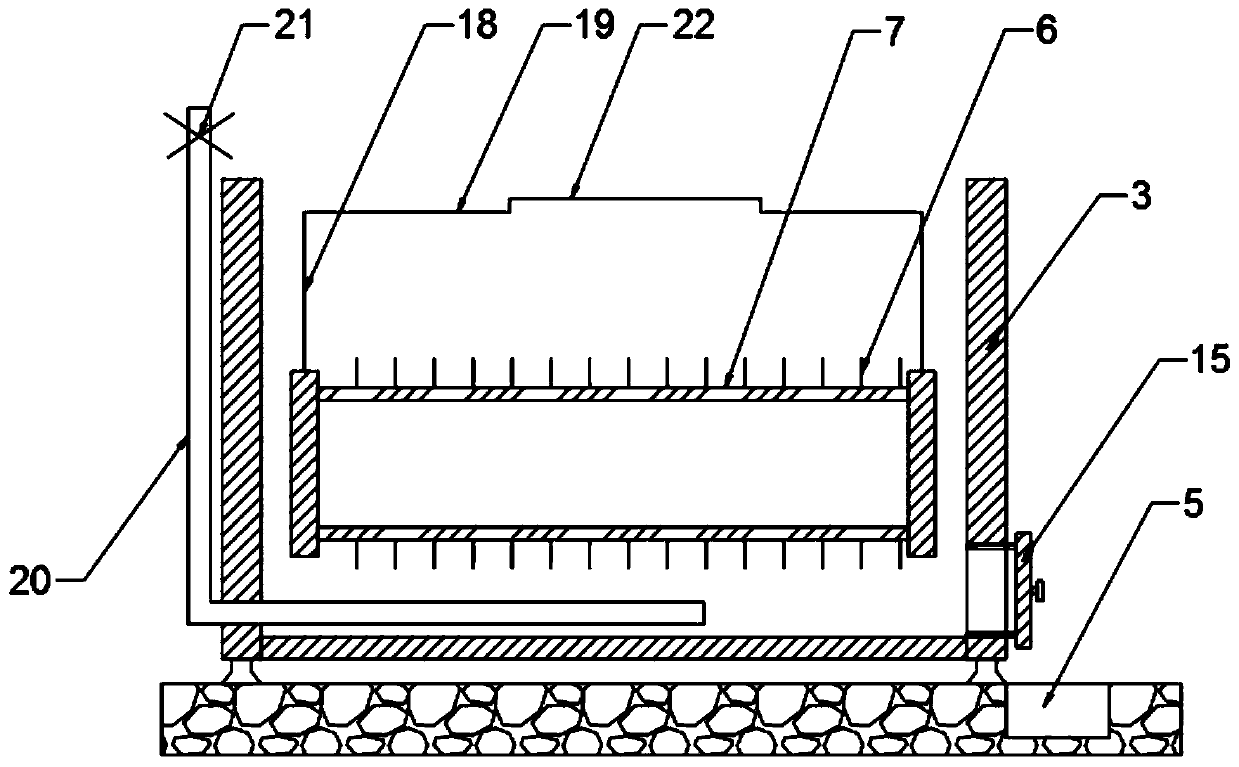

Refrigeration house

PendingCN110579065AEasy to moveEasy to change the place of useLighting and heating apparatusStationary refrigeration devicesTwo temperatureEngineering

The invention provides a refrigeration house, and relates to the technical field of refrigeration equipment. The technical problems of long construction period and high cost of a fixed refrigeration house are solved. The refrigeration house comprises a refrigeration house body, a bottom frame and a movable assembly, wherein the refrigeration house body is connected with the movable assembly through the bottom frame, free movement of the refrigeration house body can be realized through the movable assembly, and the refrigeration house further comprises a refrigeration system arranged on the refrigeration house body; assembly type connection modes are adopted between the bottom frame and the refrigeration house body, between the bottom frame and the movable assembly, and / or between the refrigeration system and the refrigeration house body; and at least two temperature zones are arranged in the refrigeration house body, and the temperature in each temperature zone adopts an independent control mode. According to the refrigeration house, the refrigeration house body is arranged on a transportation vehicle or rolling wheels, the refrigeration house can be moved, transportation and workof the equipment under different conditions can be met, the use place can be changed conveniently, the carrying link is reduced, manpower is saved during distribution, the construction period is short, and the production cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

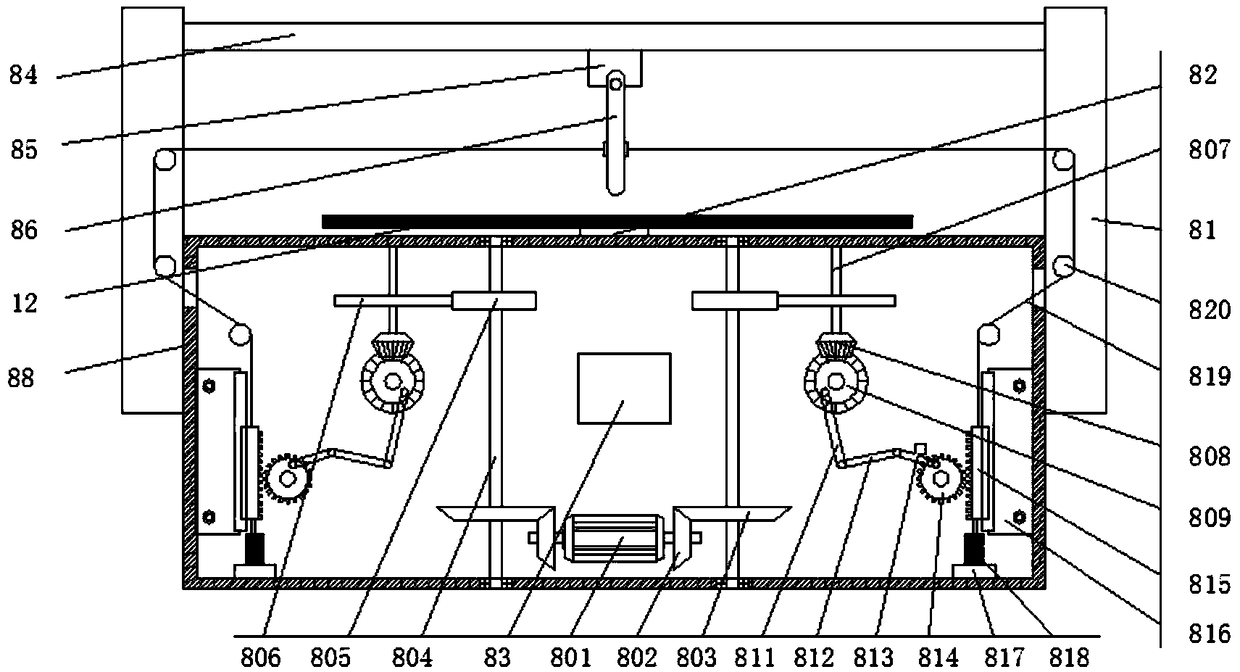

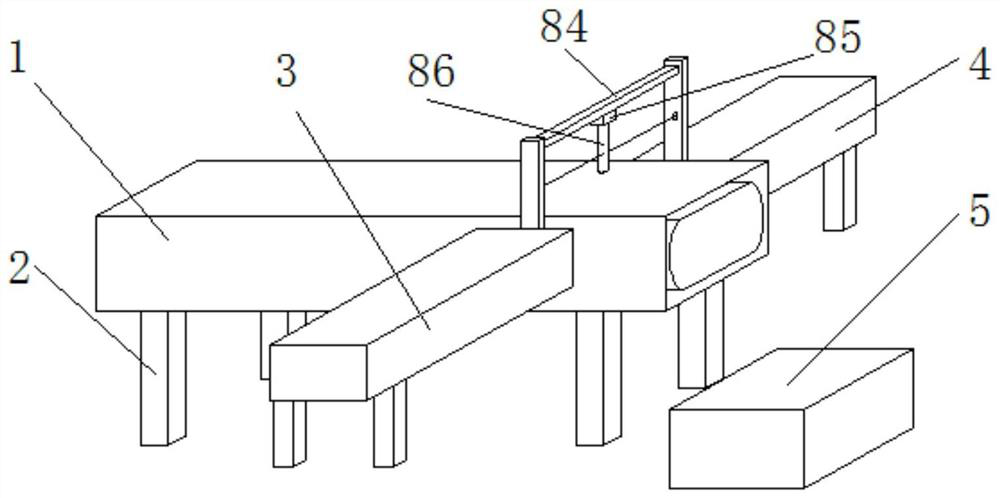

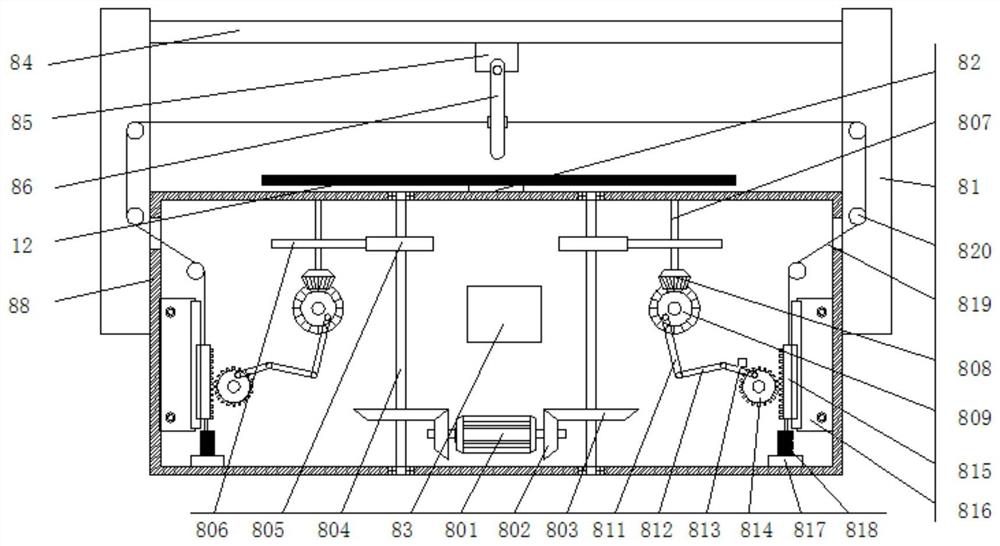

Integrated production machine for cleaning, sorting and cooking of intestinal skin

PendingCN110122537AAutomate operationReduce handling linksAnimal intestines working-upAnimal intestine cleaningSewageEngineering

The invention discloses an integrated production machine for cleaning, sorting and cooking of intestinal skin. The integrated production machine comprises a base, a cleaning groove, a cooking groove and a conveyor, the base is foxed on the ground, and a sewage drain tank is arranged in the ground on one side of the base; the conveyor is an integrated chain plate conveyor closed on both sides, a plurality of retaining piles perpendicular to the face of a chain plate is arranged on the chain plate, the conveyor is provided with a cleaning section, a sorting section, a cooking and drying section,one end of the cleaning section extends obliquely down to the bottom of the cleaning groove, and a stirring device is arranged in the cleaning groove; the other end of the cleaning section is connected with the horizontally arranged sorting section, the sorting section is open on both sides, the other end of the sorting section is connected with the cooking section, the cooking section sinks intothe bottom of the cooking groove in the shape of U, the other end of the cooling section is connected with the cooling and drying section obliquely extending upward, and the tail end of the cooling and drying section is horizontal and extends to a tie platform. By the arrangement, streamline automatic operation in cleaning and cooking is realized.

Owner:宜昌安鼎工贸有限公司

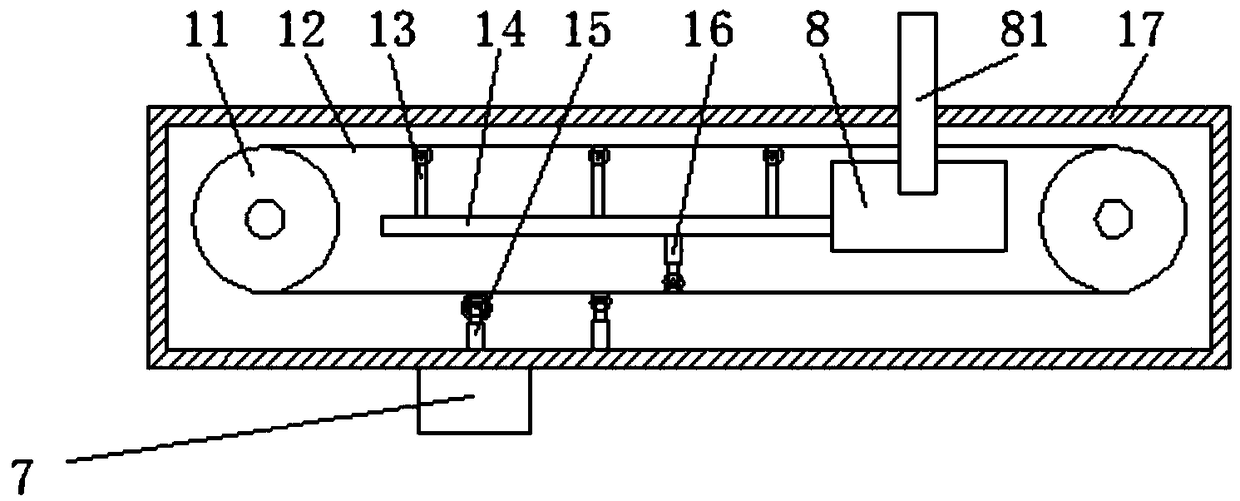

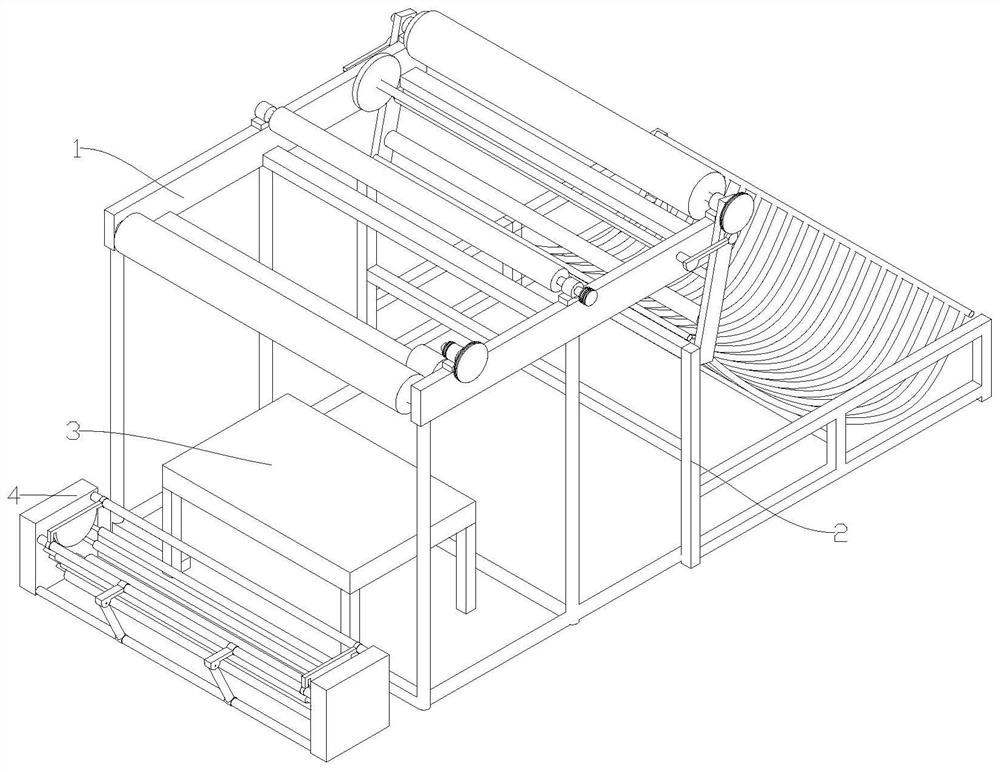

Turning, sewing, unwinding and rolling integrated device

InactiveCN112249774AReduce labor intensityReduce fatigueWebs handlingMaterials preparationAssembly line

The invention discloses a turning, sewing, unwinding and rolling integrated device. The device comprises an unwinding mechanism and a turning and sewing mechanism arranged below the unwinding mechanism, wherein a cloth bearing mechanism and a rolling mechanism are sequentially connected to the rear part of the unwinding mechanism; a material preparation mechanism is arranged in front of the unwinding mechanism; a tightening mechanism is arranged at the tail end of the unwinding mechanism; and the bottom of the unwinding mechanism is connected to the bottom of the sewing and turning mechanism through a connecting piece. The original scattered cloth turning, end sewing and rolling posts are integrated into an assembly line post, the three procedures of cloth turning, end sewing and rolling are directly and integrally completed, the original work of ten workers can be replaced only by two workers, and the labor cost is greatly reduced; and the cloth carrying among all posts is reduced, the labor intensity of workers is reduced, and the working efficiency is improved. In actual production and processing, the device has the advantages of being relatively low in labor cost, relatively high in working efficiency and higher in quality.

Owner:ZHEJIANG MIZUDA TEXTILE PRINTING & DYEING TECH CO LTD

Operation platform for fish product processing

InactiveCN106031438AConditions to reduce ZishengShort stayFood preparationStructural engineeringMechanical engineering

An operation platform for fish product processing includes a guide groove, and panels at two sides of the long edges of the guide groove; the guide groove is internally provided with a mobile mechanism moving along the long edges of guide groove, and an ultraviolet lamp is arranged in the inner wall of the guide groove; a water guiding groove is arranged at the joints of the guide groove and the panels, and the water guiding groove is parallel to the long edges of guide groove; and panels at two sides of the guide groove are inclined towards the guide groove. The invention has the advantages of reducing the breeding of bacteria exceeding the standard in the processing and achieving real-time processing and real-time transport.

Owner:CHANGYANG QINGJIANG PENGBO DEV

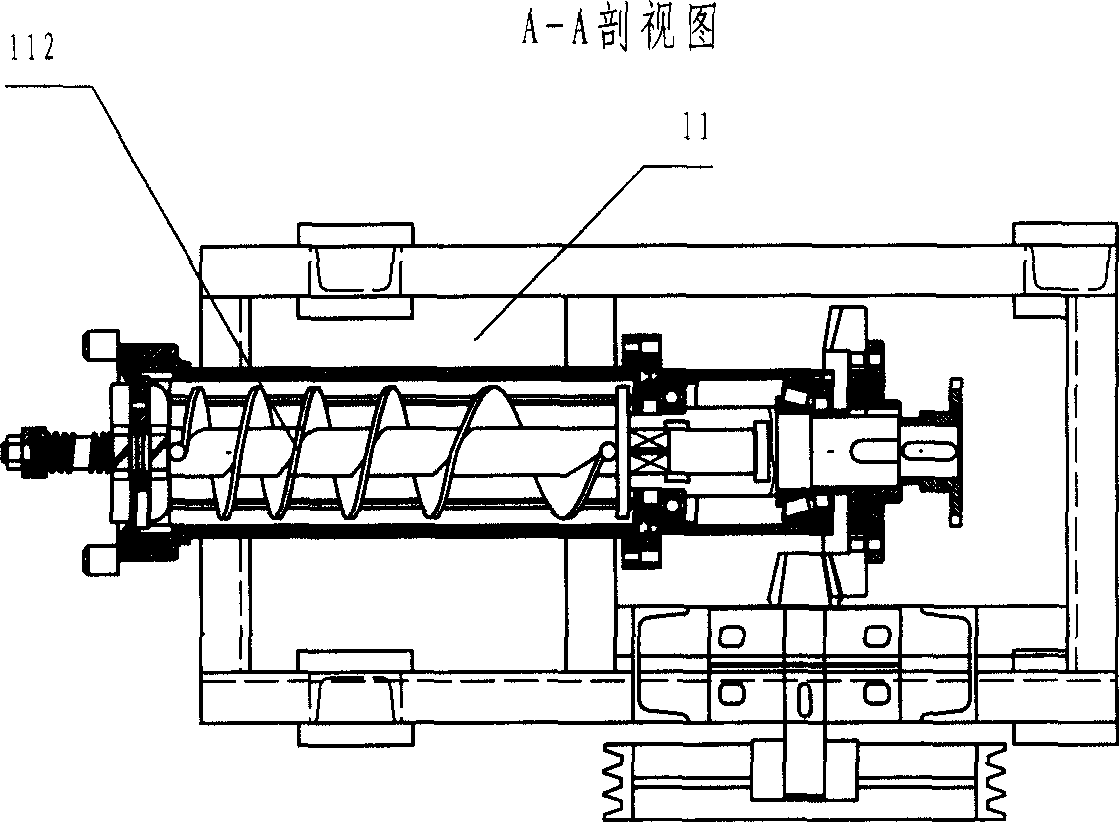

Multifunctional soft granule making machine set

InactiveCN1864559AReduce manufacturing costLower purchase costAnimal feeding stuffFood shapingFish pasteMixed materials

The multifunctional soft pellet making machine set includes one pelletizing machine with mixing bin and extruding chamber connected for conveying material. The pelletizing machine with increased mixing bin makes it possible to convey mixed material directly to the pelletizing part for pelletizing, and sharing the power source in the mixing bin and the extruding chamber can lower the manufacture cost of the whole set. In addition, one buffering bin may be set between the mixing bin and the extruding chamber for continuous production, and one forming mold and one cutter exchangeable with the forming mold may be provided simultaneously to make the set capable of being used for both pelletizing and producing fish paste, resulting in lowered cost.

Owner:FUJIAN PROV AGRI MACHANIZATION INST

Tree pruning tool for line protective area

The invention relates to a tree pruning tool for a line protective area, which belongs to the tree pruning tool field. The tree pruning tool for the line protective area comprises a pair of hydraulic scissors, a hydraulic system and a movable trolley, and is characterized in that the hydraulic system consisting of a hydraulic jack and a pedal is fixed on the movable trolley, the hydraulic jack is connected with an oil cylinder of the hydraulic scissors through an oil pipe, and a fixed bracket of the hydraulic scissors is provided with one to four sections of handheld insulation rods. By adopting the movable trolley, the tree pruning tool is convenient to transport to a work site, so that the handling procedure can be reduced, and the time and labor can be saved; the tool can prune big tree branches, so that a maintainable range of the line protective area is larger, and trees are pruned to be more tidy; and by adopting a plurality of handheld insulation rods, high voltage can be isolated, an electric shock can be prevented, the handheld insulation rods can be assembled or disassembled according to a working condition, so that the tree pruning tool is applicable to different trees in different heights. Through further improvement, and by utilizing the tree pruning tool, the workload and the labor intensity of workers can be alleviated, the tree pruning tool is applicable to different trees in different heights, and the safety running of a power line can be guaranteed.

Owner:STATE GRID CORP OF CHINA +1

A brush-like wolfberry picking end effector

The invention belongs to the technical field of agricultural machines, and particularly relates to a combing-brush profile-modeling fructus-lycii picking tail-end executor. The combing-brush profile-modeling fructus-lycii picking tail-end executor comprises a main shaft and groove cams connected to the two ends of the main shaft. A plurality of picking fingers are hinged to the middle of the mainshaft, and are combined together to be in emission shapes from inside to outside, a ring of cam groove is formed in the inner side of the each groove cam in a milled mode, and cam driven bearings arearranged in the cam grooves and can freely roll along the cam groove; pressing plates are installed between the corresponding cam driven bearings on the two groove cams, a plurality of holes are formed in the pressing plates, each picking finger penetrates through the middle of each hole, the picking fingers are driven to rotate when the main shaft rotates, and drive the pressing plates to rotate,the holes in the pressing plates slide up and down at the lower ends of the picking fingers, and therefore gap changes between the picking fingers are oppressed. The structure is simple, the cost islow, and mature fruits can be effectively screened and picked; the breakage rate of fructus lycii is greatly reduced; meanwhile, friction force between the picking fingers and the fructus lycii is enlarged, and the net picking rate is guaranteed.

Owner:CHINA AGRI UNIV

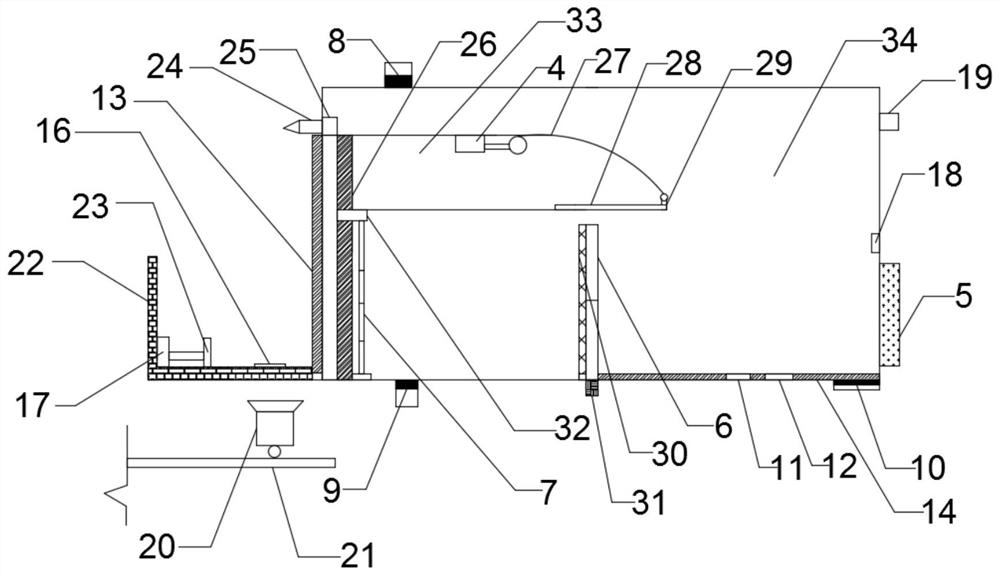

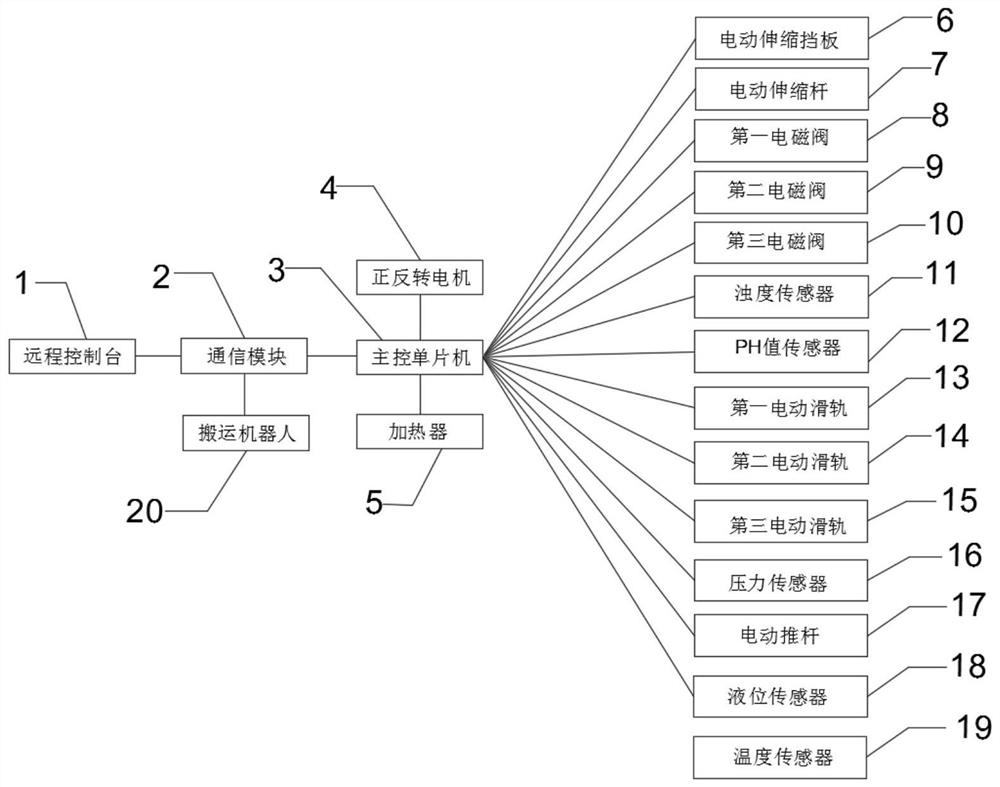

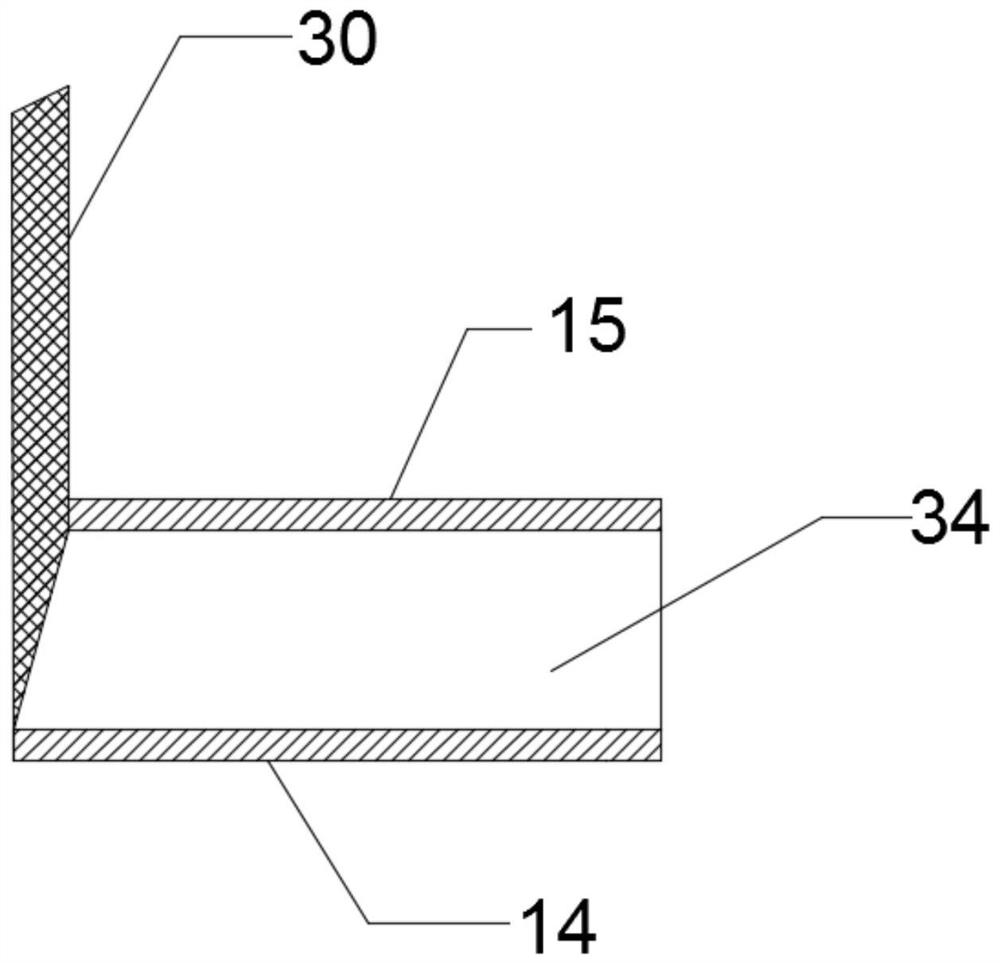

Breeding and breeding system for seed shrimps

ActiveCN113589871AReduce handling linksReduce occupancySimultaneous control of multiple variablesShrimpElectromagnetic valve

The invention provides a shrimp breeding culture system, which comprises a culture pond, a master control single-chip microcomputer, a water changing mechanism, a communication module and a detection assembly, the water changing mechanism comprises a first solenoid valve, a second solenoid valve, a third solenoid valve and an electric telescopic baffle plate which are electrically connected with the master control single-chip microcomputer, a groove is arranged in the middle of the culture pond, and the electric telescopic baffle plate is arranged in the groove for separating a culture pond to form a water changing area and a to-be-changed water area. The water changing area is provided with a water inlet pipeline and a water drainage pipeline, the first electromagnetic valve is arranged in the water inlet pipeline and used for controlling water inlet of the water changing area, the second electromagnetic valve is arranged in the water drainage pipeline and used for controlling water drainage of the water changing area, and the water changing area is provided with a shrimp fishing mechanism. The detection assembly comprises a turbidity sensor and a PH value sensor which are electrically connected with the main control single-chip microcomputer, the turbidity sensor and the PH value sensor are both arranged at the bottom of the culture pond, and the main control single-chip microcomputer is in communication connection with the remote console through the communication module. The system can improve the survival rate of the seed shrimps and increase the yield.

Owner:渤海水产育种(海南)有限公司

A branch pruning and crushing robot and its method for pruning broken branches

InactiveCN104221732BReduce handling linksSmash real timeCuttersCutting implementsRobotic armAgricultural engineering

The invention discloses a branch pruning and crushing robot and a method thereof, comprising a mechanical arm, a pruning end effector installed at the front end of the mechanical arm, a control unit, and a camera; the actions of the pruning end effector, the camera and other components are controlled by the control unit; the mechanical arm Including motor, finger driving device, forked finger, saw blade, saw blade shaft, saw blade shaft driving device; the motor drives the finger driving device and saw blade shaft driving device; the saw blade is installed on the outer periphery of the saw blade shaft, and the saw blade shaft Connect the blade shaft drive; the forked fingers connect to the finger drive. The invention integrates the selective pruning and crushing of the branches, reduces the branch handling link for the branch crushing, and can perform real-time crushing. In addition, the crushed branches and leaves are used as organic fertilizers and returned to the soil, which reduces production costs, reduces the use of chemically synthesized fertilizers by crops, and promotes the development of the organic fruit industry.

Owner:SOUTH CHINA UNIV OF TECH

A belt conveyor with distribution function

ActiveCN109018956BLarge distribution qualityFacilitate transmissionConveyorsCleaningControl engineeringControl theory

The invention discloses a belt conveyor with an allocation function. The belt conveyor comprises a conveyor body, supporting legs, a second conveying mechanism, a third conveying mechanism, a collecting device and an allocation device, and the number of the supporting legs is at least four. The supporting legs are fixed at the bottom of the conveyor body, the two sides of the conveyor body are connected with the second conveying mechanism and the third conveying mechanism, and the collecting device is arranged below the tail end of the conveyor body. The allocation device is arranged in the conveyor body, and the allocation device is located on the connecting line of the center of the second conveying mechanism and the center of the third conveying mechanism. The allocation device is arranged so that required articles can be allocated according to requirements. Due to the arrangement of the allocation device, the belt conveyor is more automatic, and the application efficiency of the belt conveyor is improved. The second conveying mechanism and the third conveying mechanism can directly transfer unnecessary articles, so that manual screening and carrying links are omitted, and the efficiency is improved.

Owner:安徽智崎环保设备有限责任公司

A simultaneous assembly tool for seat back and seat foam

InactiveCN105034907BEasy to assemble in pairsSimple structureVehicle seatsElectricityProduction line

The invention discloses a synchronous assembly tool used for a seat backrest and seat foam. The synchronous assembly tool is characterized by comprising a station plate, a foam tool and a backrest tool, and the foam tool and the backrest tools are installed on two stream line operation sides of the station plate respectively; the foam tool comprises a bottom plate, a support capable of extending into an upper concave part of the seat foam is arranged on the bottom plate, and at least one limiting plate is arranged on the bottom plate and used for limiting the upper edge of the seat foam. The backrest tool comprises a pair of upper portion supporting mechanisms arranged symmetrically on the station plate, a pair of middle supporting mechanisms arranged symmetrically on the station plate and a pair of positioning mechanisms arranged symmetrically on the station plate. The seat foam and the seat backrest can be synchronously assembled, and one production line can be saved; after the seat foam and the seat backrest are assembled, the seat foam and the seat backrest are convenient to assemble in pairs, storing and carrying steps are omitted, production efficiency can be improved, and the costs of equipment, electricity and labor are lowered.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

Large section pulling and extruding type production process and set thereof

InactiveCN101564900BReduce handling linksImprove quality stabilityQuality controlManufacturing engineering

The invention relates to a large section pulling and extruding type production method and a set thereof. The production method includes: adopting a pulling and extruding drawing tool provided with a fixed section extruding production device; when the section extruding production device working, the pulling and extruding drawing tool moving along the direction opposite to the section extruding direction. The invention eliminates the defect that the elongated large section is hard to move. The production method and the set realize the large section production on site and stable quality control in a way that the extruding device extends. The production is fast and convenient; the transportation is smooth and the waste due to improper cutting of large section is avoided.

Owner:BEIJING HAIBO SIQIANG BRIDGE NEW TECH

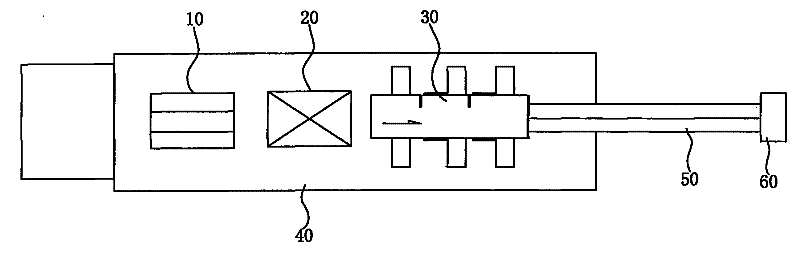

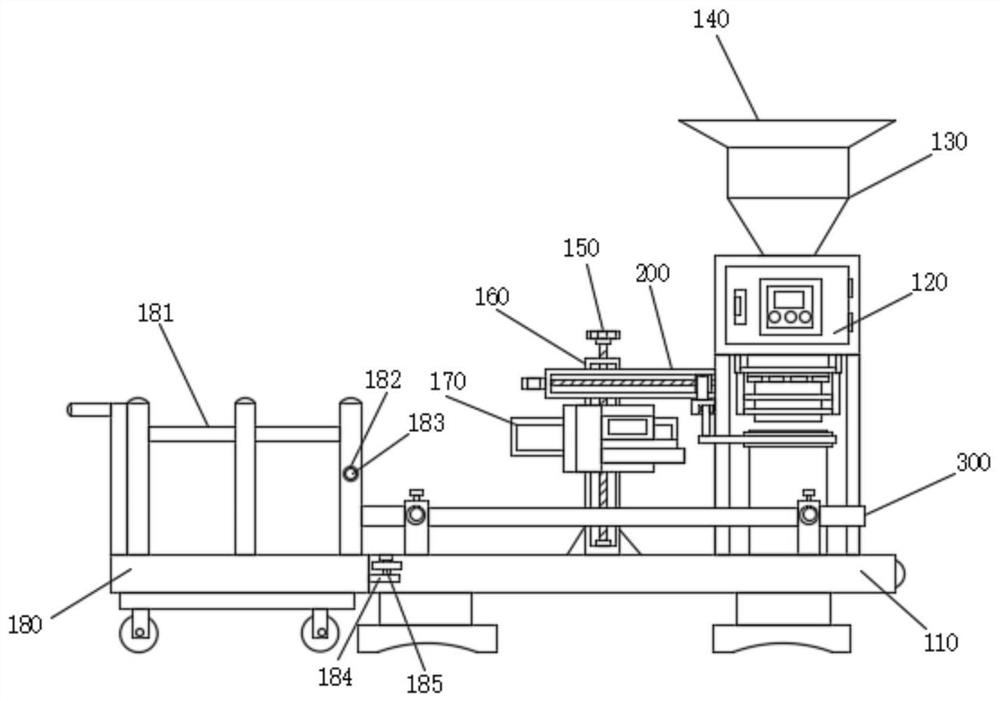

Automatic organic fertilizer packaging device

PendingCN114408292AReduce handling linksImprove work efficiencyWrapper twisting/gatheringAgricultural engineeringAgricultural science

The invention relates to the technical field of organic fertilizer packaging, in particular to an automatic organic fertilizer packaging device which comprises a supporting conveying plate, an anti-deviation mechanism is fixedly mounted at the top end of the supporting conveying plate, a conveying belt is rotatably mounted in the supporting conveying plate, and a filling box is fixedly mounted at the top end of the supporting conveying plate; a control panel is fixedly installed on one side of the filling box, a supporting rail is fixedly installed at the top end of the supporting conveying plate, and a sealing box is slidably installed in the supporting rail. The aligning and clamping mechanism comprises a second sliding rail, and the second sliding rail is fixedly installed on one side of the supporting rail. By arranging the aligning and clamping mechanism, a threaded block drives a clamping plate to be close to the upper portion of the sealing box, so that an organic fertilizer storage bag can accurately enter the sealing box to be sealed, the carrying link of workers is omitted, automatic and accurate positioning can be achieved for sealing, and the working efficiency is greatly improved.

Owner:广西凭祥市贵仁生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com