Primary refining integrated processing method of broken green tea from fresh leaves picked by machine

A processing method and technology of green crushed tea, applied in the field of processing and tea processing, can solve problems such as unstable product quality, cumbersome processing technology, and high labor intensity, so as to reduce storage and handling links, improve economic benefits, and reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with specific embodiments.

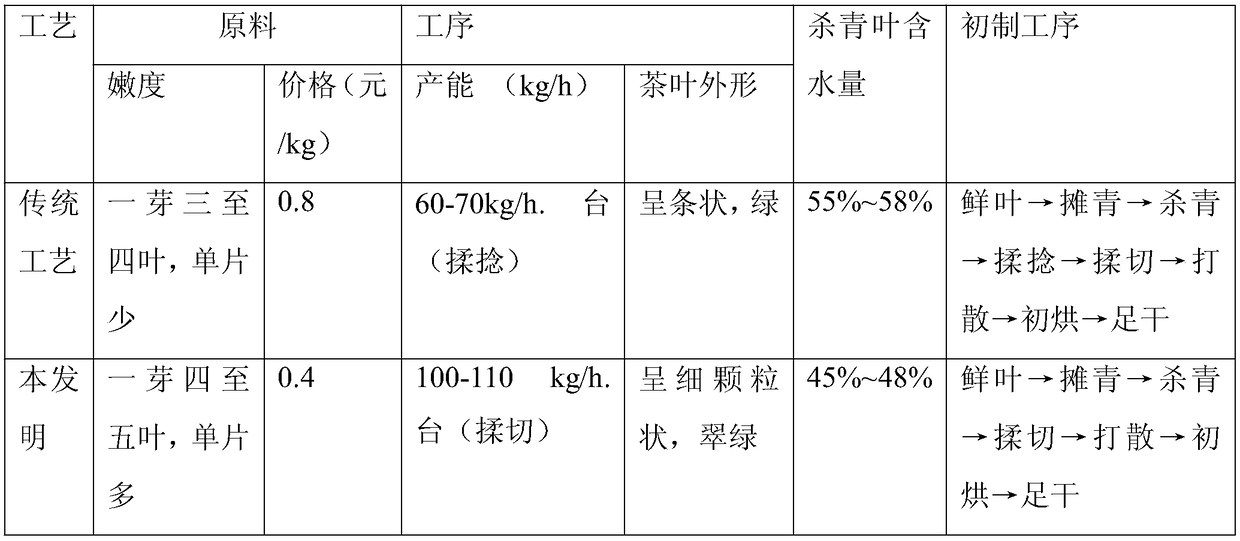

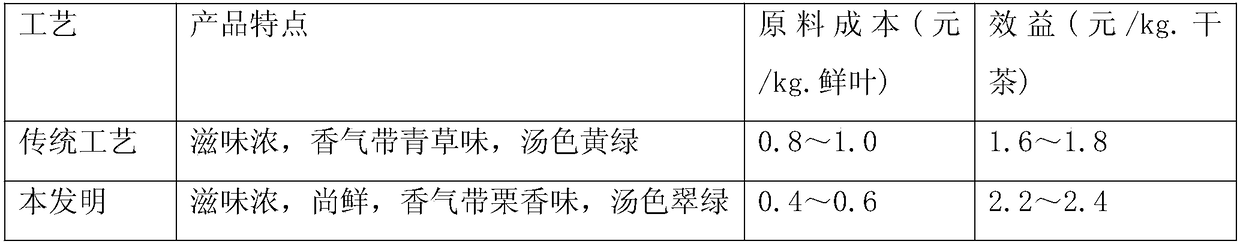

[0011] An integrated processing method for primary refining of machine-harvested fresh-leaf green crushed tea, in which raw tea is directly processed after primary processing (primary processing: fresh leaves→spreading→greening→kneading and cutting→dispersing→primary drying→sufficient drying) It is transported to the round sieve machine for subsequent refining process (refining process: raw tea→round sieve→electrostatic stem sorting), that is, firstly, the fresh leaves of the machine-picked tea tree are spread and greened, and then kneaded, cut, broken up and disassembled Afterwards, it is processed by the initial drying and full drying process, and finally the stable green broken tea product is obtained directly through the round sieve and stem sorting process. It specifically includes the following steps:

[0012] Step 1. Select the fresh leaves of a tea tree w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com