Cigarette adhesive mixing equipment

A technology of mixing equipment and cigarette glue, which is applied in the direction of mixers, dissolution, chemical instruments and methods, etc., can solve the problems of affecting the quality of finished products, high labor intensity, and large errors in manual weighing, so as to improve work efficiency and reduce labor Strength, the effect of reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

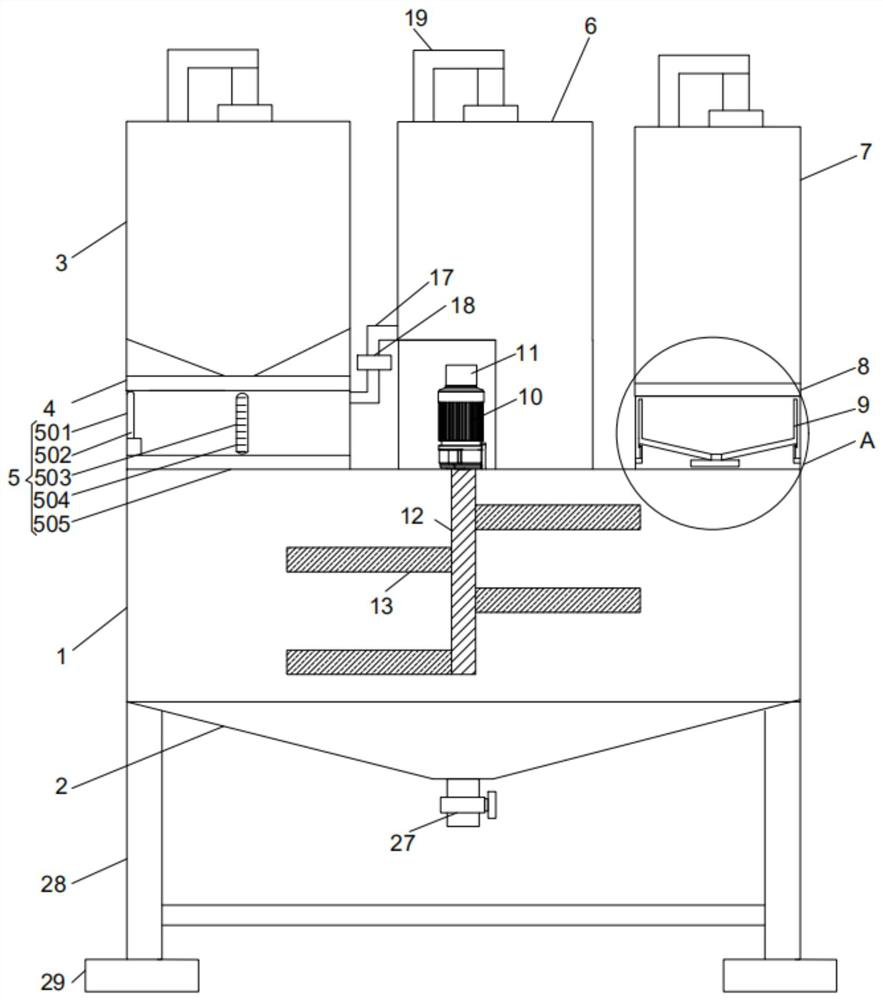

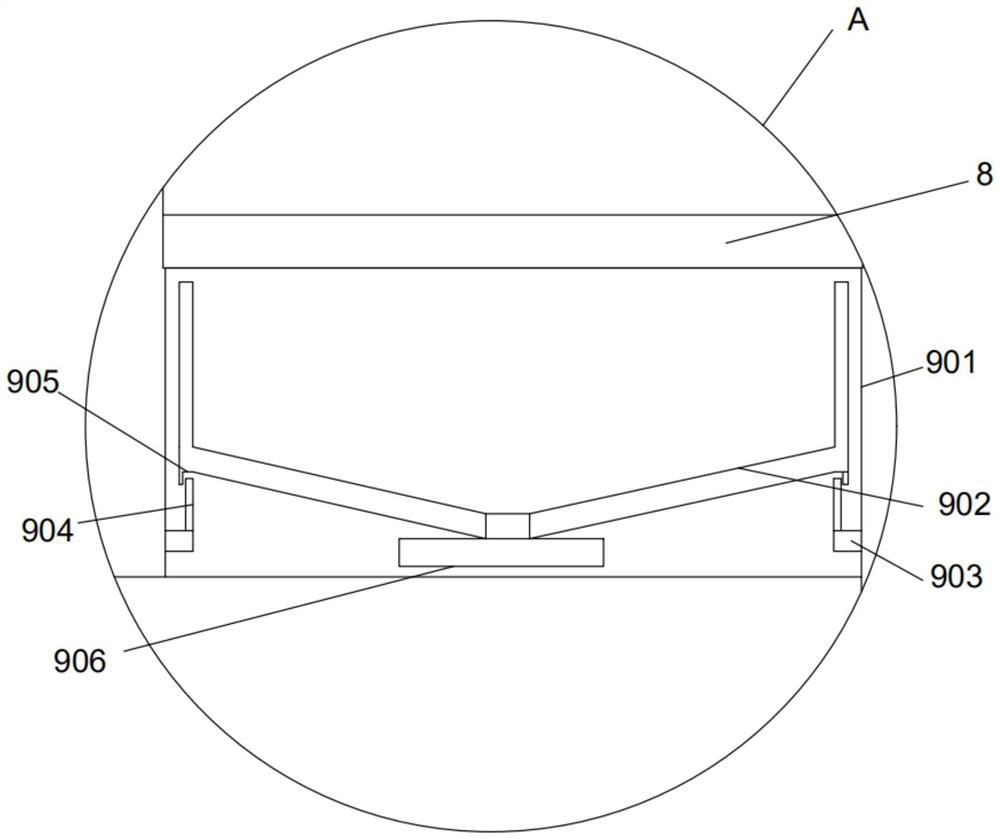

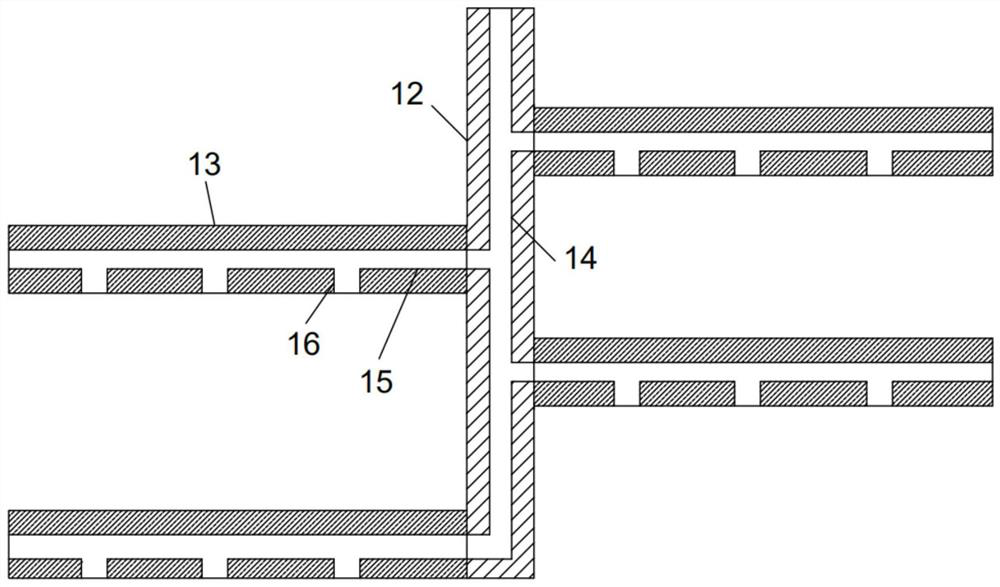

[0037] see figure 1, a cigarette rubber mixing equipment, comprising a mixing tank 1, the bottom of the mixing tank 1 is integrally connected with a drop hopper 2, a raw material tank 3 is fixedly installed on the left side of the top of the mixing tank 1, the The bottom of the raw material tank 3 is fixed with a first electric control valve 4, the bottom of the first electric control valve 4 is fixed with a metering device 5, and the top middle of the mixing tank 1 is fixed with a water tank 6. The right side of the top of the mixing tank 1 is fixed with a medicine tank 7, the bottom of the medicine tank 7 is fixed with a second electric control valve 8, and the bottom of the second electric control valve 8 is fixed with a weighing device 9, The metering device 5 includes a metering tank 501, a water level monitor 502 is fixedly installed inside the metering box, an observation window 503 is provided on the front of the metering tank 501, and a scale line 504 is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com