Large section pulling and extruding type production process and set thereof

A production device and production method technology, applied in the field of production technology and equipment of large-scale composite profiles, can solve the problems of unbalanced profile quality, difficulty in pulling and handling work, etc., achieve fast and convenient production, eliminate difficult handling defects, and avoid transportation problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

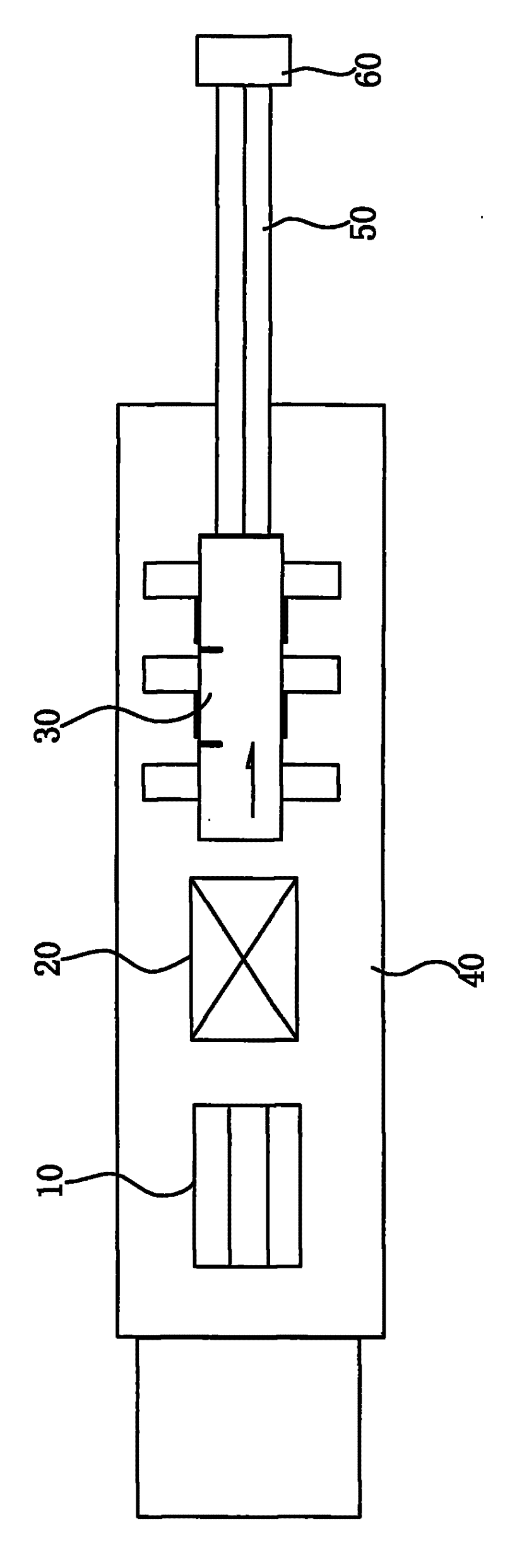

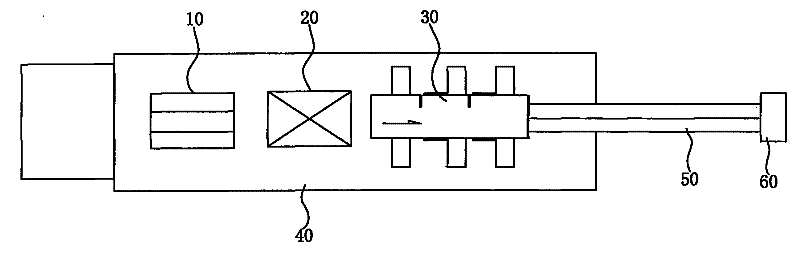

[0028] Such as figure 1 As shown, the large-scale profile pultrusion production device can be used for on-site production of FRP large-scale composite profiles. The large-scale profile pultrusion production device includes a pultrusion traction mobile tool, and the pultrusion traction mobile tool is a pultrusion traction truck 40 , The truck has a platform that is longer than the conventional vehicle body, and the glass fiber winding creel 10, the dipping and preforming equipment 20, and the hot mold extrusion molding machine 30 are arranged in sequence on the platform.

[0029] In the production of FRP composite profiles, the glass fiber skeleton model of the profile is first formed, then dipped and preformed to form the basic structure of the required profile, and then extruded by the thermal molding process, and the extrusion is carried out by a continuous pultrusion tractor. The profile 50 is stretched and formed, and one end of the produced profile is fixed on a fixing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com