Patents

Literature

99results about How to "Flexible grabbing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

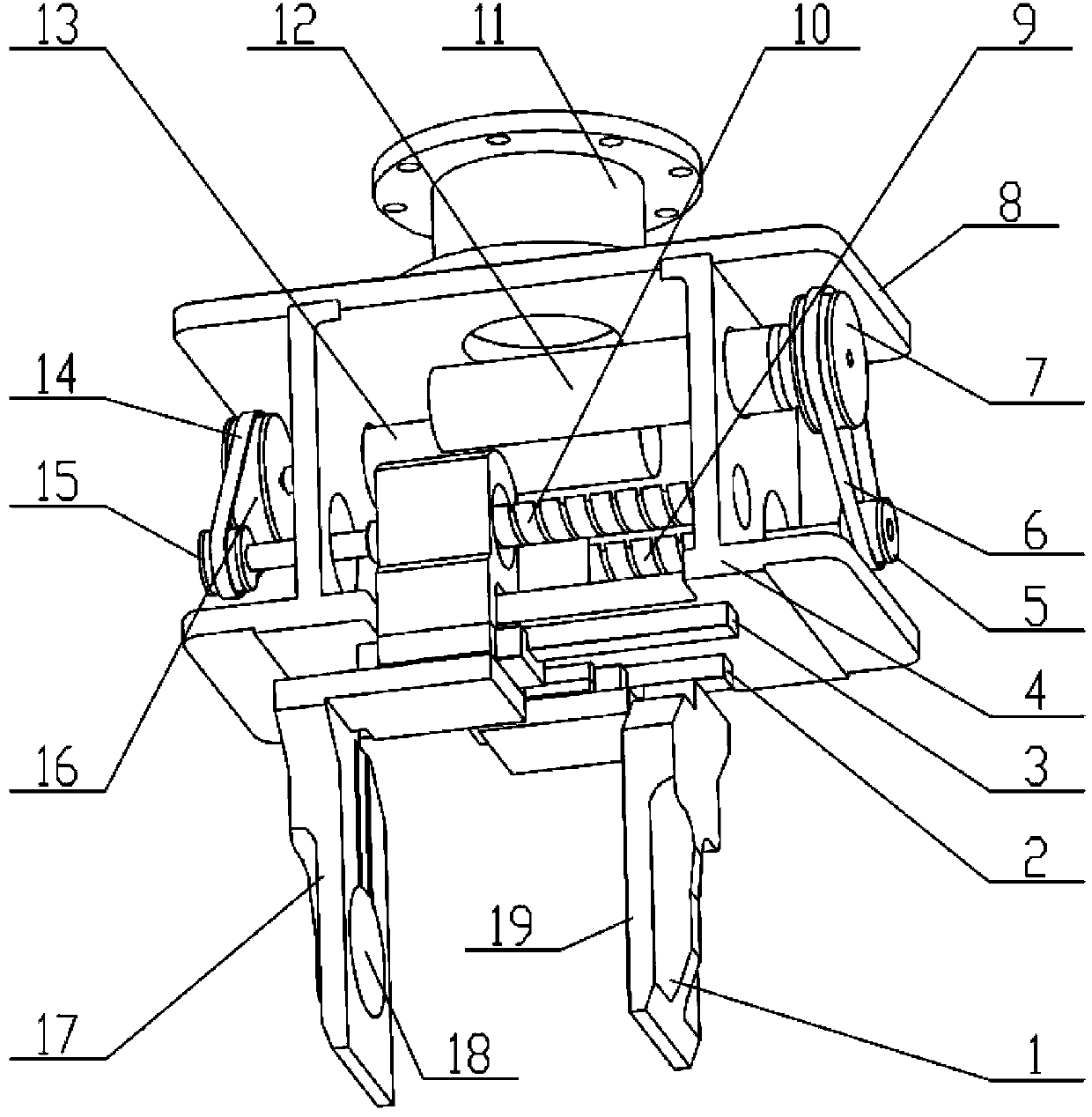

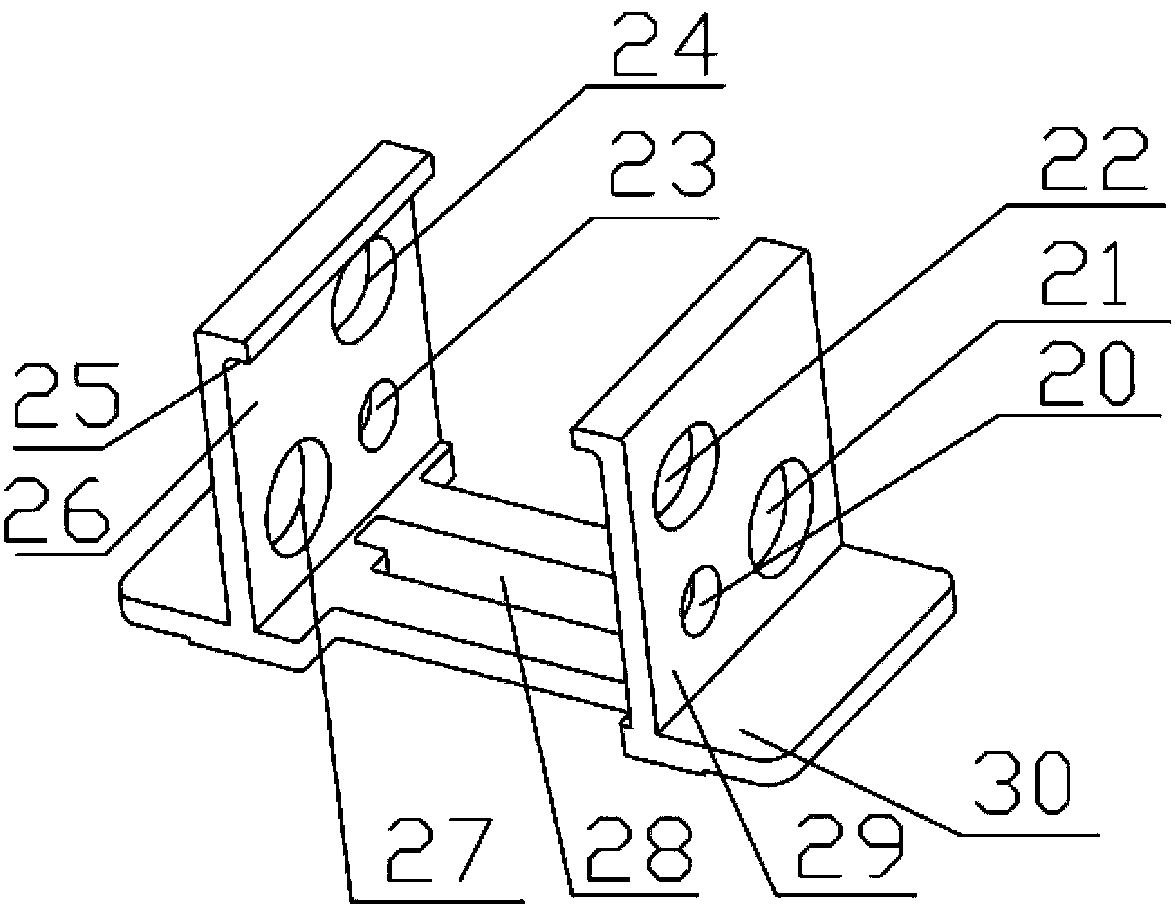

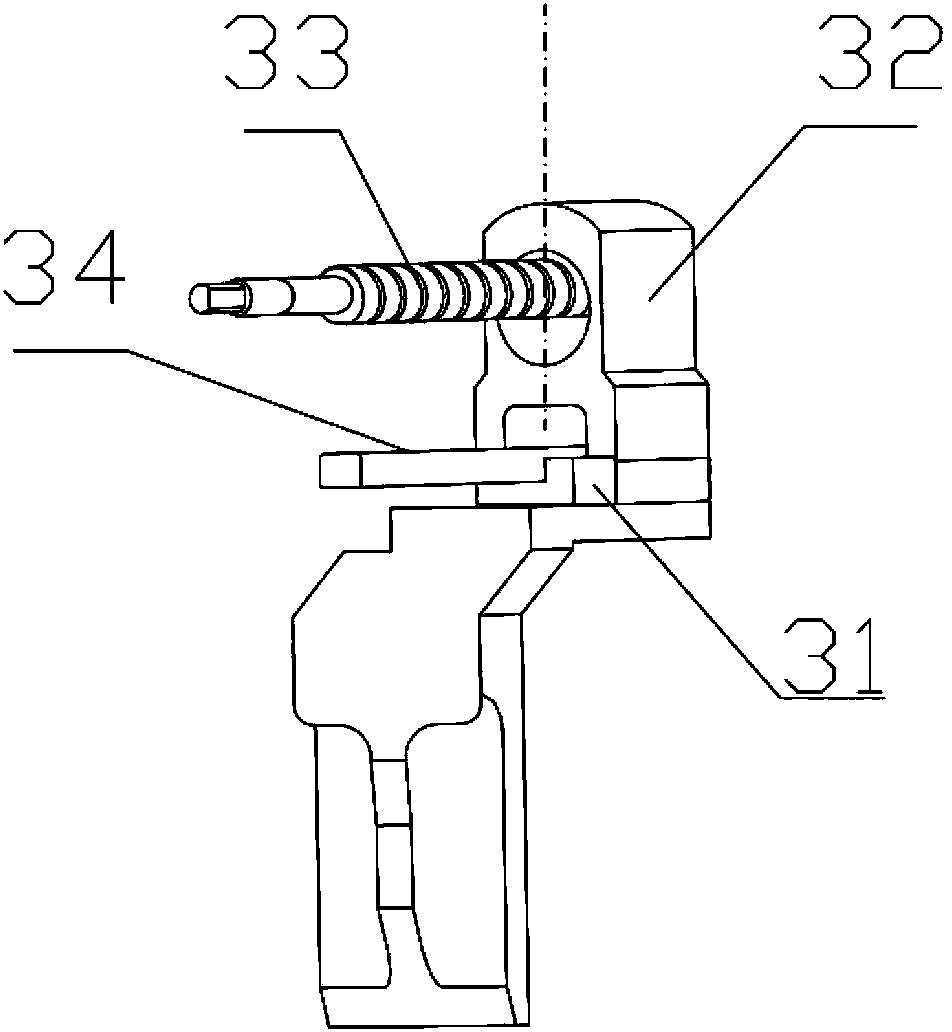

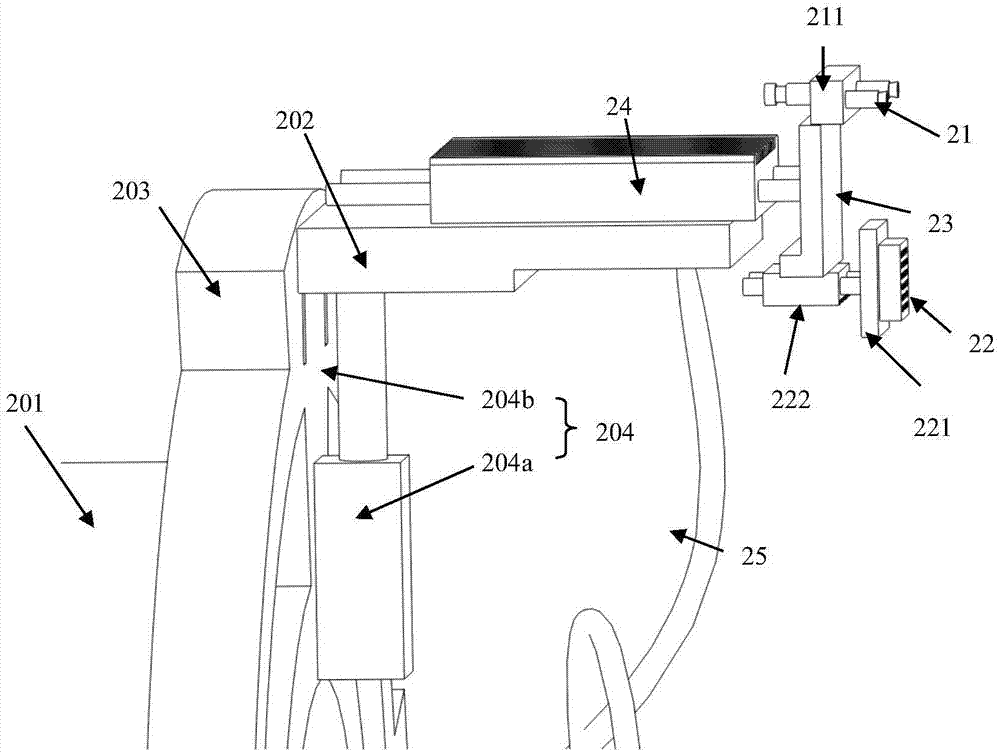

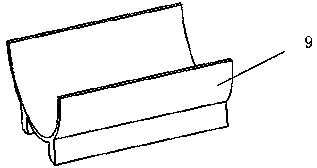

Double-finger double-driving translation clamping type flexible grip and control method

The invention discloses a double-finger double-driving translation clamping type flexible grip and a control method. The double-finger double-driving translation clamping type flexible grip comprises double servo motor systems, double motor end synchronous pulleys, double positioning sliding guide rail systems, double ball screw systems, double screw synchronous pulleys, double finger paws, a U-shaped main rack of the grip and a main rack cover plate, wherein the coordinating fetching action of two paws is realized by the control on two servo motors. A fetching method is characterized in that the double motors are used as power, double fingers are respectively fixedly arranged on two screw guide rail synchronous switching modules, through the rotation of two synchronous toothed belts between the double motor end synchronous pulleys and the ends of the double screw end synchronous pulleys, the rotation of the motor is converted into linear motion by a screw, so that the double fingers are translated respectively along two positioning sliding guide rails, and the translation switching on and off of the double paws along double guide rail surfaces can be realized. Due to the fact that the device is used for independently driving the corresponding paws to move by the double motors, so that the double fingers can more flexibly move, and different fetching speeds can be set for the double fingers, and the position precision is high.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

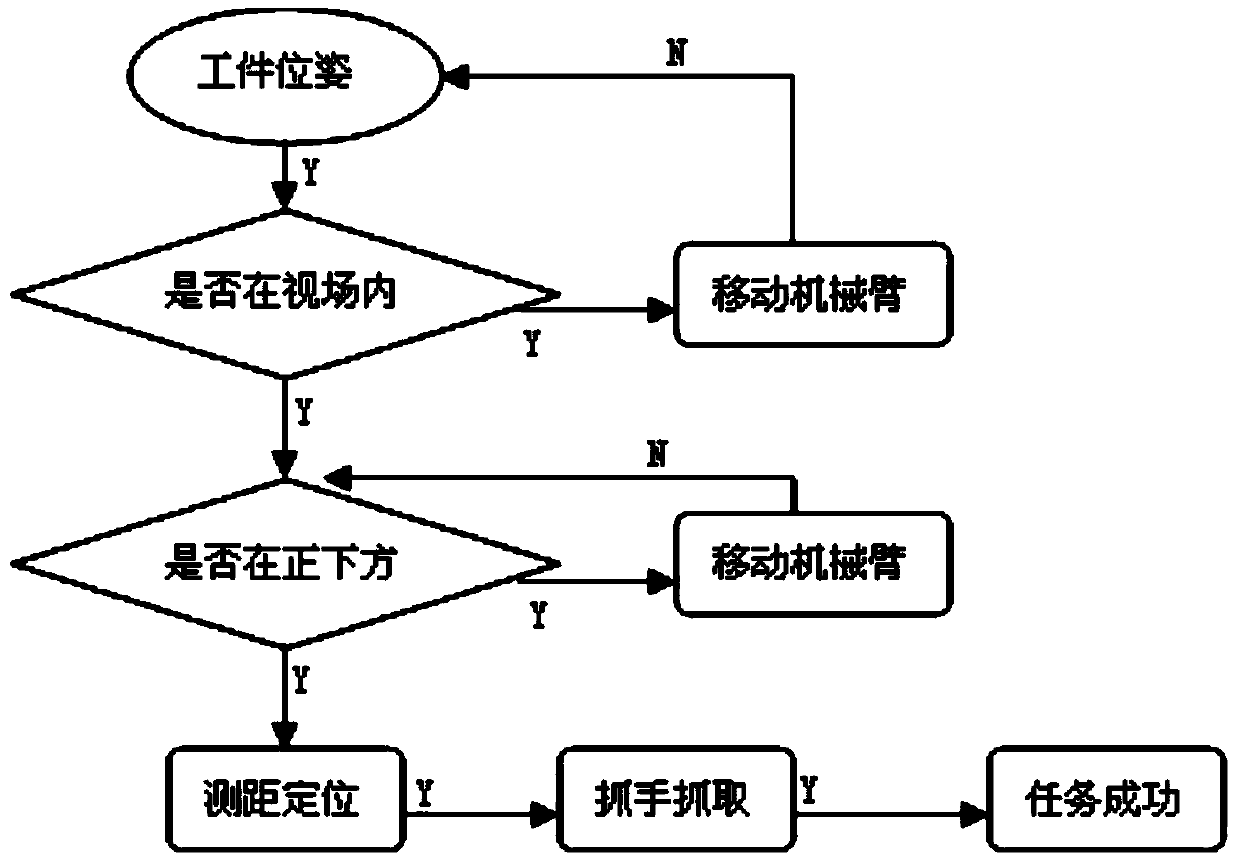

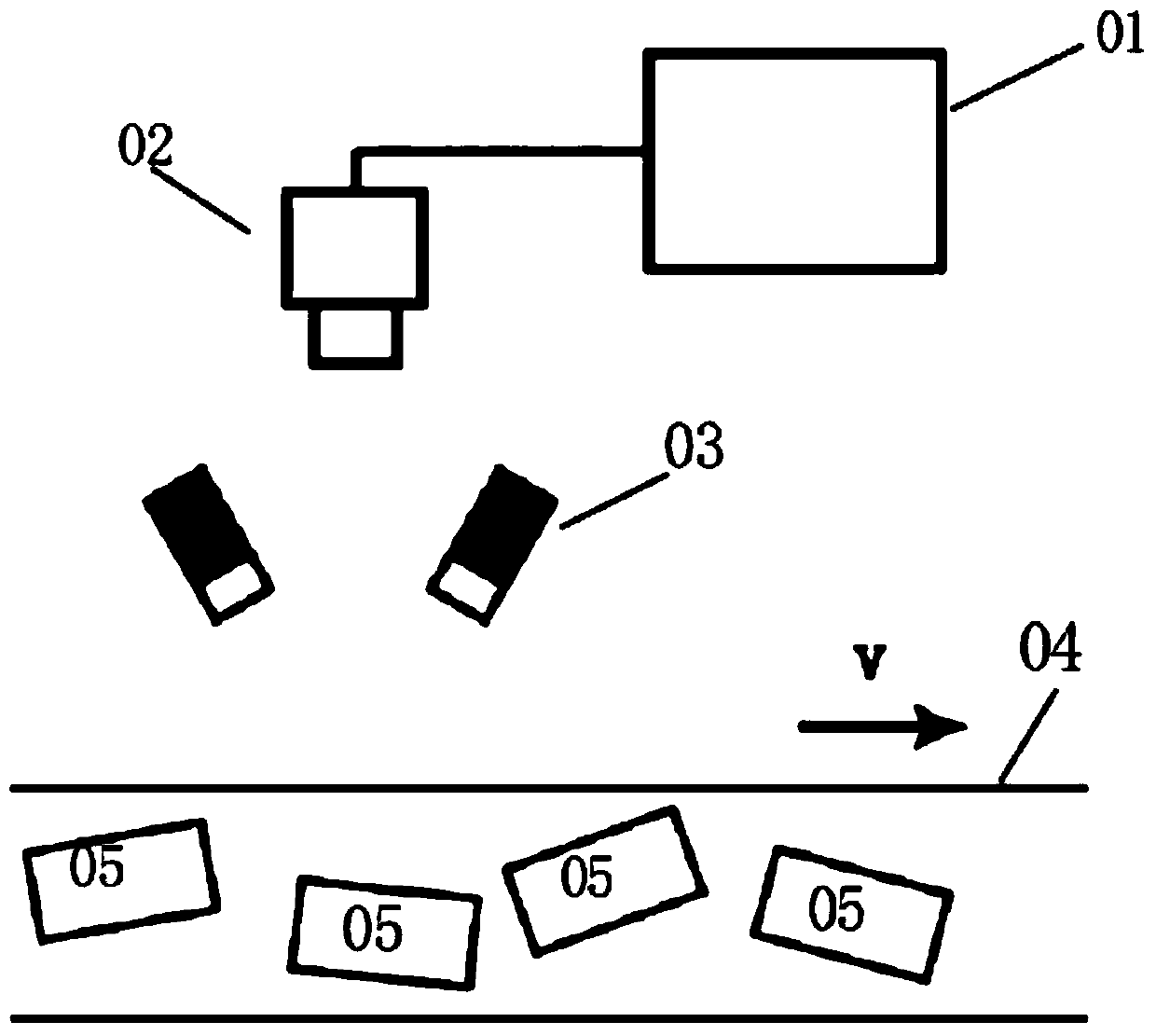

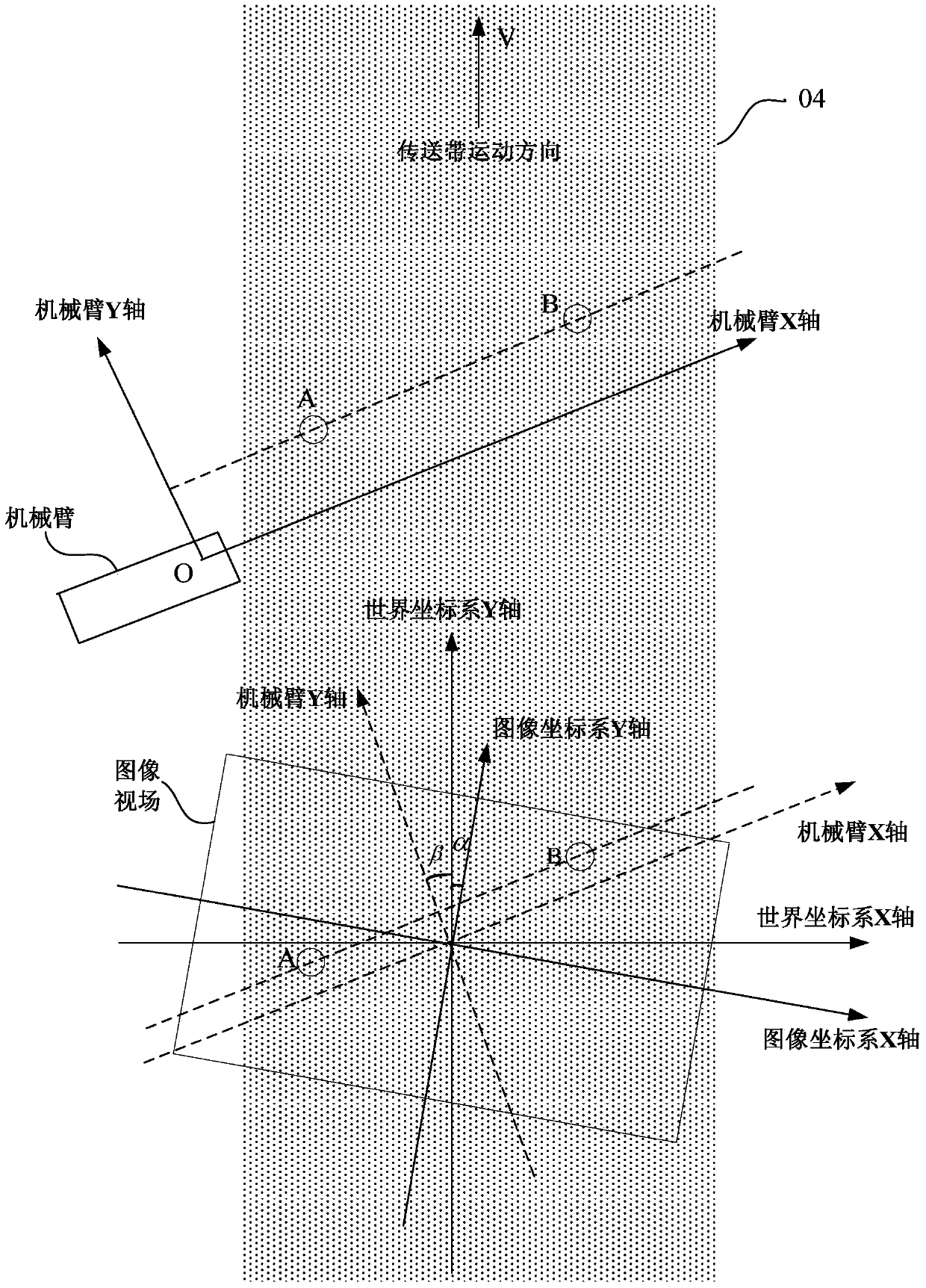

Mechanical arm positioning fetching method based on machine vision

The invention discloses a mechanical arm positioning fetching method based on machine vision. The mechanical arm positioning fetching method comprises the following steps: S1) carrying out parameter calibration on a camera and a mechanical arm, establishing relationship between an image coordinate system and a conveyor belt coordinate system as well as between a mechanical arm coordinate system and the conveyor belt coordinate system; S2) identifying a target workpiece in the image, and calculating the centroid and the angle of deflection of the target workpiece; and S3) sending the centroid and the angle-of-deflection information, which are calculated in the step2), of the target workpiece to the mechanical arm, calculating a position coordinate of the target workpiece under a mechanical arm coordinate system to fetch the target workpiece. The invention exhibits a wide application range, and a great quantity of scattered workpieces can be quickly and accurately fetched under the condition that a production line is not changed, operation is flexible, and cost is saved.

Owner:BEIJING JOINHOPE IMAGE TECH

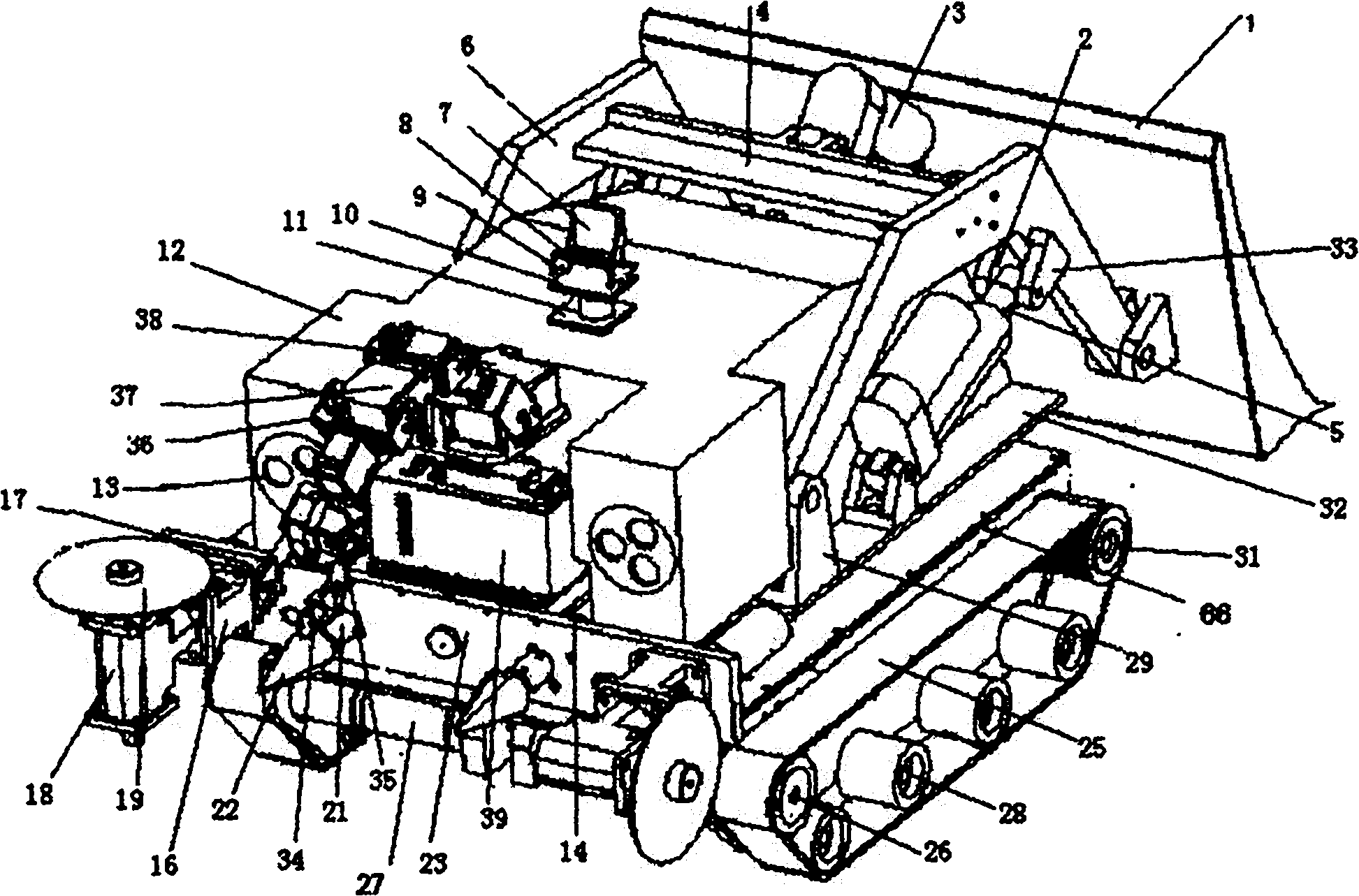

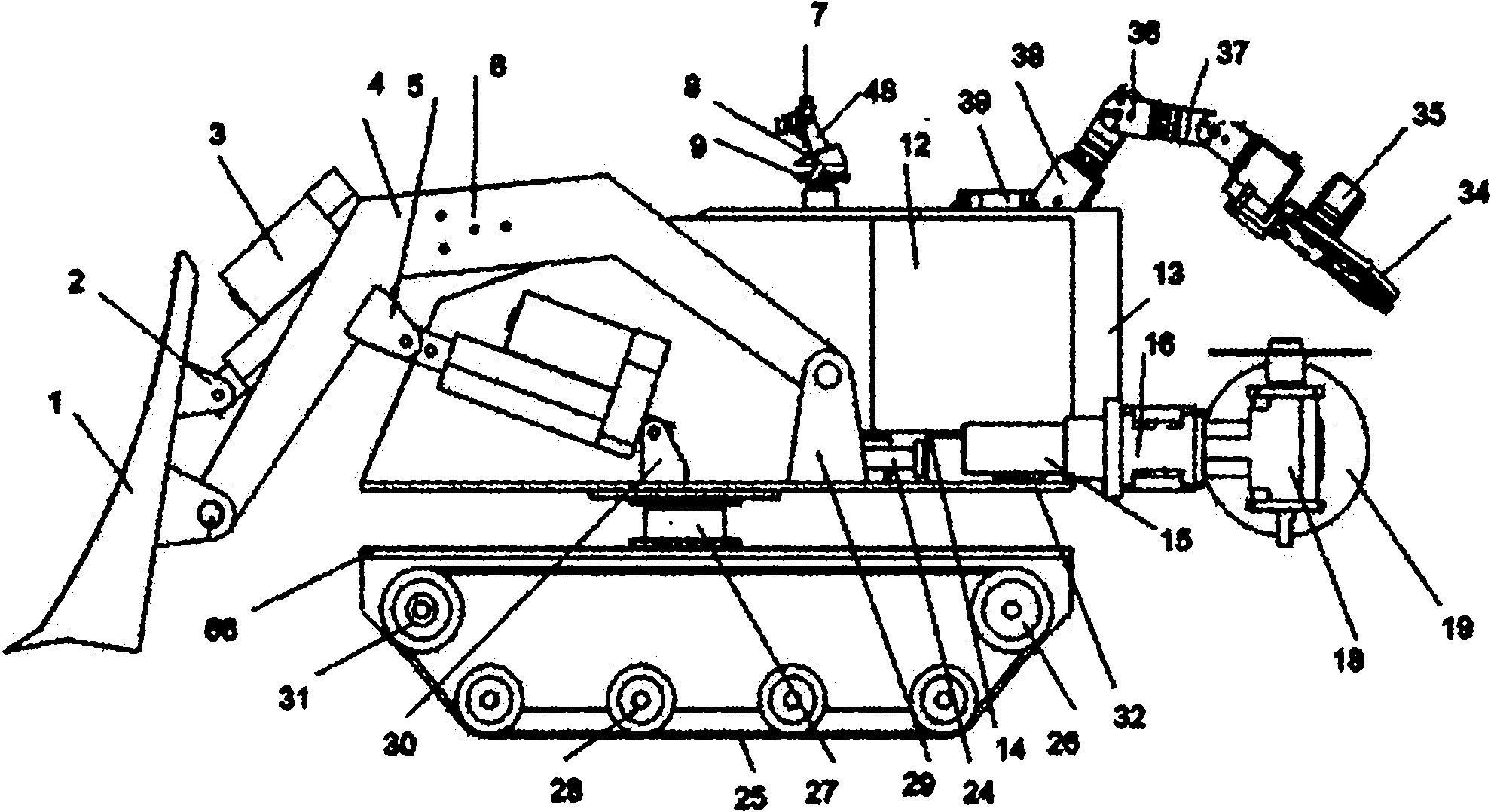

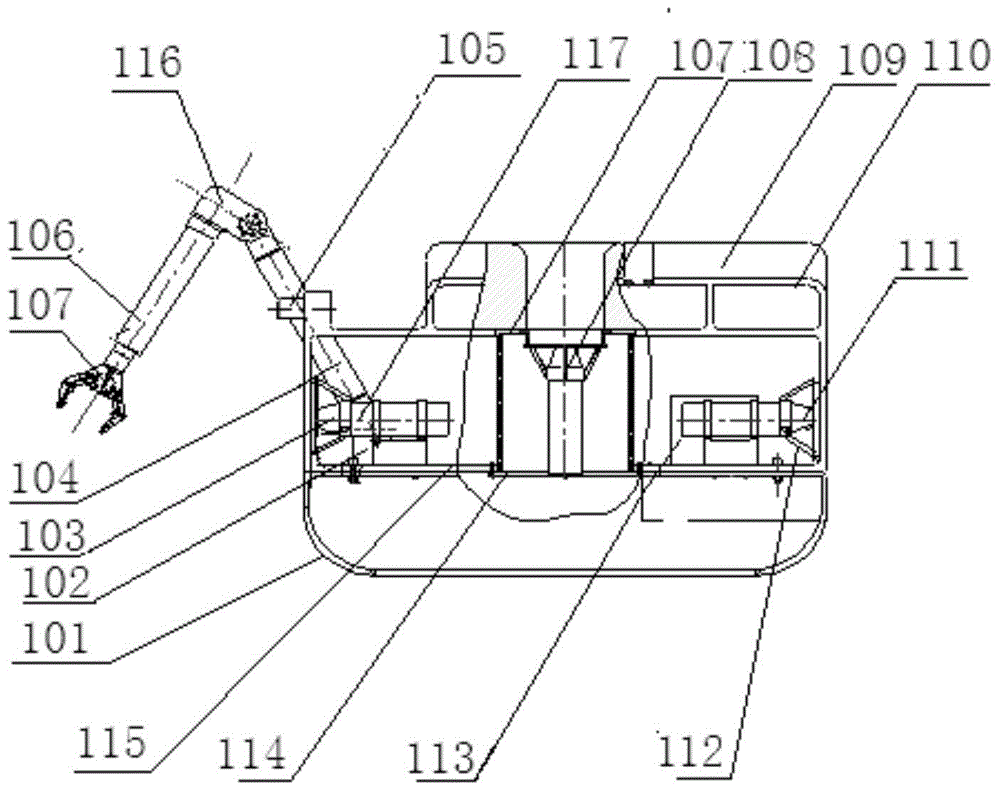

Anti-terrorist explosion-proof robot

ActiveCN102152291AAdvance and retreat freelyFlexible turningDefence devicesEndless track vehiclesEngineeringMechanical equipment

The invention discloses an anti-terrorist explosion-proof robot, comprising a chassis, a crawler traveling mechanism, an obstruction breaking mechanism, a mechanical arm mechanism, a shovel pushing mechanism, a monitoring mechanism and an electric control board control unit, wherein the electric control board control unit is positioned at the central part above the chassis; the crawler traveling mechanism is movably connected below the chassis; the obstruction breaking mechanism is positioned at the front of the chassis; the mechanical arm mechanism is positioned at the front end above the chassis; the shovel pushing mechanism is positioned at the rear end above the chassis and at the rear part of the chassis; and the monitoring mechanism is positioned above a top cover covering the electric control board control unit. The crawler traveling mechanism has a tank type traveling characteristic, so that the robot can adapt to various landforms; an explosion-proof structure can realize an obstruction-breaking cutting explosion-proof function; the mechanical arm mechanism can realize a grabbing function; the shovel pushing mechanism can realize a moving function; and the monitoring mechanism can realize an explosion-proof environmental monitoring function. In the anti-terrorist explosion-proof robot, a plurality of explosion-proof functions of explosives can be implemented at terrible sites in which people are not suitable for staying, so that a plurality of single-function mechanical equipment can be replaced.

Owner:湖南贽弘机器人科技有限公司

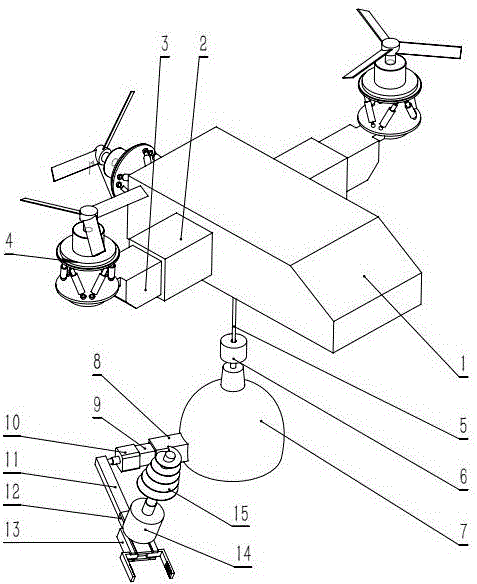

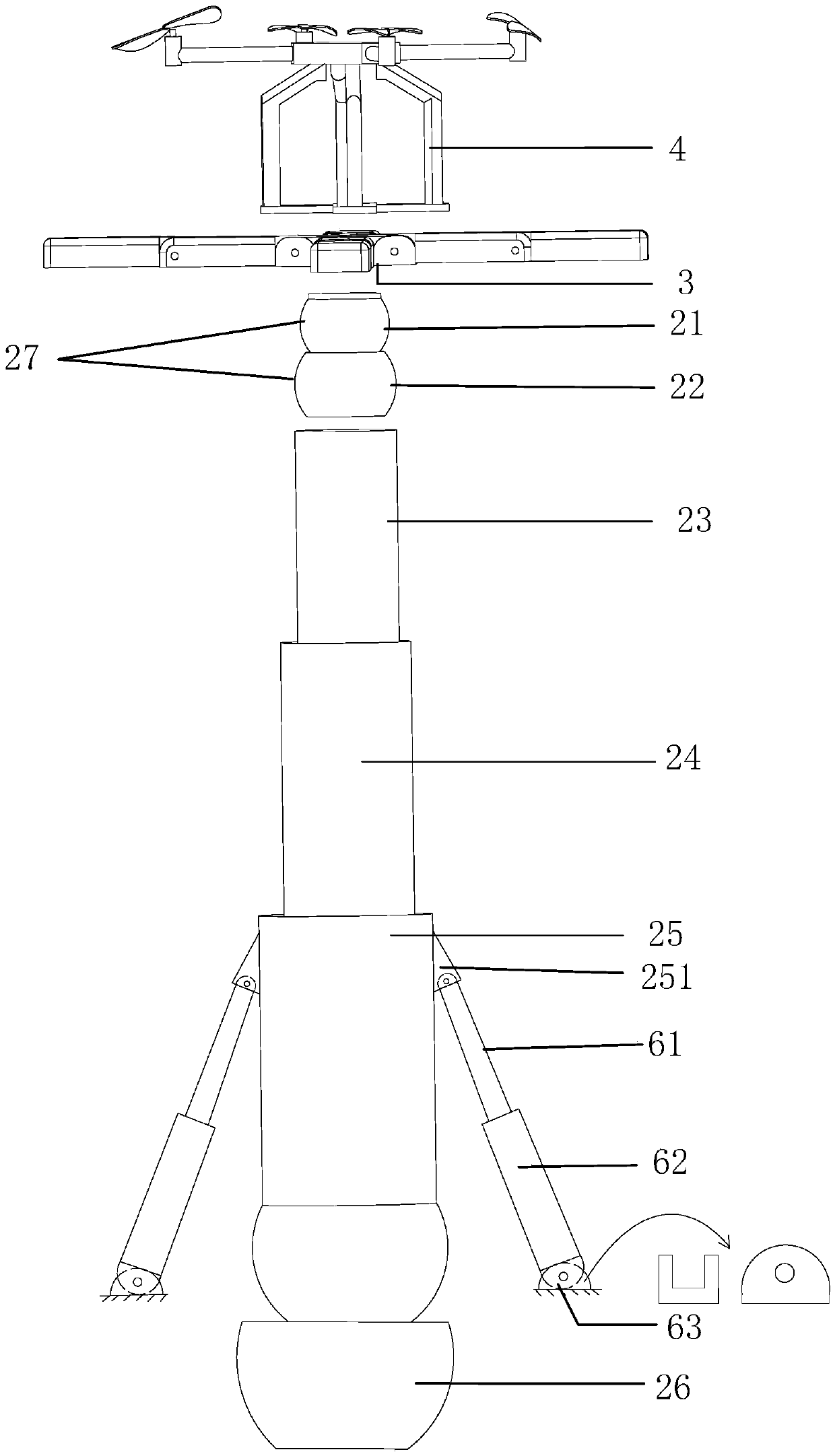

Underwater operation robot and working method thereof

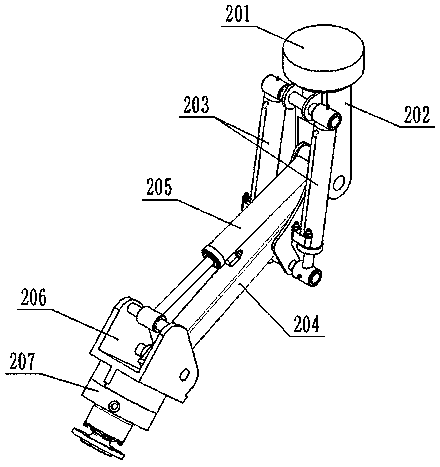

ActiveCN104960652AFlexible grabbingUnderwater operation realizedProgramme-controlled manipulatorGripping headsPropellerGravitational force

The invention discloses an underwater operation robot and a working method thereof. The underwater operation robot consists of a robot body, a pusher, an air bag, a balancing device and mechanical operation arms, wherein the advance, the backstep, the sinking, the floating, the ascending, the descending, and the left-right horizontal turning actions of the robot are realized through the pusher; the gravity of the robot is balanced through the air bag, so that the working load of propellers is relieved; through the balancing device, the robot is guaranteed to be always in a balancing state during action; underwater operation is realized through the mechanical operation arms. According to the underwater operation robot disclosed by the invention, the robot body has three degrees of freedom, so that the robot can realize advance and backstep, ascending and descending, and horizontal turn, and the position of the robot body can be adjusted according to the change of the gravity of the robot, so that the robot is balanced. The mechanical operation arms can perform flexible bending and grasping, so that underwater operation is realized.

Owner:SHANDONG UNIV OF SCI & TECH

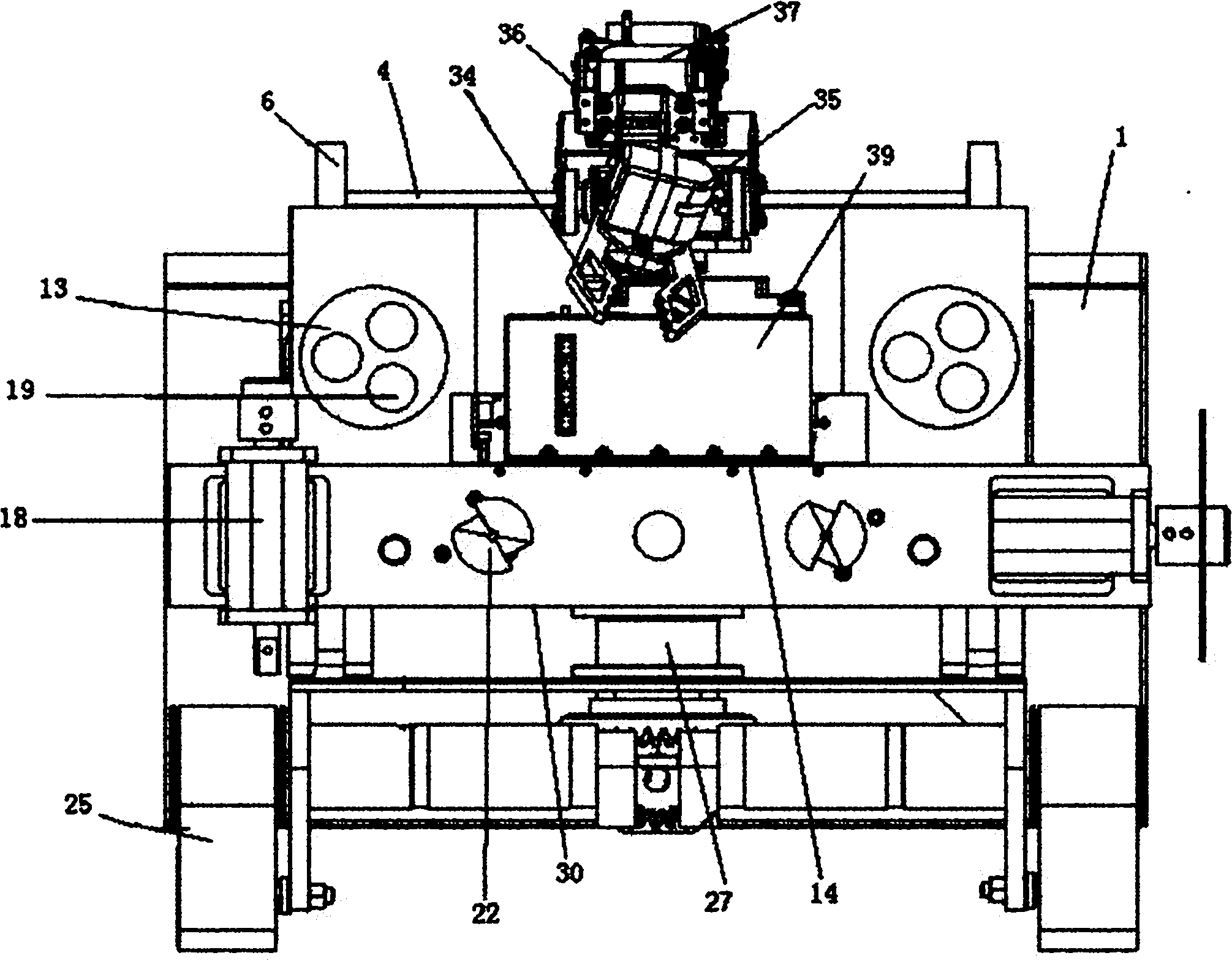

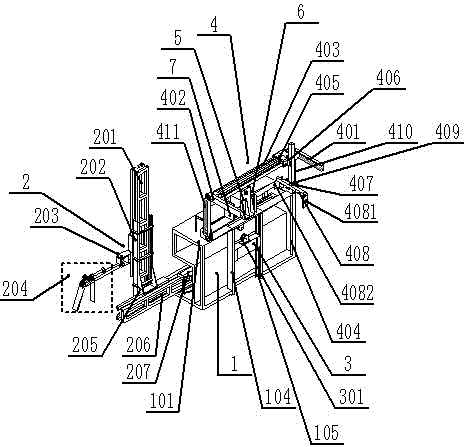

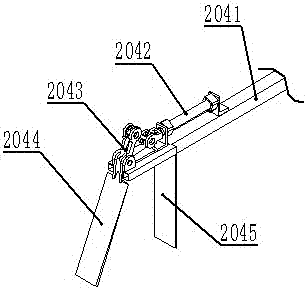

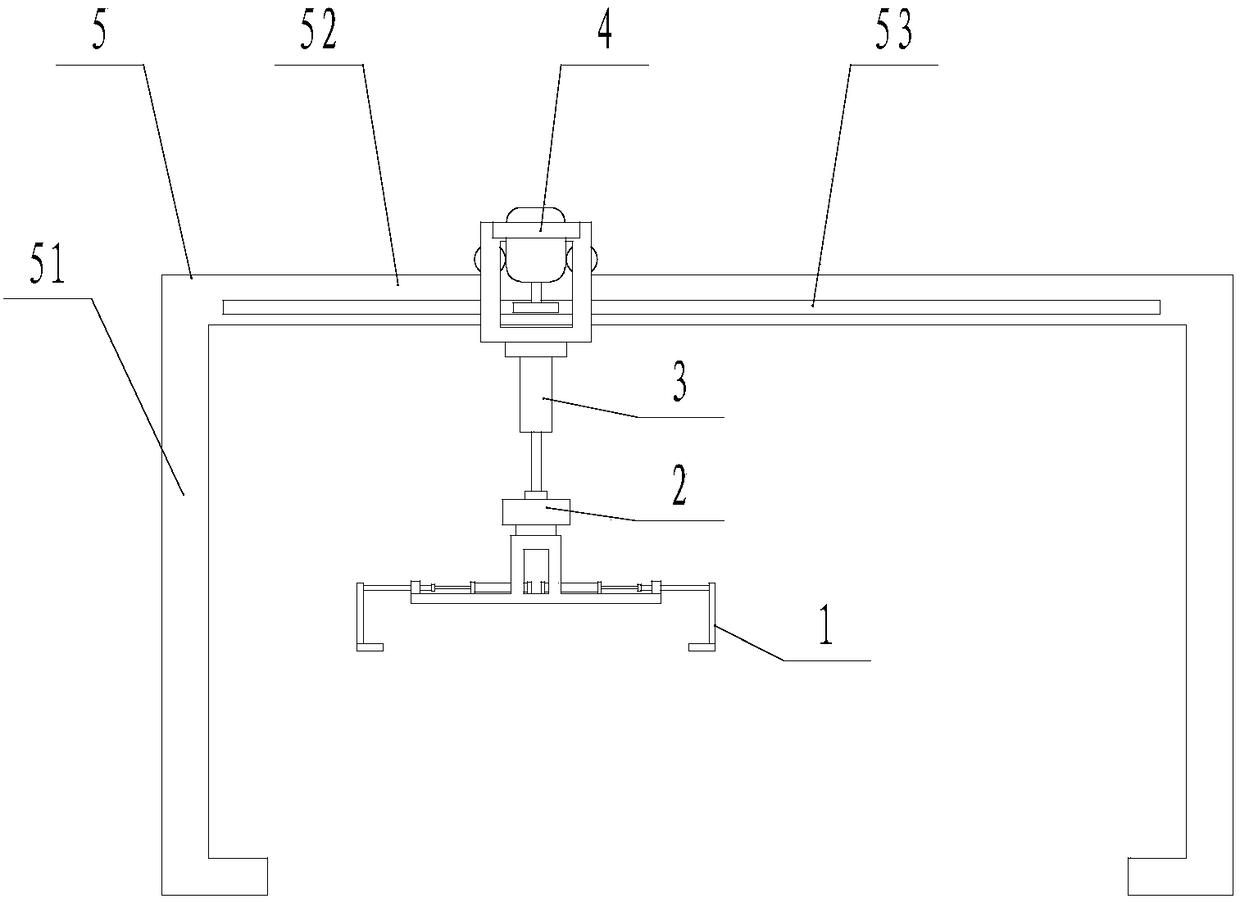

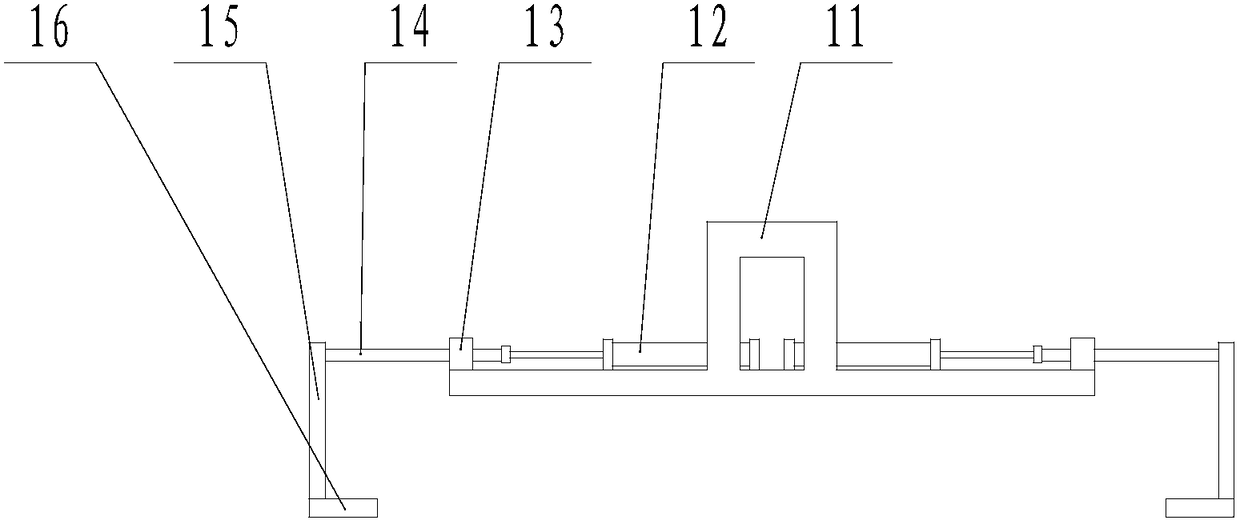

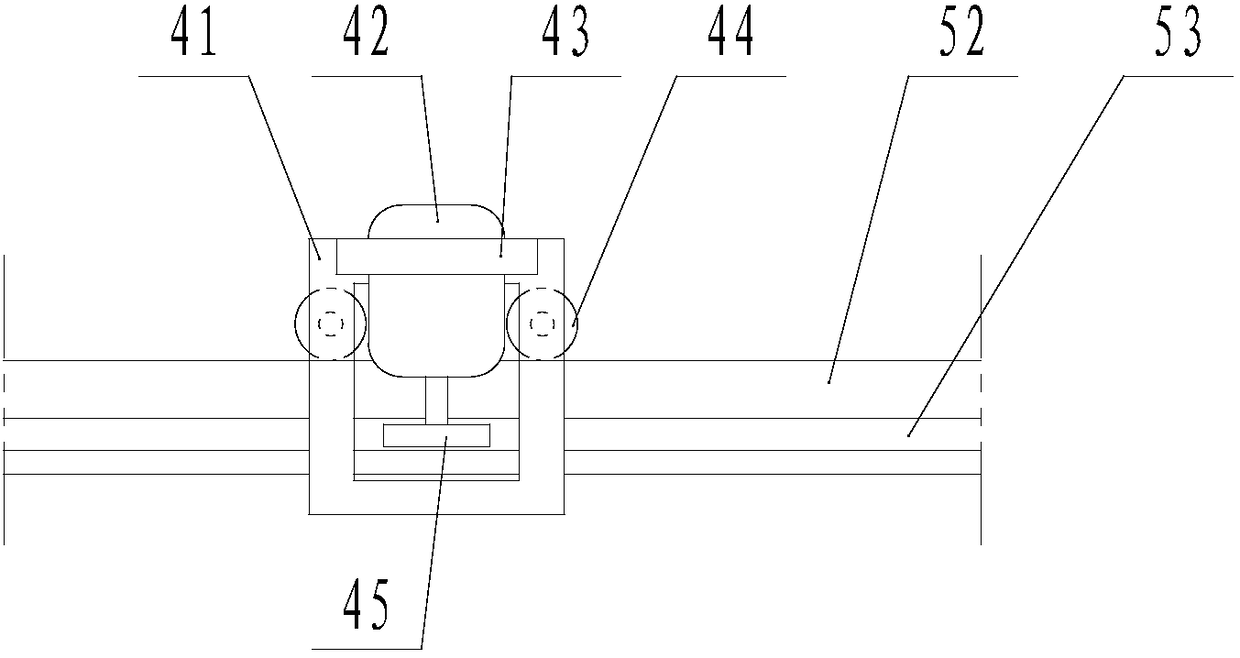

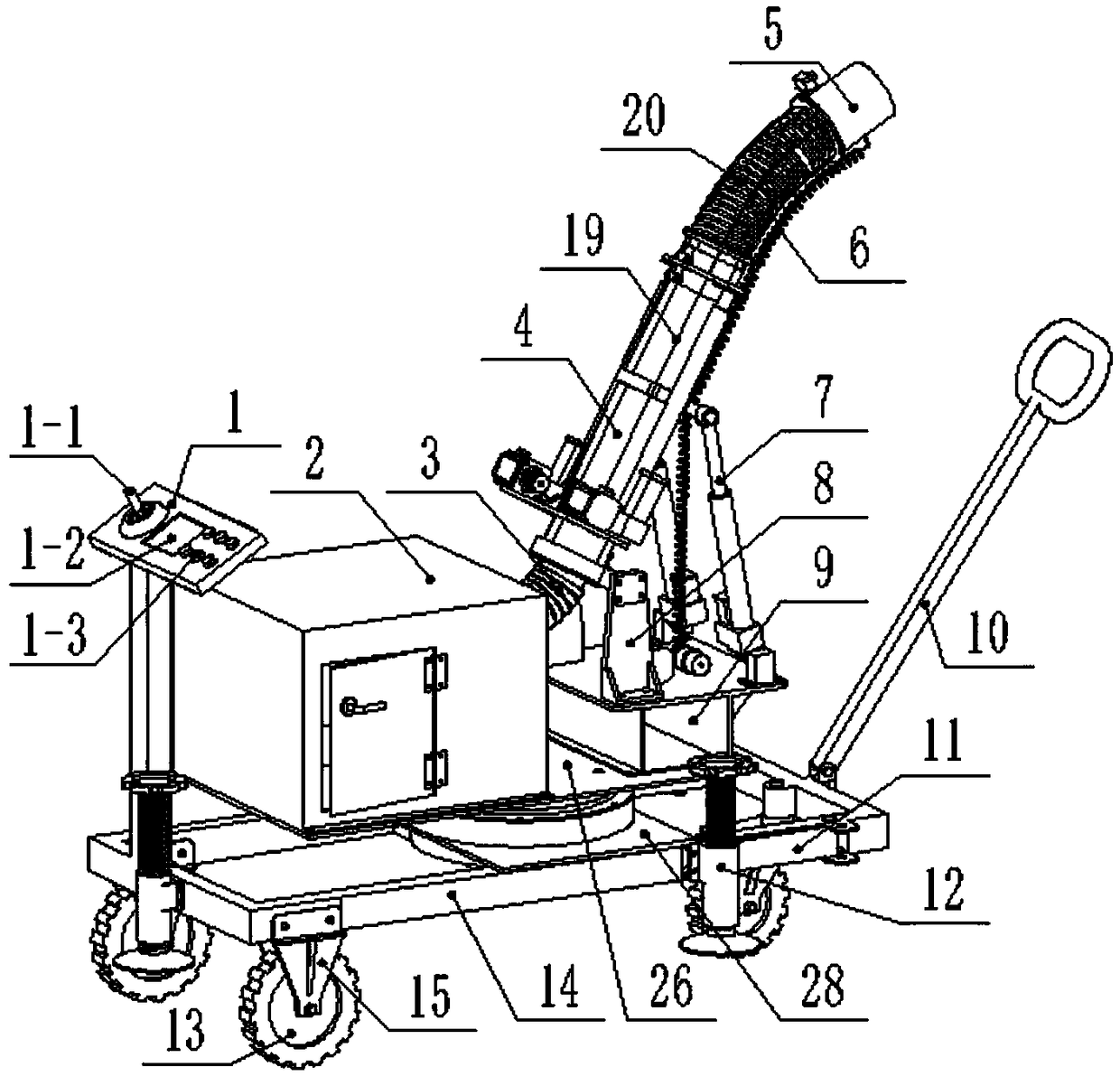

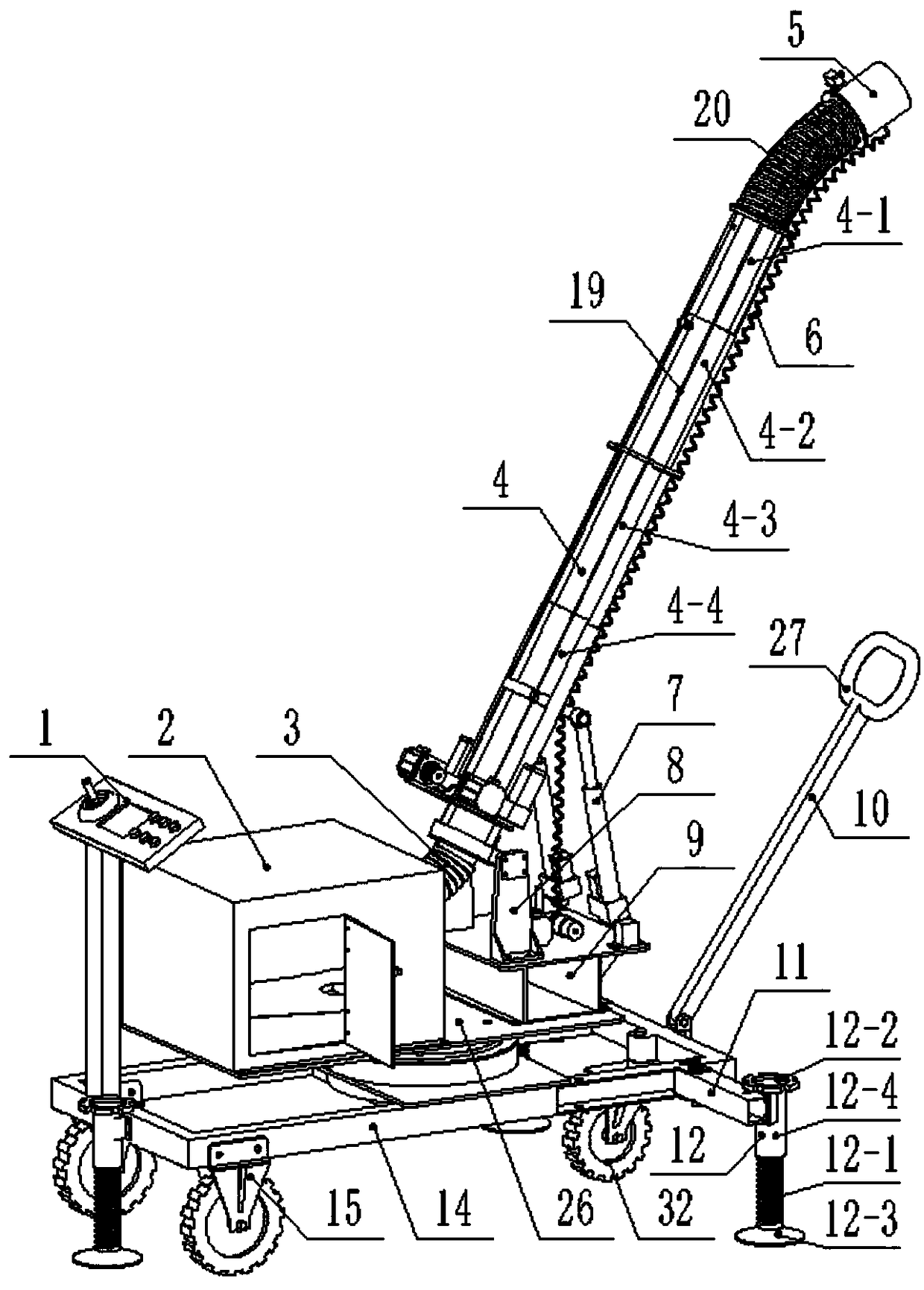

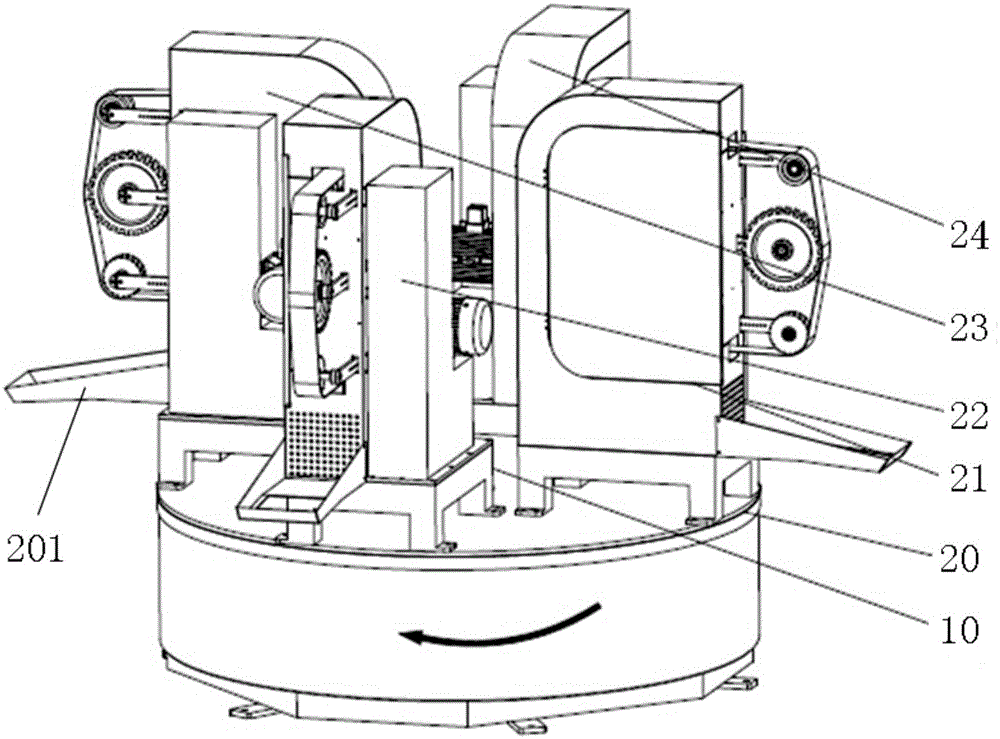

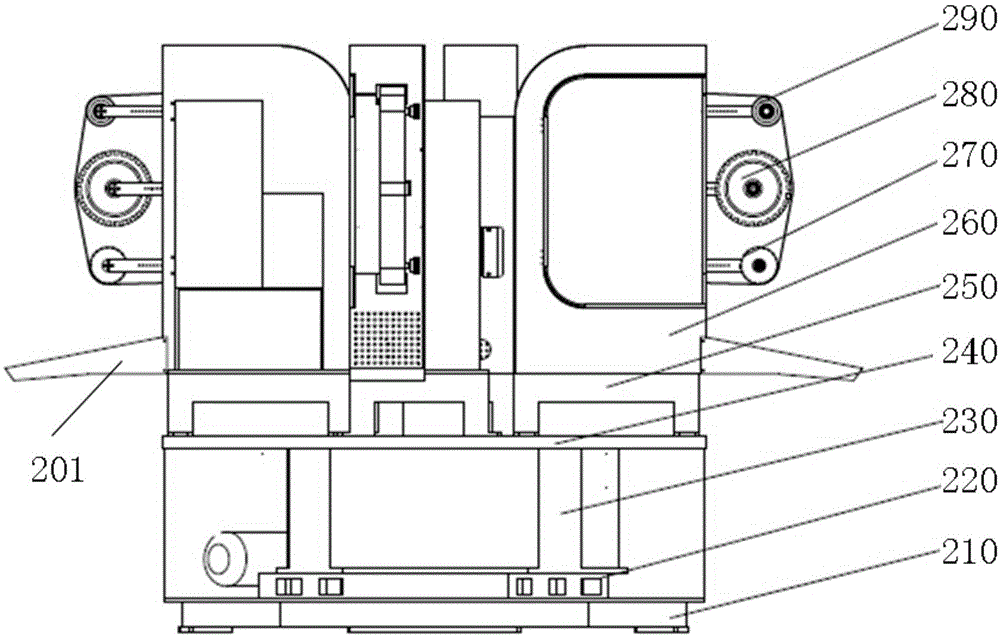

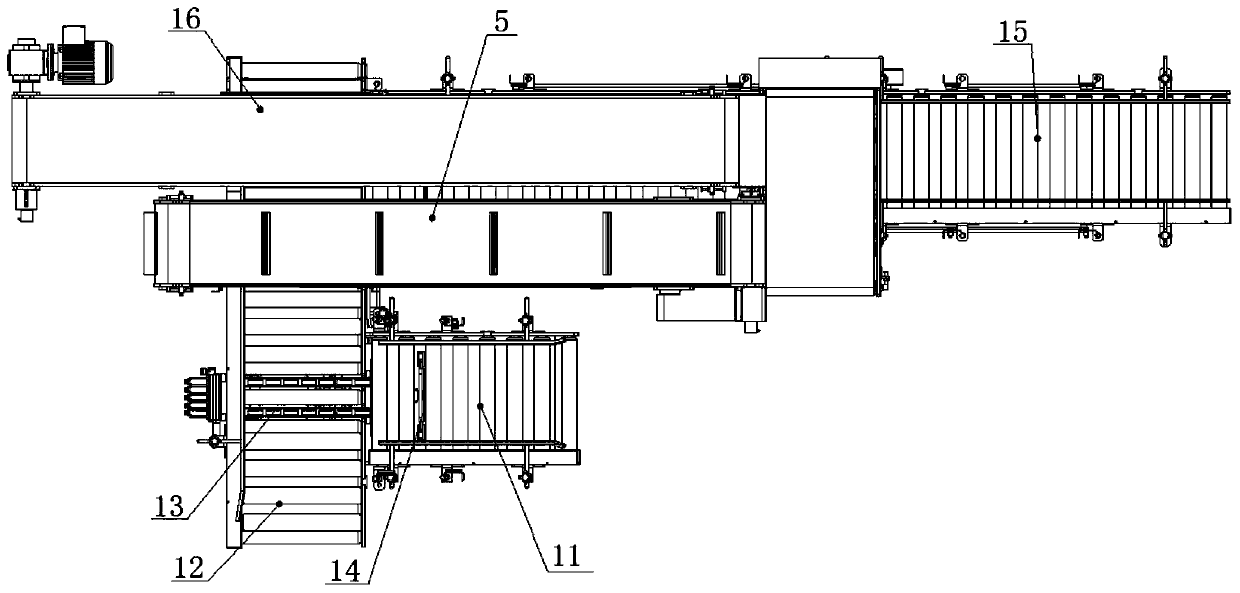

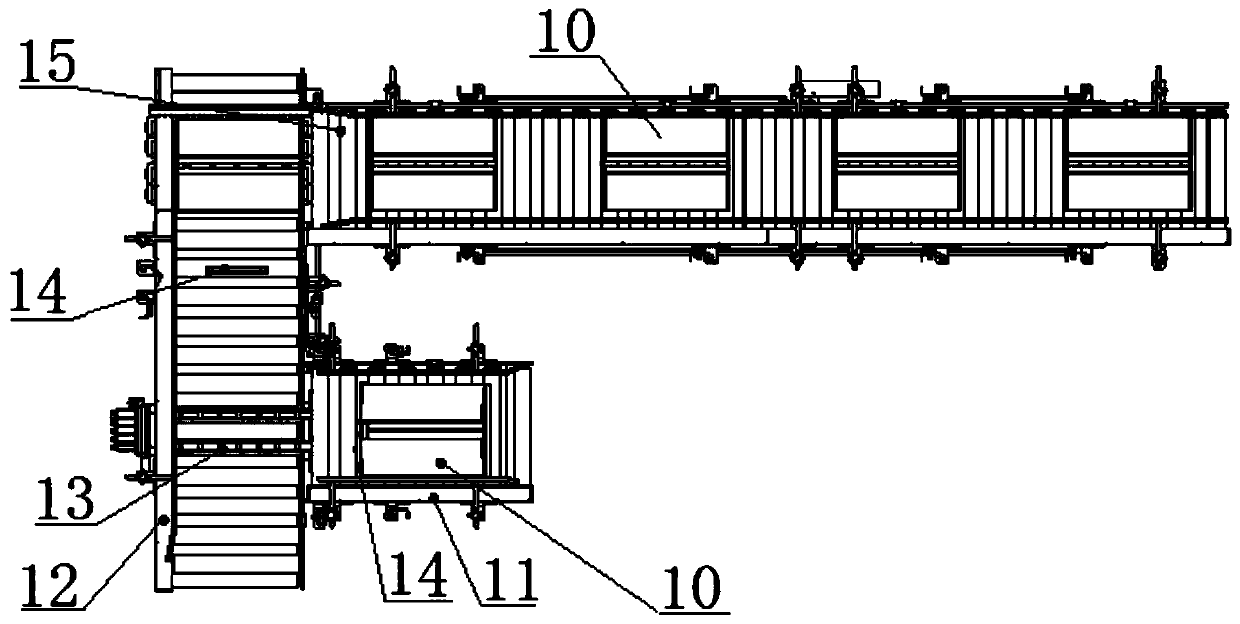

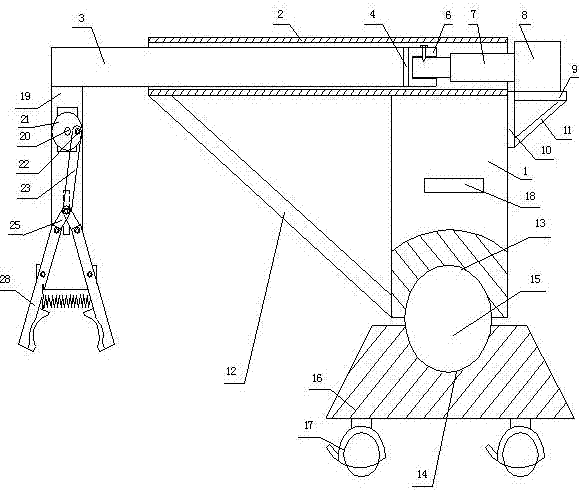

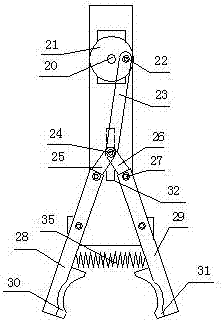

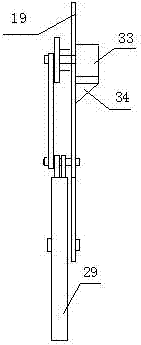

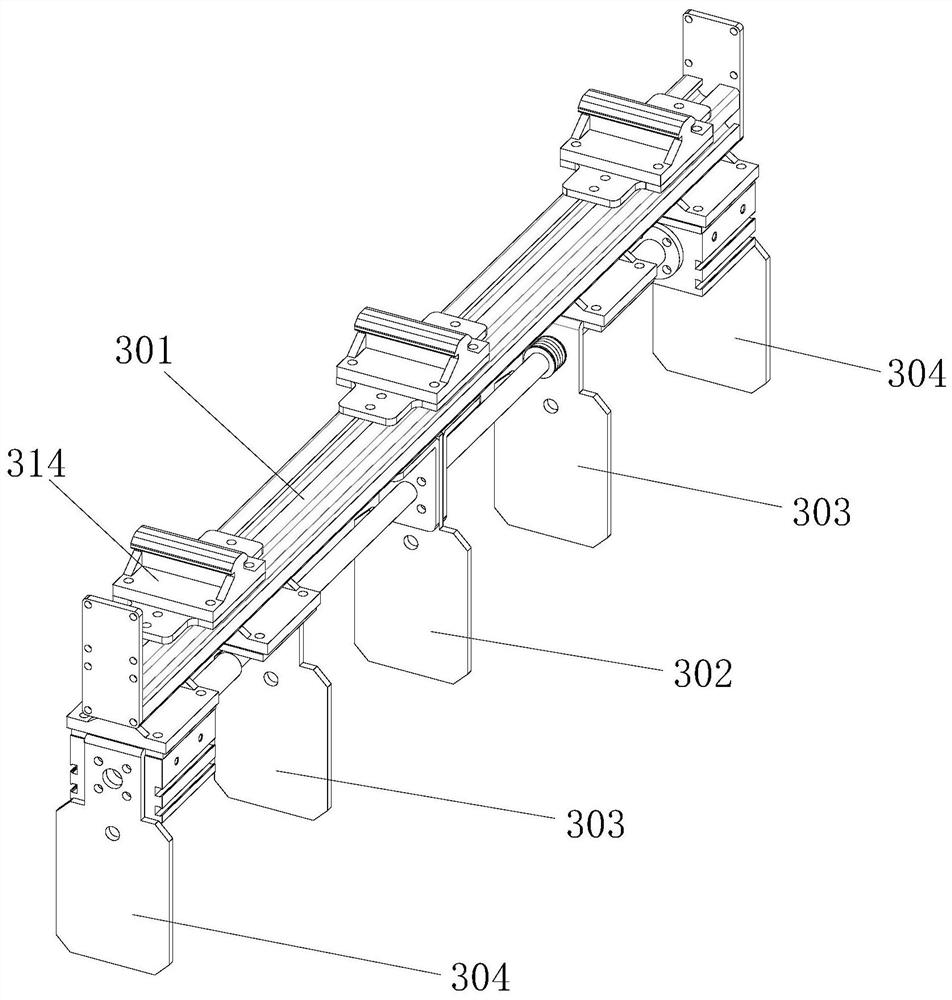

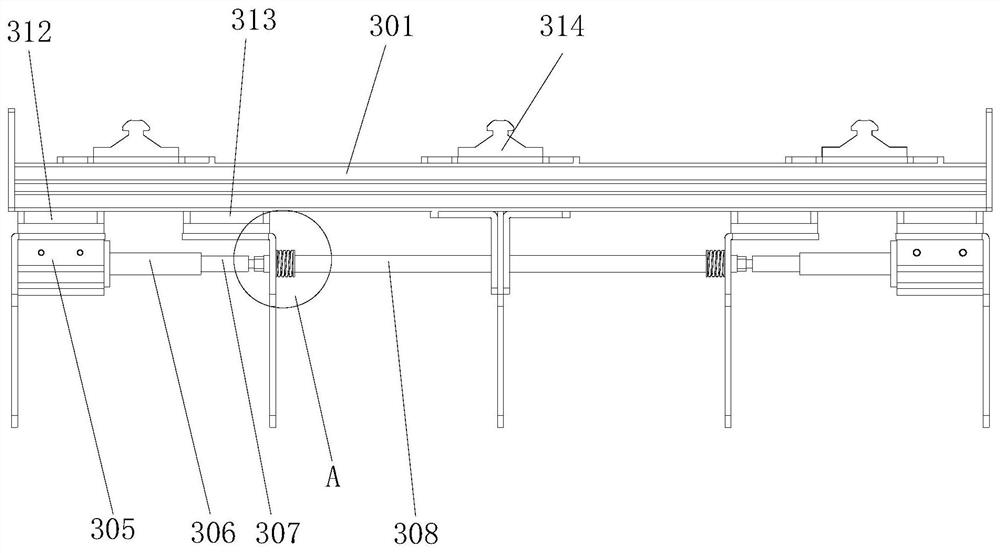

Wall building robot and working method thereof

PendingCN107443353APrecise positioningReduce mistakesProgramme-controlled manipulatorGripping headsDrive motorTransfer mechanism

A wall building robot comprises a workbench body. The workbench body is provided with a brick car transferring mechanism, a double-four-axis linkage control system, an automatic claying machine, a hydraulic brick cutting machine, a brick clamping pallet, and a lifting and translation mechanism. The brick car transferring mechanism moves up and down on a workbench through a first workbench body guide rail and a second workbench body guide rail. The double-four-axis linkage control system conducts spatial positioning and moving on a brick taking manipulator. The automatic claying machine and the hydraulic brick cutting machine are parallel to each other and are both arranged across the brick clamping pallet. The automatic claying machine is connected with the workbench body through a hopper supporting plate and provided with a hopper, an impeller, and a driving motor. The hydraulic brick cutting machine is provided with a cutting blade bracket. The lifting and translation mechanism is arranged on a hollow position between a workbench body base in the workbench body and a workbench top supporting frame. The wall building robot can replace manpower to carry out brick taking, claying, brick cutting, wall building and other action, and is high in automation degree and efficiency and convenient to use.

Owner:洛阳海特智能科技有限公司

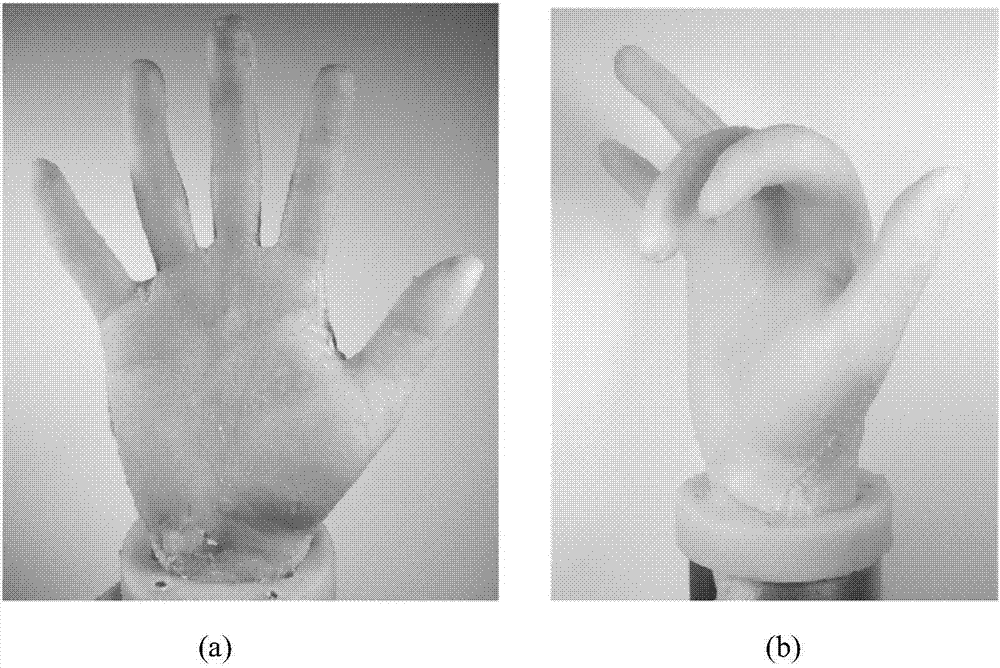

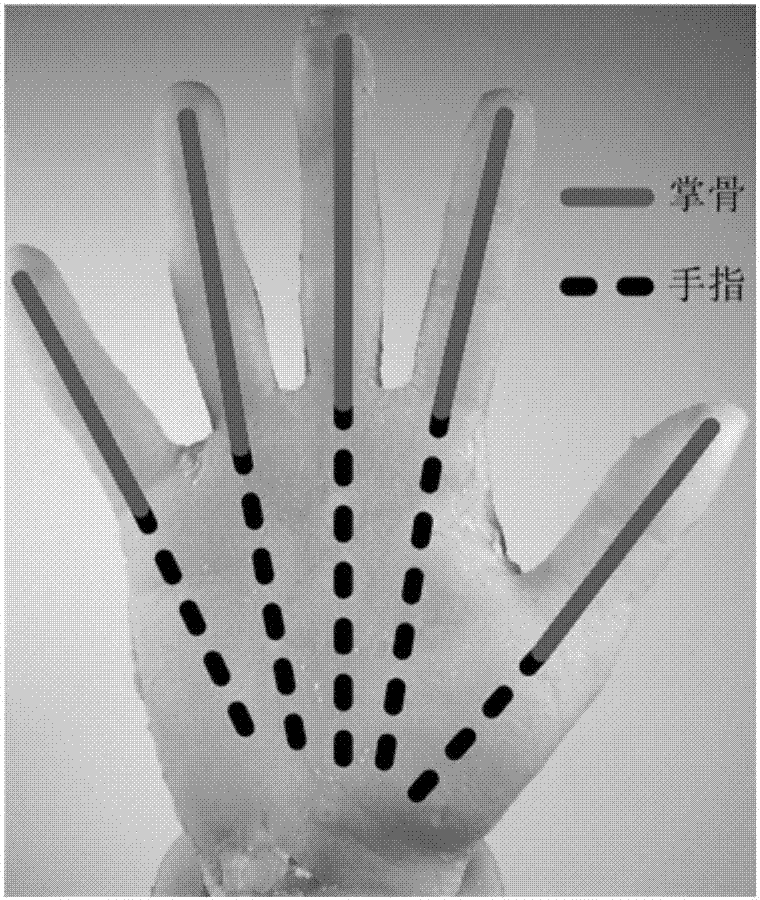

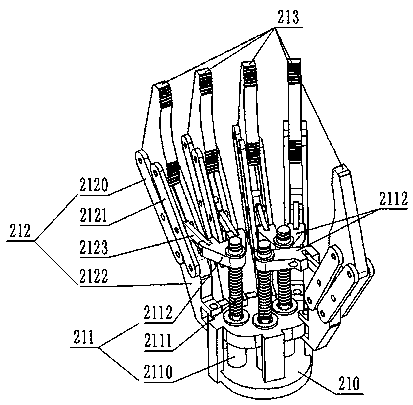

Human simulation dexterous hand based on shape memory alloy (SMA) flexible body intelligent digital composite structures

ActiveCN107081777AIncrease contact areaGuaranteed stabilityGripping headsIncreasing energy efficiencyShape-memory alloyAlloy

The invention discloses a human simulation dexterous hand based on shape memory alloy (SMA) flexible body intelligent digital composite structures. The human simulation dexterous hand is composed of the five different sizes of SMA flexible intelligent digital composite structures and flexible wrapping materials. The size of each SMA-flexible body intelligent digital composite structure corresponds to one finger and a metacarpal bone of the finger of a human hand. Each SMA flexible body intelligent composite structure is composed of two sections, one section is of a rigid structure simulating a metacarpal bone structure of the human hand, and the other section is of a flexible deformation structure simulating the finger part of the human hand. The SMA flexible body intelligent digital composite structures are composed of 3D metacarpal bones, intelligent digital driving skeletons, elastic sheets and the flexible wrapping materials. The SMA flexible body intelligent digital composite structures are composed of the intelligent digital driving skeletons, the sheets and the flexible wrapping materials, so that self-feedback control and digital bending motion can be realized. The dexterous hand has the advantages that the simulation degree of shapes and motion is high, cost is low, safety and compatibility are good, and controllability is high.

Owner:UNIV OF SCI & TECH OF CHINA

Manipulator

The invention provides a manipulator. The manipulator comprises an arm portion and a grabbing portion. The arm portion is configured to move the grabbing portion. A rotary platform is arranged at the tail end of the arm portion. The grabbing portion comprises a rotary frame and grabbing elements. The rotary frame is rotationally arranged on the rotary platform. The grabbing elements are arranged on the rotary frame. Each grabbing element comprises a sucker frame, a first sucker and a second sucker, wherein each first sucker and the corresponding second sucker are arranged on the corresponding sucker frame in a spaced manner. According to the manipulator, the grabbing portion is moved by the arm portion, the first suckers on the grabbing portion grab glass slides, meanwhile due to the fact that the second suckers are arranged on the grabbing portion, labels can be grabbed by the second suckers, accordingly the flexible grabbing and moving of the glass slides are achieved, and the labels can be grabbed and moved as well.

Owner:SHANGHAI BAIO TECH

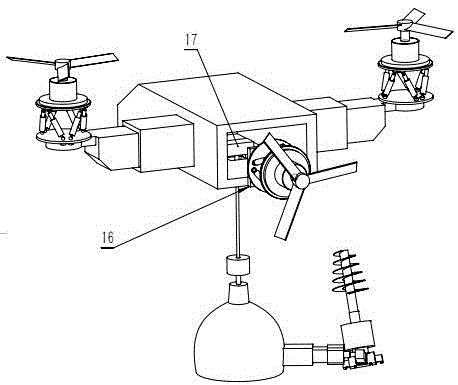

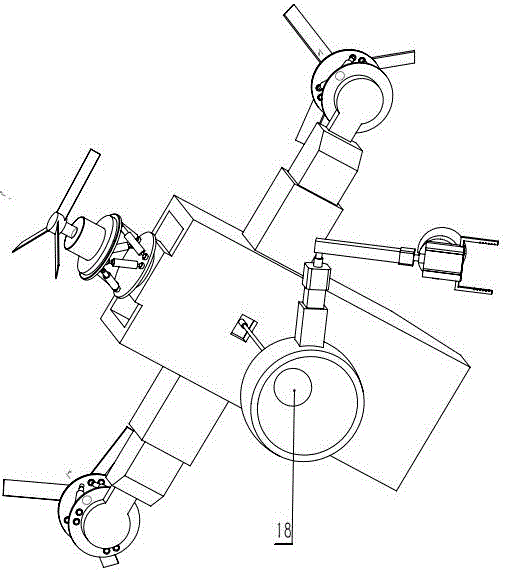

Explosive-removing unmanned aerial vehicle

ActiveCN106585988AFlexible grabbingProtection securityAircraft componentsManipulatorDrill bitAutomotive engineering

The invention provides an explosive-removing unmanned aerial vehicle comprising a vehicle body, two first square sleeves, two first telescopic rods, three power assemblies, a steel wire rope and the like. The explosive-removing unmanned aerial vehicle is characterized in that the vehicle body is of a cuboid structure; the head of the vehicle is in a point-end shape; the square sleeves are mounted on the left side and the right side of the vehicle body correspondingly; each first telescopic rod is slidably mounted in the corresponding square sleeve; two power assemblies are mounted on the upper portions of the outer end portions of the first telescopic rods correspondingly; and another power assembly is arranged on the rear portion of the vehicle body; and is mounted on the rear portion of the vehicle body through a rear portion mounting seat. The unmanned aerial vehicle can be flexibly controlled to rise up and go forward through the three power assemblies, explosive can be flexibly captured through arrangement of a mechanical arm, and drilling on the ground can be conducted through a cone-shaped spiral drill head on a pneumatic clamping jaw.

Owner:JIANGSU DONGBAO AGROCHEM

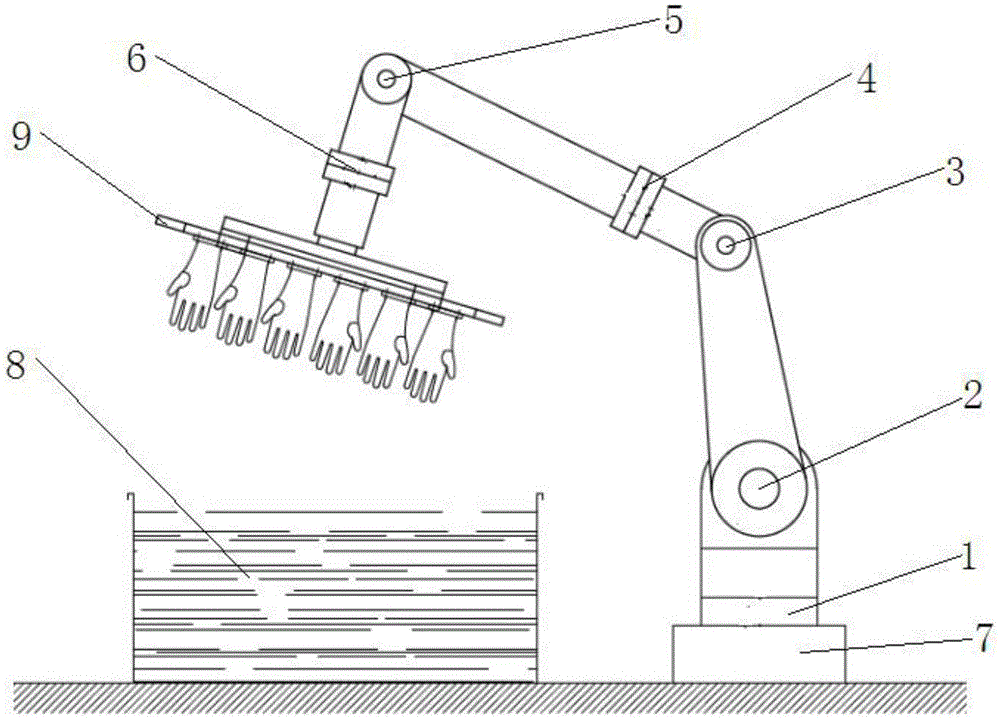

Multi-joint all-dimensional glove gum dipping device

The invention discloses a multi-joint all-dimensional glove gum dipping device which comprises a base fixed to the ground, the base is connected with a first beam through a first joint, the first beam is connected with a second beam through a second joint, the second beam is connected with a third beam through a third joint, the third beam is connected with a fourth beam through a fourth joint, the fourth beam is connected with a fifth beam through a fifth joint, the fifth beam is connected with a sixth beam through a sixth joint, the sixth beam is connected with a glove die, and a gum dipping pool is arranged below the glove die. According to the multi-joint all-dimensional glove gum dipping device, multiple 360-degree joints are designed, the whole gum dipping process is flexibly completed, existing production equipment is inflexible in grabbing and low in speed, by means of the multi-joint all-dimensional glove gum dipping device, action of human hands is stimulated according to signals of a system, and the multi-joint all-dimensional glove gum dipping device is flexible and convenient.

Owner:南通林赛尔智能装备有限公司

Plate grabbing hanging bracket

Owner:连云港森福木业有限公司

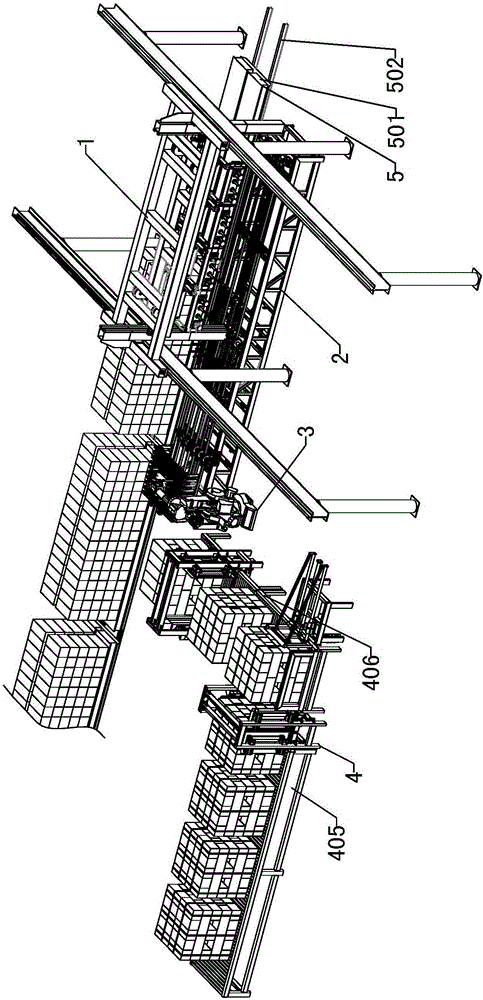

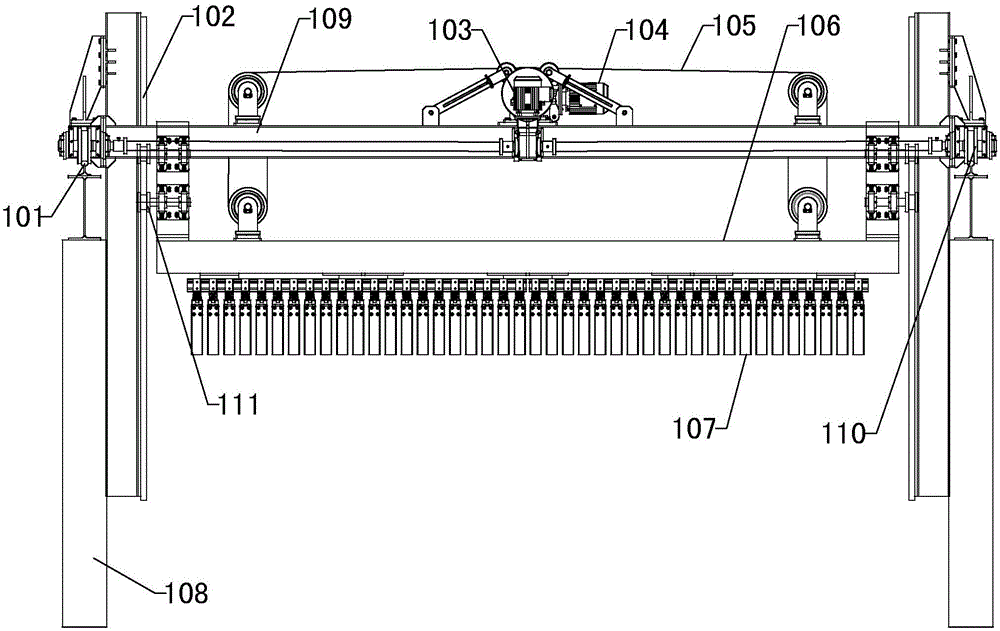

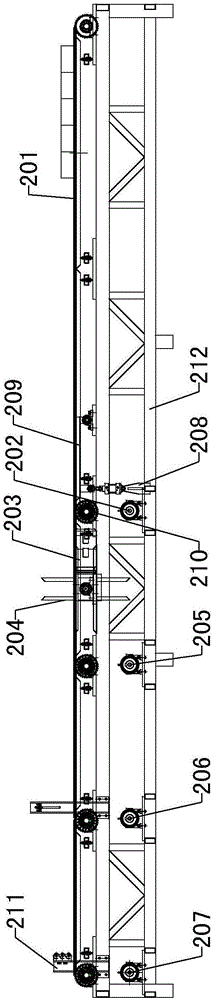

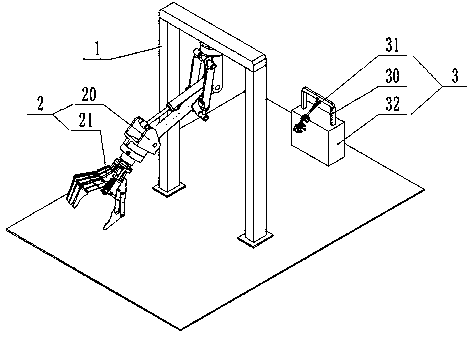

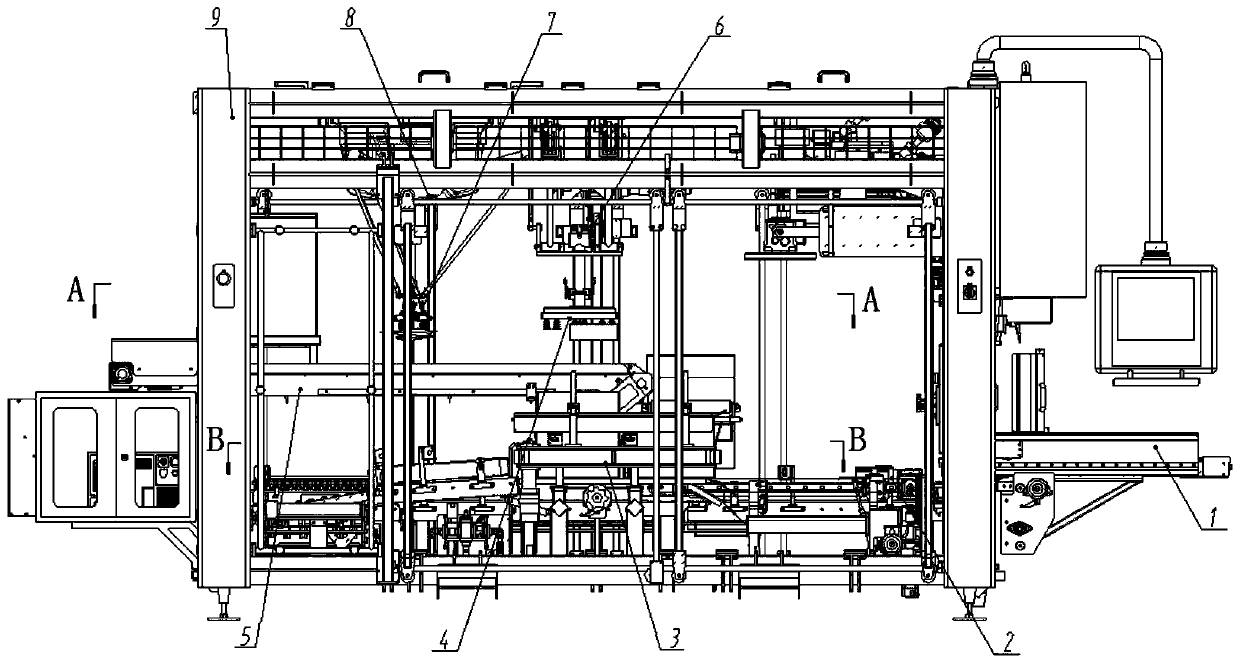

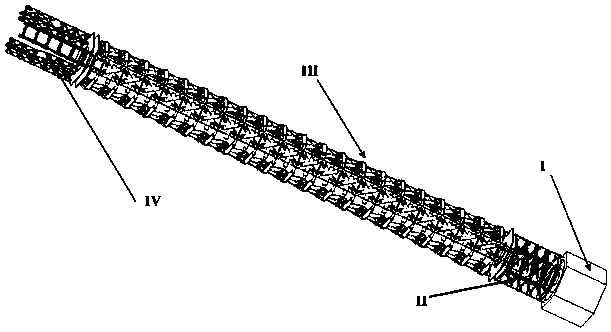

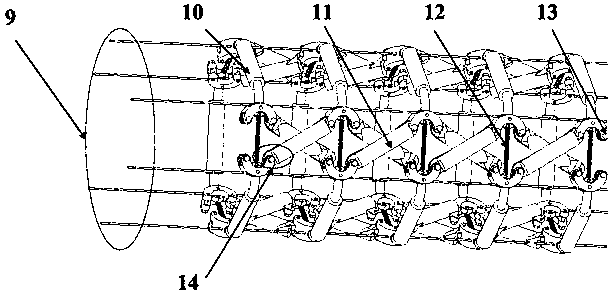

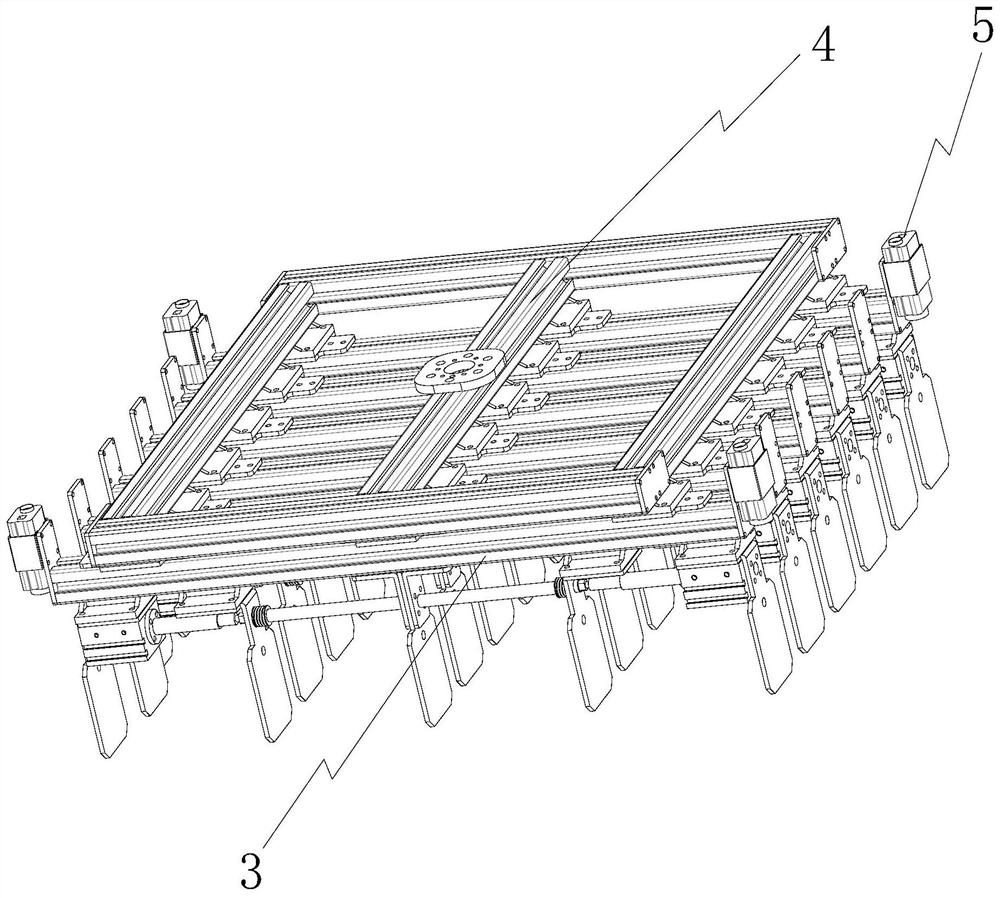

Tray-free stacking process for autoclaved lightweight concrete building blocks

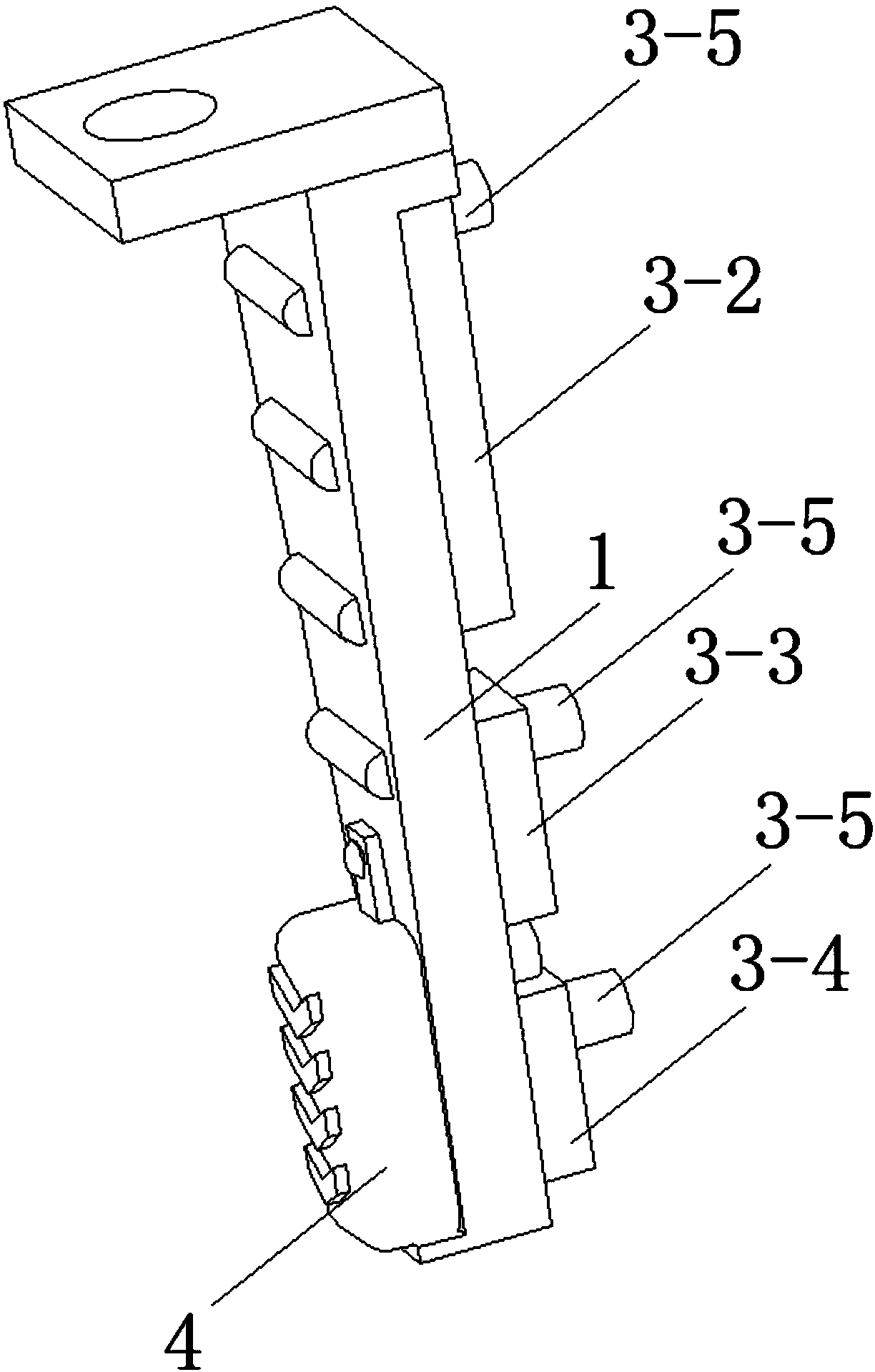

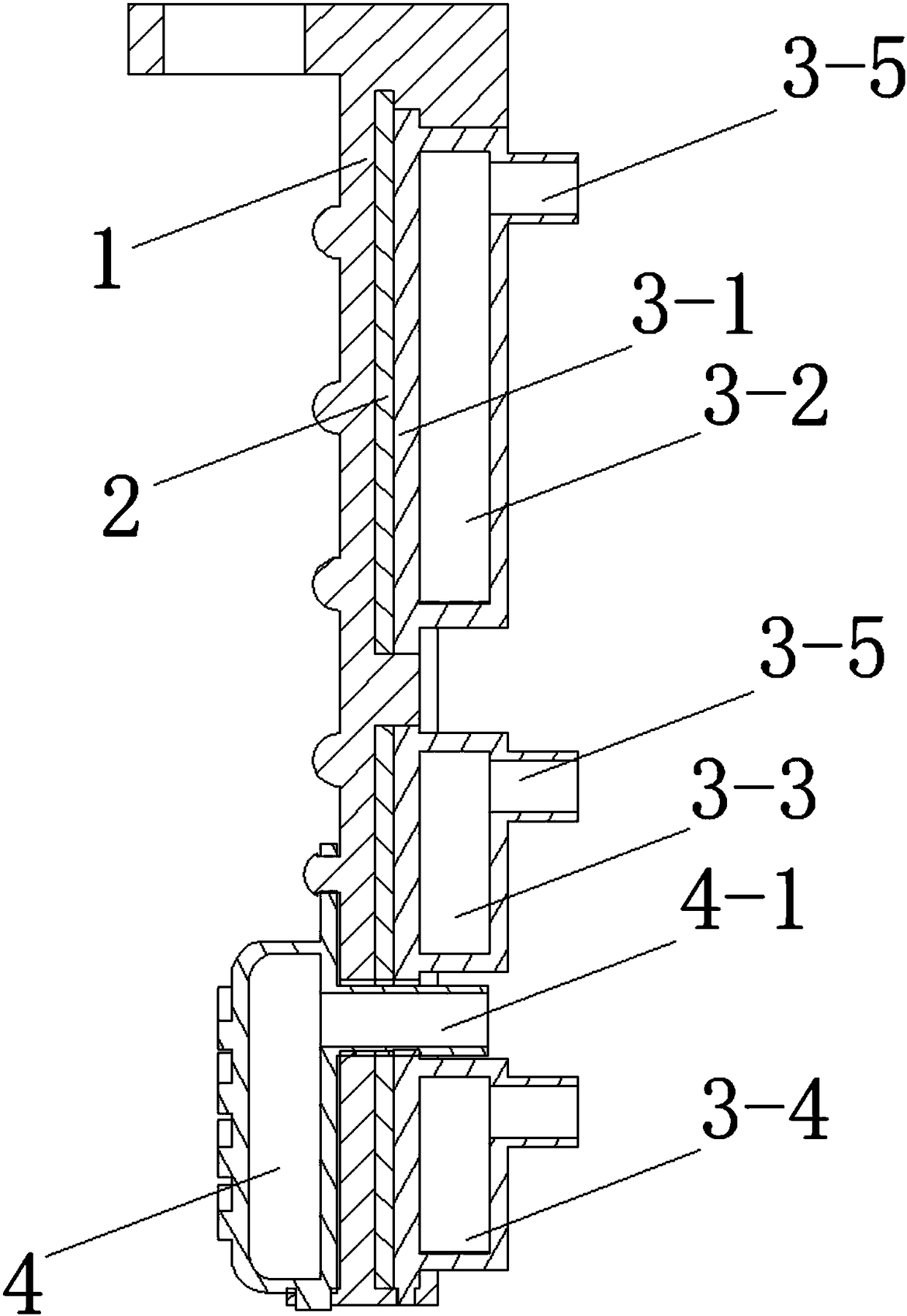

The invention discloses a tray-free stacking process for autoclaved lightweight concrete building blocks, and belongs to the field of concrete building block packaging processes. The tray-free stacking process is characterized by being implemented by a full-automatic packaging system, and each stacking clamp (302) is independently controlled to be opened and closed through a line; the tray-free stacking process comprises the following stacking steps: (1) setting the arrangement direction and the quantity of the building blocks on each layer in building block stack, and sizes of loading and unloading holes; (2) performing green brick rolling over: continuously rolling over a plurality of rows of building blocks row by row; (3) performing grounding: grouping the building blocks row by row until the quantity of building blocks for each layer is met; (4) performing layer-by-layer stacking: stacking the subsequent building blocks on the lower layer of the building block stack in sequence through a mechanical arm stacking mechanism (3); (5) reserving and setting loading and unloading holes; and (6) performing packaging. According to the tray-free stacking process for the autoclaved lightweight concrete building blocks, no tray is used in the whole conveying process, so that a large number of trays are saved; the building blocks can be directly carried by a forklift truck without the tray, so that the effect of the tray is thoroughly eliminated; and therefore, a lot of production cost is saved.

Owner:淄博捷达机械有限公司

High-precision quick reaction mechanical hand

ActiveCN110561396AReduce labor intensityImprove planting efficiencyProgramme-controlled manipulatorGripping headsEngineeringPortal frame

The invention discloses a high-precision quick reaction mechanical hand. The high-precision quick reaction mechanical hand comprises a first portal frame and a mechanical hand body. The mechanical hand body comprises a mechanical arm and a palm connected with the mechanical arm. The mechanical arm drives the palm to do rotation motion and swing motion. The palm comprises a connecting rod mechanism, a linear drive mechanism, a connecting seat and multiple clamping fingers. The connecting seat is connected with the mechanical arm. The multiple clamping fingers are connected with the linear drivemechanism through the connecting rod mechanism. The linear drive mechanism is connected to the connecting seat. The linear drive mechanism drives the connecting rod mechanism to move to drive the clamping fingers to be opened or closed. The high-precision quick reaction mechanical hand is easy and convenient to operate and high in flexibility, and can be operated by ordinary workers, the use costis reduced, and the working efficiency is improved.

Owner:HUNAN BIOLOGICAL & ELECTROMECHANICAL POLYTECHNIC

Automatic grabbing and lifting device for logistics sorting assembly line

The invention relates to the field of logistics sorting equipment, and particularly discloses an automatic grabbing and lifting device for a logistics sorting assembly line. The automatic grabbing andlifting device comprises a base, wherein a supporting back plate is further arranged on the base; a supporting top seat is fixedly arranged at the top end of the supporting back plate; a rotating disc is rotationally arranged in an opening in the bottom of the supporting top seat; a height adjusting component used for adjusting the height position of an infrared code scanning camera is arranged on the rotating disc; a second positive and negative rotation servo motor is arranged on one side of the rotating disc; a vertical electric telescopic rod is arranged on an output shaft of the second positive and negative rotation servo motor; and an angle adjusting component for adjusting an inclination angle of a grabbing component is arranged at the telescopic end of the vertical electric telescopic rod. According to an embodiment of the invention, a barcode on a logistics object can be scanned through the infrared code scanning camera in order to obtain the position of a target logistics object, and then the grabbing component can be flexibly placed on the two sides of the infrared code scanning camera conveniently when the rotating disc rotates, so that the range of grabbing the targetlogistics object by the grabbing component is extended.

Owner:袁欢

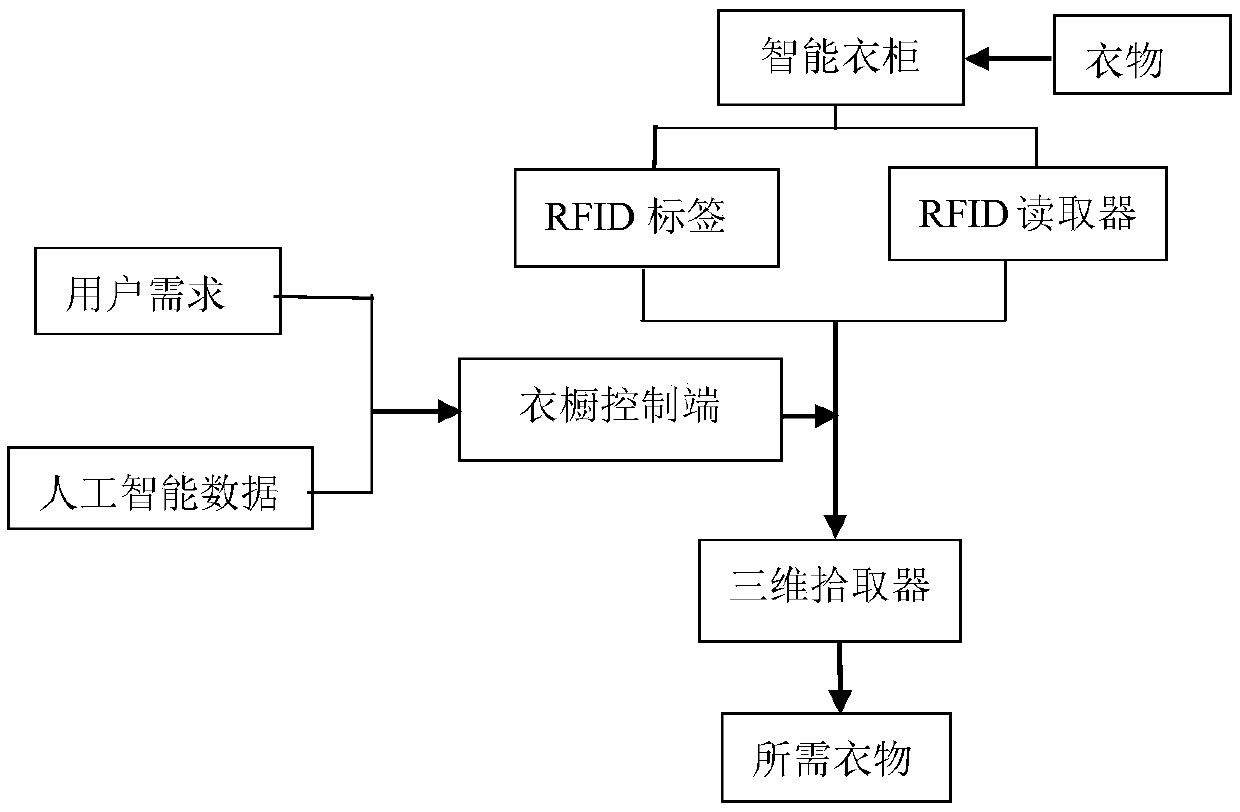

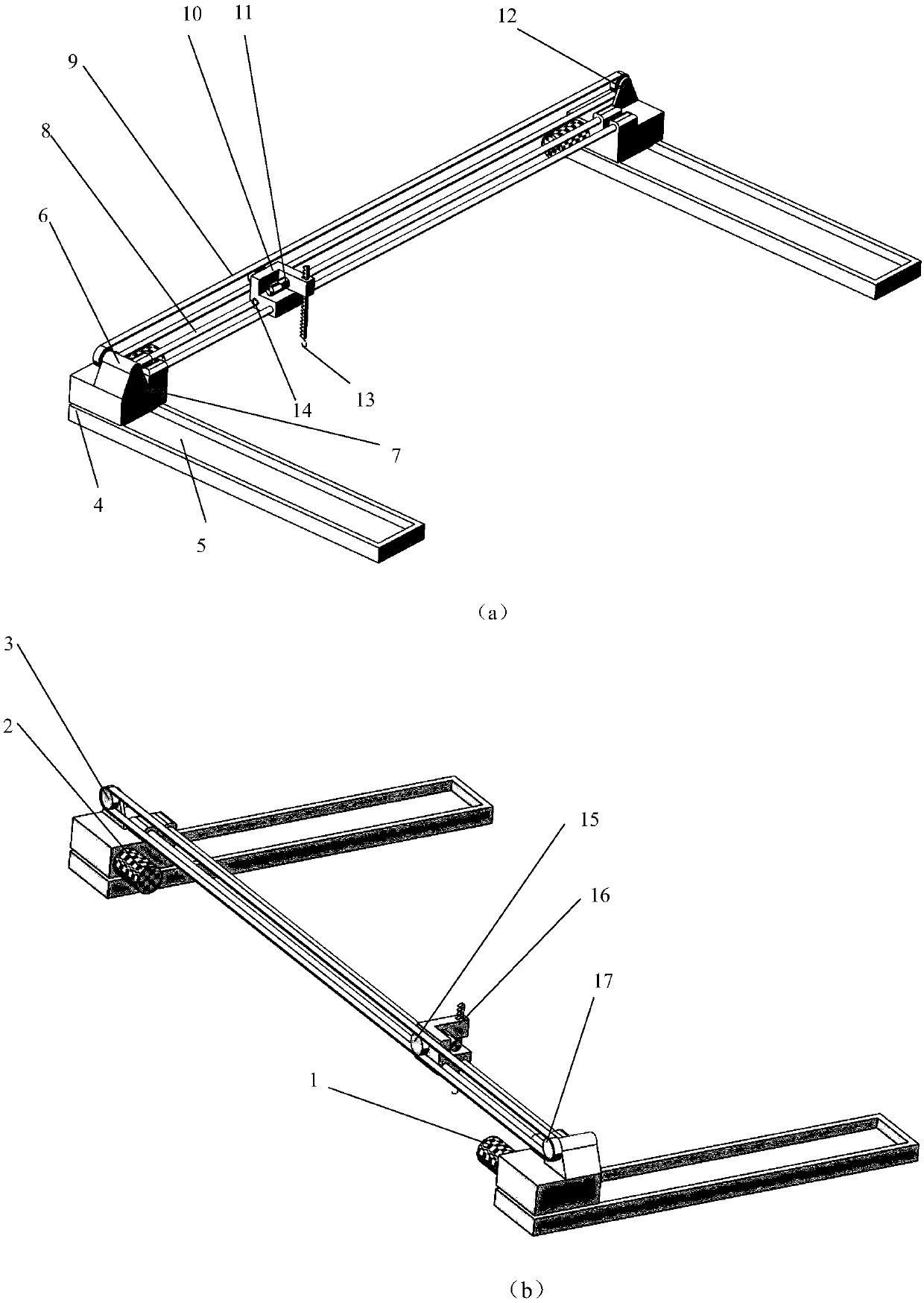

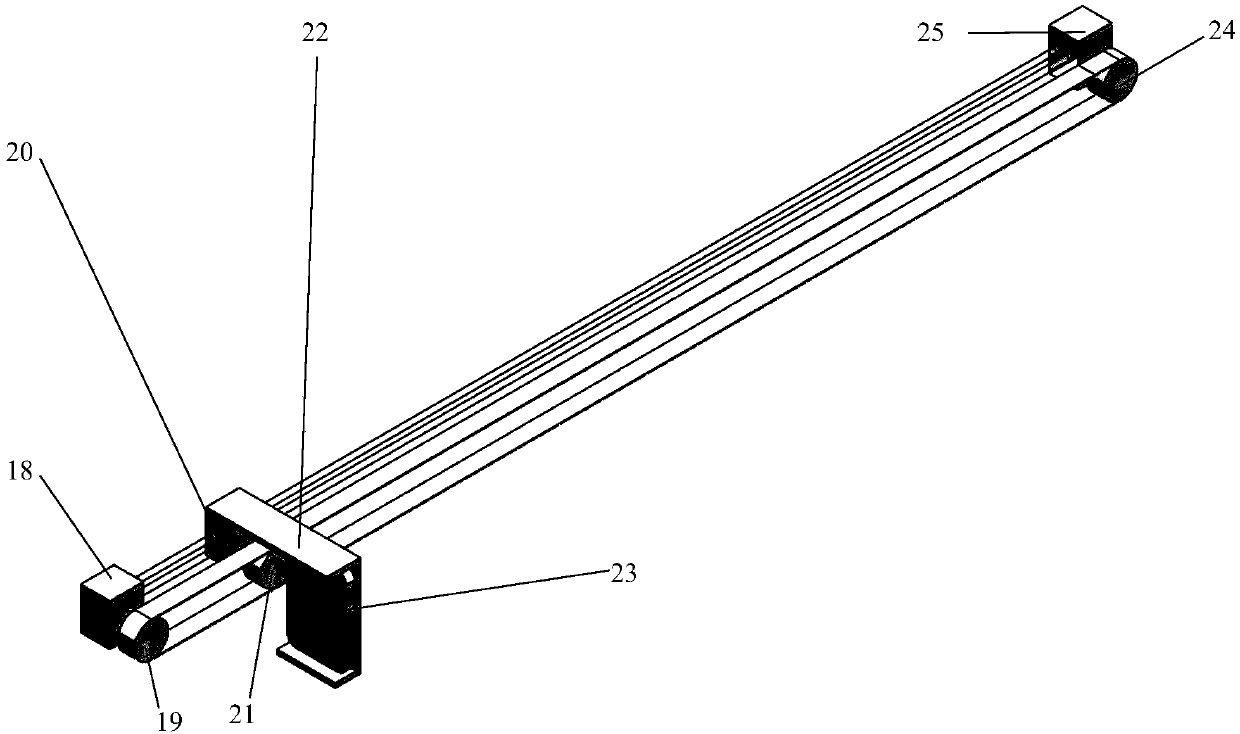

Intelligent clothes storage and distribution system based on tags

PendingCN109512155AEasy to manageMeet human needsWardrobesCo-operative working arrangementsDistribution systemComputer science

The invention discloses an intelligent clothes storage and distribution system based on tags. The system is characterized by comprising an intelligent wardrobe and a wardrobe control terminal; the intelligent wardrobe is in communication connection with the wardrobe control terminal; a signal sending and receiving device, a radio frequency identification reader and a three-dimensional pickup device are arranged on the intelligent wardrobe; the radio frequency identification reader is used for reading clothes information in the intelligent wardrobe in real time and sending the clothes information to the wardrobe control terminal; the wardrobe control terminal is used for storing the clothes information stored in the intelligent wardrobe, and sending and receiving clothes placing or taking instructions to the signal sending and receiving device; the signal sending and receiving device is used for receiving the instructions sent by the wardrobe control terminal and sending the instructions to the three-dimensional pickup device; the three-dimensional pickup device is used for placing or taking clothes according to the received instructions; the clothes are provided with the RFID tagsrespectively. The system can achieve rapid management of the clothes.

Owner:刘华斌

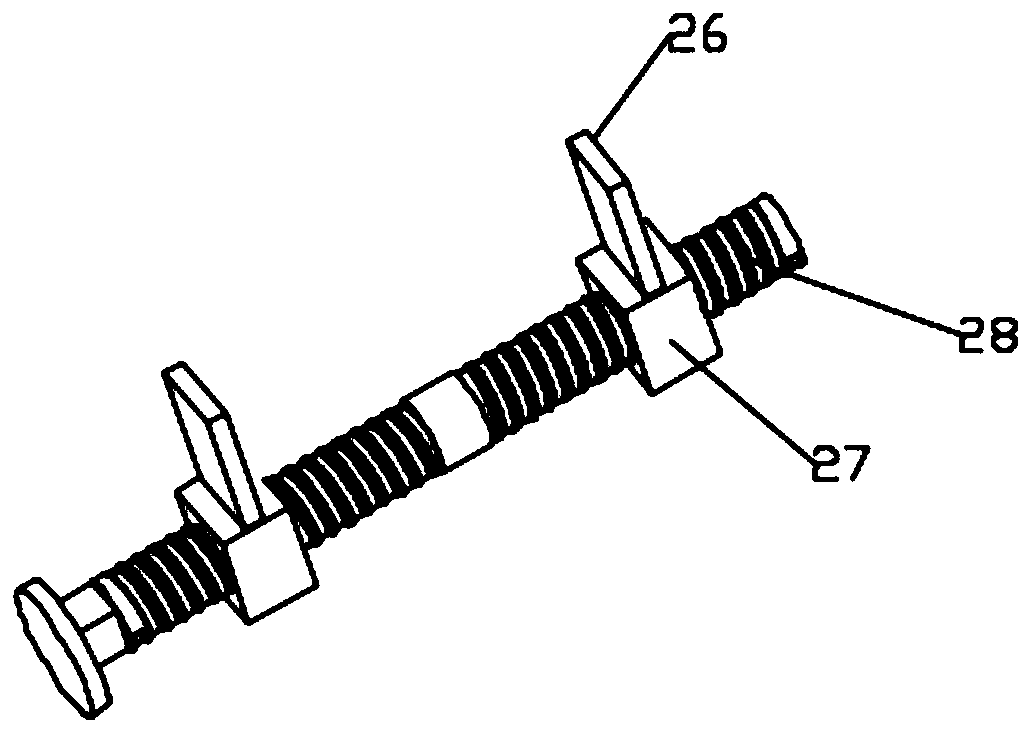

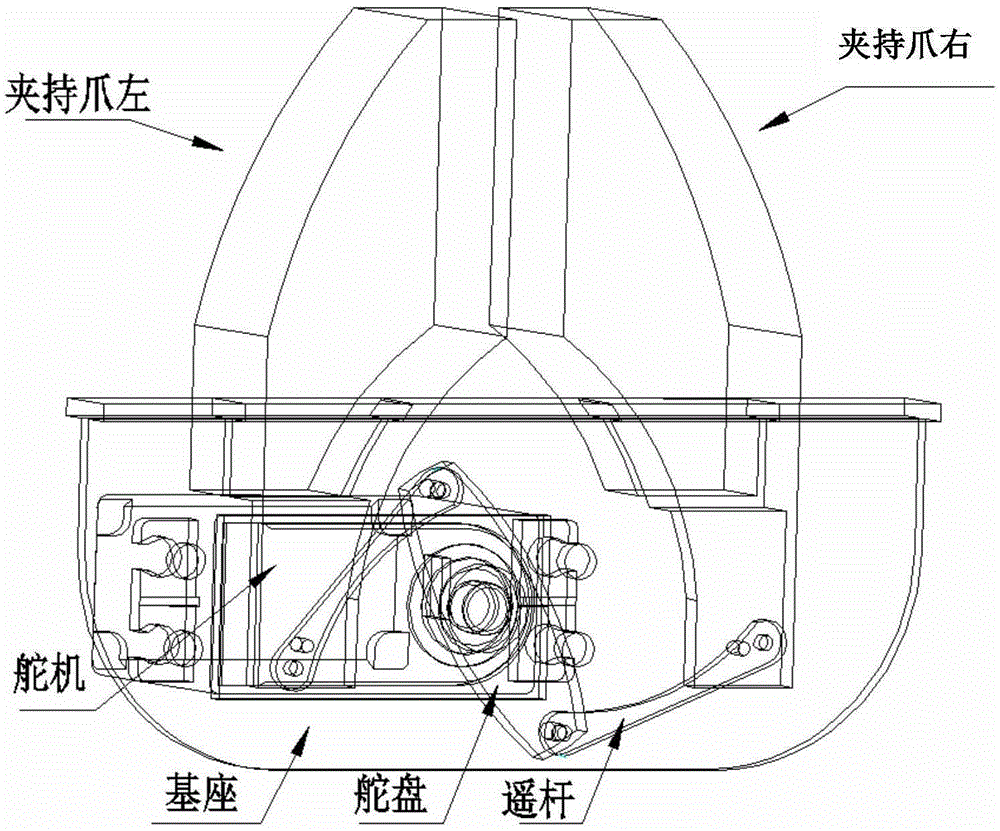

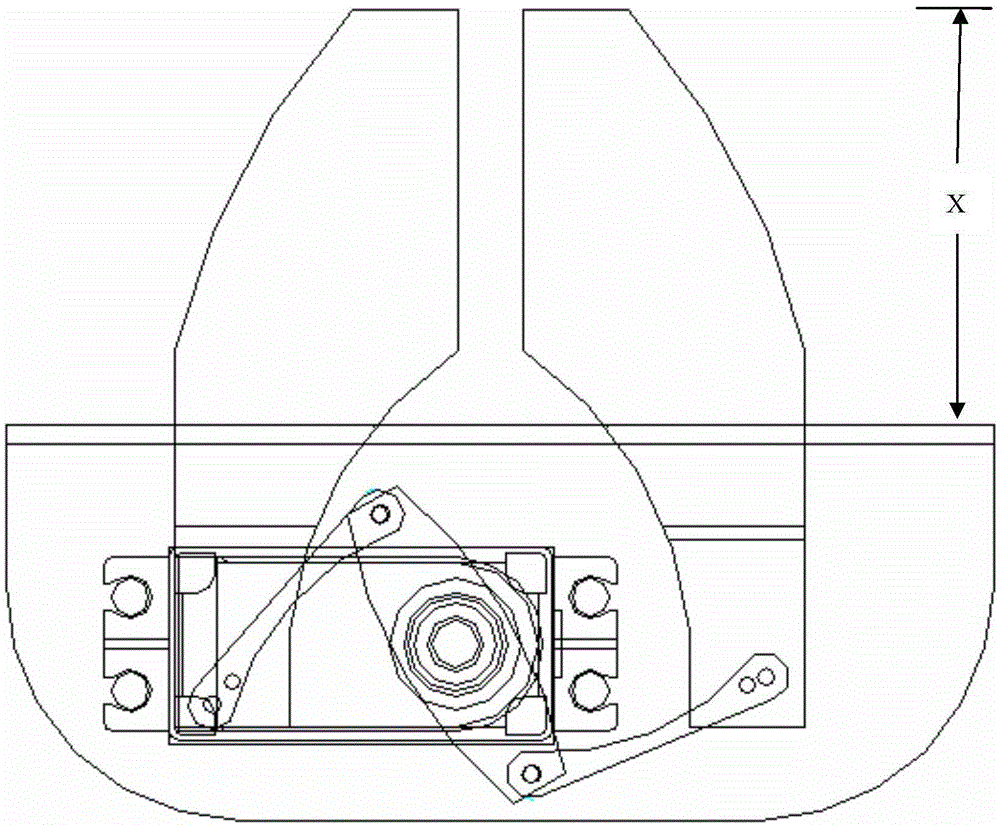

Mechanical gripper

The invention discloses a mechanical gripper. The mechanical gripper comprises a base, gripper jaws, a steering engine, a steering wheel, a helm disc and a rocking bar, wherein the gripper jaws are mounted on slideways of the base; the steering engine drives the helm disc to rotate; the helm disc drives the rocking bar, and then the rocking bar drives the gripper jaws, so that the gripper jaws slide on the slideways and an object can be clamped or released. The mechanical gripper disclosed by the invention can work in a narrow operation space; the mechanical gripper is light in overall weight, simple and reliable in structure, and high in stability, so that the mechanical gripper is particularly suitable for being used in aircrafts or other special industry.

Owner:湖南哈工机器人研究院有限公司

Fruit picking and collecting integrated robot

PendingCN108811765AFlexible grabbingImprove picking efficiencyPicking devicesEngineeringBolt connection

Disclosed is a fruit picking and collecting integrated robot. A control console is connected and installed at the tail of a walking device through a bolt. A conveying device and a posture adjusting device are connected and installed at the upper portion of the walking device through bolts, the tail end of one side of the conveying device is connected with a fruit collecting box, a tail end grabberis installed at the other side of the conveying device, expansion and retraction of three air bags inside the tail end grabber can be controlled through an air pump, then, fruits are grabbed and picked, after the fruits are picked, the fruits are conveyed to the collecting box through the conveying device, and therefore fruit picking and collecting are achieved. Flexible grabbing can be achievedby driving a rope to control a flexible mechanical arm, nondestructive grabbing can be achieved through the tail end grabber containing the air bags, the characteristics of the whole structure can beutilized, the function of picking and collecting integration is achieved, and therefore the picking efficiency is greatly improved.

Owner:YANSHAN UNIV

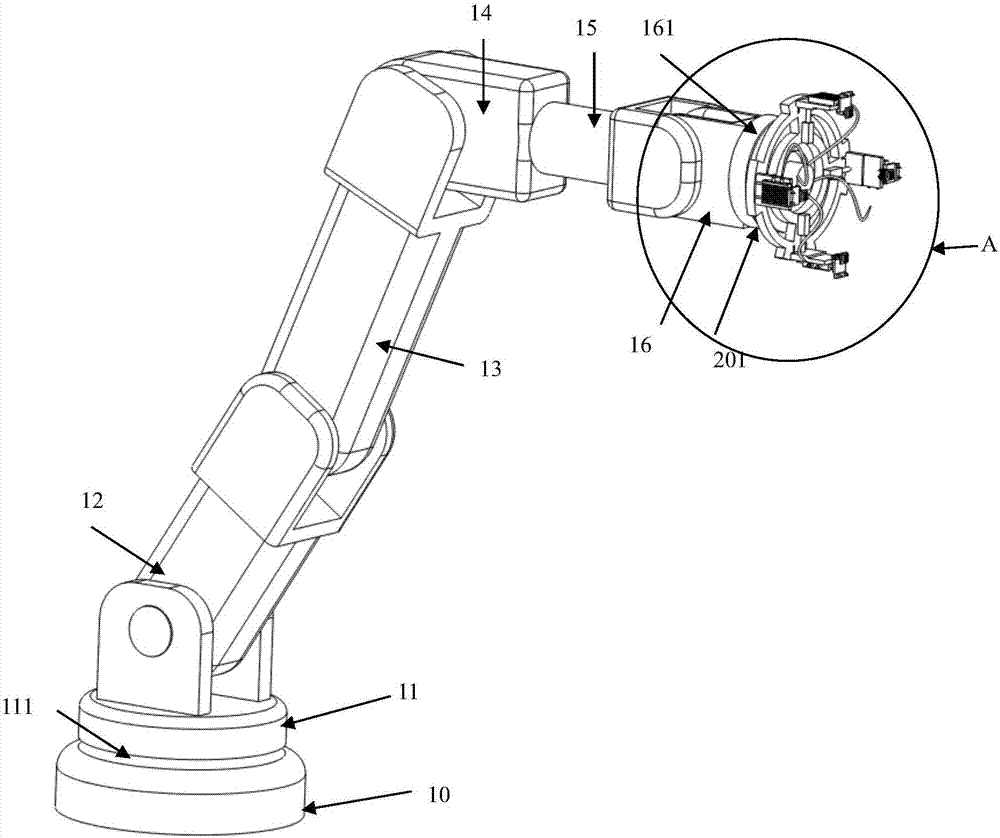

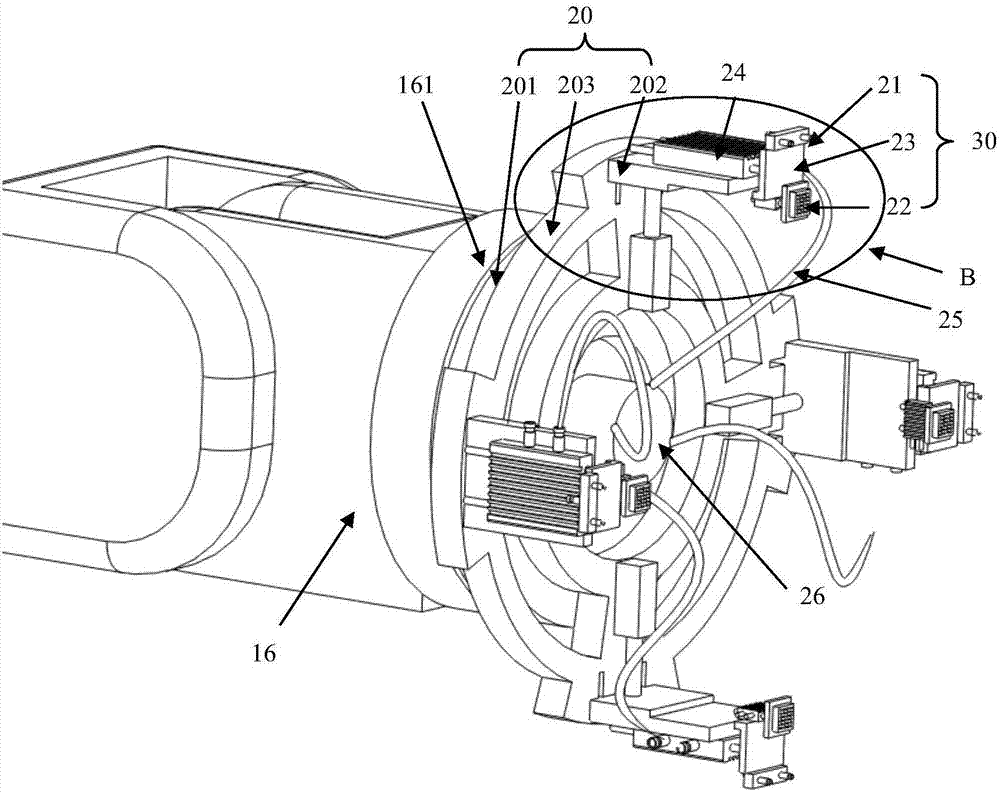

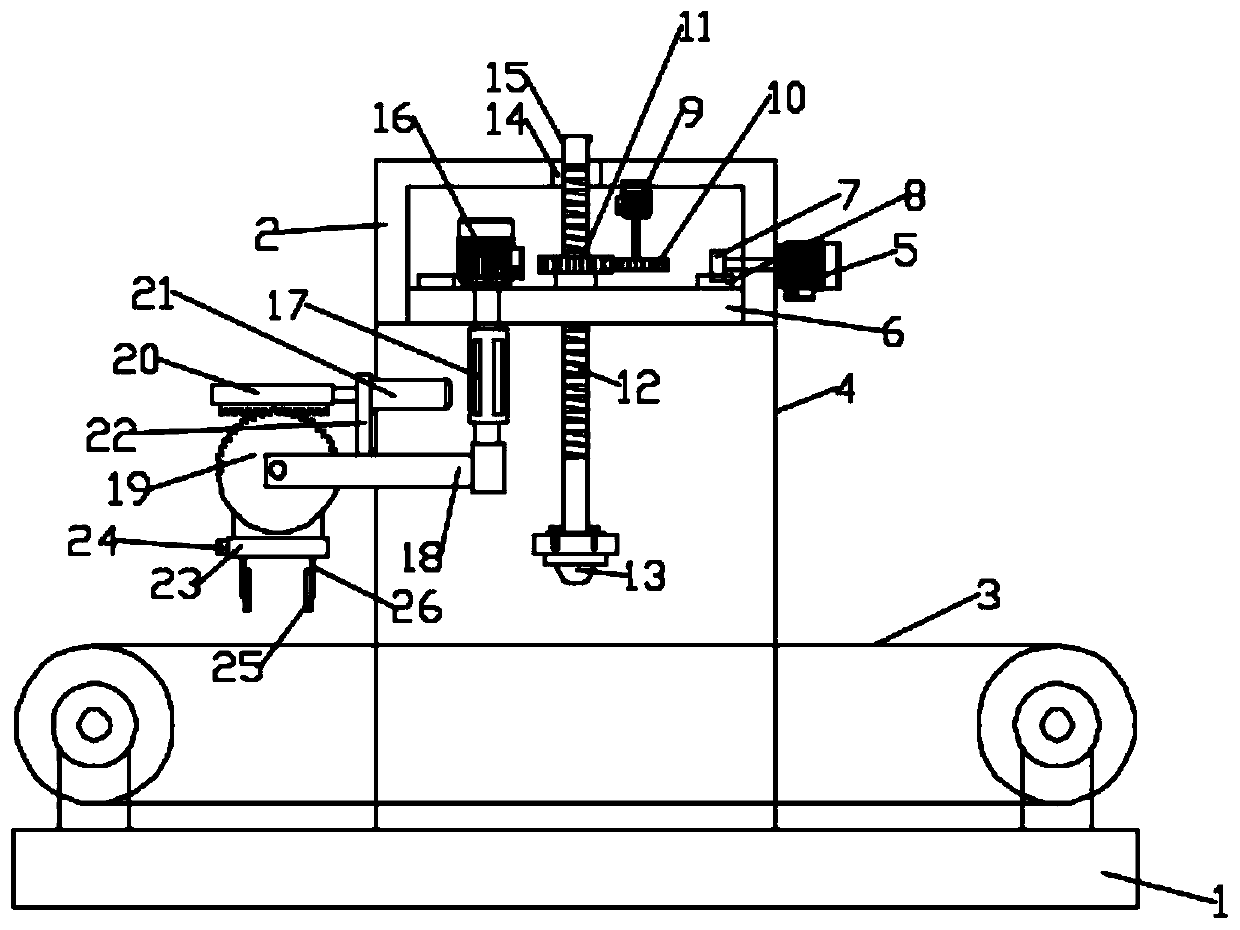

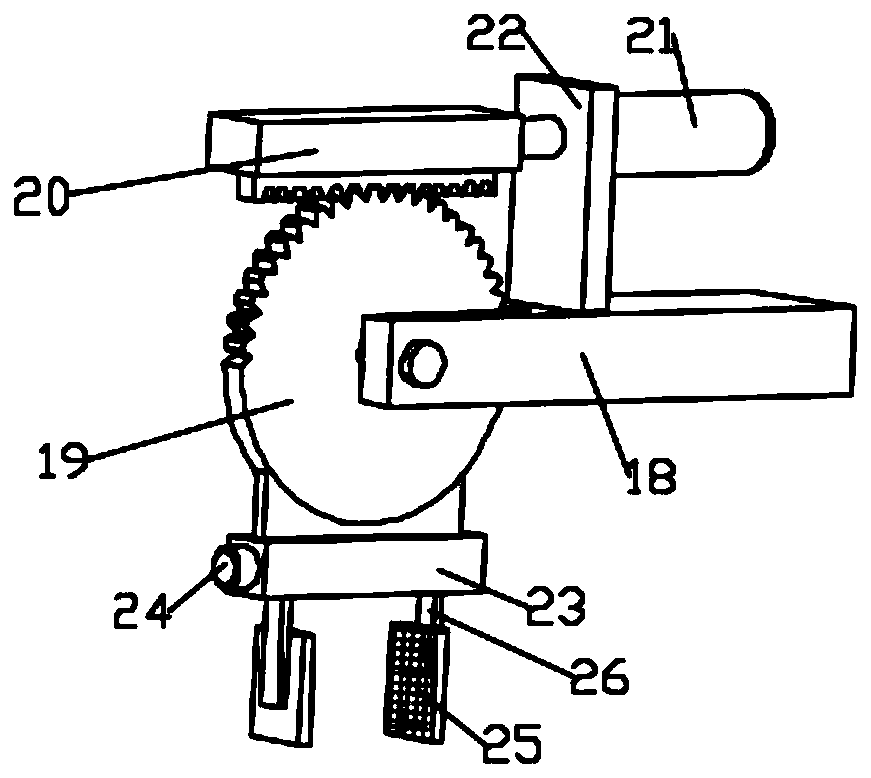

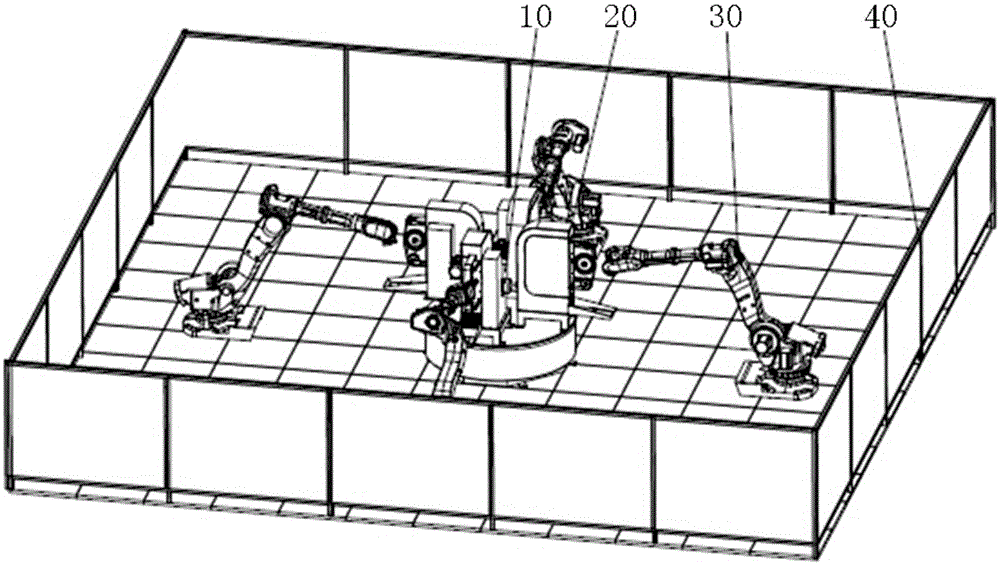

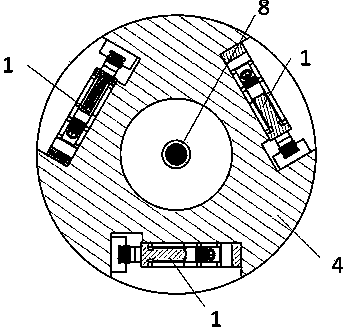

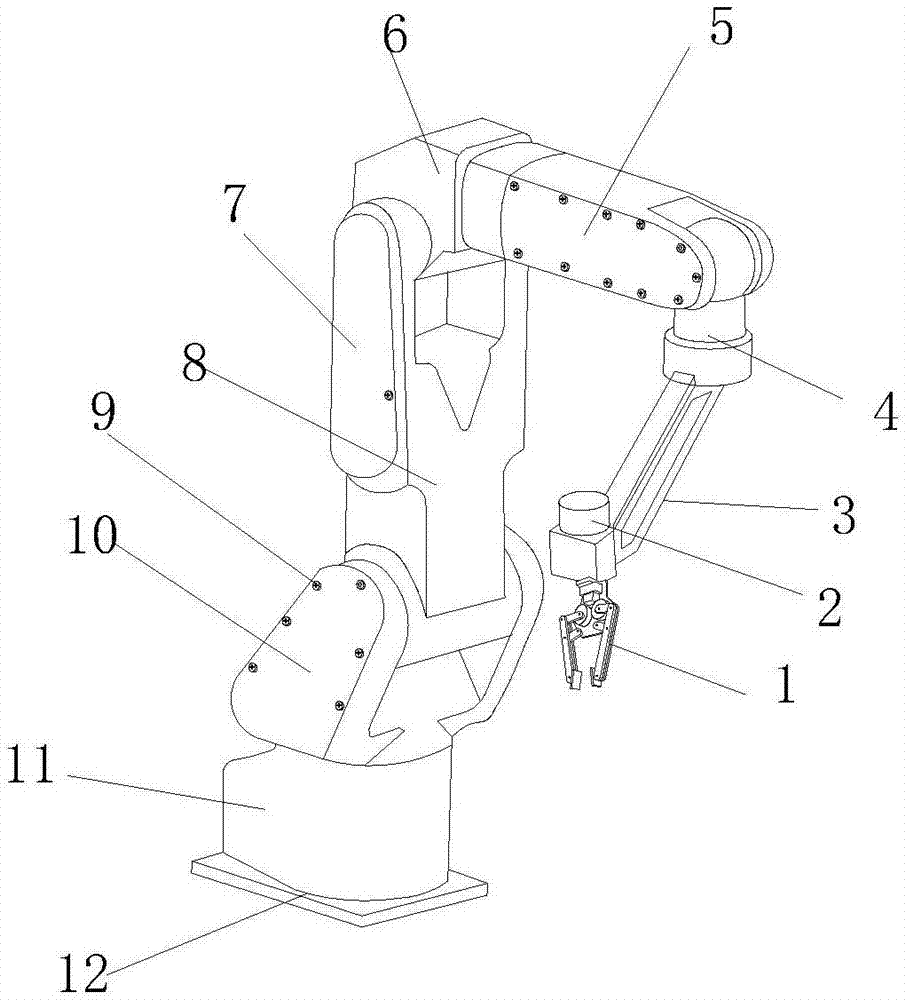

Polishing and grinding device with six-freedom-degree mechanical arms

InactiveCN105033822AAchieve polishingFlexible grabbingBelt grinding machinesGrinding feedersCircular discControl system

The invention provides a polishing and grinding device with six-freedom-degree mechanical arms. The polishing and grinding device comprises a control system, an index plate grinding workstation and the six-freedom-degree mechanical arms, wherein the index plate grinding workstation and the six-freedom-degree mechanical arms are connected with the control system. The index plate grinding workstation comprises an index plate mechanism, a plurality of belt sanding mechanisms evenly distributed on the index plate mechanism and an electric ring arranged in the center of the index circular disc grinding workstation. The six-freedom-degree mechanical arms are arranged on the periphery of the index circular disc grinding workstation and correspond to the belt sanding mechanisms. According to the six-freedom-degree mechanical arm polishing and grinding device, the number of the belt sanding mechanisms can be increased and decreased at will according to the process requirements, and polishing and grinding in a circular disc assembly line are achieved; in this way, the working efficiency is improved, the labor intensity of workers is lowered, and the cost is saved; and the belt sanding mechanisms are arranged on circular plates, and the effect of saving the space is achieved.

Owner:广东遂芯源精密智能制造有限公司

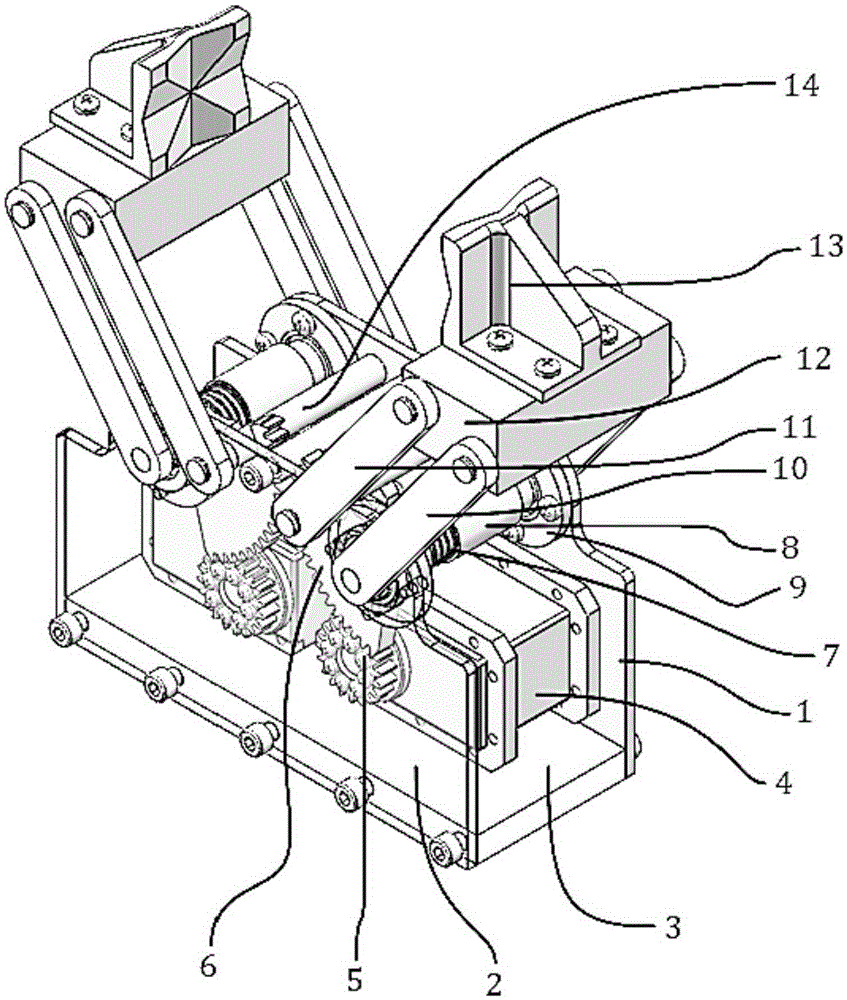

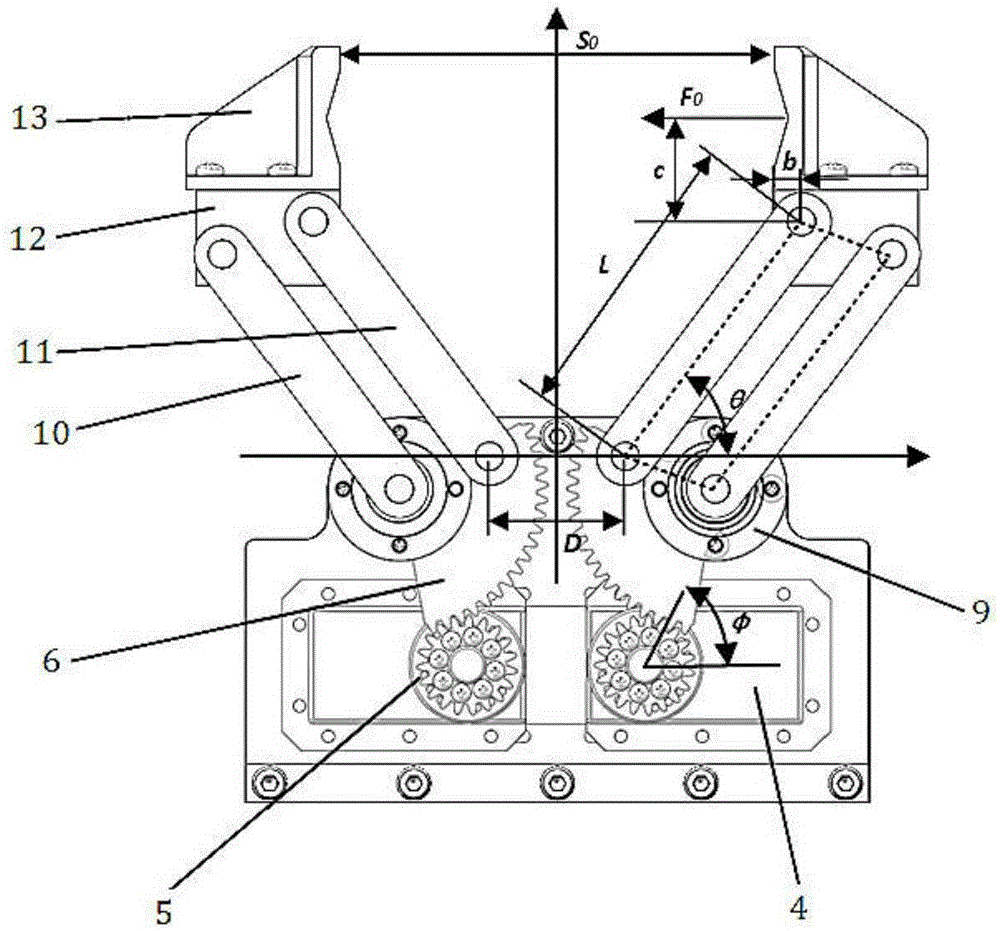

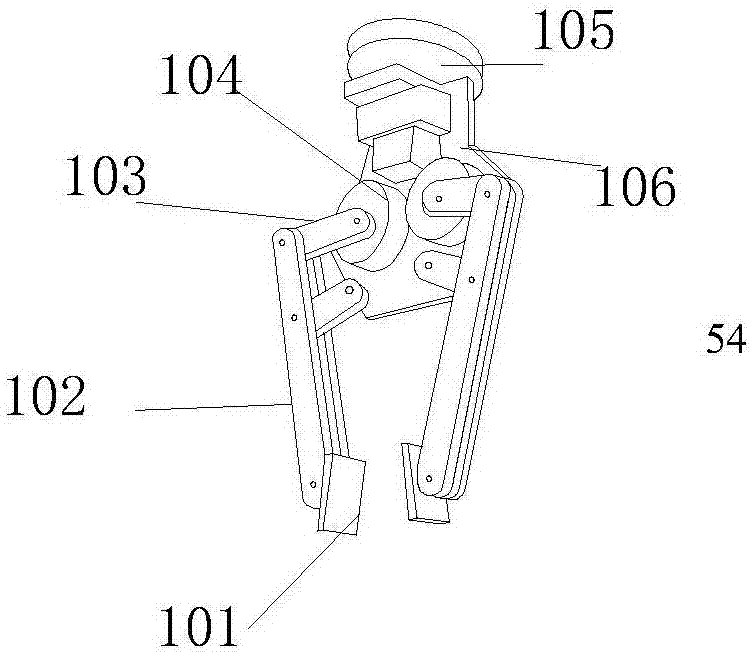

Clamping force and clamping speed online controllable robot gripper

InactiveCN105415361ARealize online controllableFlexible grabbingProgramme-controlled manipulatorTorsion springBilateral symmetry

A clamping force and clamping speed online controllable robot gripper comprises steering engines, fingers, a bottom plate, a main substrate, an auxiliary substrate, driven connecting rods, a rotating shaft, a gear, sector-shaped gears, a gear shaft, driving connecting rods and a transverse plate. The gears are meshed with the sector-shaped gears, the sector-shaped gears are connected with the gear shaft, and a torsion spring is arranged between the sector-shaped gears and the gear shaft; driving connecting rods are located on the outer side of the main substrate and the outer side of the auxiliary substrate respectively, one ends of the driving connecting rods are connected with the two ends of the gear shaft respectively, and the other ends of the driving connecting rods are connected through the transverse plate; one ends of the driven connecting rods are connected with the two ends of the transverse plate respectively, and the other ends of the driven connecting rods are connected through the rotating shaft; and the steering engines are arranged in a bilateral symmetry manner and are fixedly arranged on the inner side of the main substrate. The steering engines output the rotating angle and the rotating angular speed to the fingers, the clamping force and the clamping speed of the gripper can be controlled in an online manner, and the robot gripper is simple in structure, reasonable in design and stable and flexible in work.

Owner:SHANGHAI JIAO TONG UNIV

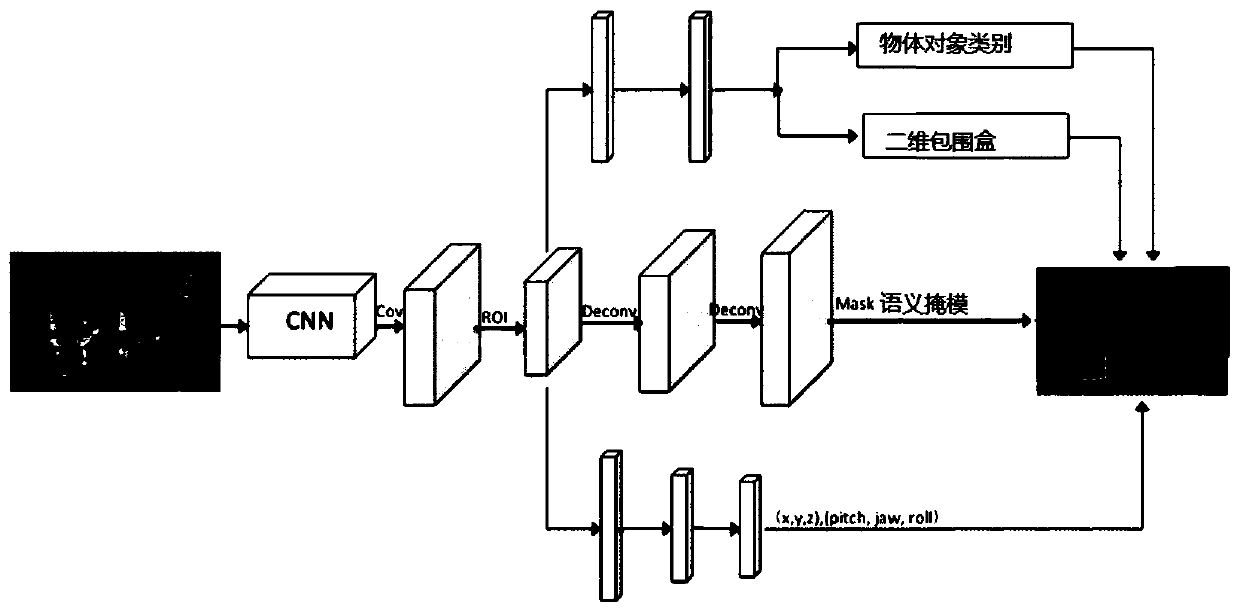

Robot object grabbing system, method and device

PendingCN111383263AFlexible grabbingReduce complexityProgramme-controlled manipulatorImage analysisRobot hardwareObject category recognition

The invention discloses a robot object grabbing system, method and device, a robot and electronic equipment. The robot acquires a current environment image through the image acquisition device, and extracts object grabbing features from the current environment image by using an object grabbing feature extraction sub-network included in the object grabbing information identification model; the category of at least one object in the current environment image is obtained according to the object grabbing features through an object category recognition sub-network of the model; through a pose parameter identification sub-network of the model, pose parameters of at least one object in the current environment image relative to a camera coordinate system are obtained according to the object grabbing features; the pose parameters under the camera coordinate system are converted into pose parameters under a world coordinate system; and a target object is captured according to the pose parametersunder the world coordinate system and the type of at least one object in the current environment image. By means of the processing mode, the hardware cost of the robot can be effectively reduced, andthe grabbing accuracy and efficiency are improved.

Owner:ALIBABA GRP HLDG LTD

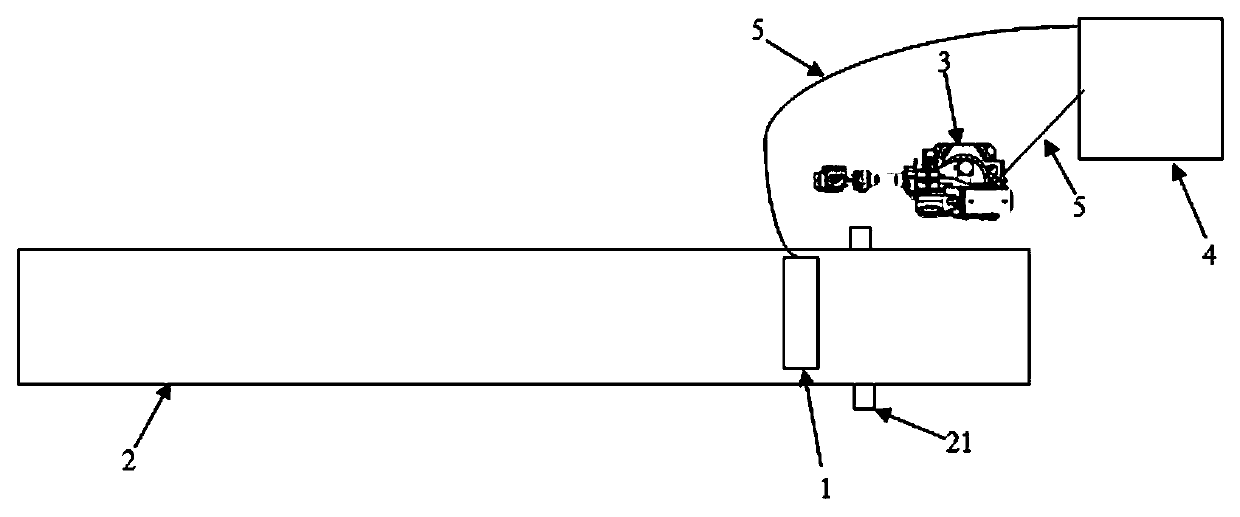

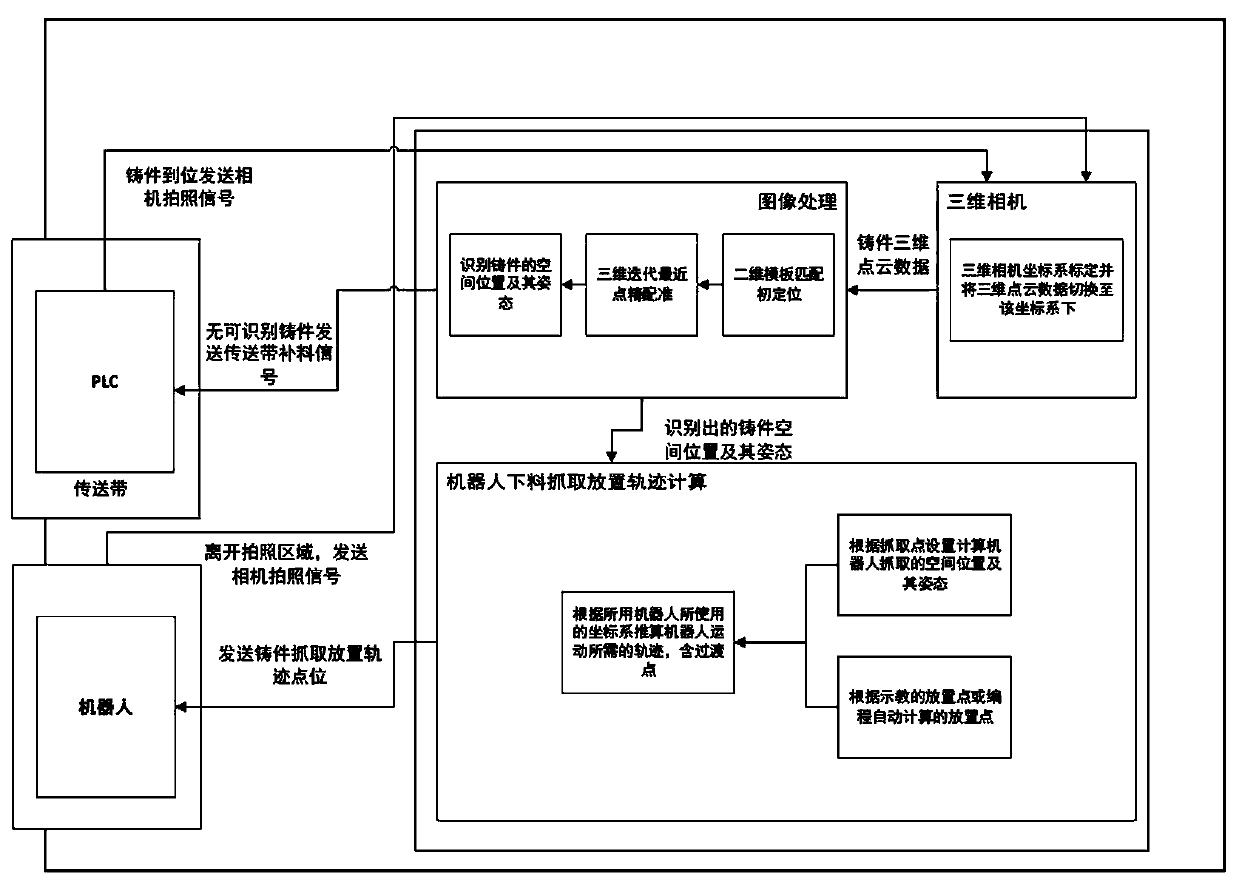

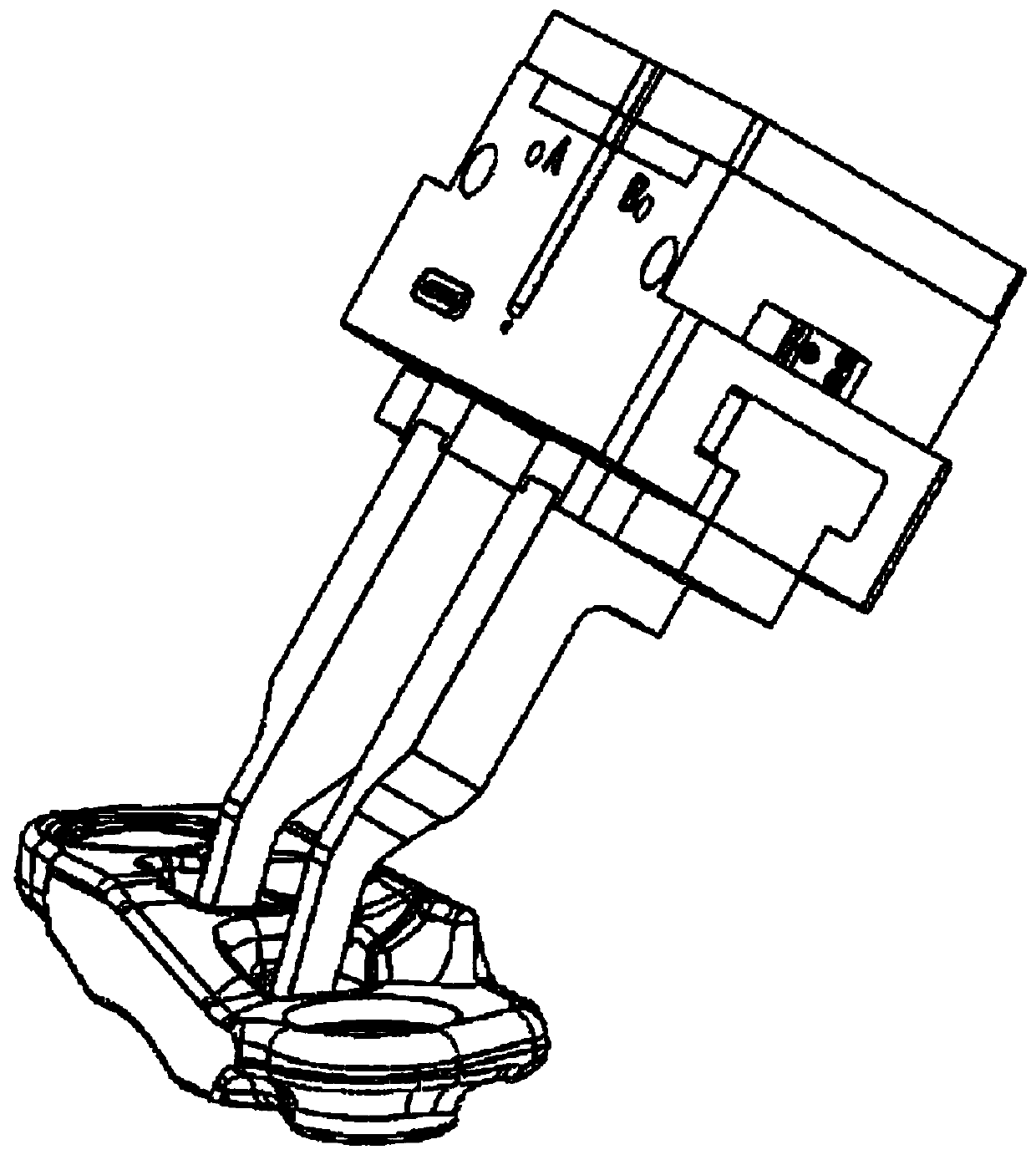

Method for implementing automatic casting discharging through cooperation of three-dimension vision and robot

ActiveCN110980276AFlexible grabbingOptimize layoutImage enhancementImage analysisImaging processingPoint cloud

The invention discloses a method for implementing automatic casting discharging through cooperation of three-dimension vision and a robot. A three-dimension camera is adopted for shooting castings ona conveying mechanism, and three-dimension point cloud data collection is conducted; the collected data are processed, and recognition of the multiple castings is finished; the space positions of therecognized castings and the robot grabbing motion track are calculated; a robot finishes casting grabbing according to the received grabbing point positions and the posture movements corresponding tothe grabbing point positions; when the robot leaves the shooting area, the three-dimension camera conducts shooting for data collection, and new point cloud data are calculated when the robot conductssubsequent work; and after grabbing is finished, the robot can place the grabbed castings to the assigned positions according to the previously-demonstrated placing points or the automatically-calculated placing points. According to the method, full-automatic casting discharging track measurement and control are achieved, the three-dimension image technology is used, and the problems including casting incoming material stacking, large-angle inclination and other problems which cannot be solved through traditional two-dimension image processing can be solved.

Owner:EUCLID LABS NANJING CORP LTD

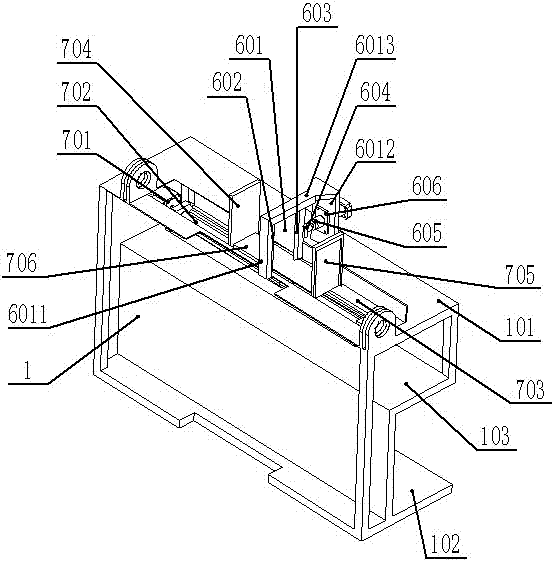

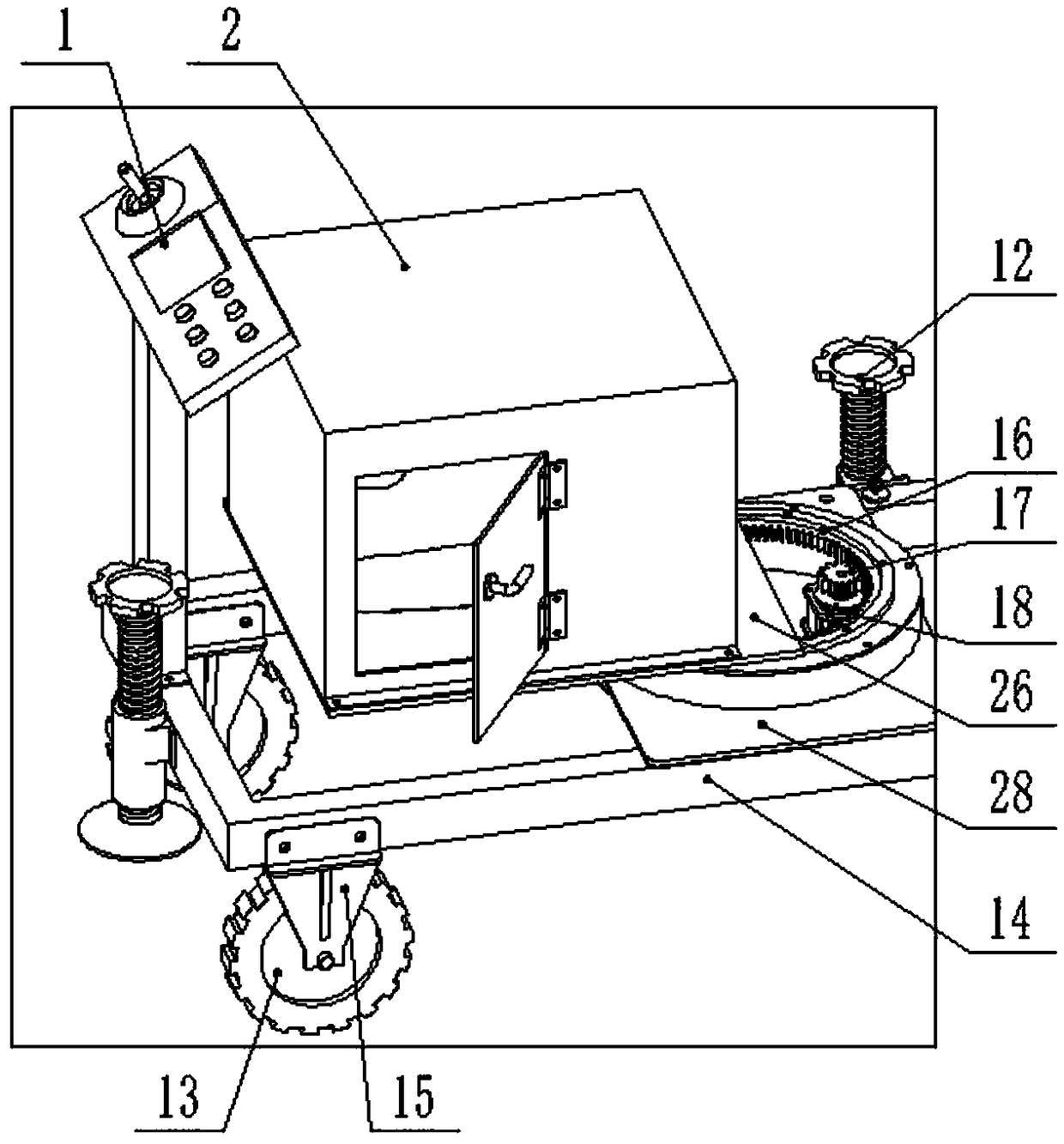

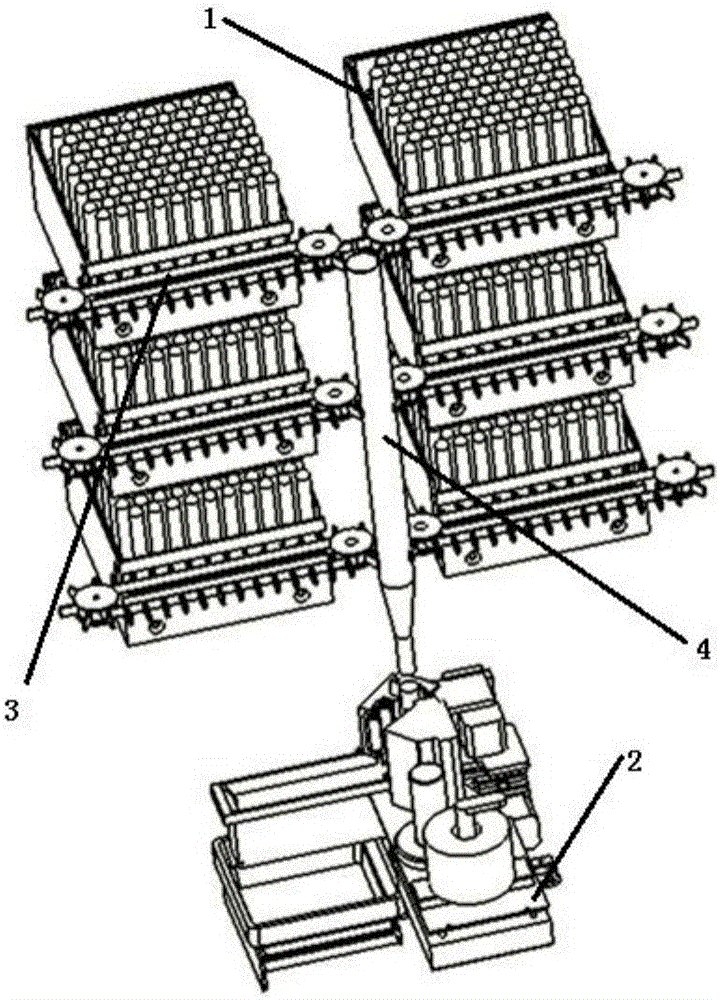

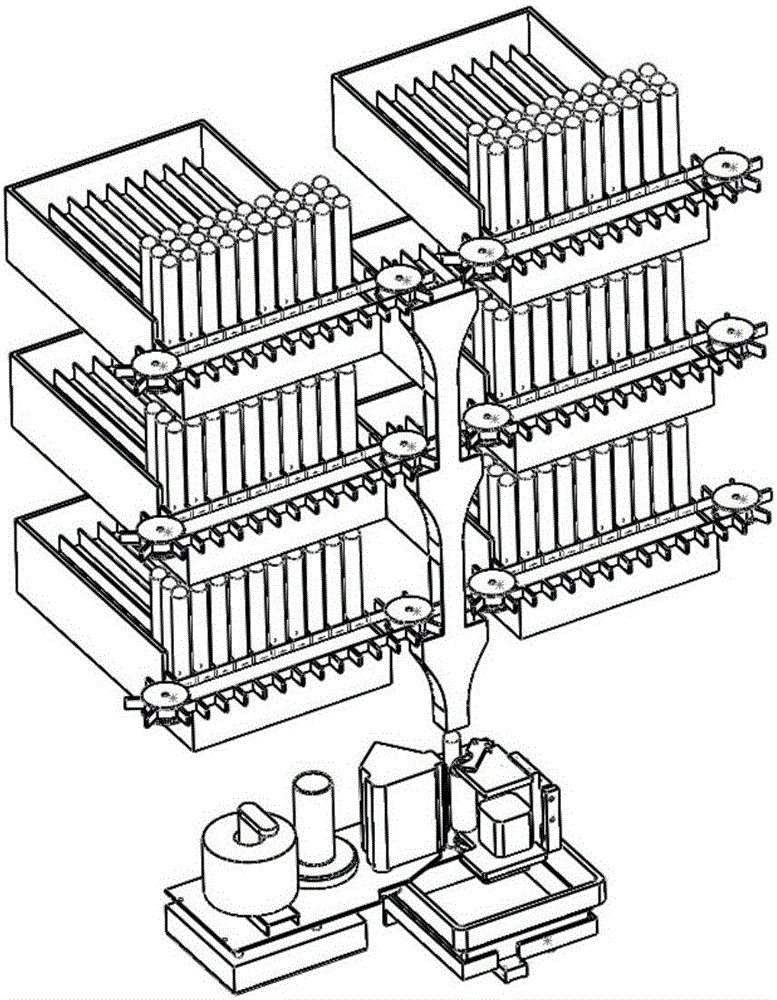

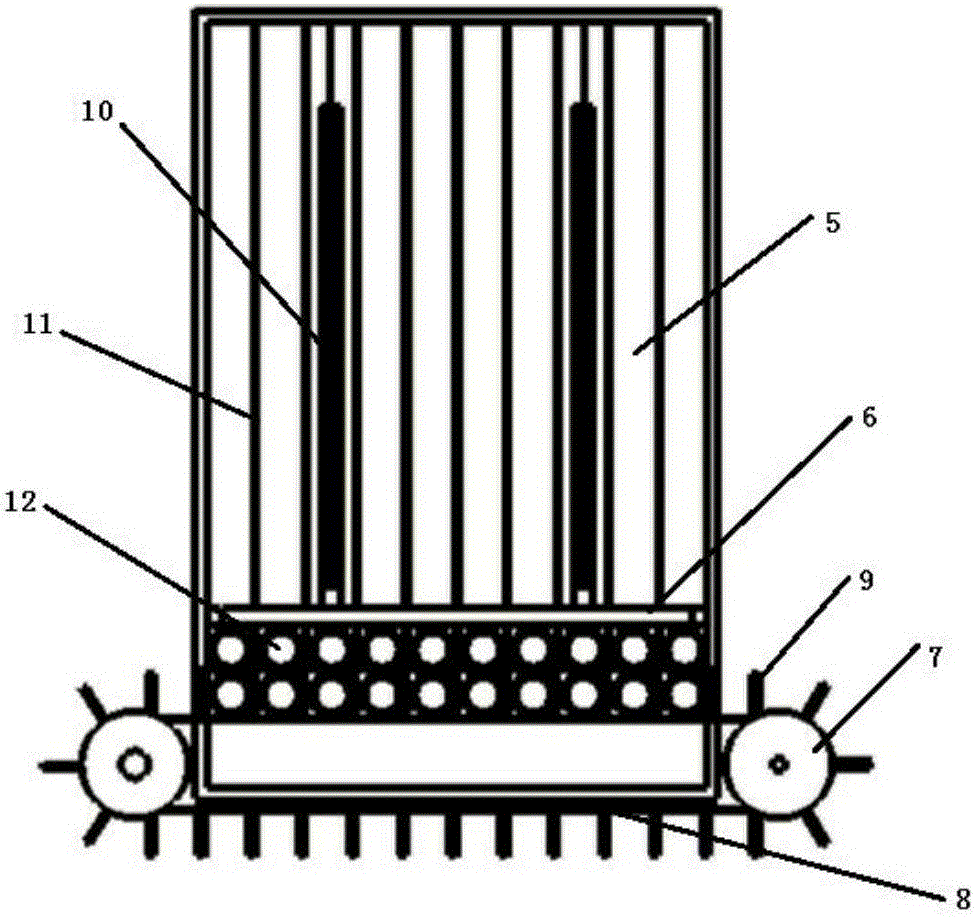

Self-propelling slip type medical blood sampling tube preparation machine

ActiveCN105836451ASimple structureFlexible grabbingConveyorsDiagnostic recording/measuringUnit/actuationBiomedical engineering

The invention relates to a self-propelling slip type medical blood sampling tube preparation machine. The self-propelling slip type medical blood sampling tube preparation machine comprises self-propelling type rapid installing boxes used for containing medical blood sampling tubes, and mechanical belt type pushing mechanisms matched with the self-propelling type rapid installing boxes and used for pushing the medical blood sampling tubes into an identification printer. Each self-propelling type rapid installing box comprises a medical blood sampling tube storage area and a pushing device, wherein the pushing device can push the medical blood sampling tubes placed in the medical blood sampling tube storage area to move forwards. Each mechanical belt type pushing mechanism comprises a drive unit, a belt wheel and a tooth type tube pushing belt. The pushing devices push the medical blood sampling tubes into the part between pushing teeth of the tooth type tube pushing belts. When the drive units drive the belt wheels to rotate, the tooth type tube pushing belts push the medical blood sampling tubes into a slip channel one by one and then the medical blood sampling tubes slip into the identification printer to be printed. Due to the fact that the self-propelling type rapid installing boxes are matched with the mechanical belt type pushing mechanisms, the self-propelling slip type medical blood sampling tube preparation machine is simple in structure, flexible in grabbing and higher in efficiency.

Owner:KINGCON INTELLIGENT TECH CO LTD

Small-bag-grabbing packing machine

The invention discloses a small-bag-grabbing packing machine. The small-bag-grabbing packing machine comprises a machine frame component, a carton billet transporting mechanism, a carton billet sucking taking and molding mechanism, a carton transporting and positioning mechanism, a material belt conveyor, a material arraying belt conveyor, a first robot and a second robot connected to the machineframe component, the material arraying belt conveyor is arranged on one side of the material belt conveyor, the first robot is arranged above the material arraying belt conveyor and the material beltconveyor, the carton transporting and positioning mechanism is arranged on one side of the material arraying belt conveyor, the second robot is arranged above the carton transporting and positioning mechanism and the material arraying belt conveyor, the input end of the carton transporting and positioning mechanism is docked with the output end of the carton billet sucking taking and molding mechanism, and the input end of the carton billet sucking taking and molding mechanism is docked with the carton billet transporting mechanism. The small-bag-grabbing packing machine is simple in structure, reliable in performance and simple and convenient to operate, the fact that the material produced and transported by a front end production line is arrayed is achieved, and the full-automatic packing operation is completed.

Owner:WUHAN RENTIAN PACKAGING TECH

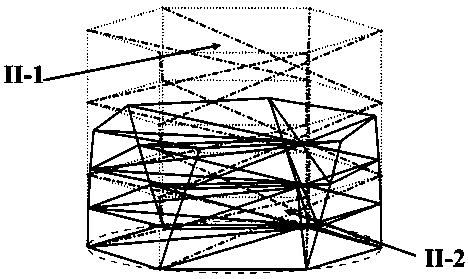

Multi-degree-of-freedom continuous robot with flexible target grabbing function

ActiveCN111300385AImprove flexibilityEasy and flexible gripProgramme-controlled manipulatorArmsComputer visionRobot locomotion

The invention discloses a multi-degree-of-freedom continuous robot with a flexible target grabbing function, belongs to the technical field of robots, and relates to a multi-degree-of-freedom continuous robot capable of flexibly grabbing small-size objects and curling and winding large-size objects. The multi-degree-of-freedom continuous robot comprises a driving device module, an imitation trunkmodule and a dexterous finger module, and the imitation trunk module is composed of a rotary compression module and a bending compression module; uniform connecting interfaces are reserved at the endsof the modules, and the modules are combined and spliced according to actual requirements; the driving module is arranged on a base of the robot to achieve driving work of all the ropes and control the robot to move; the rotary compression module can simultaneously generate rotation and compression motion, so that the dead angle defect of the bending compression module is overcome; the bending compression module can independently realize compression deformation and bending deformation of the module; and the dexterous finger module achieves the grabbing function through multi-finger cooperation. The robot is simple in structure and flexible to use, and the robot structure has the characteristic of light weight.

Owner:DALIAN UNIV OF TECH

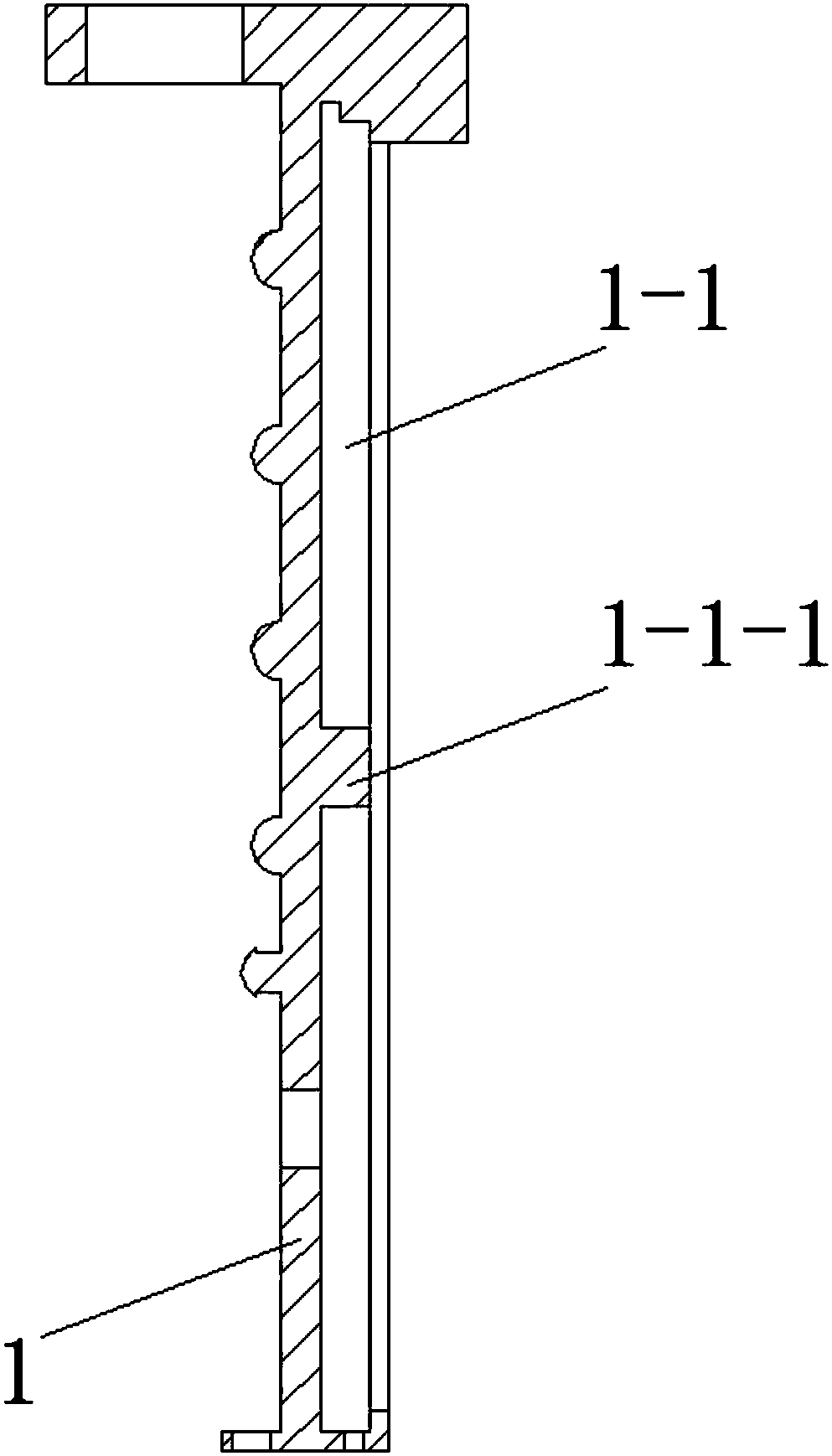

Conveying mechanical hand with controlled rotary arm

The invention discloses a conveying mechanical hand with a controlled rotary arm. The conveying mechanical hand comprises an upright post (1), wherein the upright post (1) is perpendicularly welded to a transverse fixed hollow sleeve (2); a transverse extension arm (3) is inserted into the transverse fixed hollow sleeve (2); a tail end of the transverse extension arm (3) is fixedly connected with a plugging circular ring (4); the plugging circular ring (4) is connected with two crossed fixed plates (5); the fixed plates (5) are connected with a circular inserting sleeve (6); the circular inserting sleeve (6) is connected with an end part of a starting rod (7) and is fixed to the end part of the starting rod by a screw; the starting rod (7) is connected with an air pump (8); the air pump (8) is fixed to an arc support plate (9); the arc support plate (9) is connected with a fixed connecting plate (10); the fixed connecting plate (10) is adhered to the top of the upright post (1) and is fixed to the top of the upright post by a screw; and the air pump (8) is connected with a power source. The conveying mechanical hand disclosed by the invention is provided.

Owner:芜湖挺优机电技术有限公司

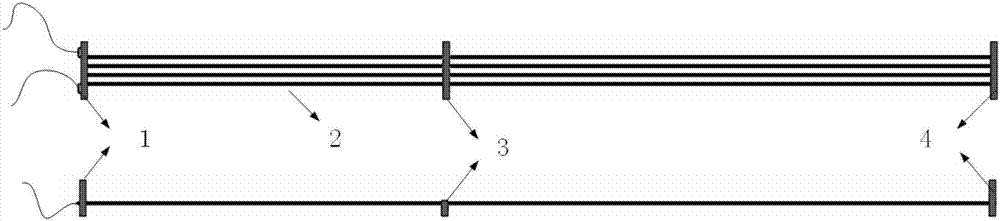

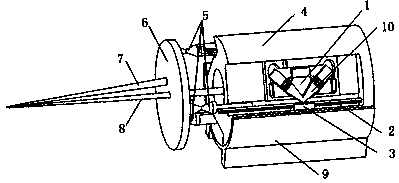

Linear supersonic motor-based two-finger parallel connection micro operation hand and operation method

InactiveCN103950027AQuick responseFlexible grabbingProgramme-controlled manipulatorMicromanipulatorLong fingersMicro-operation

The invention discloses a linear supersonic motor-based three-freedom degree two-finger parallel connection micro operation hand method and belongs to the field of biomedical engineering. An operation hand comprises an arm, linear supersonic motors, flexible joints, a disc, a long finger, a short finger and a base, wherein the arm is fixed on the base, the three linear supersonic motors are all formed by stators and sliders which are fixed on the arm as well as linear guide rails positioned between driving feet of the stators and the sliders; the three linear supersonic motors are uniformly distributed around the middle axis of the arm and are differenced by 120 degrees two by two. The disc is arranged at the tail ends of the guide rails of the linear supersonic motors by the flexible joints; the long finger is fixed on the arm, and the fingertip of the long finger penetrates through a central hole in the disc; the finger root of the short finger is fixed on the disc. The operation hand is compact in structure and simple in control method, and has larger operation range and higher location precision.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

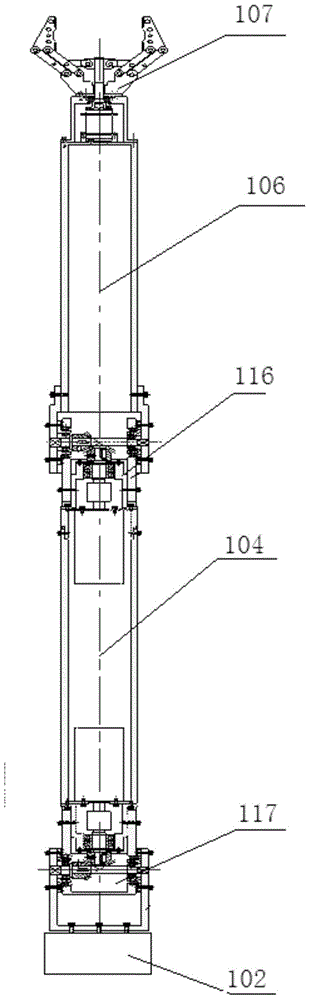

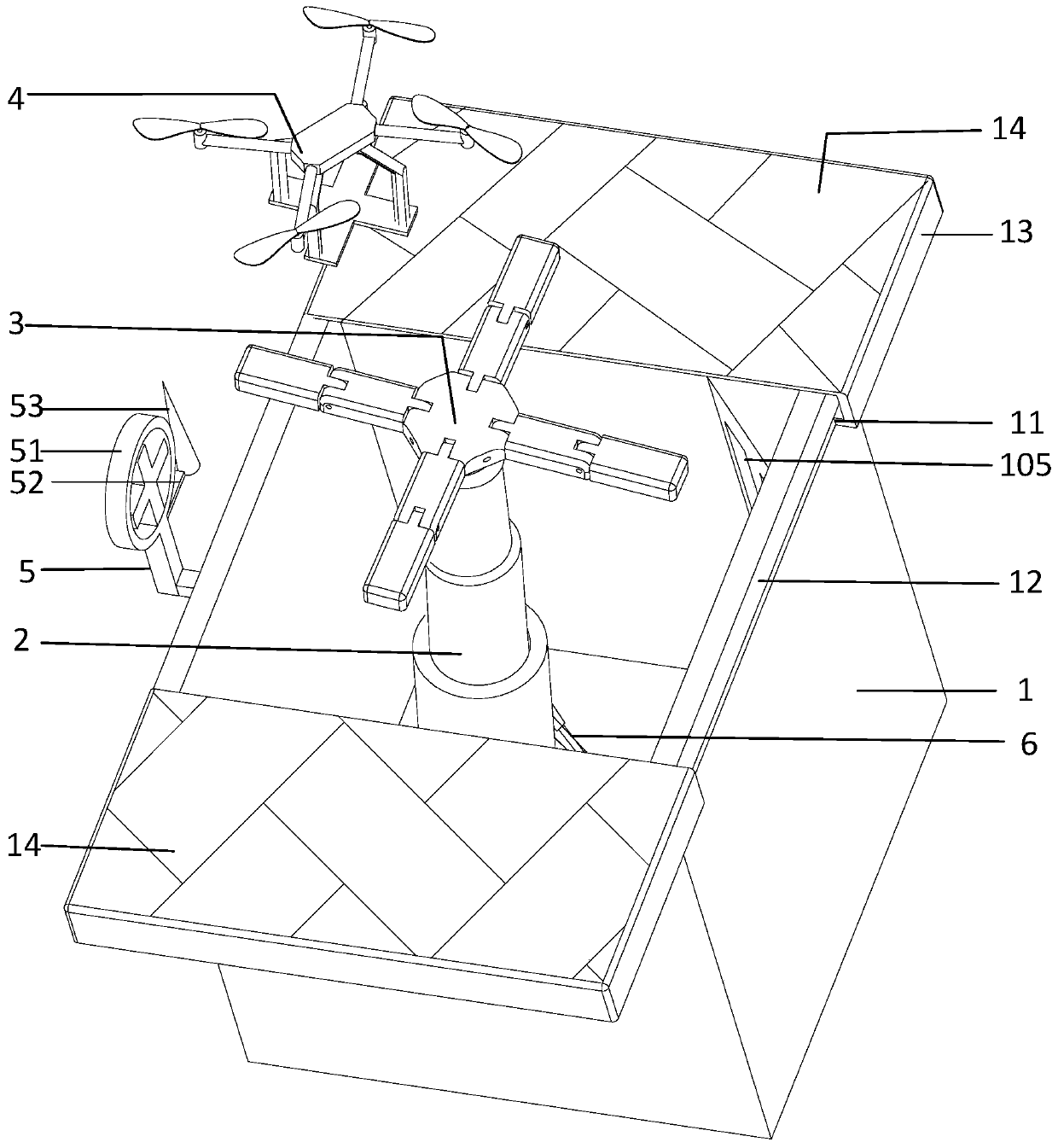

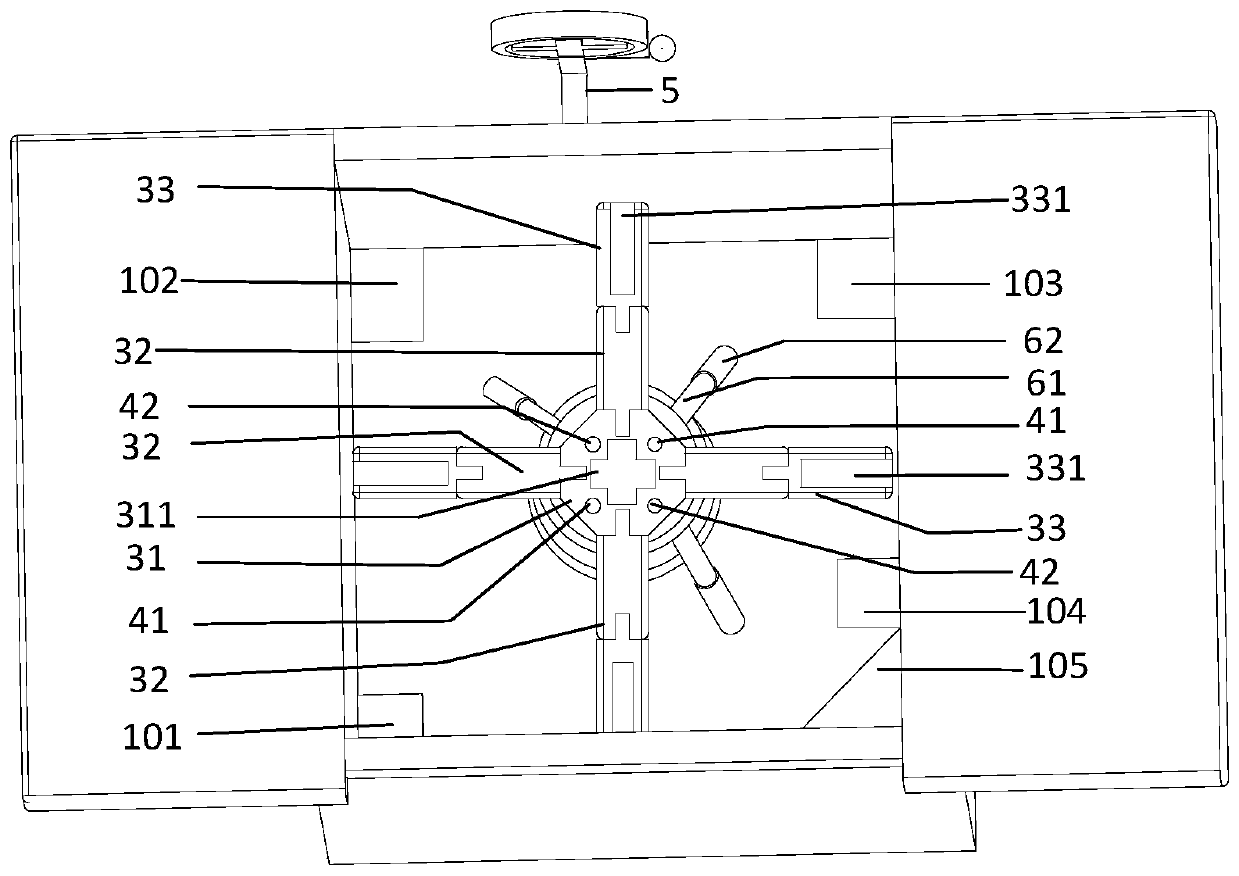

Heavy-load industrial-grade multi-rotor unmanned aerial vehicle hangar

ActiveCN110589007AImprove carrying capacityFree stretchArresting gearVehicular energy storageUncrewed vehicleManipulator

The invention relates to an unmanned aerial vehicle, and provides a heavy-load industrial-grade multi-rotor unmanned aerial vehicle hangar. The hangar comprises a hangar body with an opening, a multifunctional manipulator capable of freely moving, and a mechanical arm of a heavy-load unmanned aerial vehicle, and the hangar further comprises a motion booster used for free movement of the mechanicalarm. The heavy-load industrial-grade multi-rotor unmanned aerial vehicle hangar with the structure can overcome the defects of inaccurate full autonomous recovery and inaccurate landing positioning of the heavy-load industrial-grade unmanned aerial vehicle at the present stage, and meanwhile, the quick charging of the unmanned aerial vehicle and the protection of the unmanned aerial vehicle are facilitated.

Owner:SHENYANG AEROSPACE UNIVERSITY

Stamping mould mechanical arm

InactiveCN107378916AFlexible grabbingNot easy to dropProgramme-controlled manipulatorEngineeringManipulator

The invention discloses a stamping die manipulator, the structure of which comprises a flexible grasping device, a connecting head, a support rod, a wrist, a forearm, an elbow, a fixed plate, a large arm, a fixed bolt, a shoulder, a base, and a bottom plate; The grabbing device consists of a non-slip grabbing plate, fingers, a transmission rod, a turntable, a rotating shaft, and a fixed palm. The non-slip grabbing plate is installed on the inner side of the finger, and the finger is connected to the rotating shaft through the driving rod. The bottom of the rotating shaft is vertically connected to the front side of the fixed palm. The top of the fixed palm is movably connected to the bottom of the rotating shaft, and the top of the rotating shaft is fixed to the bottom of the connecting head. The manipulator of the stamping die of the present invention adds a flexible grasping device, which is flexible enough when grasping, and can also be rotated to pick up parts, which is not easy to drop and tight. Solidity is better.

Owner:广州市鹭江远科技有限公司

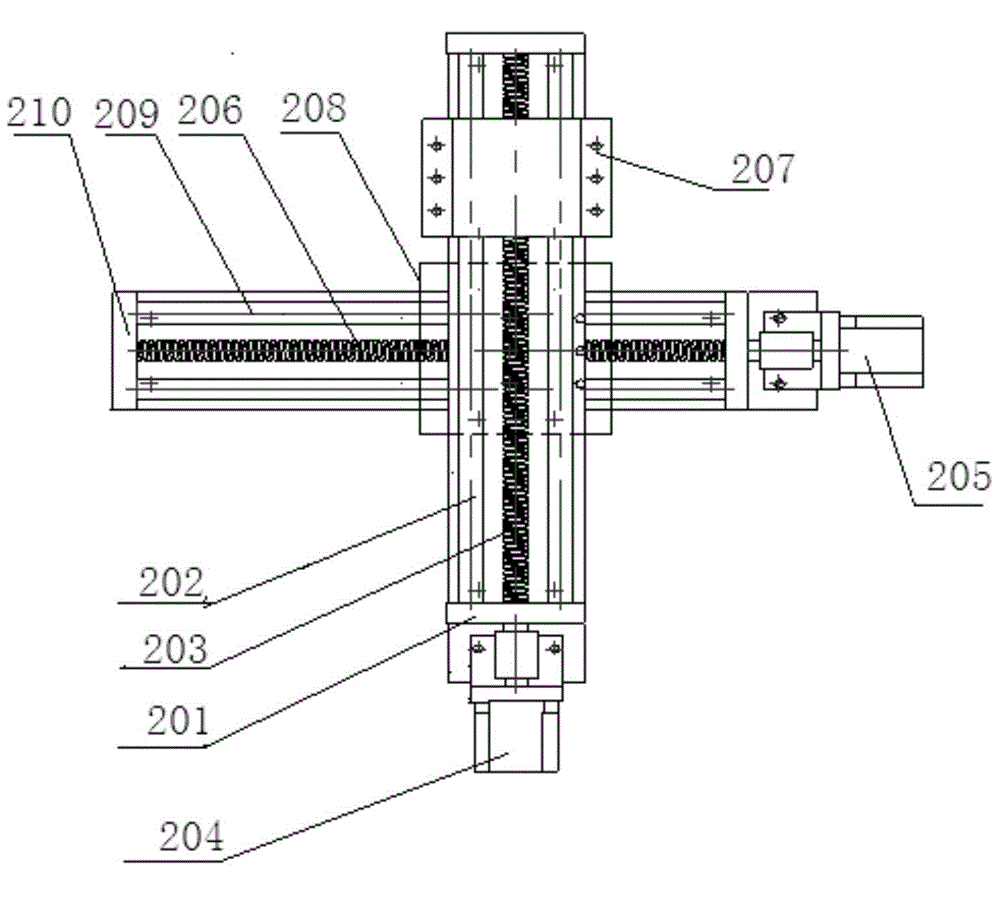

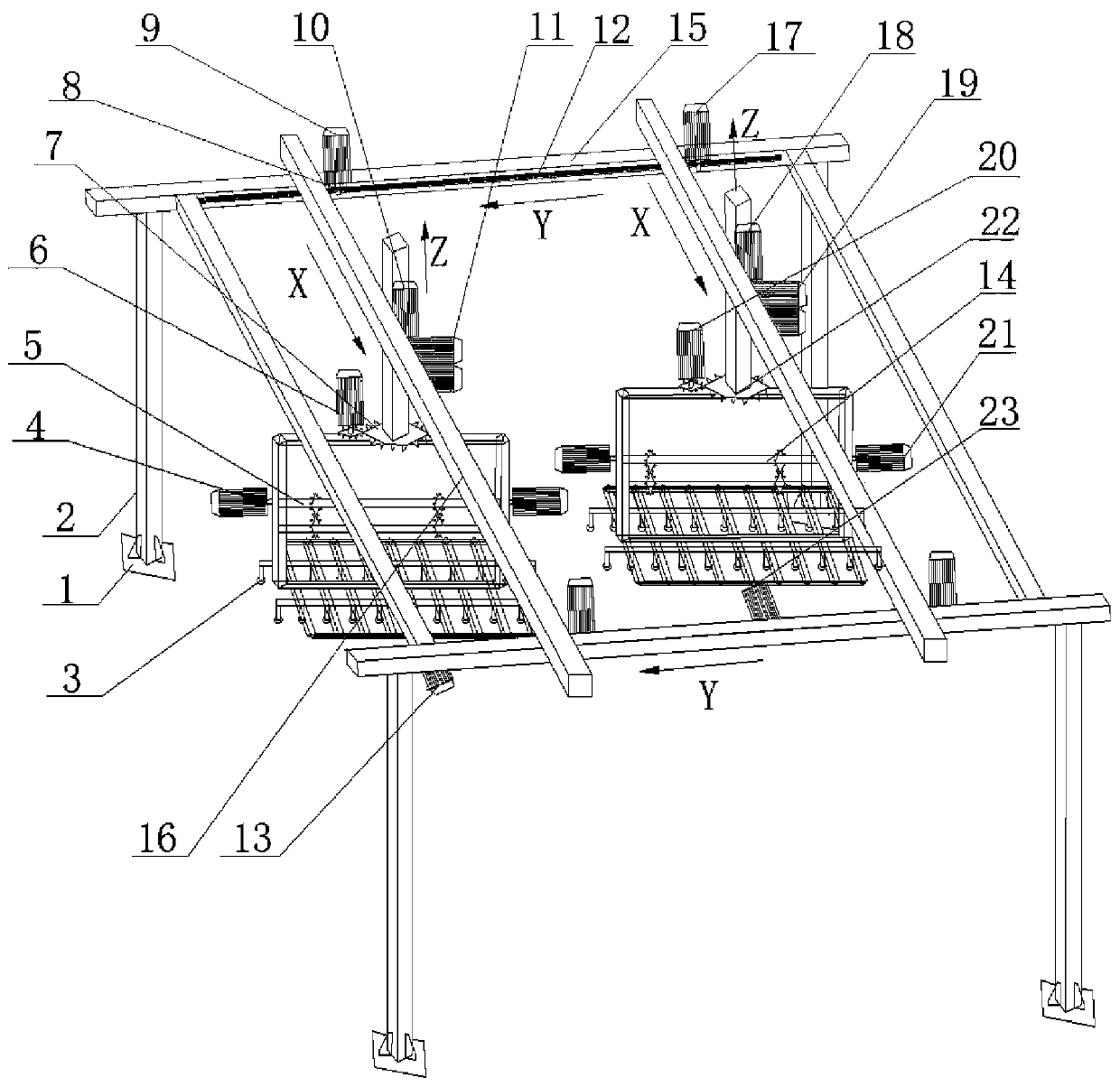

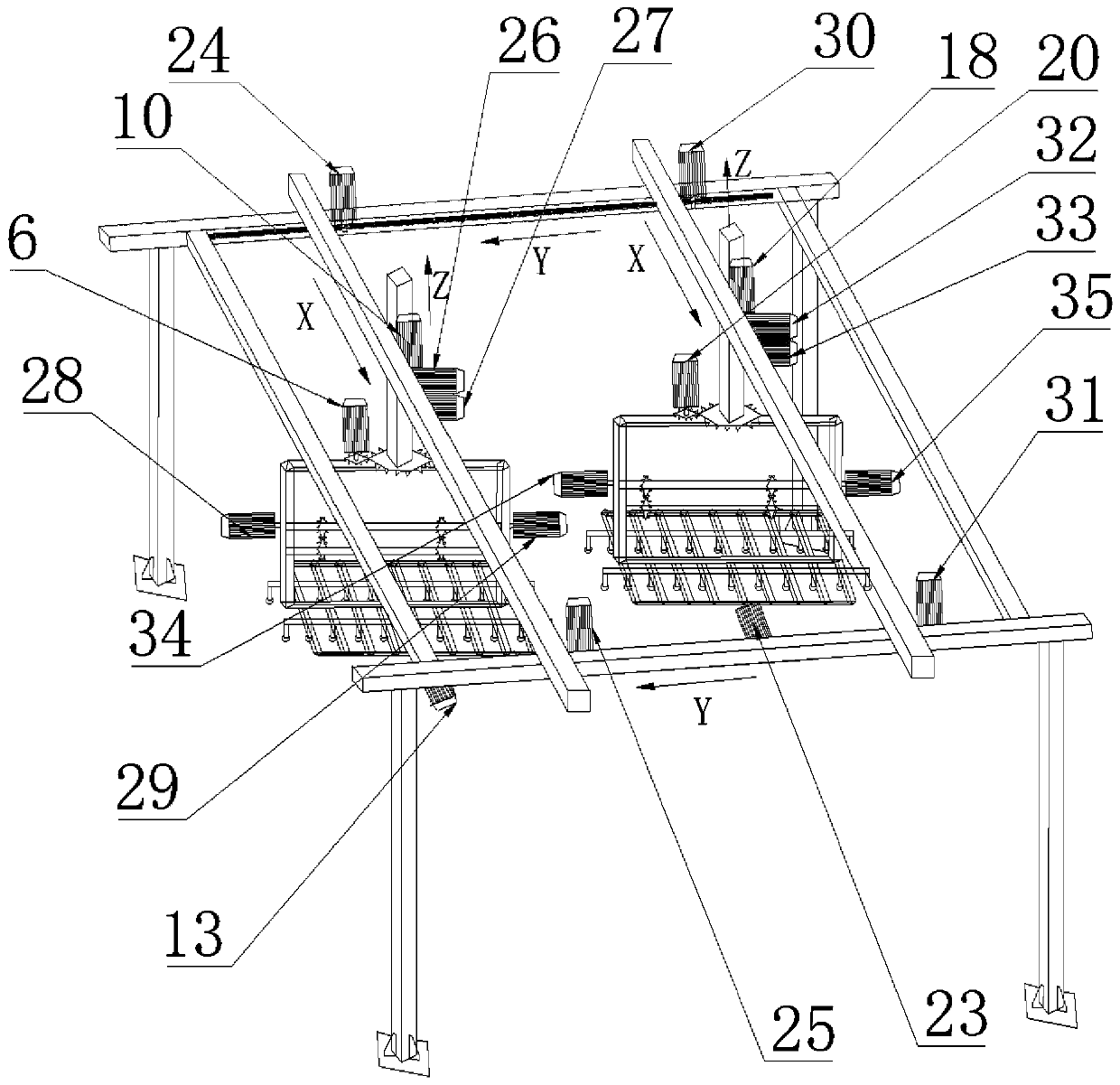

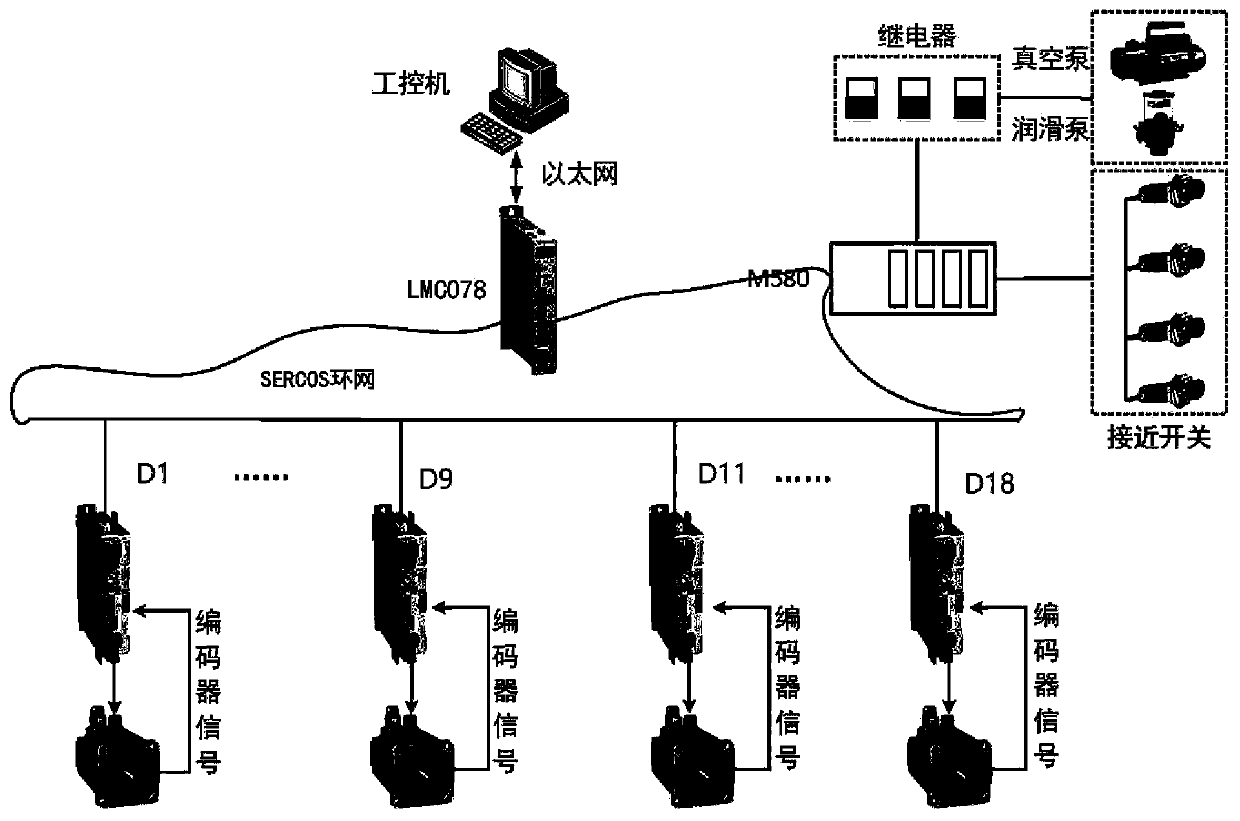

Electronic cam-based CAM variable assignment method and truss double manipulator

PendingCN110815232ALess programming effortMeet the production needs of rapid adjustment processProgramme-controlled manipulatorGripping headsControl systemControl engineering

The invention relates to an electronic cam-based CAM variable assignment method and a truss double manipulator and aims at solving the problems that a traditional cam mechanism is easy to wear, poor in flexibility and single in trajectory, needs to receive an electronic cam curve provided by a control system by connecting in parallel with a servo and the like. According to the technical scheme atpresent, aiming to avoid the situation that generation of a cam curve is not flexible, and secondary development is relatively difficult in the later stage, the invention creates and designs a CAM assignment method, through assignment on key process points on the electronic cam, interpolation is performed between every two process points through a quintic polynomial algorithm, the electronic cam curve can be flexibly generated online, and the process requirements are met; and meanwhile, a soft platform and a hardware platform of the electronic cam control system are built, experiments verify that an output motion track of the manipulator is more flexible, and the electronic cam-based CAM variable assignment method and the truss double manipulator are formed.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Brick moving clamp and intelligent brick stacking robot based on visual identification

PendingCN113460716AHigh adjustment accuracyAvoid boring workStacking articlesDe-stacking articlesVision basedEngineering

A brick moving clamp comprises a clamping mechanism, the clamping mechanism comprises a guide rail, a fixed clamping piece and a clamping assembly, the clamping assembly comprises a telescopic piece, a first clamping piece, a second clamping piece and an ejector rod, the fixed clamping piece is fixedly connected with the guide rail, the first clamping piece and the second clamping piece are slidably connected with the guide rail, and the first clamping piece, the second clamping piece and the fixed clamping piece are arranged in parallel; and the second clamping piece is located between the first clamping piece and the fixed clamping piece, the telescopic piece is connected with the first clamping piece and the fixed clamping piece, so that the telescopic piece stretches out and draws back to drive the first clamping piece to be away from or close to the fixed clamping piece, the ejector rod is located between the first clamping piece and the second clamping piece and fixedly connected with the first clamping piece, and one end of the ejector rod faces the second clamping piece. The intelligent brick stacking robot based on visual identification adopts the brick moving clamp and comprises a base, a five-axis manipulator, a visual identification system and a control system. According to the brick moving clamp, the target area needing to be clamped can be accurately recognized and positioned, intelligent clamping is achieved, and the brick moving clamp belongs to the field of automatic stacking.

Owner:FOSHAN UNIVERSITY

Pneumatic finger with replaceable contact

InactiveCN108189064AIncreased grasping rangeIngenious structureGripping headsEngineeringMechanical engineering

The invention discloses a pneumatic finger with a replaceable contact. The pneumatic finger comprises a base framework, a supporting elastic sheet, an outer side driving assembly and the detachable contact, the supporting elastic sheet is arranged in the base framework, the outer side driving assembly comprises a base sheet and further comprises a finger root driving cavity, a finger middle driving cavity and a finger tip driving cavity which are sequentially arranged from top to bottom, the base sheet is detachably fixed to one side of the base framework, and the finger root driving cavity, the finger middle driving cavity and the finger tip driving cavity are each provided with an air pipe communicating to respective cavities; and the finger root driving cavity, the finger middle drivingcavity and the finger tip driving cavity generate deformation after inflation of gas to drive upper, middle and lower parts of the base framework to bend to the other side. The pneumatic finger is ingenious in structure, the outer side driving assembly adopts three-section type independent ventilation drive, the base framework grabbing motion range is increased, motion is more flexible, local motion of a finger tip and a finger middle can be achieved, the motion efficiency is improved, and energy consumption is reduced.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com