Patents

Literature

96results about How to "Less programming effort" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mobile robot automatic spraying device and mobile robot automatic spraying control system and method

PendingCN107908152AImprove adaptabilityLess programming effortNumerical controlSimulationVisual perception

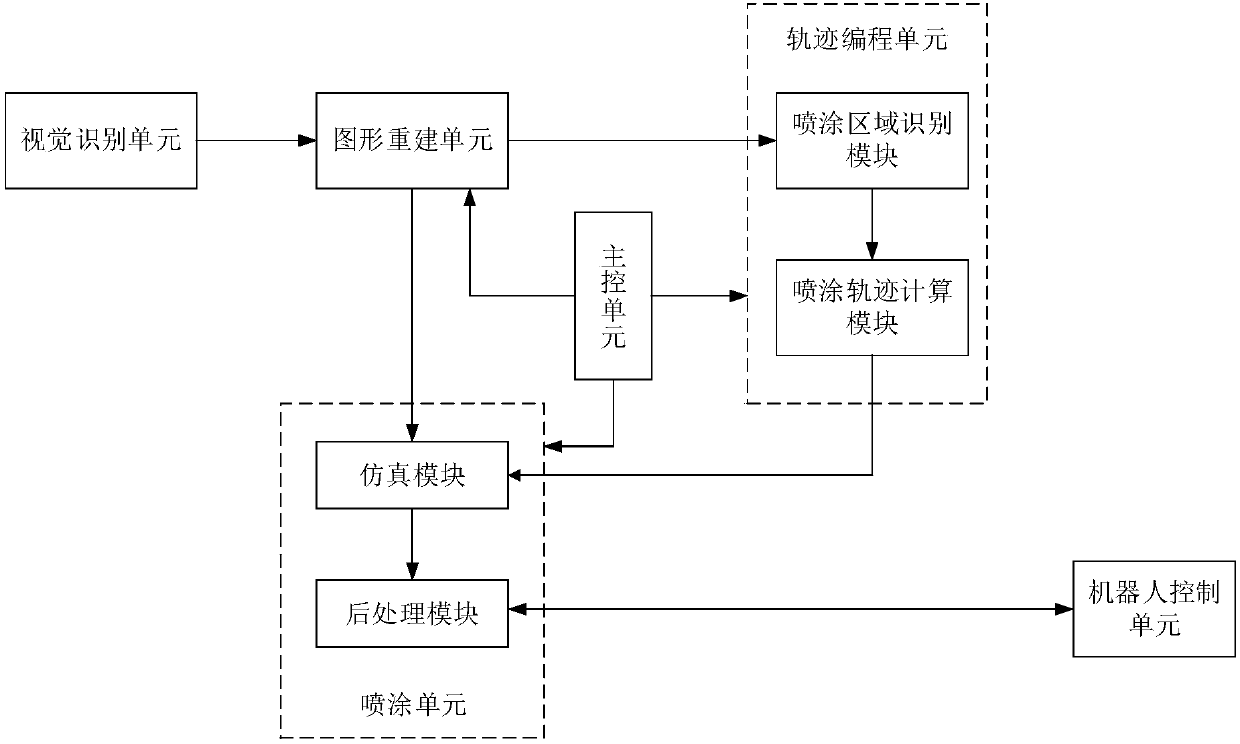

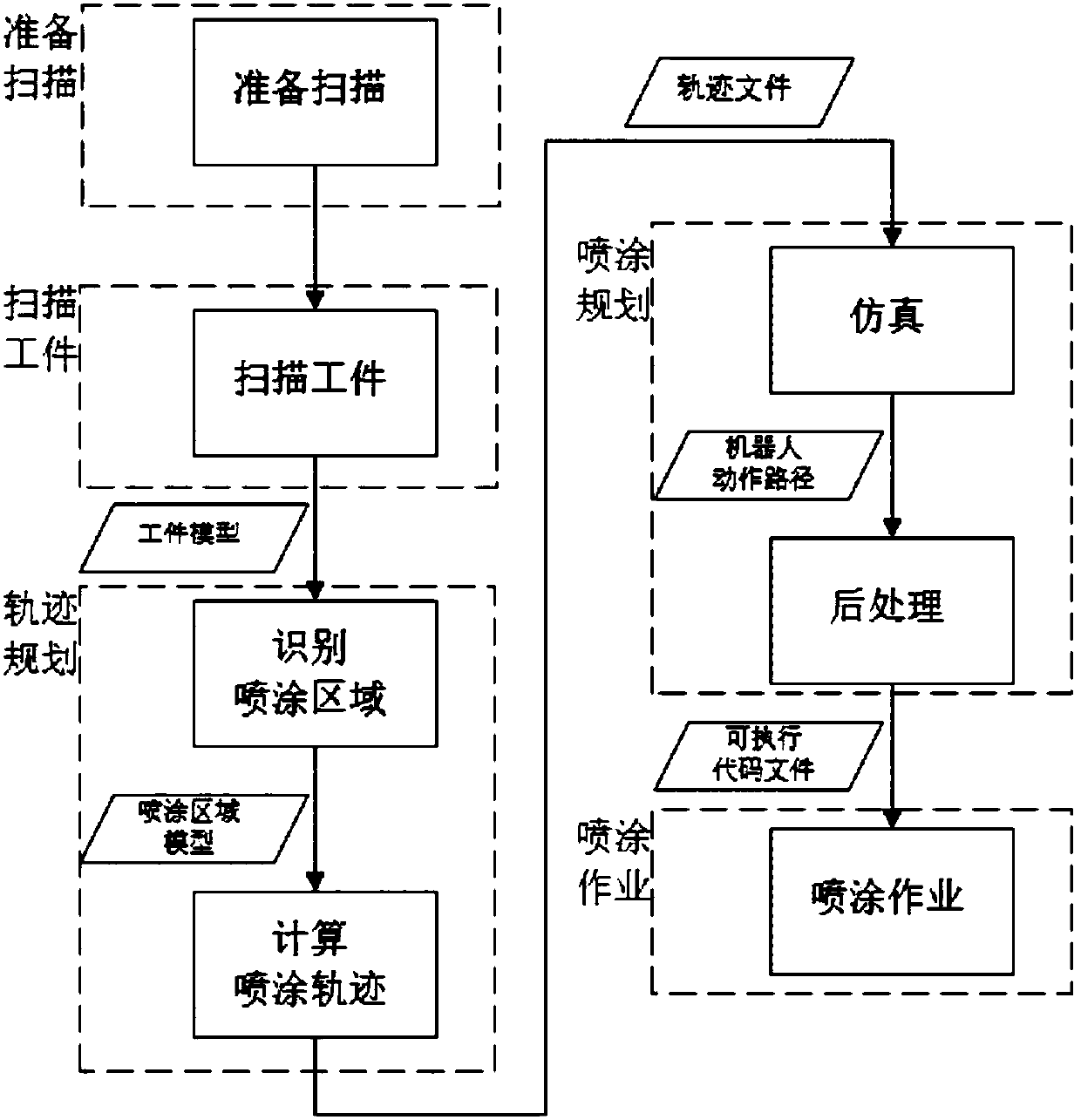

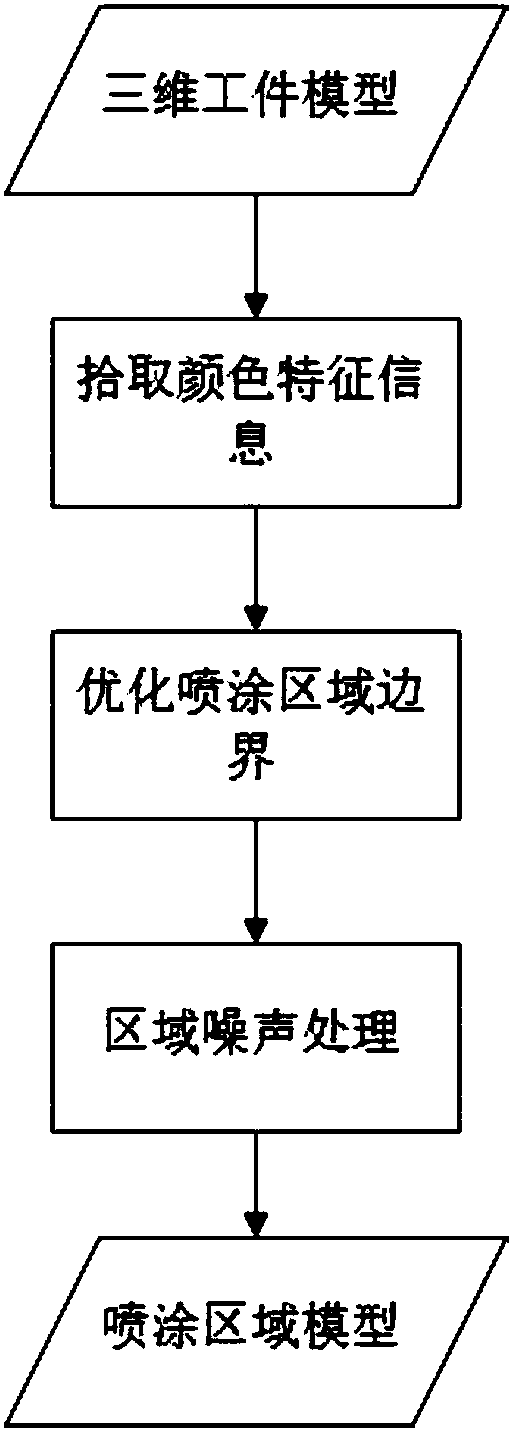

The invention discloses a mobile robot automatic spraying device and a mobile robot automatic spraying control system and method. The mobile robot automatic spraying control system comprises a visualrecognition unit, a main control unit, a graphic reconstruction unit, a trajectory programming unit, a spraying unit and a robot control unit, wherein the visual recognition unit performs processing on collected image information of a workpiece to obtain geometric information; the graphic reconstruction unit performs optimization processing on the geometric information of the workpiece to obtain agridding three-dimensional model of the workpiece; the trajectory programming unit automatically recognizes a spraying area and calculates a spraying trajectory strategy to obtain a spraying trajectory file; the spraying unit plans a spraying path according to a positional relation between the workpiece of a robot and the spraying trajectory file, and generates codes capable of being executed bythe robot; and the robot control unit controls the industrial robot to execute a spraying action according to the code file. According to the invention, a visual recognition based trajectory planningmethod is adopted, the spraying trajectory is automatically planned in allusion to a workpiece to be sprayed, the robot automatically completes the paint spraying work, the work flexibility is increased, and the programming workload is reduced.

Owner:苏州瀚华智造智能技术有限公司

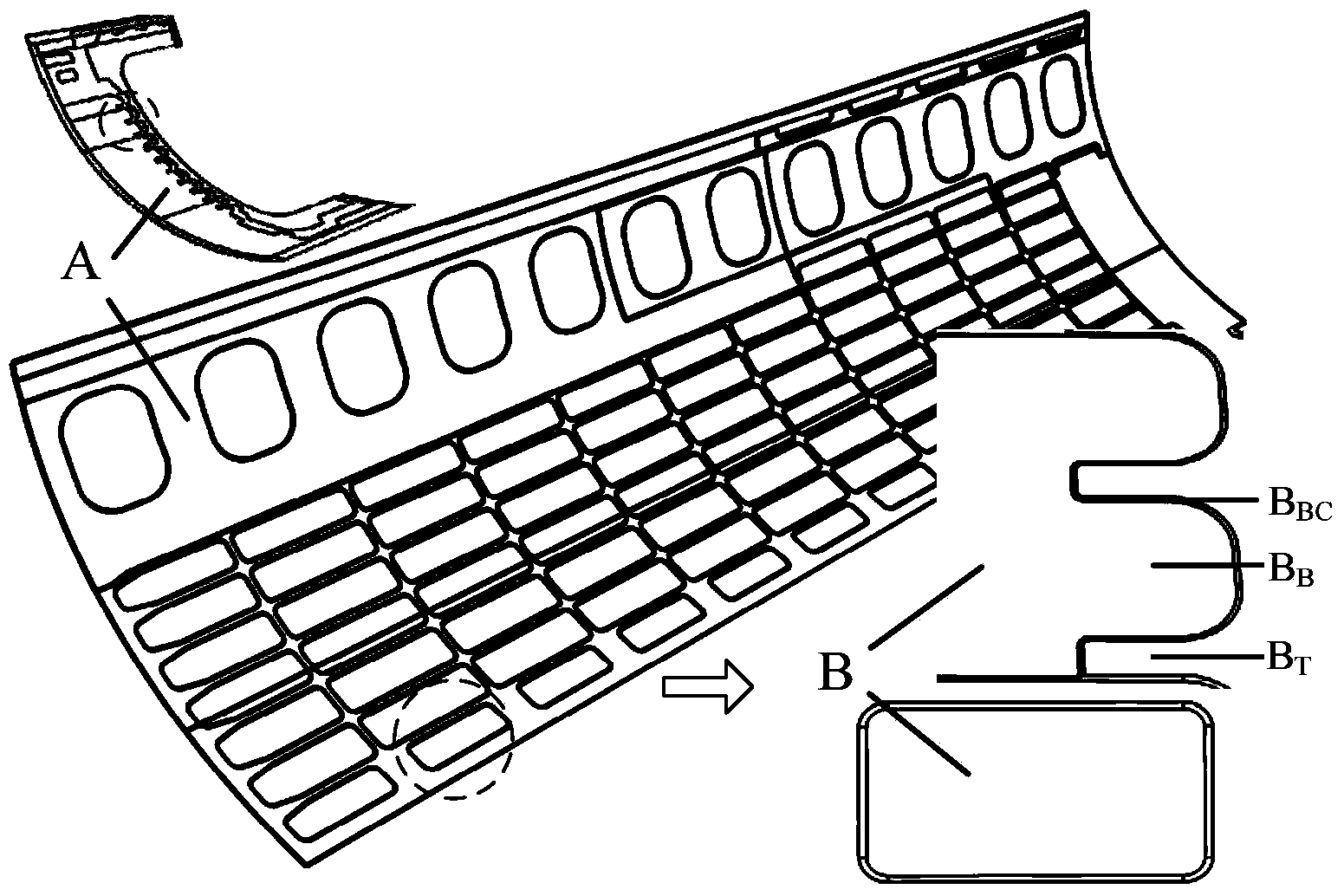

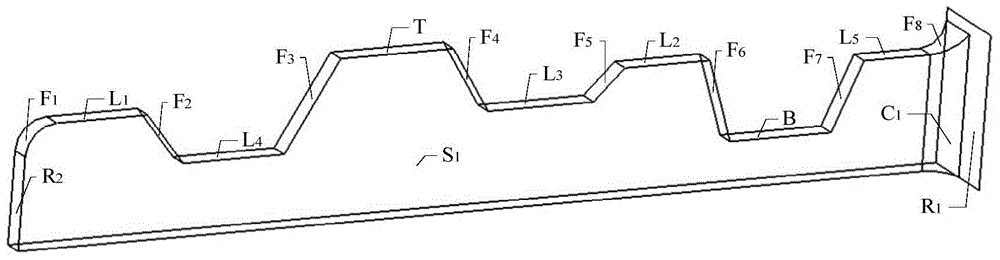

Aircraft skin milling efficient machining path automatic generating method

ActiveCN104375464ALess programming effortImprove computing efficiencyProgramme controlComputer controlNumerical controlCam

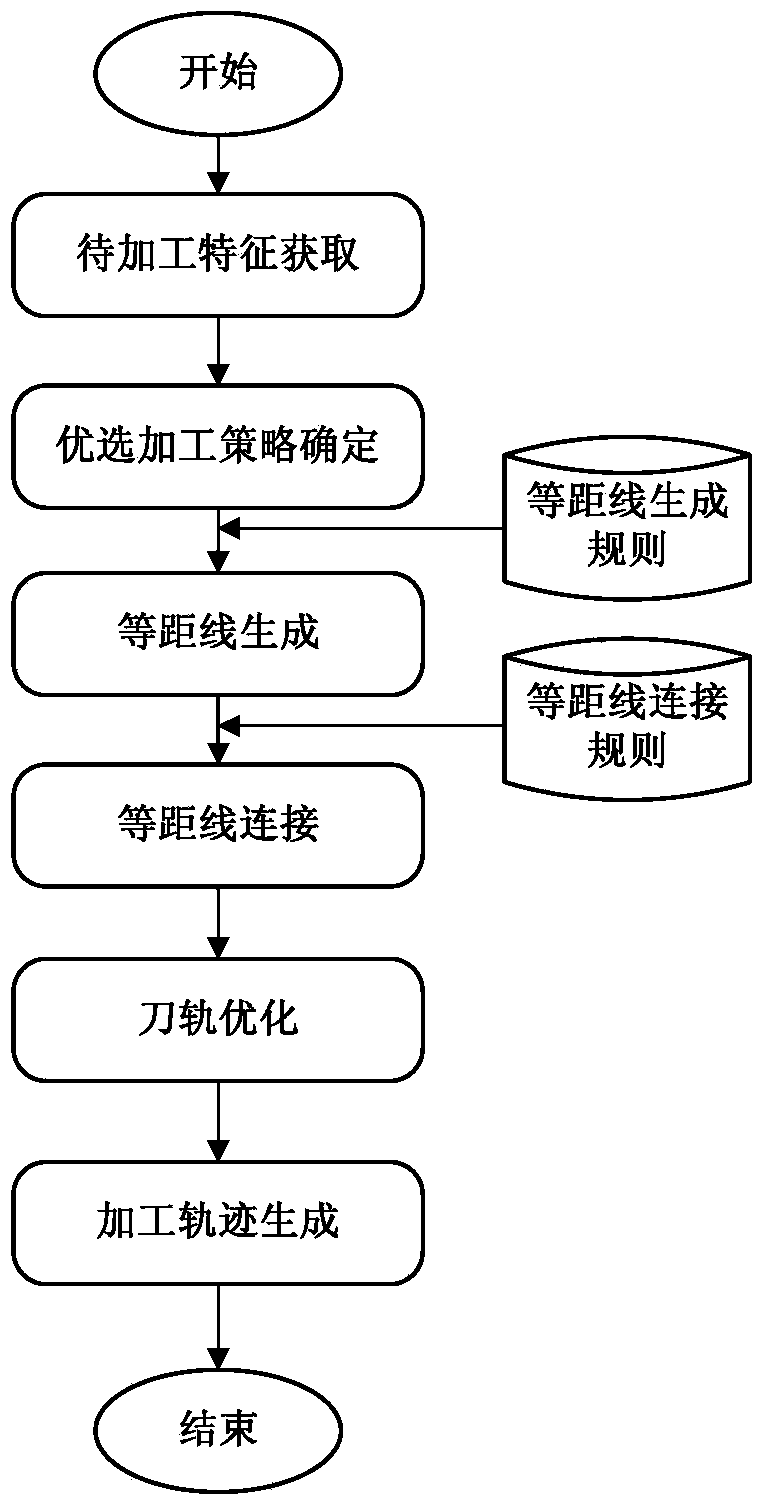

The invention discloses an aircraft skin milling efficient machining path automatic generating method and belongs to the technical field of CAD / CAM. The method is characterized by comprising the steps that skin part subsidence machining features are obtained at first; an preferable machining strategy is determined according to geometrical features of the subsidence machining features; an equidistant line is generated based on the subsidence preferable machining strategy and the typical machining technology; a machining path is generated based on the equidistant line connection rule; an equal-step-pitch, cross-free, cutter-lifting-free and residue-free efficient subsidence feature machining path is generated finally through residue detection processing. The efficient tool path generating method is provided for skin part numerical control milling, and the aircraft skin milling efficient machining path automatic generating method is particularly applied for tool path generation in the skin mirror image milling machining method, and is high in calculation efficiency, accuracy and applicability, and capable of relieving programming workloads of engineers greatly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

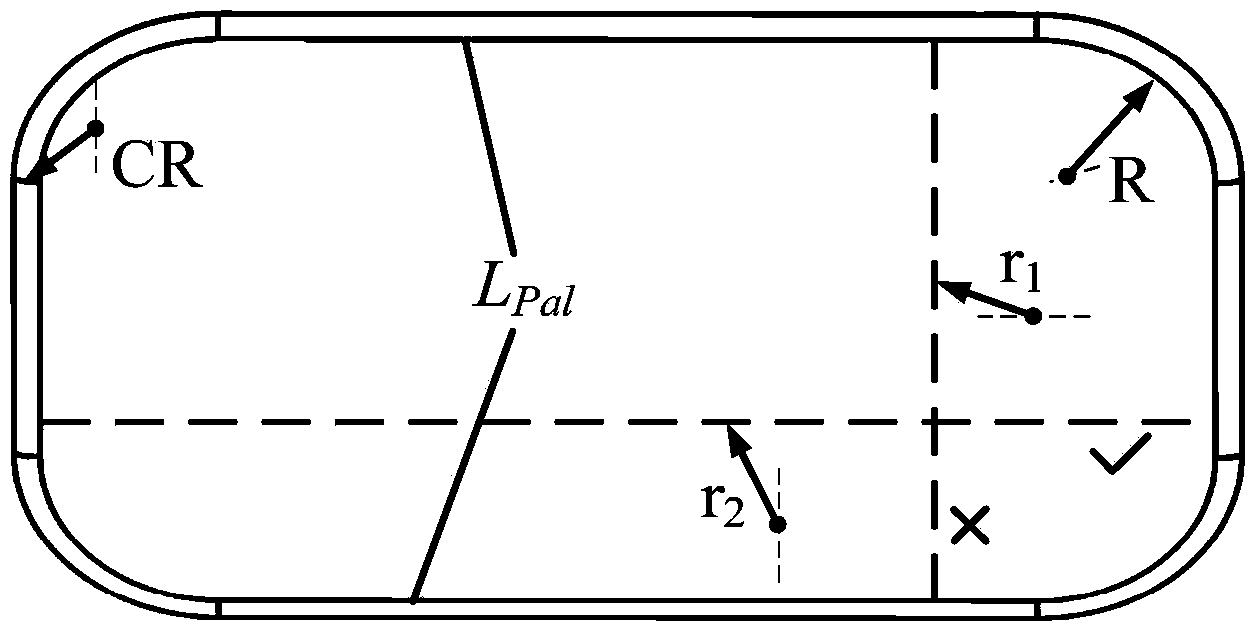

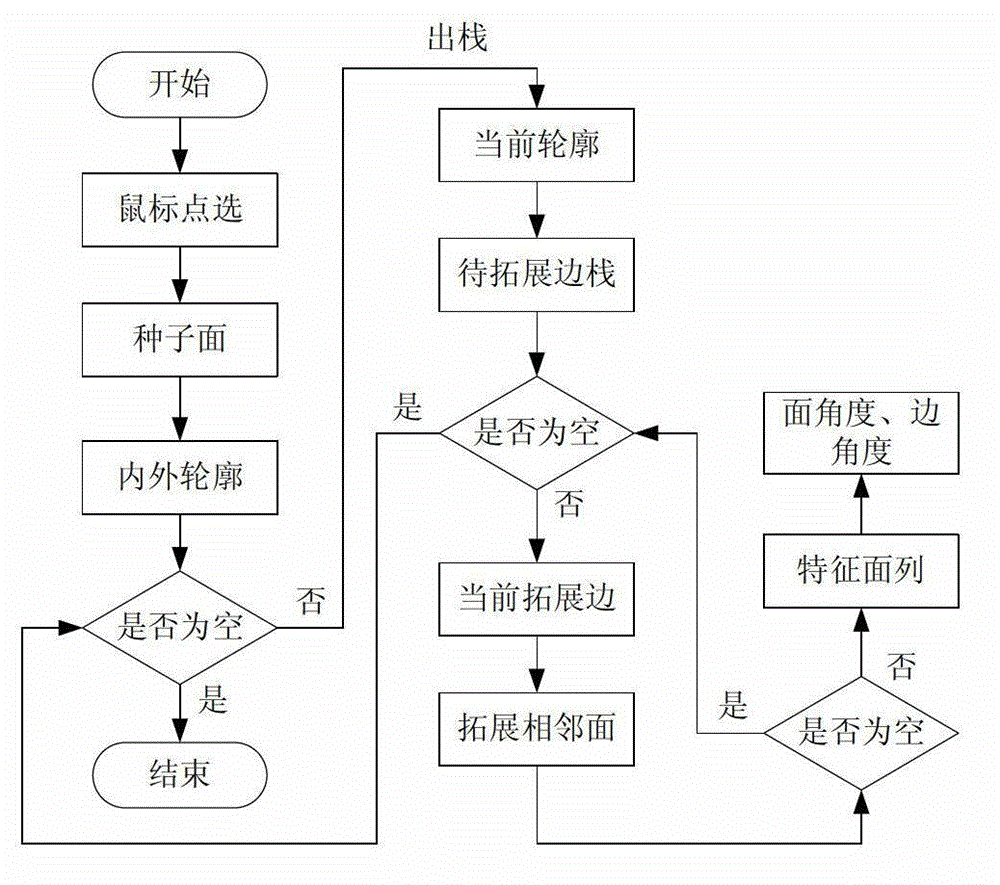

Rapid generating method of milling path of web of airplane structural member

ActiveCN103336485AQuick buildLess programming effortProgramme controlComputer controlBatch processingWorkload

A rapid generating method of the milling path of a web of an airplane structural member belongs to the technical field of CAM. The rapid generating method comprises the following steps: at first, clicking a web surface on which a tool path needs to be generated in a part model through a mouse in a CAM system, automatically constructing a milling area of the web of the clicked web surface, then selecting processing technology information of the clicked web surface automatically generated or manually inputted according to data in a process database, and achieving the rapid and automatic generation of the processing area and the processing path. The method is high in computing efficiency and strong in flexibility, reduces the programming workload of engineers, meanwhile, supports the batch processing to a single web surface and a plurality of web surfaces, and can meet different requirements of engineers.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

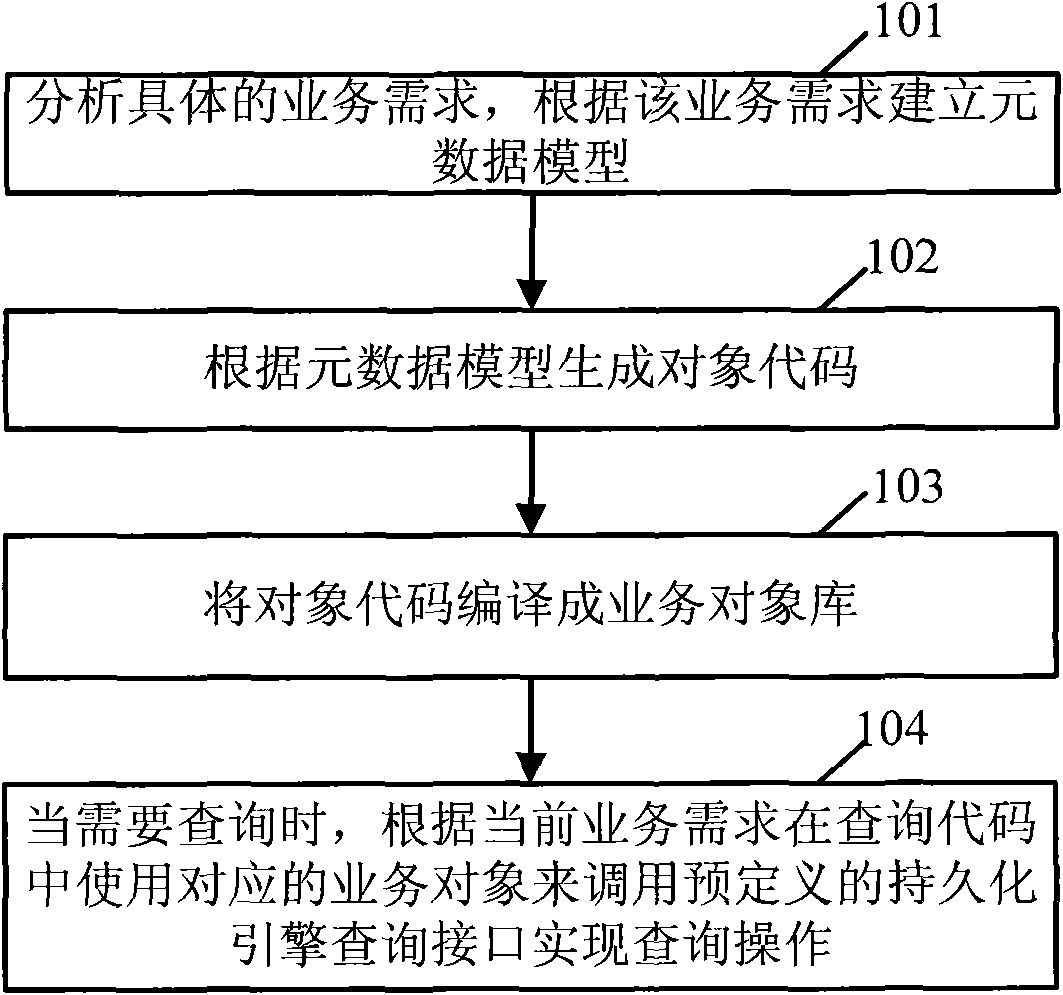

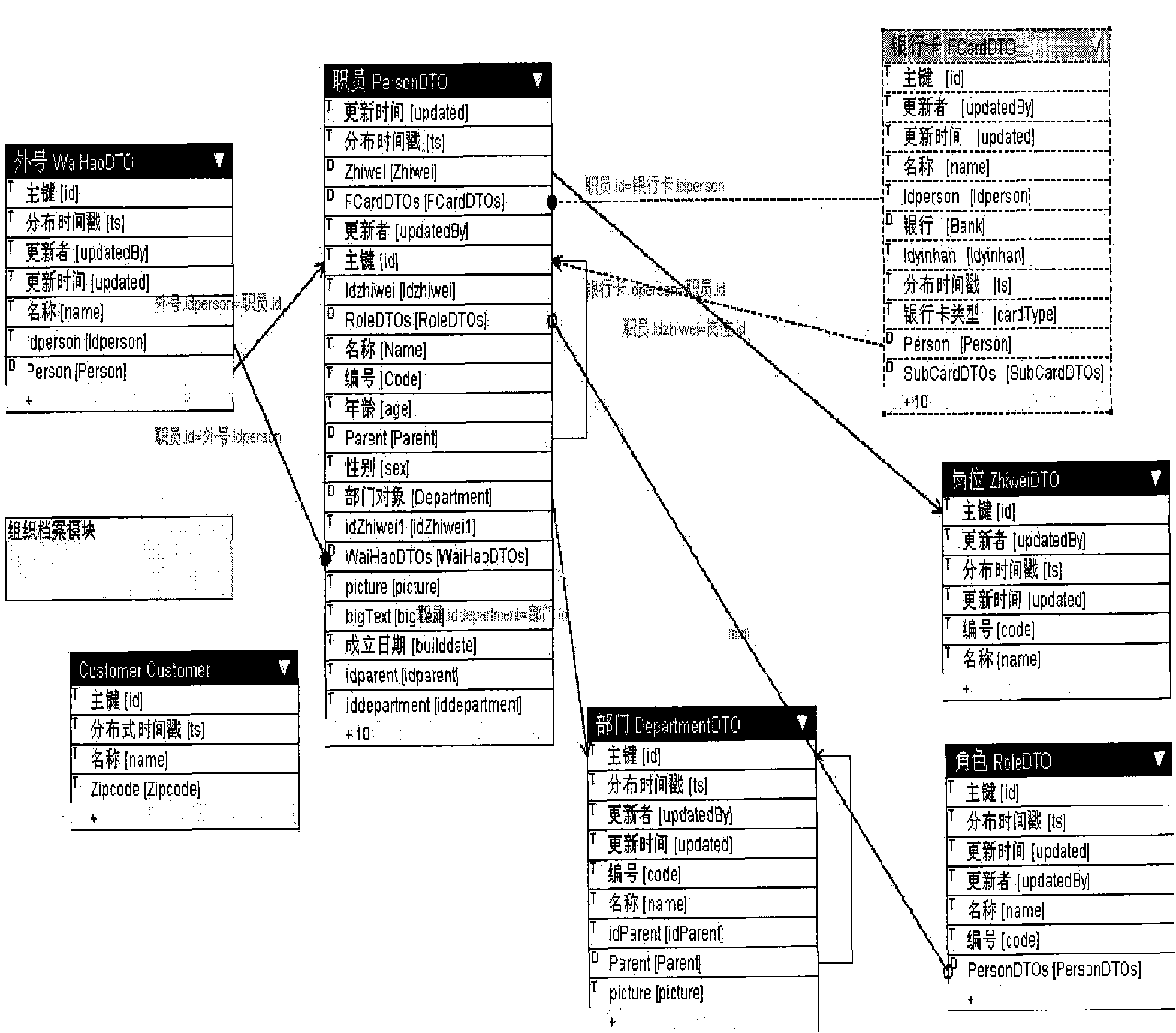

Object query method and device

InactiveCN101582079AProgramming threshold is highLess programming effortSpecial data processing applicationsMetadataSQL

The invention discloses an object query method and a device, wherein, the method comprises: step A, setting up a metadata model according to the business demand and generating an object code corresponding to the metadata model; step B, executing the query operation, according to the object code and a predefined persistence engine query interface. By adopting the invention, the query operation can be carried out by directly using the operational object without needing to compile complicated SQL sentences like the prior art.

Owner:YONYOU NETWORK TECH

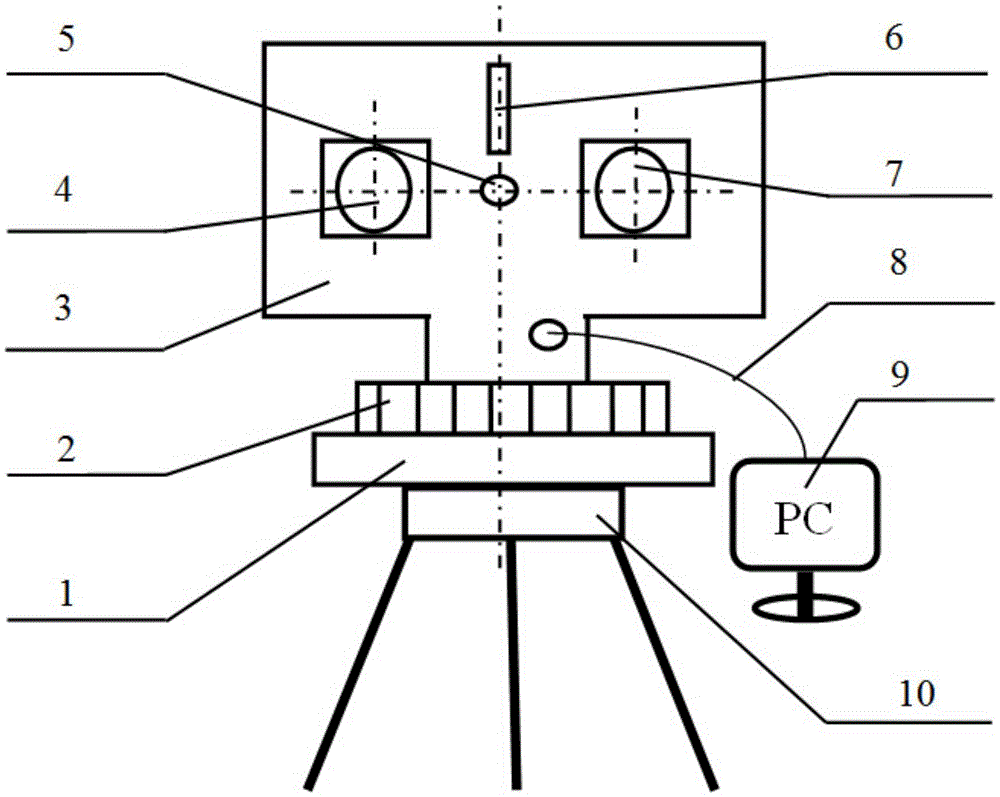

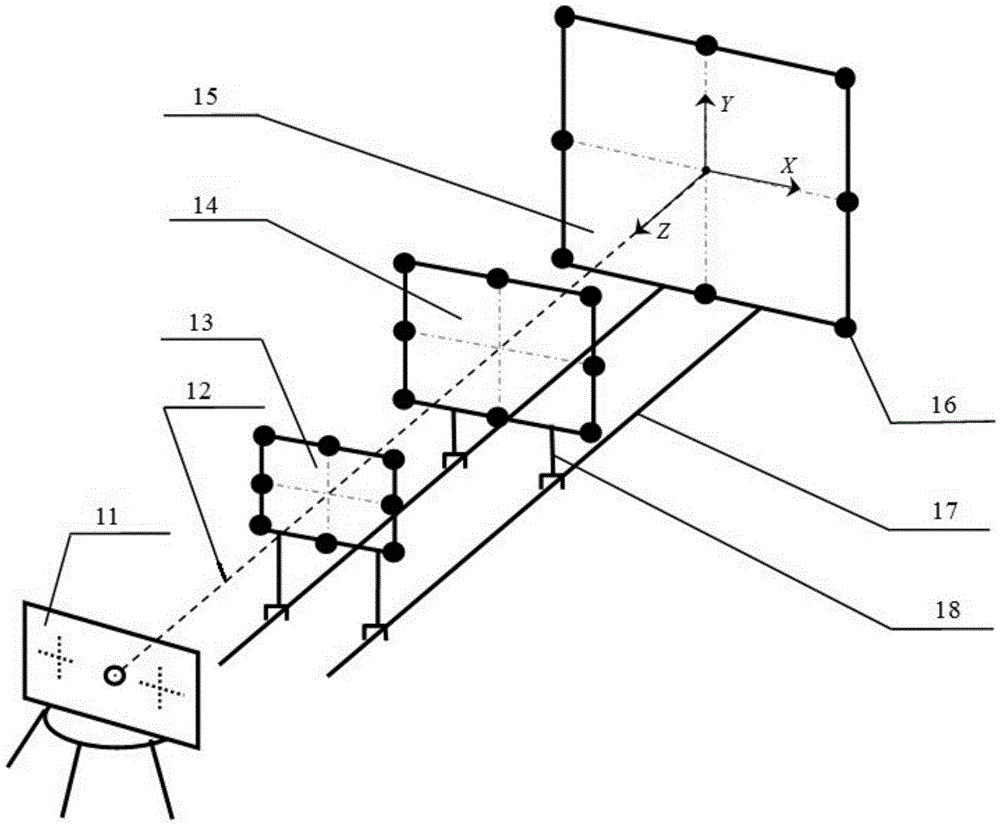

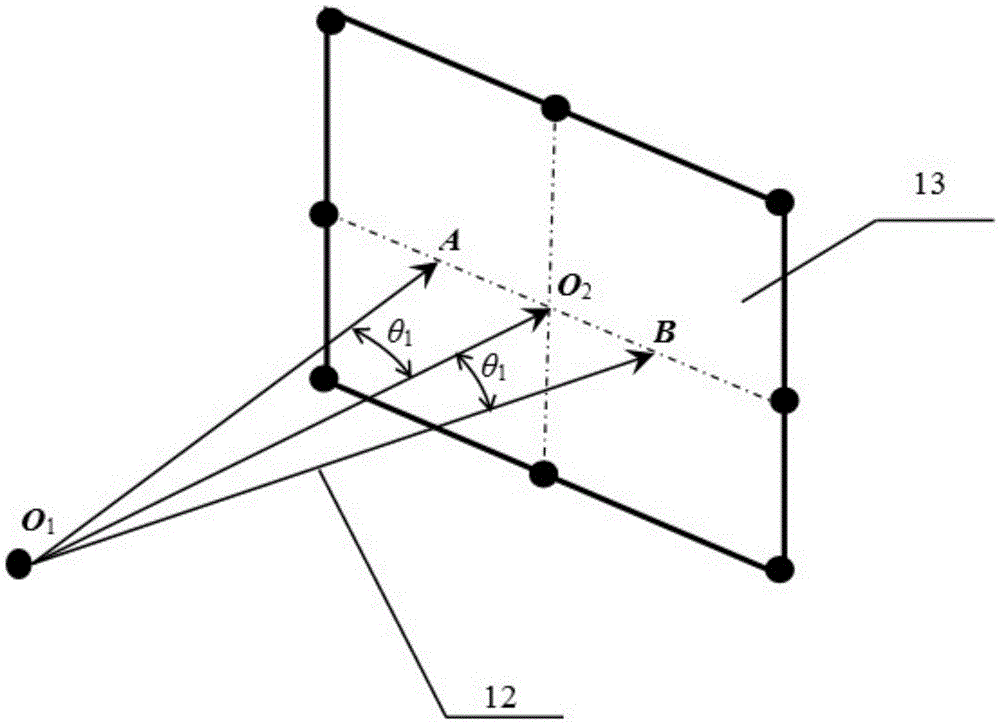

Laser photography measuring system and camera calibration method

ActiveCN105486289ASimple structureEasy to operatePicture taking arrangementsElectricityLaser transmitter

The invention relates to a laser photography measuring system and a camera calibration method. The system comprises a measuring device and a calibration device. The measuring device comprises a base, a support and a computer. The support is rotationally arranged on the base, the support is provided with cameras, a laser distance measuring device and a linear laser emitter, the laser distance measuring device and the linear laser emitter are located on the same vertical line, the two cameras are symmetrically arranged on the two sides of the laser distance measuring device, and the computer is electrically connected with the cameras, the laser distance measuring device and the linear laser emitter. The calibration device comprises three object space plates and evenly-distributed object space identification points. By means of the measuring device, the calibration device, the object space plates and the object space identification points, precise calibration of the cameras of the measuring system can be effectively achieved through photographing of the cameras and corresponding subsequent programmed programs. The camera calibration method is simple in step and easy to operate, and reliable bases are provided for subsequent laser photography measuring.

Owner:SHANDONG UNIV OF SCI & TECH

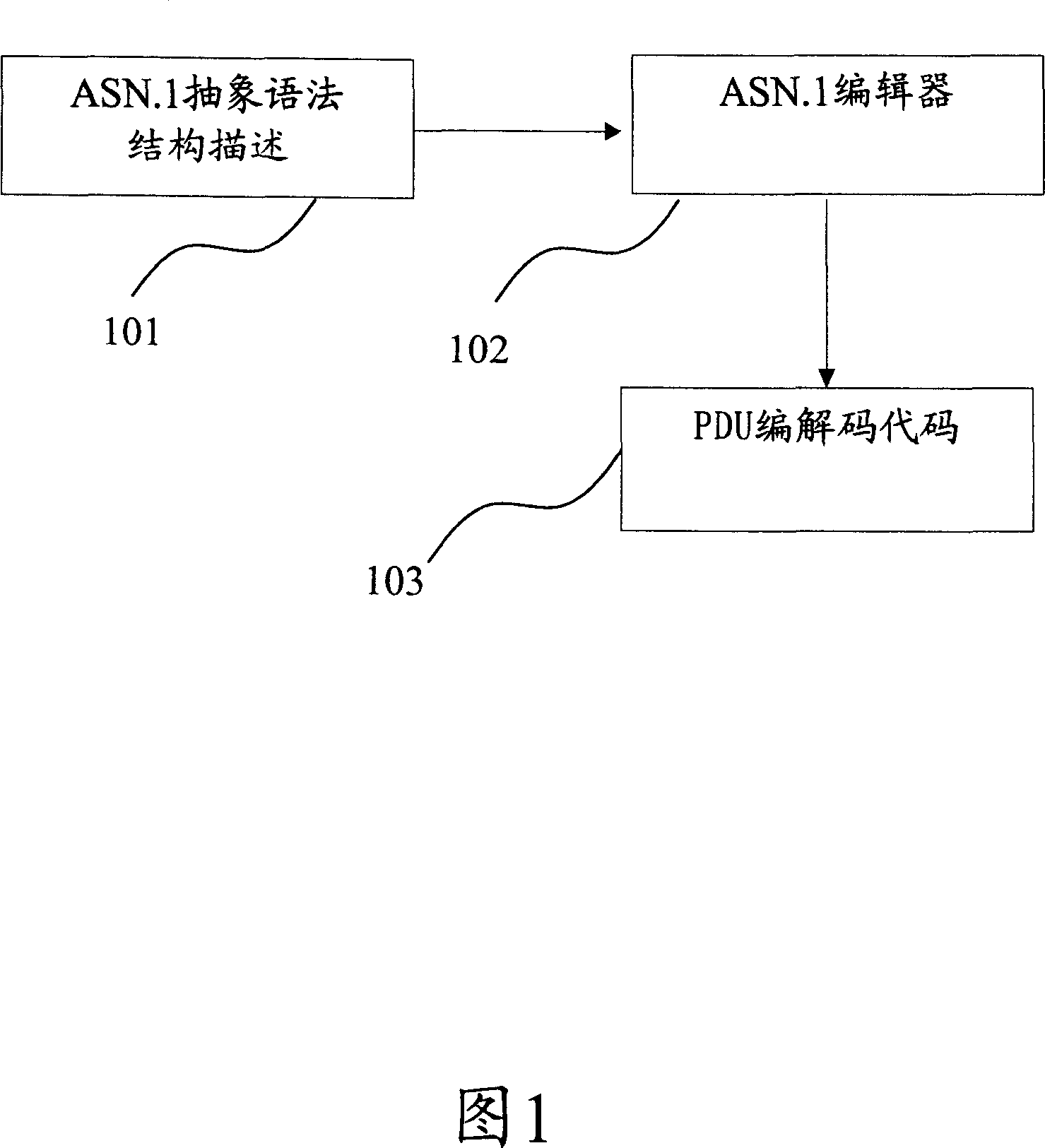

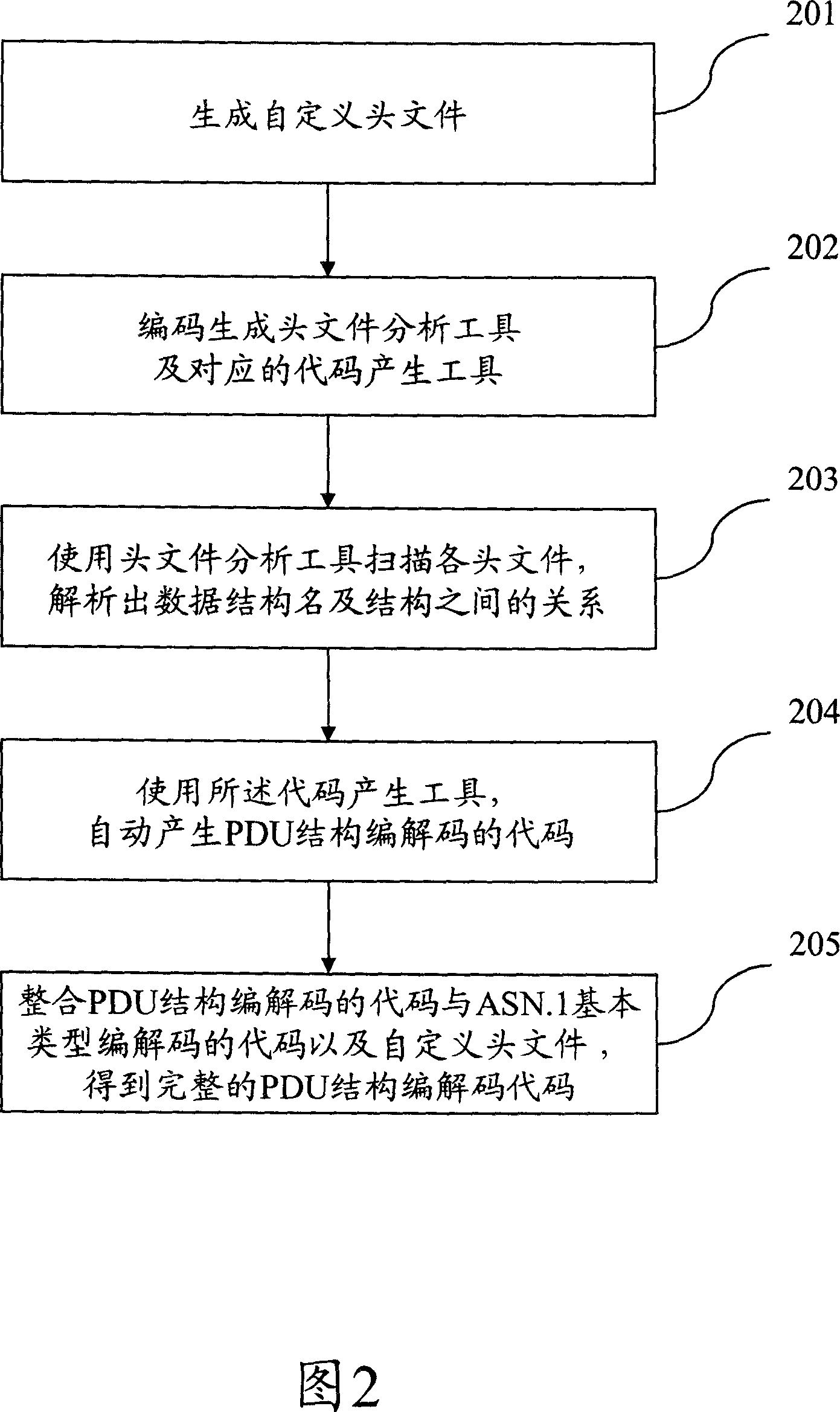

Implementation method for automatic generation of PDU coding/decoding code based on ASN.1 definition

InactiveCN1992715AAvoid the incompatibility of generated code in terms of programming specifications, etc.Avoid incompatible issues such as programming specificationsTransmissionData typeData structure

The invention relates to a method for automatically generating PDU code / decode, based on ASN. 1, wherein said method comprises that: fixing the define rule and mark rule of used data type in self-defined head document; via said rules, generating head document; via said rules, coding head document analyzer, and relative code generator; using said document analyzer to scan the head document to obtain the relation between data structure name and structure defined in head document; then using code generator, via the relation, to automatically generate the PDU code / decode. The invention has low cost.

Owner:ZTE CORP

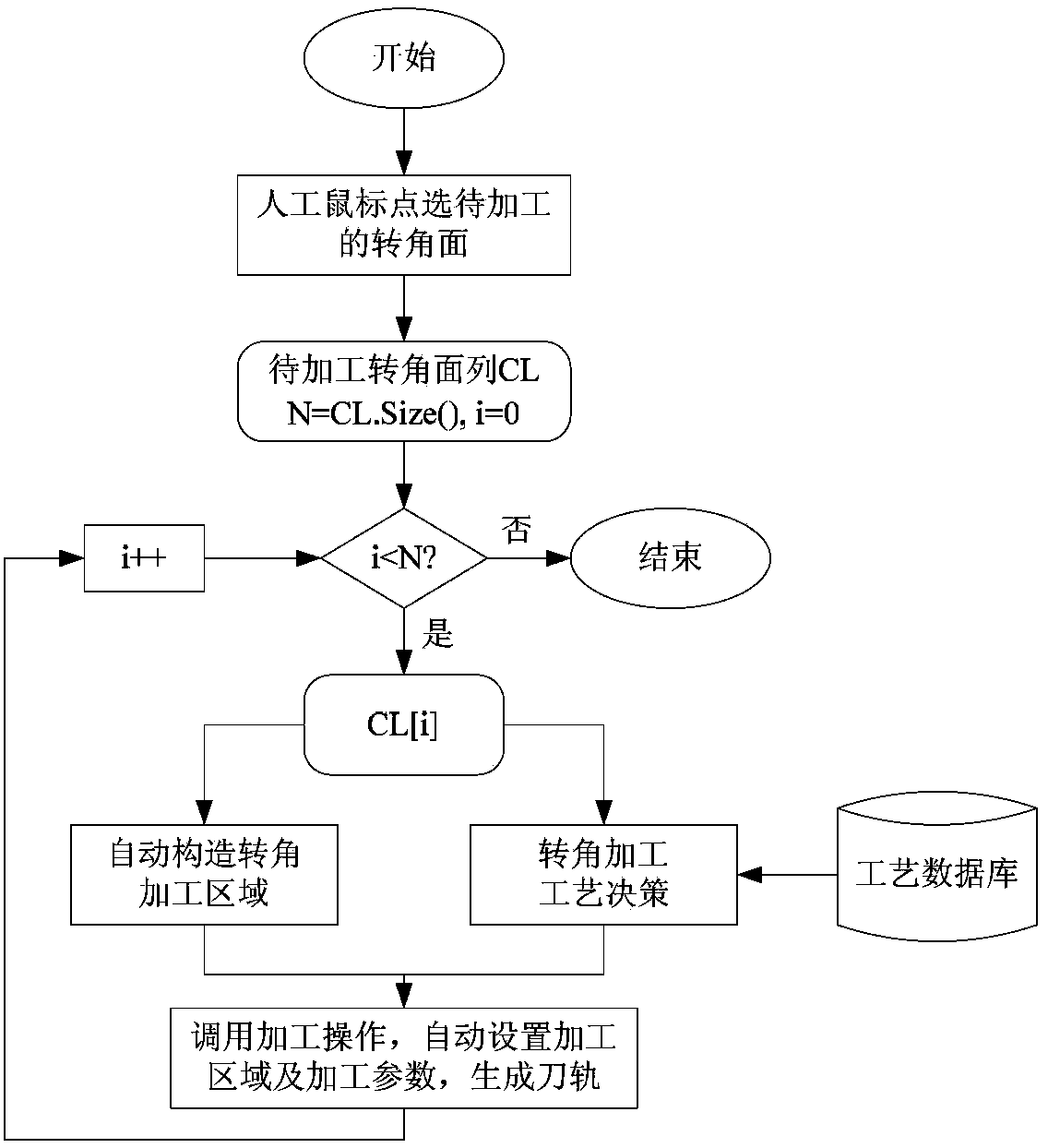

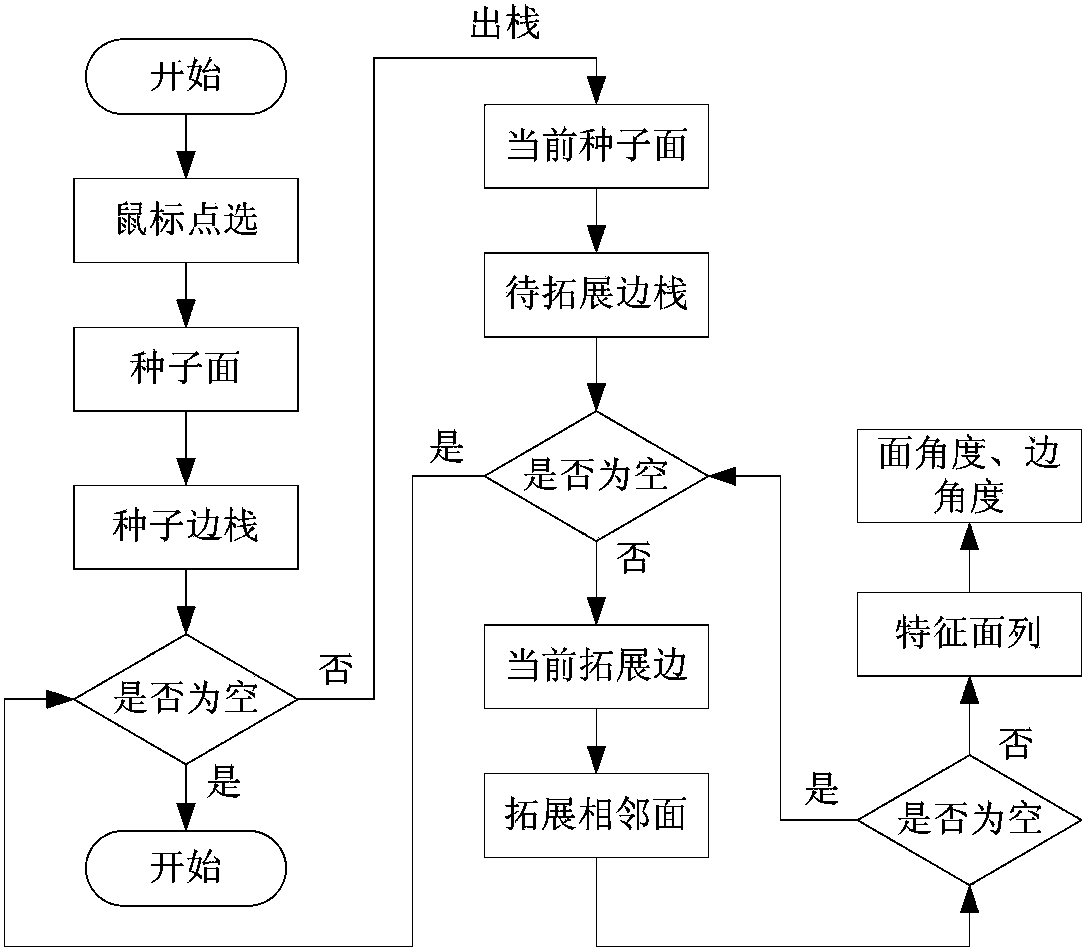

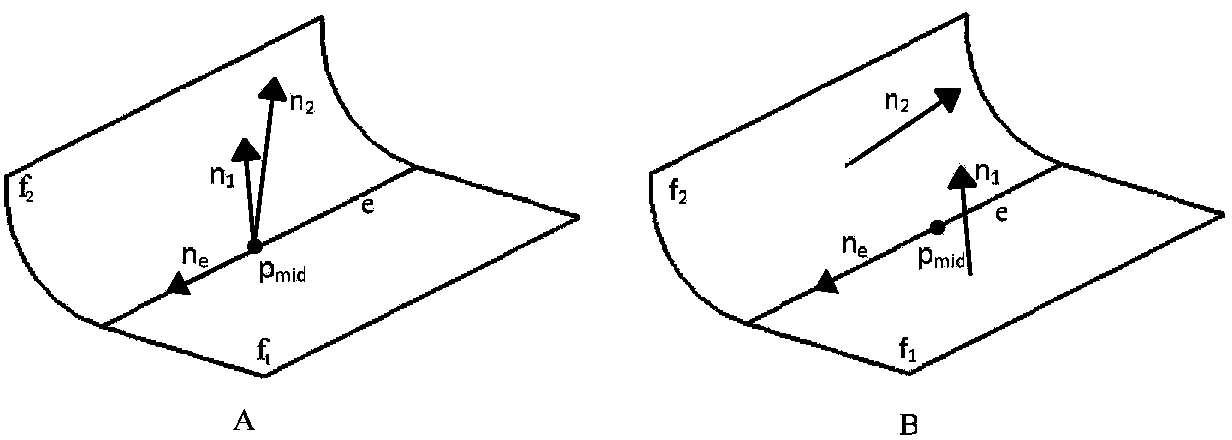

Method for rapidly generating corner side milling process path

The invention discloses a method for rapidly generating a corner side milling process path, which belongs to the technical field of CAD (Computer Aided Design) / CAPP (Computer-Aided Process Planning) / CAM (Computer Aided Manufacturing). The method comprises the following steps: firstly, clicking a corner surface needing to generate a tool path in a CAM system via a mouse; automatically constructing a processing area for side milling processing of the selected corner surface; and generating corner processing process information by combining automatic generation and manual interaction according to data in a process database so as to realize rapid automatic generation of a processing area and a processing path. The method for rapidly generating the corner side milling process path has the advantages of high calculation efficiency, high flexibility and relieving of the editing workload of engineering personnel; and meanwhile, the method supports processing of a single corner and batch processing of a plurality of corners, so that different demands of engineer personnel can be met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Automated data migration

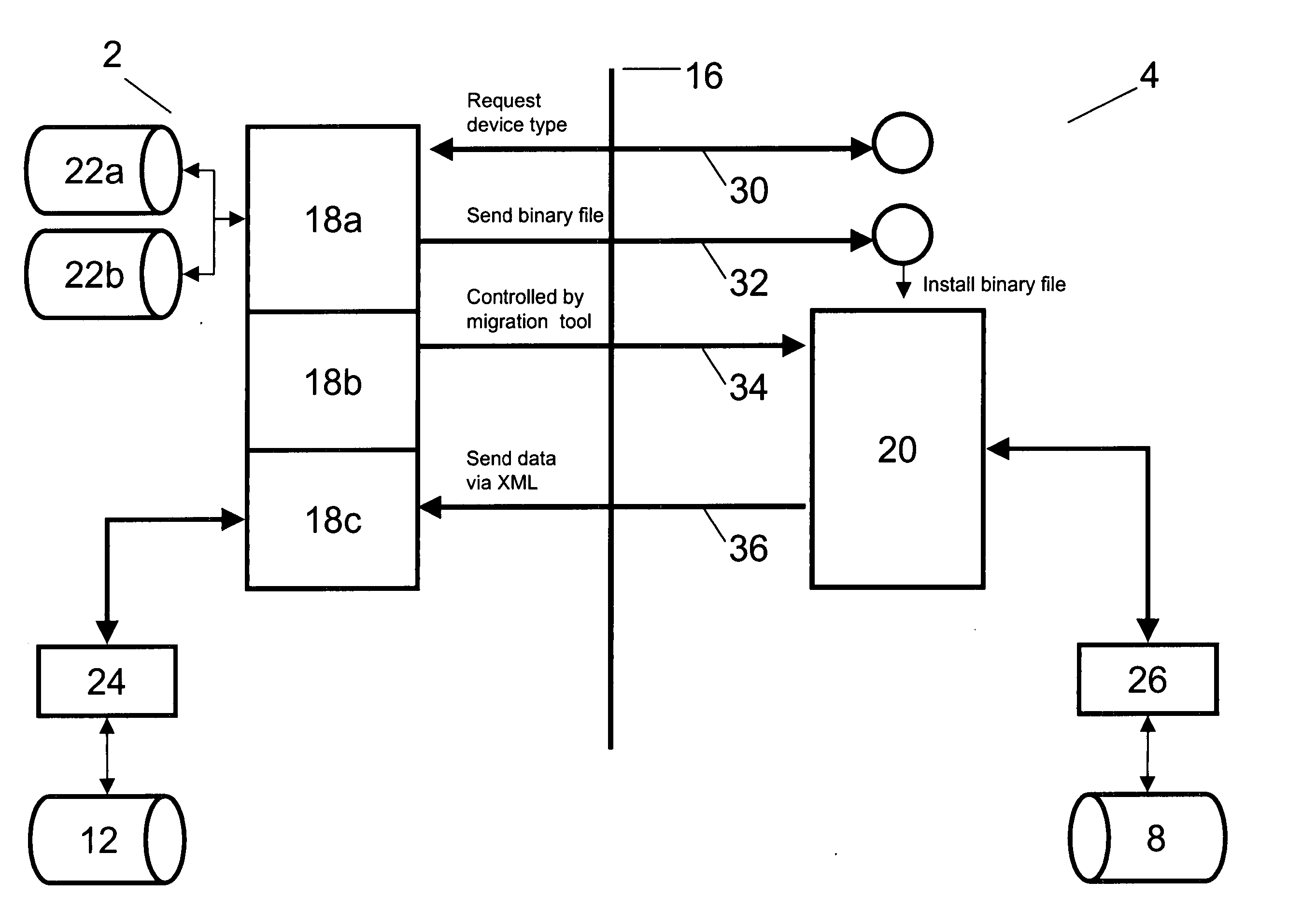

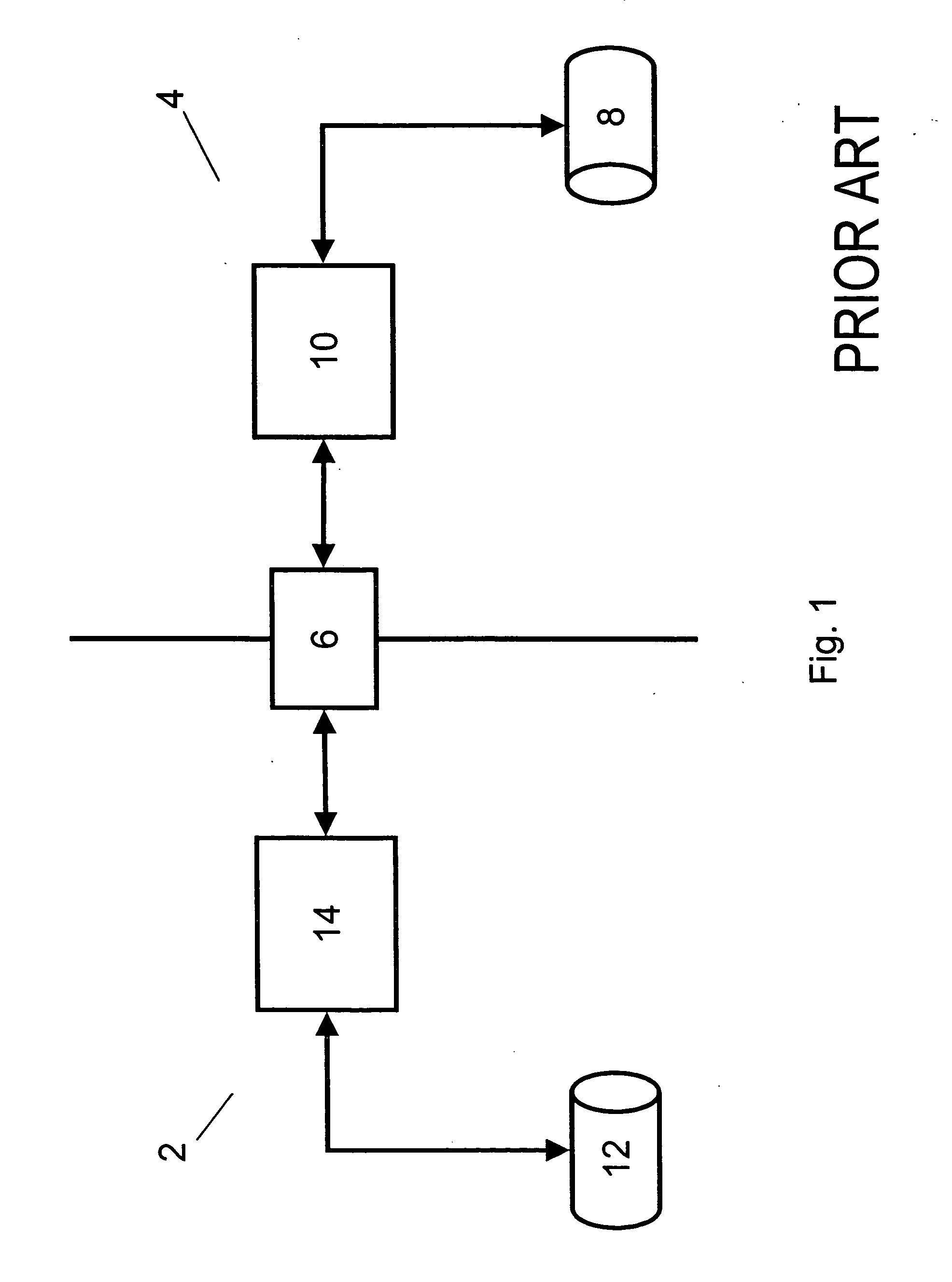

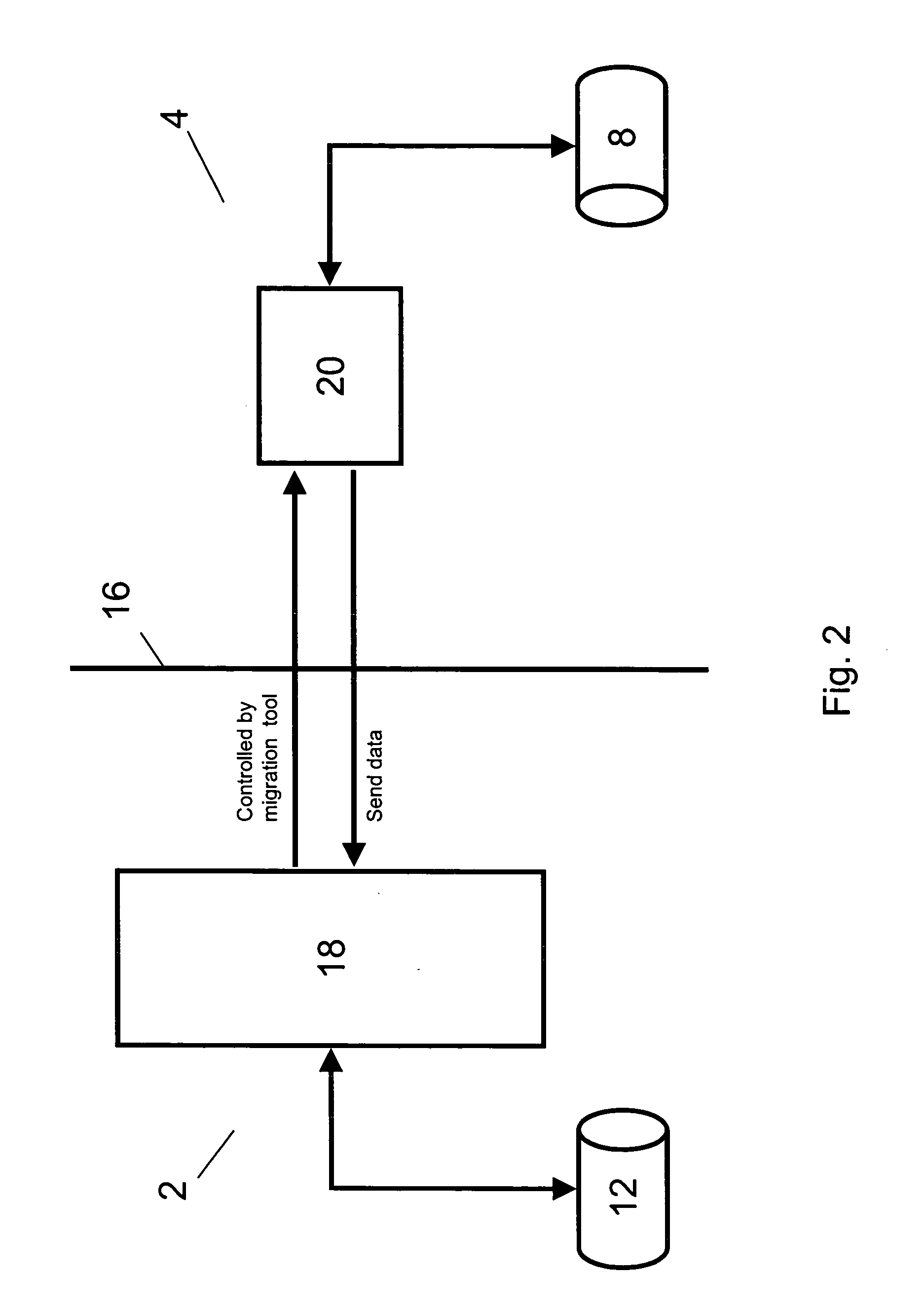

InactiveUS20050198352A1Easy to useReduce the amount requiredMultiple digital computer combinationsRadio/inductive link selection arrangementsData connectionComputer science

The invention relates to a method for transferring data from a source communication device to a destination communication device. To allow automatic transfer of data between the devices, it is proposed to establish a data connection between the source communication device and the destination communication device, transfer a data collector means from the destination communication device to the source communication device, collect data to be transferred from the source communication device to the destination communication device using the data collector means, and to transfer the collected data from the source communication device to the destination communication device using the data collector means.

Owner:MALIKIE INNOVATIONS LTD +1

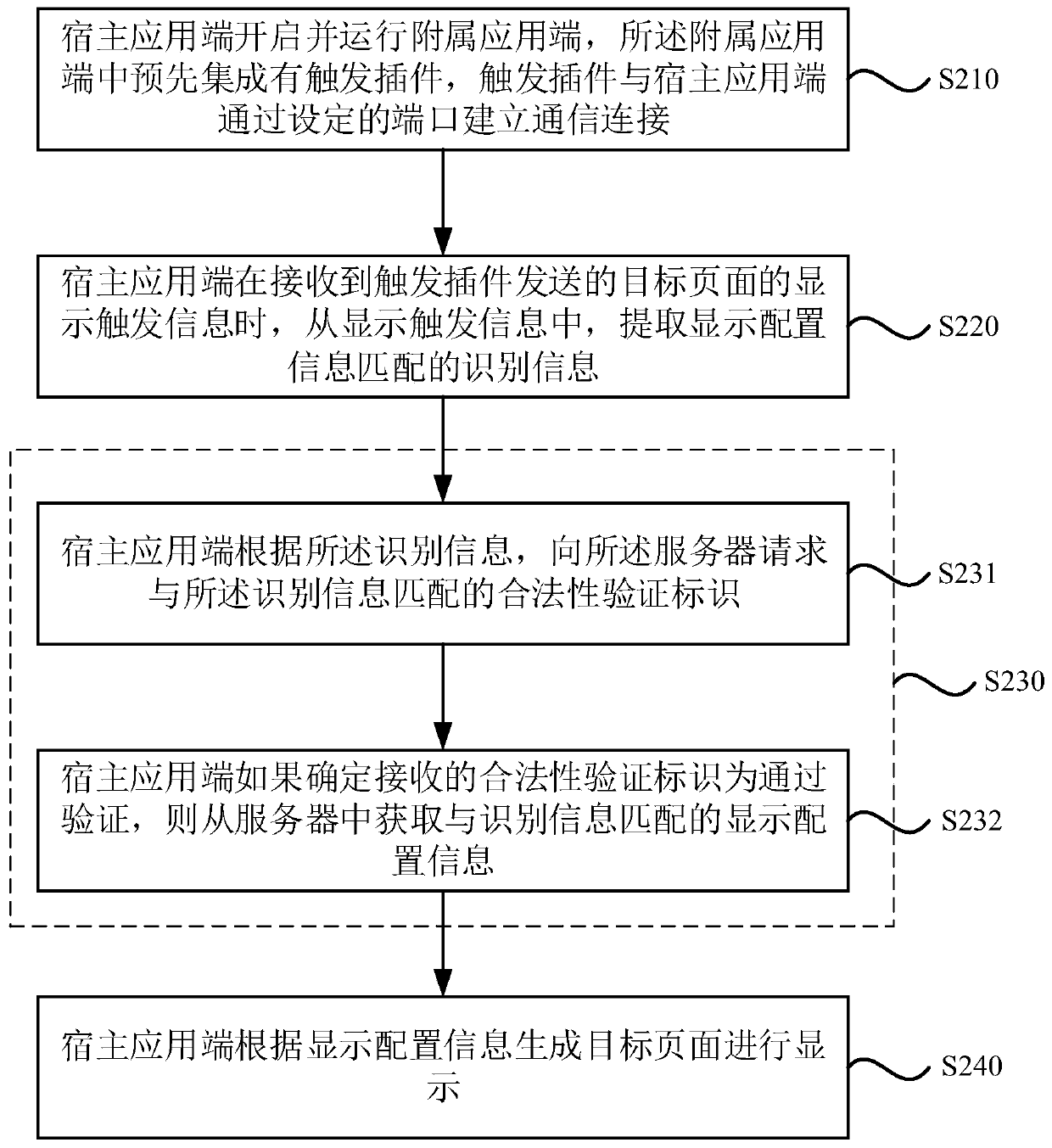

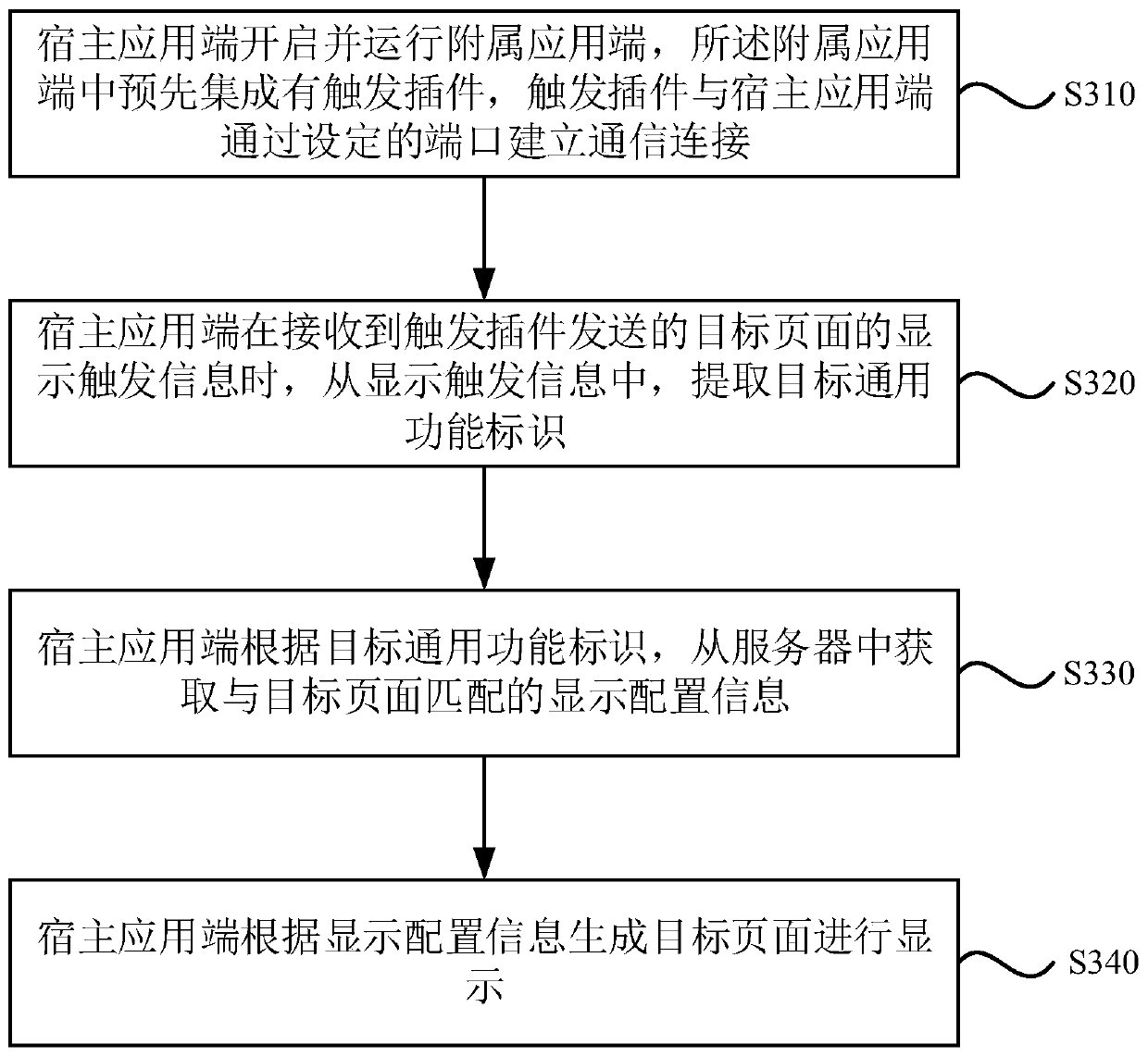

Page display method and device, equipment and storage medium

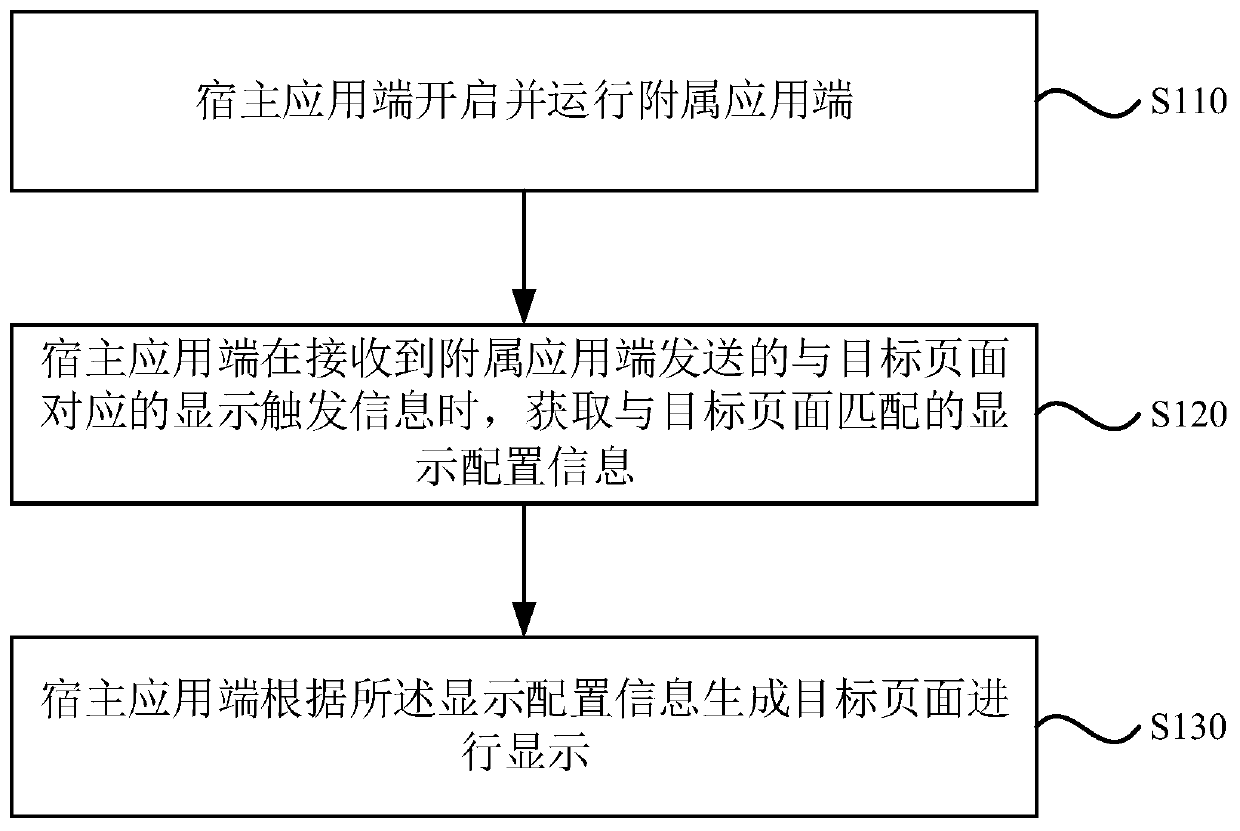

ActiveCN110297635ALess programming effortReduce review workloadSoftware engineeringProgram loading/initiatingWorkloadComputer engineering

The embodiment of the invention discloses a page display method and device, equipment and a storage medium. The method comprises the steps that a host application end starts and runs an auxiliary application end; when the host application end receives display trigger information which is sent by the auxiliary application end and corresponds to a target page, the host application end obtains display configuration information matched with the target page; and the host application end generates the target page according to the display configuration information and displays the target page. Basedon the technical scheme, the programming workload of the auxiliary application ends and the auditing workload of the host application platform are reduced, the display consistency of different auxiliary application ends in the host application ends for the same target page is ensured, and the consistency of user experience is also ensured.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

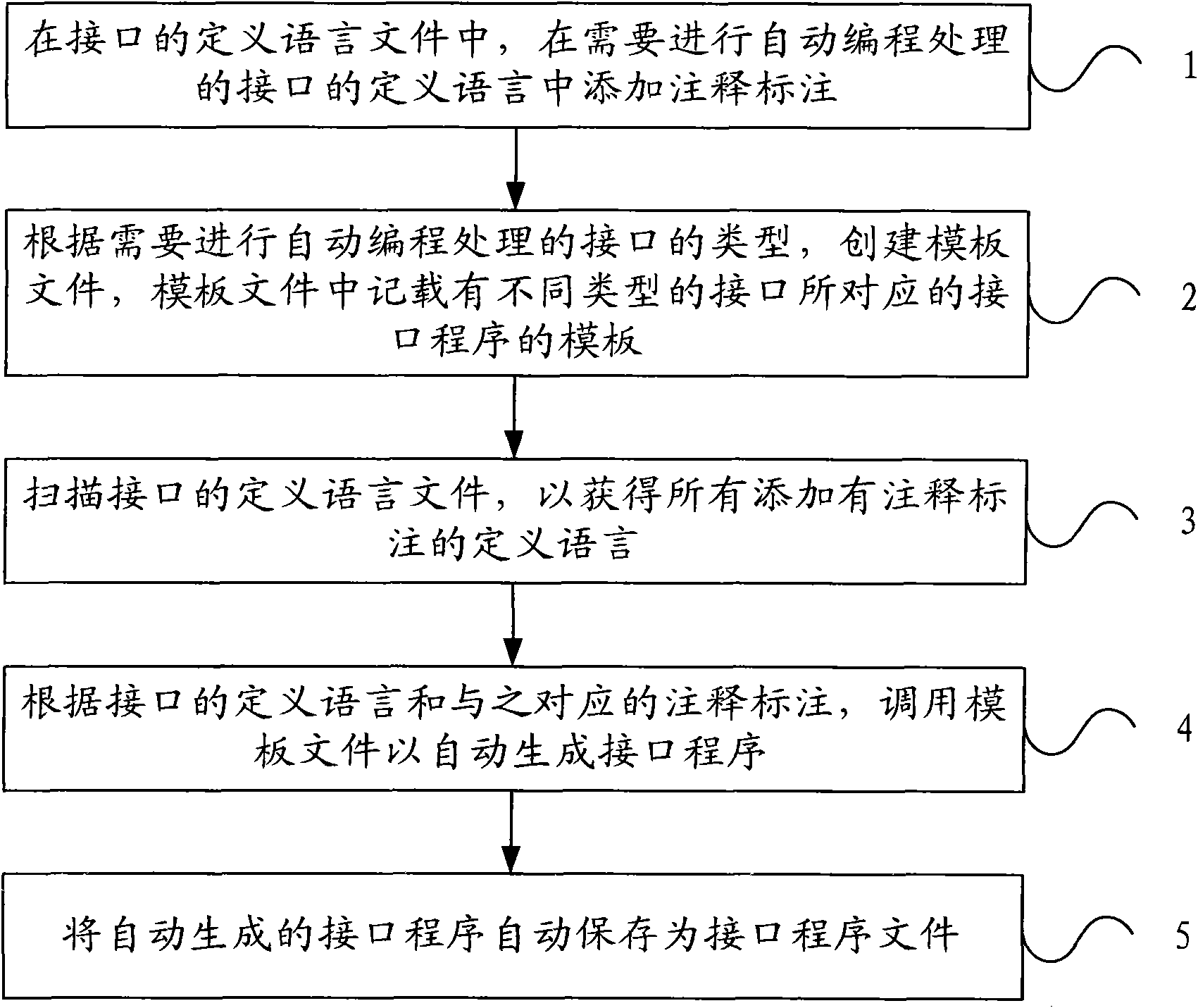

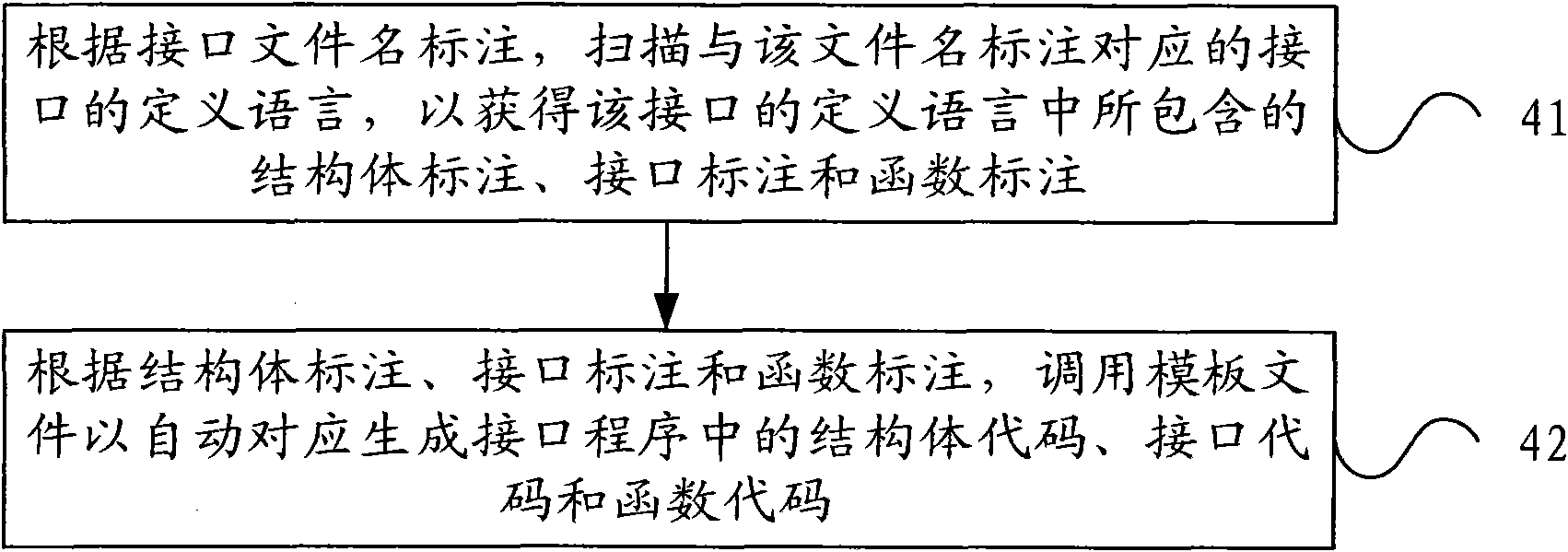

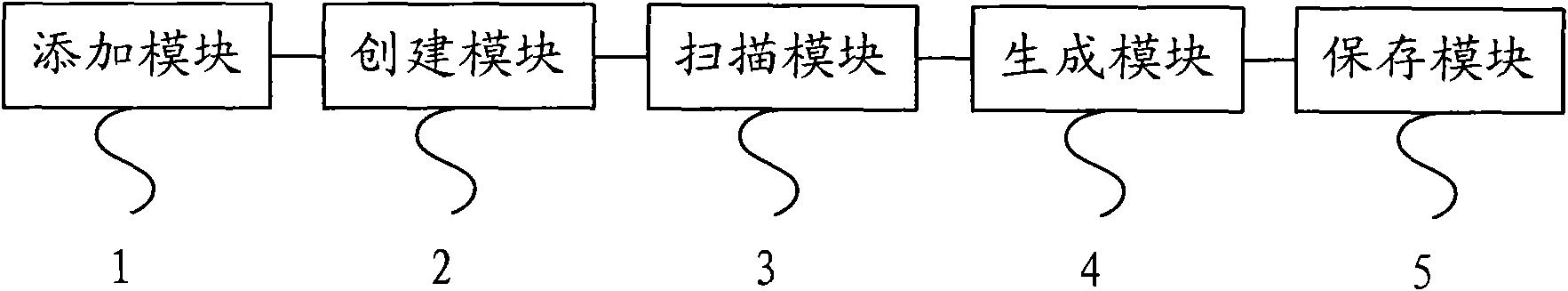

Method for automatically programming intermediate communication interface and device

ActiveCN102043624ALess programming effortEasy to maintain laterSpecific program execution arrangementsCommunication interfaceWorkload

The invention provides a method for automatically programming an intermediate communication interface and a device. The method comprises the following steps of: adding notes and labels to a definitional language of an interface requiring automatic programming processing in a definitional language file of the interface; establishing a template file according to the type of the interface requiring automatic programming processing, wherein templates of interface programs corresponding to different types of interfaces are recorded in the template file; scanning the definitional language of the interface to acquire all the definitional languages with notes and labels; and calling the template file to automatically generate an interface program according to the definitional language of the interface and the corresponding notes and labels. Regarding the interface requiring automatic programming processing, in the definitional language file of the interface, the notes and labels are added to the definitional language of the interface, and the interface program corresponding to the interface is automatically generated according to the notes and labels and the established template file, so that the programming workload is reduced by the method for automatically programming the intermediate communication interface, and subsequent maintenance is facilitated.

Owner:QINGDAO HISENSE TRANS TECH

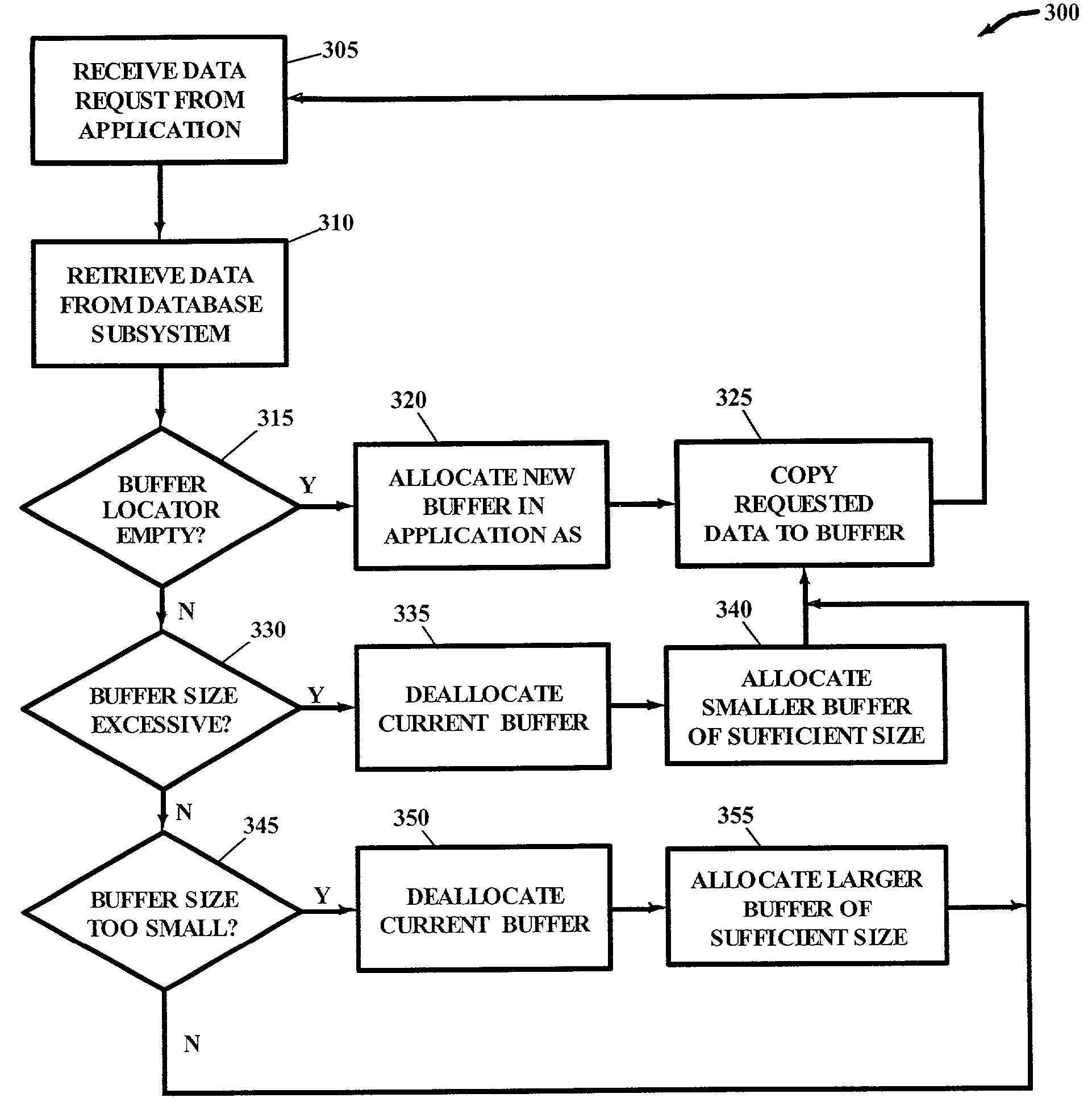

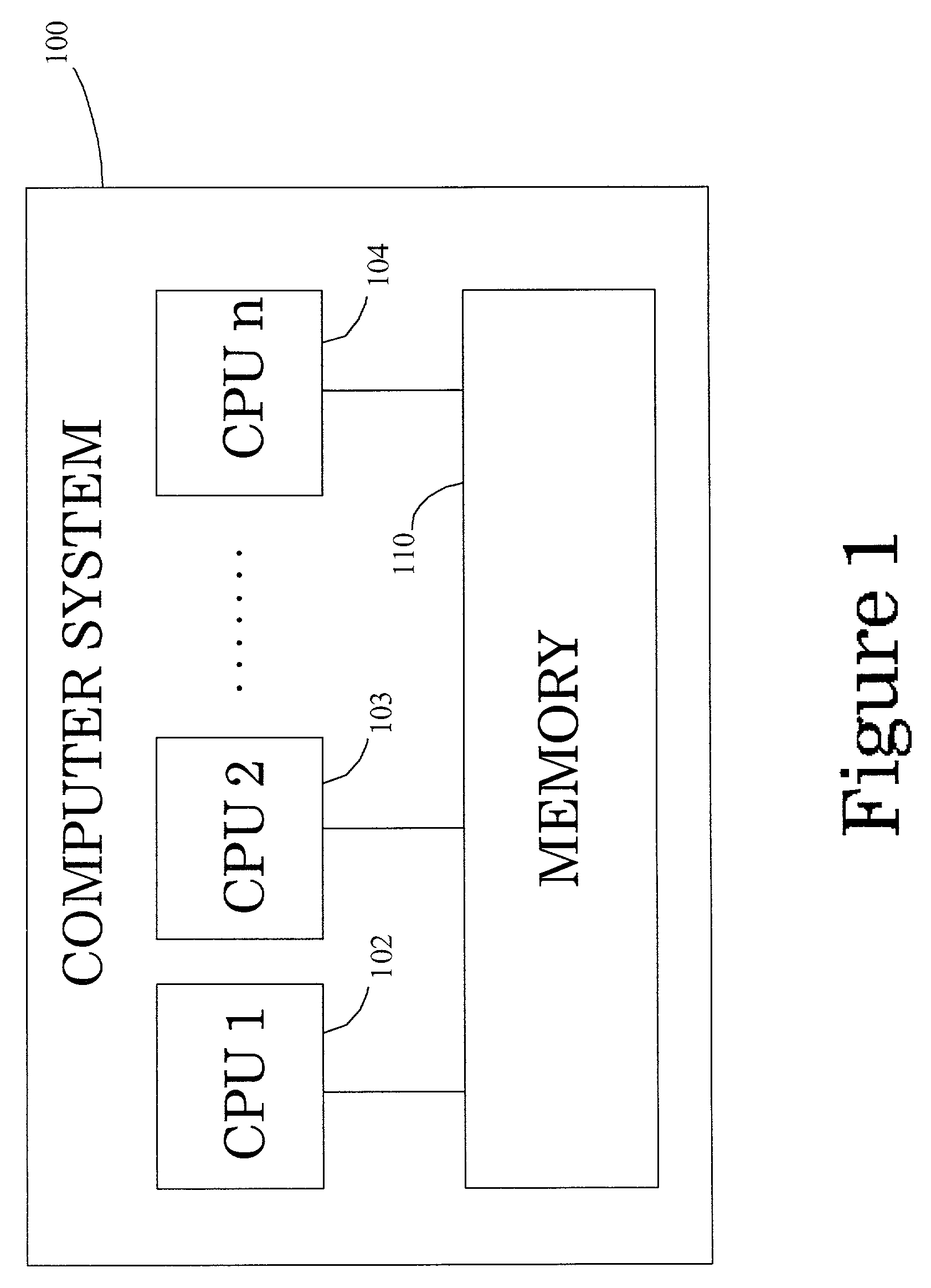

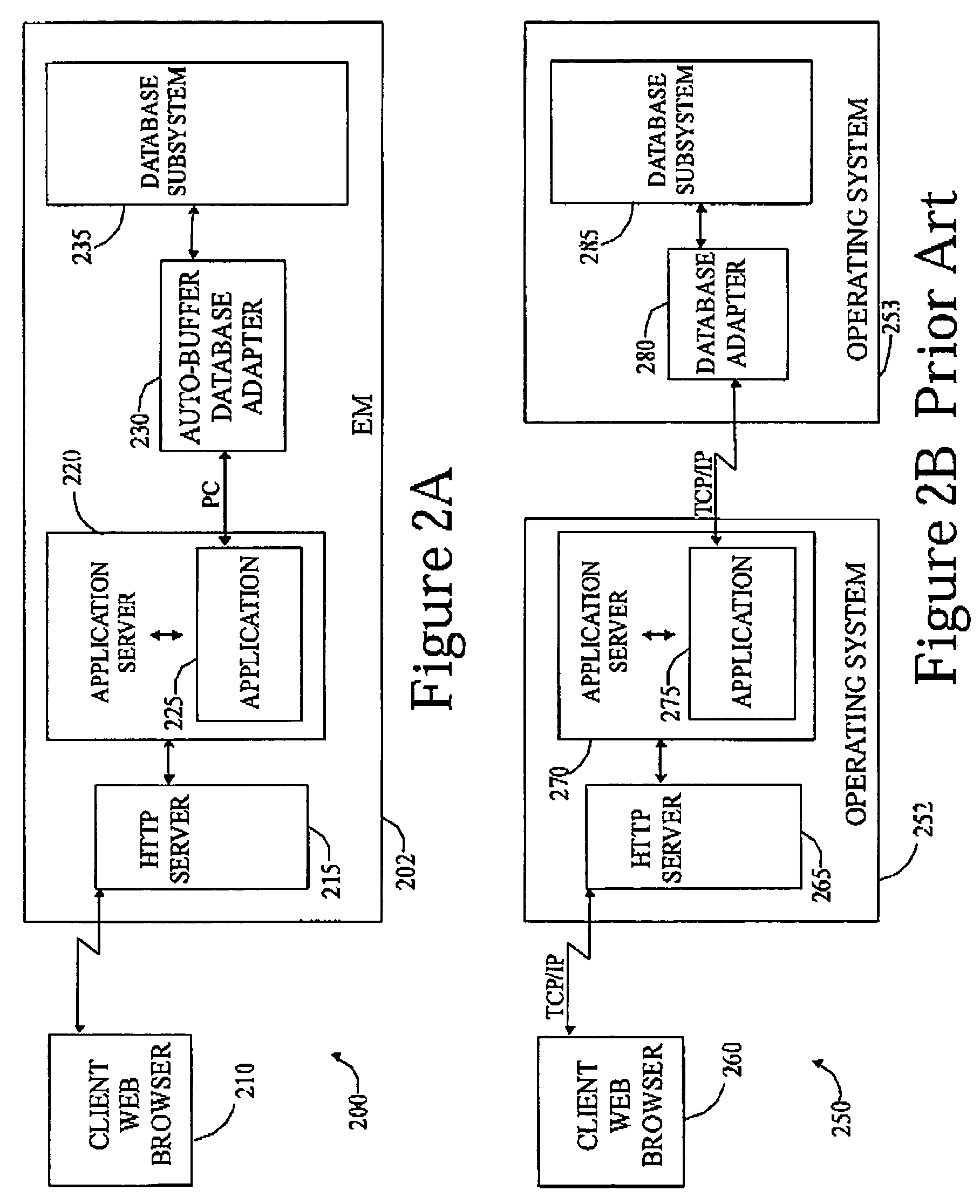

Method, computer program product, and system for automatic application buffering

InactiveUS7266622B2Efficient utilization of system resourceLess programming effortData processing applicationsMultiprogramming arrangementsApplication serverApplication software

A buffer accessible by an application executing under an application server in a first address space is managed by a database adapter executing in a second address space. A data request from the application executing in said first address space, comprising a buffer locator in the empty state, is received by the database adapter executing in the second address space. A buffer is allocated in the first address space and the address of this buffer is stored in the buffer locator. Data associated with the data request, received from a database subsystem, is copied to the buffer. Control is then transferred back to the application whereby the application utilizes the buffer locator to access the buffer and process the data contained therein. A database adapter automatically managing application buffers across address spaces in accordance with the present invention may be referred to as an “auto-buffer database adapter”.

Owner:GOOGLE LLC

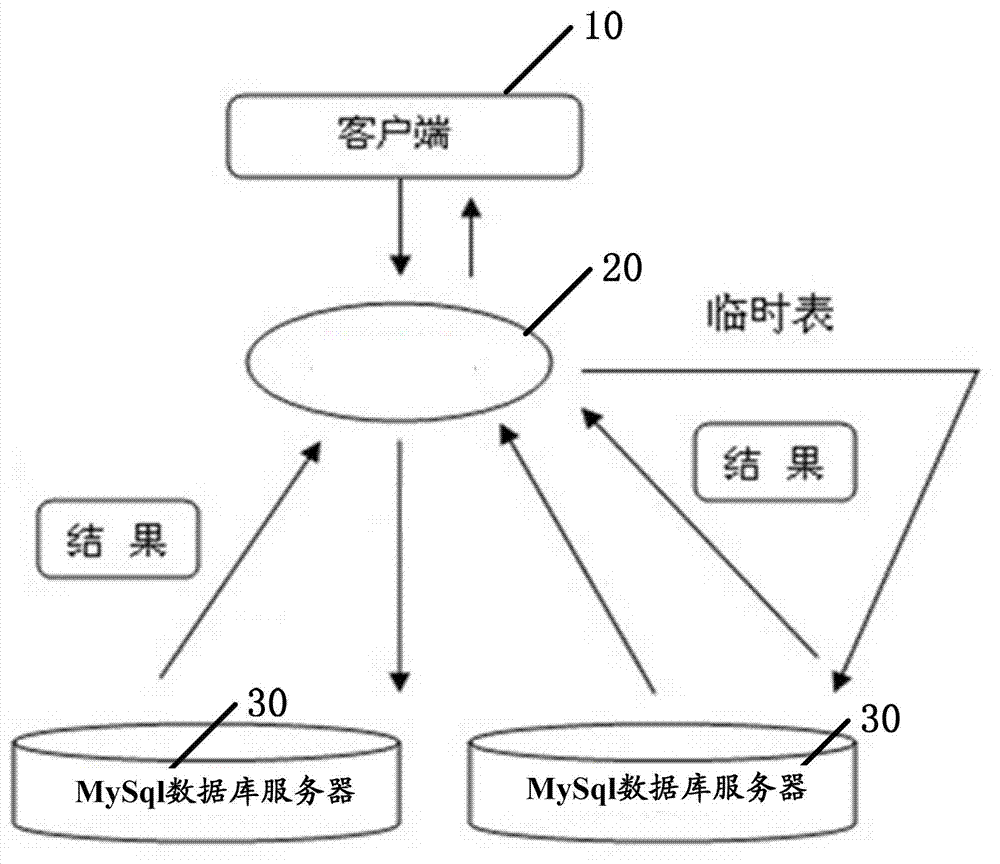

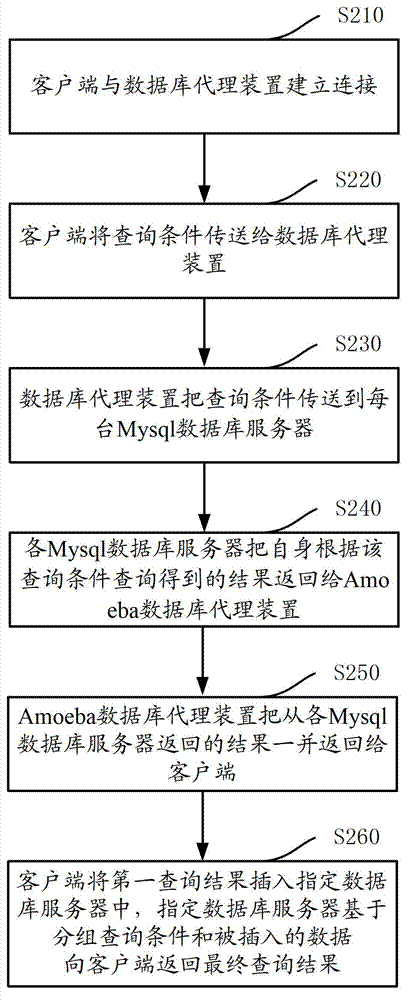

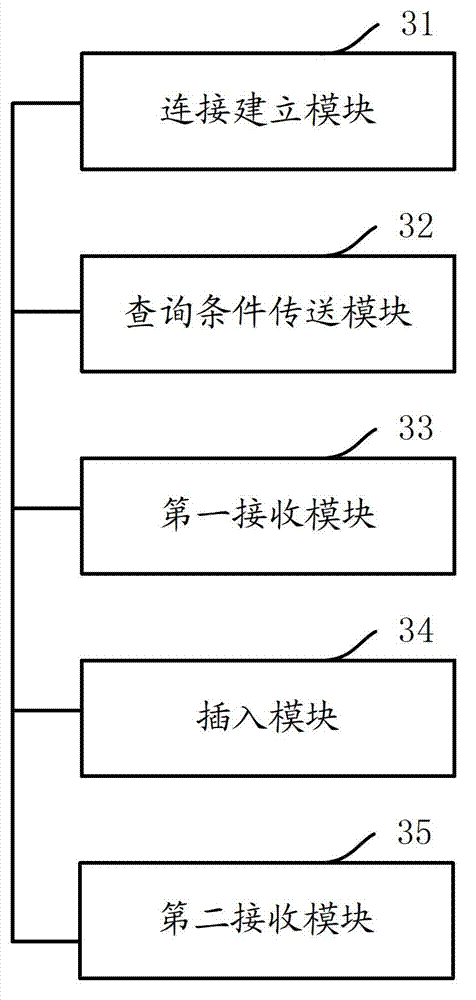

Clustered data query method, client side and system

ActiveCN103116655AImprove processing efficiencyReduce query response latencySpecial data processing applicationsClustered dataDatabase server

Owner:SHENZHEN GLOBEBILL TECH CO LTD

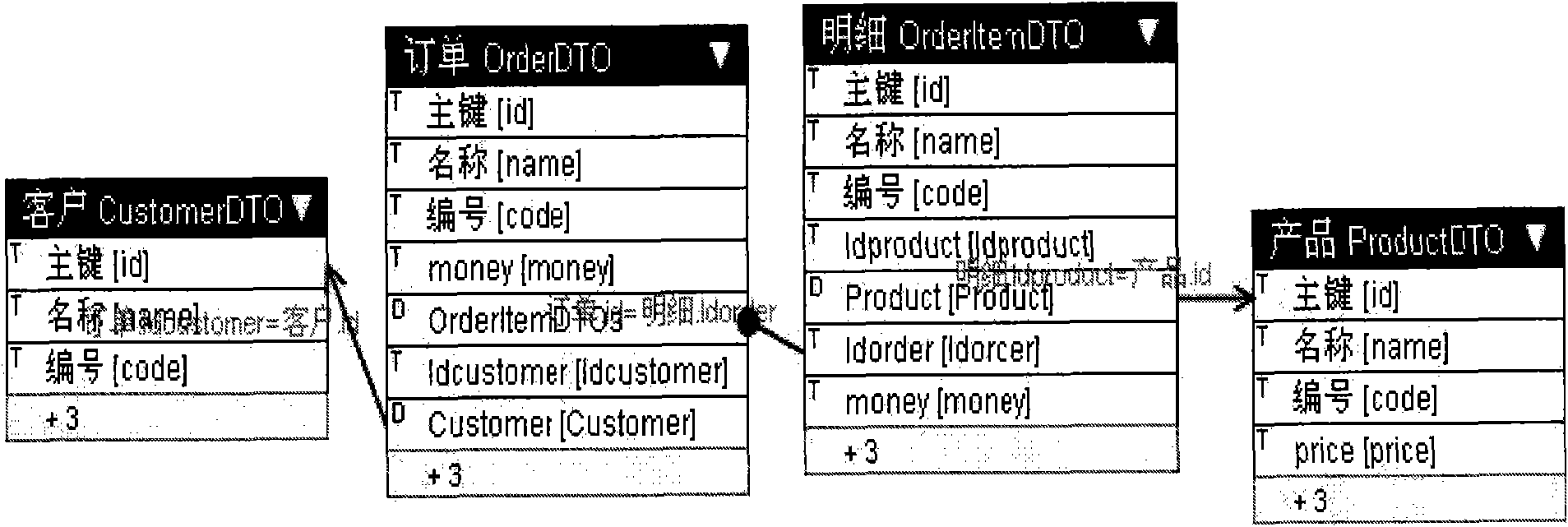

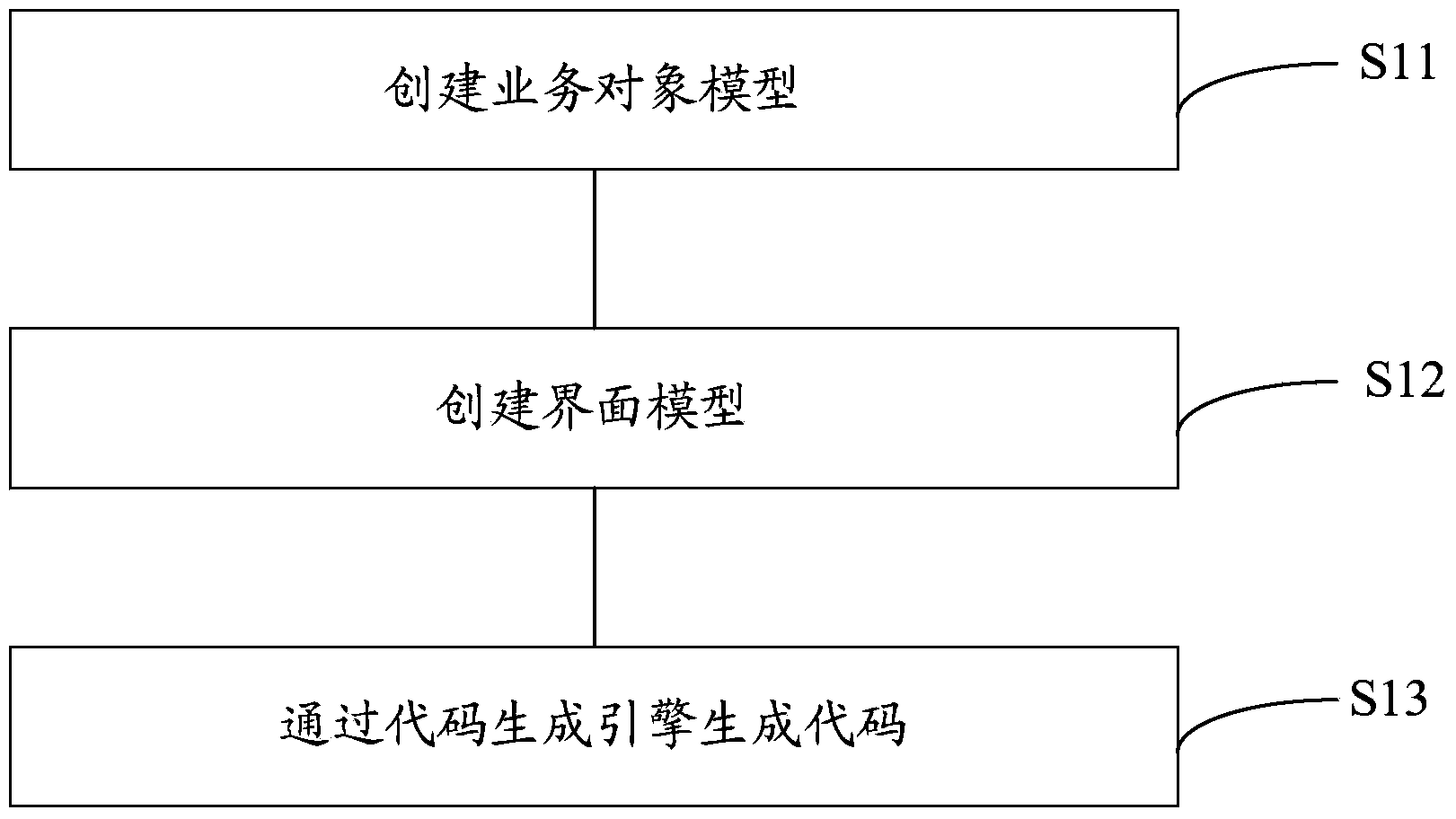

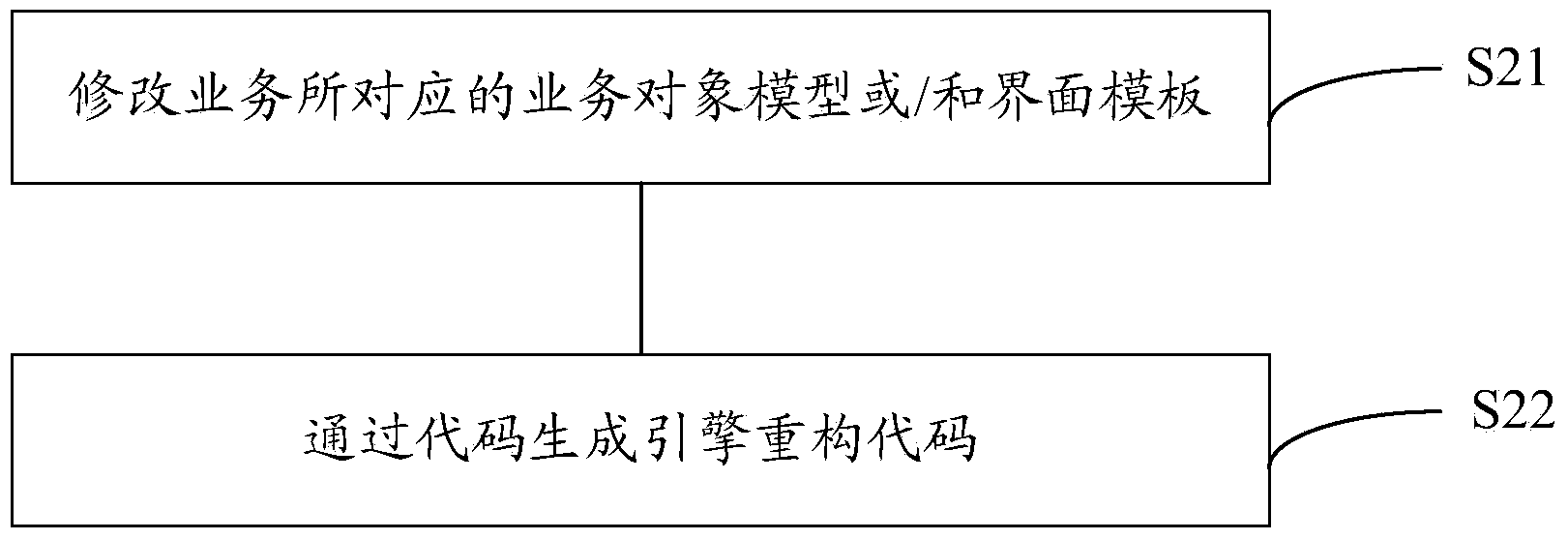

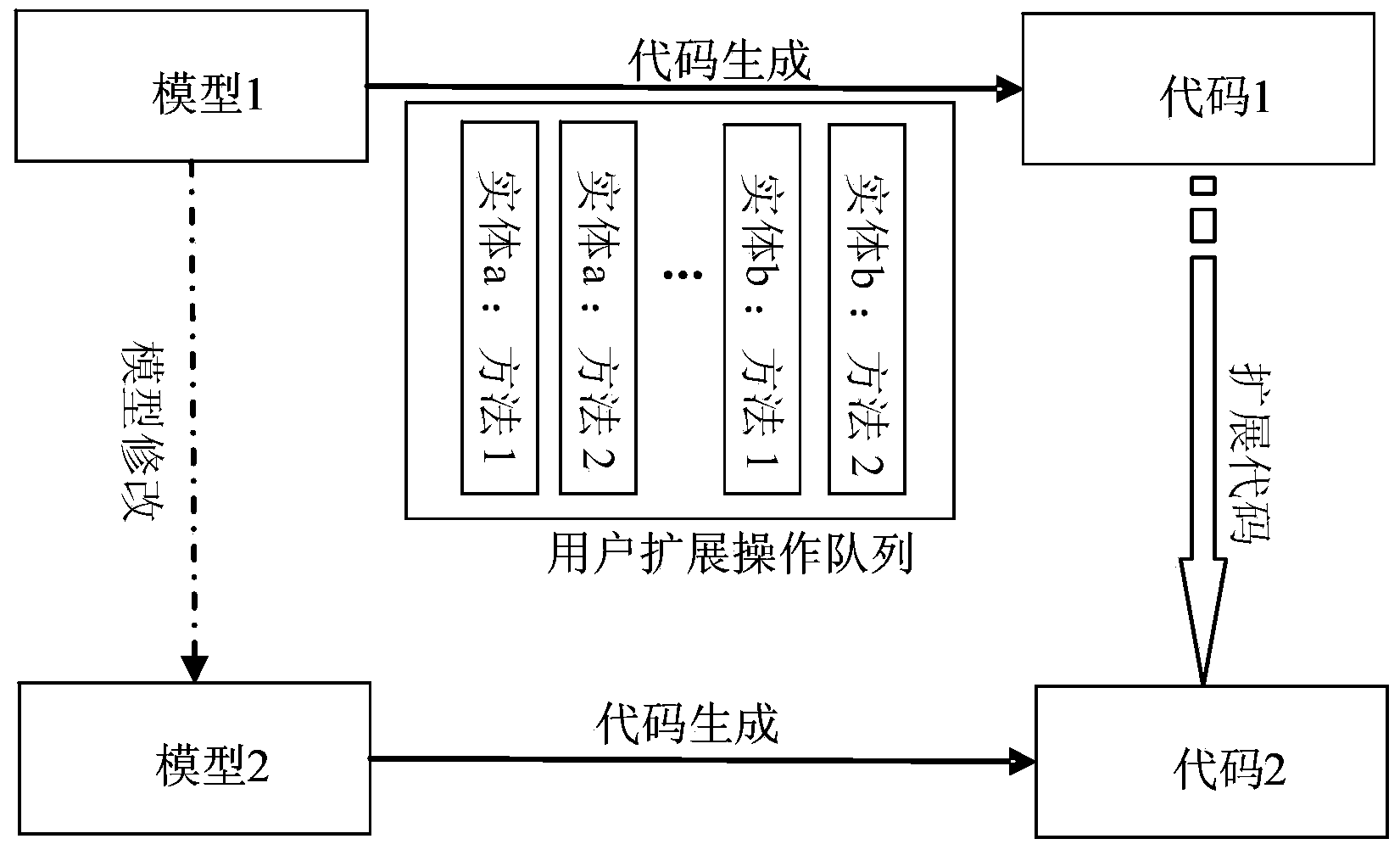

Method and device for generating codes

ActiveCN103593197ALess programming effortImprove development efficiencySpecific program execution arrangementsObject modelApplication software

The invention provides a method and device for generating codes. The method comprises the steps that service object models are created for all services of the Web application, wherein creation of the service object models comprises creation of service entities of the services and creation of associated relations of all service entities; an interface model is created for the Web application, wherein the interface model comprises interface templates corresponding to the service entities in the service object models; the codes are generated by a code generation engine according to the service object models and the interface model. Due to the fact that the service object models of all services of the application are created, the interface model of the application is created, and then the codes are generated by the code generation engine according to the service object models and the interface model, developers can obtain needed program codes through the code generation engine after creating the service object models and determining display forms of all services in the interface of application software, a large amount of programming work of the developers is omitted, and further application development efficiency is effectively improved.

Owner:STATE GRID CORP OF CHINA +2

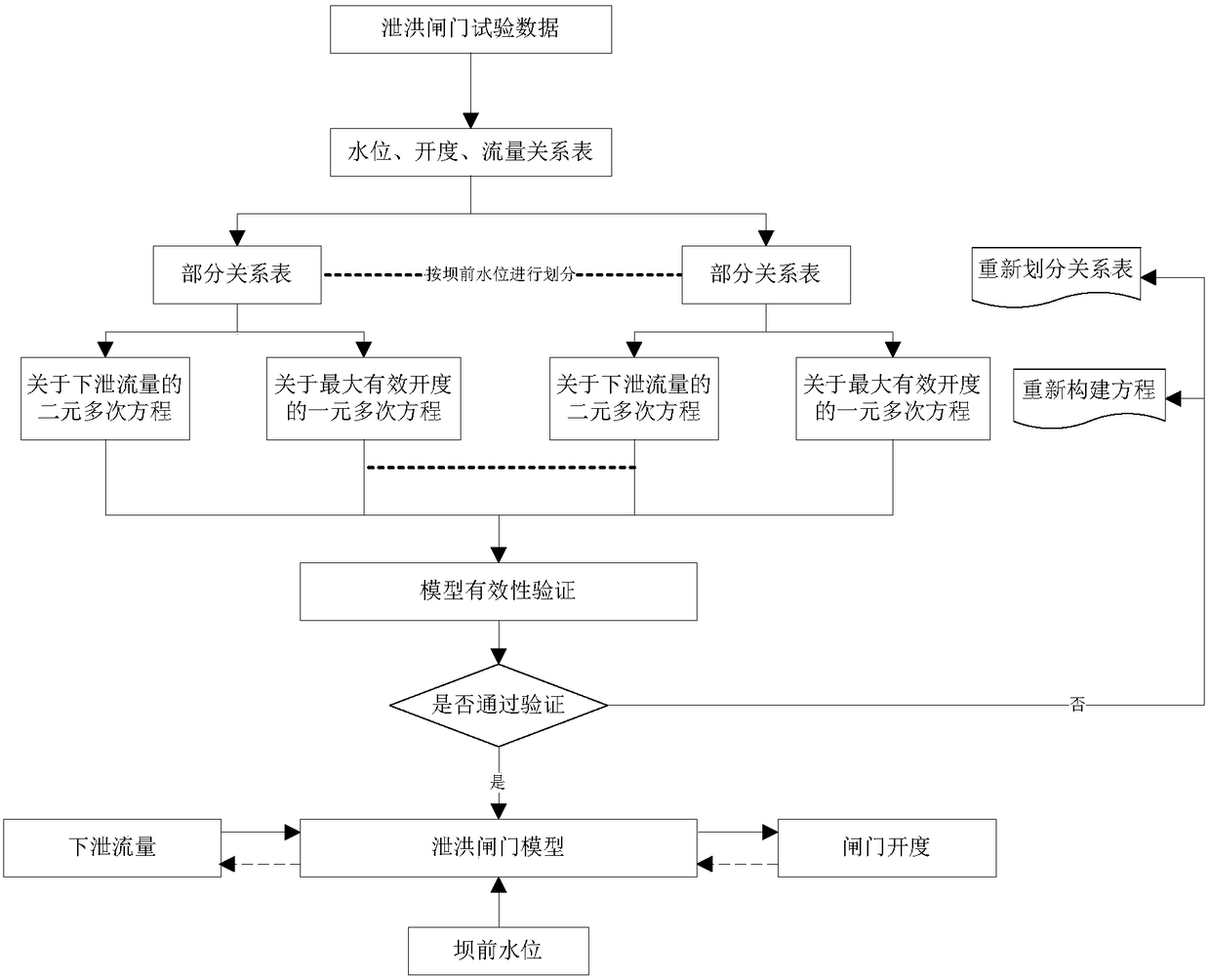

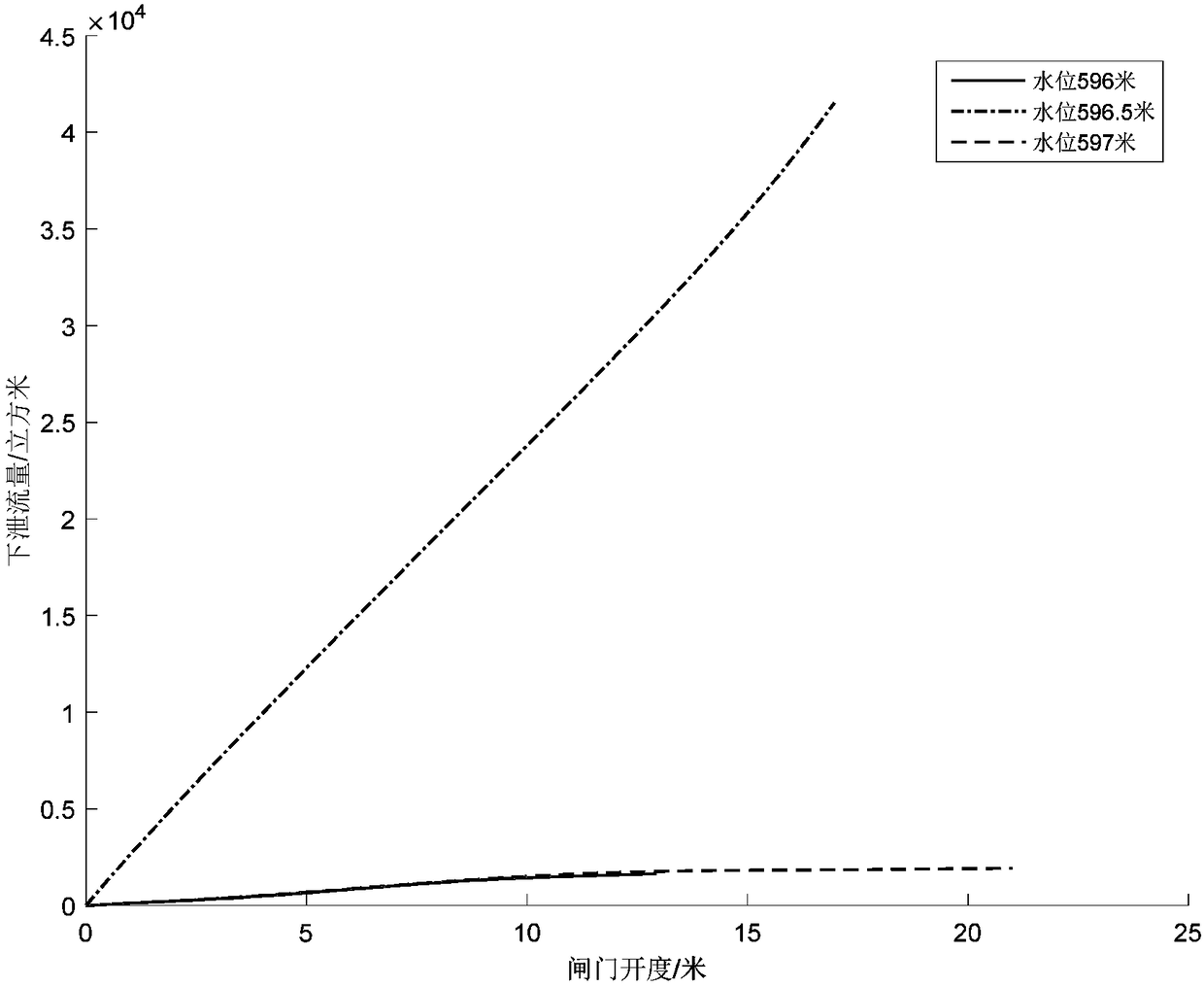

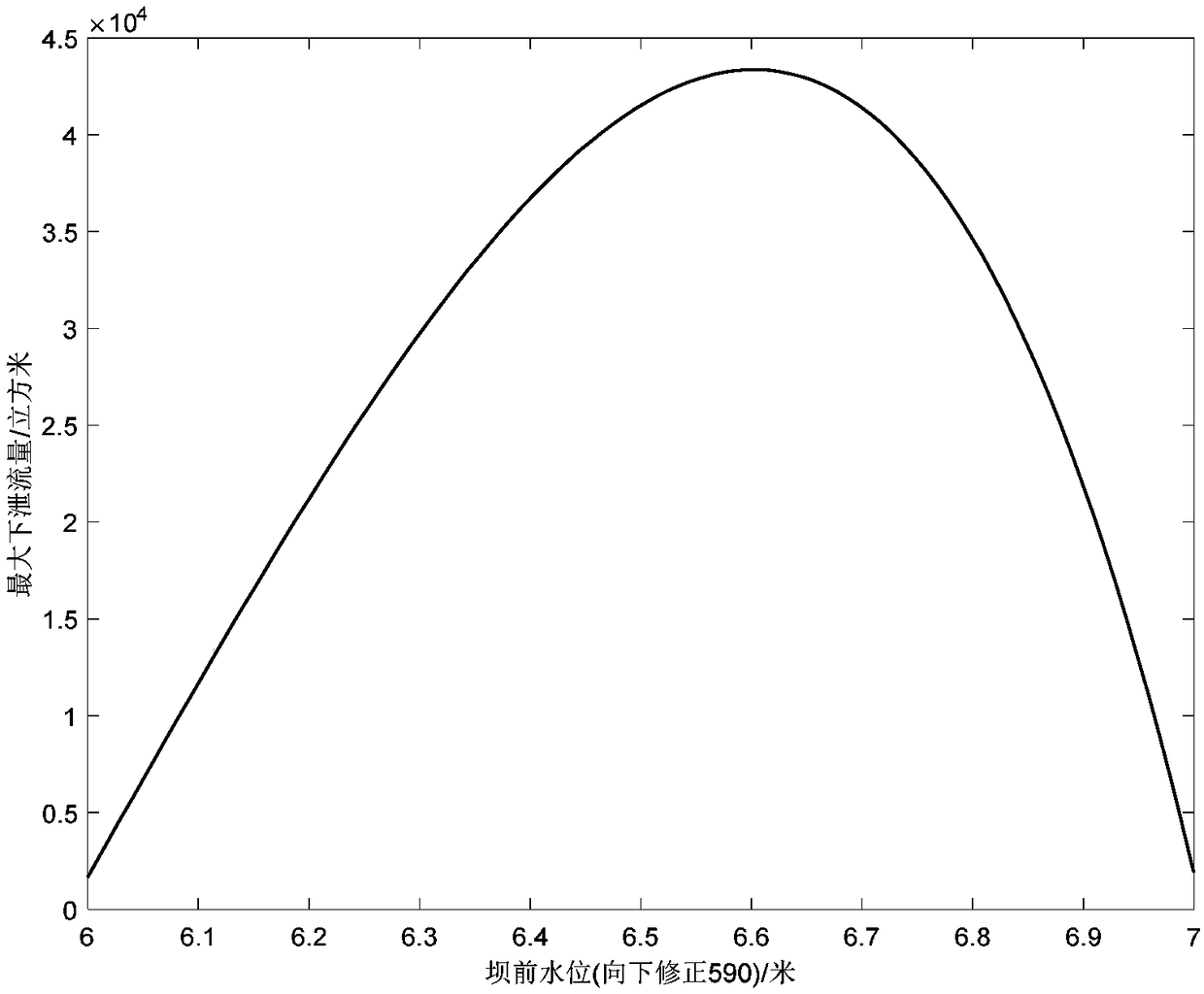

Hydropower station flood discharge gate modeling and calculating method based on multiple regression algorithm

The invention discloses a hydropower station flood discharge gate modeling and calculating method based on a multiple regression algorithm. A flood discharge gate model with three variables includingthe dam front water level, the gate opening degree and the discharge flow is established according to the water level, opening degree and flow relation table of a flood discharge gate; one of the twovariables including the gate opening degree and the discharge flow is calculated according to the other and the dam front water level through the flood discharge gate model for different requirementsof different links of automatic water supplementation. The high-precision calculation of the dam front water level, the gate opening degree and the discharge flow is realized, the high-precision calculation of the dam front water level, the discharge flow and the gate opening degree is also realized, and the model effectiveness and tendency correctness are remarkably improved when the number, correctness and precision of test data are improved.

Owner:HUANENG LANCANG RIVER HYDROPOWER

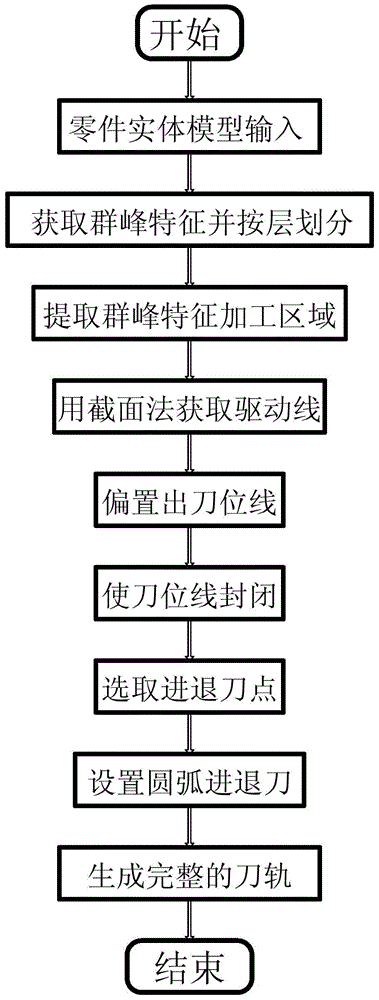

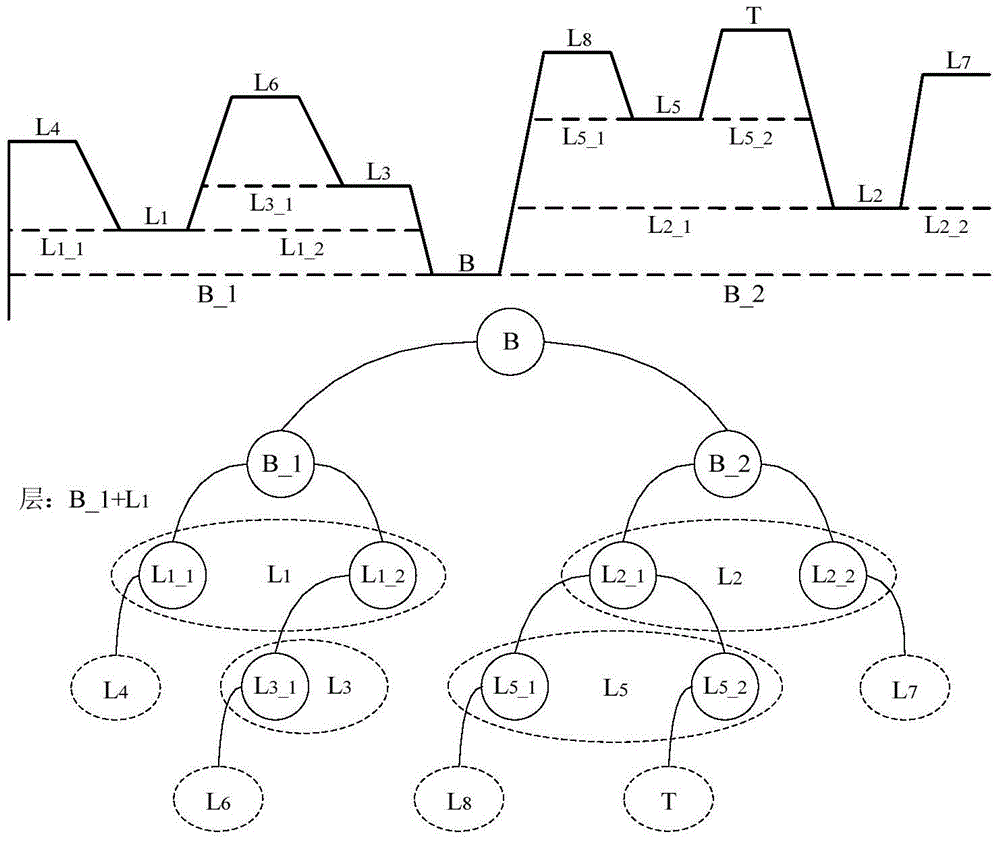

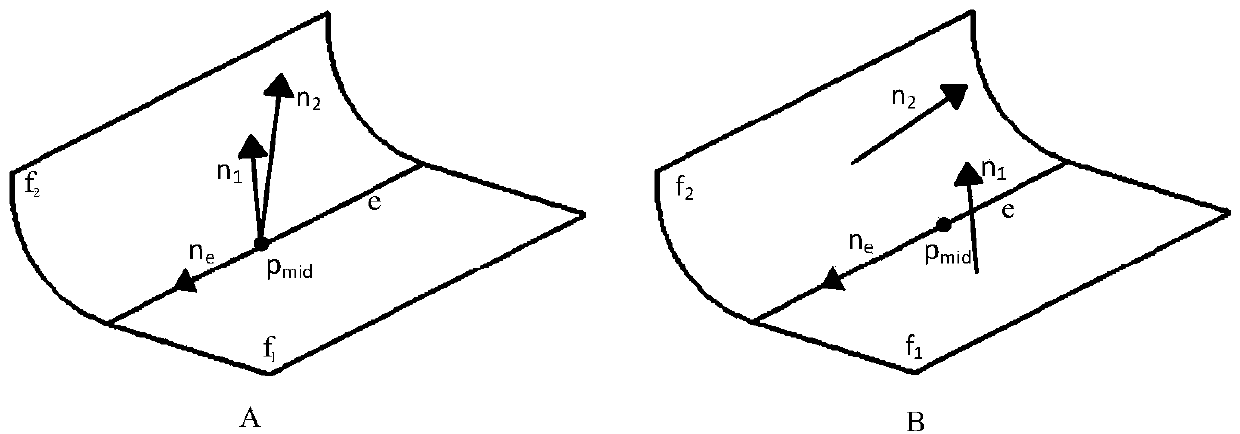

Method for determining self-adaptive outline surrounding milling tool path according to peak characteristics of complex structural member

ActiveCN103984289AHigh speedImprove accuracyProgramme controlComputer controlEngineeringMachining process

A method for determining a self-adaptive outline surrounding milling tool path according to the peak characteristics of a complex structural member is characterized by including the steps of firstly, setting up a machining coordinate system of a part, obtaining the peak characteristics in the part, dividing the peak characteristics according to layers, and obtaining a machining area of each layer; secondly, obtaining a driving line of each layer through the method of sections, obtaining a tool position line for machining through the offset method, adding the required tool advancing and retracting mode, and generating the complete machining tool path. The milling tool path generated through the method is accurate, the tool void feeding route in the machining process can be reduced, machining efficiency of the part is improved, and meanwhile machining quality of the part can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

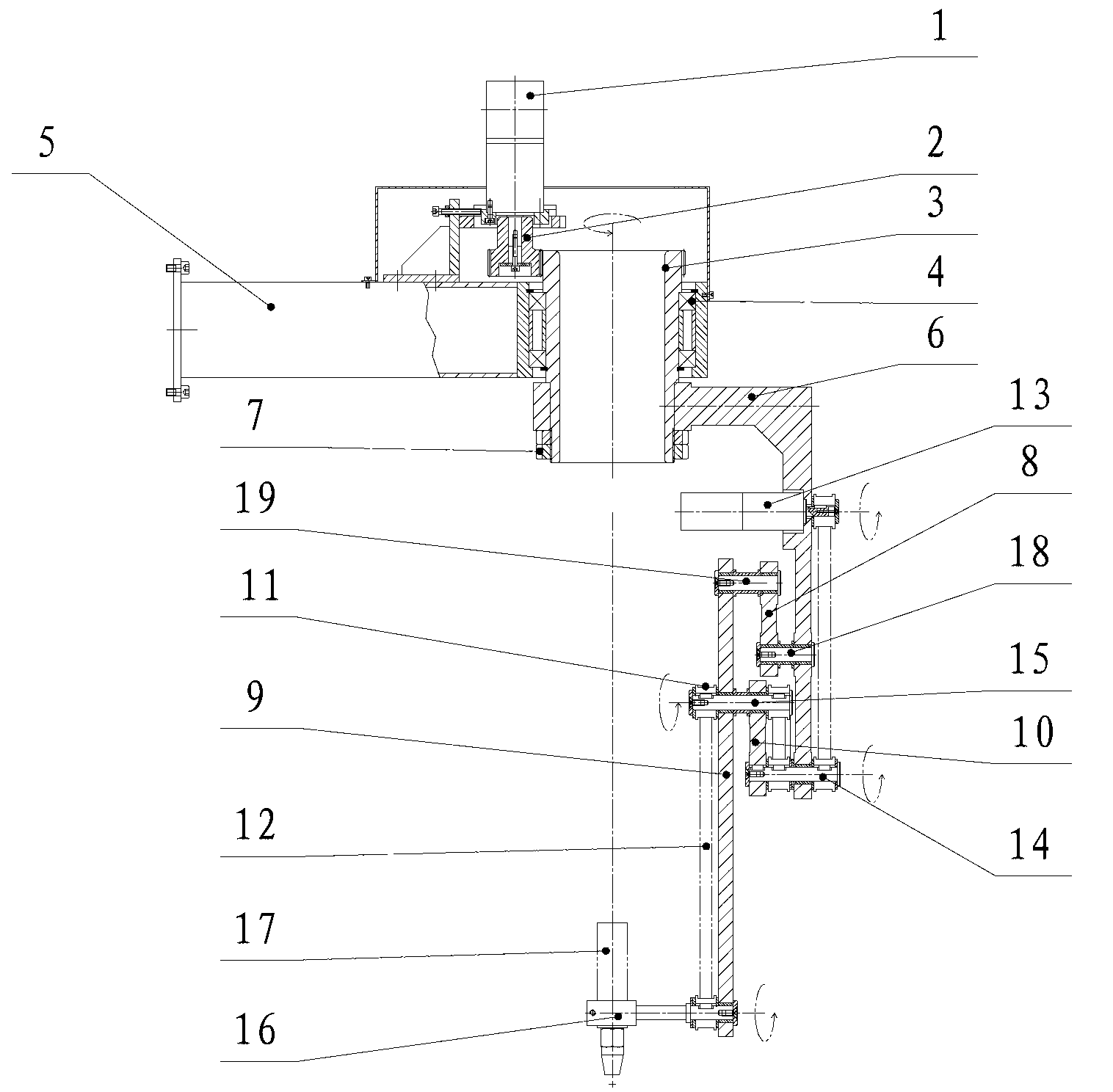

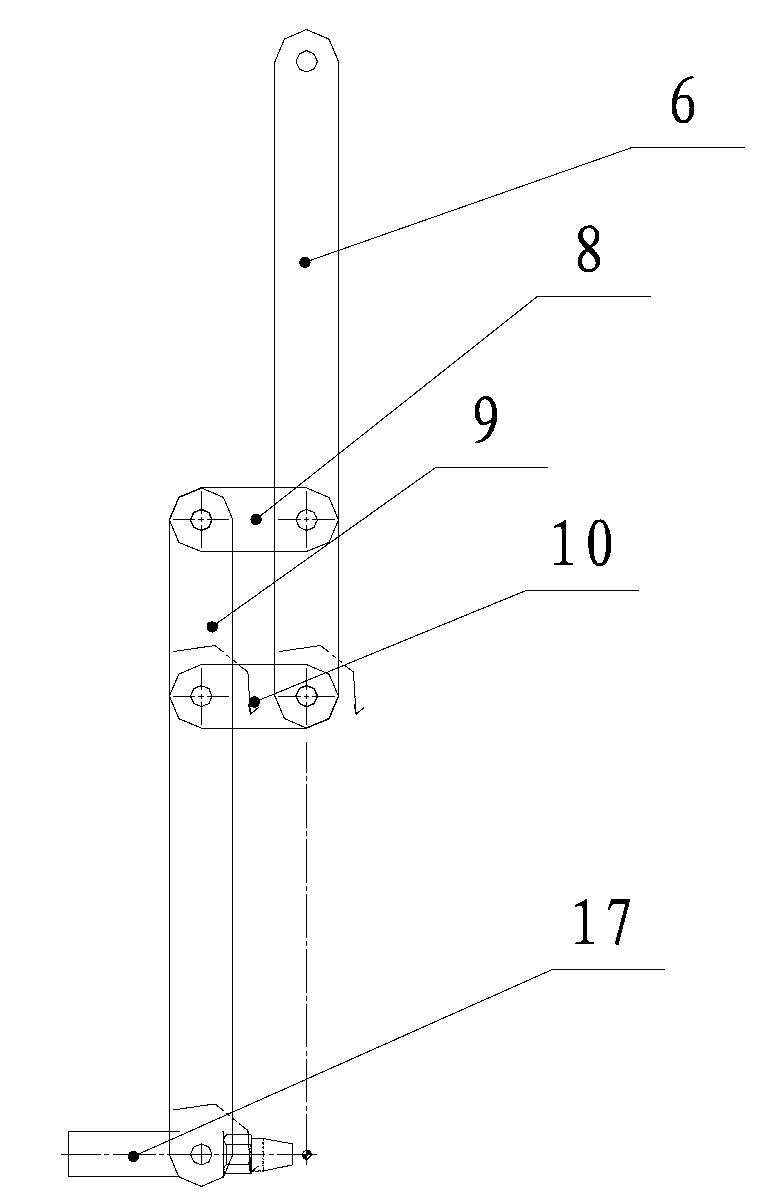

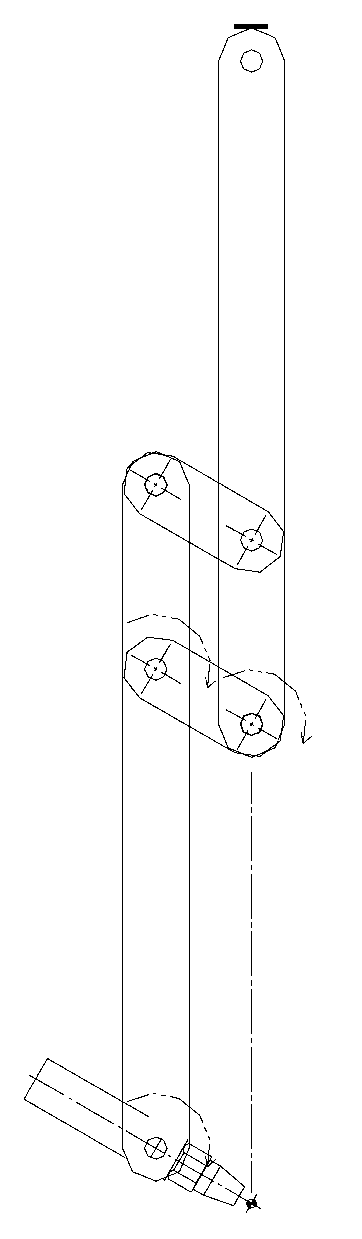

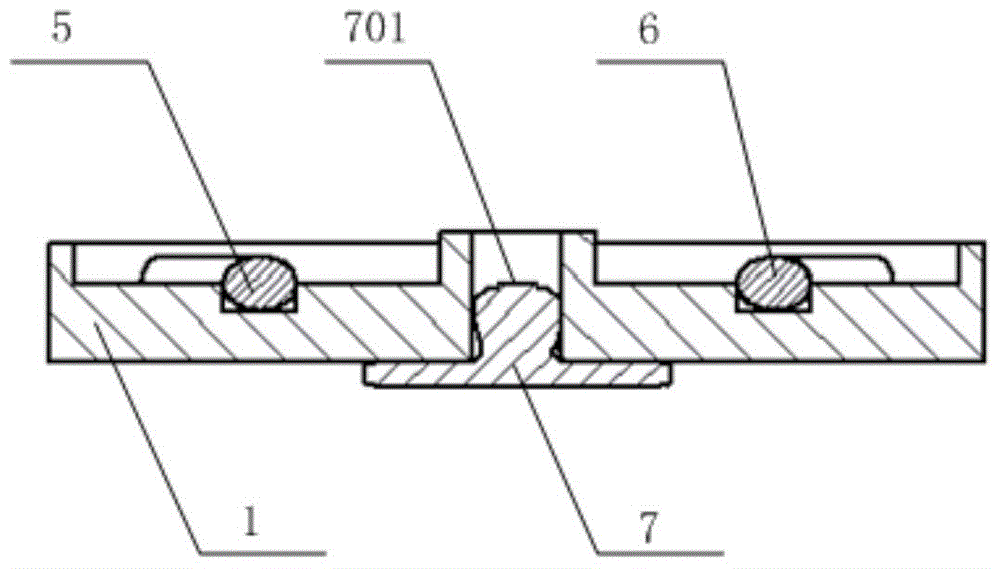

Vertical-type and connecting-rod-type intersecting line cutting head

ActiveCN103157933ASimple electrical controlLess programming effortWelding/cutting auxillary devicesAuxillary welding devicesElectrical controlEngineering

The invention discloses a vertical-type and connecting-rod-type intersecting line cutting head which comprises a main arm, a driven gear shaft and a pivot angle assembly installed on the driven gear shaft. The driven gear shaft is installed on the main arm through a bearing; a rotating speed reduction motor is installed on the main arm. A driving gear installed on the rotating speed reduction motor is meshed with a driven gear installed on the driven gear shaft to drive the driven gear shaft to rotate. A frame is fixed installed on the lower portion of the driven gear shaft through a round nut. The pivot angle assembly is installed on the frame. + / -90 degrees of an accurate pivot angle of a cutting torch is achieved through a four-connecting-rod mechanism of the pivot angle assembly. Mechanism motion needed by pipe cutting can be achieved through the combination of a rotating mechanism and the pivot angle assembly. The vertical-type and connecting-rod-type intersecting line cutting head guarantees a constant height position of a cutting point in the lifting process of the pipe; and because only a rotating shaft and a pivot angle shaft are linked, electrical control is relatively simple and programming workloads are substantially reduced.

Owner:南京奥特自动化有限公司

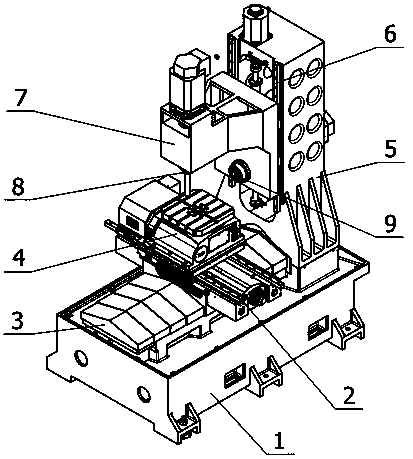

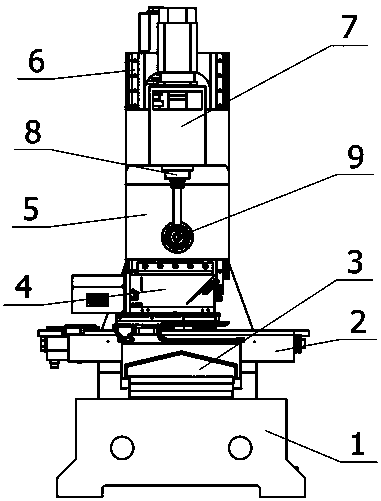

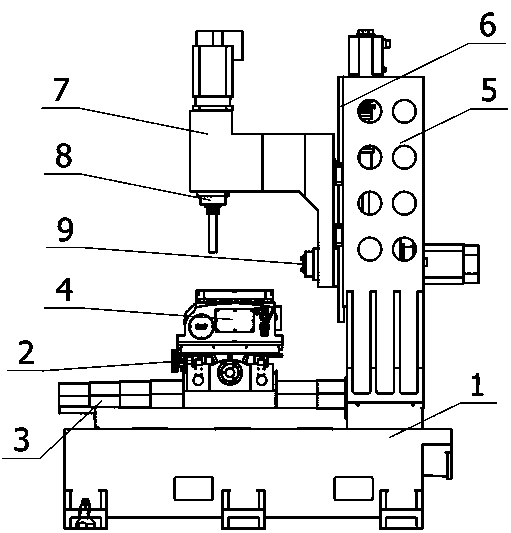

Multi-surface integrated processing center

PendingCN108274248AReduce processing timeReduce precision errorFeeding apparatusLarge fixed membersEngineeringWorkload

The invention discloses a multi-surface integrated processing center. The multi-surface integrated processing center is characterized by only comprising a stand column, wherein a set of Z-axis motionmechanisms is utilized to drive a main shaft mounting frame; a vertical type main shaft and a horizontal type main shaft are simultaneously integrated on a main shaft mounting table; the vertical typemain shaft is mounted on a horizontal extending part of the main shaft mounting frame; the horizontal type main shaft is mounted on a vertical extending part; or the horizontal type main shaft and the vertical type main shaft are integrated on the horizontal extending part. A workpiece is mounted on a workbench which rotates by 360 degrees, and the rotary workbench is additionally arranged on a rail of an axis X and a rail of an axis Y. The multi-surface integrated processing center can complete processing processes for the top surface and four side surfaces of the workpiece once, does not need to re-clamp the workpiece halfway, reduces replacement time, and solves the problem that precision is reduced as the workpiece is clamped by many times. According to the multi-surface integrated processing center disclosed by the invention, one stand column and one set of Z-axis lifting mechanisms are adopted, so that equipment cost is reduced, programming simplification is facilitated, and programming workload of an operator is reduced.

Owner:宁波江北百吉机械有限公司

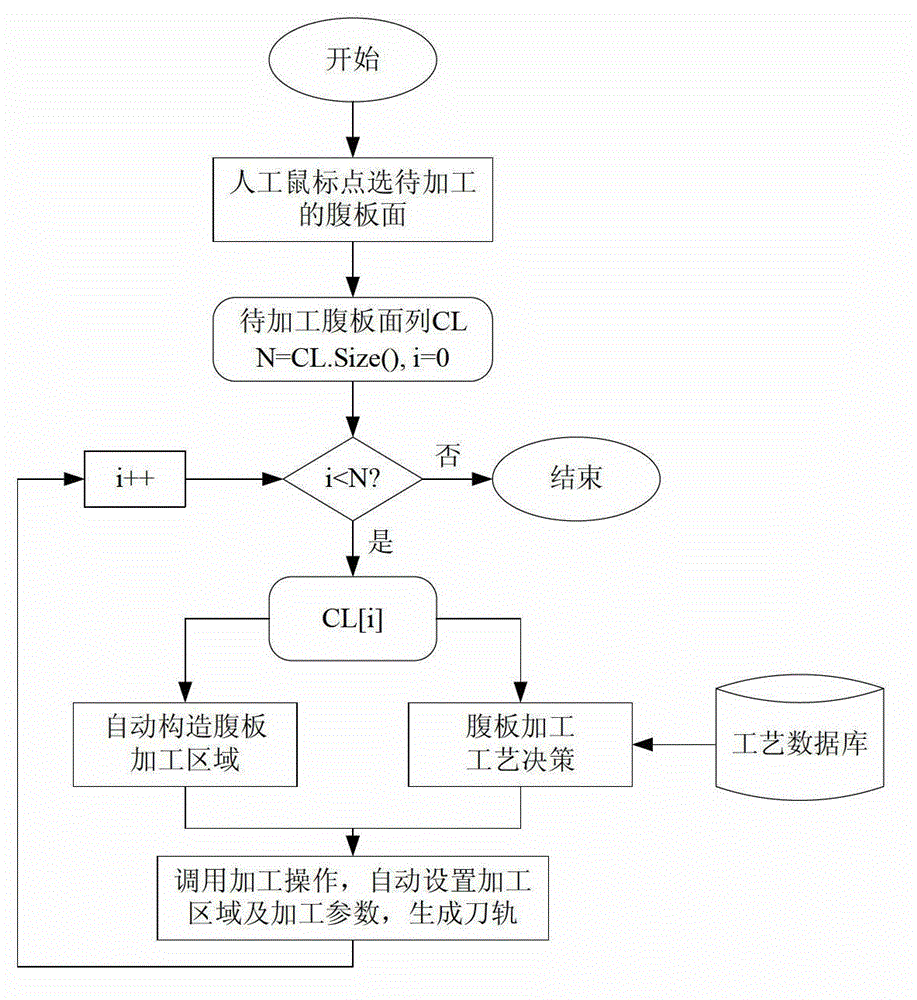

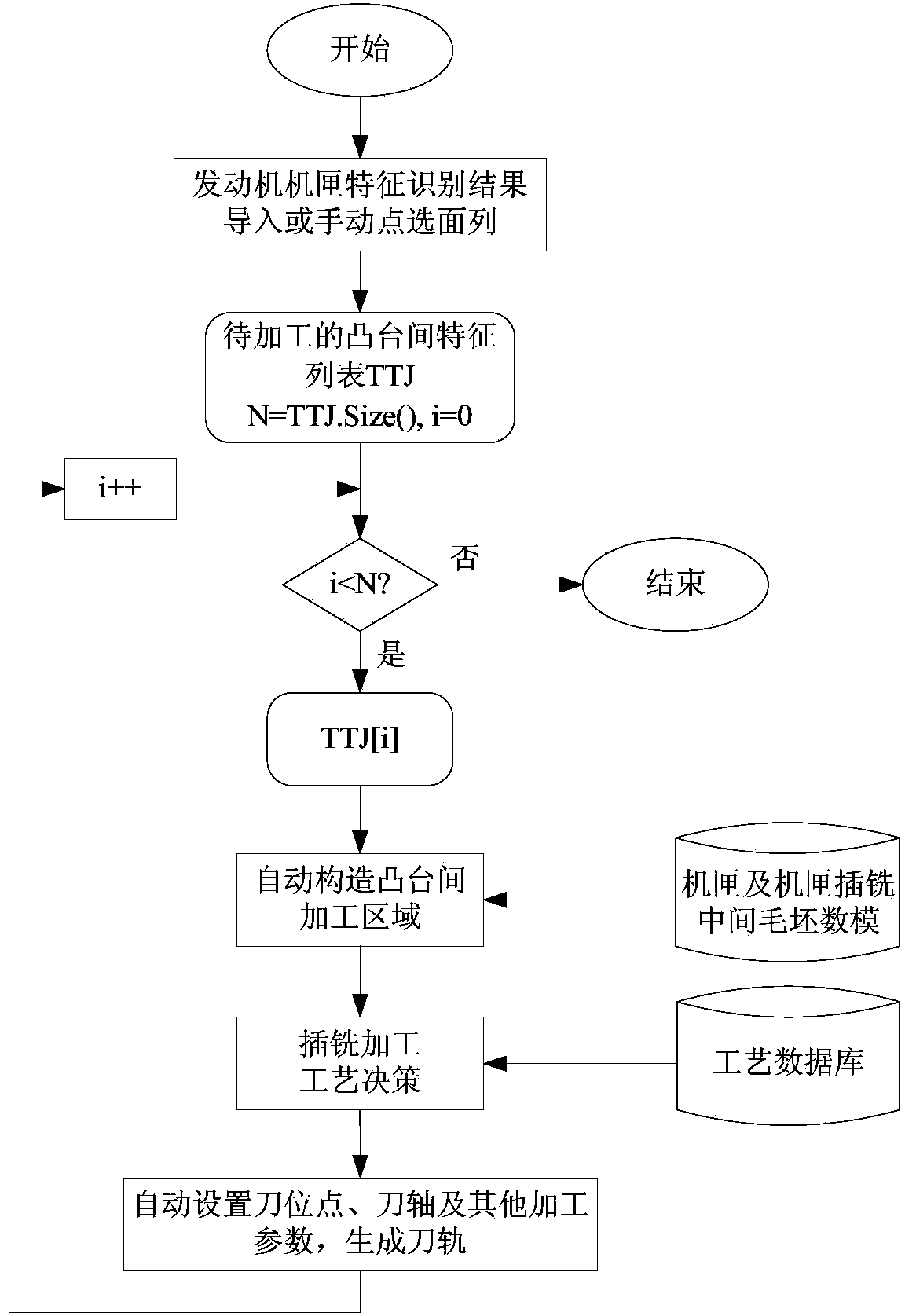

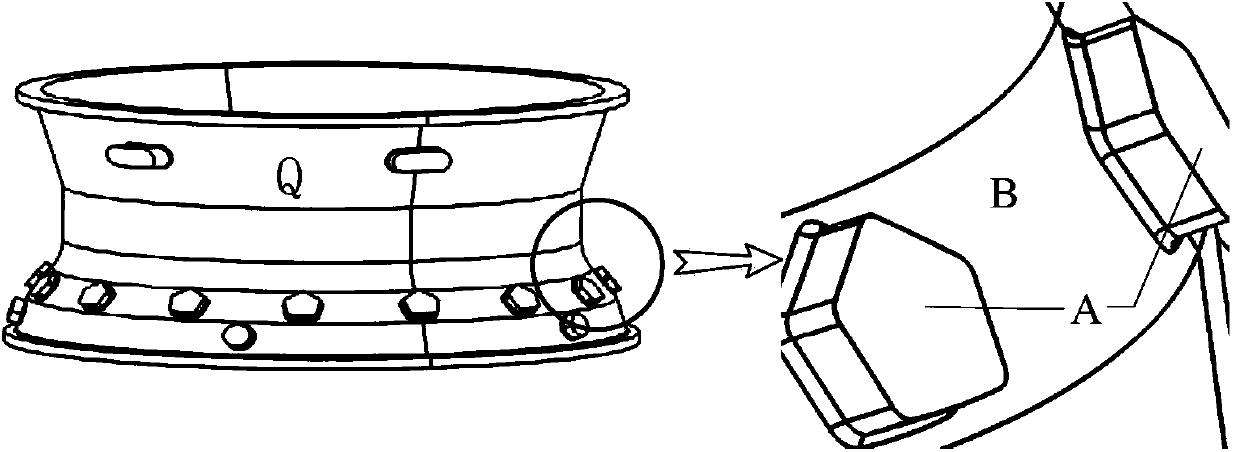

Casing boss channel machining method based on characteristics

ActiveCN104216335ALess programming effortMeet different needsProgramme controlComputer controlWorkloadMachining process

A casing boss channel machining method based on characteristics is characterized by including casing model and casing boss characteristic information, establishing a boss channel machining region automatically, selecting automatically generating or manually inputting machining process information of machined boss characteristics, and finally generating rough and fine machining tracks automatically. The method can be applied to rough and fine machining of boss channels, the cutter track calculating efficiency is high, the correct rate is high, the flexibility is high, the programming workload of engineering staffs is reduced greatly, single or batched multiple boss channels can be machined, and the different requirements of the engineering staffs can be met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

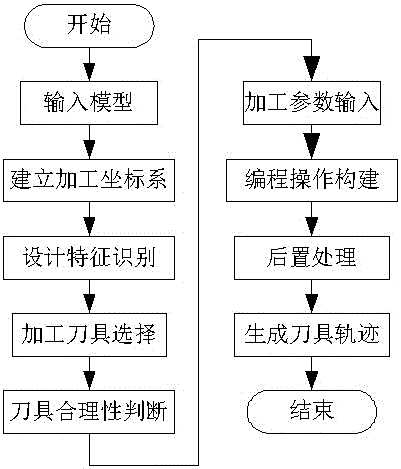

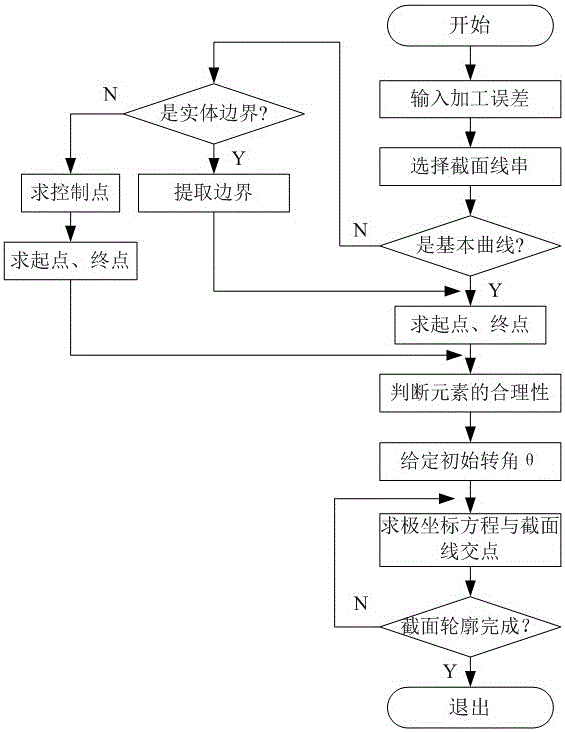

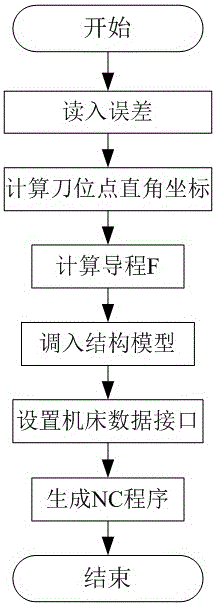

Non-cylindrical curved surface numerical control turning processing automatic programming method

InactiveCN106774169AJudgment of fitnessAdaptableProgramme controlComputer controlNumerical controlEntity model

The invention relates to the field of numerical control processing in the aspect of machine manufacturing, and discloses an intelligent and automatic compilation method for a non-cylindrical curved surface numerical control turning processing program. The method aims at a wireframe model, a curved surface model and an entity model part, and information such as processed non-cylindrical curved surface is acquired by performing feature identification on the models. A processing coordinate system is set, a cutting cutter is defined, and a cutting parameter is set. Processing adaptability detection is conducted, non-cylindrical curved surface numerical control turning intelligent programming operation is defined, interpolate points are calculated, and a processing program is generated through post-processing. By the numerical control turning processing automatic and intelligent programming method, the processing range of a numerical control lathe is enlarged, and programming quality and efficiency are improved, so that part processing quality and efficiency are improved.

Owner:SHENYANG INST OF ENG

Internal business data system and processing method of enterprise

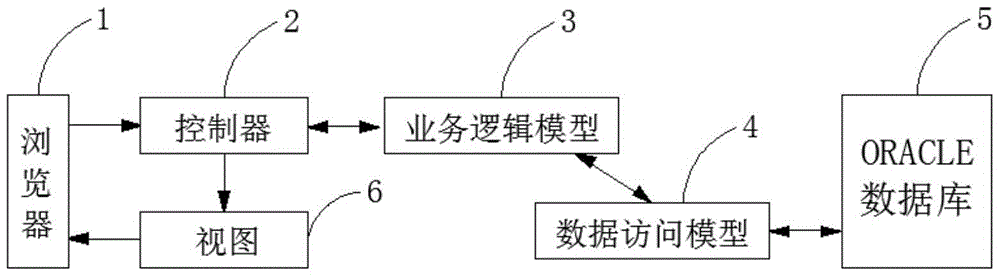

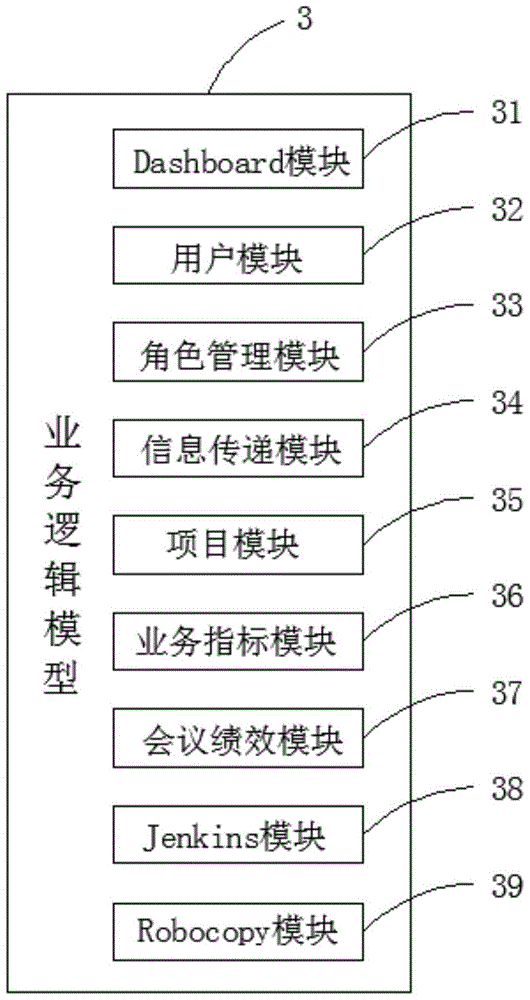

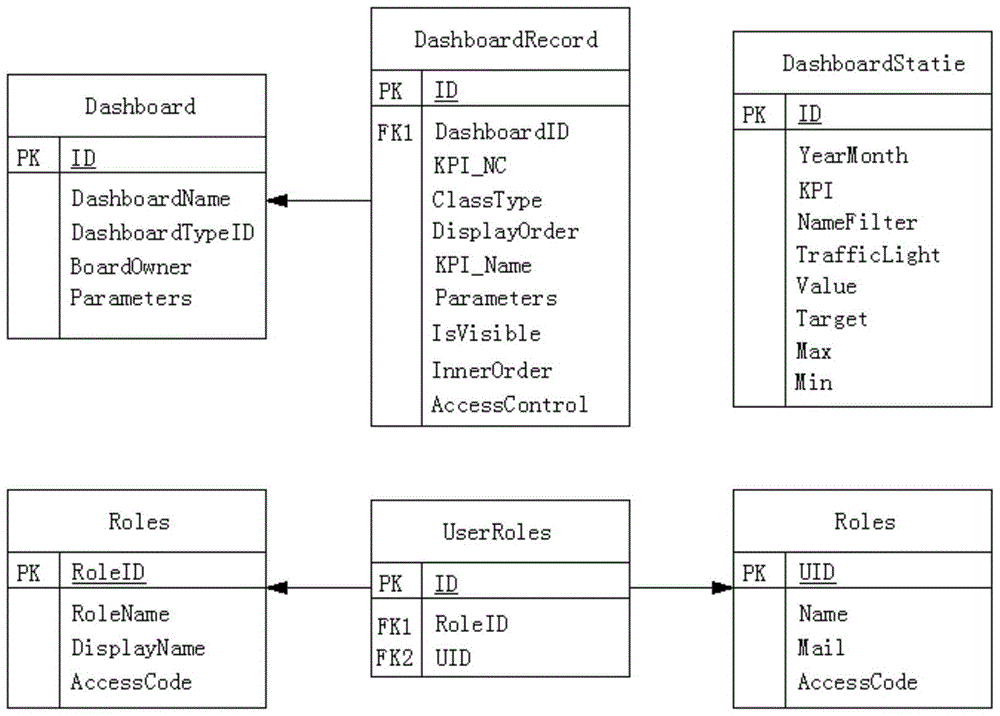

ActiveCN105701220AImprove reuseFacilitate the development of sub-modulesRelational databasesSpecial data processing applicationsOriginal dataMaintainability

The invention relates to an internal business data system and method of an enterprise. The system comprises a browser used for sending a data request to a controller, the controller used for forwarding the data request to a business logic model and also for transmitting the business data to a view, the business logic model used for requesting a data access model of data access according to the data request and also for carrying out business logic processing on verified and assembled original data to obtain business data, the data access model used for accessing the data of an ORACLE database through a ODAC module and also for verifying and assembling the original data according to a corresponding entity class, the ORACLE database used for retrieving the original data to the data access model, and the view used for presenting business data to a user. Compared with the prior art, the system and the method, provided by the invention, have the advantages of reducing workload, improving the reuse rate of codes, facilitating module-based development, enhancing the maintainability and cost of programs and realizing timely updating of version and data.

Owner:周敏

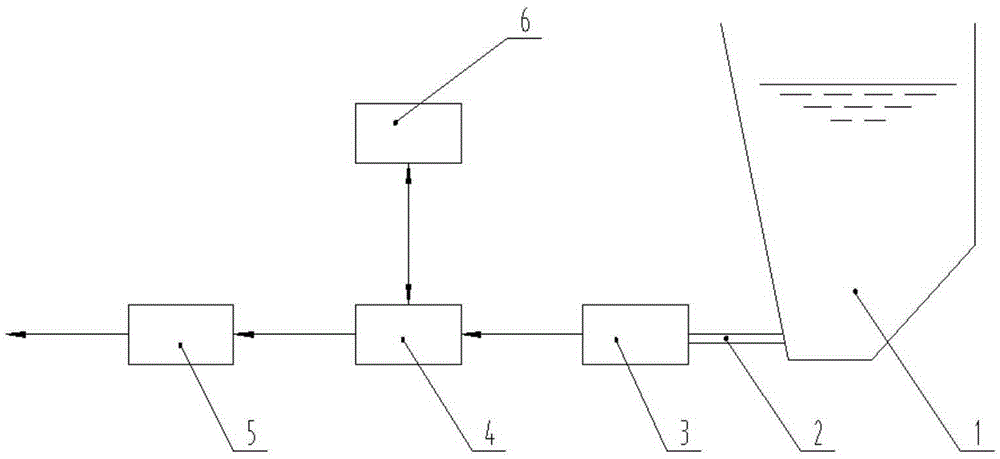

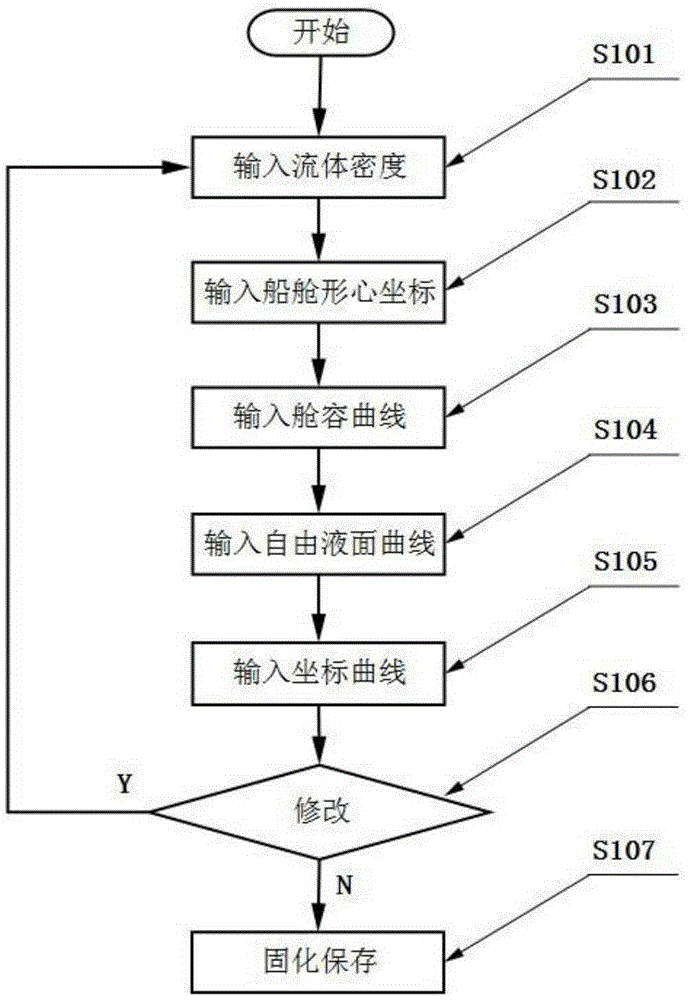

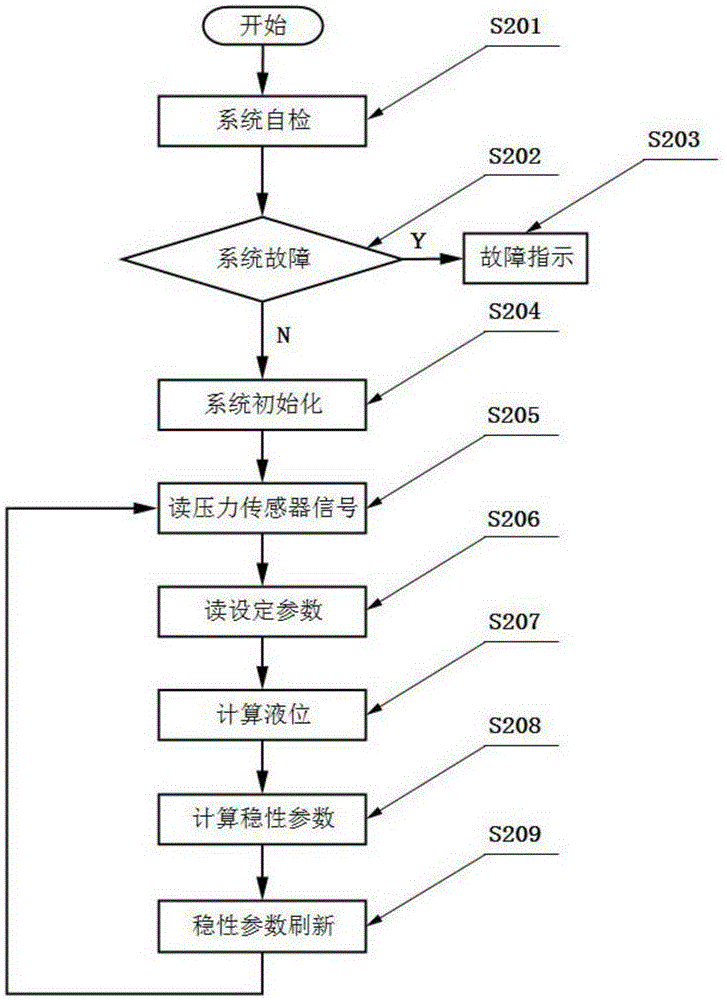

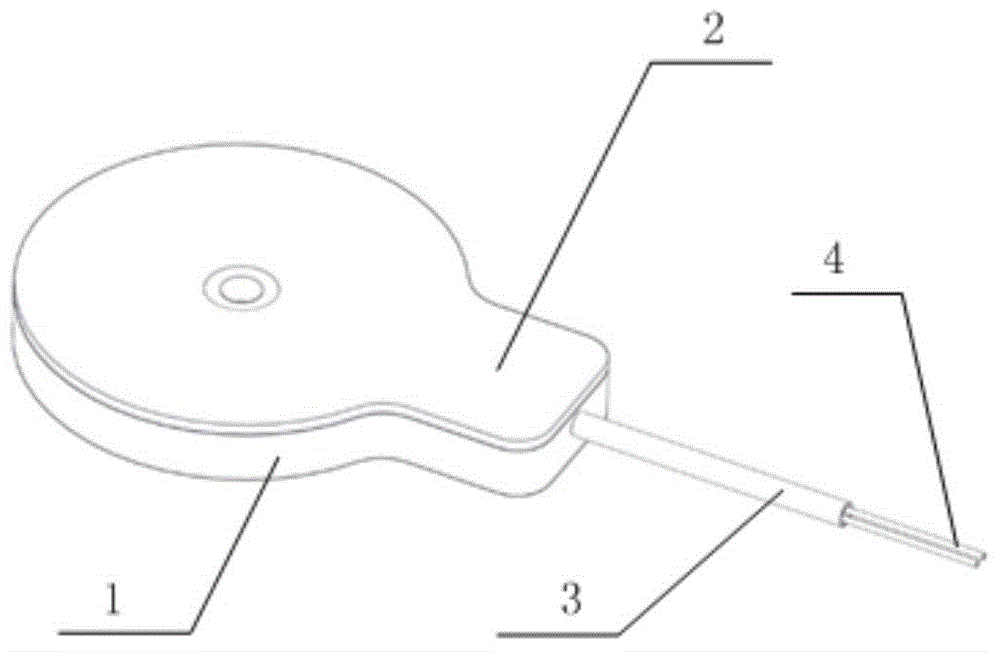

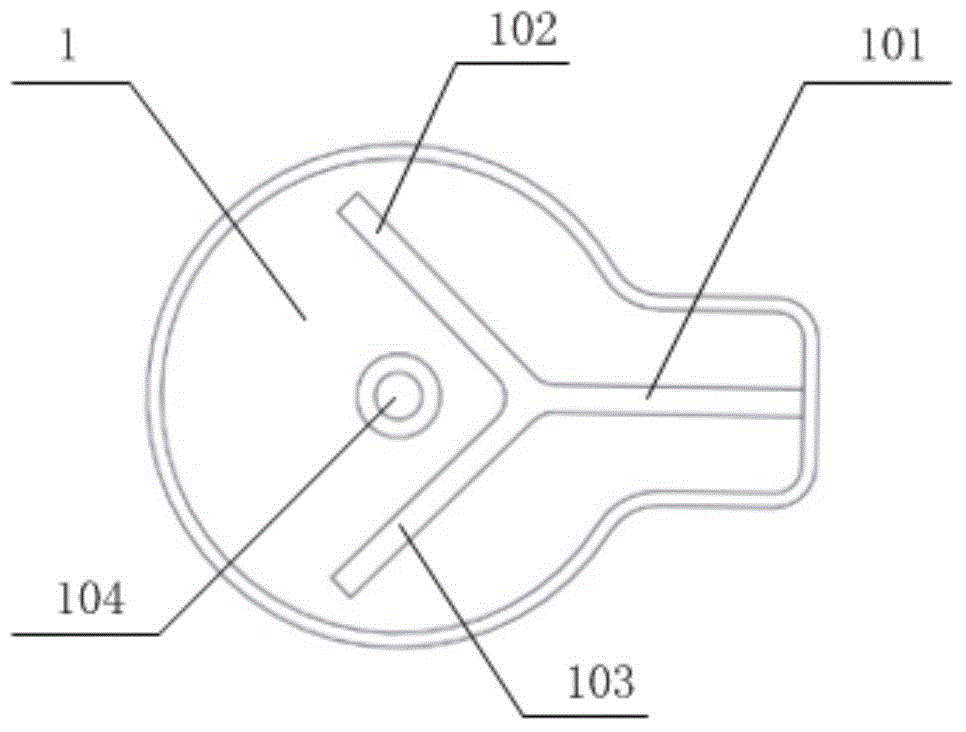

Ship liquid tank stability measuring system and measuring method

ActiveCN105270579AReduced data handling and programming effortSimple system structureVessel movement reduction by mass displacementMovement controllersAccuracy and precisionData processing

The invention discloses a ship liquid tank stability measuring system and a measuring method. The system comprises a liquid tank, a sensor connection pipe, a pressure sensor, a data processing unit, a signal output unit and a parameter setting and state displaying unit. The pressure sensor is communicated with the bottom of the liquid tank through a connection pipe; the data processing unit is respectively connected with the pressure sensor, the signal output unit and the parameter setting and state displaying unit through leads; and the signal output unit is connected with a computer in an external stability collecting system through a lead. The ship liquid tank stability measuring system disclosed by the invention has the advantages of simple structure, low manufacturing cost and convenience in use; as stability data processing is integrated in a measuring unit, the stability calculating task is moved forwards so that the data processing and programming workloads of a ship stability centralized control computer are greatly reduced; and meanwhile, the measuring accuracy and intelligent level of the measuring system are enhanced.

Owner:JIANGSU UNIV OF SCI & TECH

Electromagnetic positioning marking device as well as electromagnetic positioning system and method

ActiveCN105616001AEliminate the effects of inaccuraciesThe effect of inaccuracy is reducedSurgeryComputerised tomographsDegrees of freedomEngineering

The invention provides an electromagnetic positioning marking device as well as an electromagnetic positioning system and method. The device comprises a sensor positioning mounting block, an upper cover covering the sensor positioning mounting block, a first positioning sensor and a second positioning sensor, wherein a positioning hole allowing metal marking points to be movably embedded is further formed in the sensor positioning mounting block; the first positioning sensor and the second positioning sensor are fixed in the sensor positioning mounting block, the first positioning sensor, the second positioning sensor and the center of the positioning hole are located on the same plane, and the positioning hole is formed in the midpoint position of a connecting line of the first positioning sensor and the second positioning sensor. A six-DOF (degree of freedom) sensor is synthesized through two five-DOF positioning sensors, and the manufacturing cost is low; besides, work for manually finding the point by a doctor is omitted, the operation procedure is simplified, and the operation efficiency is improved.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

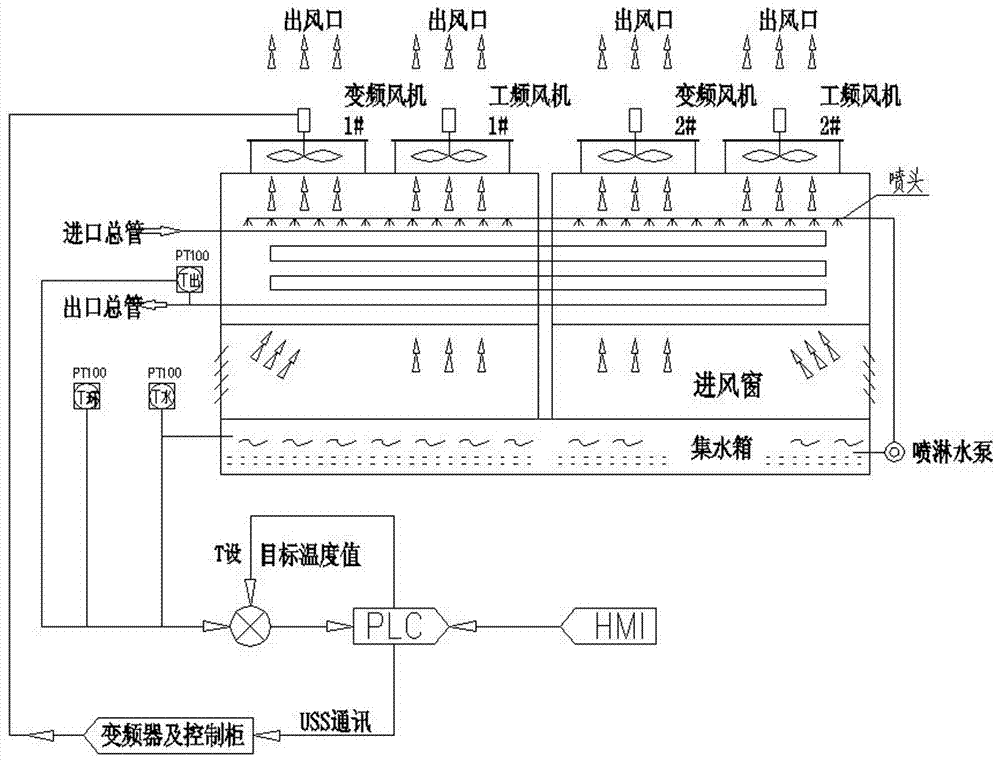

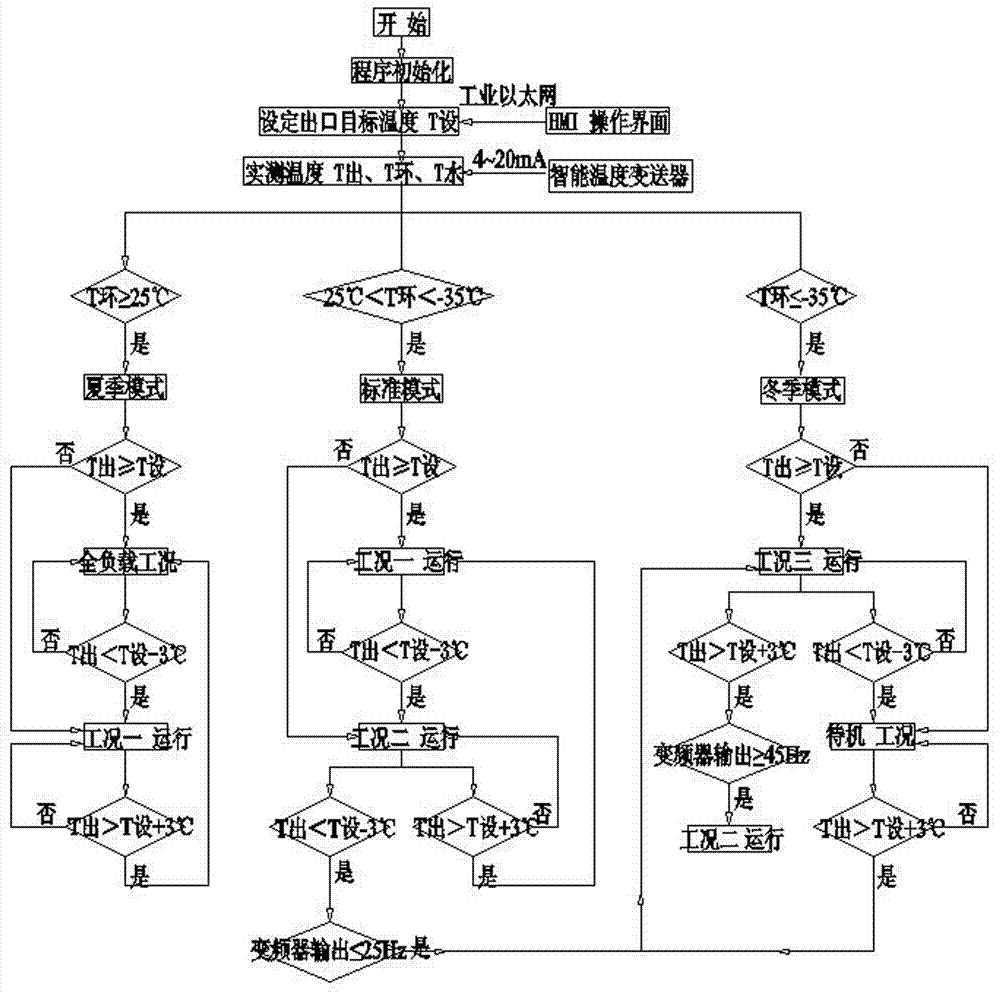

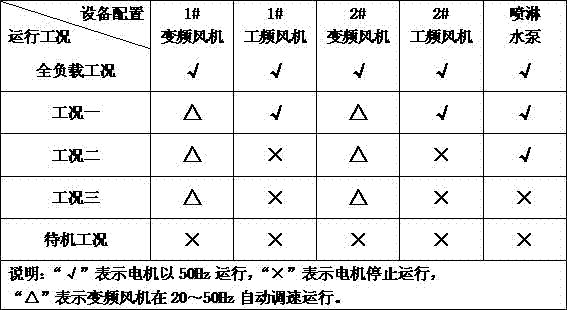

Energy-saving automatic control system and method of evaporative type cooling/condensing device

ActiveCN107289811AAutomatically adjust operating conditionsImprove operational efficiencyEnergy industryHeat exchange apparatusAutomatic controlAutomatic train control

The invention relates to an energy-saving automatic control system of an evaporative type cooling / condensing device. The system comprises an intelligent temperature transmitter, a control unit, a transducer and an efficient energy-saving motor. According to the energy-saving automatic control system, the temperature value which is monitored by the intelligent temperature transmitter in real time and a target set temperature value of an HMI are compared and analyzed through a PLC program, a logic control instruction is output based on the analysis result according to the running mode and the running conditions preset by the PLC program, the transducer receives the control instruction and a speed regulation signal through a USB communication protocol, accordingly, a frequency conversion fan motor is driven to start or stop and automatically run in a speed regulation mode, so that it is achieved that the evaporative type cooling / condensing device automatically regulates the output power according to the temperature variation, and the automatic energy-saving running is achieved. Compared with an existing control technology, the energy-saving automatic control system has the advantages of reducing the energy loss of the device, improving the running efficiency and achieving automatic energy-saving running.

Owner:LONGHUA TECHNOLOGY GROUP (LUOYANG) CO LTD

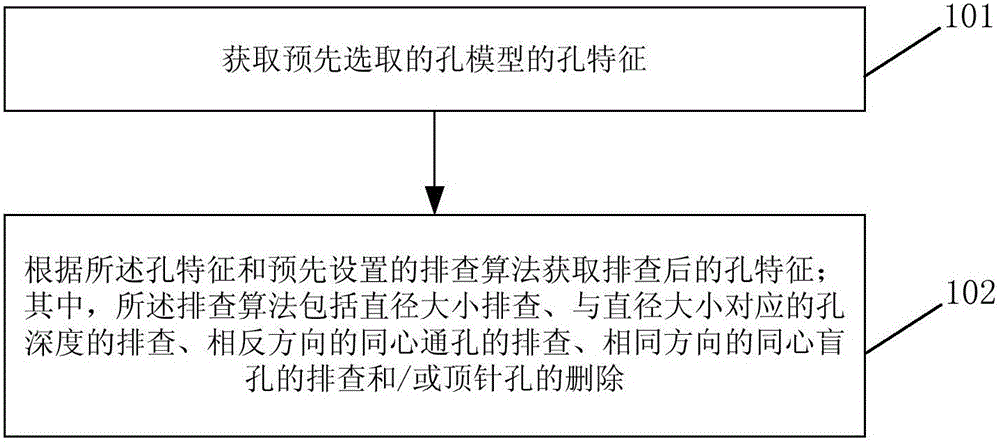

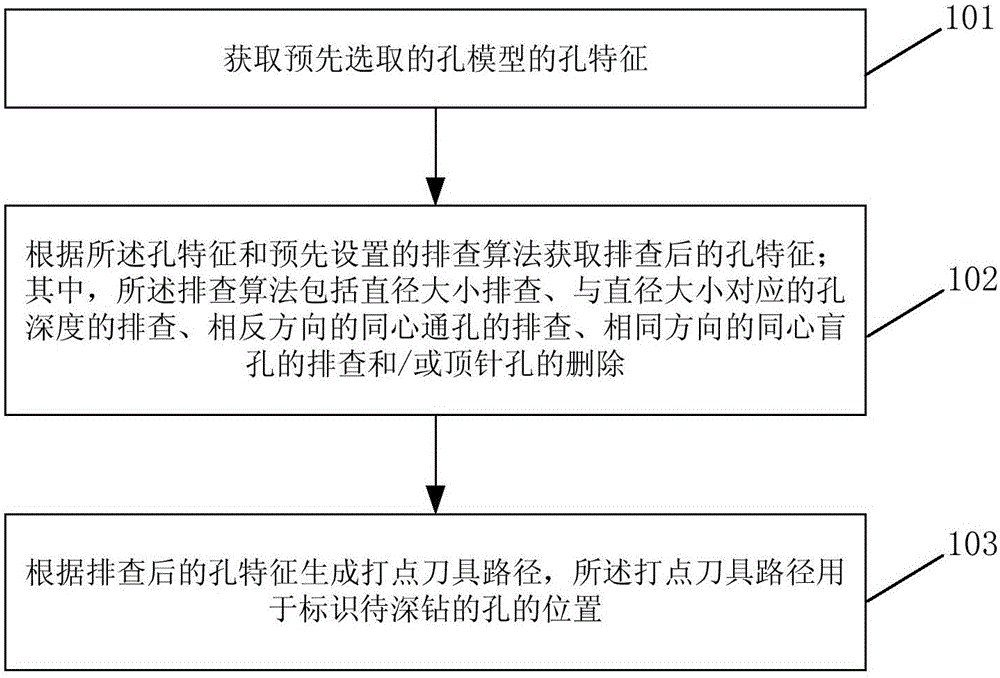

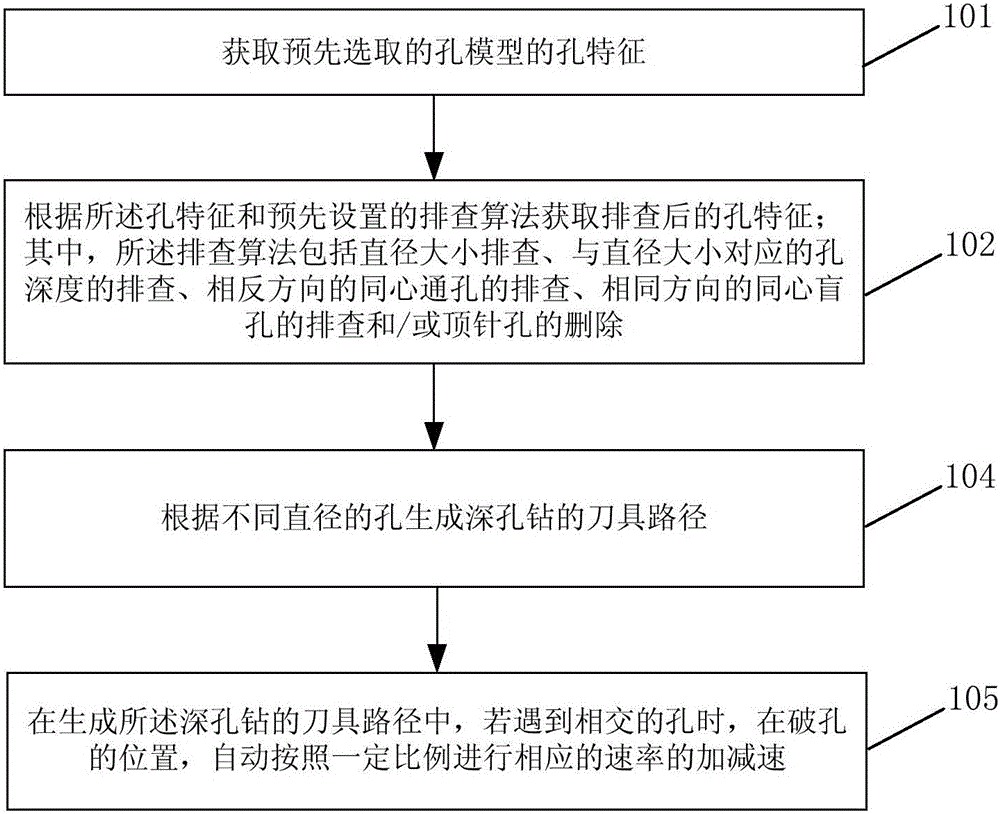

Deep hole drill programming method and device

ActiveCN104985223ALess programming effortImprove processing qualityBoring/drilling machinesDrill bitWorkload

The embodiment of the invention discloses a deep hole drill programming method and device. By obtaining hole features of a hole model selected in advance, the hole features after checking are obtained according to the hole features and a preset checking algorithm, wherein the checking algorithm comprises diameter checking, checking of the hole depth corresponding to the diameter, checking of concentric through holes in opposite directions, checking of concentric blind holes in the same direction and / or deletion of a centre hole, so that programming of full-automatic deep drilling is achieved, the programming workloads of programmers and machining personnel can be greatly reduced, the machining quality of a deep hole drill is improved, and the machining efficiency is also improved. As the efficiency and quality are both considered, the service life of a drill bit is prolonged, and the production cost is reduced.

Owner:GUANGZHOU DEKANG SOFTWARE CO LTD

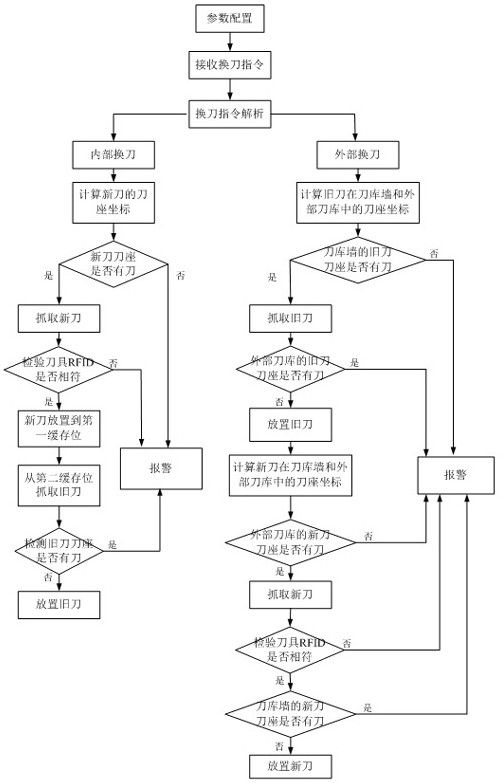

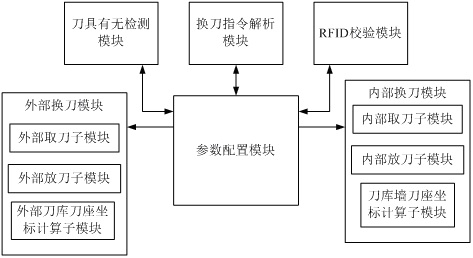

Robot tool magazine tool changing control method and control system

ActiveCN113843645ASimplify the commissioning processAvoid changePositioning apparatusMetal-working holdersControl systemProcess engineering

The invention belongs to the technical field of tool changing control of numerical control machine tools, and relates to a robot tool magazine tool changing control method and system. The method comprises the steps: carrying out the parameter configuration on a tool magazine wall and an external tool magazine according to structures of the tool magazine wall and the external tool magazine; receiving a tool changing instruction, and determining the type of the tool changing instruction; calculating corresponding tool apron coordinates according to tool apron numbers of a new tool and an old tool on the tool magazine wall and theoretical offsets and actual offsets of corresponding tool aprons, and completing replacement of the new tool and the old tool if the instruction is an internal tool changing instruction from a machine tool numerical control system; and calculating corresponding tool apron coordinates according to the tool apron numbers of the old tool and the new tool in the tool magazine wall, tool apron numbers of the old tool and the new tool in the external tool magazine and the theoretical offsets and the actual offsets of the corresponding tool aprons, and completing replacement of the new tool in the external tool magazine and the old tool in the tool magazine wall if the instruction is an external tool changing instruction from the external tool magazine system. According to the control method, the programming difficulty of the tool changing process in the tool magazine of a robot is reduced, and the tool changing debugging, maintenance and operation processes are simplified.

Owner:通用技术集团沈阳机床有限责任公司

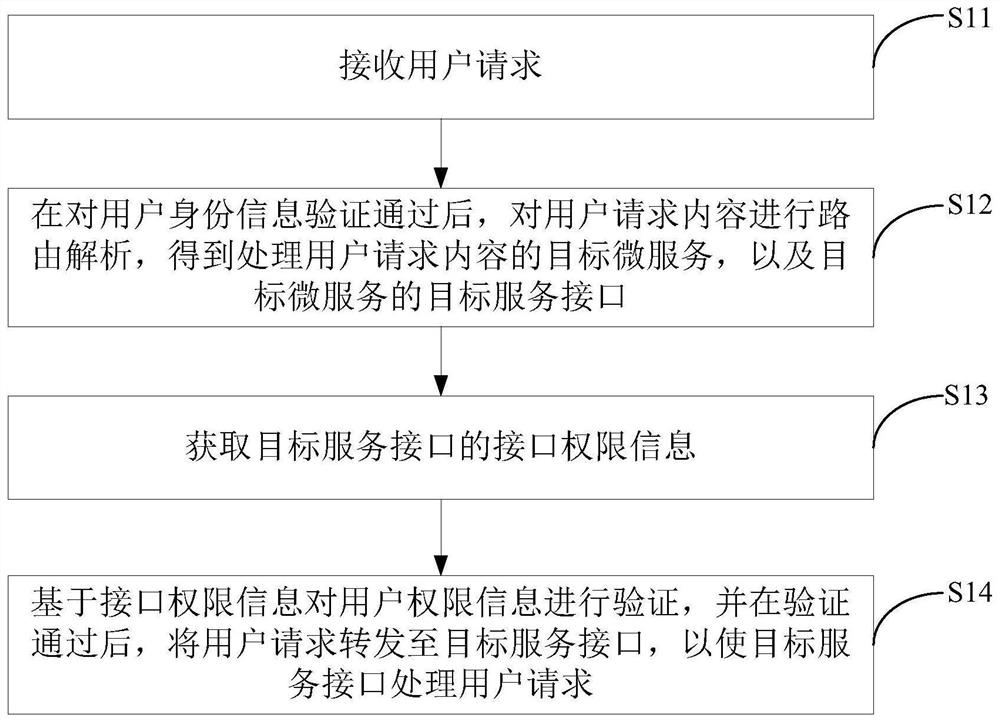

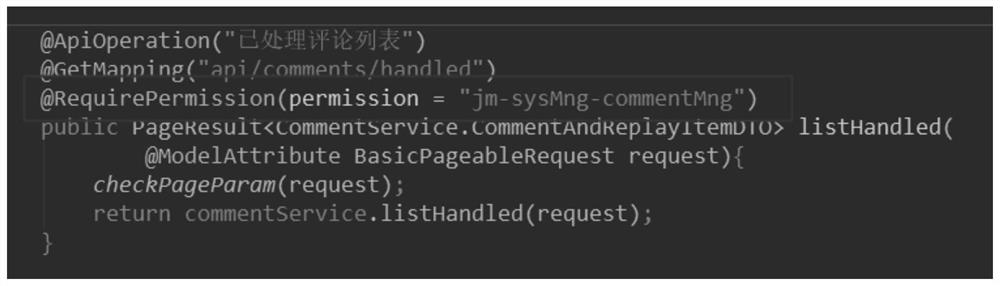

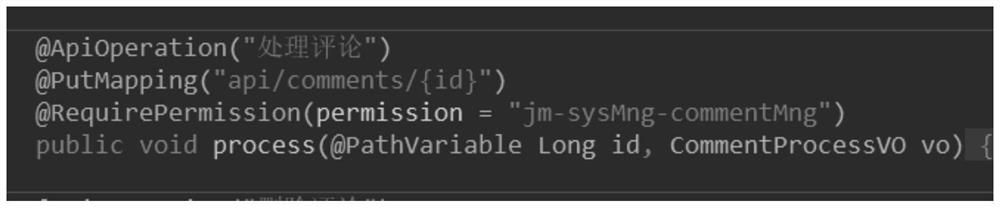

User request processing method and device

PendingCN114692172AImprove programming efficiencyThe verification method is simpleDigital data protectionComputer networkUser Privilege

The invention provides a user request processing method and device, and the method comprises the steps: carrying out the verification of a user permission through a micro-service gateway based on the interface permission information of a target service interface for processing a user request during the verification of the user permission, and forwarding the user request to a target service interface of a target micro-service after the verification is passed, and the target micro-service processes the user request without verifying the user permission. Therefore, when the micro-service is called in a chained manner, the micro-service gateway only needs to verify the user permission once, and each micro-service does not need to verify the user permission any more, so that the verification mode is simplified, and the verification efficiency is improved. Furthermore, according to the invention, the micro-service does not need to perform user permission verification, so that the programming workload during micro-service writing can be reduced, and the micro-service programming efficiency can be improved.

Owner:北京国双千里科技有限公司

Unmanned aerial vehicle formation light performance method

ActiveCN110658849ALess programming effortImprove lighting programming efficiencyPosition/course control in three dimensionsComputer visionEngineering

The invention discloses an unmanned aerial vehicle formation light performance method. The method comprises the following steps: S1, acquiring coordinate points of all unmanned aerial vehicles corresponding to a preset display plane; S2, projecting a to-be-displayed light picture into the preset display plane; and S3, acquiring corresponding pixel points of all unmanned aerial vehicles on the to-be-displayed light picture through the coordinate points, and performing light displaying by all unmanned aerial vehicles according to the corresponding pixel points. According to the unmanned aerial vehicle formation light performance method provided by the invention, light programming does not need to be performed in advance, so that the programming workload of users is greatly reduced; when theunmanned aerial vehicle formation shape and the number of the unmanned aerial vehicles are changed each time, the coordinate points, corresponding to the preset display plane, of all unmanned aerial vehicles are obtained again and then the to-be-displayed light picture is projected into the preset display plane again to avoid reselection of an unmanned aerial vehicle, thereby improving the light programming efficiency substantially and bringing the great convenience for implementation by users.

Owner:SHENZHEN CENCOM TECH

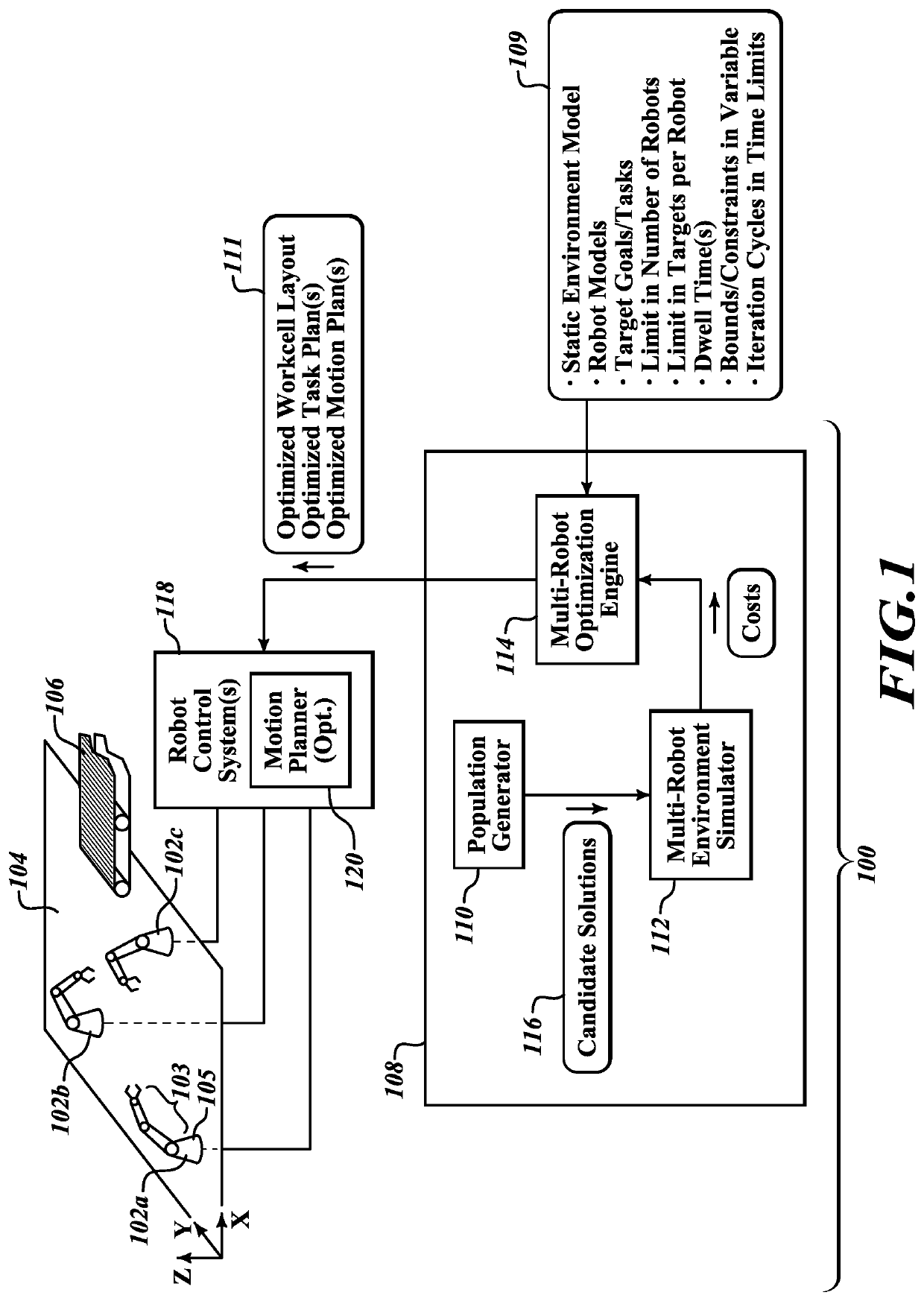

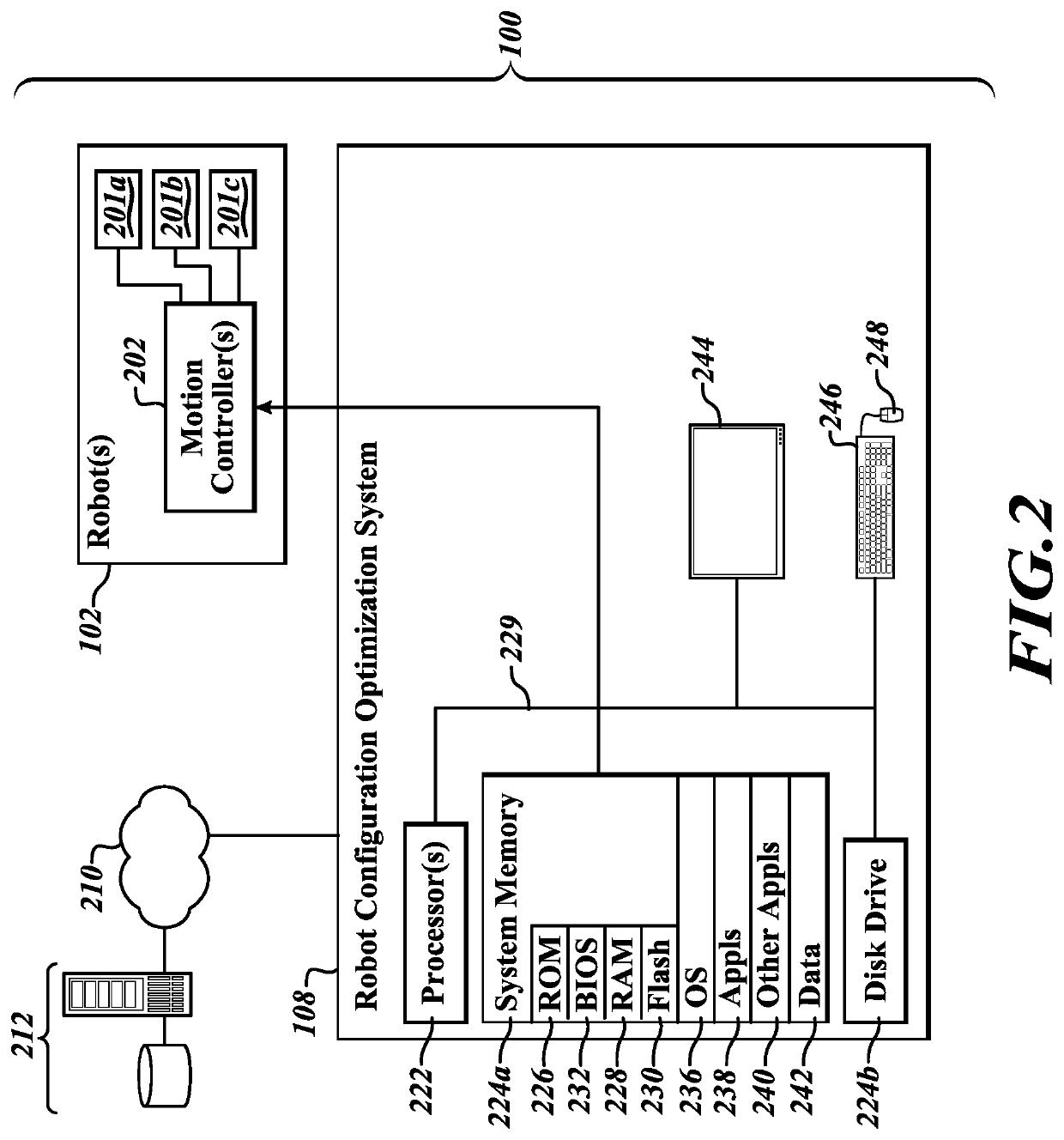

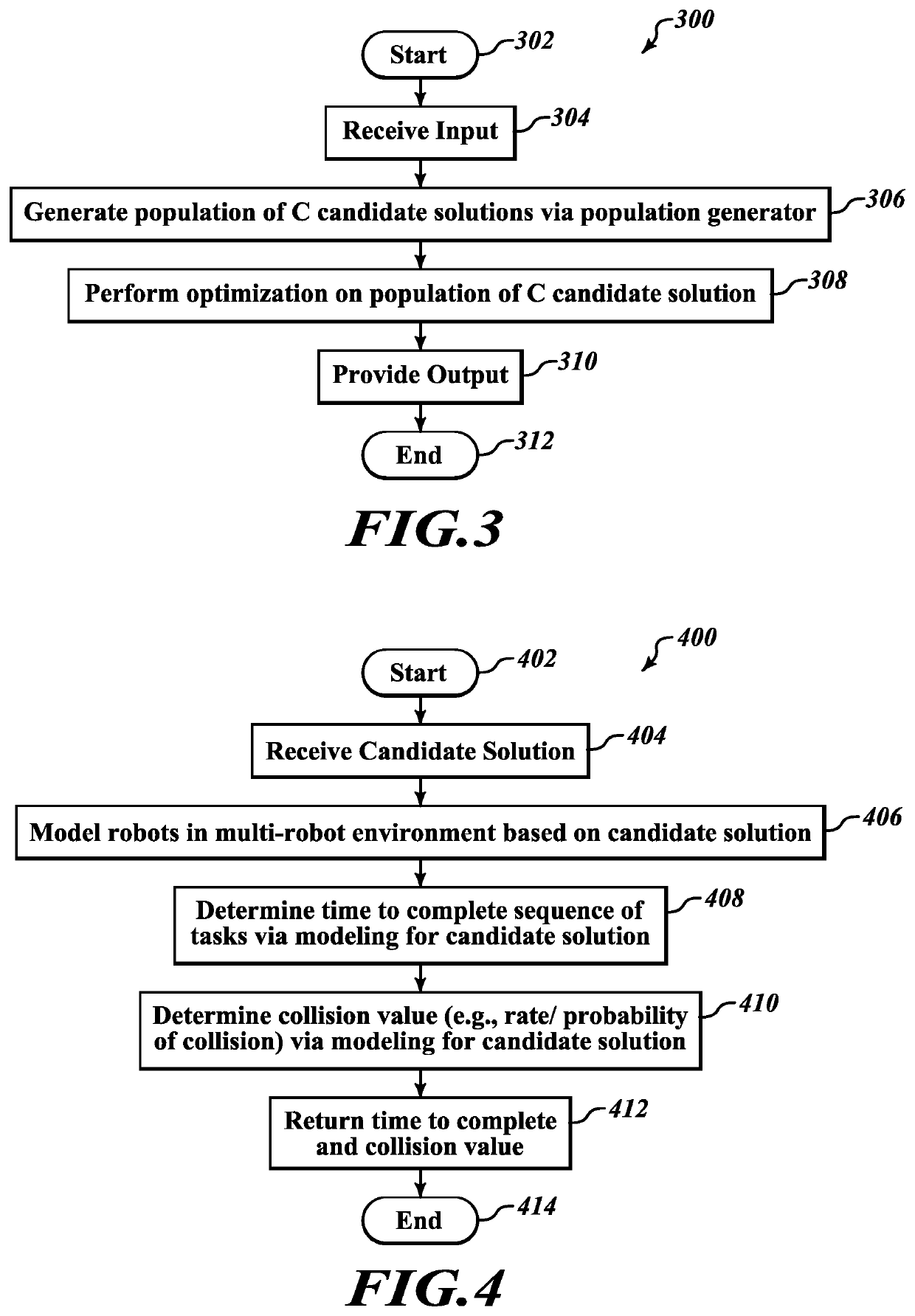

Configuration of robots in multi-robot operational environment

ActiveUS20210220994A1Efficient of energy consumptionEfficient of expenditureProgramme controlProgramme-controlled manipulatorWorkcellSimulation

Solutions for multi-robot configurations are co-optimized, to at least some degree, across a set of non-homogenous parameters based on a given set of tasks to be performed by robots in a multi-robot operational environment. Non-homogenous parameters may include two or more of: the respective base position and orientation of the robots, an allocation of tasks to respective robots, respective target sequences and / or trajectories for the robots. Such may be executed pre-runtime. Output may include for each robot: workcell layout, an ordered list or vector of targets, optionally dwell time durations at respective targets, and paths or trajectories between each pair of consecutive targets. Output may provide a complete, executable, solution to the problem, which in the absence of variability in timing, can be used to control the robots without any modification. A genetic algorithm, e.g., Differential Evolution, may optionally be used in generating a population of candidate solutions.

Owner:REALTIME ROBOTICS INC

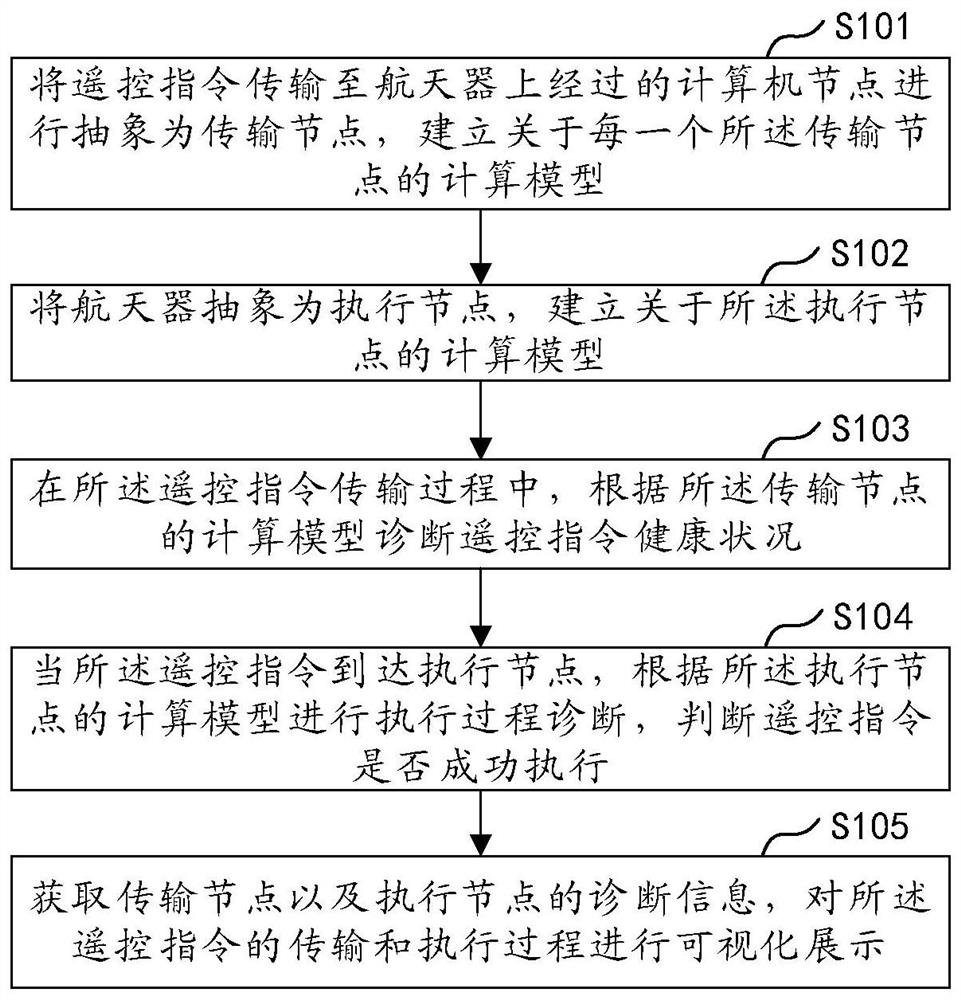

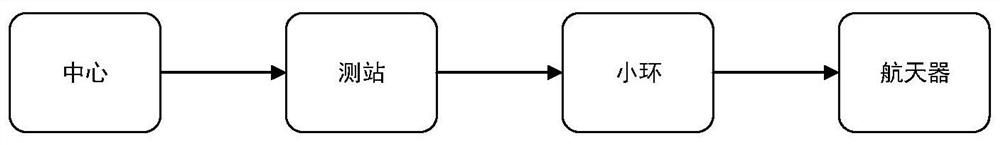

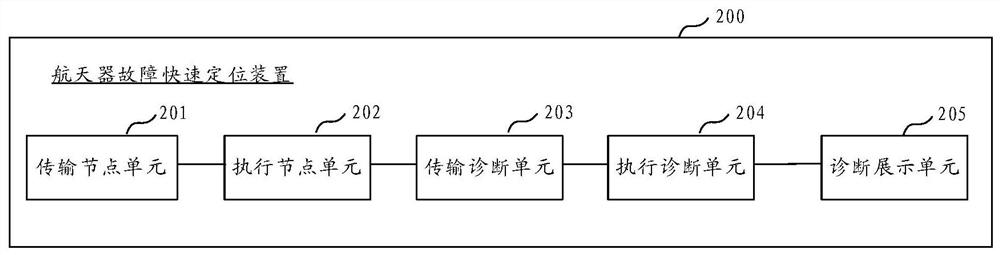

Spacecraft fault rapid positioning method and device, computer equipment and storage medium

InactiveCN111983995ARapid positioningLess programming effortElectric testing/monitoringData switching networksRemote controlComputational model

The invention discloses a spacecraft fault rapid positioning method and device, computer equipment and a storage medium. The method comprises the following steps: abstracting computer nodes, which a remote control instruction passes through when the remote control instruction is transmitted to a spacecraft, into transmission nodes, and building a calculation model for the transmission nodes; abstracting the spacecraft as an execution node, and establishing a calculation model about the execution node; in the remote control instruction transmission process, diagnosing the remote control instruction health condition according to the calculation model of the transmission nodes; when the remote control instruction reaches the execution node, performing execution process diagnosis according tothe calculation model of the execution node, and judging whether the remote control instruction is successfully executed; and acquiring diagnosis information of the transmission nodes and the execution nodes, and visually displaying the transmission and execution process of the remote control instruction. According to the method, the nodes where the remote control instruction fails to be transmitted or executed can be quickly positioned, the reason why the remote control instruction fails to be transmitted and executed is diagnosed, and the fault node and diagnosis process information are displayed visually.

Owner:西安寰宇卫星测控与数据应用有限公司

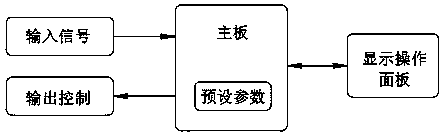

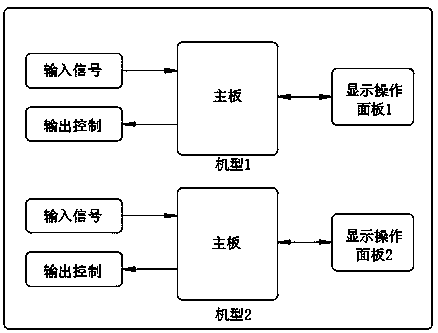

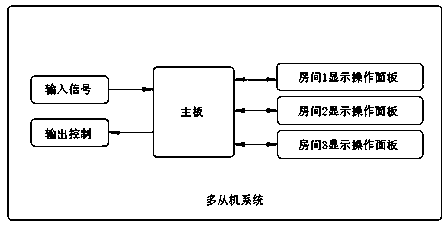

Fully-automatic thermostatic water heater operating plate communication system

InactiveCN107676987ALess programming effortAchieve diversificationFluid heatersCombustionCommunications system

The invention discloses a fully-automatic thermostatic water heater operating plate communication system. The fully-automatic thermostatic water heater operating plate communication system comprises ahost and display operating panels. The host is internally provided with a main plate. The main plate can be connected with water heaters of various models. When different models are arranged, the display operating panels are only needed to be operated, and different water heater display interfaces can be selected. The main plate transmits information of temperature sampling, water flow detecting,flame detecting, wind pressure signal detecting, fan output, combustion status and failure status to the display operating panels. The host is provided with a control switch. The control switch is connected with a plurality of water heaters. The display operating panels and the control switch are connected. The control switch can be operated on the display operating panels. The host is externallyconnected with the display operating panels through communication protocol simultaneously. The display operating panels are mounted in a plurality of rooms correspondingly. The fully-automatic thermostatic water heater operating plate communication system greatly improves the product development speed, meanwhile, provides various selected spaces for customers, and realizes the product diversification.

Owner:GUANGDONG HUAMEI JUNDA ELECTRIC APPLIANCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com