Method for rapidly generating corner side milling process path

A technology for processing trajectory and corner, applied in the direction of electrical program control, digital control, etc., can solve the problems of insufficient flexibility, low efficiency, poor quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The following is a detailed description of the technical solution of the present invention in conjunction with the accompanying drawings.

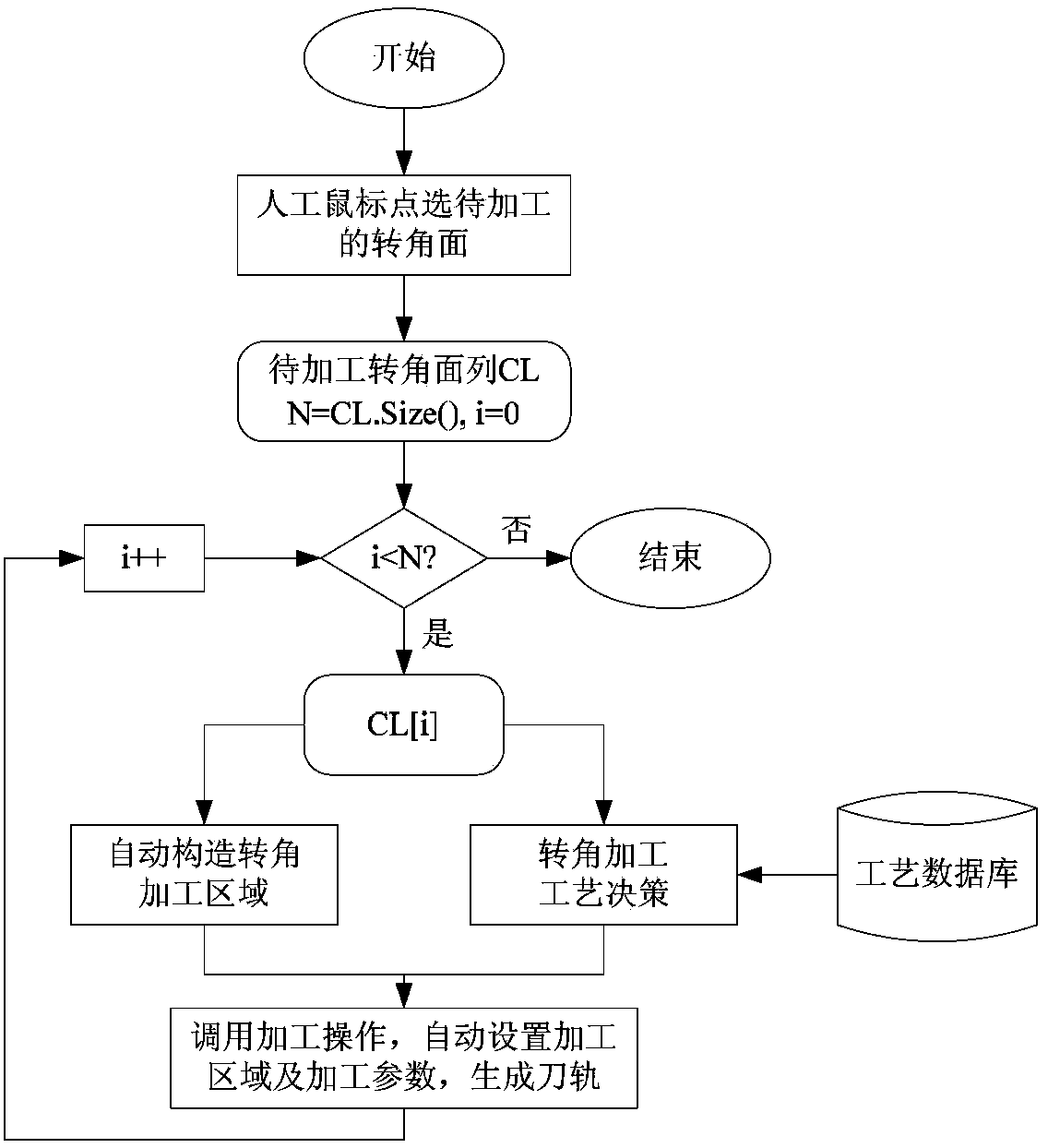

[0077] A method for quickly generating machining paths in corner side milling, the process of which is as follows figure 1 As shown, it includes the following steps:

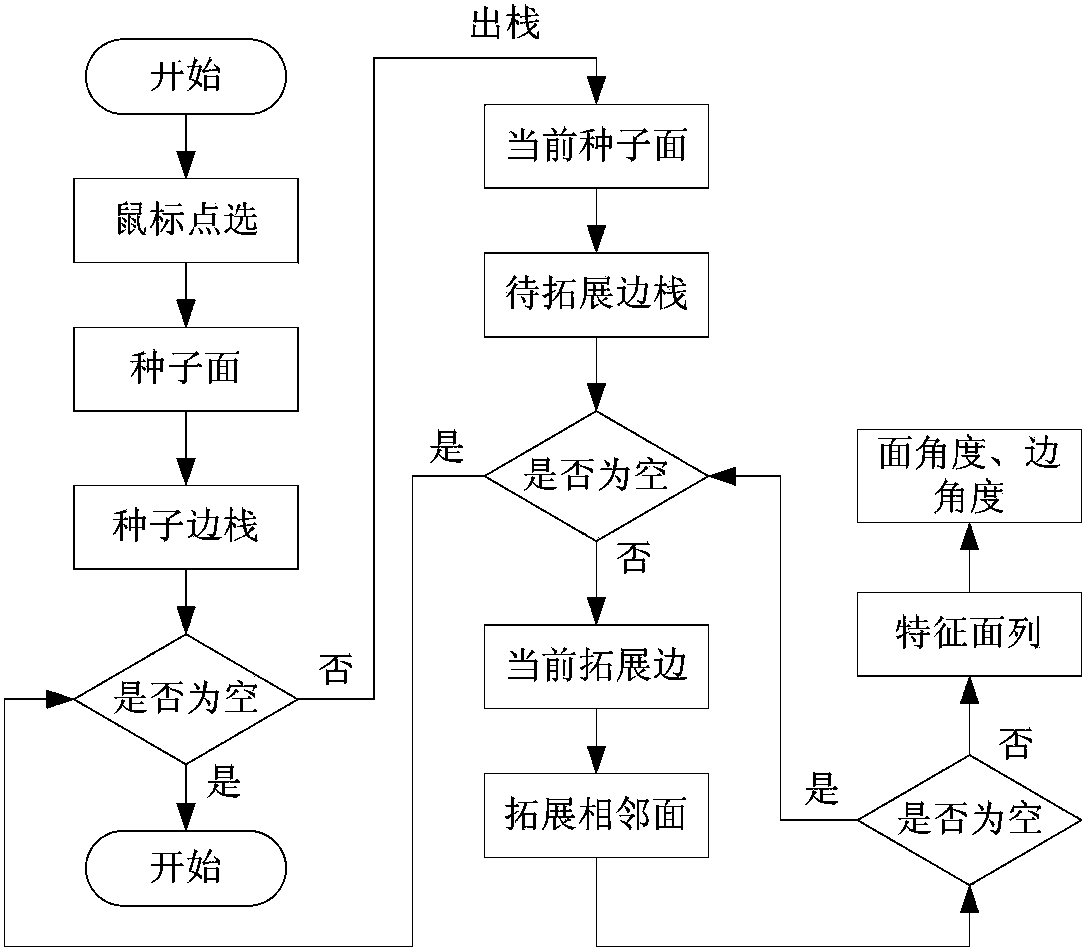

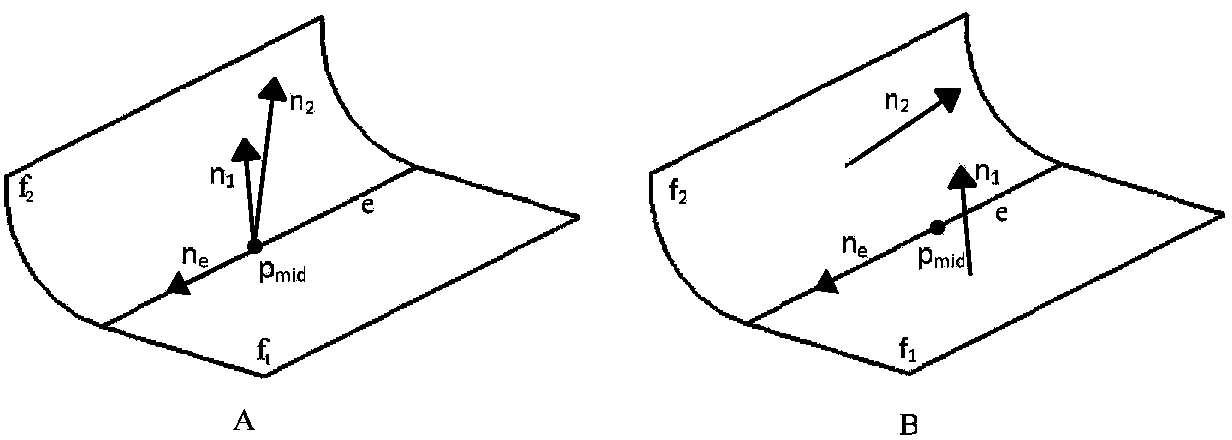

[0078]First, in the CAM environment, select the corner surface to be processed by clicking the mouse; secondly, use the graph-based feature recognition method to select the corner surface, use the selected corner surface as the seed surface, and perform surface expansion to obtain the feature surface corresponding to the corner surface column, and then match the feature surface column through the corresponding rules, and finally realize the automatic construction of the corner side milling processing area.

[0079] The following five parts are detailed as follows:

[0080] 1. Selection of corner faces.

[0081] The corner surface to be processed is obtained by cli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com