Patents

Literature

297 results about "Computer-aided manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Computer-aided manufacturing (CAM) or Computer-aided Machining is the use of software to control machine tools and related ones in the manufacturing of workpieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the machine tool. CAM is used in many schools alongside Computer-Aided Design (CAD) to create objects.

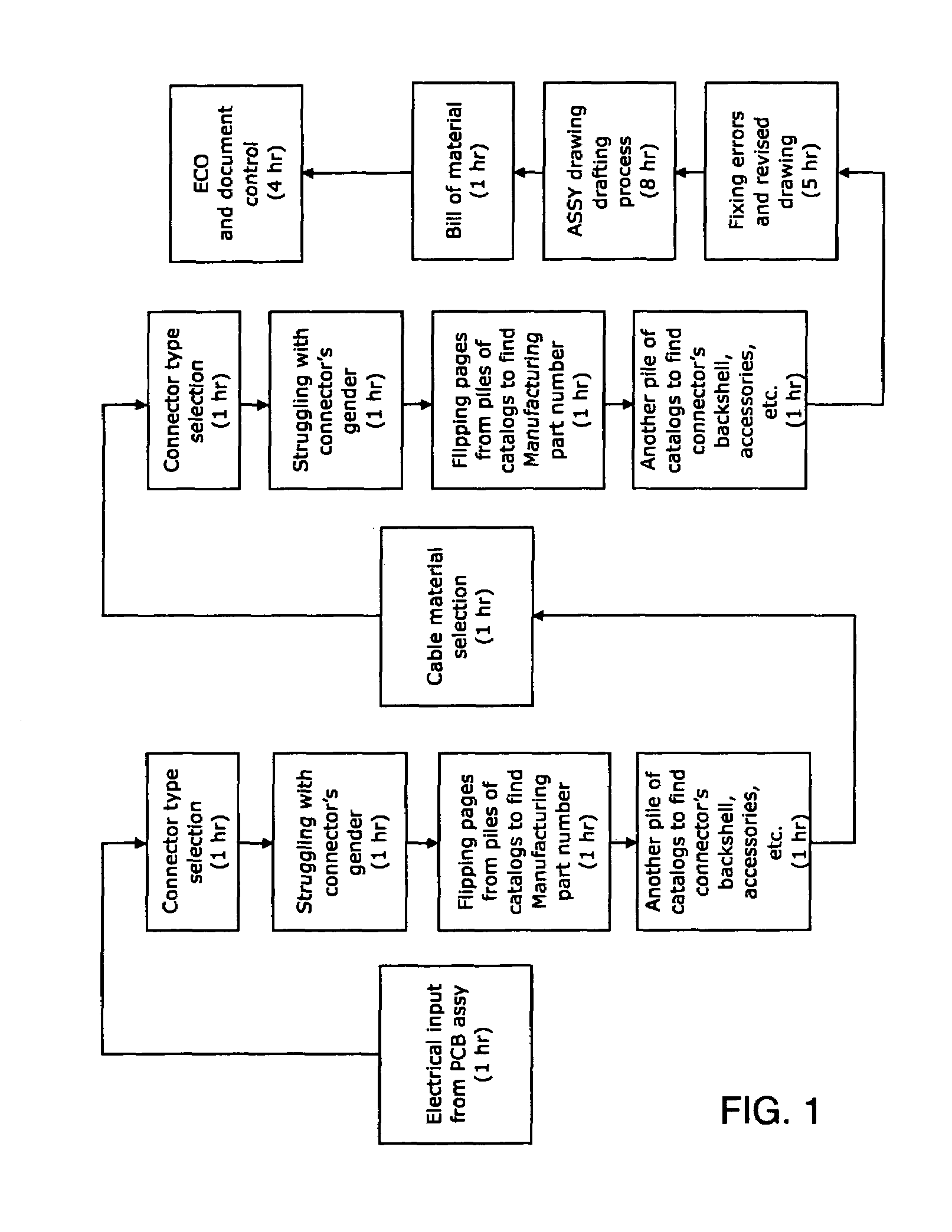

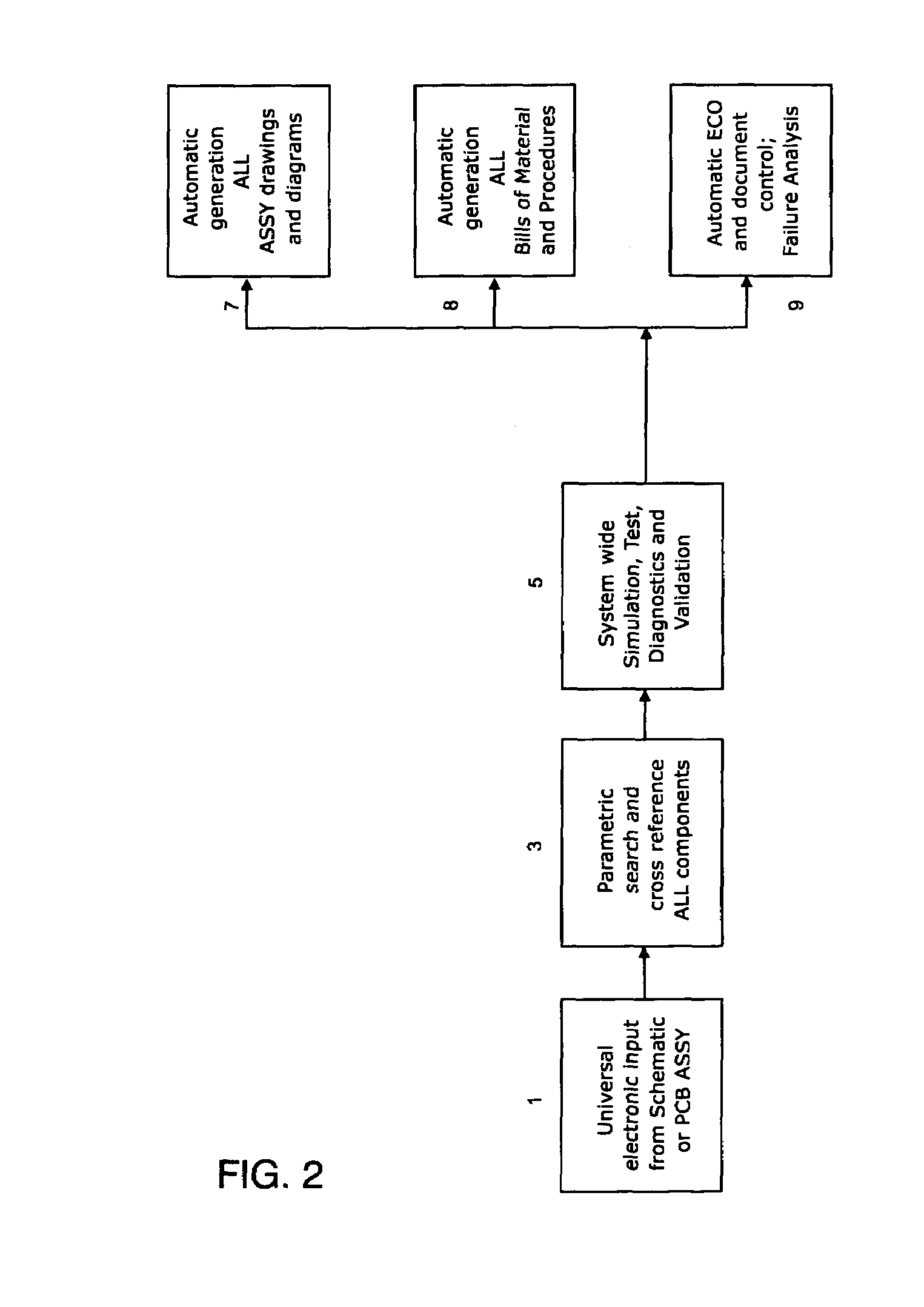

PLM-supportive CAD-CAM tool for interoperative electrical & mechanical design for hardware electrical systems

InactiveUS20050080502A1Reduce frictionCAD network environmentComputer programmed simultaneously with data introductionTask completionBill of materials

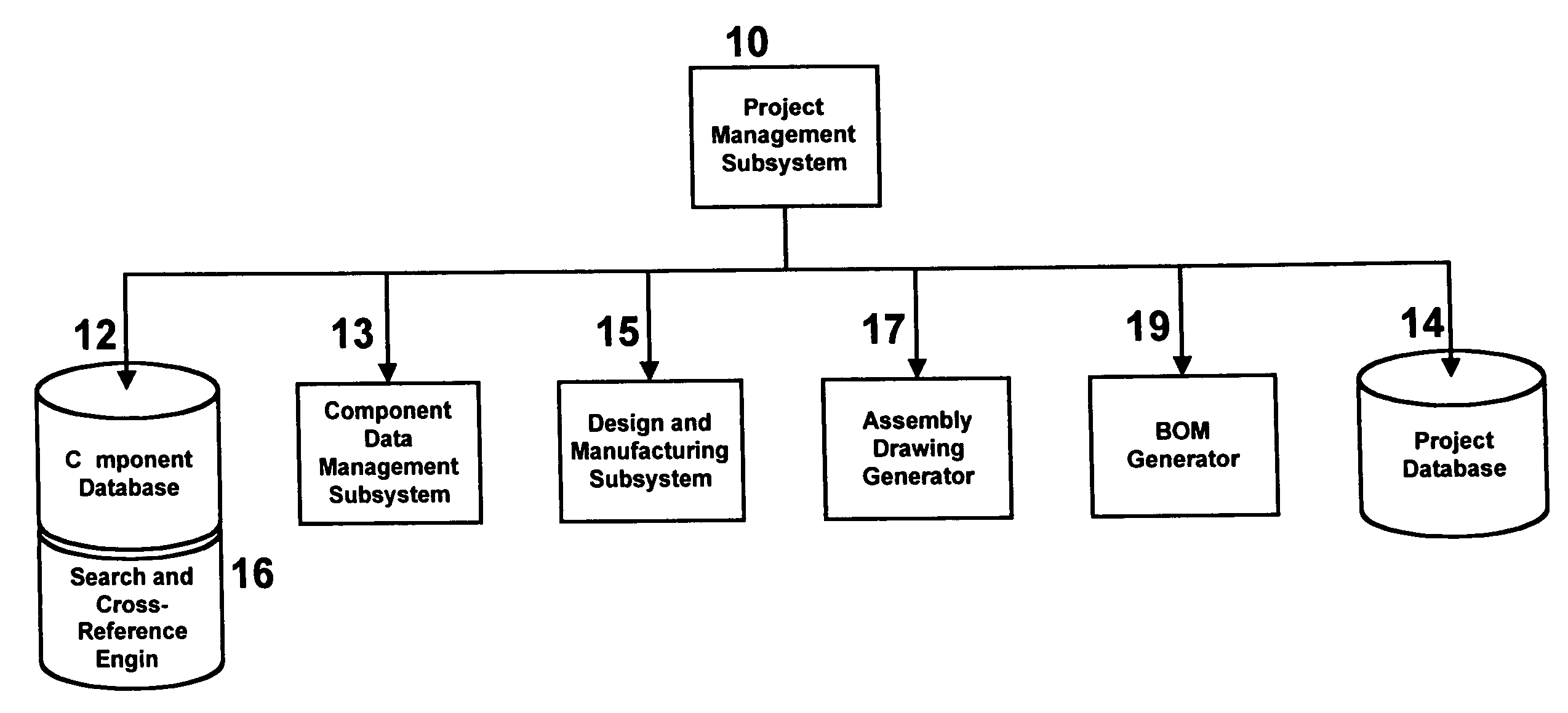

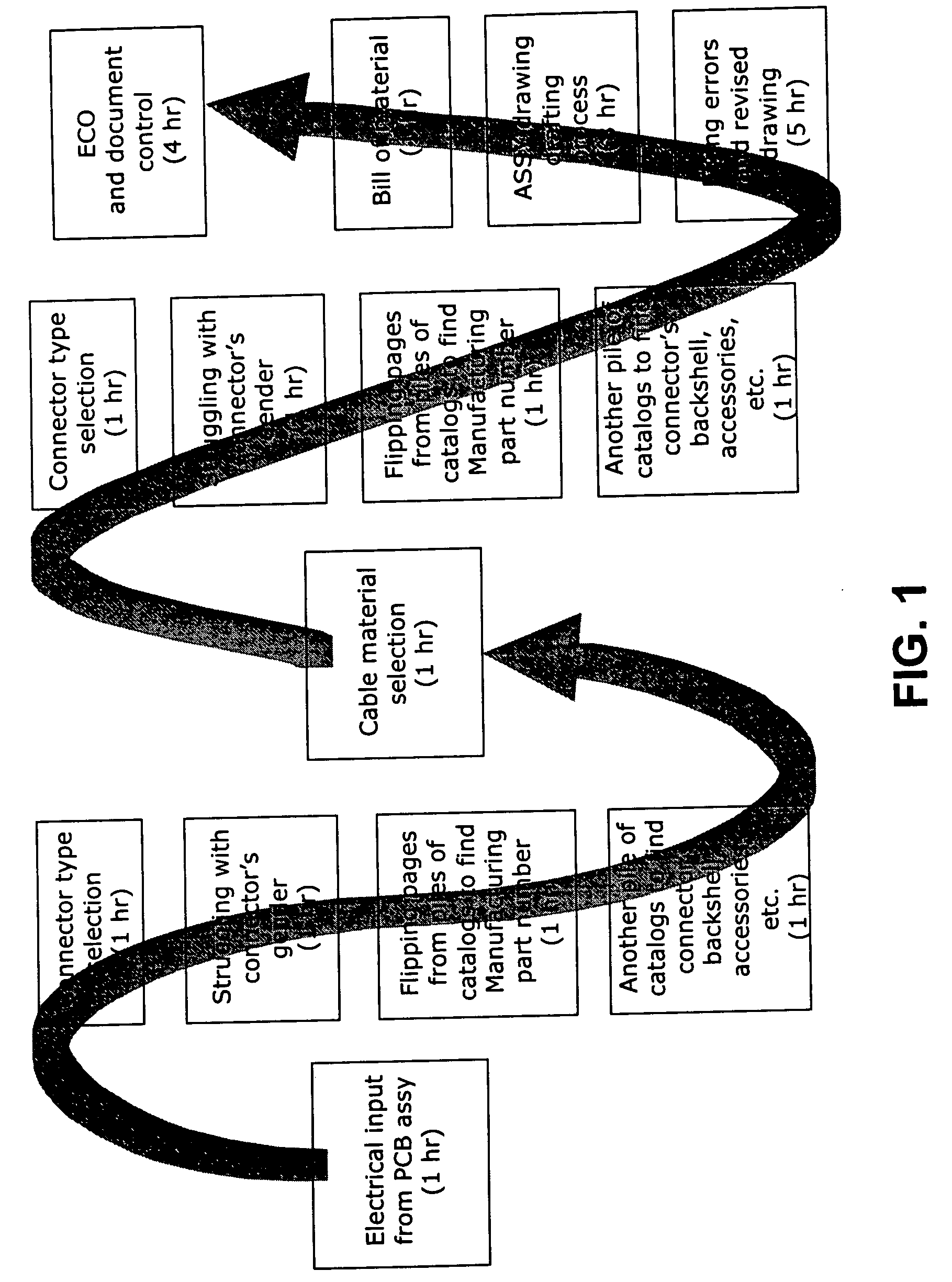

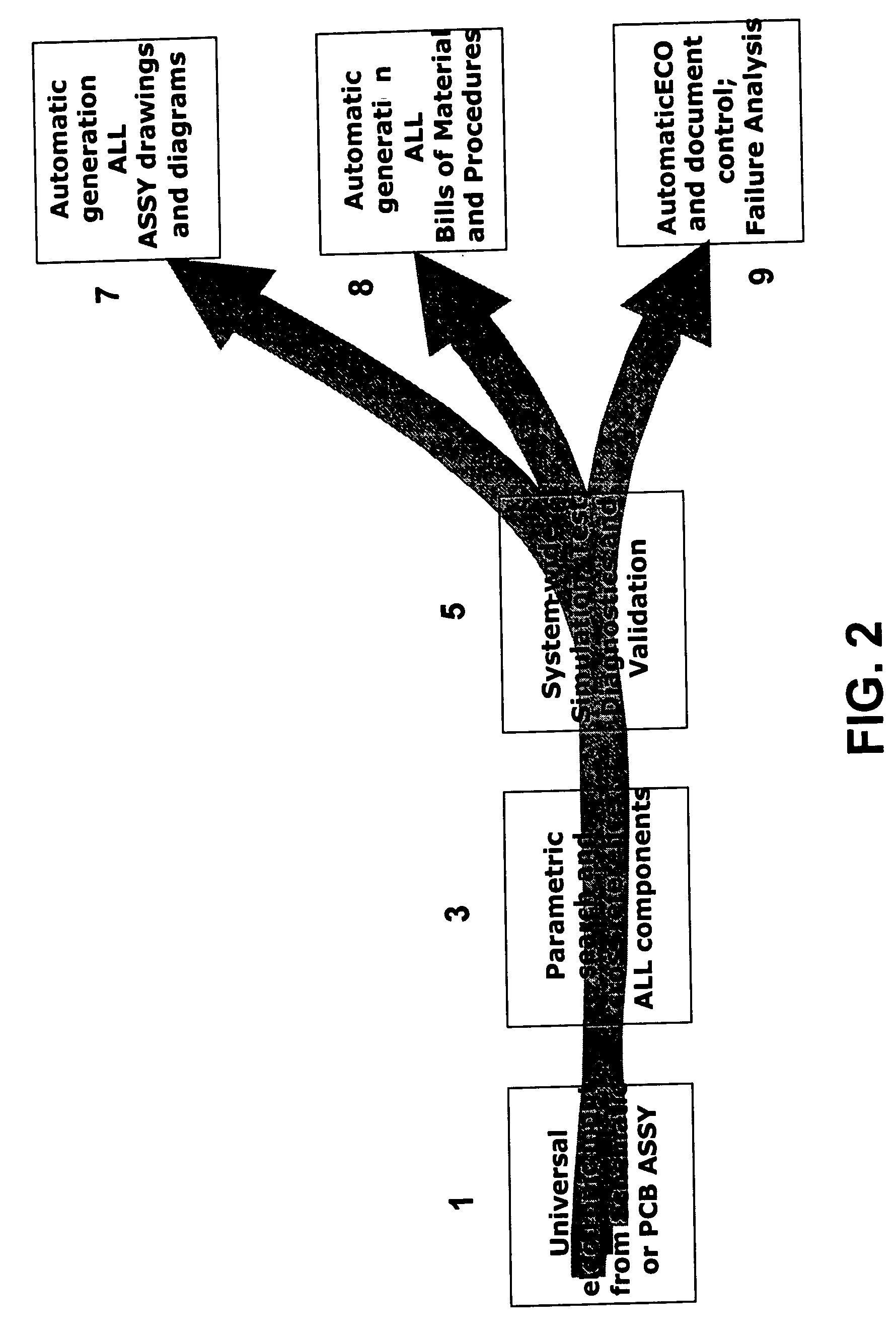

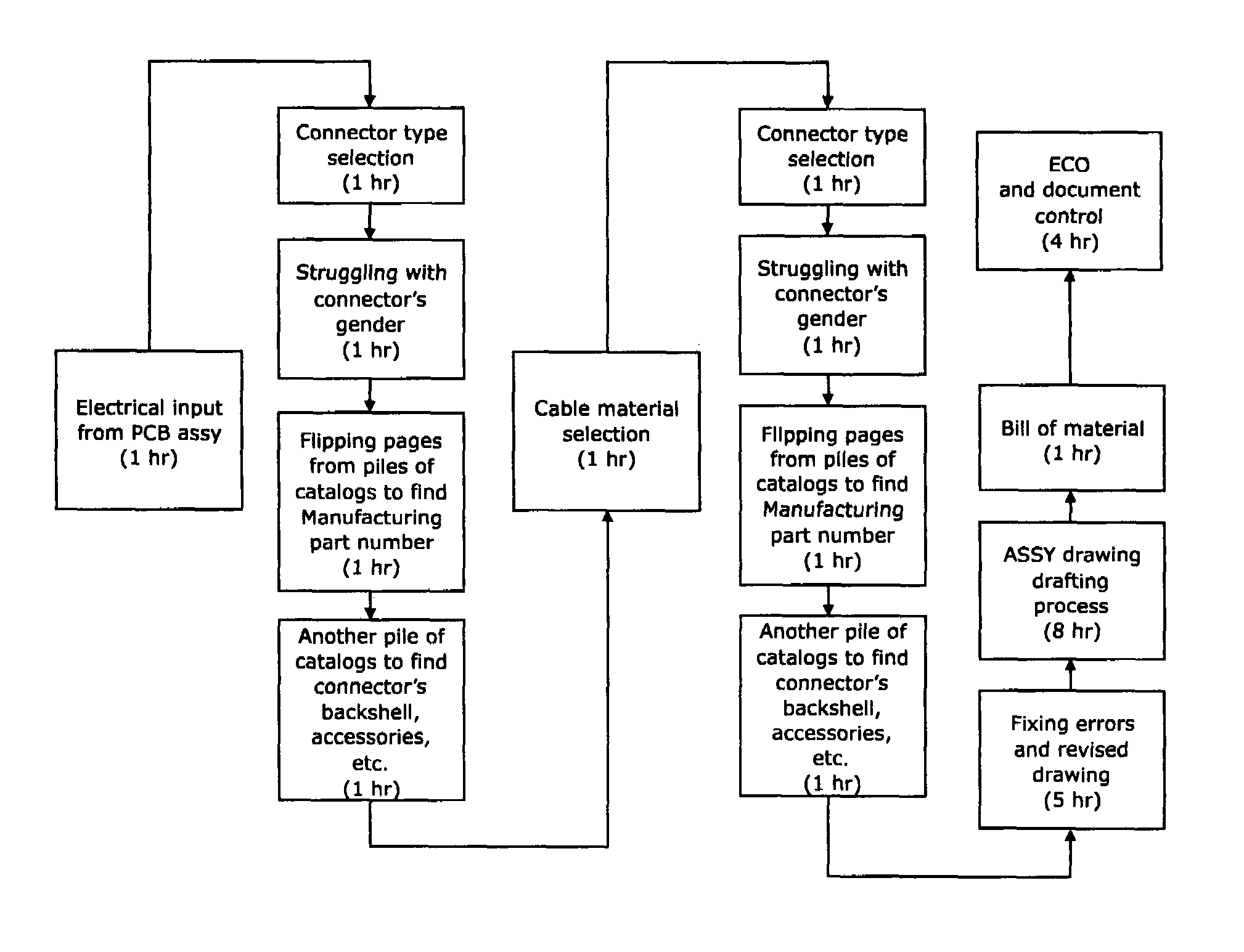

This invention is a tool for computer-aided design, computer-aided manufacturing forming a Project Management System, comprising: (1) a Component Database; (2) a Component Data Management System; (3) a Design and Manufacturing System; (4) an Assembly Drawing Generator; (5) a Bill of Materials Generator; and, (7) a Project Database. The Project Manager tracks the process and actions, recording and supervising version and change order compliance and task completion, from the start through verification of a production-ready finished version. Each project uses a master workbench. On it design specifications are entered for each subassembly element and connector. Then the user consults the Component Database using a Search and Cross Reference engine for components meeting those design specifications, until a constraint-satisfying design is completed. The tool generates a Bill of Materials, Assembly Drawings, and process records for the project in process.

Owner:CHERNYAK ALEX H +3

PLM-supportive CAD-CAM tool for interoperative electrical and mechanical design for hardware electrical systems

InactiveUS7103434B2Reduce frictionCAD network environmentComputer programmed simultaneously with data introductionTask completionBill of materials

Owner:CHERNYAK ALEX H +3

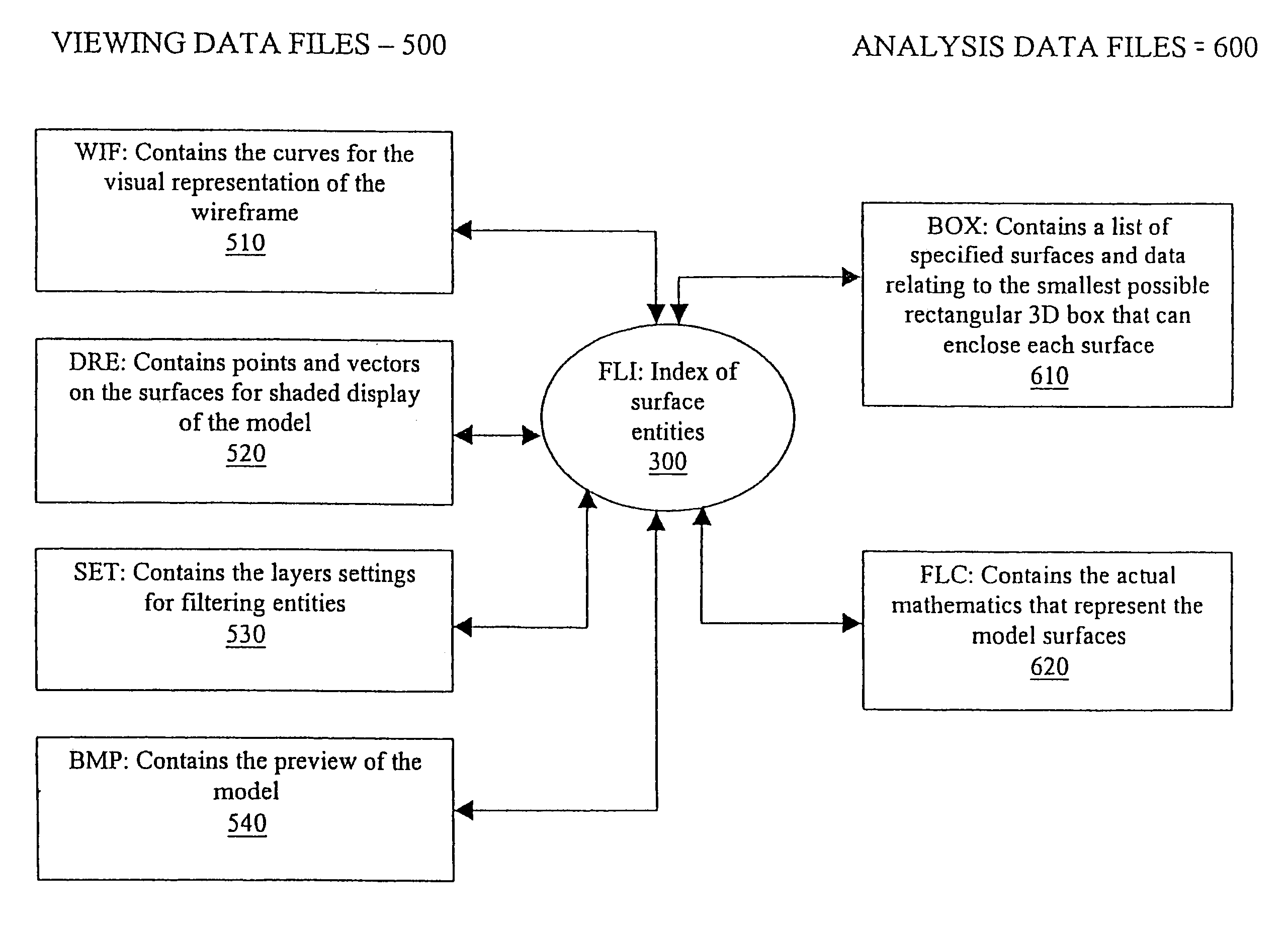

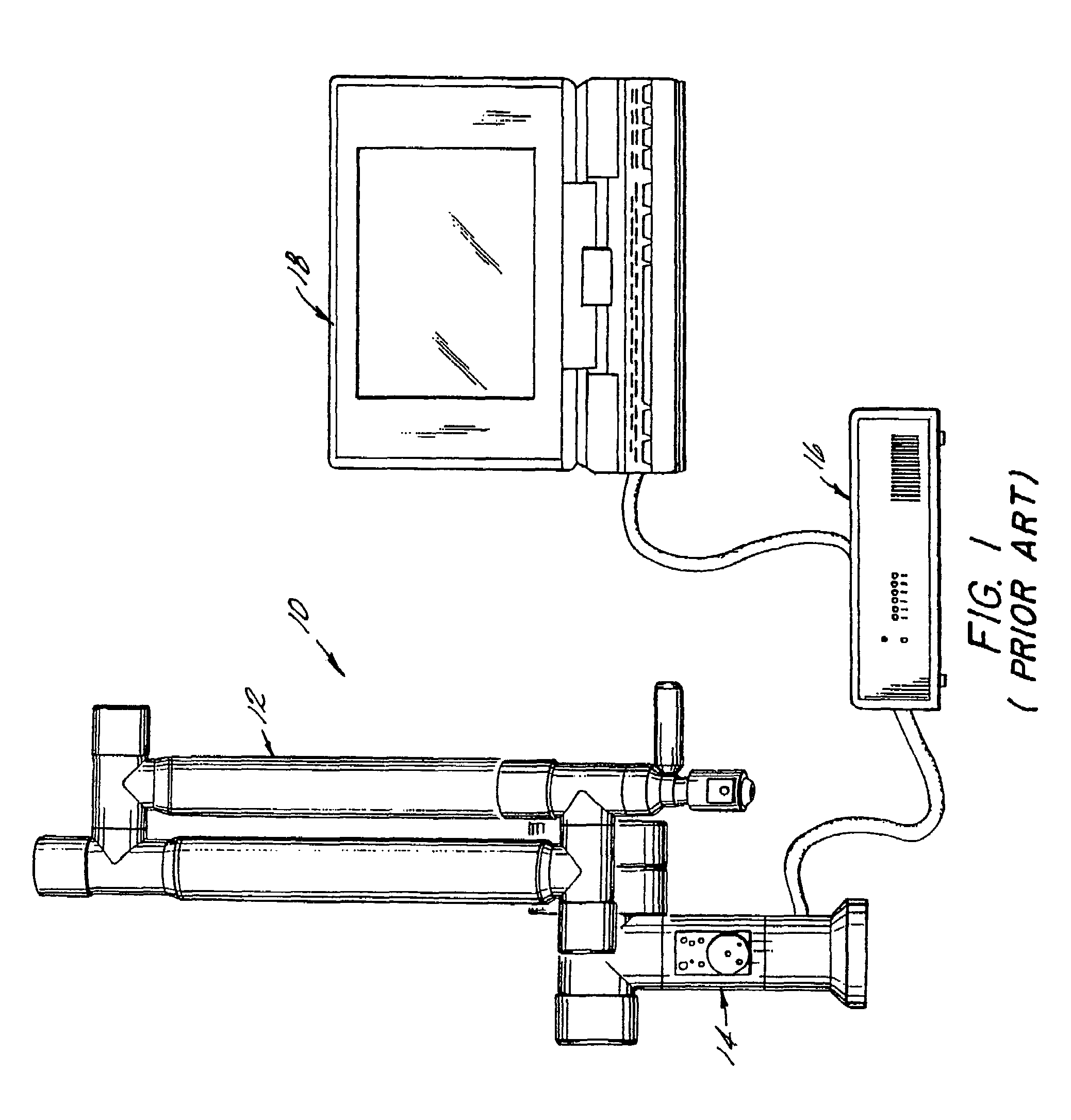

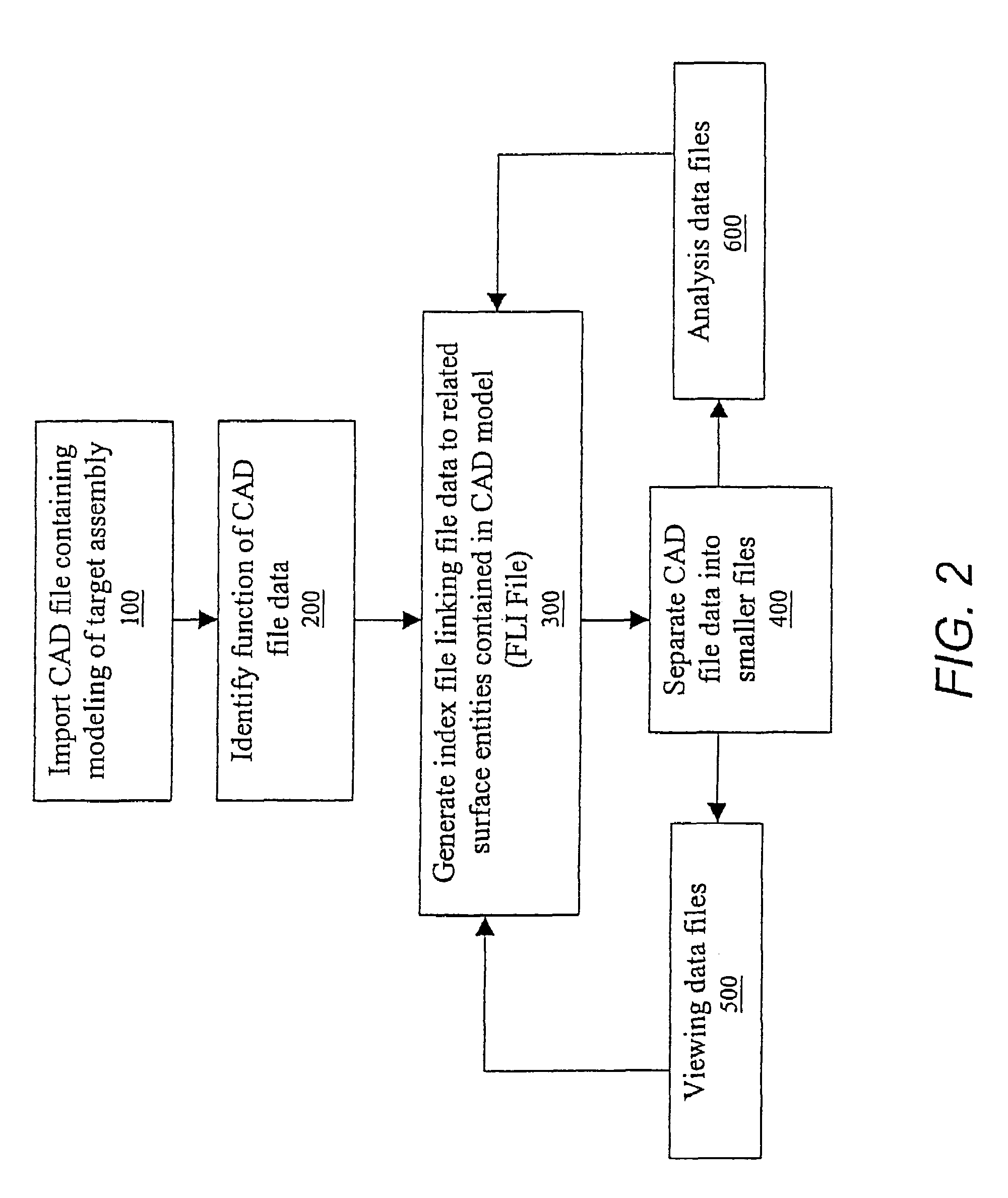

Method and system for computer aided manufacturing measurement analysis

InactiveUS7006084B1Improve quality controlReduce decreaseComputer controlSimulator controlMeasurement pointQuality control

The invention relates to a computer-based method and system to facilitate quality control for manufactured assemblies based on computer aided design (CAD) files. The instant invention mitigates the problems encountered with large CAD files by decomposing each of such files into a multi-file format. A large CAD file is thereby broken-down into smaller files that organize the information contained in the larger file. The organization is performed in such a way that the information pertinent to the measurement process is segregated into a different smaller file than the information not needed to calculate measurements. Thus, the computer running the computation accesses a smaller file containing a higher percentage of required information. Additionally, assisting the user in coordinating a match-up between the physical surfaces being measured and the proper associated CAD model version of that surface further increases the handling speed. In particular, the instant invention uses selection regions for each surface. A selection region consists of the representation of a three-dimensional rectangle region just large enough to enclose each individual surface. A selection region indexes each surface. Thus, when a measurement point is taken, a list of surface regions is automatically scanned in order to determine which region contains that point. The corresponding distance of that measurement point to the surface is then calculated.

Owner:FARO TECH INC

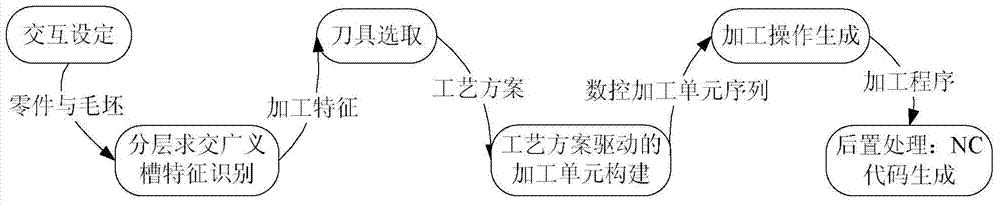

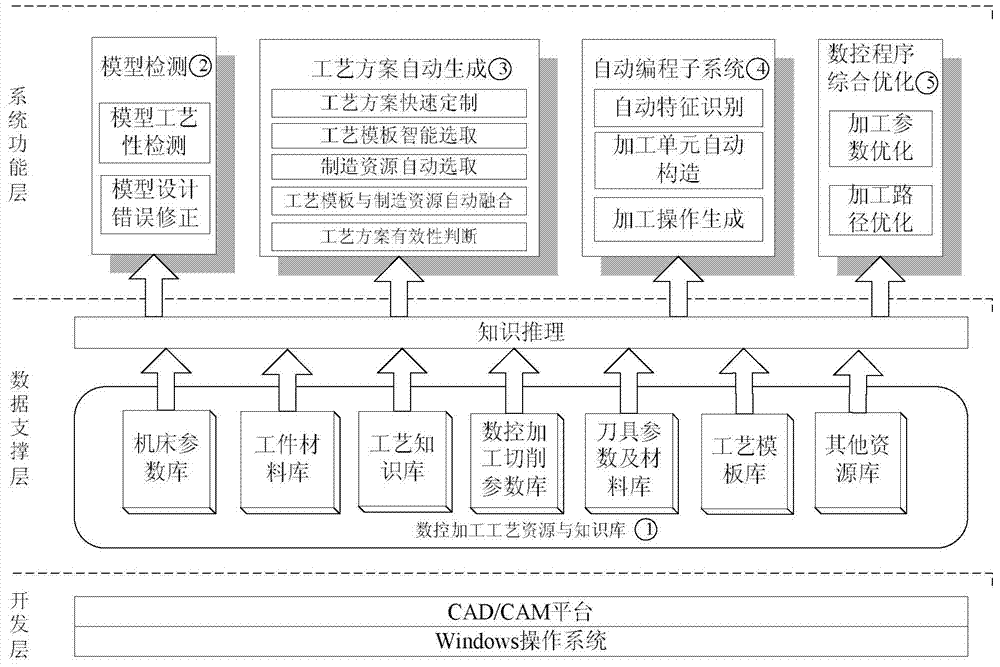

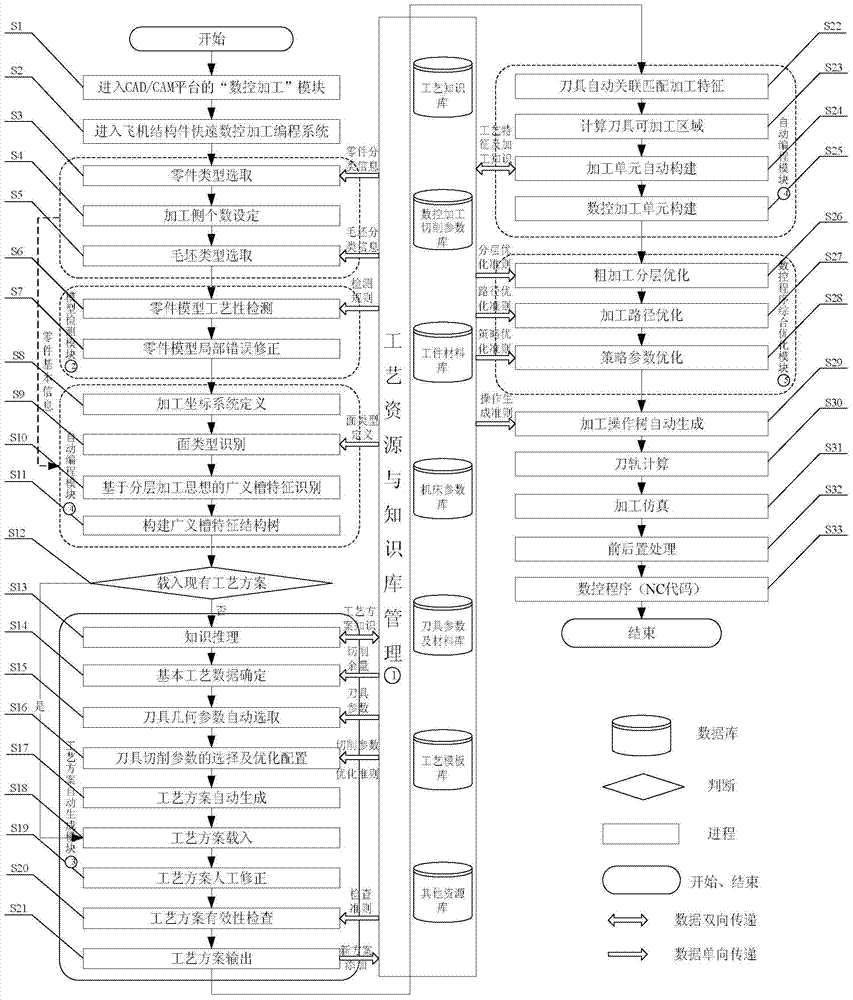

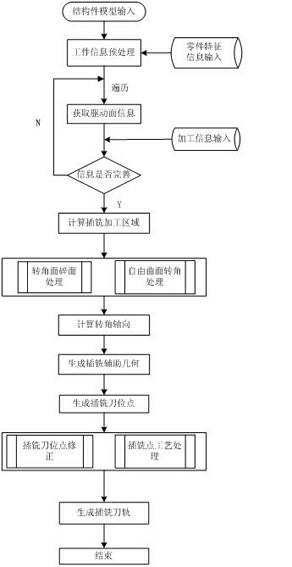

Intelligent numerical control machining programming system and intelligent numerical control machining programming method for aircraft structural parts

ActiveCN103699055AReasonableHigh automatic generation efficiencyProgramme controlComputer controlNumerical controlHuman–computer interaction

The invention relates to an intelligent numerical control machining programming system and an intelligent numerical control machining programming method for aircraft structural parts. According to the system, an existing CAD / CAM (Computer-Aided Design / Computer-Aided Manufacturing) system is taken as a platform; the system comprises a model detection module, a process scheme automatic generation module, a process resource and knowledge base management model, an automatic programming subsystem module and a numerical control program intelligent optimization module. The system is established on the basis of a three-dimensional model, the numerical control machining programming specialization process of the aircraft structural parts is relatively systematically and accurately reflected and supported, the man-machine interaction operation required in the technological preparation and programming process can be greatly reduced, the problems of unstable program, long programming period and the like caused by interactive programming based on universal platform and artificial experience are effectively solved, the numerical control machining preparation and programming efficiency and quality can be obviously improved, and the specialization level and the intelligence level of the CAD / CAM system are promoted.

Owner:SHENYANG AIRCRAFT CORP

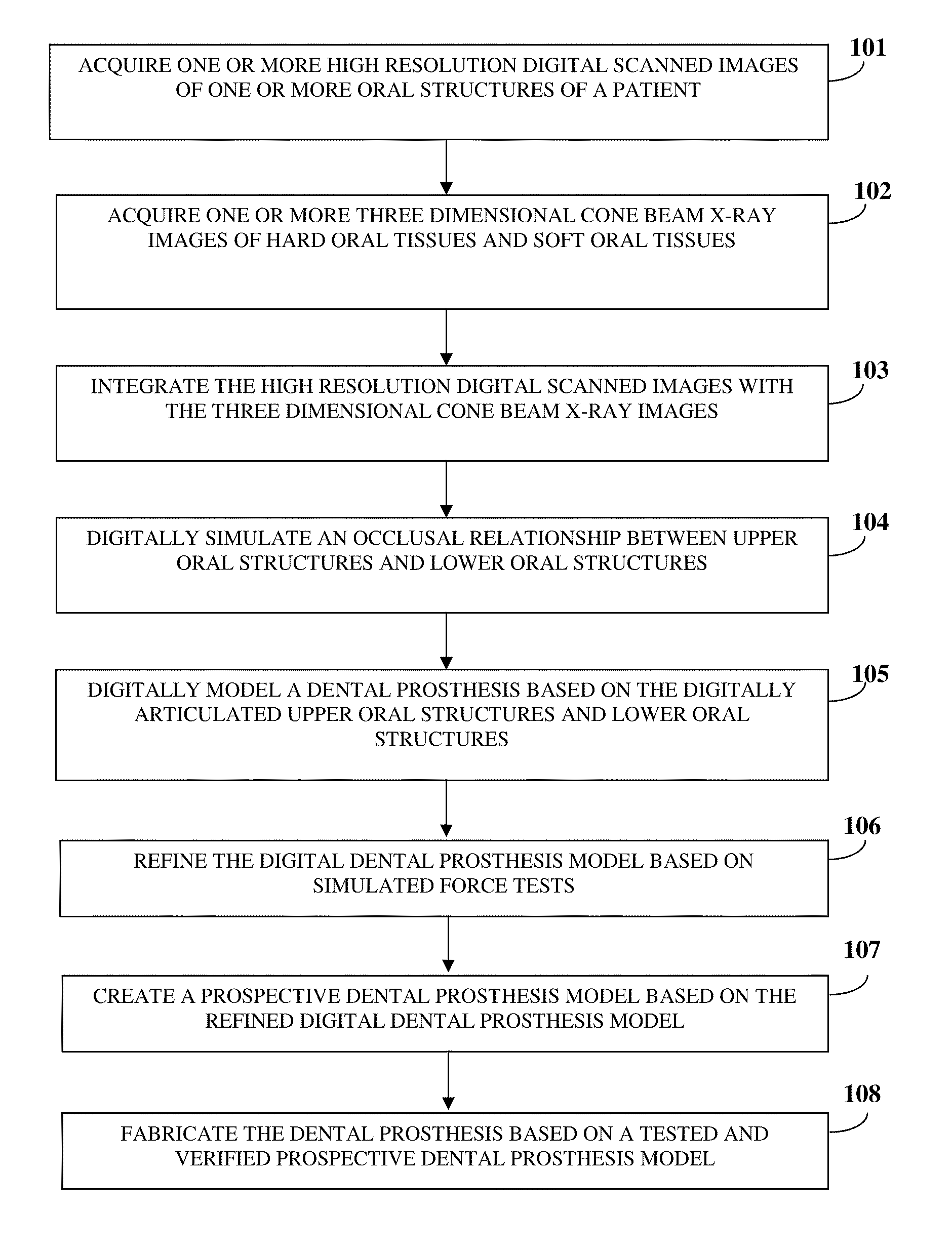

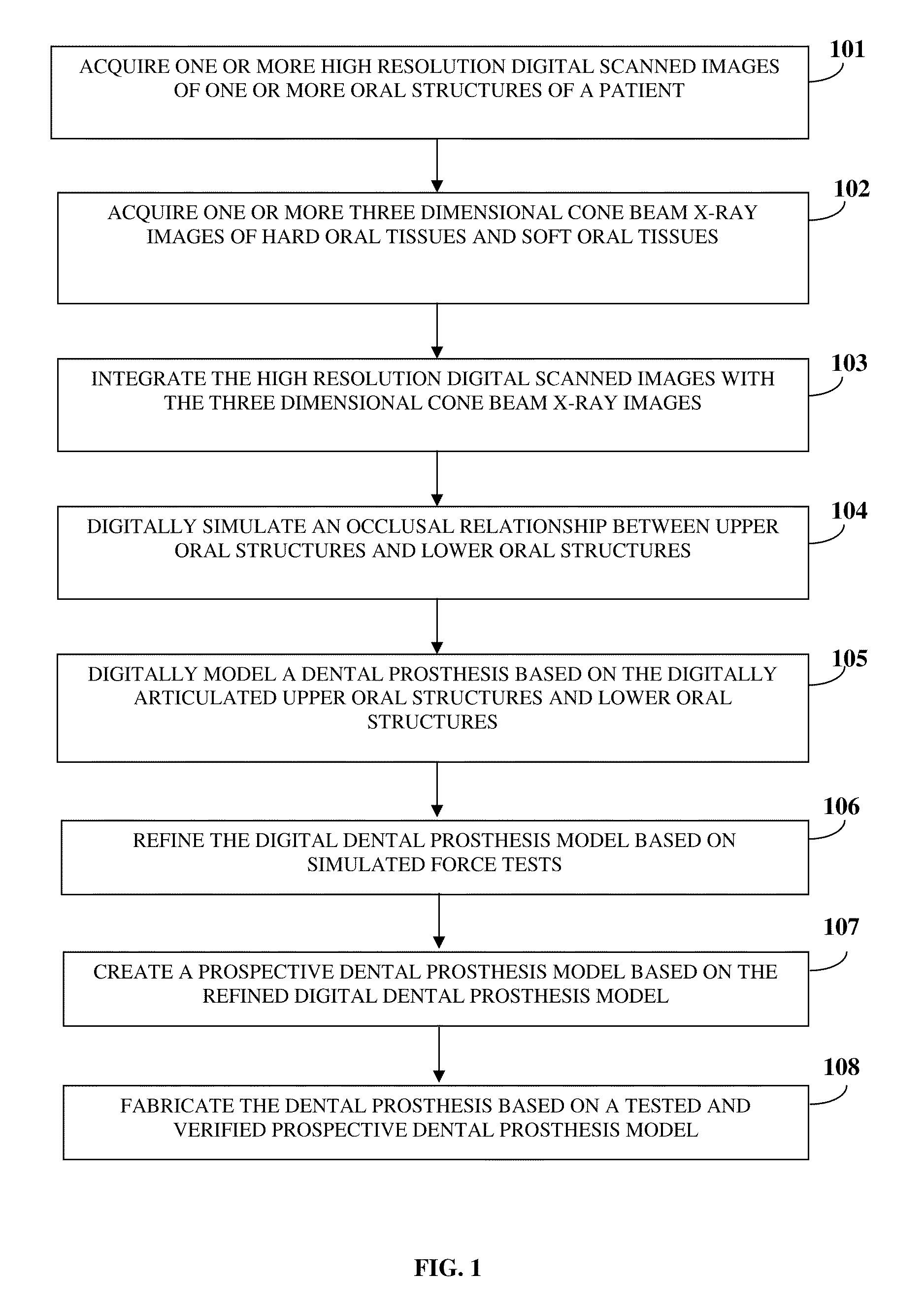

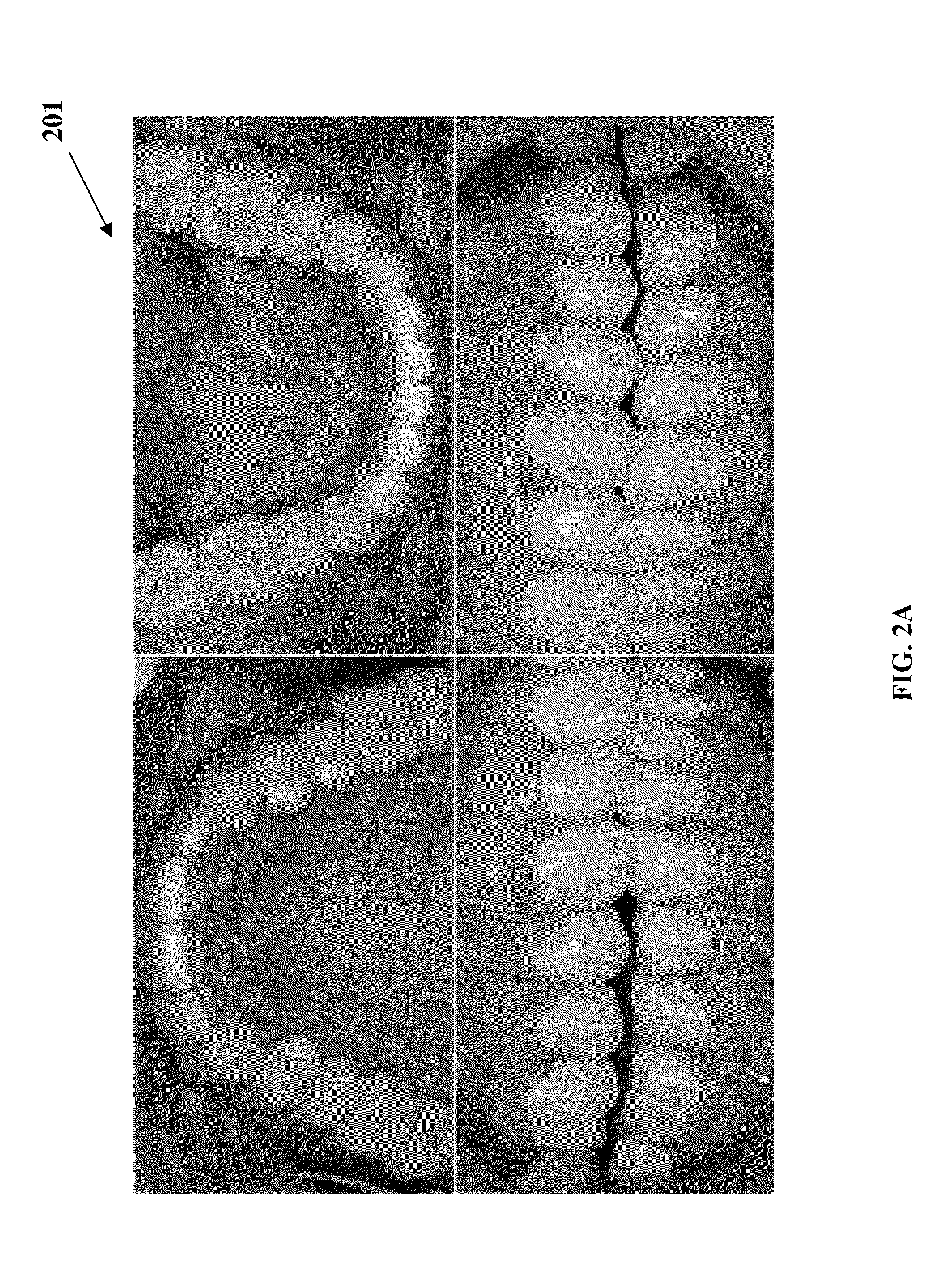

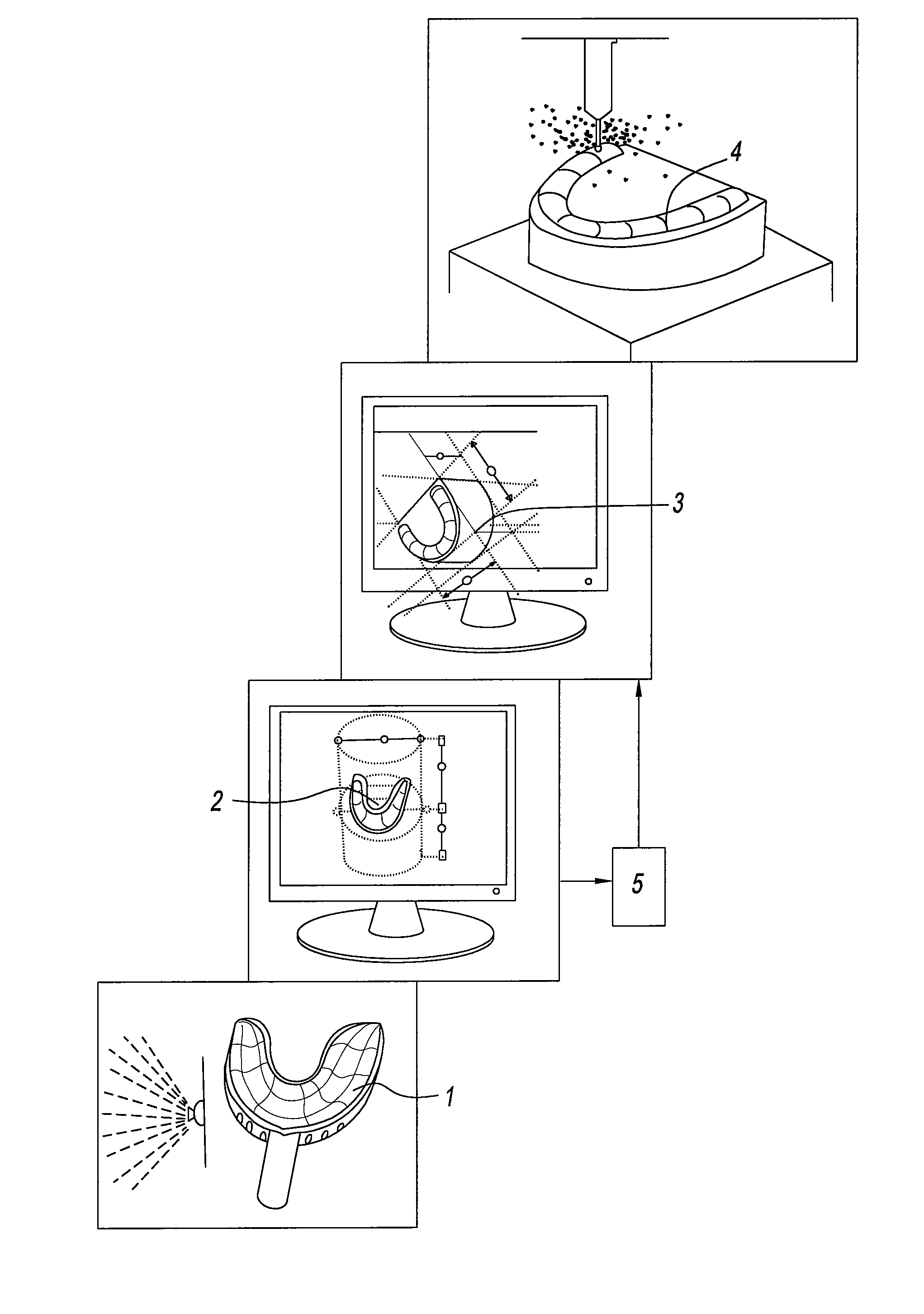

Computer-aided Fabrication Of A Removable Dental Prosthesis

InactiveUS20110276159A1Maximizing retention and functionHighly accurate model-lessAdditive manufacturing apparatusDental articulatorsX-rayComputer aid

A method and system for fabricating a dental prosthesis are provided. High resolution digital scanned images of a patient's oral structures are acquired. Three dimensional (3D) cone beam X-ray images of hard and soft oral tissues are acquired. The scanned images are integrated with the 3D cone beam X-ray images in a 3D space to obtain combined three dimensional images of the oral structures. The occlusal relationship between upper and lower oral structures are digitally simulated using the combined three dimensional images. The dental prosthesis is digitally modeled for planning intra-oral positioning and structure of the dental prosthesis. The digital dental prosthesis model is refined based on simulated force tests performed for assessing interference and retention of the digital dental prosthesis model. A prospective dental prosthesis model is created based on the refined digital dental prosthesis model. The dental prosthesis is fabricated based on a verified prospective dental prosthesis model.

Owner:HANKOOKIN

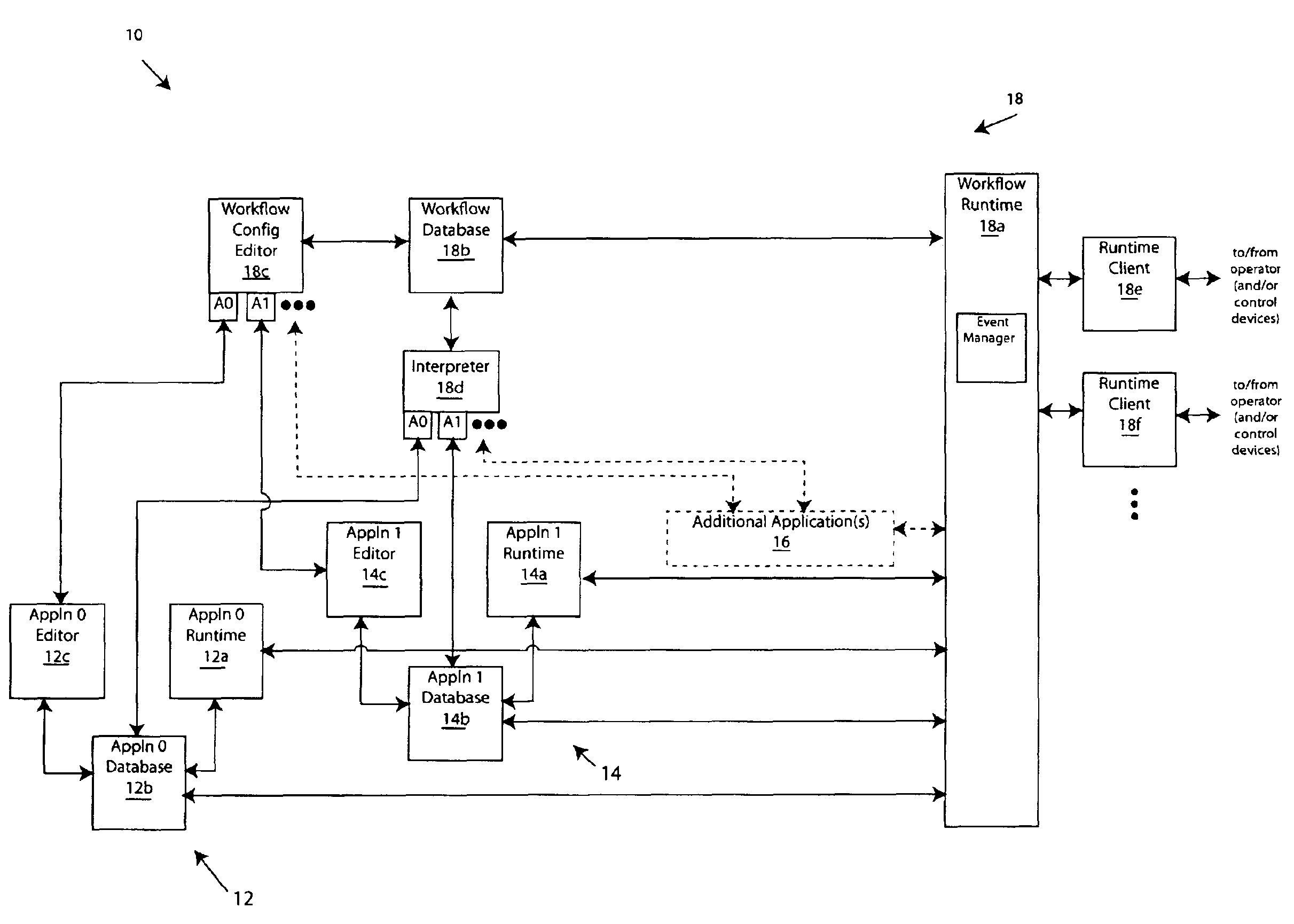

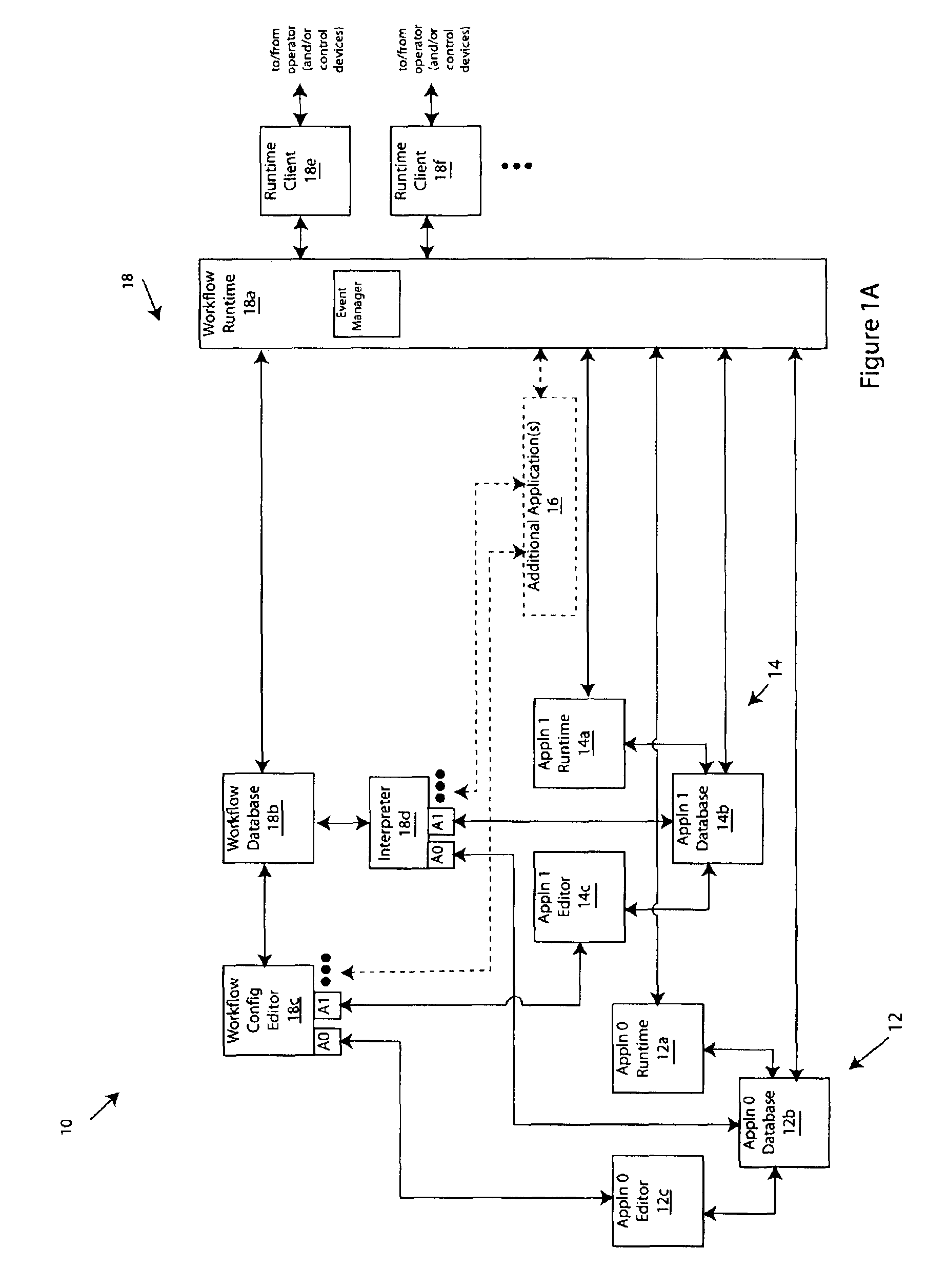

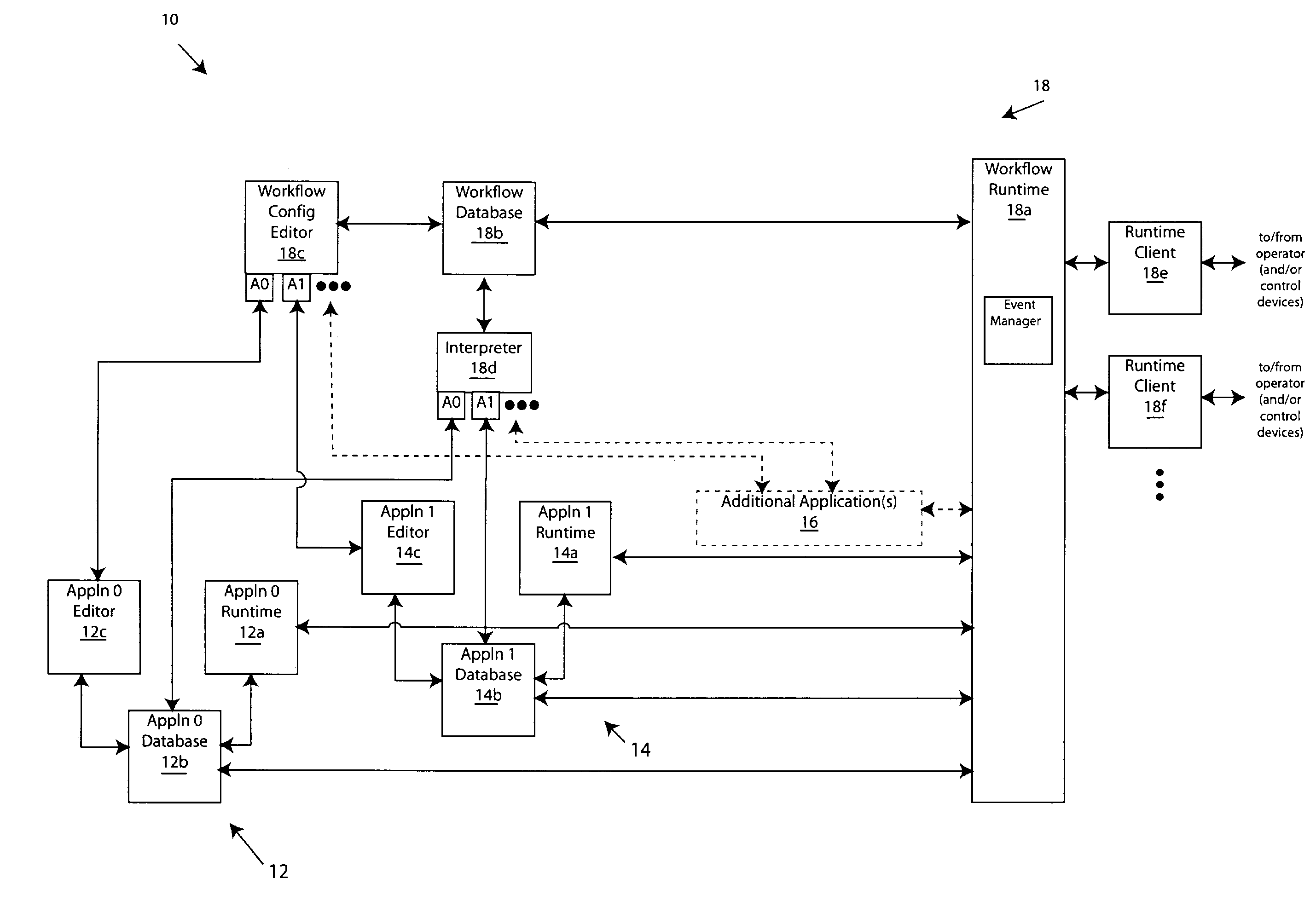

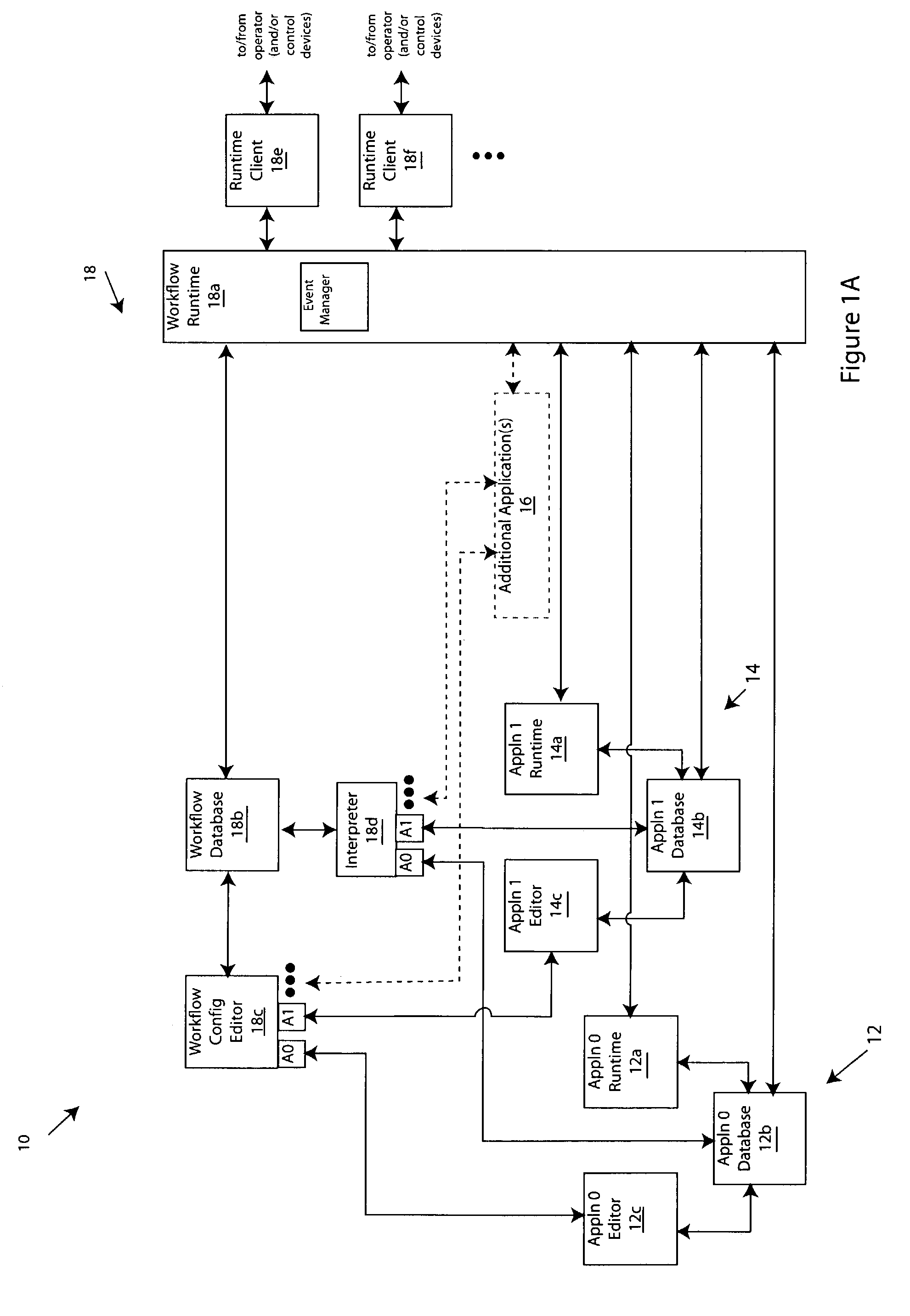

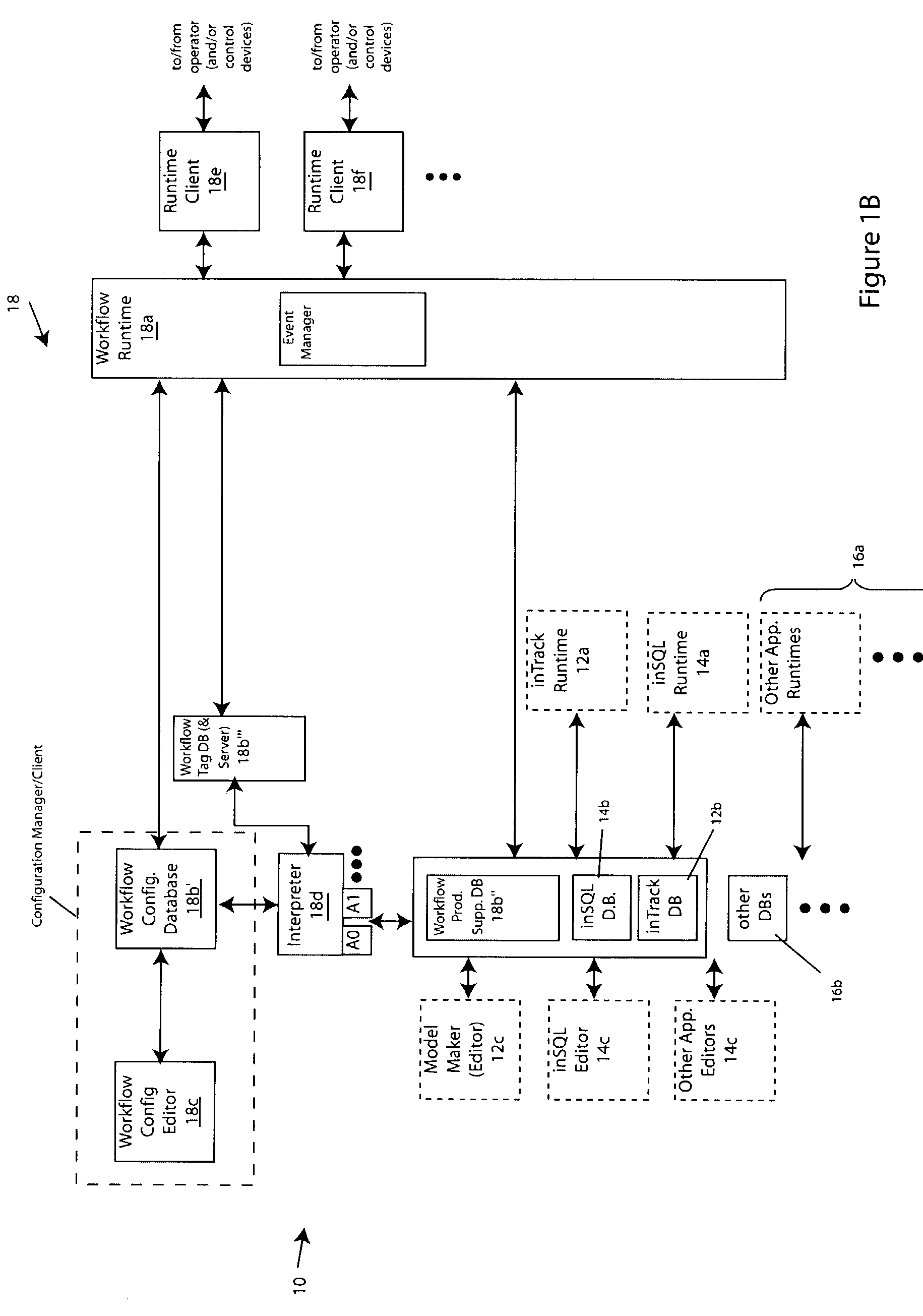

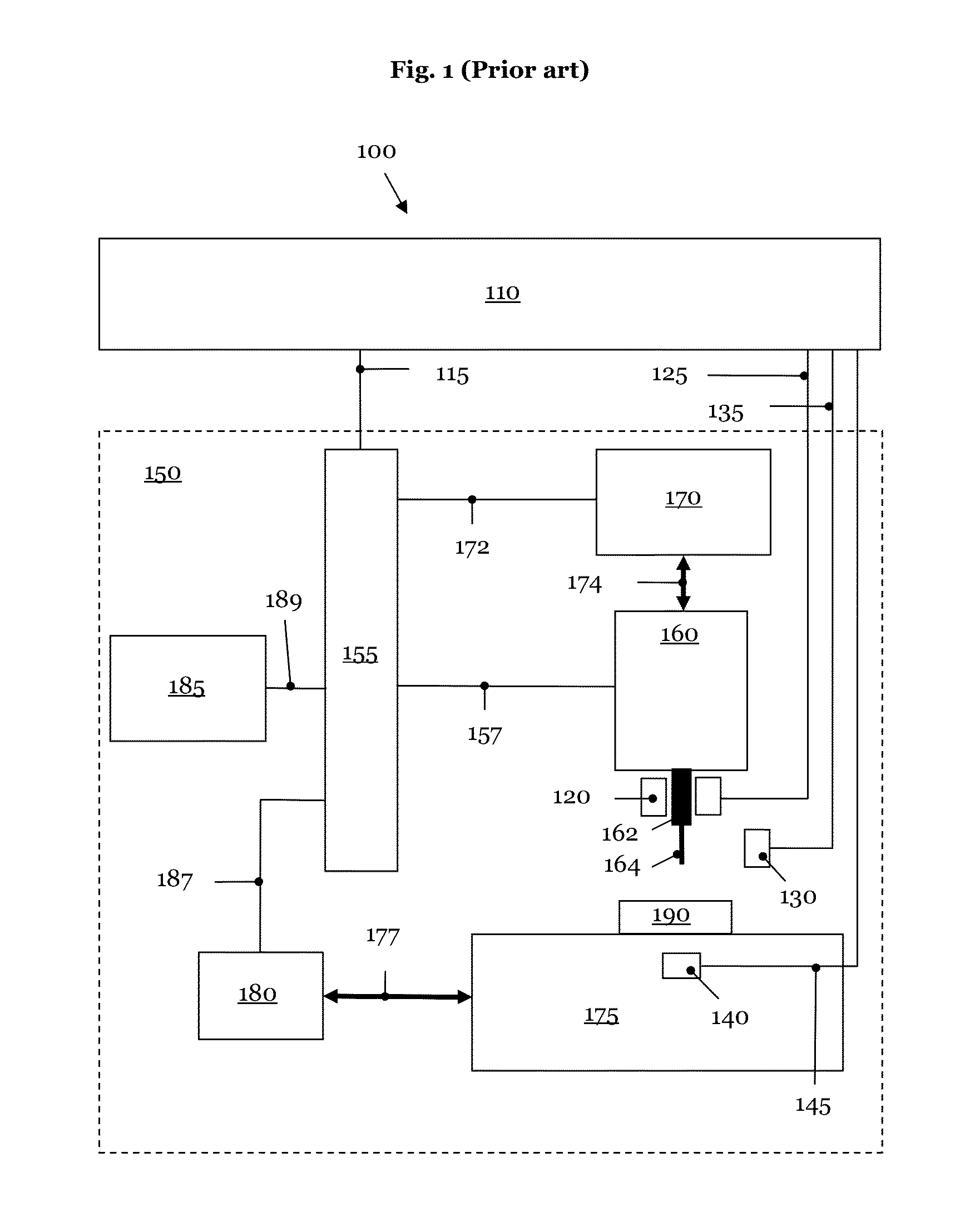

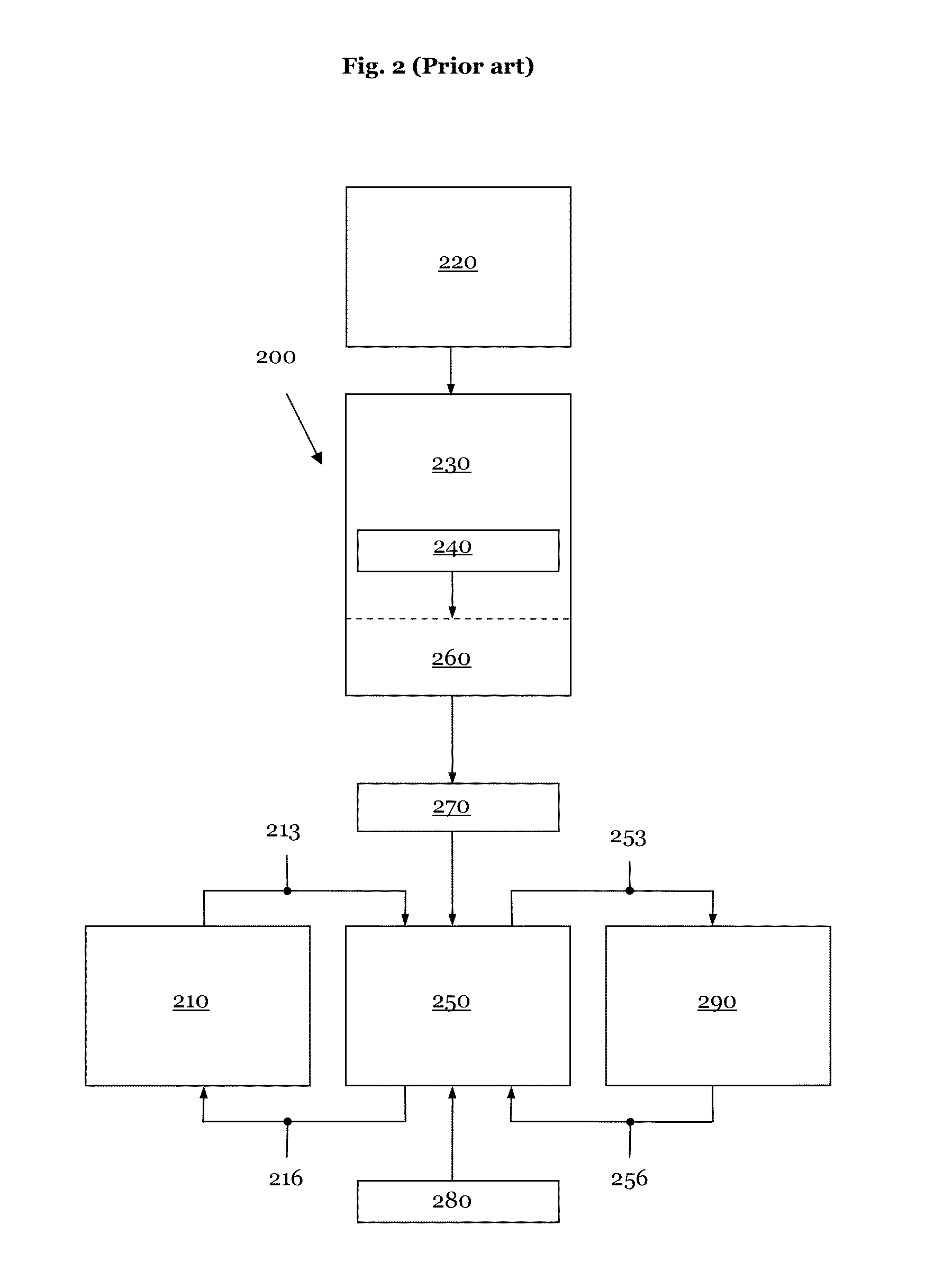

Methods and apparatus for process, factory-floor, environmental, computer aided manufacturing-based or other control system with unified messaging interface

InactiveUS6975914B2Enhanced informationFacilitate communicationComputer controlDigital data processing detailsProgram planningControl system

The invention provides improved methods and apparatus for workflow editing. Such methods and apparatus permit, for example, user-defined and / or other tasks to be combined in any combination or combinations to specify a workflow. The tasks can be linked for direct, serial processing and / or for conditional processing that includes branching and / or looping. The invention also improved methods and apparatus of workflow definition and processing with extensible actions. The invention provides, further, improved methods and apparatus for workflow definition and processing which utilize workflow variables for communication of data and control information among tasks within a workflow. The invention provides, still further, improved methods and apparatus of workflow definition and processing with enhanced messaging. The invention provides, still yet further, improved methods and apparatus for workflow definition and processing which permit definition of hierarchically enumerated data types and for for definition of “plans” to collect, e.g., for storage, data such as the aforementioned hierarchical data types.

Owner:SCHNEIDER ELECTRIC SOFTWARE LLC

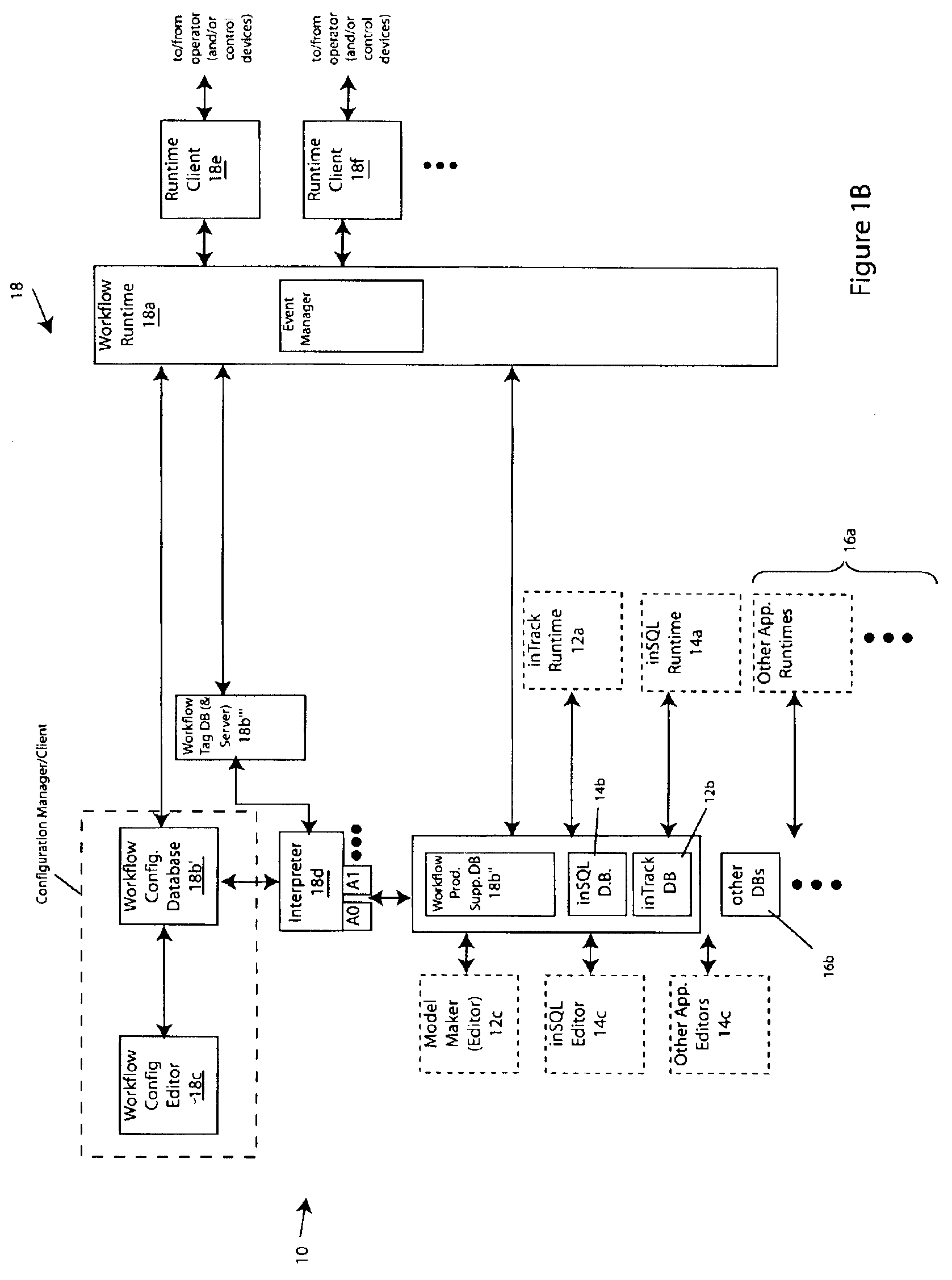

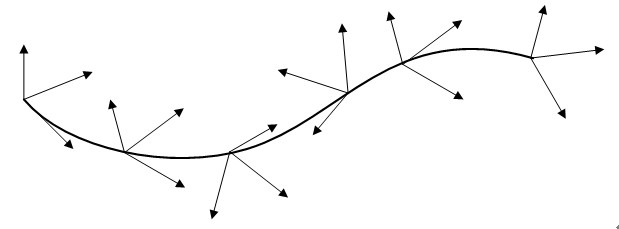

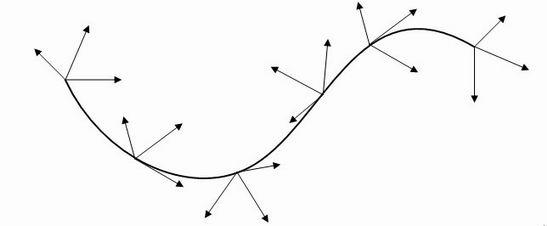

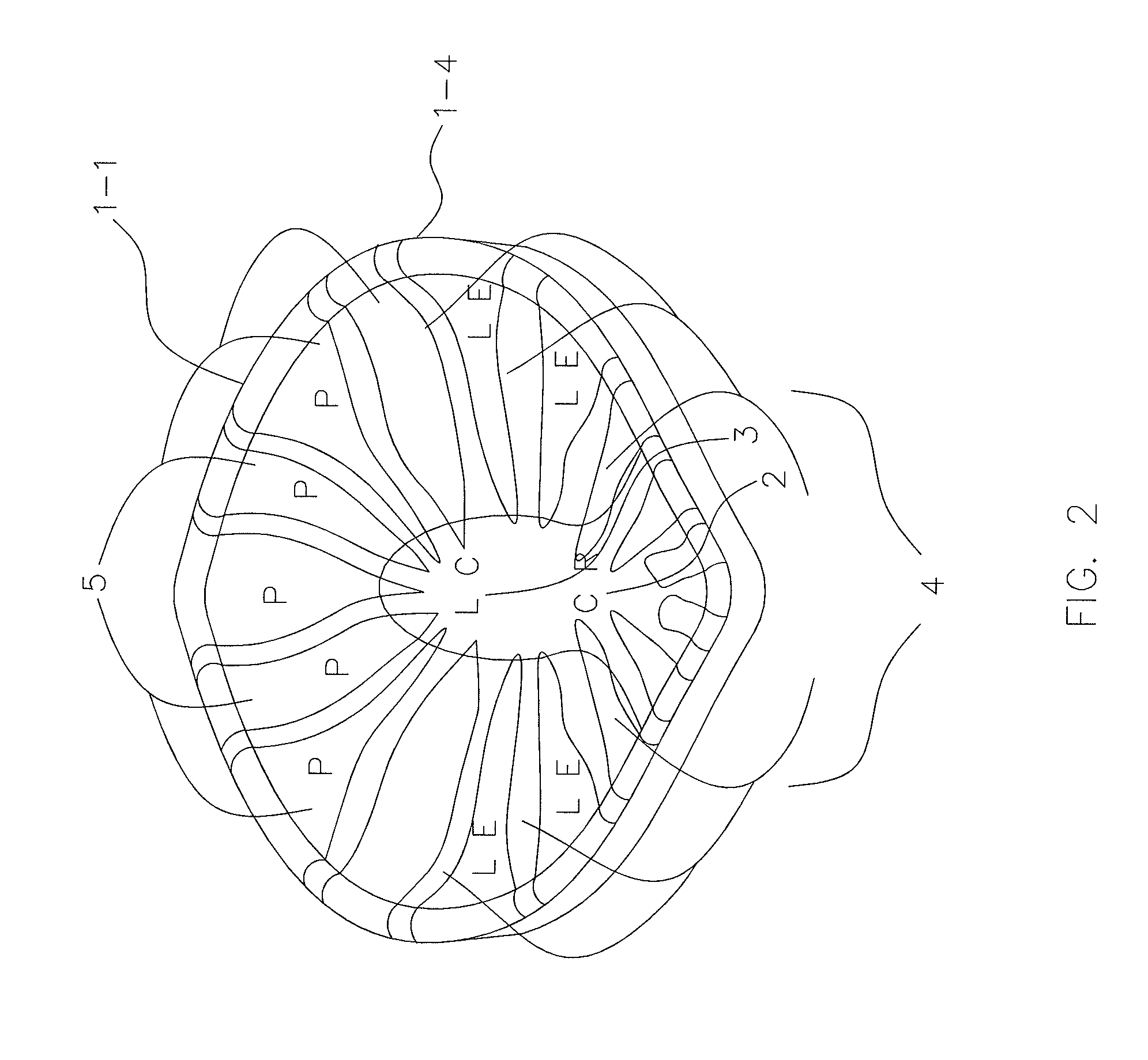

Ruled surface impeller tool path planning and processing method

InactiveCN101271326ASolving the Problems of Five-Axis MachiningHigh degree of automationProgramme controlComputer controlImpellerNumerical control

A path planning processing method of a ruled surface impeller cutter relates to a cutter path planning processing method. The invention solves the problems of the prior numerical control processing method of an impeller part, the problem are that a whole processing technology for processing a integral type ruled surface impeller is not proposed, the calculating method of the point of a knife centre or the point of a knifepoint is not given, the processing cutting efficiency is low, the operation is complex and the degree of automation is low and the five-axis processing of the ruled surface impeller can not be realized etc. The main steps of the method are the establishment of the calculator assistant manufacturing model CAM of an impeller part, the calculation of the vector of a cutter shaft, the calculation of the point of the knife centre, the planning of whole cutter path and the achievement of the processing of the impeller part. The method of the invention solves the problem of the five-axis processing of the ruled surface impeller and has the advantages of high processing cutting efficiency, easy operation and high degree of automation The ruled surface impeller processed by the method has the characteristics of orderly linage of flow passage, symmetrical structure and the uniform distribution of cutter path at the surface of the flow passage, thus reducing the workload of subsequent polishing processing greatly.

Owner:哈尔滨工大宏图橡塑科技有限公司

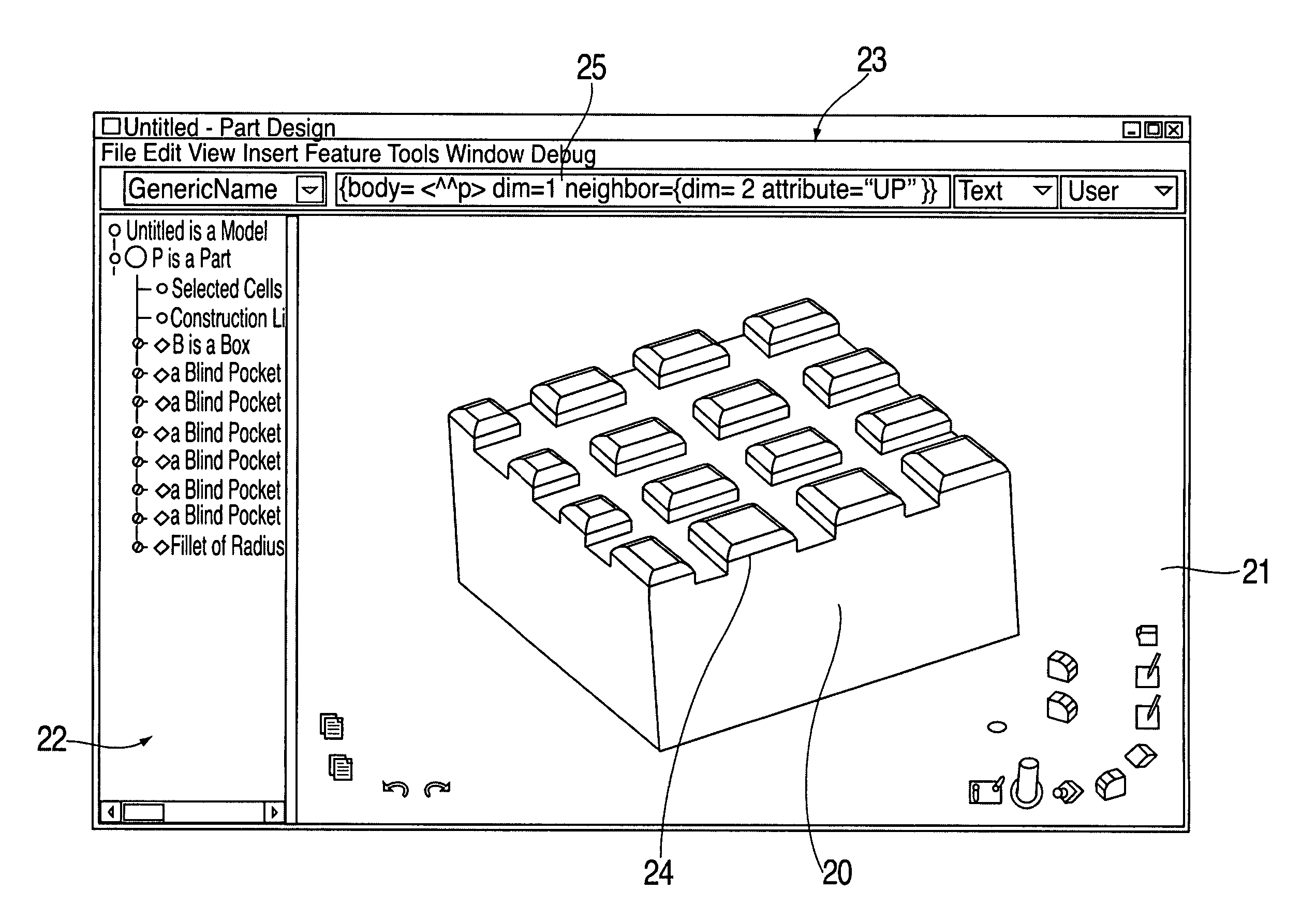

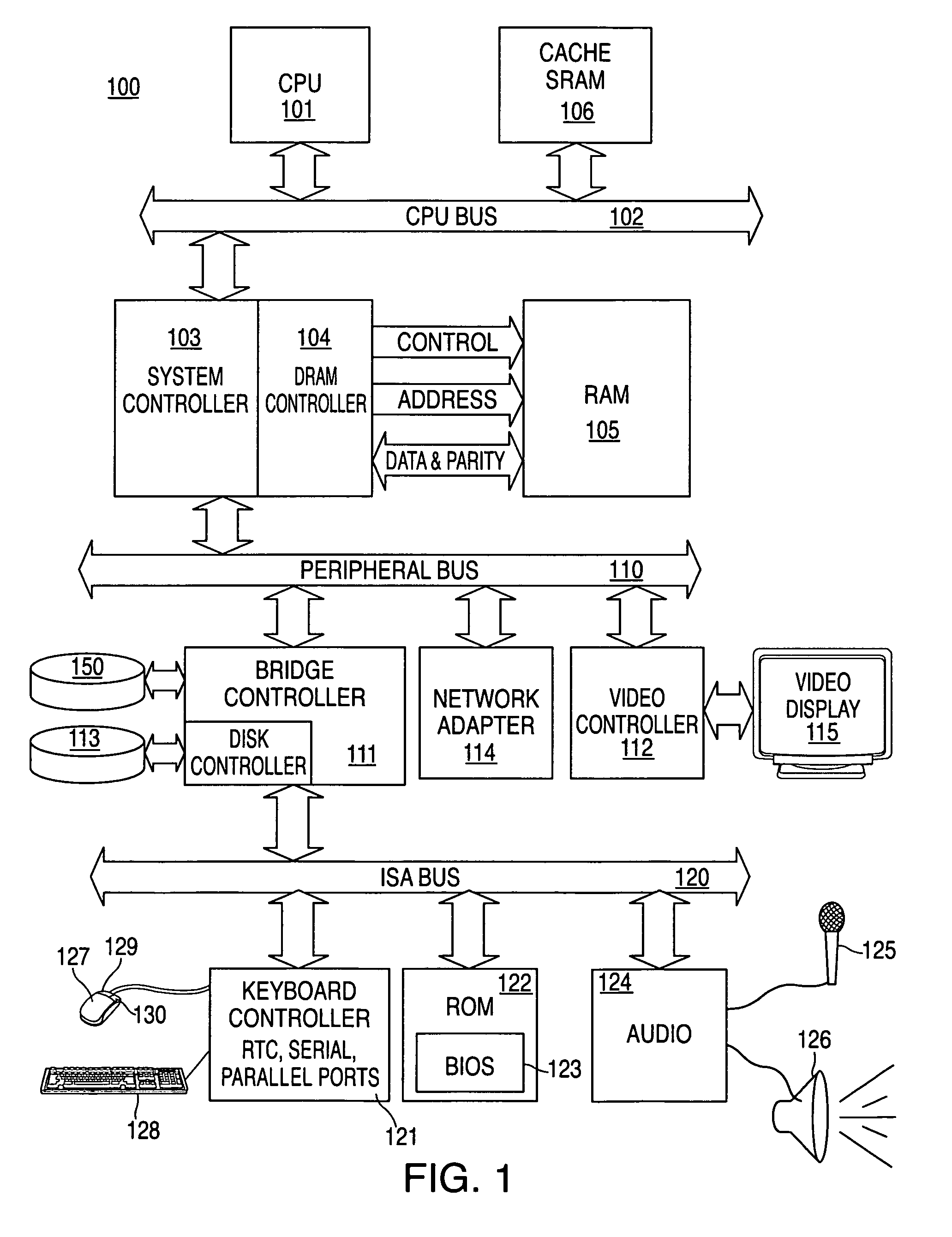

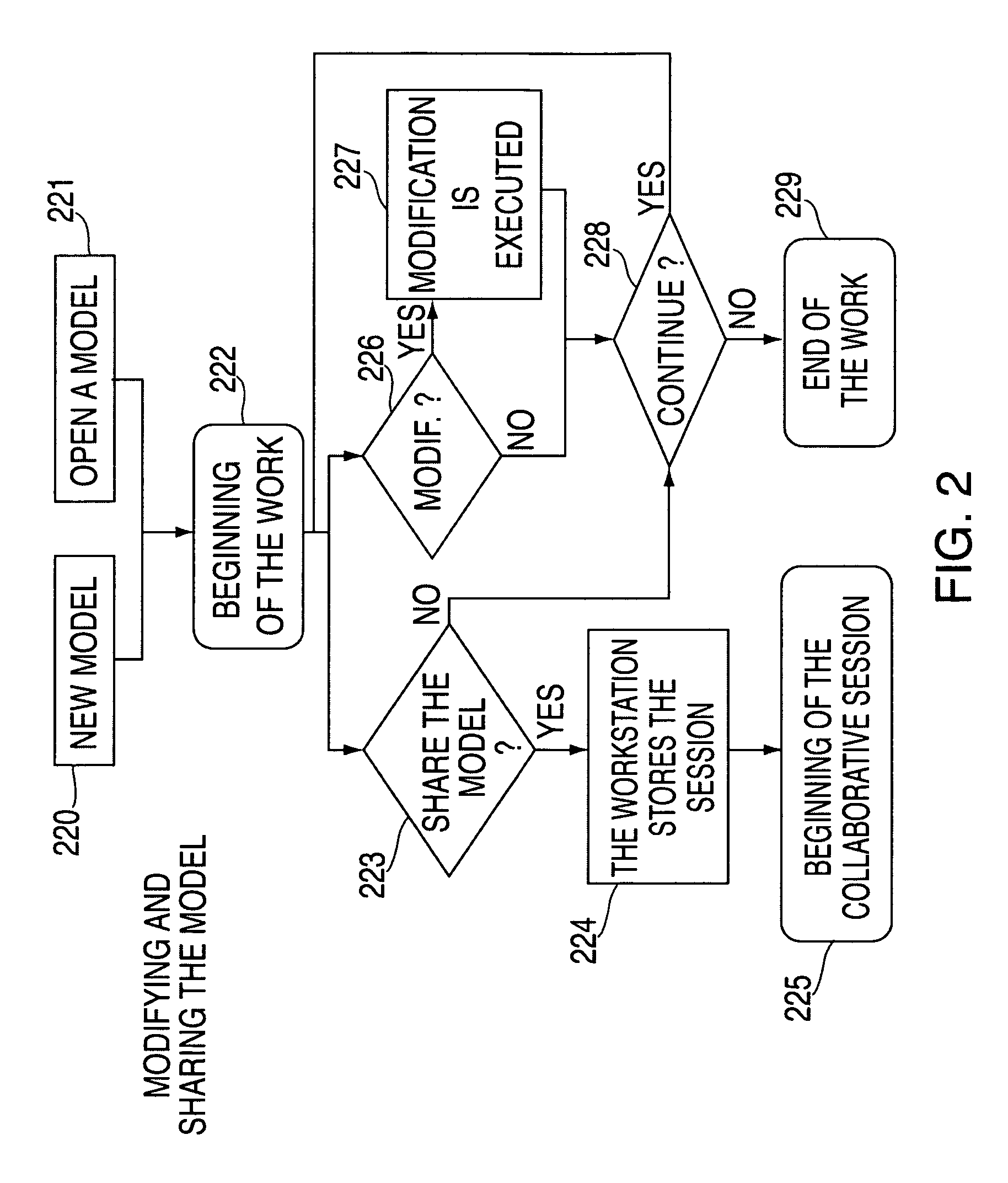

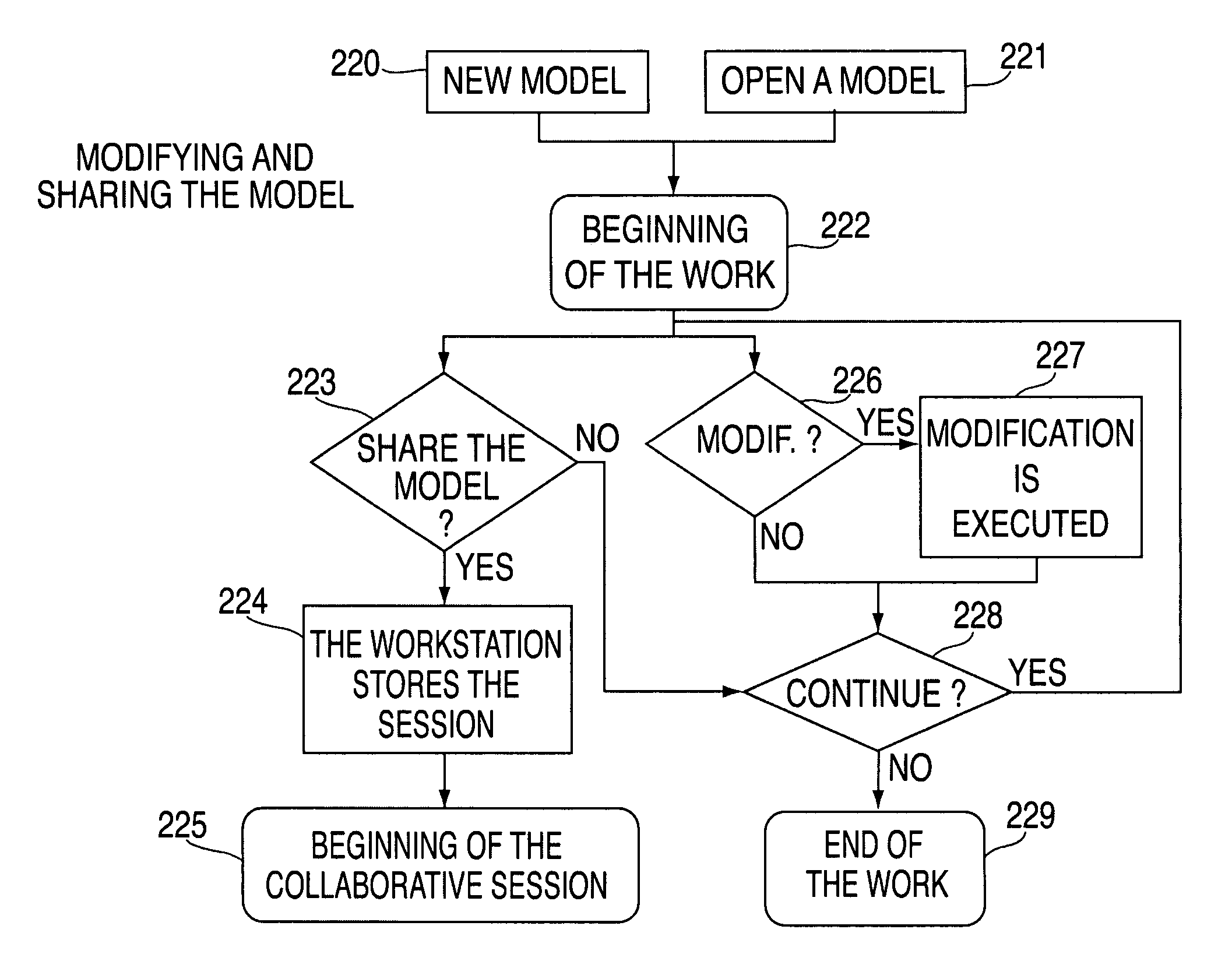

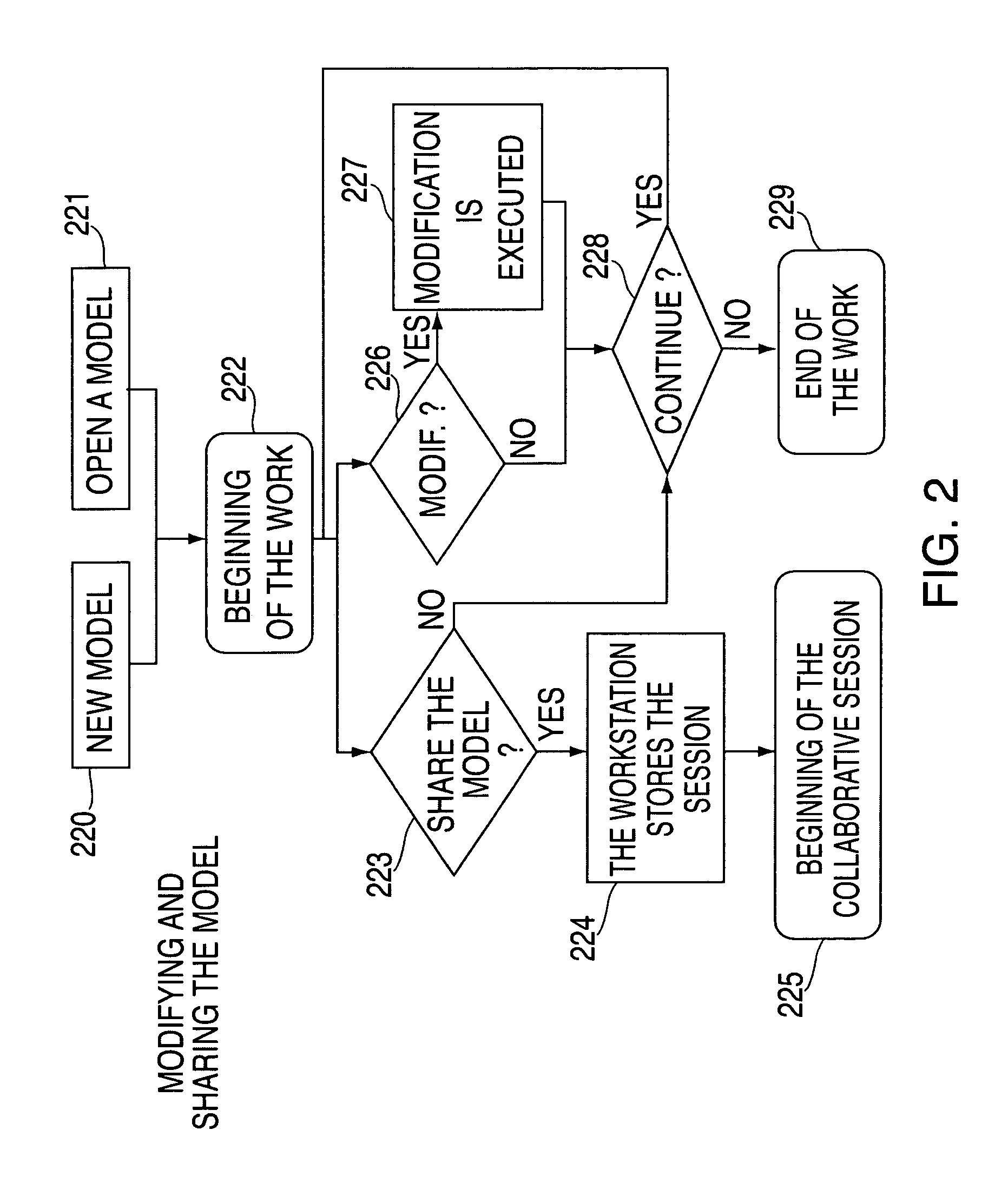

Collaborative design

InactiveUS20060250418A1Improve productivityLess timeData processing applicationsDrawing from basic elementsSoftware engineeringWorkstation

A method, system and apparatus for use in computer-aided design, computer-aided manufacturing, computer-aided engineering and product lifecycle management. An efficient, non-centralized communications framework makes “synchronous” collaborative design possible. Users are resident at workstations that are connected in a peer-to-peer arrangement. In a collaborative design session, the model is resident in memory at each workstation. Modifications are made at any workstation, and commands, which are interpreted at each workstation to effect the modifications, are transmitted over the network. In addition, cell descriptors may be used to identify one or more geometric cells of a model. The cell descriptors are in the form of scripts specifying constraints or filters for identifying cells. The constraints are based on characteristics of items in the model, or associations between items in a model, that are readily discernable to the user, and are therefore easily written and susceptible to easy distribution to other systems.

Owner:DASSAULT SYSTEMES

Workflow control configurator for use with process, factory-floor, environmental, computer aided manufacturing-based or other control system

ActiveUS7242991B2Enhancement in definitionFacilitate communicationComputer controlDigital data processing detailsMessage deliveryControl system

The invention provides improved methods and apparatus for workflow editing. Such methods and apparatus permit, for example, user-defined and / or other tasks to be combined in any combination or combinations to specify a workflow. The tasks can be linked for direct, serial processing and / or for conditional processing that includes branching and / or looping. The invention also improved methods and apparatus of workflow definition and processing with extensible actions. The invention provides, further, improved methods and apparatus for workflow definition and processing which utilize workflow variables for communication of data and control information among tasks within a workflow. The invention provides, still further, improved methods and apparatus of workflow definition and processing with enhanced messaging. The invention provides, still yet further, improved methods and apparatus for workflow definition and processing which permit definition of hierarchically enumerated data types and for for definition of “plans” to collect, e.g., for storage, data such as the aforementioned hierarchical data types.

Owner:SCHNEIDER ELECTRIC SOFTWARE LLC

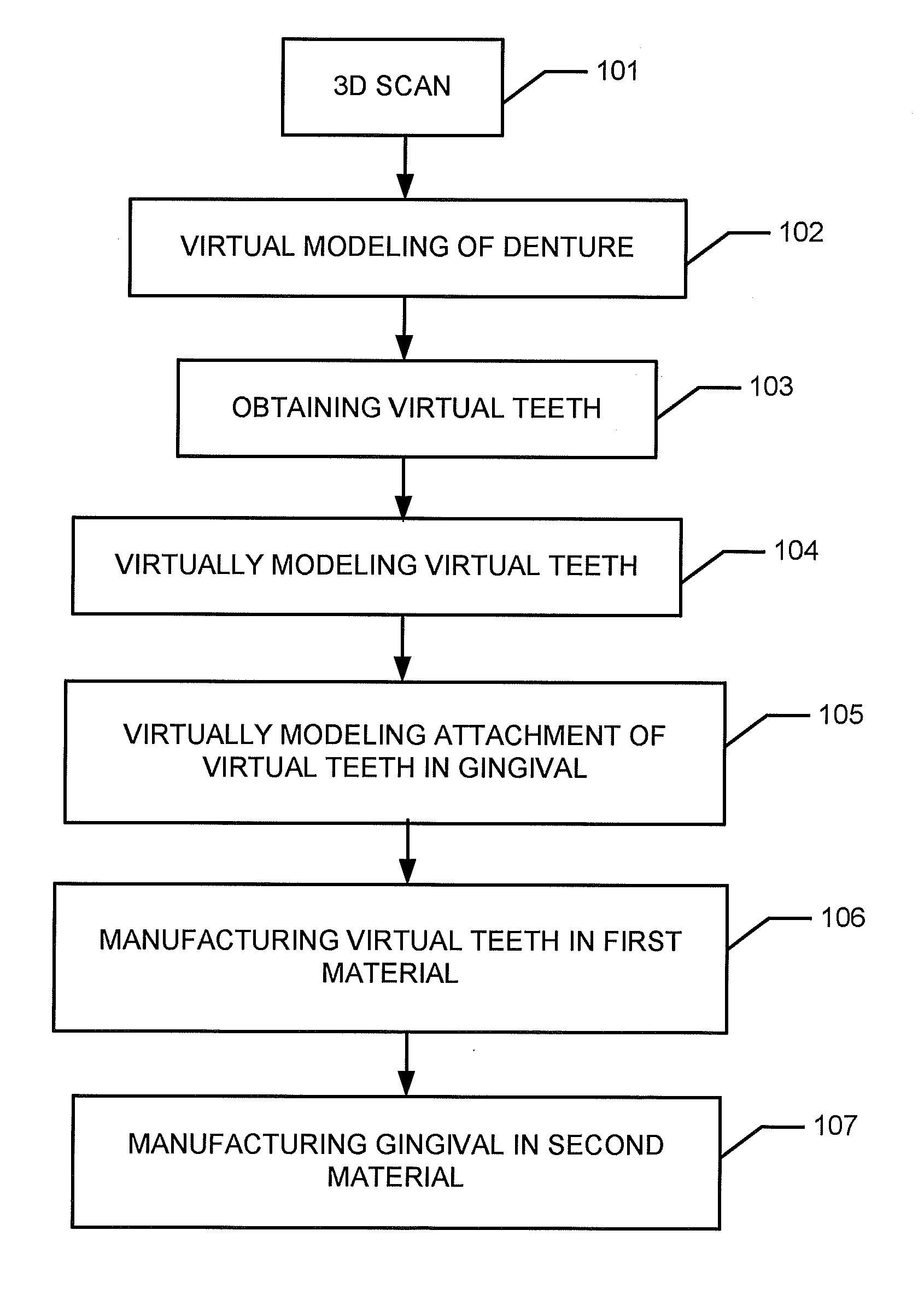

Modeling and manufacturing of dentures

ActiveUS20130316302A1Improve aestheticsImprove functionalityDental implantsImpression capsDenturesCam

Disclosed is a method for modeling and manufacturing a denture for a patient, where the denture comprises a gingival part and artificial teeth, wherein the method comprises: providing a 3D scan comprising at least part of the patient's oral cavity; virtually modeling at least part of the denture using the 3D scan; obtaining virtual teeth to represent the artificial teeth; virtually modeling at least one of the virtual teeth to obtain a set of modeled virtual teeth; manufacturing the modeled virtual teeth in a first material; manufacturing the gingival part in a second material; and manufacturing at least part of the denture by means of computer aided manufacturing (CAM).

Owner:3SHAPE AS

Collaborative design

InactiveUS7176942B2Improve productivityLess timeData processing applicationsDigital computer detailsApplication lifecycle managementWorkstation

A method, system and apparatus for use in computer-aided design, computer-aided manufacturing, computer-aided engineering and product lifecycle management. An efficient, non-centralized communications framework makes “synchronous” collaborative design possible. Users are resident at workstations that are connected in a peer-to-peer arrangement. In a collaborative design session, the model is resident in memory at each workstation. Modifications are made at any workstation, and commands, which are interpreted at each workstation to effect the modifications, are transmitted over the network. In addition, cell descriptors may be used to identify one or more geometric cells of a model. The cell descriptors are in the form of scripts specifying constraints or filters for identifying cells. The constraints are based on characteristics of items in the model, or associations between items in a model, that are readily discernable to the user, and are therefore easily written and susceptible to easy distribution to other systems.

Owner:DASSAULT SYSTEMES

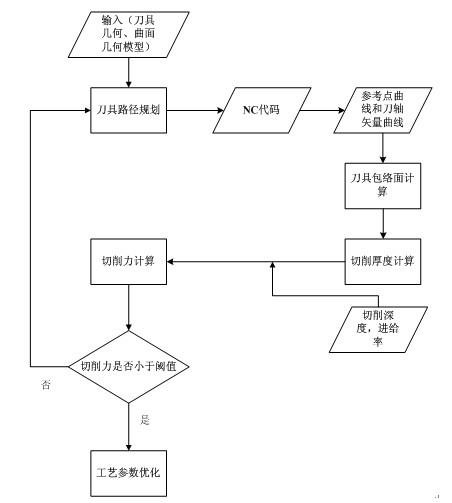

Five-axis side milling machining process parameter design method

InactiveCN102129232AAccurate transient cutting thicknessImprove accuracyNumerical controlNumerical controlAnalytical expressions

The invention discloses a five-axis side milling machining process parameter design method, belongs to the technology of numerical control (NC) machining, and solves the problem that real machining conditions cannot be reflected in cutting force calculation in the conventional process parameter design method. The method comprises the following steps of: tool path planning, cutting force calculation and process parameter optimization; in the tool path planning step, an NC code is generated by using computer-aided manufacturing (CAM) software; in the cutting force calculation step, first, a continuous tool path is generated from the NC code; then, a cutting thickness is obtained; and finally, the cutting force is calculated according to the cutting thickness; and in the process parameter optimization step, whether the calculated cutting force is not greater than a design threshold is judged; if the calculated cutting force is not greater than the design threshold, the NC code, the cutting depth and a feed rate are taken as input parameters; and otherwise, an NC code is regenerated. In the method, the real machining conditions are reflected by utilizing a tool enveloping surface analytical expression and the obtained transient cutting thickness is more accurate, so that the accuracy of the calculation of the cutting thickness and the cutting force is improved, and reliable assurance is provided for precisely and efficiently machining a spatial curved surface.

Owner:HUAZHONG UNIV OF SCI & TECH

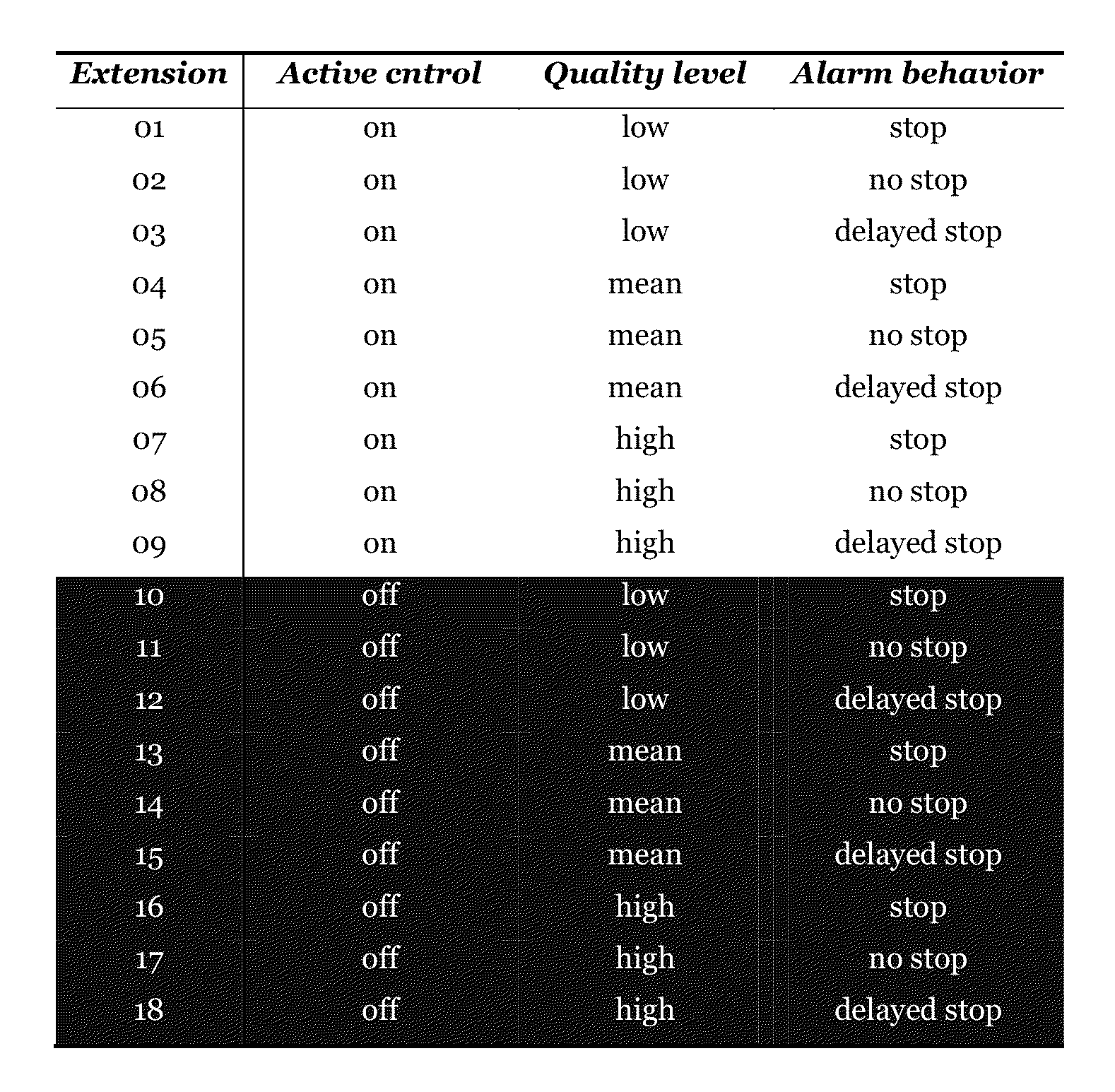

Method and Apparatus for Automated Configuration of a Monitoring Function of a Machine Tool

ActiveUS20130304248A1Good synchronizationTotal factory controlSpecial data processing applicationsPost processorCam

System and method for automated provision of a monitoring function for a machining process which is to be executed by a machine tool. A computer-aided manufacturing (CAM) program of the machining process is automatically analyzed by means of a postprocessor in order to determine processing steps to be monitored. At least one monitoring instruction may be automatically inserted into a control program of the machine tool by the postprocessor, wherein the control program is executed during the machining process.

Owner:MARPOSS MONITORING SOLUTIONS GMBH

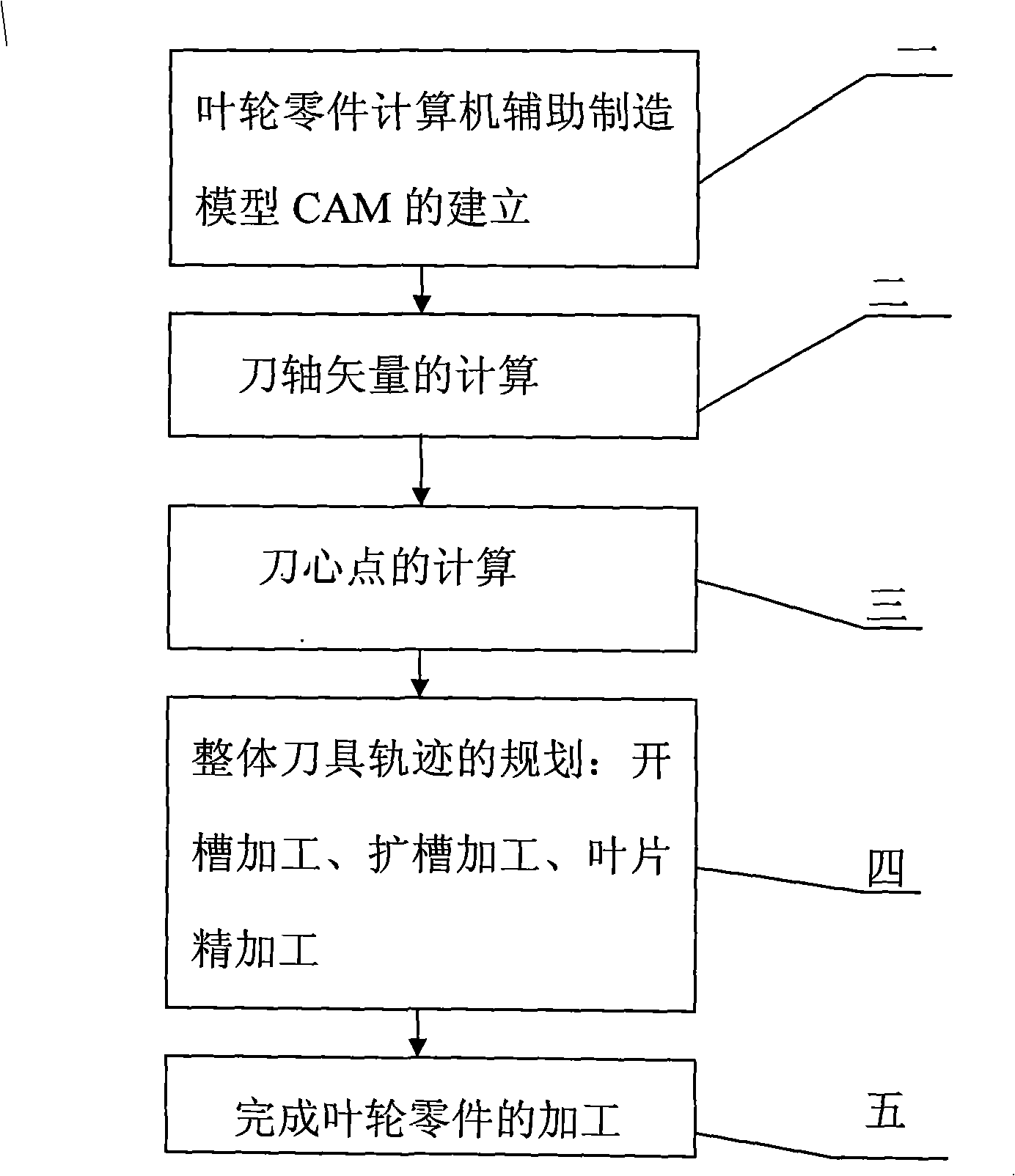

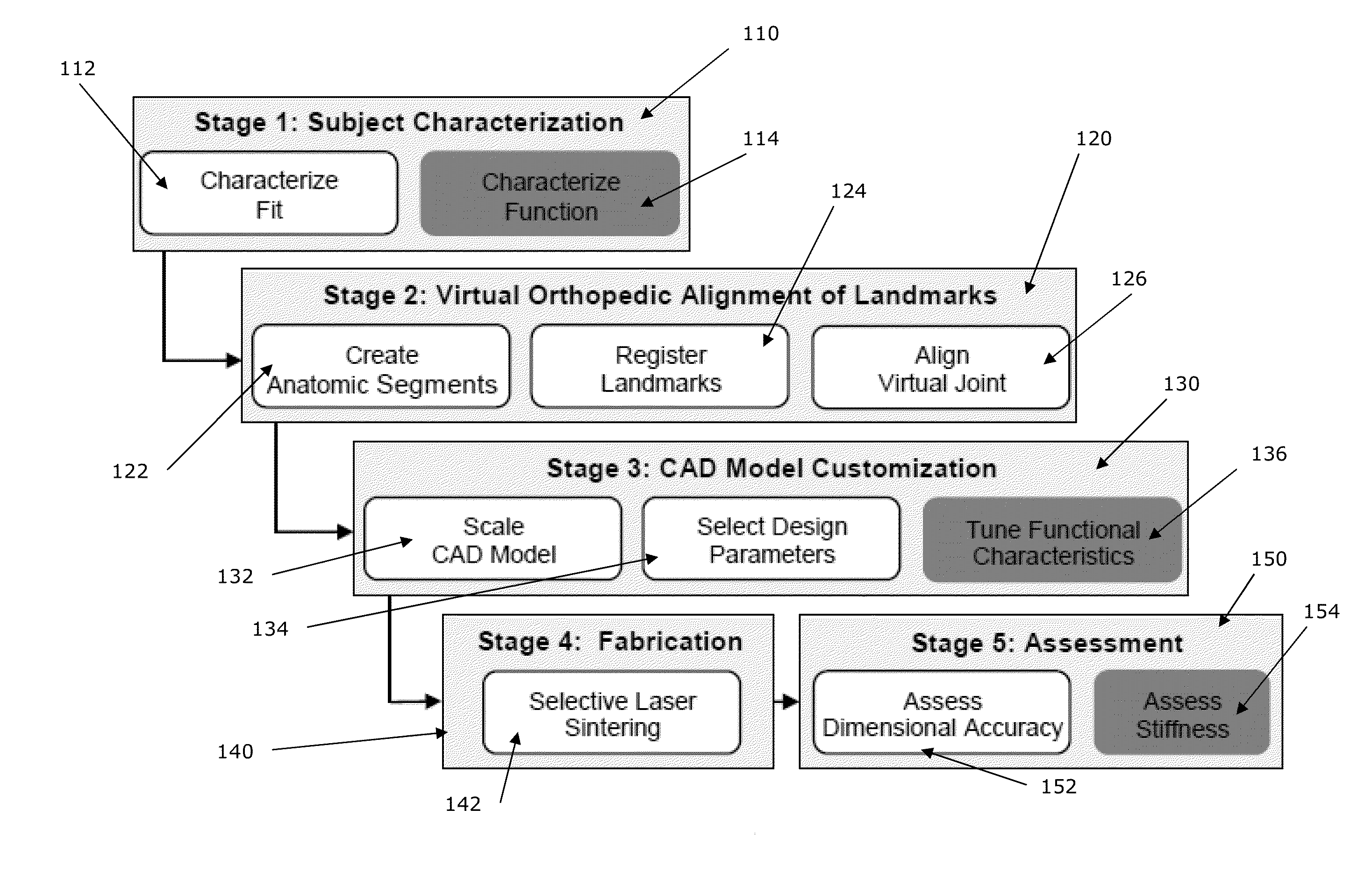

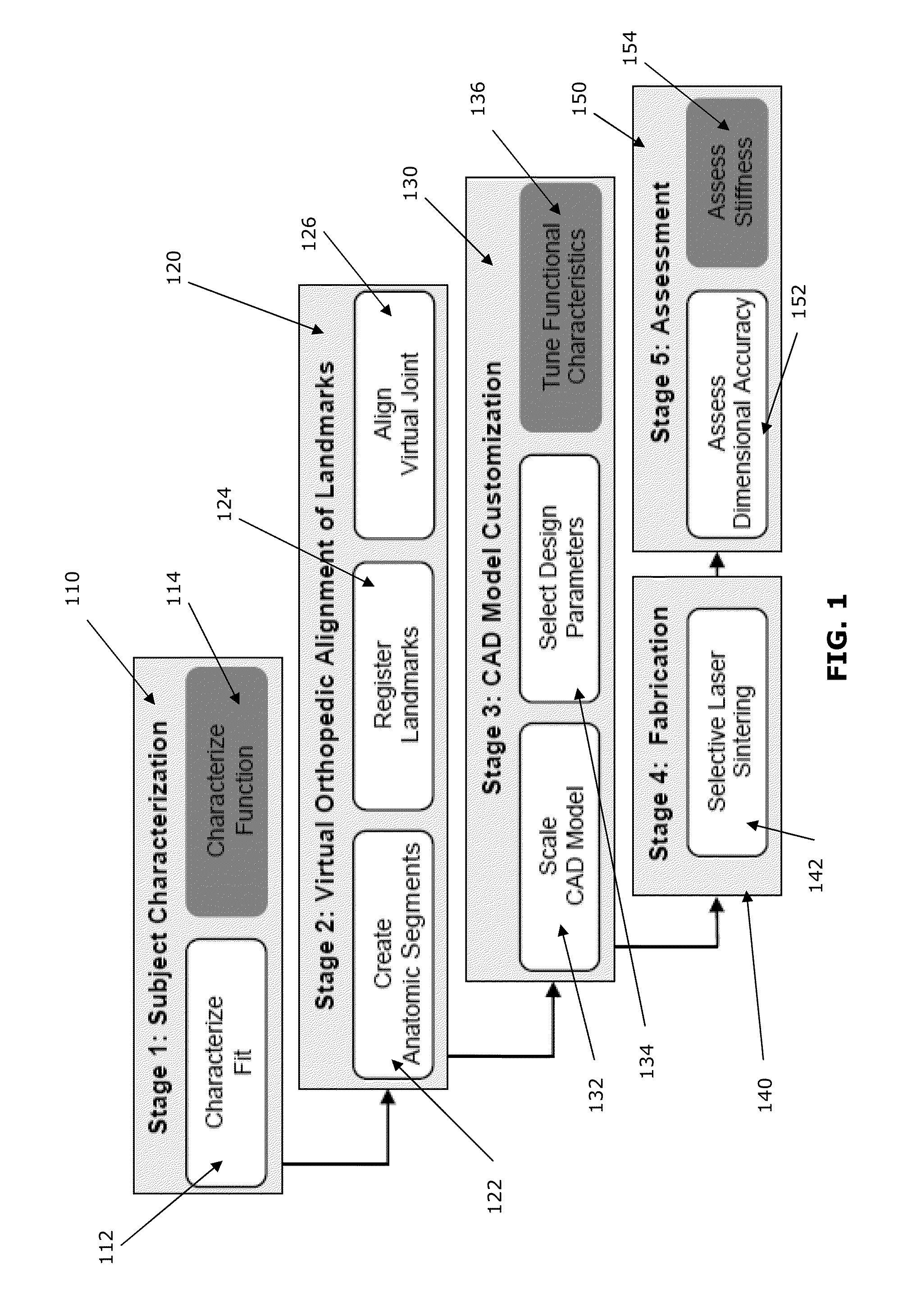

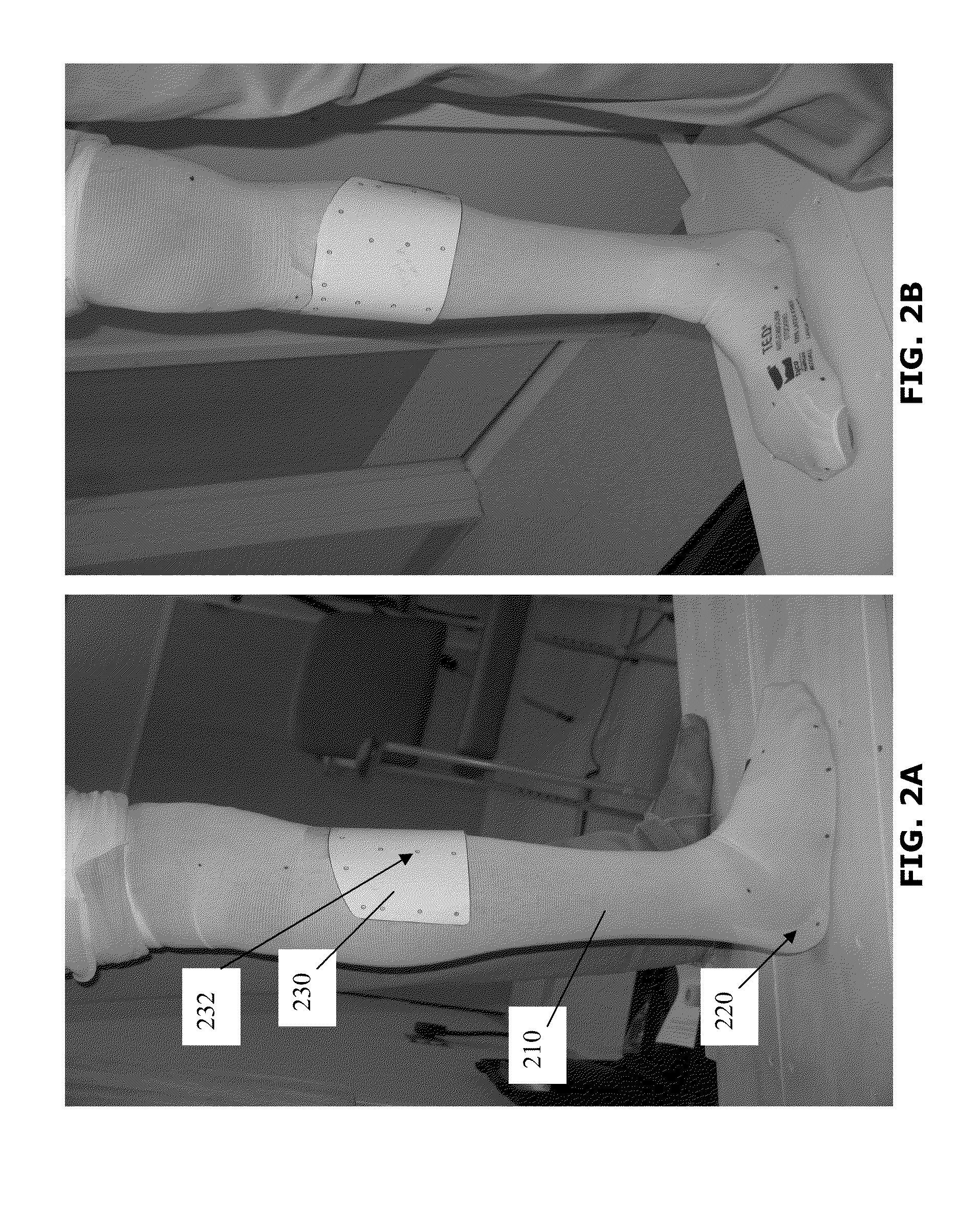

Process and System for Manufacturing a Customized Orthosis

InactiveUS20110082578A1Additive manufacturing apparatusCharacter and pattern recognitionDigital mockupComputer-aided

A process and system for fitting, customizing and manufacturing an orthosis for a subject. 3-dimensional coordinates for a plurality of landmarks corresponding to anatomical characteristics of the subject, means for attachment of the orthosis to the subject, and a reference plane are digitally acquired. Then, coordinates of one or more virtual landmarks corresponding to one or more anatomical joint centers or joint projection locations are calculated. The landmarks are clinically aligned in a reference position of one of the anatomical joint centers and a customized digital model of the orthosis is created using the clinically aligned landmarks. Finally, the orthosis is fabricated using a computer aided manufacturing process, based upon an output from the customized digital model.

Owner:UNIVERSITY OF DELAWARE

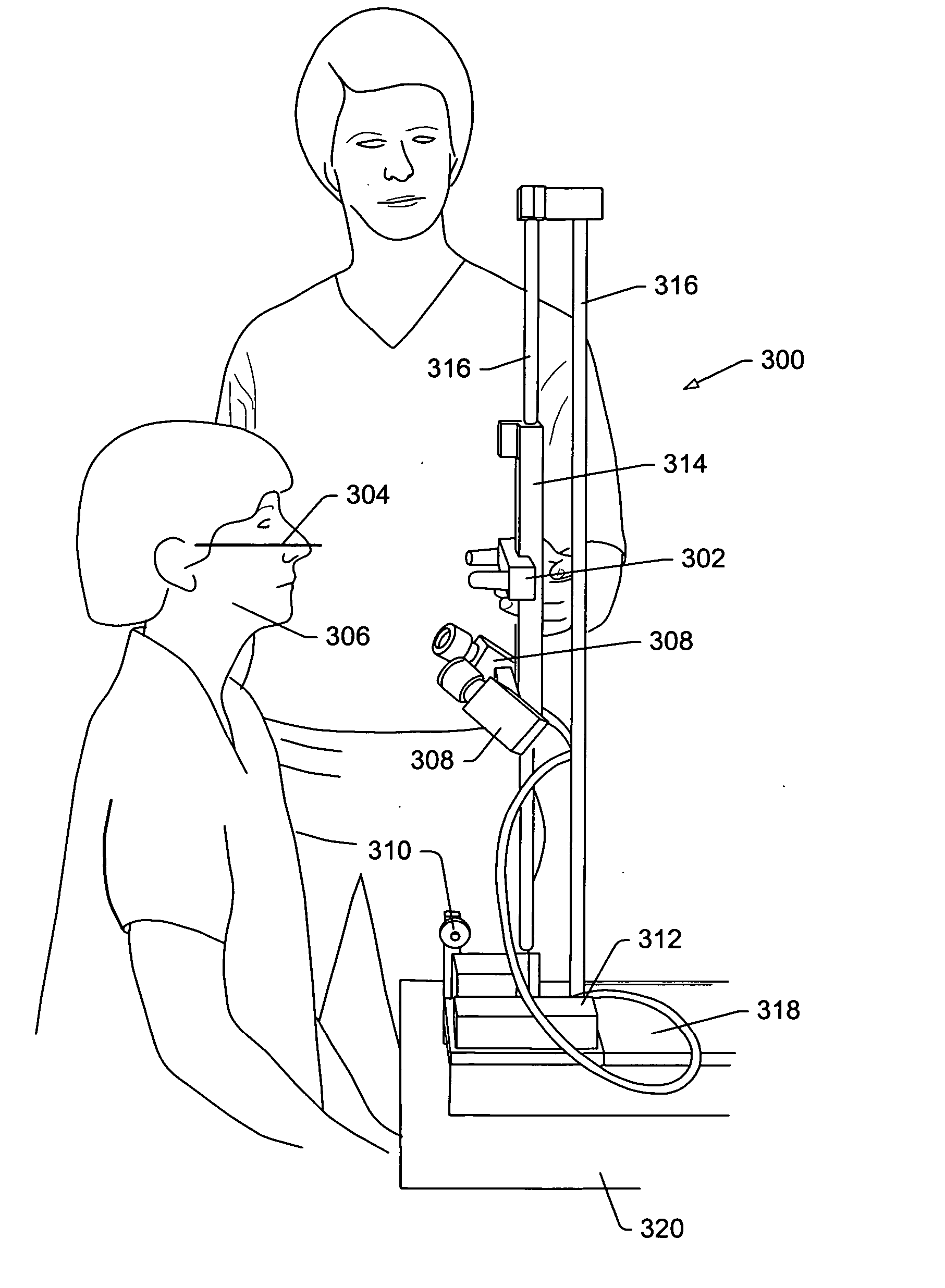

System and method for design and manufacture of custom face masks

Methods and systems for forming face masks are disclosed. Embodiments may utilize computer-aided design and computer-aided manufacturing to form custom fitted face masks. System software may be configured to acquire facial topography information, design a mask based on the topography information, and send mask information to a computerized manufacturing device. The software may communicate with a scanning device for facial topography acquisition and a milling machine for pattern fabrication. In an embodiment, the scanning device may include a linear scan non-contact laser imager. In an embodiment, the scanning device may be manually moved with respect to an individual being scanned, thereby eliminating the need for motive apparatus. In such embodiments, position information may be determined based on data from a position sensor coupled to the scanning device.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

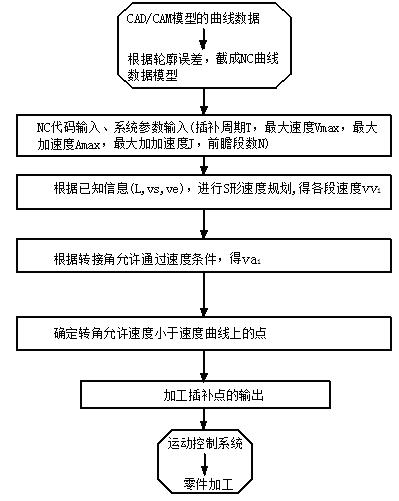

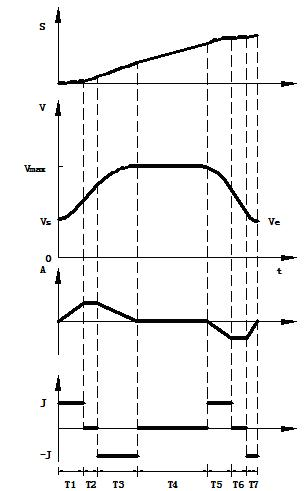

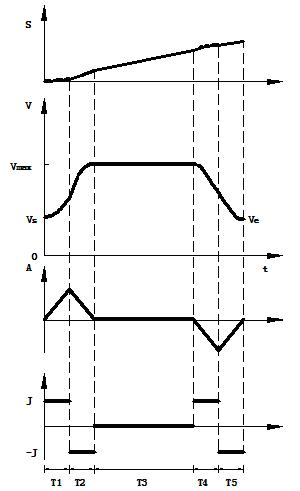

Acceleration and deceleration look-ahead control method for high-speed machining of numerical control machine tool

InactiveCN102419570AOvercoming flexible impactGuaranteed accuracyProgramme controlComputer controlControl systemEngineering

The invention relates to an acceleration and deceleration look-ahead control method for the high-speed machining of a numerical control machine tool. The method comprises the following operation steps of: (1) cutting the curve data of a CAD / CAM (Computer-Aided Design / Computer-Aided Manufacturing) model into a NC (Numerical Control) curve data model according to a contour error; (2) inputting system parameters, such as interpolation cycle T, maximum speed Vmax, and the like, on the basis of a NC code; (3) carrying out microfield integral S-shaped speed planning on the basis of the system parameters and determining the corresponding speed (i is equal to 1:N, N is a look-ahead field number, that is to say, a speed value from the first field to the Nth field is determined) of all fields on a S-shaped speed curve; (4) determining a microfield adapting angle allowed passing speed (i is equal to 1:N); (5) determining a point at which the adapting angle allowed speed is smaller than planned speed; (6) outputting a machining interpolation point; and (7) executing the information and finishing the machining of parts by a motion control system. In the step (5), the reasonable speed at which the microfield machining can be carried out is determined on the basis of comparing the speed on the S-shaped speed curve with the adapting angle allowed passing speed, and thereby, the S-shaped speedcurve with highest efficiency is obtained; and finally, the machining interpolation point is output to the motion control system. According to the method, the machining precision is ensured, the machining efficiency is greatly increased, the flexible impact of the machine tool is effectively prevented and the service life of the machine tool and cutters is prolonged.

Owner:SHANGHAI UNIV

CAD-CAM AGP splint- A method of automatically producing or reproducing a customized AGP (Anterior Guidance Package) equipped splint for a patient with/without a severe malocclusion via one time dentist visit

ActiveUS20140370465A1Increased mechanical advantageEliminate distractionsImpression capsOthrodonticsAnatomyCam

A method of automatically producing or reproducing a customized AGP (Anterior Guidance Package) equipped splint for a patient with or without a severe malocclusion is provided. The method of automatically producing or reproducing an AGP equipped splint according to current invention comprises of combining Virtual Articulation, CAD (Computer Aided Design)-CAM (Computer Aided Manufacturing) method with AGP and special retentive piece technology. The method of the current invention enables a patient with or without a severe malocclusion to receive his / her customized AGP equipped splint or a replacement thereof automatically without visiting the dentist again and again.

Owner:LUCAS KELLY

Method for preparing veneer ceramic-free full anatomic form zirconia dental crown

ActiveCN102302381AHigh strengthHigh transparencyTooth crownsTeeth cappingComputer assistanceTooth Preparations

The invention relates to a method for preparing a veneer ceramic-free full anatomic form zirconia dental crown. The method comprises the steps of: adopting a CAD (Computer-aided Design) / CAM (Computer-aided Manufacturing) system, and clinically fabricating an impression and a plaster model after tooth preparation; scanning by using a three-dimensional model scanner, establishing a digital model ona computer, and designing a dummy form through computer assistance; cutting a dummy form through a numerically-controlled lathe, trying wearing on the model, and adjusting the form; burnishing; painting; and glazing, and finally completing the fabrication of the dummy. The veneer ceramic-free full anatomic form zirconia dental crown provided by the invention has high strength and good light transmission, the treatment of applying ceramics is not required, and no hazard of ceramic fracture exists; the degree of precision is high due to computer control during the overall process; and the grinding amount for tooth preparation is small, and an ideal effect can be achieved with 1mm space.

Owner:SHENZHEN UPCERA DENTAL TECH

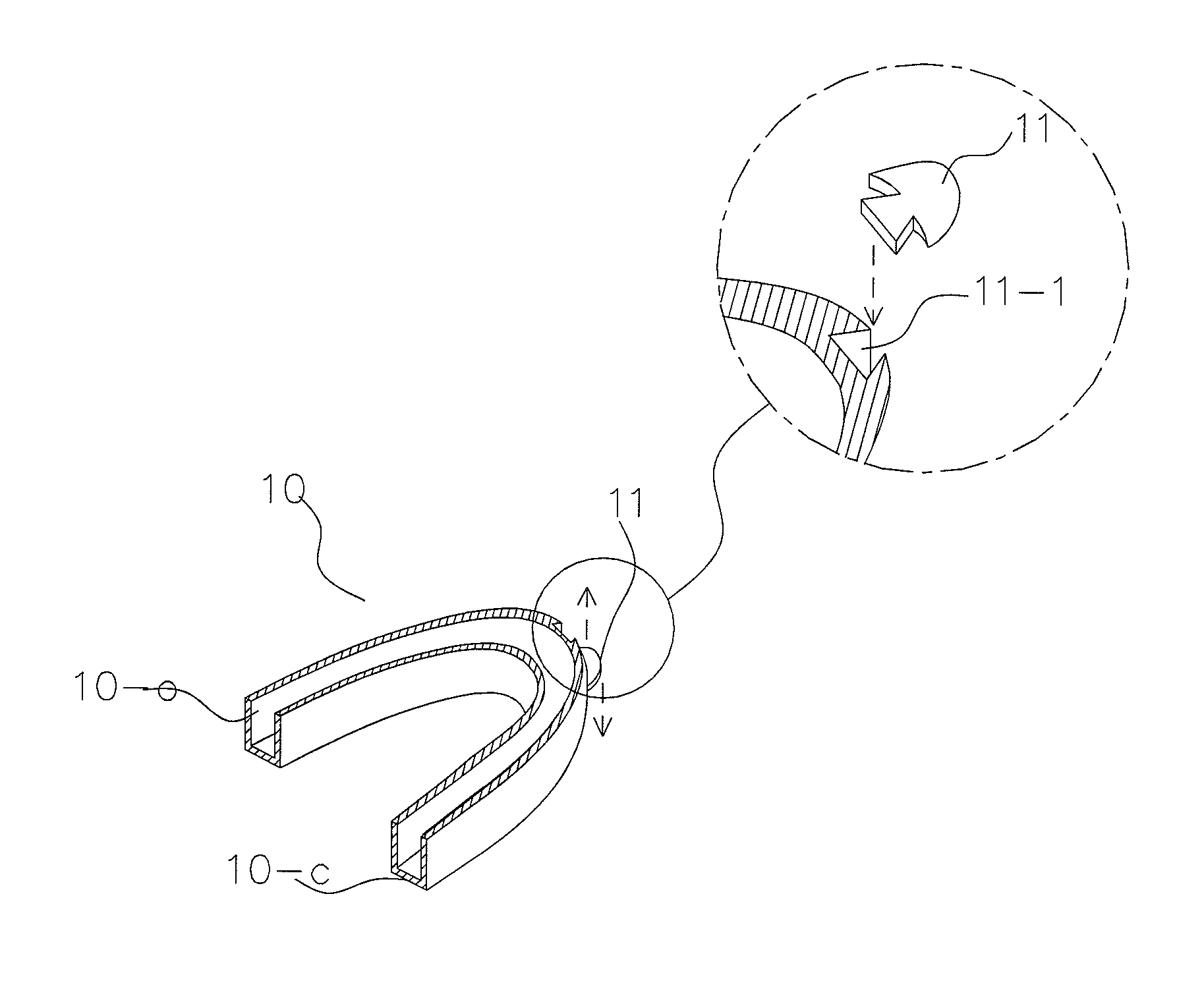

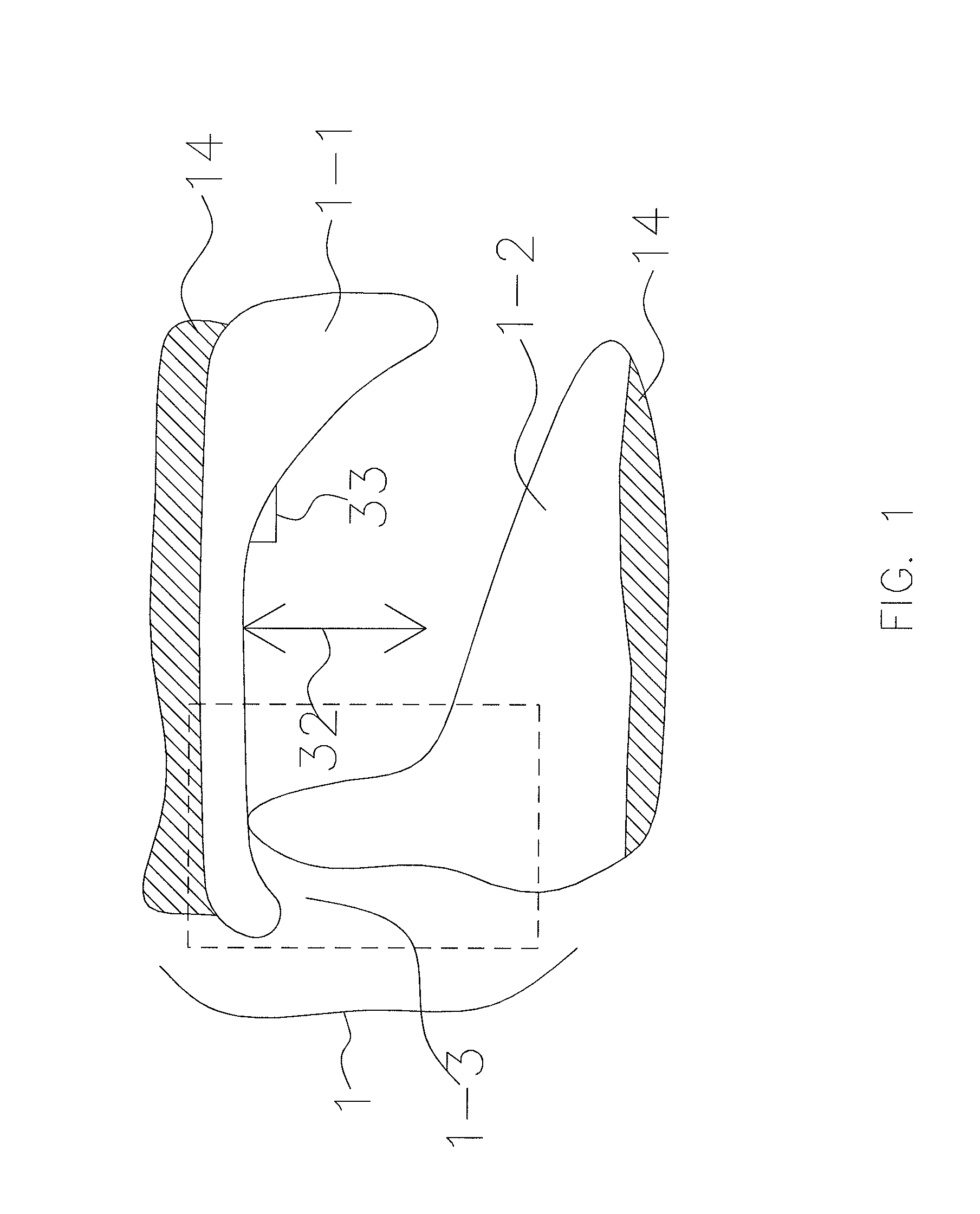

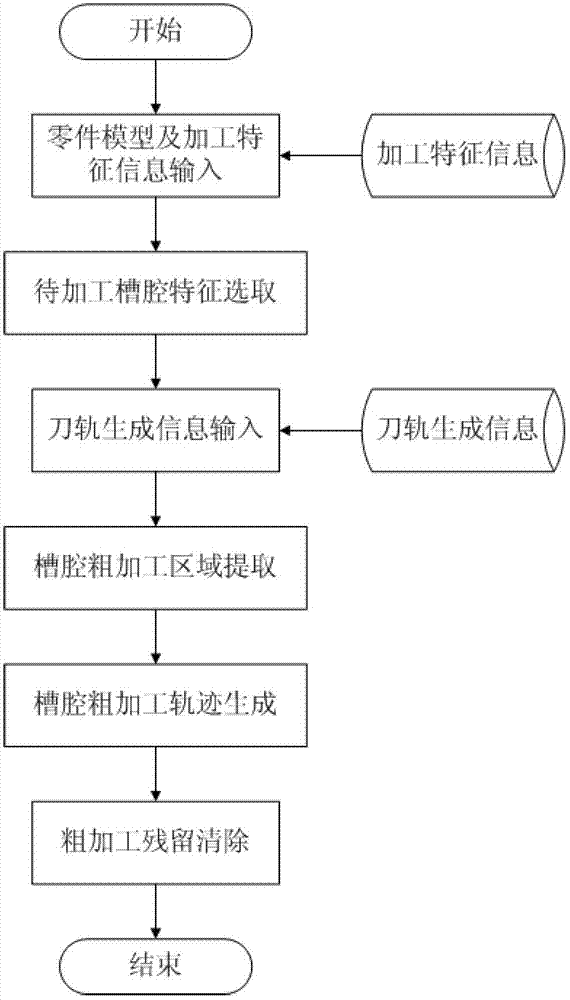

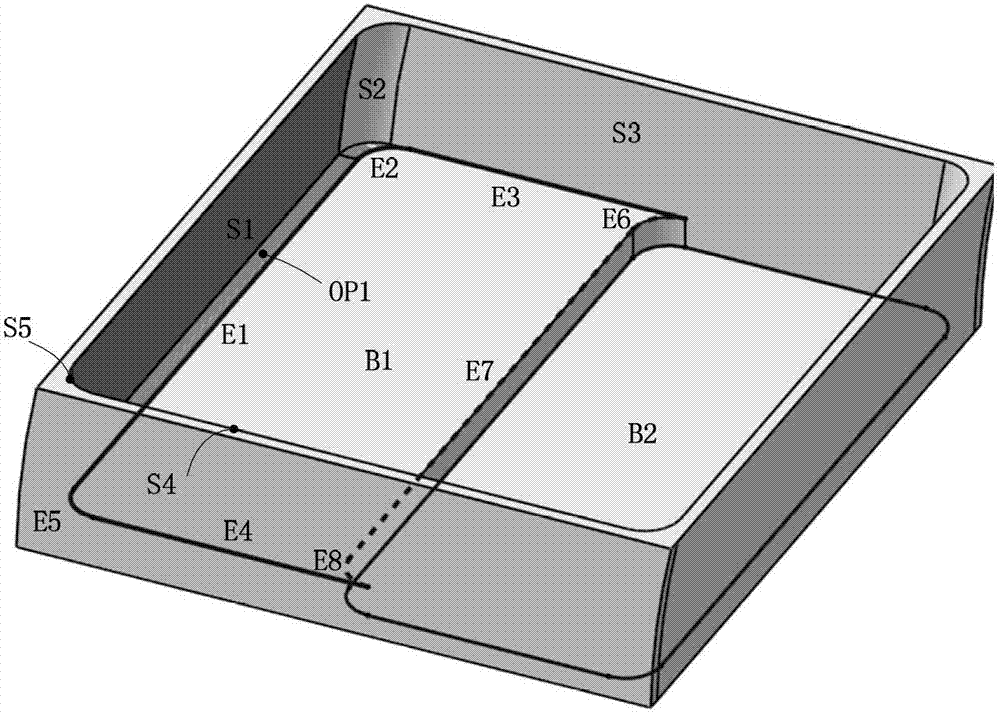

Cavity-characteristic-based high-efficiency rough machining method of aircraft structural part

ActiveCN102922013AReduce lossImprove efficiencyAutomatic control devicesFeeding apparatusCamComputer science

The invention discloses a cavity-characteristic-based high-efficiency rough machining method of an aircraft structural part, which belongs to the technical field of CAD / CAPP / CAM (Computer Aided Design / Computer Aided Process Planning / Computer Aided Manufacturing). The method is characterized by comprising the following steps of: firstly, performing preprocessing such as input of a part and read-in of characteristic information of the part; selecting characteristic of a cavity to be subjected to rough machining, automatically generating a cavity rough machining region according to information such as rough machining margin, diameter of a tool and cutting depth of the tool, and calculating a plunge milling tool site for rough machining of the cavity; and finally, generating a plunge milling rough machining track and a saw tooth residue clear track according to a set feeding strategy. By utilization of the method, rough machining of the aircraft structural part is performed, so that the rough machining efficiency of the aircraft structural part can be greatly improved, the loss of the tool is reduced, and the cost is saved. The method has great application and promotion prospect in rough machining of a difficult-to-machine material of the aircraft structural part.

Owner:SUZHOU MACHINING PRECISION ELECTRONICS

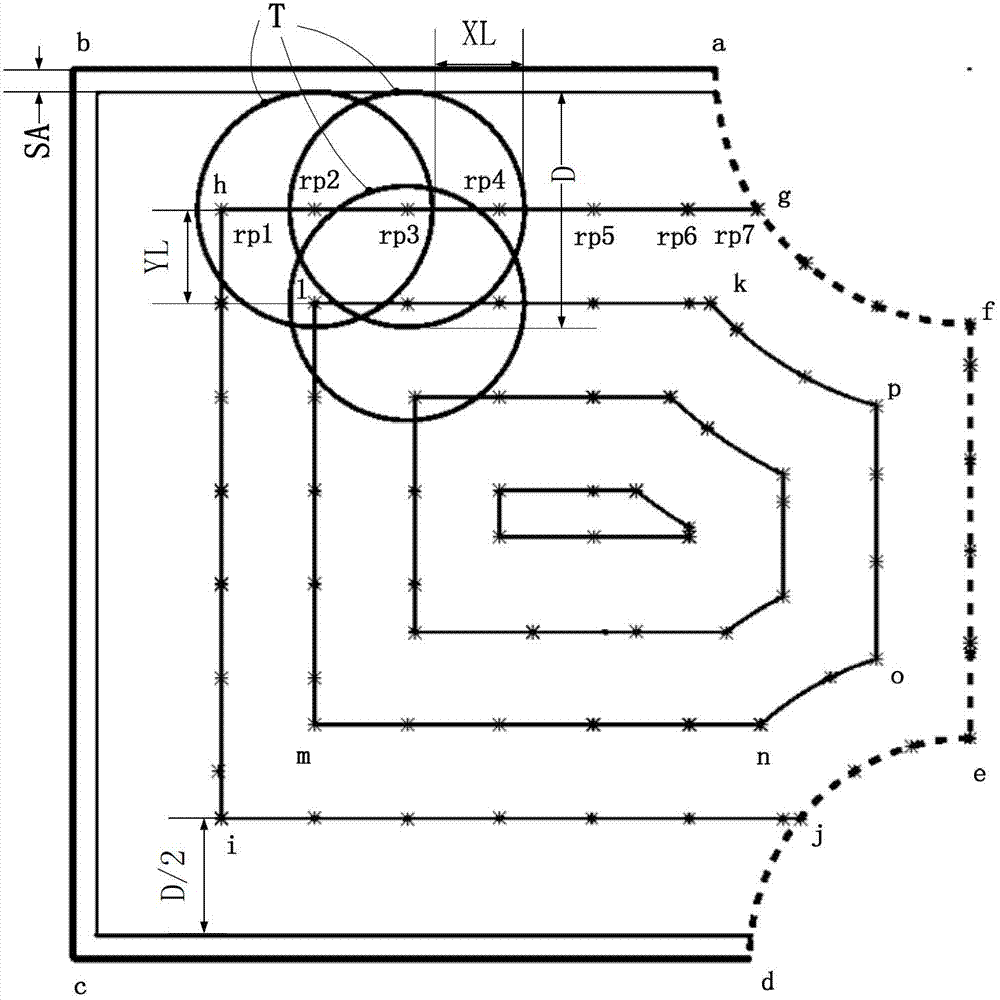

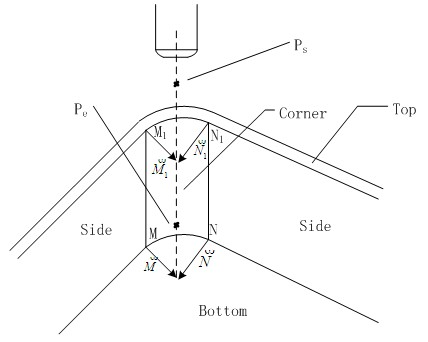

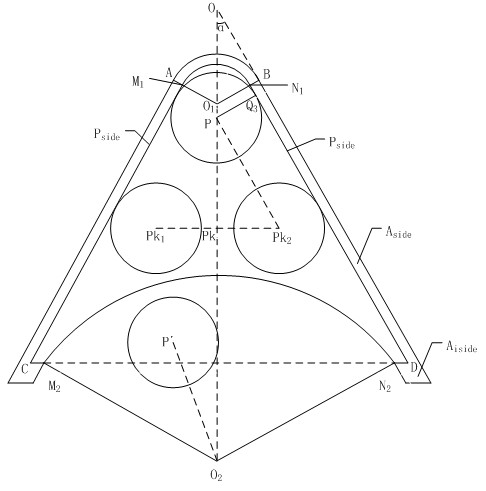

Automatic generation method of plunge milling toolpath for corner features

ActiveCN102629289AImprove efficiencyImprove accuracySpecial data processing applicationsCamProgramming process

The invention discloses an automatic generation method of a plunge milling toolpath for corner features, and belongs to the technical field of CAD (Computer-Aided Design) / CAPP (Computer-Aided Process Planning) / CAM (Computer-Aided Manufacturing). The automatic generation method comprises the following steps: firstly, conducting the pretreatment such as part selection, part feature information read-in and the like; secondarily, obtaining geometric surfaces needed in corner processing from the part feature information, and automatically calculating the corner plunge milling area geometric auxiliary point, the axial corner geometric auxiliary point and the plunger milling generation geometric auxiliary point according to information such as the plunger milling processing redundancy, the radius of a cutting tool in the former process or work step as well as the rough processing redundancy and the like; and finally, generating the plunger milling tooth-paths of all part corners through the auxiliary points automatically. The plunge milling tool-paths for corners, generated through the invention, are high in speed and high in accuracy rate, and can process a corner in a large processing area, a corner containing scattered surfaces, a five-axis corner, and a corner of which the proximal surface is a big-curvature side surface, so that the method solves the problem that the manual corner plunger milling programming process is trivial and complicated and low in efficiency. Through the invention, a good effect on plunger milling of corners of an aircraft structural part can be obtained.

Owner:SUZHOU MACHINING PRECISION ELECTRONICS

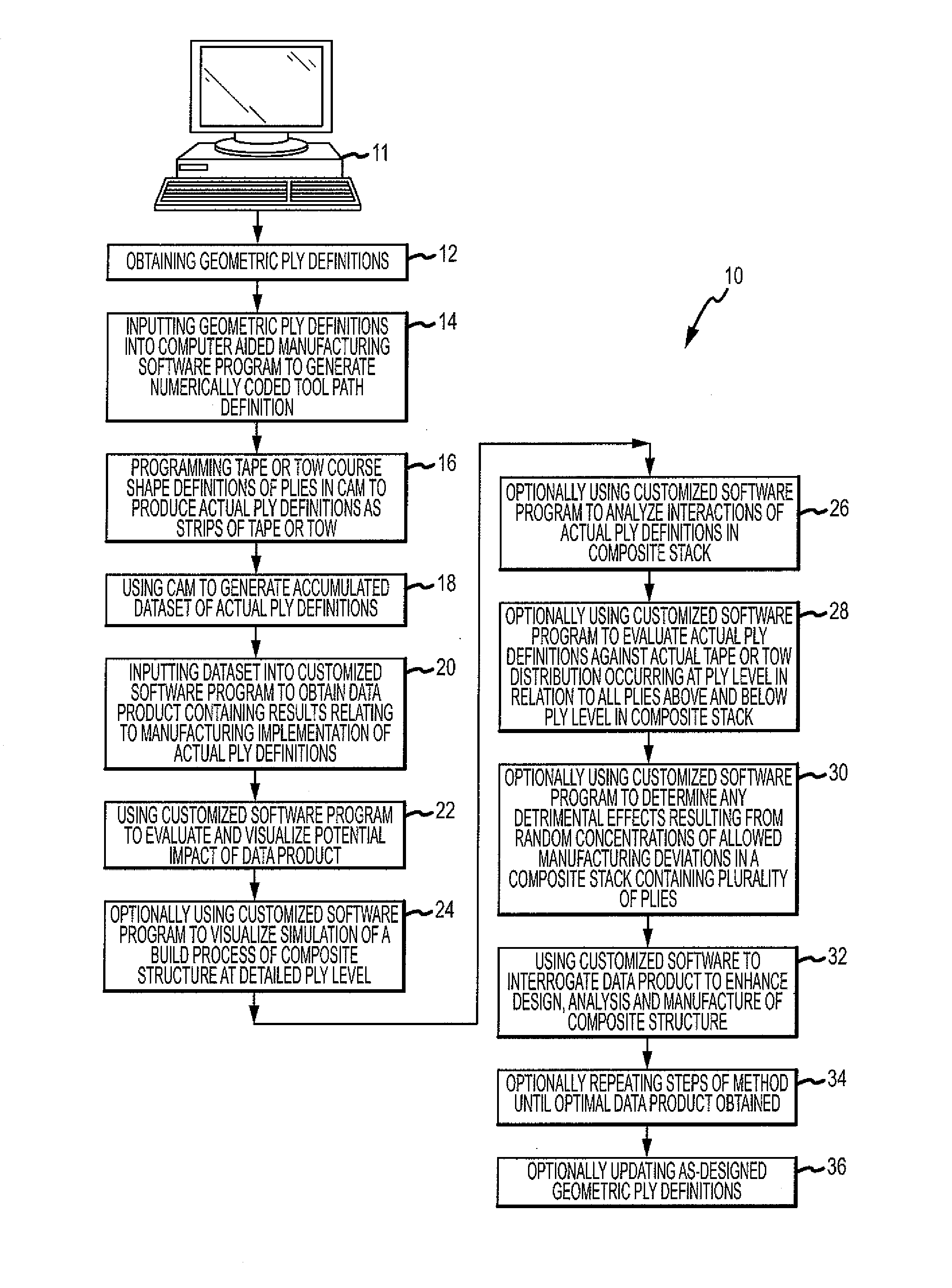

Composite stack analysis method

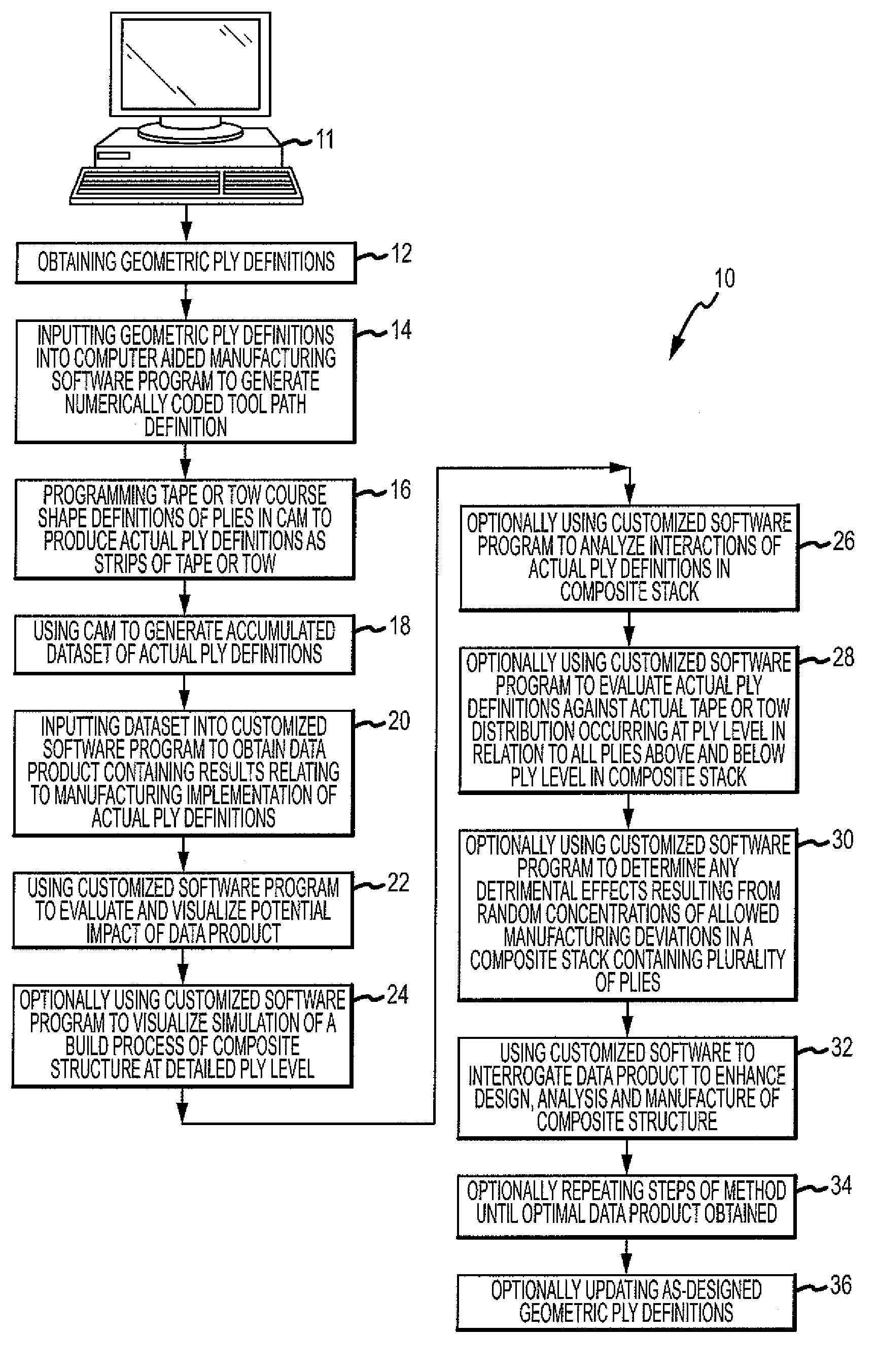

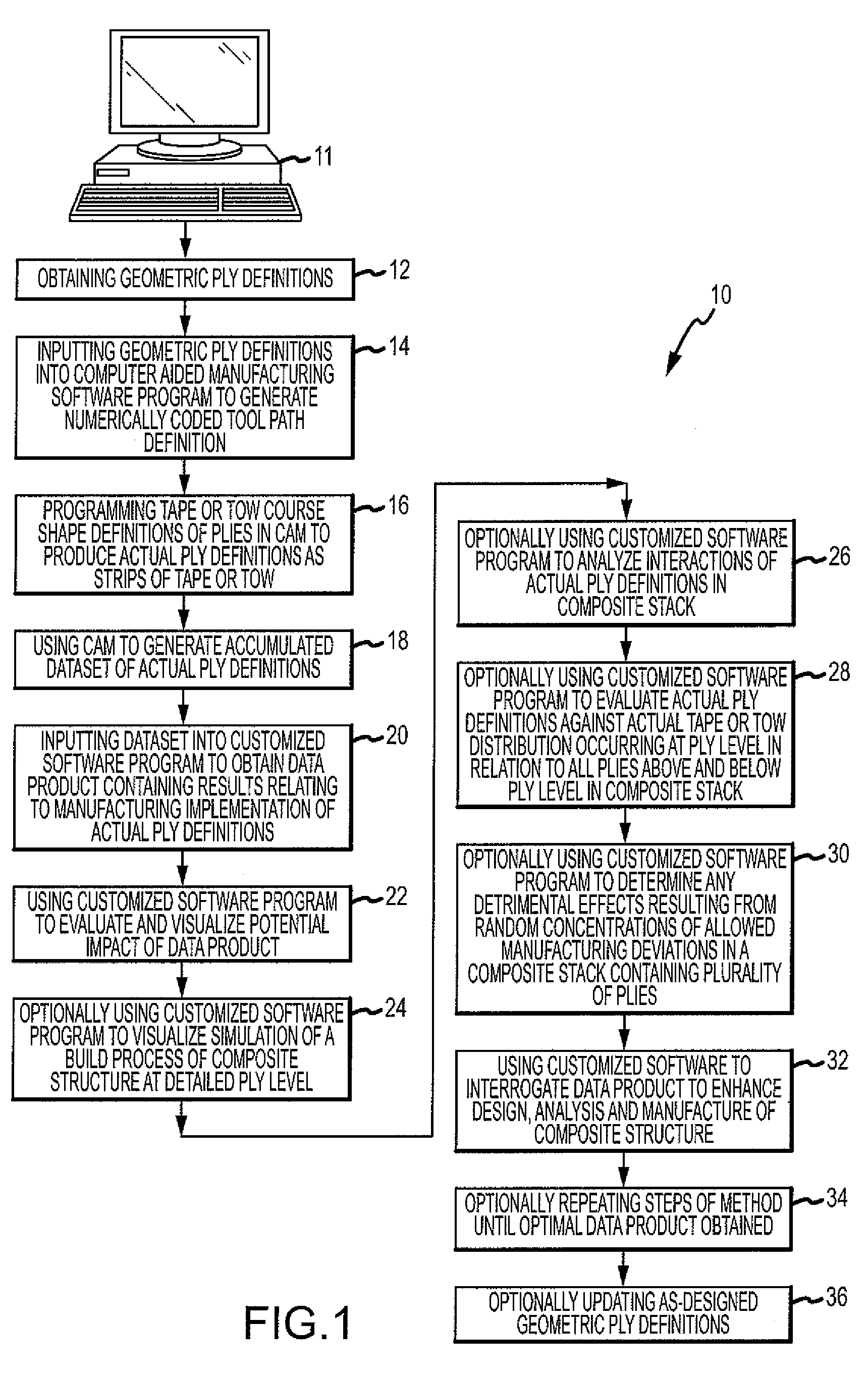

ActiveUS20100204815A1Improve manufactureStructural Design ImprovementProgramme controlComputer controlData setAnalysis method

A method is provided for generating a data product that allows for enhanced design, analysis and manufacture of a composite structure comprising a plurality of plies. The method comprises the steps of obtaining geometric ply definitions, inputting the geometric ply definitions into a computer aided manufacturing (CAM) software program to generate a numerically coded tool path definition containing centerline data for each tape or tow comprising a ply, programming tape or tow course shape definitions of a plurality of plies in CAM to produce actual ply definitions, using CAM to generate an accumulated dataset of actual ply definitions, using a customized software program to analyze the dataset to obtain a data product containing results relating to manufacturing implementation of the actual ply definitions, and using the customized software program to evaluate and visualize potential impact of the data product and to interrogate the data product.

Owner:THE BOEING CO

Method of analyzing composite structures

ActiveUS8108058B2Simple designImprove manufactureProgramme controlTotal factory controlData setPotential impact

A method is provided for generating a data product that allows for enhanced design, analysis and manufacture of a composite structure comprising a plurality of plies. The method comprises the steps of obtaining geometric ply definitions, inputting the geometric ply definitions into a computer aided manufacturing (CAM) software program to generate a numerically coded tool path definition containing centerline data for each tape or tow comprising a ply, programming tape or tow course shape definitions of a plurality of plies in CAM to produce actual ply definitions, using CAM to generate an accumulated dataset of actual ply definitions, using a customized software program to analyze the dataset to obtain a data product containing results relating to manufacturing implementation of the actual ply definitions, and using the customized software program to evaluate and visualize potential impact of the data product and to interrogate the data product.

Owner:THE BOEING CO

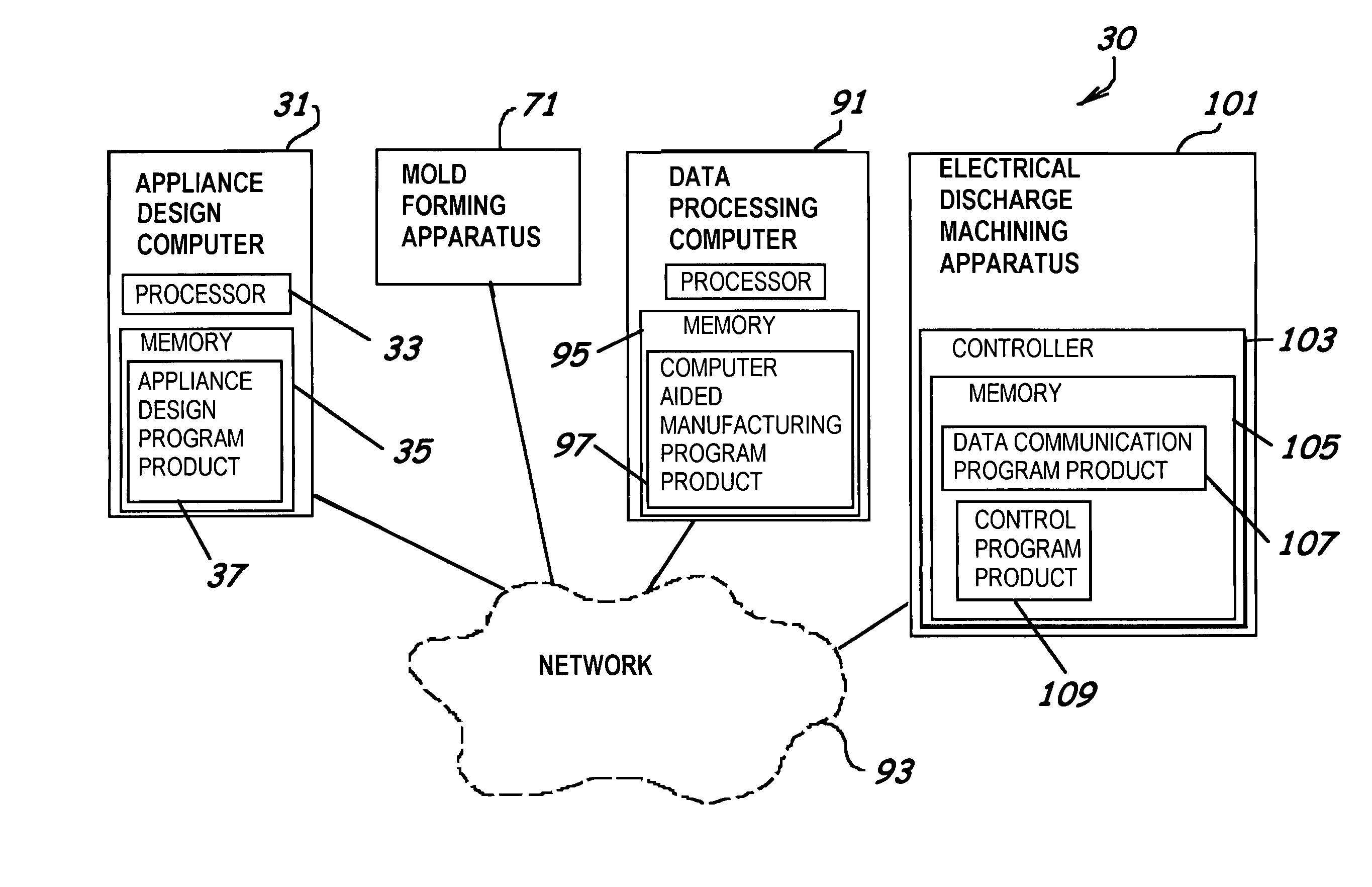

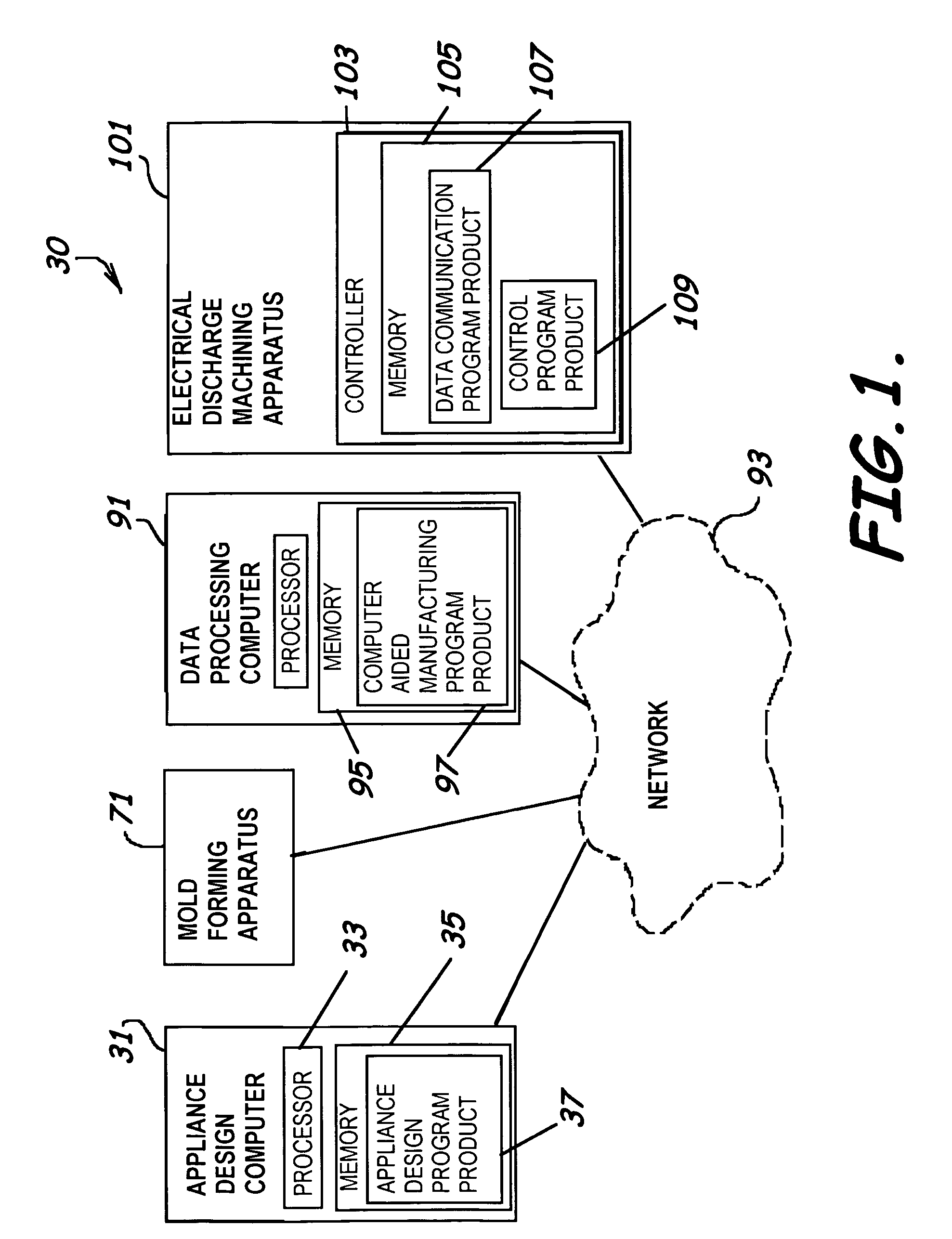

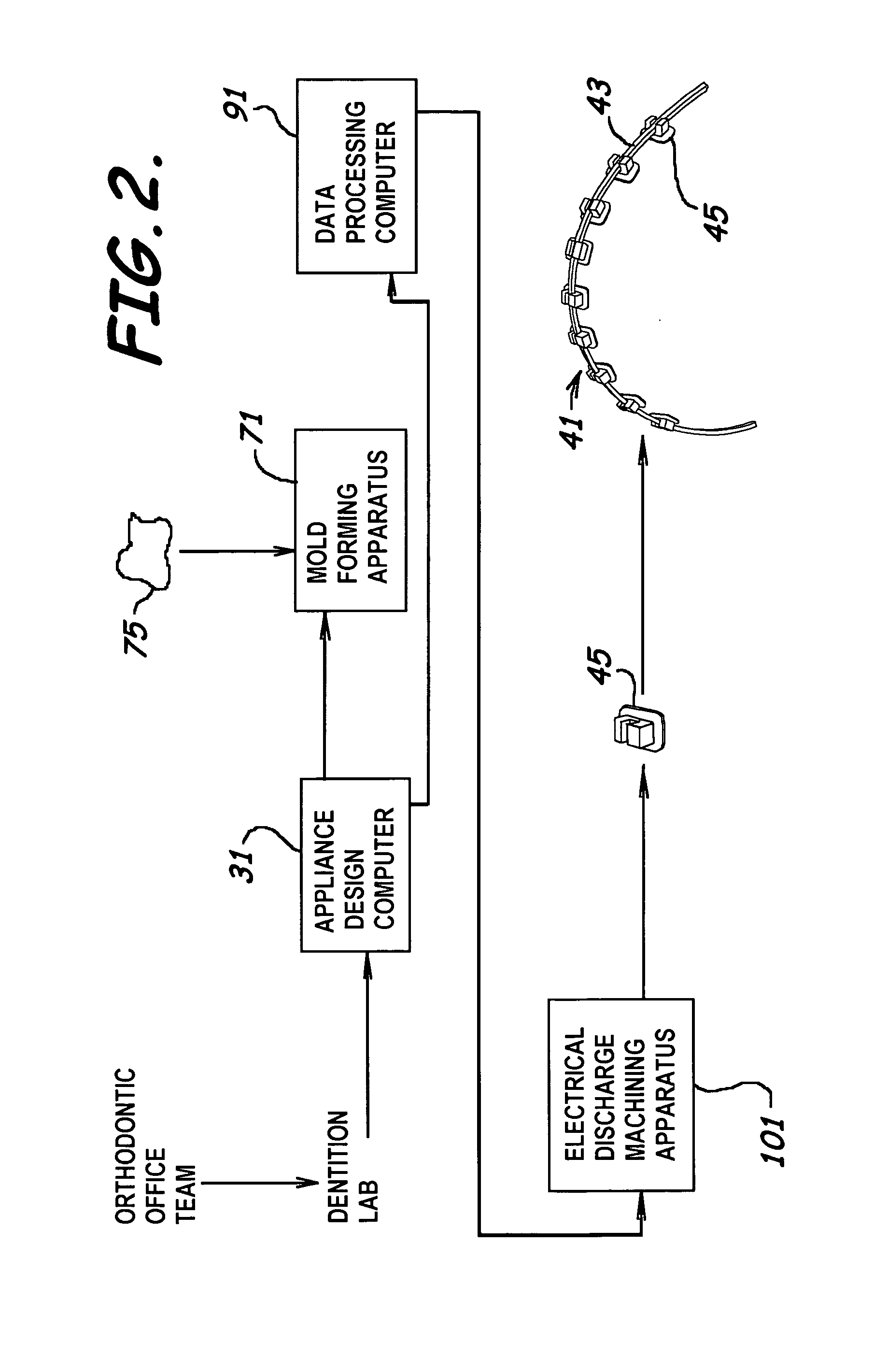

System to manufacture custom orthodontic appliances, program product, and related methods

ActiveUS20070178423A1High precision cuttingLevel of precision and efficiencyAdditive manufacturing apparatusBracketsControl signalComputer-aided

A system to manufacture orthodontic appliances, program product, and associated methods are provided. An embodiment of a system can include a virtual orthodontic appliance design computer having orthodontic appliance design program product provided to design a virtual dimensional representation of an orthodontic appliance including bracket bodies and bracket pads, and a mold apparatus positioned to form each bracket body and bracket pad. The system also includes a data processing computer including computer-aided manufacturing program product provided to derive electrical discharge device control instructions including a virtual dimensional representation of a bracket slot in the bracket, and an electrical discharge machining apparatus. The electrical discharge machining apparatus can include a controller including control program product to derive a control signal carrying the electrical discharge device control instructions and an electrical discharge device.

Owner:3M INNOVATIVE PROPERTIES CO

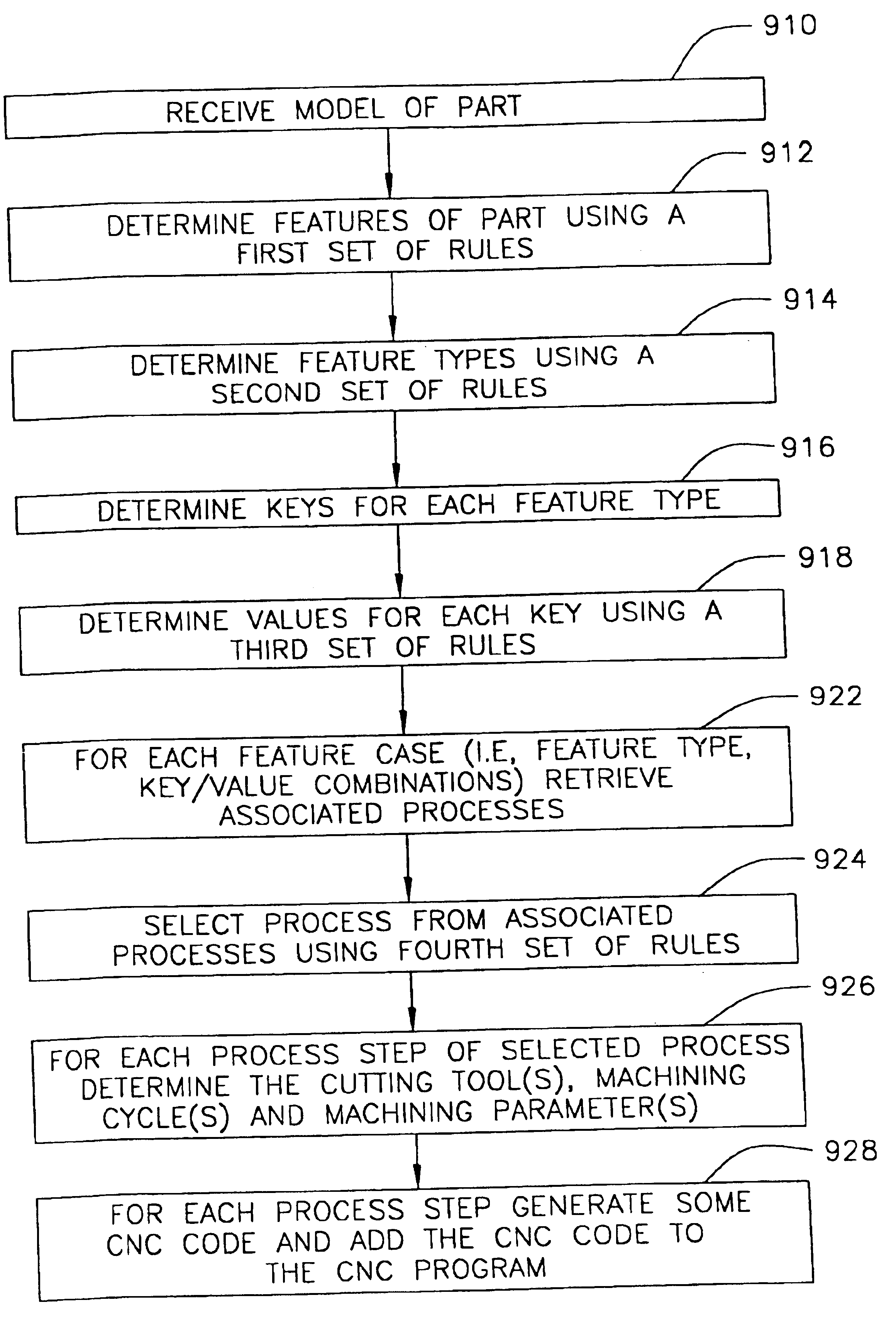

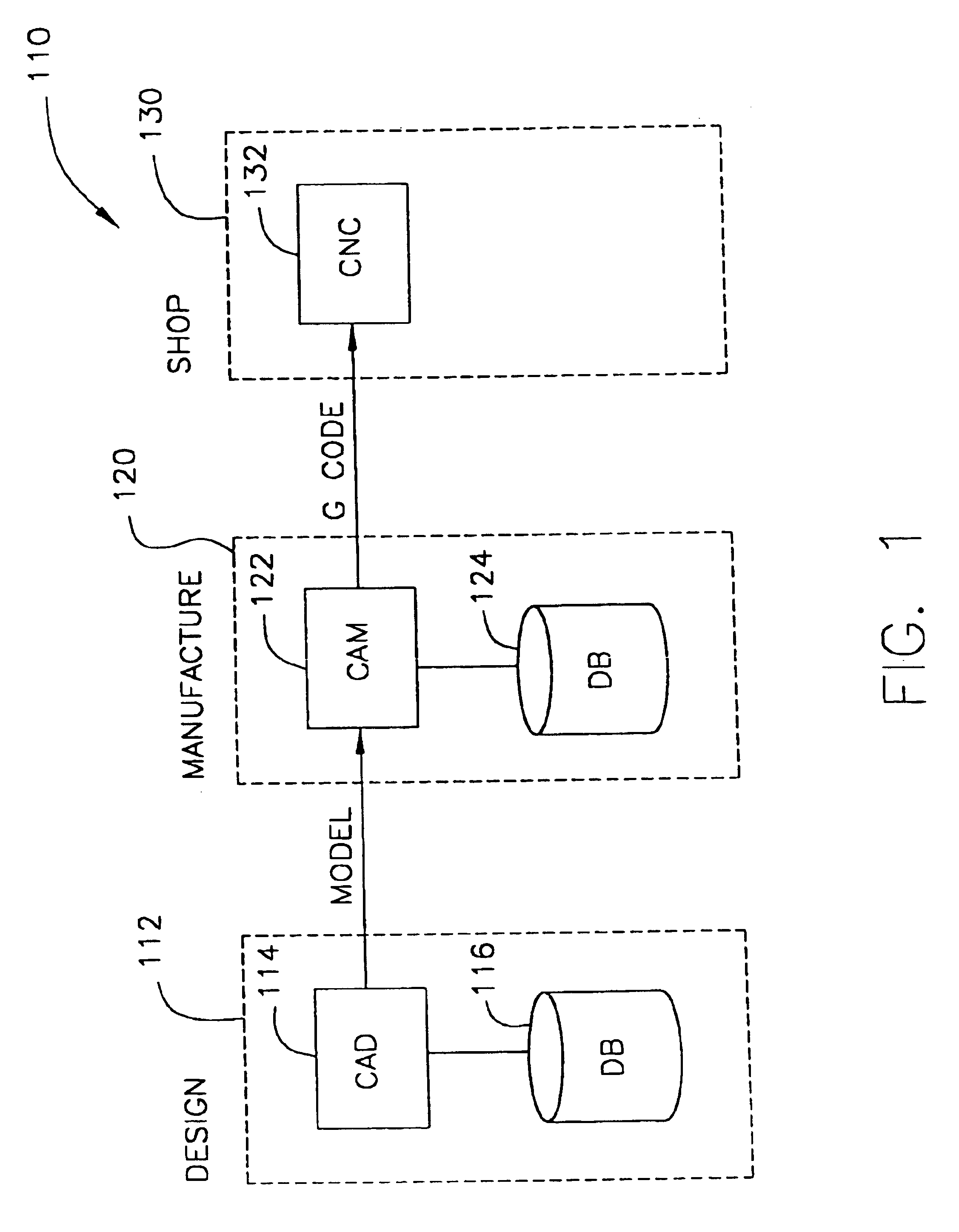

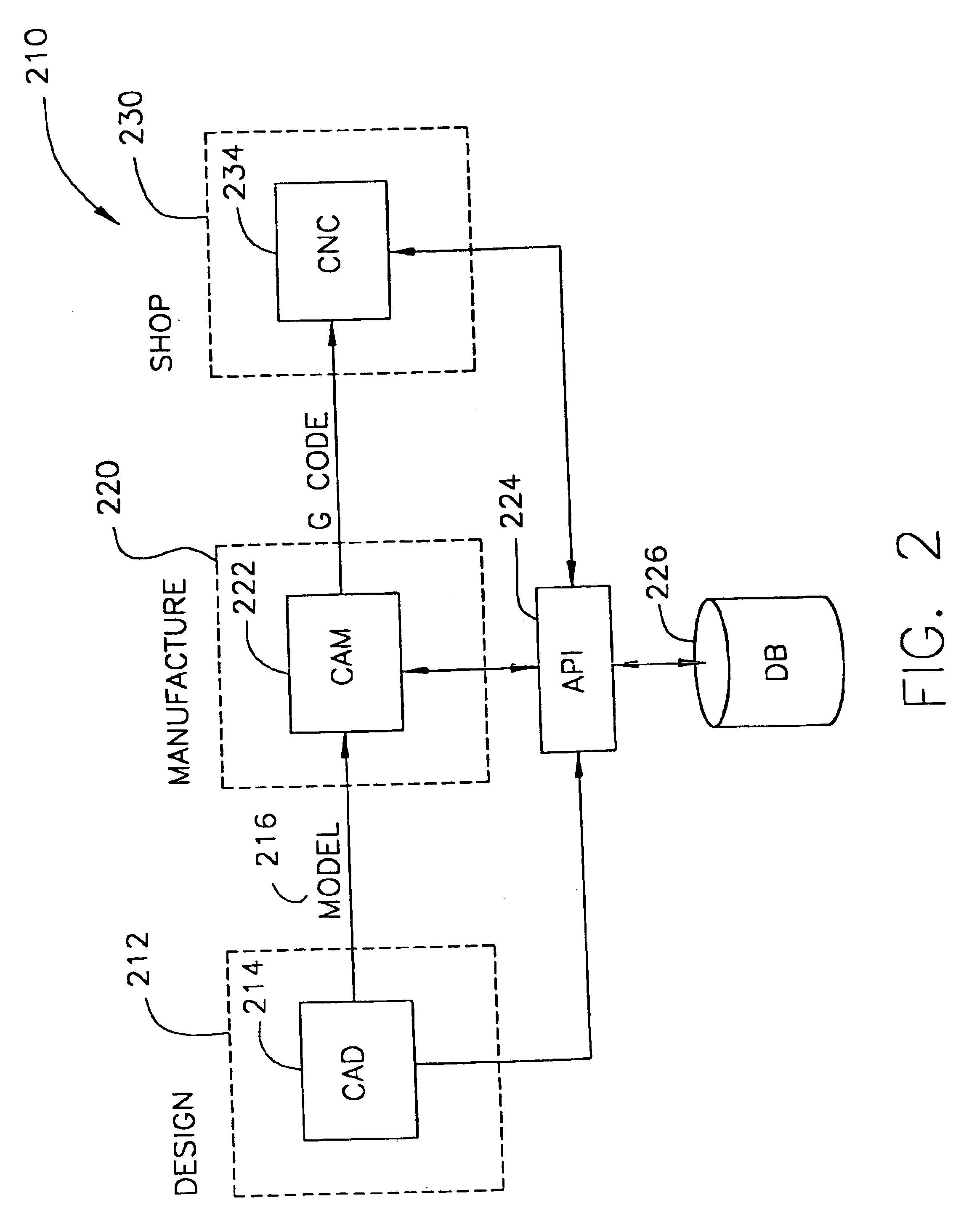

Method and system for computer aided manufacturing

A system and method is disclosed for centralizing knowledge and improving programming for manufacturing a part. An embodiment includes a method for manufacturing the part. First, a model of the part is received. Next, a predetermined rule is retrieved from a computer readable medium having a plurality of predetermined rules. A feature of the geometric model is selected by evaluating the retrieved predetermined rule and a process is determined that is associated with the feature. Based on the process, computer code is generated to manufacture the part on a computer controlled machine.

Owner:HEXAGON TECH CENT GMBH

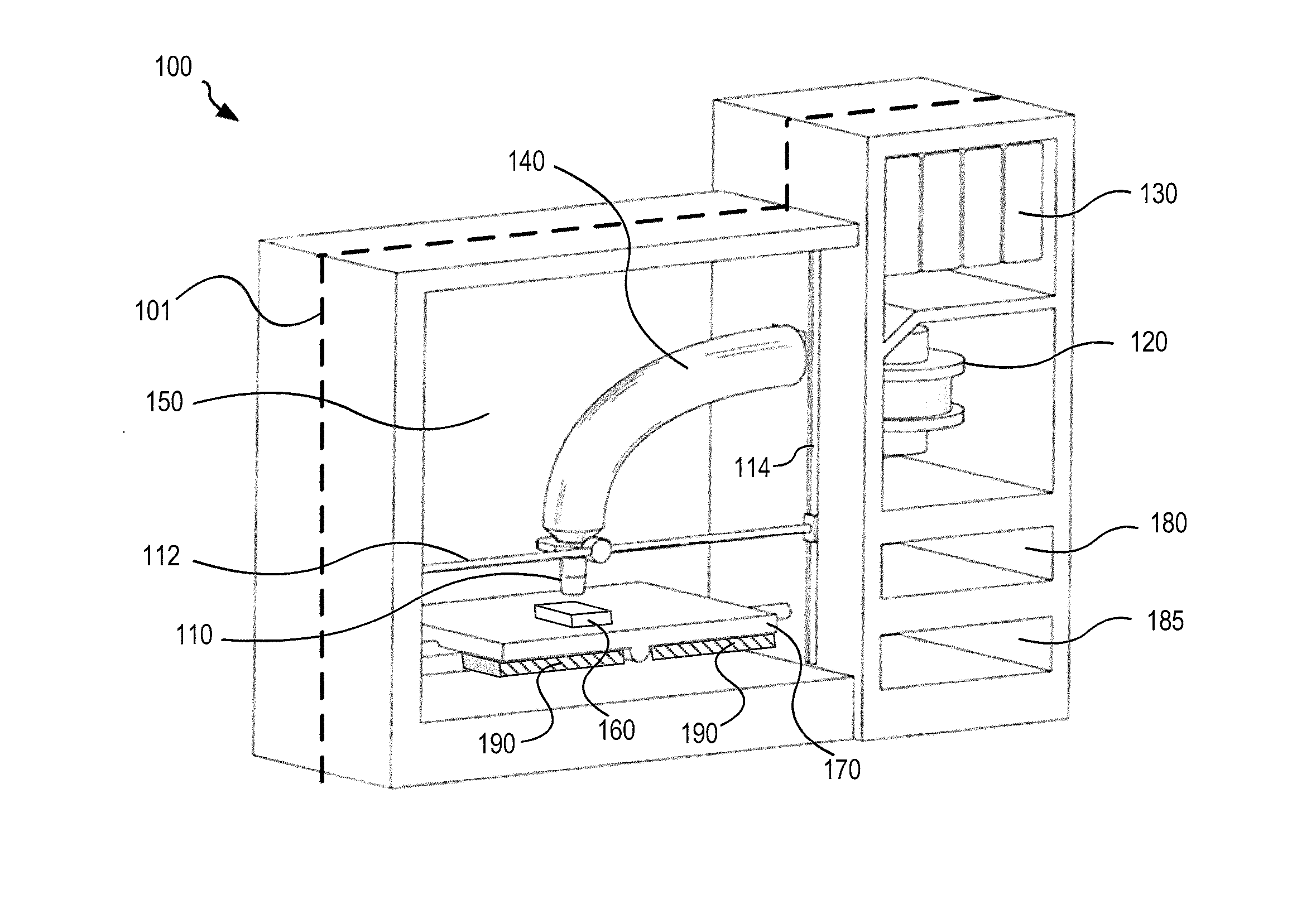

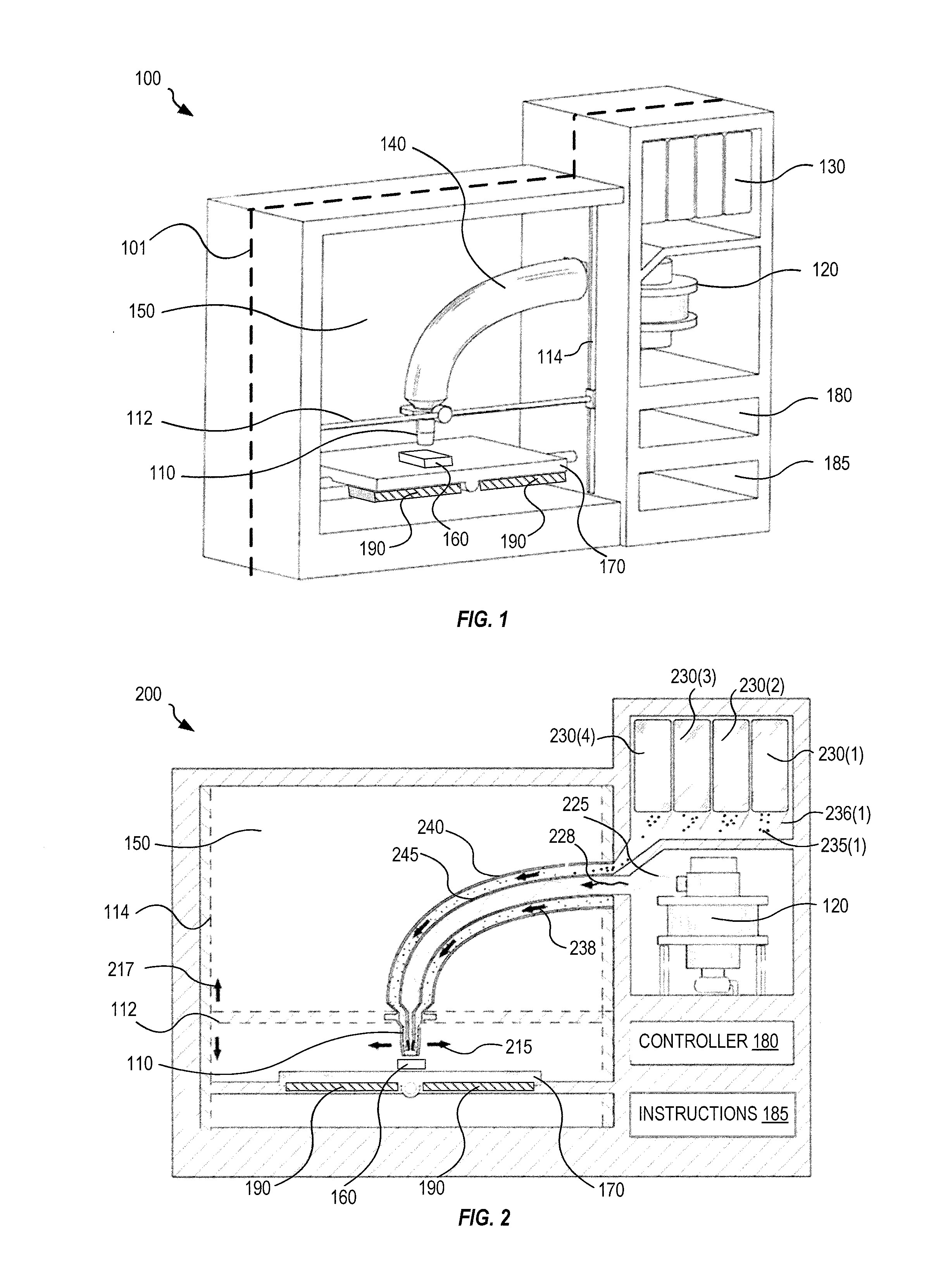

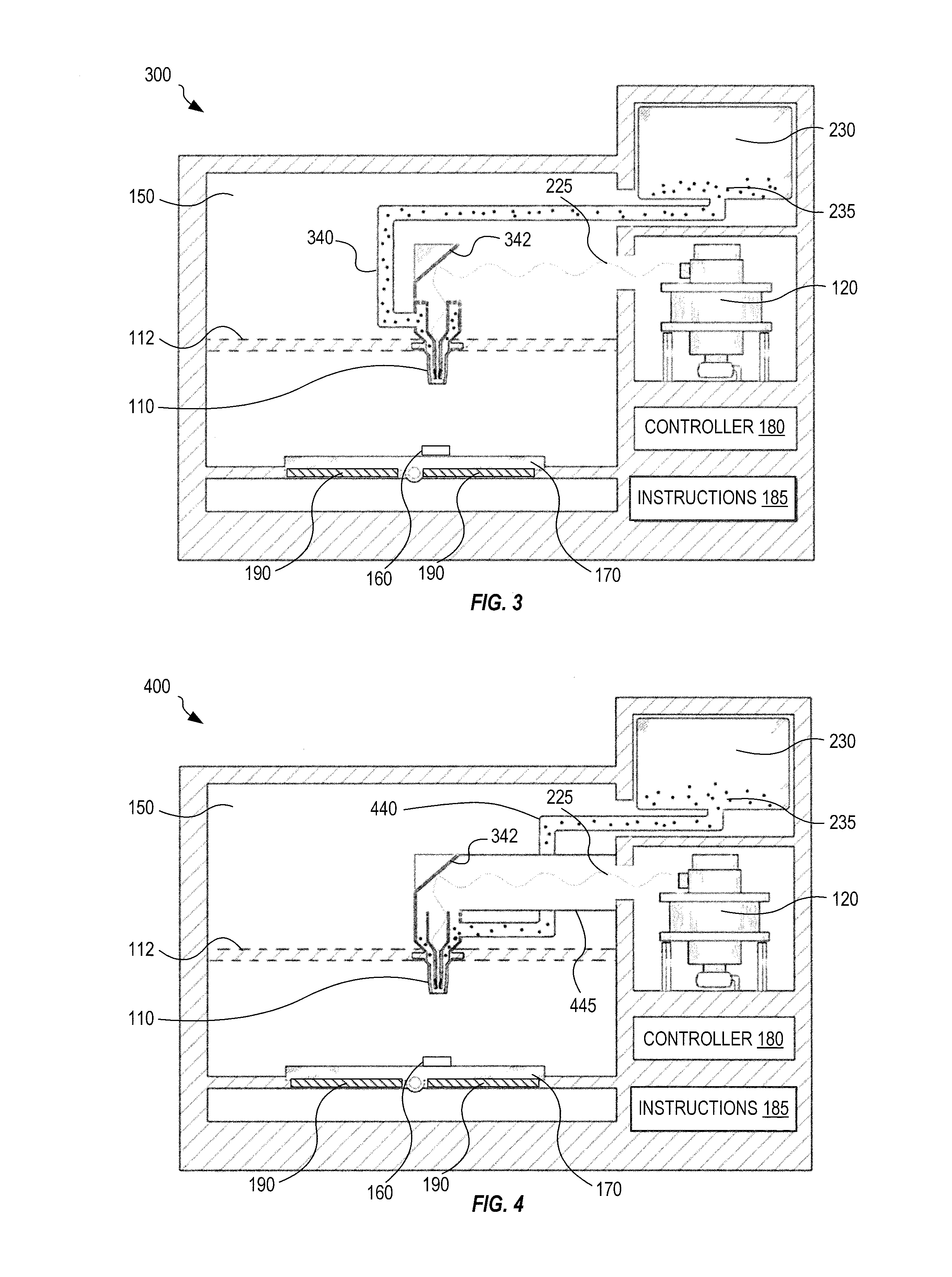

Fused Material Deposition Microwave System And Method

InactiveUS20160230283A1Additive manufacturing apparatusAdditive manufacturing with liquidsMicrowaveSpray nozzle

A fused material deposition microwave system and method include at least one high power microwave source, at least one deposition nozzle having adjustable outlet diameter for depositing one or more materials, a waveguide for guiding microwave energy to the deposition nozzle to melt the materials, and a material source to supply one or more materials to the deposition nozzle. The system and method further include a controller for controlling the deposition nozzle, microwave energy, and material source according to a computer-aided manufacturing set of instructions to deposit and fuse molten material on a workpiece. The system and method provide improvements in additive manufacturing of three-dimensional objects that are particularly beneficial for manufacturing objects made of metals and ceramics.

Owner:ESCAPE DYNAMICS

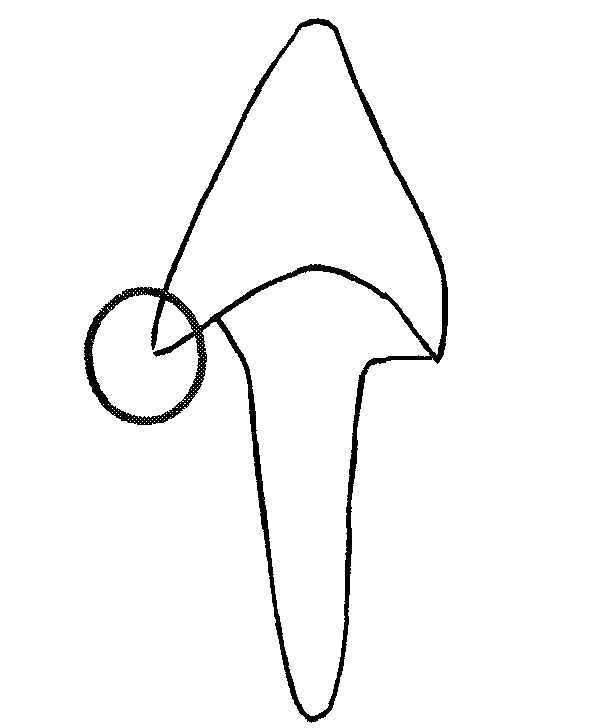

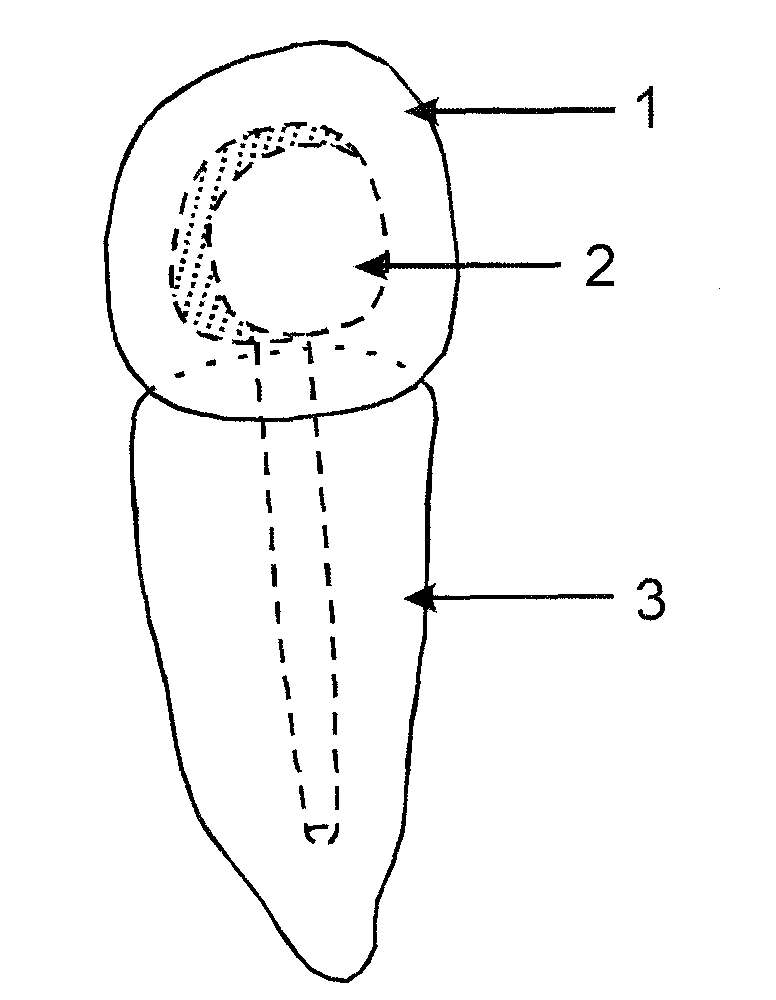

Integrated fiber post for dental restoration and preparation method thereof

ActiveCN101803958AHigh strengthImprove stress distributionImpression capsFastening prosthesisNumerical controlStress concentration

The invention discloses an integrated fiber post for dental restoration and a preparation method thereof. The integrated fiber post for dental restoration is characterized by integrating a post and a core and comprising a post and core tail part and a head core part; the conical structure of the post and core tail part is consistent with the conical structure of a dental drilling head; the head core part is in an umbrella cap structure; the lower edge of the umbrella cap structure is fully matched with the residual part of a defected tooth; the outline part of the umbrella cap structure is fully matched with a crown part; and a porcelain crown is directly sleeved on the head core part. The method for forming and machining the integrated fiber post comprises the following steps of: (1) acquiring CT (computed tomography) data of the defected tooth; (2) reconstructing the three-dimensional model of the tooth and a post and core crown through a computer; (3) building a CAD (computer-aideddesign) model of the integrated post and core; (4) transferring the information of the CAD model of the integrated fiber post and core into a CAM (computer-aided manufacturing) numerical control center; and (5) cutting and machining the integrated fiber post and core by a machining center of a numerical control machine. The fiber post of the invention has improved strength, reduced post and core abhesion in application, and avoidances of breakage of tooth posts and failure of restoration caused by stress concentration.

Owner:北京欧亚瑞康新材料科技有限公司

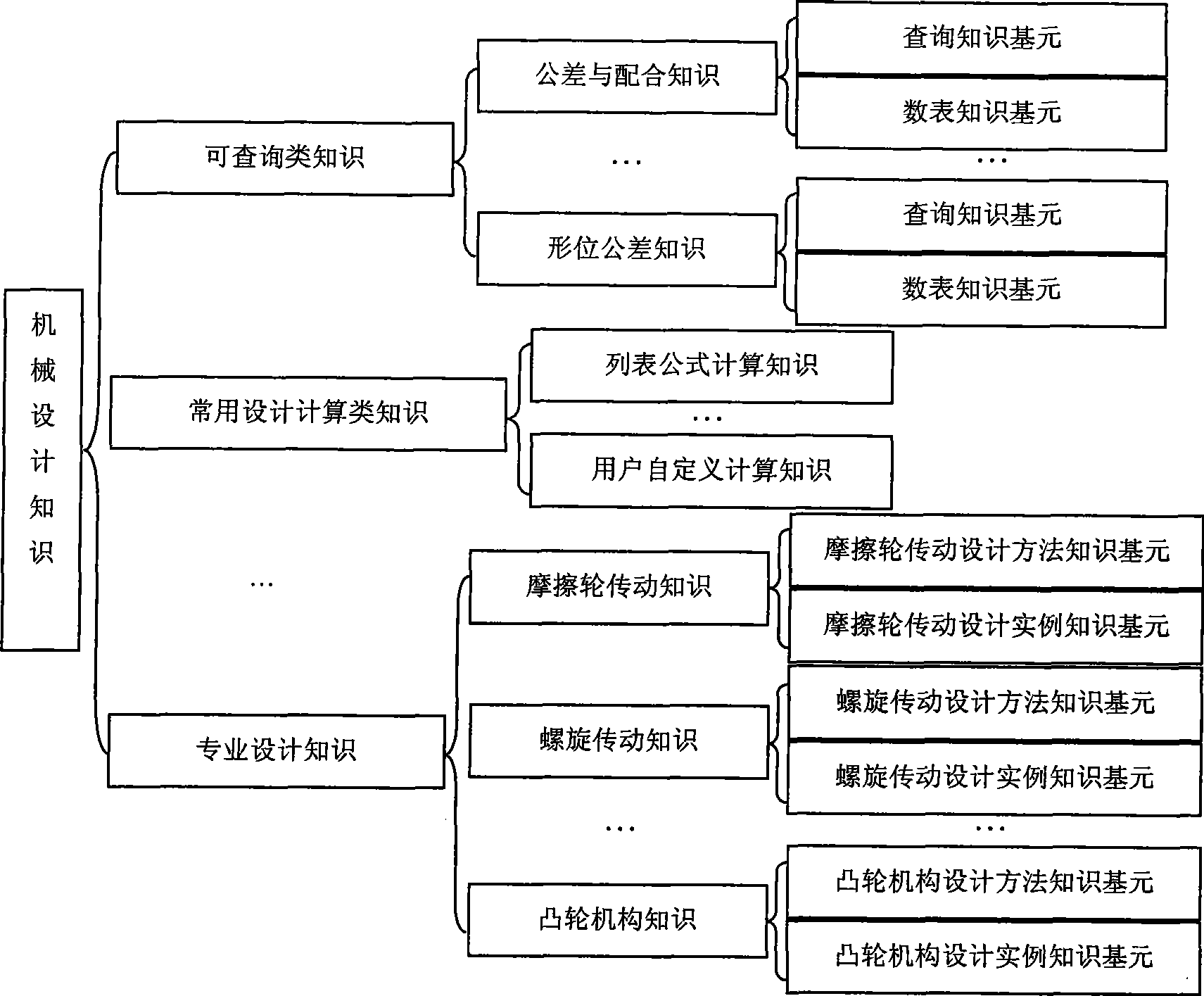

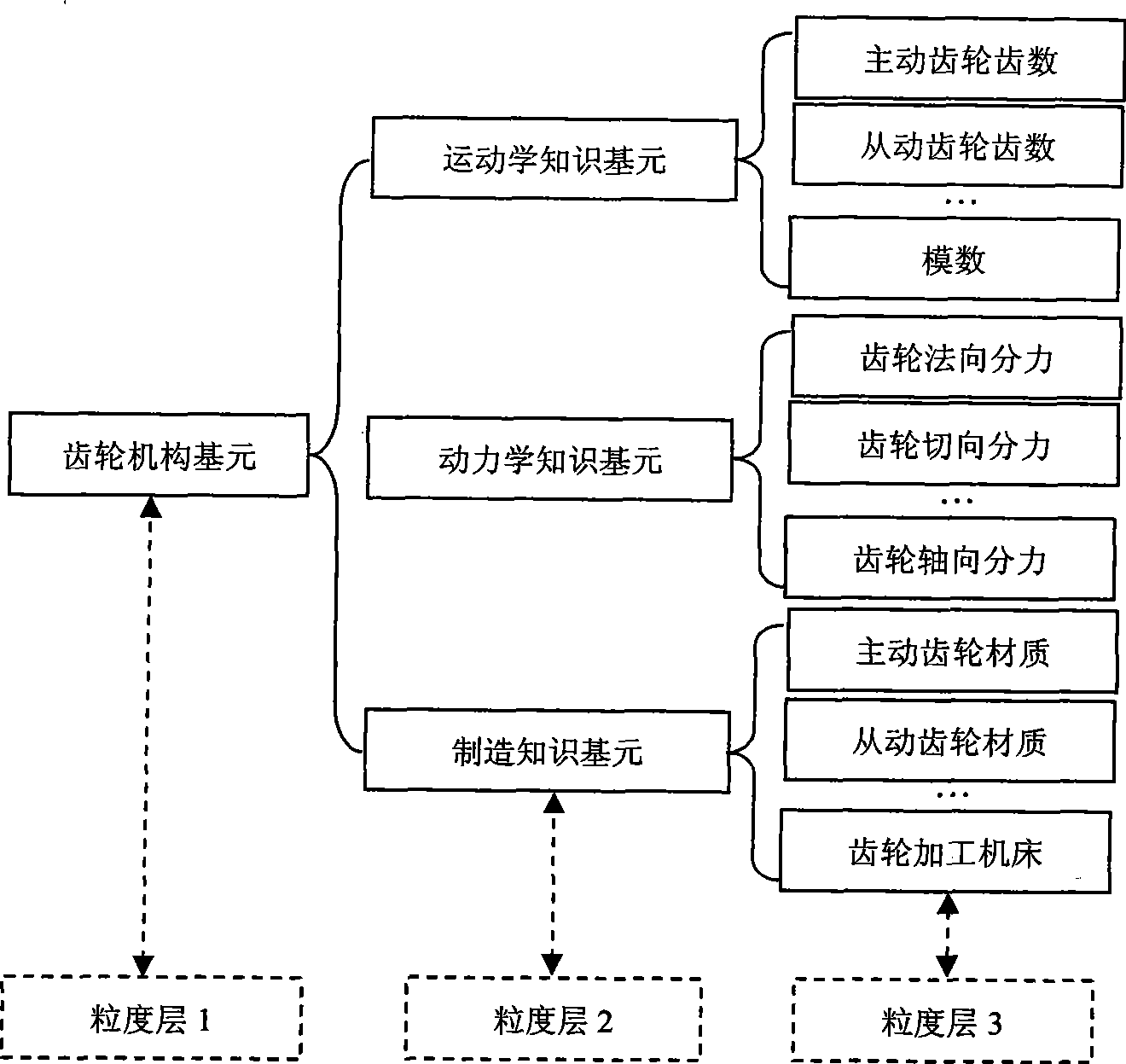

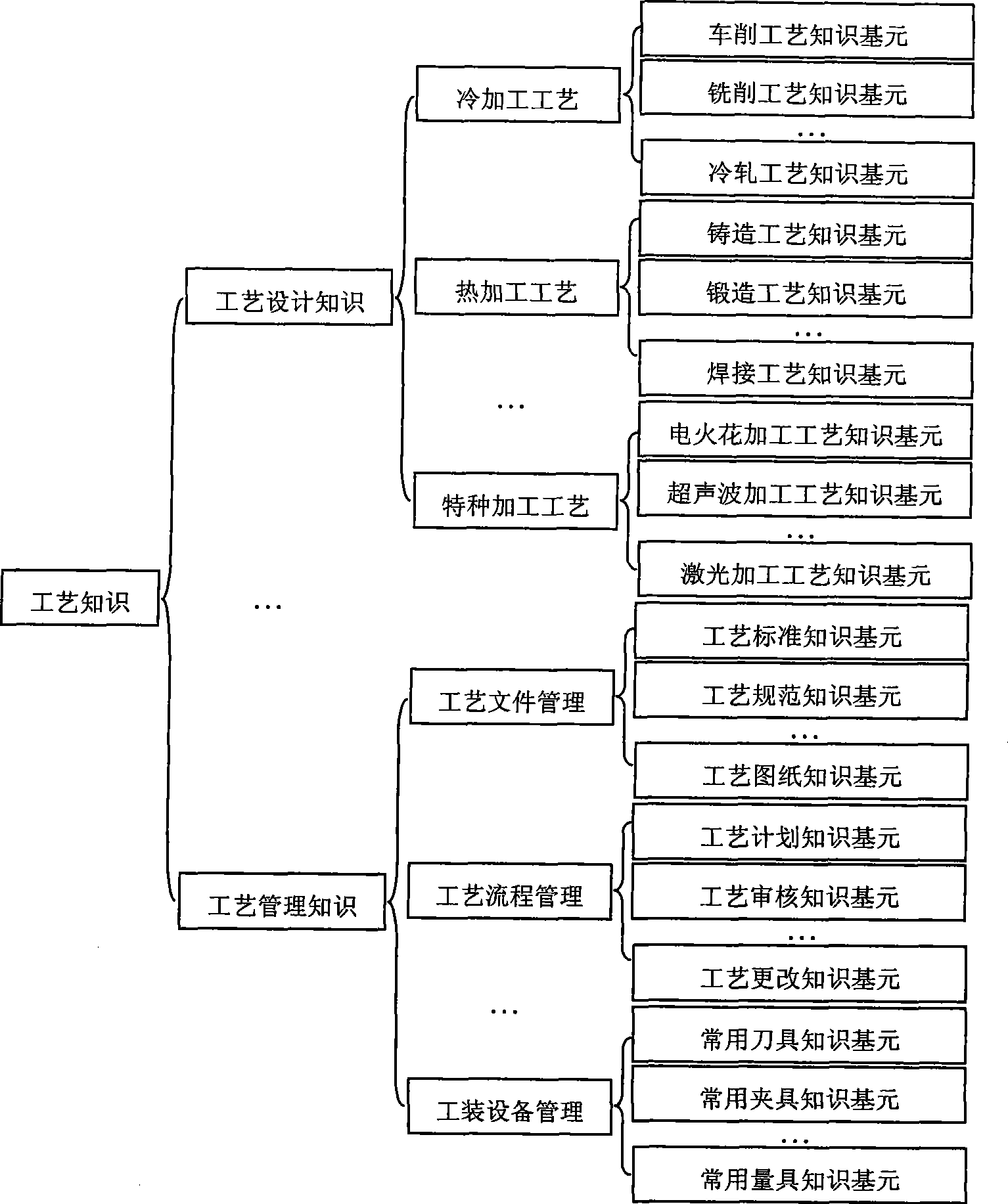

Non-standard knowledge acquisition method used for constructing mechanical product design knowledge base

InactiveCN101477521AEliminate transmissionEliminate DiffusionSpecial data processing applicationsInformation processingInformatization

The invention discloses a method for obtaining irregular knowledge used for constructing a mechanical product design knowledge base. Aiming at the requirements for knowledge processing and knowledge base system development in the mechanical product design field, the invention defines the irregular knowledge, discloses a computation module for dividing irregular knowledge granularity by adopting granularity calculation principle, studies mechanical product design irregular knowledge base structure system and basic format, discloses an irregular knowledge base display method based on metadata, and invents a method for obtaining semantic matching, irregular knowledge base in serial data source, and multi-mode irregular knowledge based on irregular example knowledge obtaining of cluster analysis; and on the basis, designs a system frame and a prototype software system for mechanical product design knowledge base system construction and application. The invention can be used to solve the technical problem of treating irregular knowledge in an information processing system such as CAD (computer-aided design), CAM (computer-aided manufacturing), CAE (computer-aided engineering) or PDM (products data management) in manufacturing industry, so as to satisfy the requirements for the deepening development of the manufacturing industry information project technology.

Owner:SICHUAN UNIV

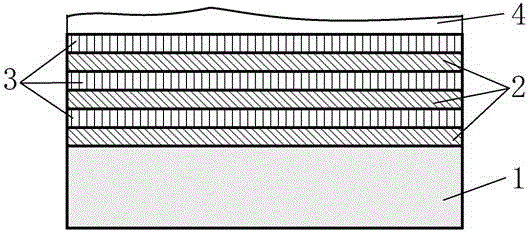

Method used for manufacturing multi-layer circuit board by employing 3D printing technology

InactiveCN104486910ALess prone to defectsReduced responseConductive pattern formationInsulation layerCam

The invention provides a method used for manufacturing a multi-layer circuit board by employing the 3D printing technology. The method is additionally provided with a heatproof insulation layer on the basis of an original printed circuit board. Raw material powder of the circuit comprises copper alloy powder and tin powder which are in a certain proportion, the heatproof insulation layer is ceramic powder, the 3D molding method is a laser irradiation molding method. During processing, the computer auxiliary manufacturing (CAM) technology is firstly utilized, circuit board design is accomplished on computer software and is transmitted to a 3D printer. The ceramic powder is fixed on the circuit board to form the heatproof insulation layer by utilizing the laser 3D printer, circuit molding of the powder is directly carried out on the heatproof insulation layer base body by utilizing the 3D printing technology, the steps above are repeated, and thereby the multi-layer circuit board is formed. Compared with a traditional printed circuit board, the multi-layer circuit board can be rapidly produced in a lab or under the small-batch production condition, moreover, the circuit does not easily generate defects, cost is low, response is rapid, equipment investment is small, and the method employing the 3D printing technology provides feasible small-batch customized production.

Owner:ANHUI NEOFOUND TECH +2

Methods and Apparatus for Producing Dental Stones Base Plates Used in Making Dentures

InactiveUS20110045442A1Quicker time frameEasy and quick stone model preparationDental implantsImpression capsDenturesComputer-aided manufacturing

This disclosure relates to a method for rapidly producing stone models used in manufacturing dentures. In particular, the method utilizes computer aided design and computer aided manufacturing.

Owner:GLAXO SMITHKLINE LLC

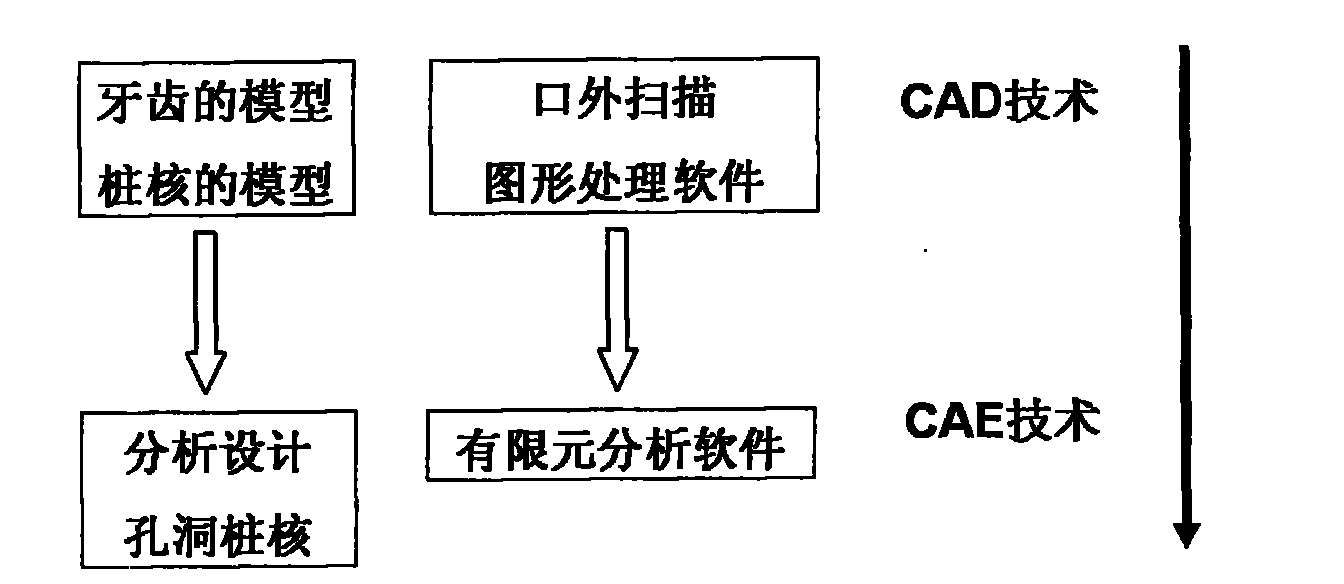

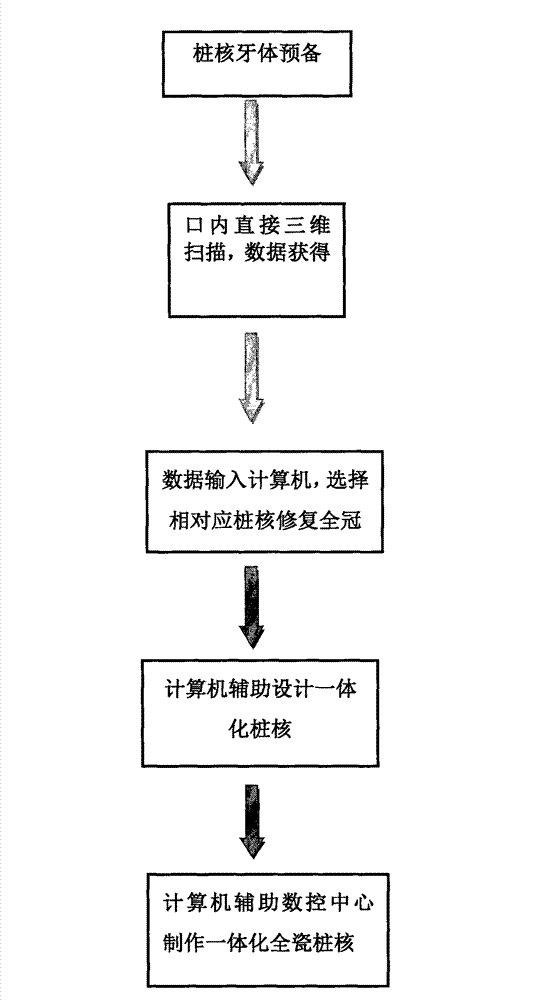

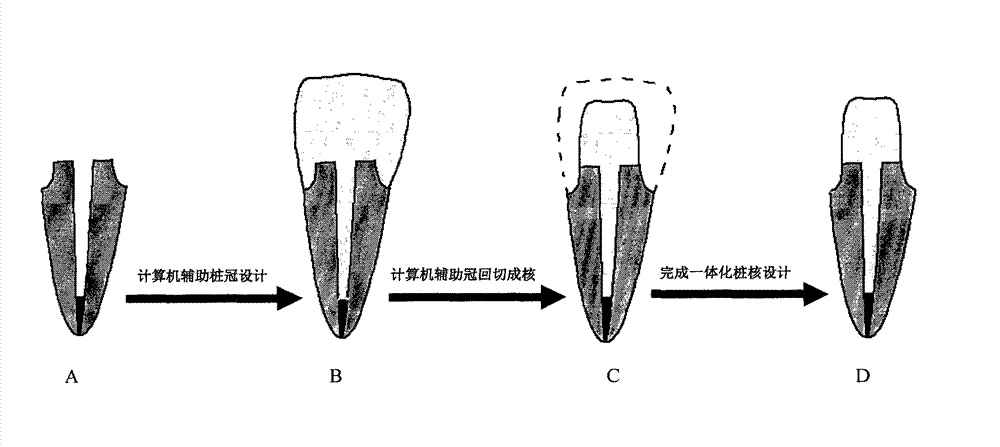

Preparation method of personalized and integrated all-ceramic post-and-core of dentistry

InactiveCN103083094AShorten visit timeShorten the overall cycleMechanical/radiation/invasive therapiesFastening prosthesisPersonalizationNumerical control

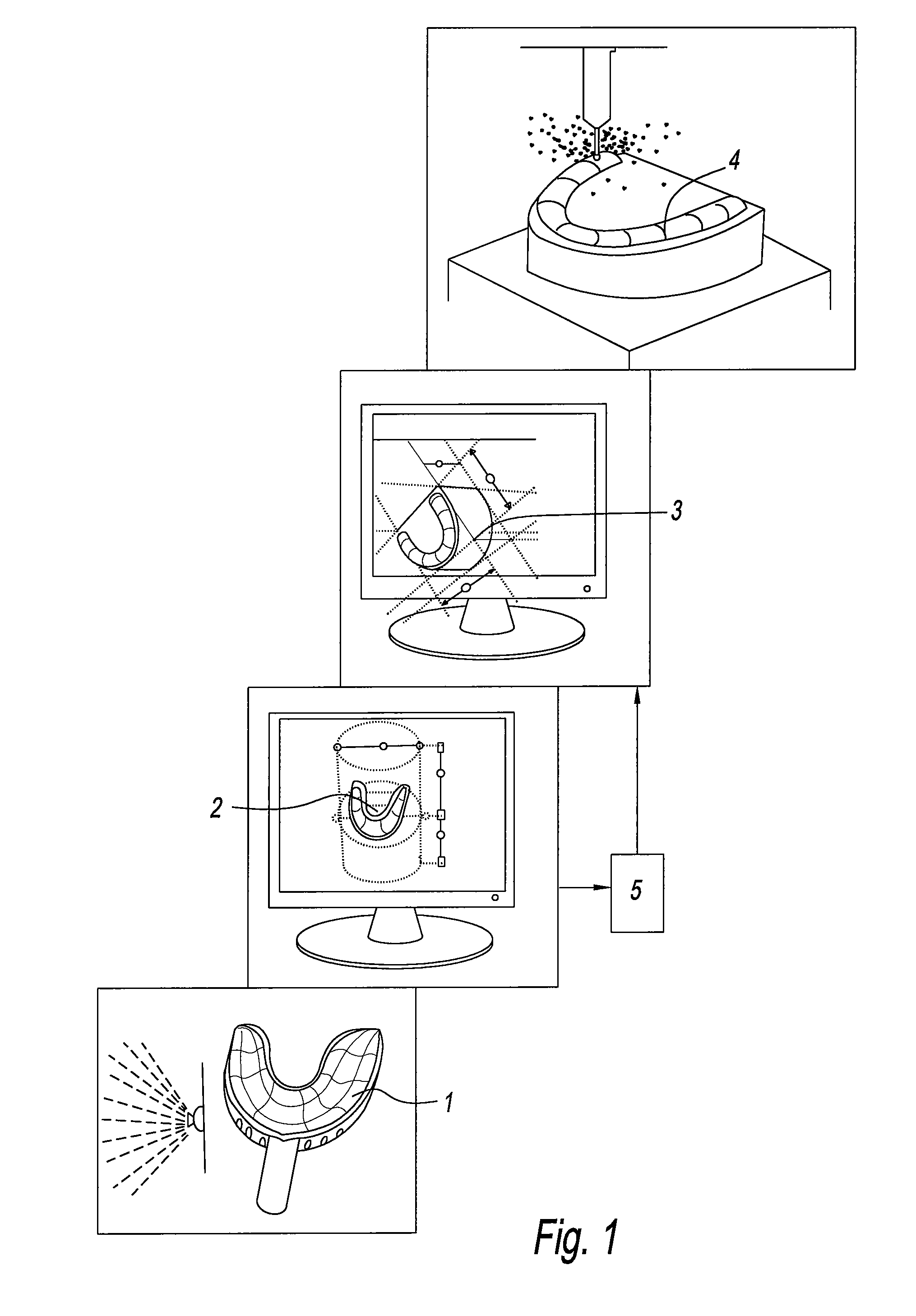

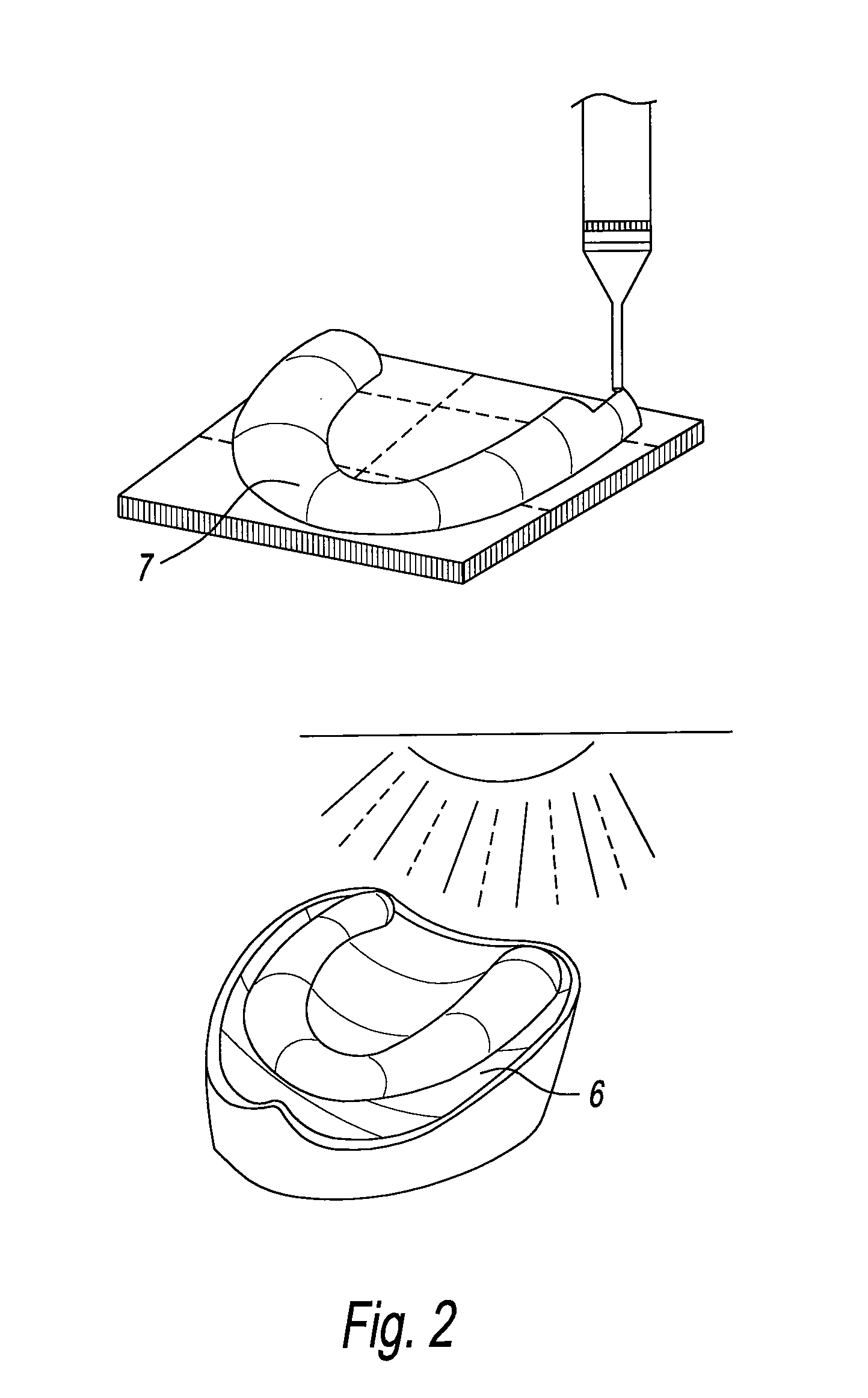

The invention provides a manufacture method of a clinical personalized and integrated all-ceramic post-and-core of dentistry. The manufacture method is characterized in that a high-precision and short-wavelength visible scanner is adopted and directly used for scanning intraoral defected teeth subjected to root canal preparation, the CAD / CAM (Computer Aided Design / Computer Aided Manufacturing) central incisor prosthetic design is adopted, the design of integrating the post and the core is accomplished, and then the incisor back-cut method design is carried out to accomplish the design of the integrated all-ceramic post-and-core, and numerical control processing equipment is adopted and used for processing in order to accomplish the manufacture of the all-ceramic post-and-core.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com