Intelligent numerical control machining programming system and intelligent numerical control machining programming method for aircraft structural parts

A technology for aircraft structural parts and programming system, which is applied in the field of intelligent numerical control machining programming system for aircraft structural parts, can solve problems such as multi-manual interactive operation, inapplicability to complex parts, etc., so as to ensure the correctness of models, improve processing efficiency, and reduce computational complexity. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific implementation processes are provided, but the scope of protection of the present invention does not Limited to the following implementation examples.

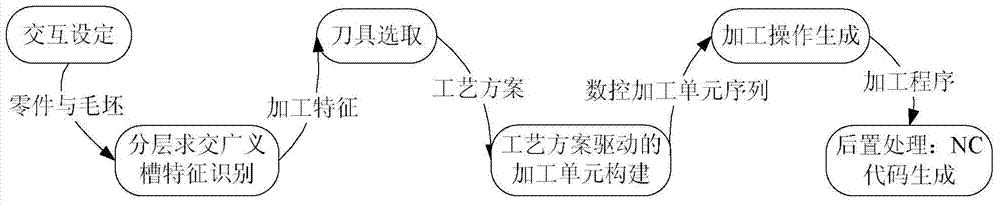

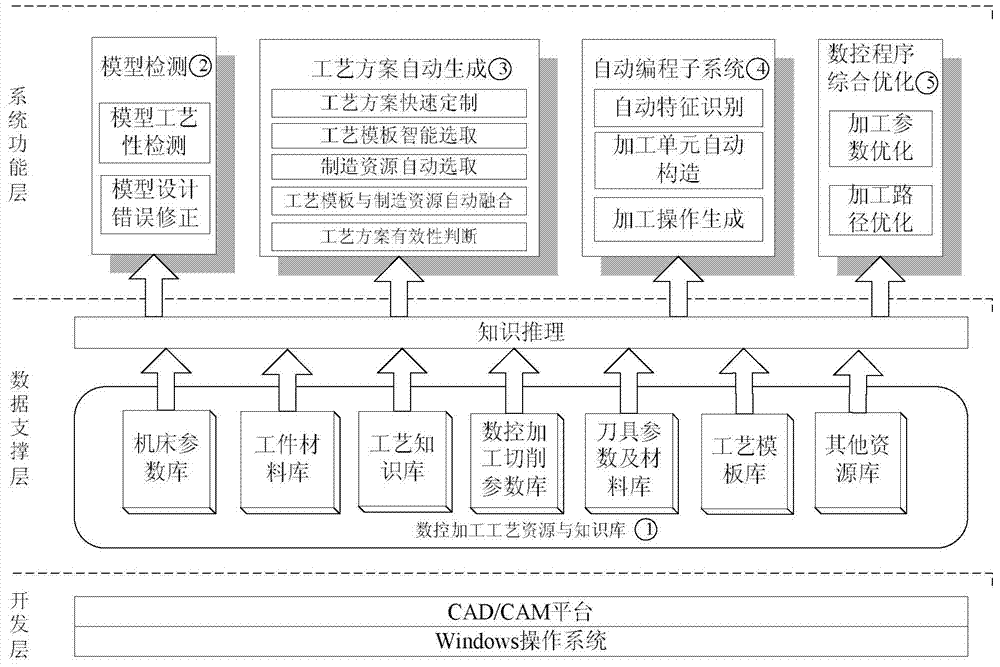

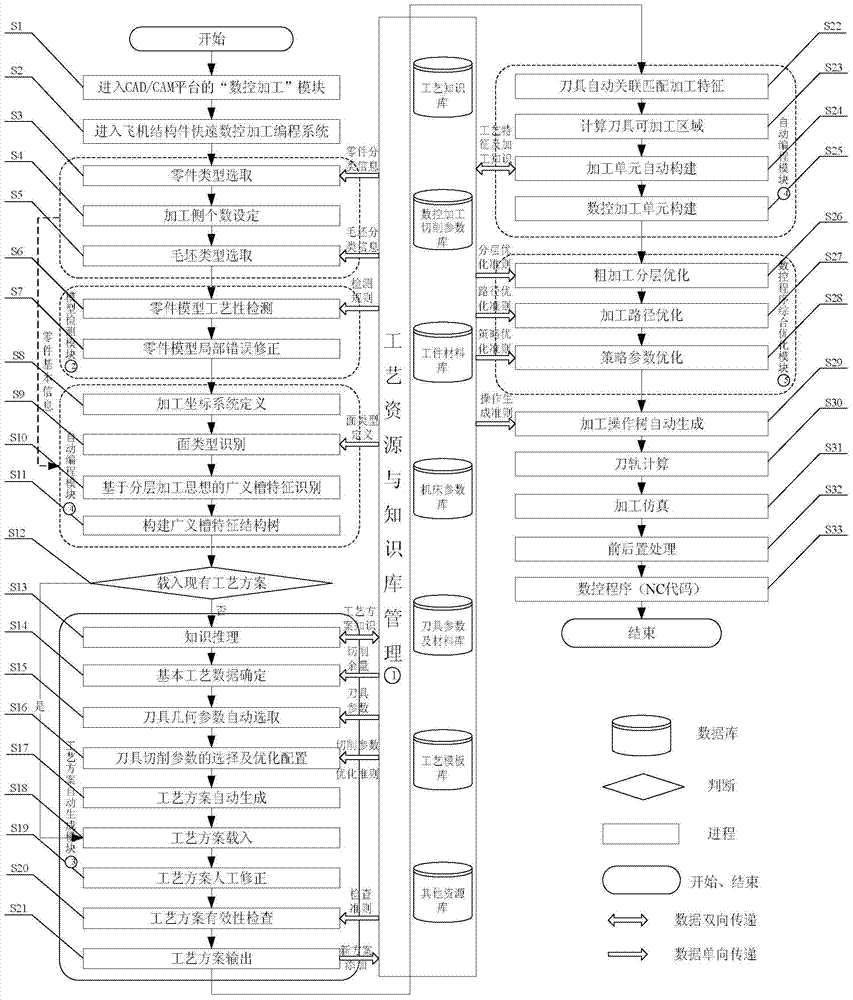

[0028] figure 1 It is the model diagram of the intelligent CNC machining programming system for aircraft structural parts (INCPro for short). The intelligent programming of aircraft structural parts is driven by the process plan, which realizes the intelligentization, standardization and self-optimization of programming. The compiled program highly meets the process requirements and can Reflect the programmer's thinking. The main idea is: according to the idea of layered rough machining method, the layered feature recognition method is used to identify ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com