Method used for manufacturing multi-layer circuit board by employing 3D printing technology

A multi-layer circuit board, 3D printing technology, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of high missed inspection rate, unrealizable, high labor intensity, etc., and achieve small equipment investment, less defect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better illustrate the present invention and facilitate understanding of the technical solutions of the present invention, typical but non-limiting examples of the present invention are as follows.

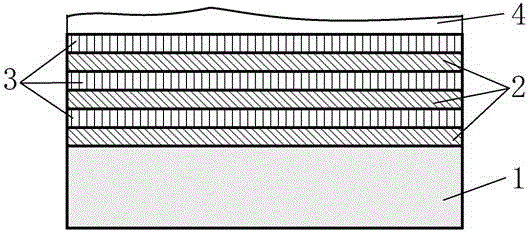

[0016] Use protel DXP software to design a 3-layer circuit board, convert the circuit board design into Gerber data format, and then send it to the laser 3D printer.

[0017] The raw material of the heat-resistant insulating layer is alumina ceramic powder; the ratio of circuit raw material powder is 95% Cu alloy and 5% tin-lead alloy.

[0018] Using a laser 3D printer, the ceramic powder is molded using the selective laser sintering (SLS) method to form a heat-resistant insulating layer and protective layer, and the circuit is formed using the direct metal laser sintering (DMLS) method. So back and forth, and finally complete the printing.

[0019] The applicant declares that the above content is a further detailed description of the present invention in conj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com