Full-automatic argon arc welding method of circumferential weld of large-caliber bimetal composite pipe

A bimetallic composite pipe, argon arc welding technology, applied in welding equipment, metal processing, welding accessories, etc., to achieve the effect of refining grains, not easy to blow hole defects, and ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0050] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

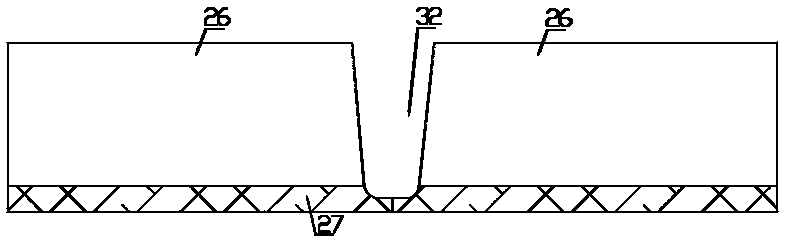

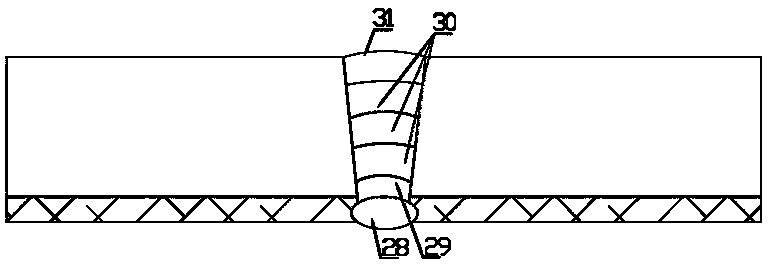

[0051] Such as Figures 1 to 5 Shown, the present invention adopts following steps:

[0052] The first step, pre-welding preparation process:

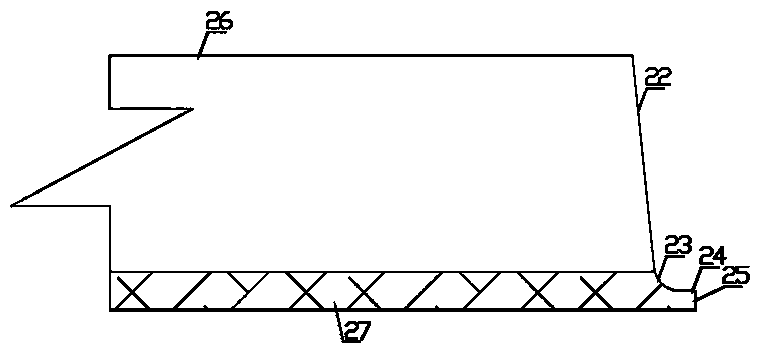

[0053] Such as figure 1 As shown, ① use a beveling machine to prepare a bevel on the bimetallic composite pipe 26, and machine the bevel; Scrub with acetone or alcohol; the groove angle 22 is 8 degrees, the half width of the opening is 6mm, and the error is ±0.1mm; the root arc 23 of the groove is a radius of 2.4mm; the root arc 23 is tangent to the blunt inner platform 24, and the blunt edge The size of the inner platform 24 is: 1.5mm±0.1mm; the thickness of the blunt edge 4 of the groove is: 1.8mm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com