Patents

Literature

36results about How to "Easy to escape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing furfural by xylose dehydration through fixed bed catalysis

The invention discloses a method for preparing furfural by xylose dehydration through fixed bed catalysis, which comprises the following steps: adding a 1-3 mol / L acid catalyst solution into a reaction vessel, adding a cocatalyst of NaCl till saturation is achieved, heating to backflow, stirring to form a rotating liquid level of a catalyst layer with a fixed volume and concentration, jetting 10-20 wt% of xylose solutions obtained by straw hydrolyzation through dilute acid catalysis into the reaction vessel with a certain speed, performing xylose dehydration, and performing rectification to obtain a furfural solution with a purity of up to above 99% and a furfural yield of 50-70 wt%. The advancement of the invention is that the heating temperature is adjustable, which allows the volume of the xylose solution jetted into the reaction vessel to be maintained to be equal to the volume of the distilled furfural solution; the concentrations of the acid catalyst and the cocatalyst are constant; the volume of the catalyst layer is constant; the reaction process is maintained to be stable; continuous production is realized; the water phase of furfural-water separation returns to the hemicellulose hydrolyzation procedure for recycle; no waste water is discharged; the furfural yield is increased twice when compared with the yield of traditional production processes.

Owner:JILIN UNIV

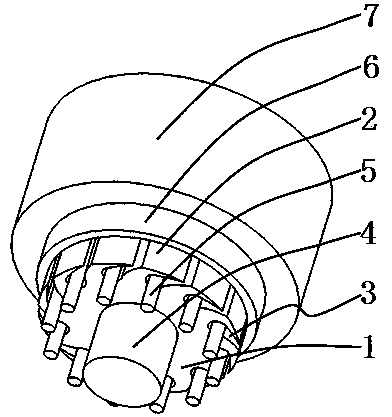

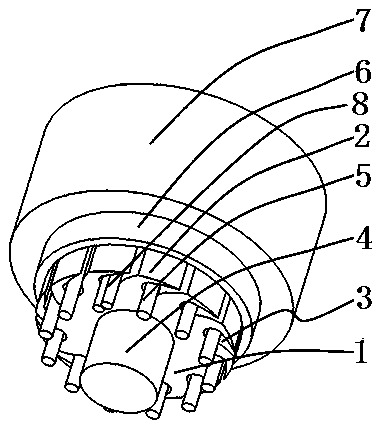

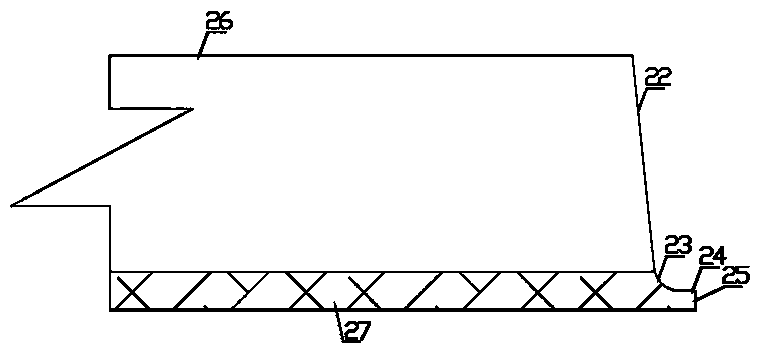

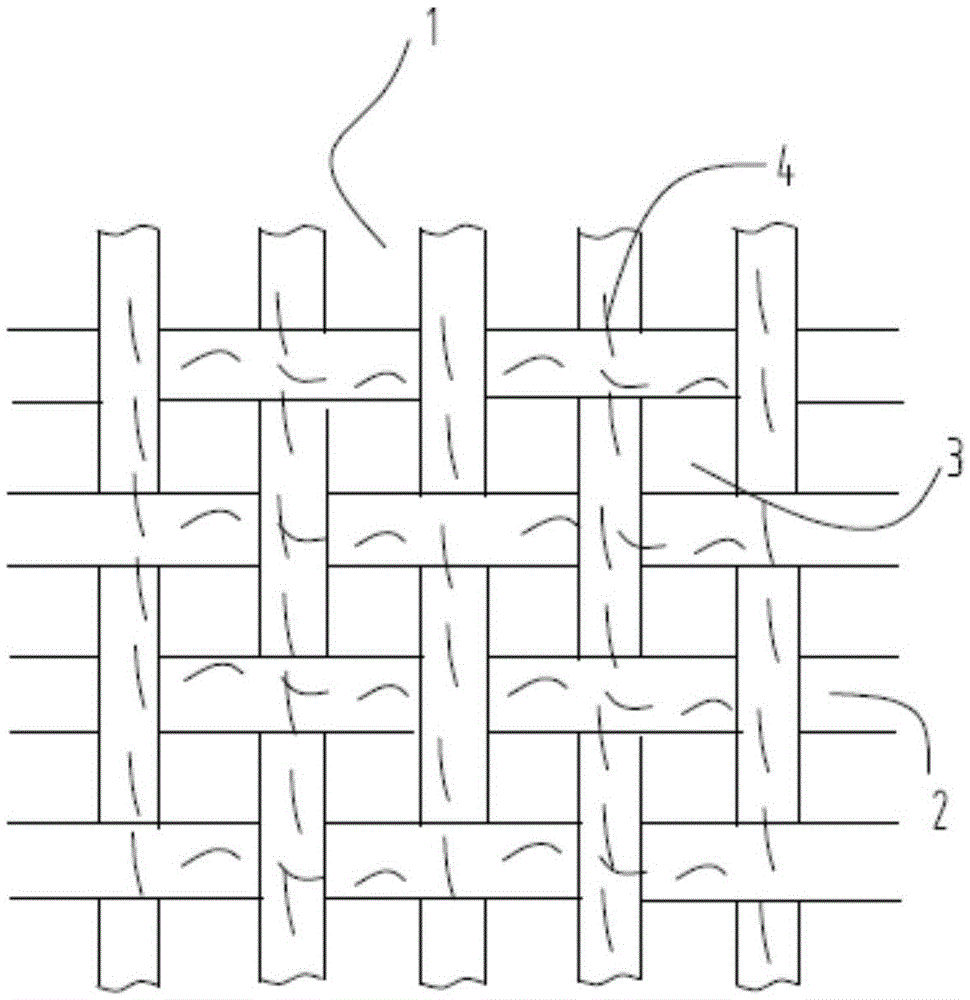

Microgroove cable

InactiveCN104078139ANot easy to escapeNot easy to escape, but easy to take out during constructionInsulated cablesPower cablesStructural engineeringProtection layer

The invention belongs to the technical field of cables and particularly relates to a microgroove cable, which comprises a framework body, a plurality of framework blades, a plurality of framework slots, a reinforcing piece, a plurality of cable cores, a protective layer and a protective sleeve layer, wherein the framework body, the framework blades, and the framework slots are integrally formed; the framework blades are positioned on the edge of the framework body; the reinforcing piece is positioned in the center of the framework body; one framework slot is formed between each two adjacent framework blades; the cable cores are positioned in the framework slots; the framework blades are coated with the protective layer; the protective layer is coated with the protective sleeve layer in an extrusion manner; the microgroove cable is characterized in that the outer edges of the framework blades, and the outer edges of the framework slots are positioned on the side surface of the same cylinder, and at any cross section, the midpoint of the connecting line of the two ends of the opening of each framework slot and the connecting line of the top point of the bottom of each framework slot do not pass through the center of the reinforcing piece; all the framework slots are in the same direction. The microgroove cable has the main benefits as follows: the microgroove cable is easy to produce, higher in qualification rate of finished products, low in production equipment input, less in resource consumption, higher in product density, and more stable in product quality.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

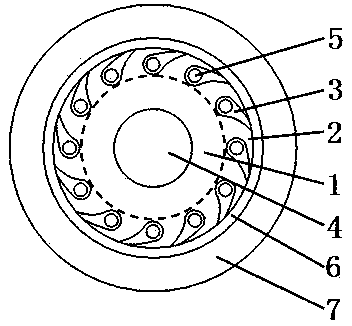

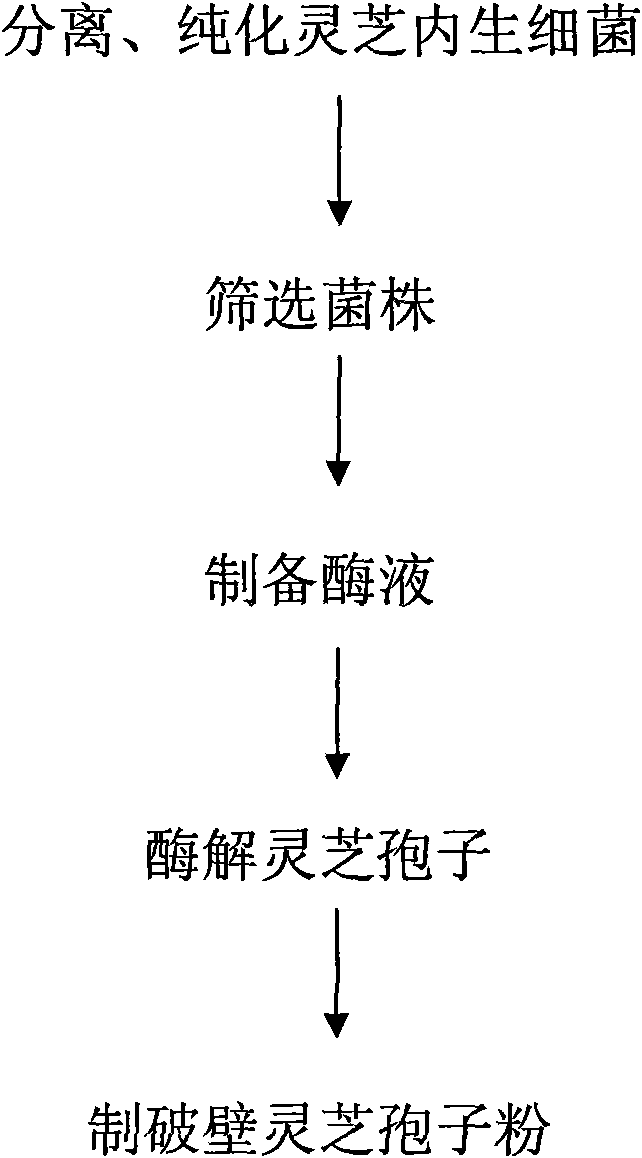

Wall-breaking method of ganoderma lucidum spore

The invention relates to a wall-breaking technique of ganoderma lucidum spore, in particular to a biologic method for carrying out wall breaking on the ganoderma lucidum spore. The method comprises the following steps of: separating and purifying ganoderma endophytic bacteria from ganoderma; sieving strains; preparing enzyme liquid; carrying out enzymolysis on the ganoderma lucidum spore; and preparing wall-breaking ganoderma lucidum spore powder. The invention utilizes the self symbiotic bacteria of the ganoderma to carry out fermentation on the spore and a fruiting body of the ganoderma, the effective ingredients of the ganoderma more easily escape from cells, a human body can successfully absorb and digest the effective ingredients, and the effective ingredients can be fully utilized. The difficulty that biologic residues caused by introducing foreign bacteria are hard to remove can be eliminated, and the safety of a product is ensured.

Owner:西藏月王药诊生态藏药科技有限公司

Stabilization in gamma-ray spectometry

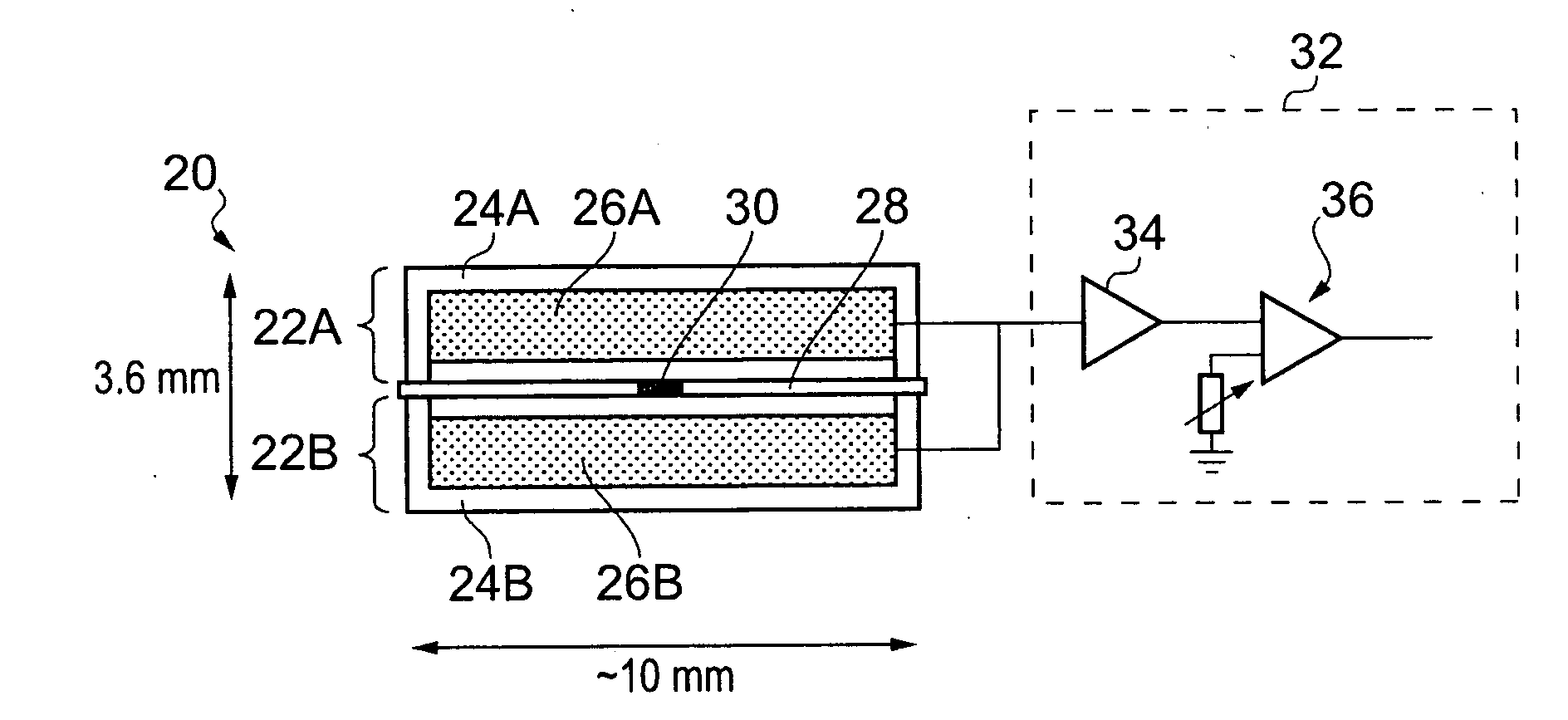

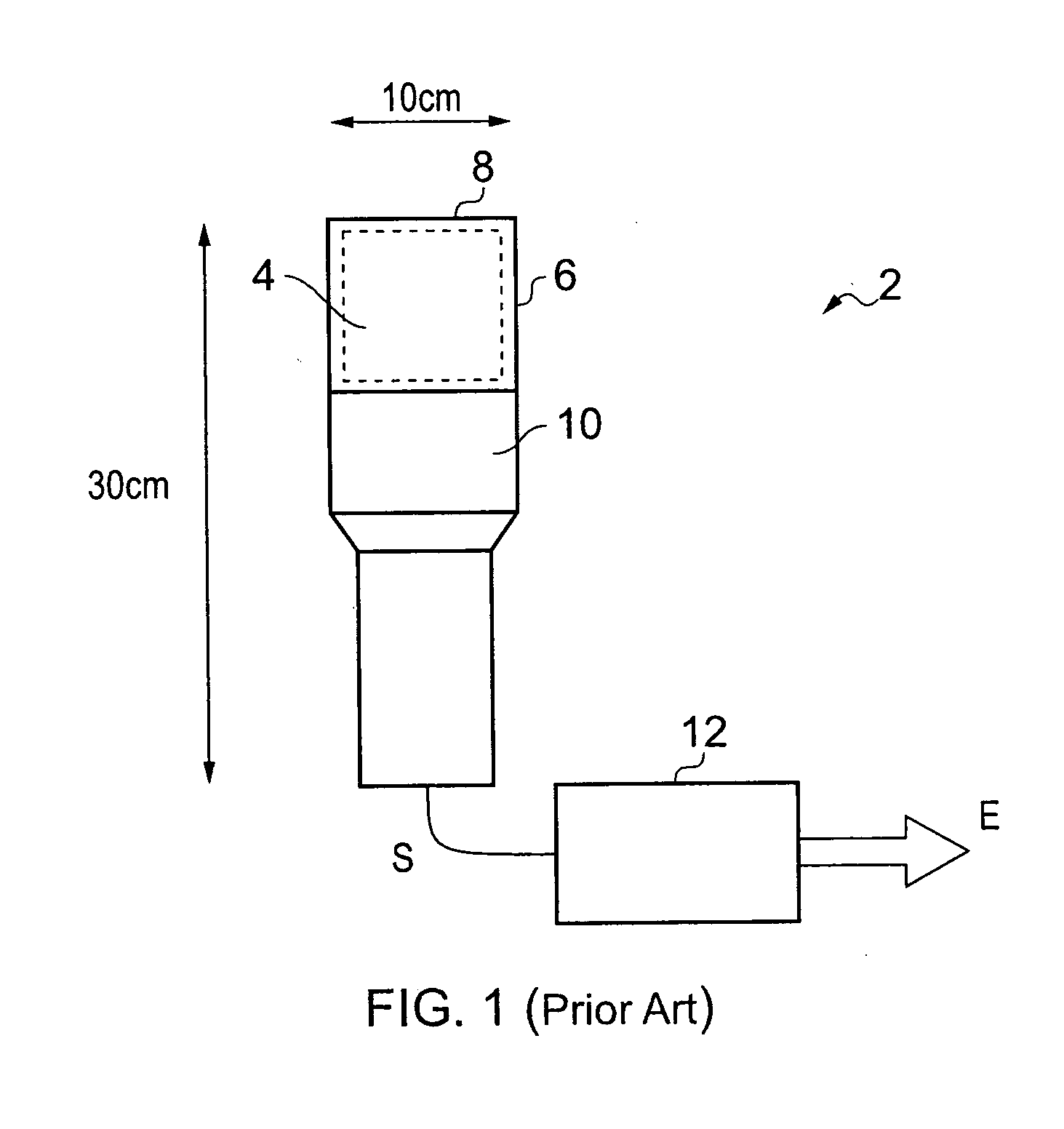

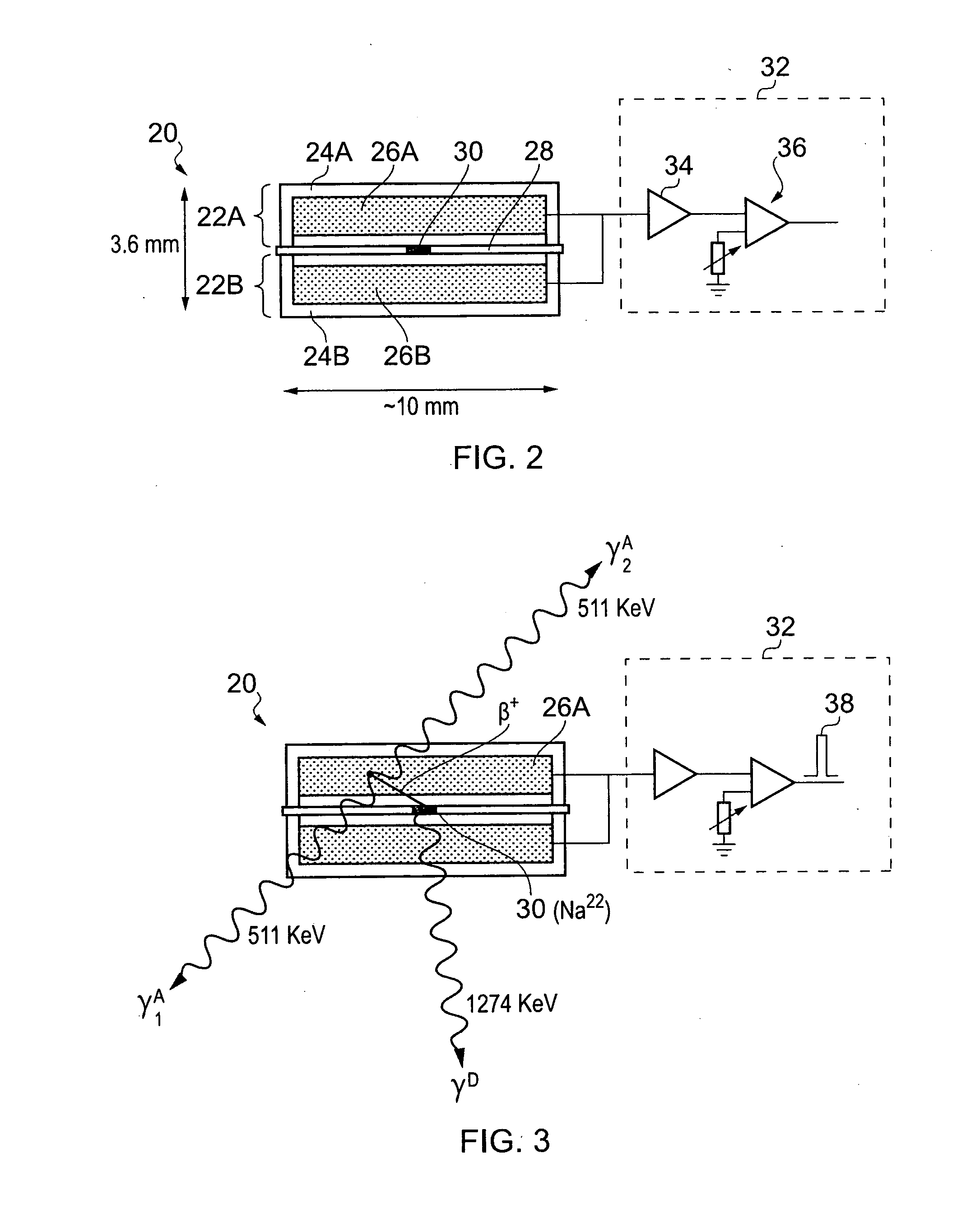

ActiveUS20110211675A1Easy to escapeSmooth responseX-ray spectral distribution measurementCalibration apparatusSolid state detectorGamma ray spectrometer

A calibration source (20) for a gamma-ray spectrometer (40) is provided. The calibration source comprises a radioactive material (30) comprising a radioactive isotope having a decay transition associated with emission of a radiation particle and a gamma-ray having a known energy, e.g. Na-22, and a solid-state detector (26A, 26B), e.g. a PIN photodiode, arranged to receive radiation particles emitted from the radioactive material. A gating circuit (32) is coupled to the solid-state detector and is operable to generate a gating signal in response to detection of a radiation particle in the solid-state detector. The gating signal may thus be used as an indicator that an energy deposit in a nearby gamma-ray spectrometer is associated with a decay transition in the radioactive isotope. Since these energy deposits are of a known energy, they can be used as reference points to calibrate the spectrometer response. Thus with calibration sources according to embodiments of the invention, spectral stabilization (i.e. accounting for a changing spectrometer response, as well as base calibration) may be performed in real time and in parallel with obtaining a spectrum of observed signal events (i.e. the spectrum of interest). Furthermore, this is achieved with little contamination of the spectrum events of interest.

Owner:SYMETRICA

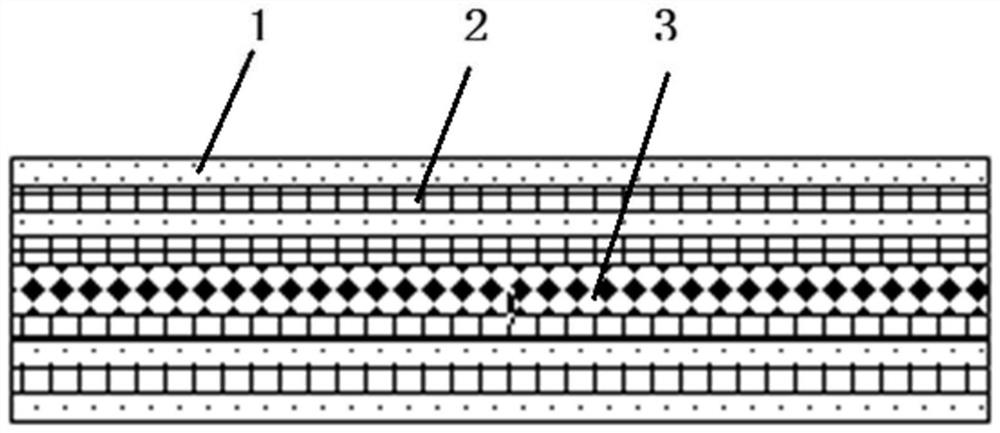

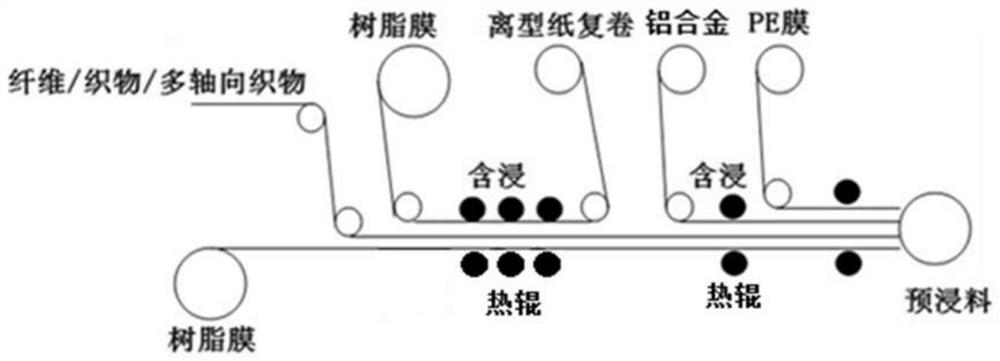

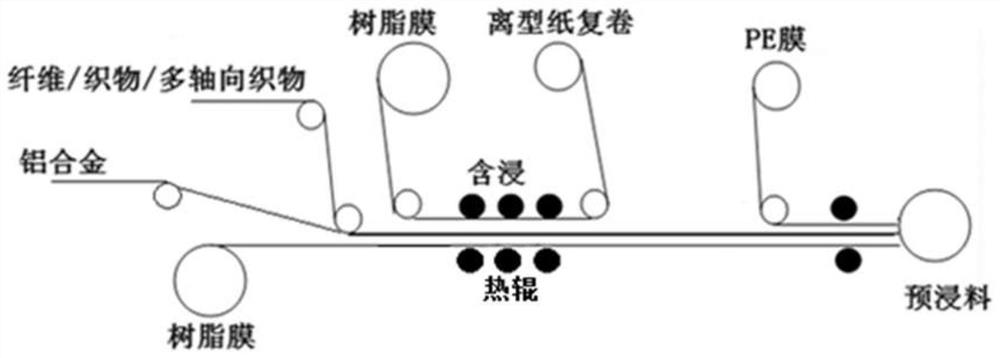

Super-hybrid fireproof prepreg for new energy automobile battery box and preparation method

PendingCN112976748AImprove fire performanceGas escapeLamination ancillary operationsSynthetic resin layered productsAutomotive batteryNew energy

The invention discloses a super-hybrid fireproof prepreg for a new energy automobile battery box and a preparation method. The super-hybrid fireproof prepreg comprises a resin matrix layer, an aluminum alloy layer and a fiber layer. The preparation method comprises the following steps of firstly, preparing the resin matrix into an adhesive film, and then infiltrating and fusing the adhesive film with the fiber layer and the aluminum alloy layer to form the super-hybrid fireproof prepreg. The new energy automobile battery box prepared from the super-hybrid fireproof prepreg not only can reduce the weight of the battery box, but also has the characteristics of high specific strength and high specific modulus of a fiber reinforced resin-based composite material and good fireproof and impact damage resistance of a metal material.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

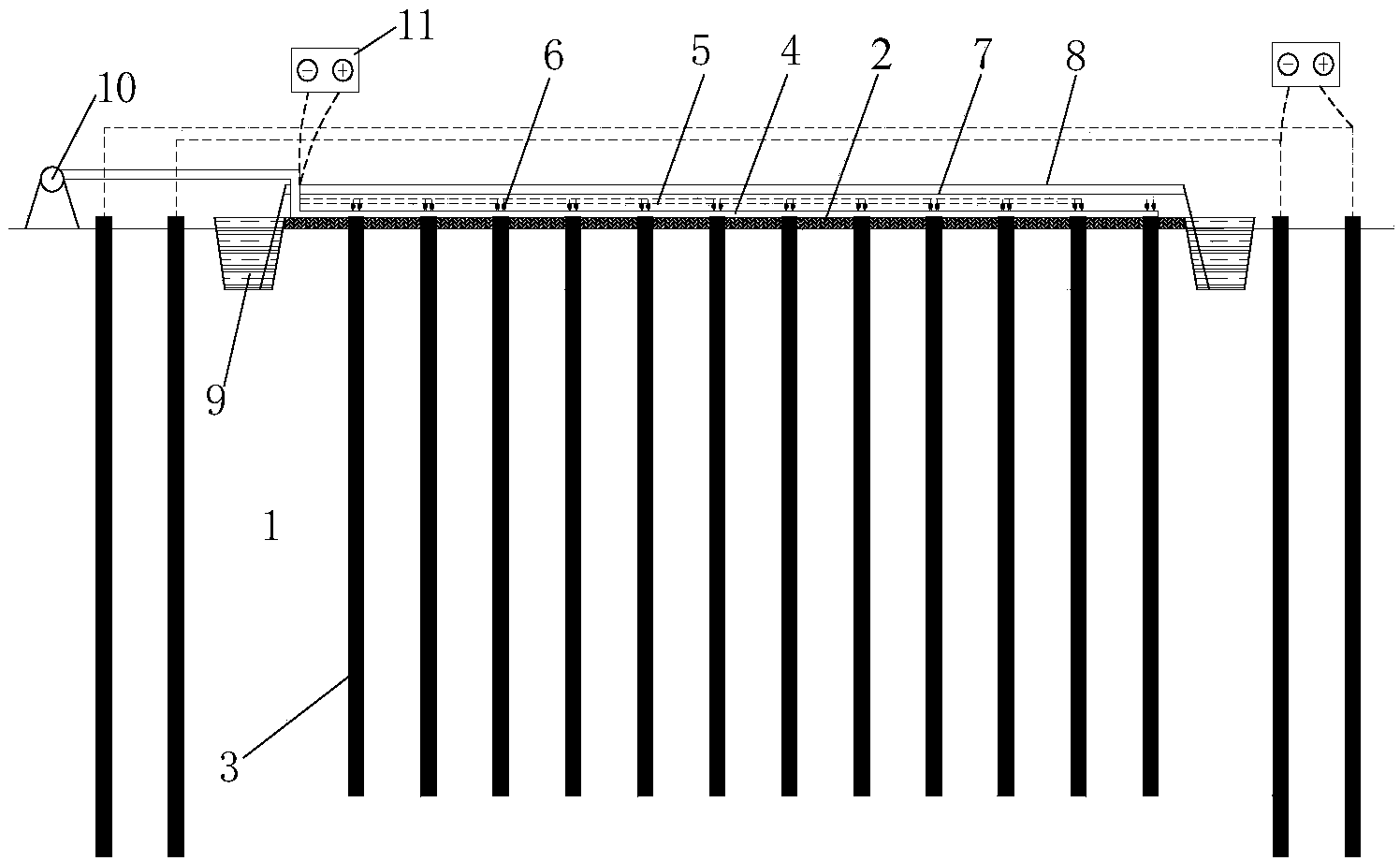

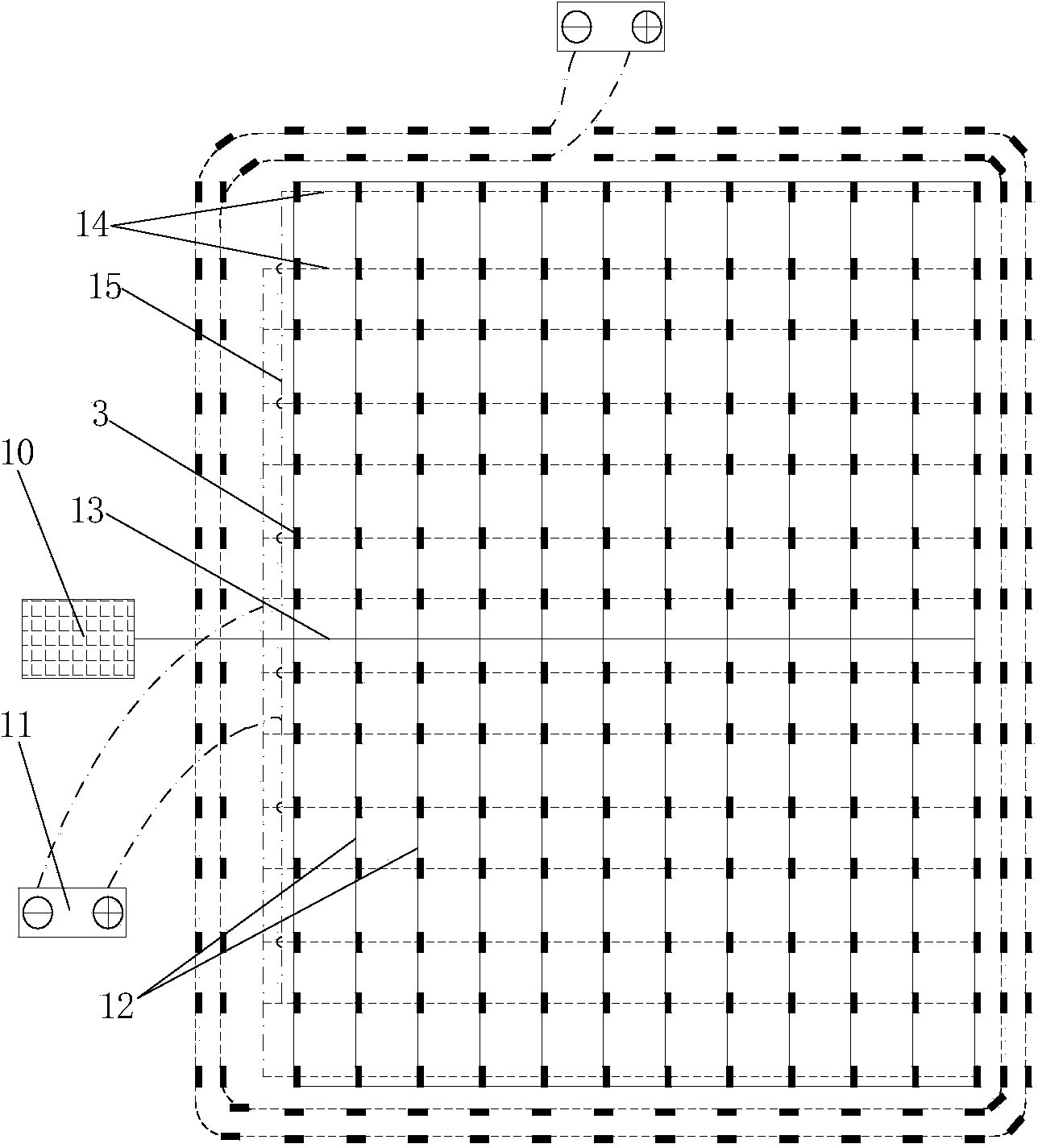

Method for reinforcing soft clay foundation

InactiveCN103758110AEffective reinforcementEasy to escapeSoil preservationSoil scienceWater discharge

The invention discloses a method for reinforcing a soft clay foundation. The method comprises the following steps that equipment needed by a vacuum preloading method and an electroosmosis method is arranged on a pre-reinforced foundation; and the foundation is processed through an intermittent vacuum preloading method and a vacuum preloading-electroosmosis alternating method. At the early stage, soil body water content is high, most free water in soil is discharged through the intermittent vacuum preloading method, the problem that upper layer soil body solidification is too quick, so that lower portion soil body upward water discharging is affected can be avoided, pore water in a deep foundation layer can be driven to flow from an anode to a cathode through the electroosmosis method, the pore water is dredged upwards along a conducting plastic water discharging plate and is accumulated in a shallow soil layer, and water in the shallow soil layer can be effectively discharged by vacuum preloading. Accordingly, the advantages of the two methods can be combined in vacuum electroosmosis alternating reinforcement to achieve effective reinforcement on the soft clay foundation, loss of electroosmosis energy by vacuum preloading is avoided, energy using rate is improved, great reinforcing effect is achieved, and the reinforced soft clay foundation has high bearing force.

Owner:HOHAI UNIV

Method for recovering triethylamine, removing phosphorus pollutants and recovering phosphorus resources in glyphosate mother liquor

InactiveCN105130822AReduce contentHigh total removal rateAmino compound purification/separationMultistage water/sewage treatmentDesorptionWater vapor

A method for recovering triethylamine, removing phosphorus pollutants and recovering phosphorus resources in glyphosate mother liquor comprises operation steps as follows: (1) calcium hydroxide powder or a calcium hydroxide emulsion is added to the glyphosate mother liquor, the mixture is evenly mixed, the calcium hydroxide powder or the calcium hydroxide emulsion is required to be added to enable the pH value of the glyphosate mother liquor to range from 10.5 to 12.3, then the glyphosate mother liquor is heated to the temperature higher than 85 DEG C for a reaction for 0.5-3 h while stirring is performed, triethylamine vapor produced in the reaction is collected and condensed, and a triethylamine solution is obtained; (2) a solid-liquid mixture formed through the reaction is subjected to water vapor gas-stripping desorption, a gas discharged through water vapor gas-stripping desorption is condensed, and a triethylamine solution is obtained; (3) the triethylamine is obtained through dehydration treatment of the obtained triethylamine solutions; (4) a coagulant is added to the solid-liquid mixture obtained after water vapor gas-stripping desorption while stirring is performed, the mixture is evenly mixed, then solid-liquid separation is performed after a reaction while stirring is performed, obtained solid substances are used as the phosphorus resources to be recycled, and an obtained liquid is collected for further treatment.

Owner:SICHUAN LECHUANG TECH CO LTD

Automobile air conditioner compressor hollow piston and production method thereof

ActiveCN104805339AHigh tensile strengthHigh yield strengthPositive displacement pump componentsPositive-displacement liquid enginesPorosityWeld seam

The invention discloses an automobile air conditioner compressor hollow piston, which comprises aluminum alloy prepared from the following ingredients in percentage by weight: 11 to 13 percent of Si, 3.5 to 4.5 percent of Cu, 0.2 to 0.5 percent of Mg, 0.8 to 1.5 percent of Ni, 0.1 to 0.3 percent of Cr, 0.1 to 0.3 percent of C, 0 to 0.1 percent of Mn, 0 to 0.5 percent of Zn, 0 to 0.15 percent of Ti, 0.1 to 0.3 percent of RE and the balance Al. The invention also provides a production method of the automobile air conditioner compressor hollow piston. Through the selection and the control on elements in the aluminum alloy for the hollow piston, the intensity and the hardness of the piston are improved; through further improvement on the laser welding process, the welding seam fine porosity rate is reduced, the welding tension is enhanced, and the welding quality is improved, so the use performance of the hollow piston is improved, and the service life of the hollow piston is prolonged.

Owner:SHANDONG HUICHUAN AUTO PARTS

Nano-mesoporous oxygen carrier and preparation method thereof

InactiveCN106943987AImprove stabilityImprove adsorption capacityHydrogenOther chemical processesWater vaporRedox

The invention discloses a nano-mesoporous oxygen carrier. The oxygen carrier comprises, by mass, 20-50 parts of montmorillonite, 5-10 parts of TiO2, 5-10 parts of NiO, 5-10 parts of CeO2 and 10-20 parts of CaO. The invention also discloses a preparation method of the oxygen carrier. Multibasic oxide is compounded based on the nanolayer structure of natural montmorillonite, so the oxygen carrier is nano-mesoporous, and cheap large-scale industrial application is reached. Methane and water vapor enter the mesoporous structure prosperous in the surface of the oxygen carrier, the methane, water and the oxygen carrier undergo a surface redox reforming hydrogen production reaction, CO2 is adsorbed in situ, the endothermic reaction and the exothermic reaction are coupled in the hydrogen production process, and highly pure hydrogen is prepared in a high-efficiency and energy-saving manner. The preparation method has the advantages of simplicity, controllability and very low cost. The nano-mesoporous oxygen carrier improves the catalysis performance and the thermal stability of the oxygen carrier, and is friendly to environment.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

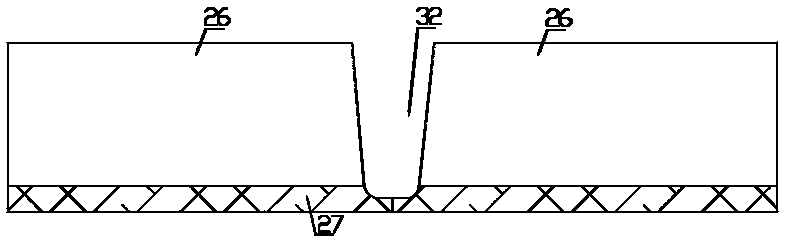

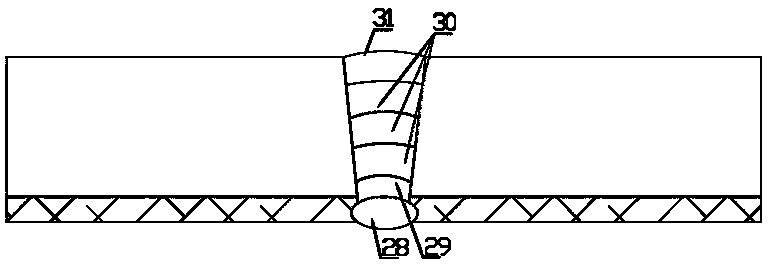

Full-automatic argon arc welding method of circumferential weld of large-caliber bimetal composite pipe

PendingCN110576244AEliminates the problem of unmelted sidewallsStrong penetrating powerShielding gas supply/evacuation devicesElectrode holder supportersSmall amplitudeShielding gas

The invention relates to the technical field of a full-automatic welding method of a circumferential weld of a large-caliber bimetal composite pipe, and discloses a full-automatic argon arc welding method of a circumferential weld of a large-caliber bimetal composite pipe. The method includes the following steps of firstly, making a preparation before welding; secondly, conducting root welding, wherein the root welding is conducted through a full-automatic argon tungsten-arc welding machine in the upward direction from the 6 o'clock position to the 12 o'clock position, the protection gas introduced into a welding gun is argon or mixed gas of argon and helium, the volume percentage of the helium in the mixed gas is 15-20%, the purity of the argon is larger than 99.99%, the purity of the argon for welding is not lower than 99.99%, the dew point is not higher than -50 DEG C, and the oxygen content is not larger than 500 ppm. The method has the advantages that root welding is conducted bymeans of the welding gun small-amplitude swinging process, so the back of the weld is well formed, grasping is easy, and defects can hardly appear; and hot welding and filling welding are conducted through U-type swinging adaptive to the groove type, so an electric arc can more easily reach a groove face, and the side wall non-welding problem easily appearing in an existing welding process is eliminated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

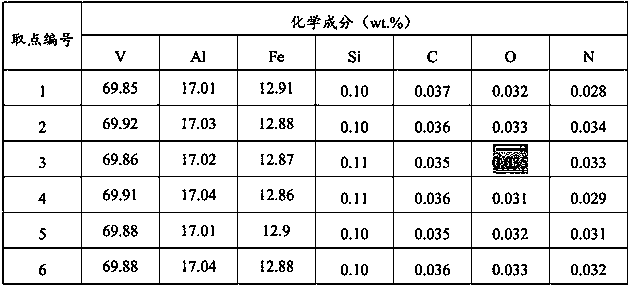

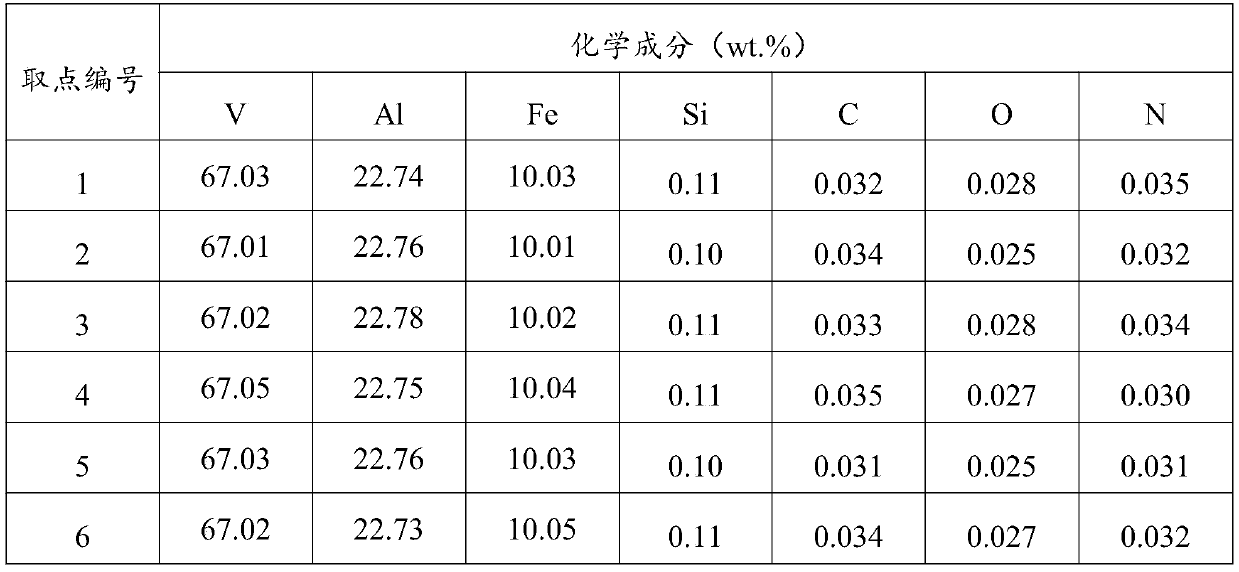

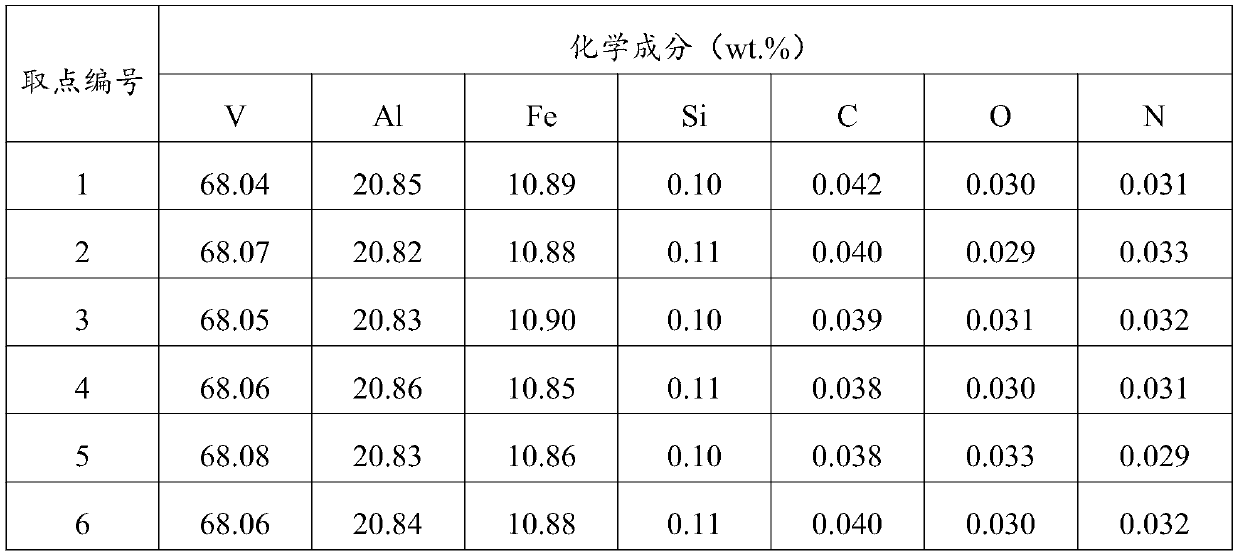

Vanadium-aluminum-iron intermediate alloy and preparation method thereof

The invention provides a vanadium-aluminum-iron intermediate alloy and a preparation method thereof, and relates to the technical field of metal materials. The preparation method of the vanadium-aluminum-iron intermediate alloy comprises the following steps that aluminum, vanadium pentoxide and iron are mixed to obtain a mixed material; the mixed material is subjected to vacuum aluminothermic reaction to obtain alloy liquid; and the alloy liquid is cooled to obtain the vanadium-aluminum-iron intermediate alloy. According to the vanadium-aluminum-iron intermediate alloy and the preparation method thereof, aluminum, vanadium pentoxide and iron serve as raw material, the vanadium-aluminum-iron intermediate alloy is prepared through a vacuum aluminothermic reduction method, the prepared vanadium-aluminum-iron intermediate alloy is high in purity, compact, uniform in component and low in gas-phase impurity content, the defects of element segregation, poor compatibility, high gas-phase impurity content and the like in titanium alloy are effectively overcome, and titanium alloy production and operation are facilitated.

Owner:CHENGDE TIANDA VANADIUM IND

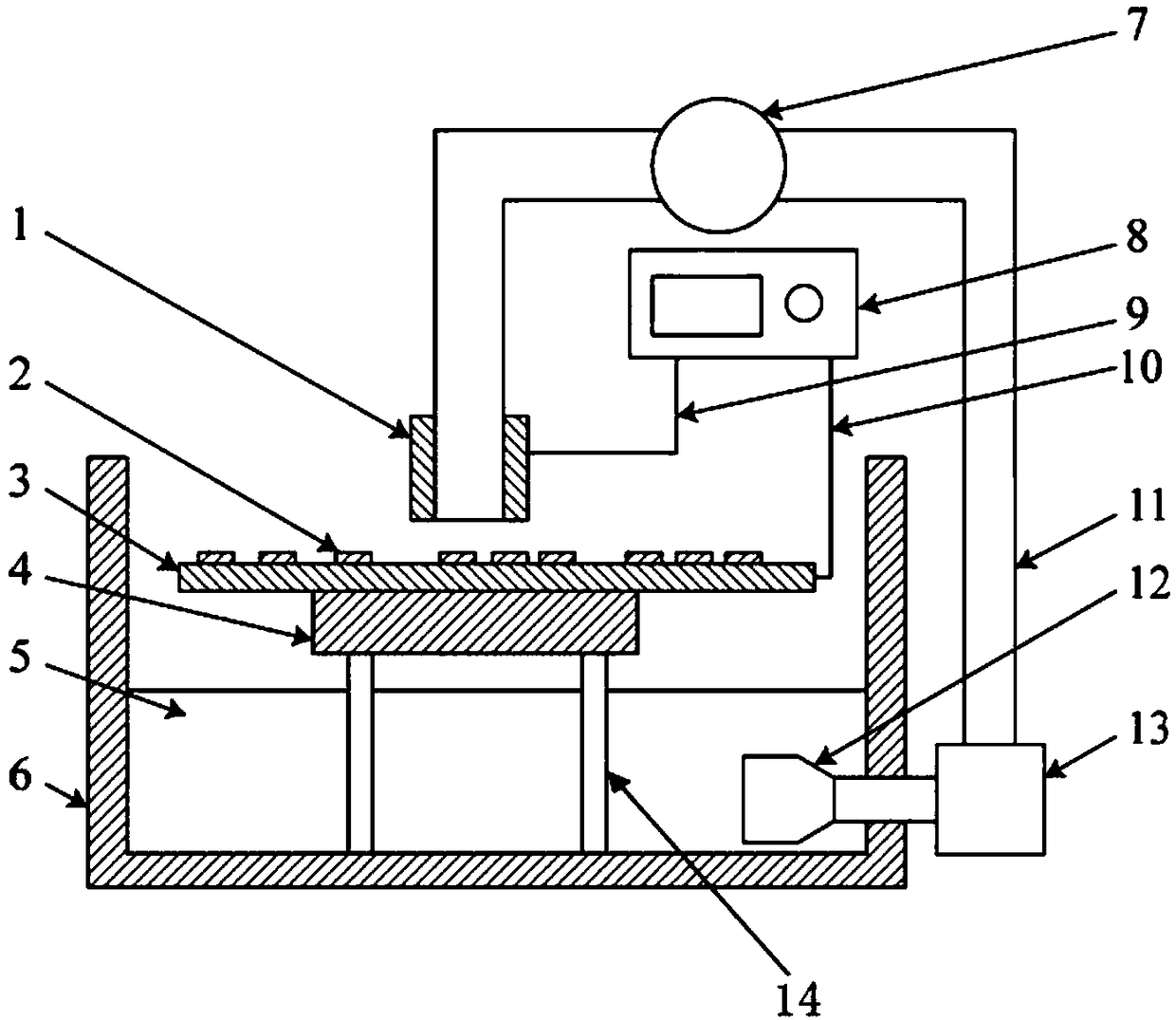

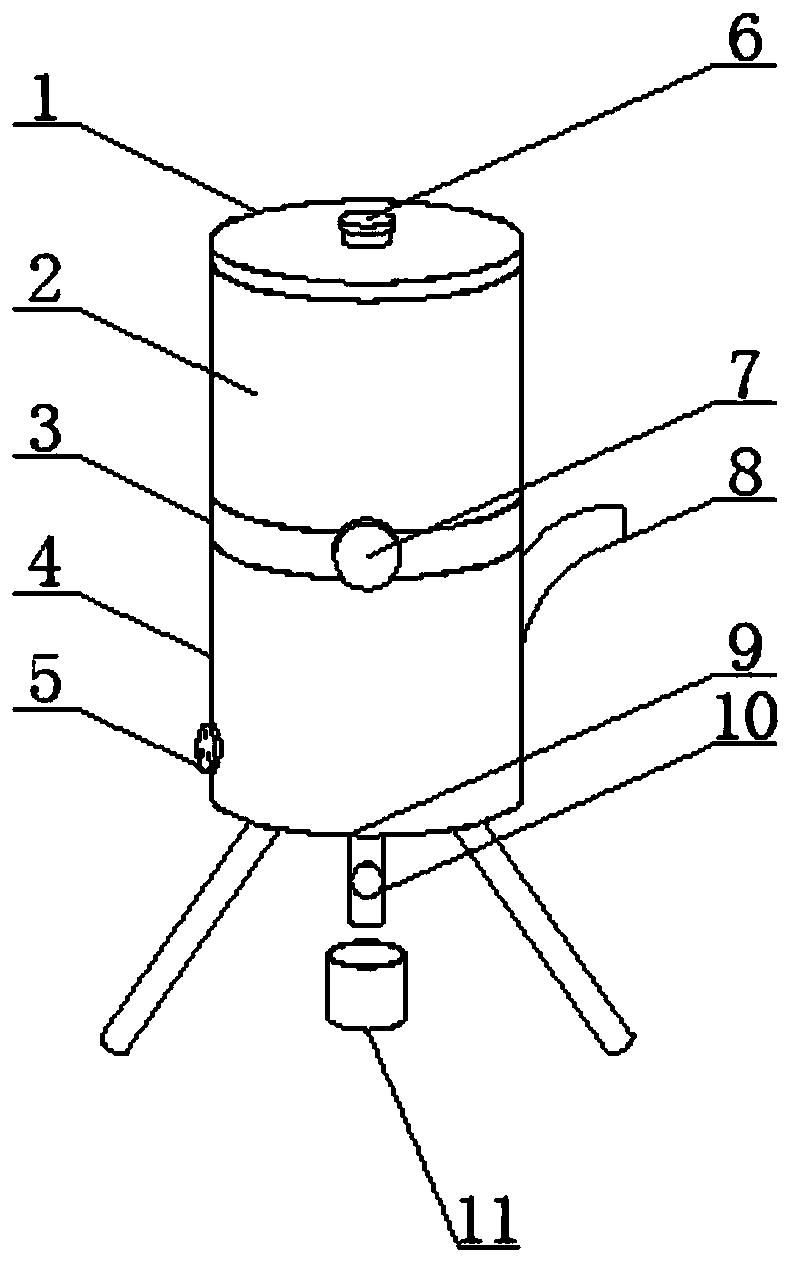

Defoaming apparatus, system, and method

The invention relates to a defoaming apparatus, system, and method. The defoaming apparatus comprises a tank, which comprises a lateral wall. The upper part of the tank is provided with a material inlet. A projecting disc for bearing materials and a plurality of defoaming assemblies, which are arranged under the projecting disc in sequence, are arranged in the tank. Each defoaming assembly comprises an upper partition plate and a lower partition plate, which is under the upper partition plate. An upper through hole is arranged in the upper partition plate. A channel for delivering materials isarranged between the lower partition plate and a lateral wall. The upper partition plate is upwards inclined. The lower partition plate is downwards inclined. At least a part of the lower partition plate is right under the upper through hole. After a material passes through the channel, the material falls on the upper partition plate under the channel. Resin is always in a thin film state, no resin is stored, defoaming is carried out when resin is always in a thin film state; the problem that foams in resin are hard to remove is solved; after defoaming, the foam content of the resin is very low; and the problems such as whitening, bubbling, and the like, in blade infusion are solved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

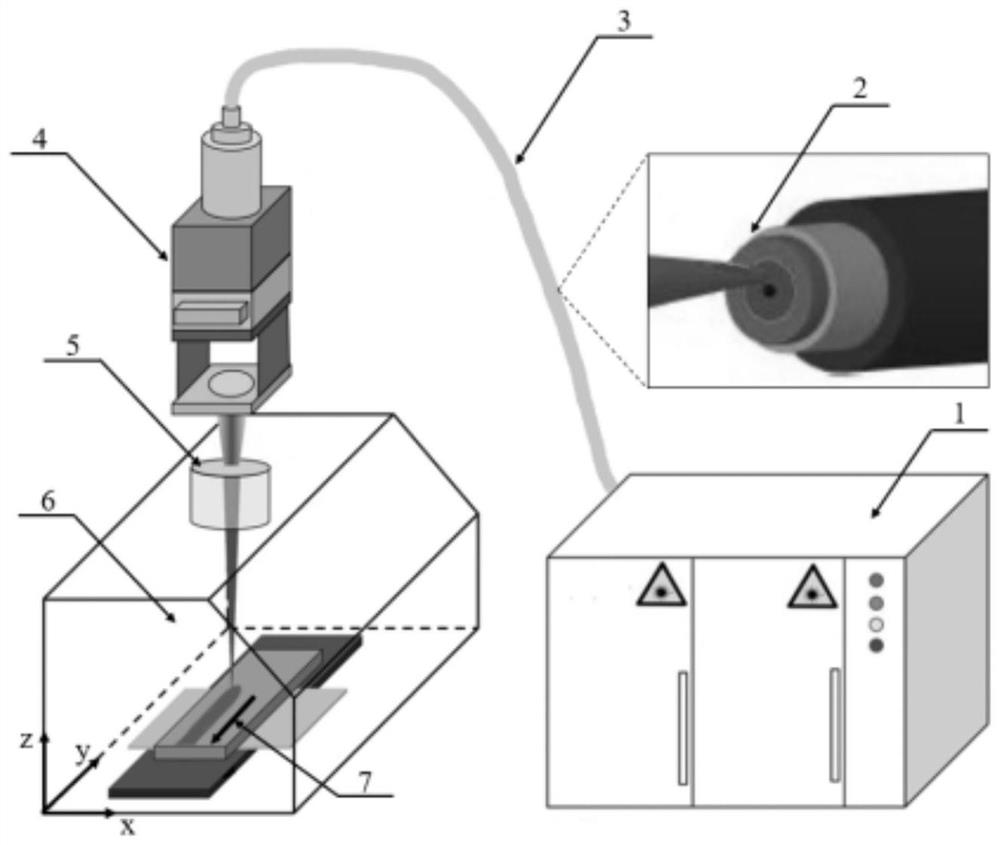

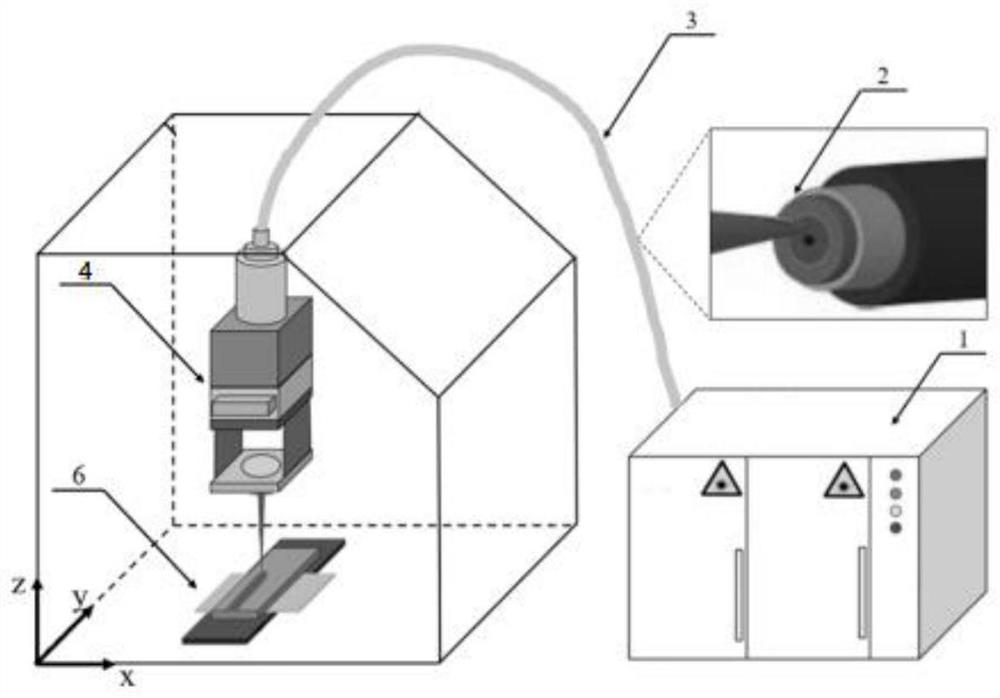

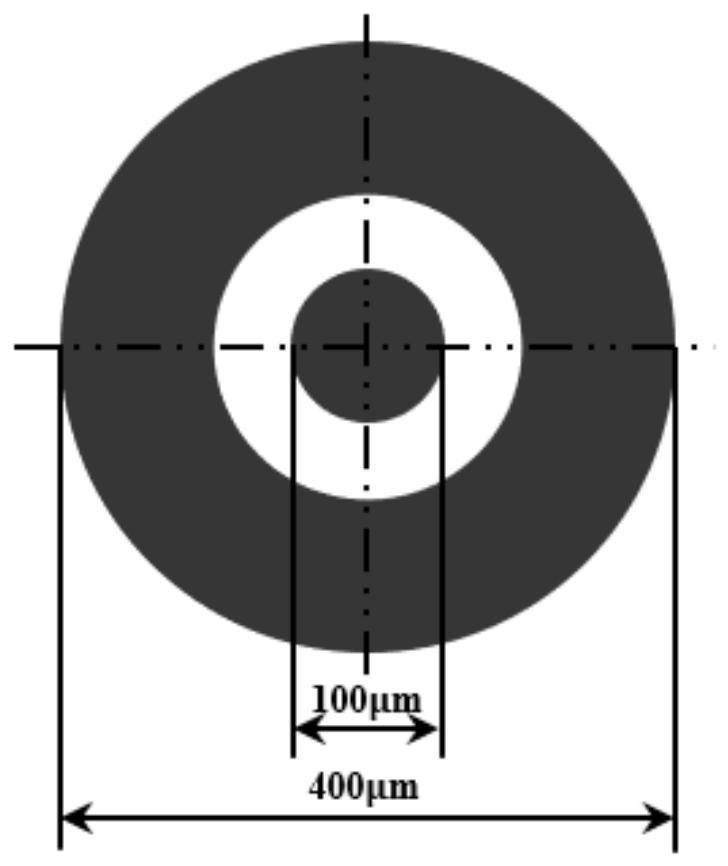

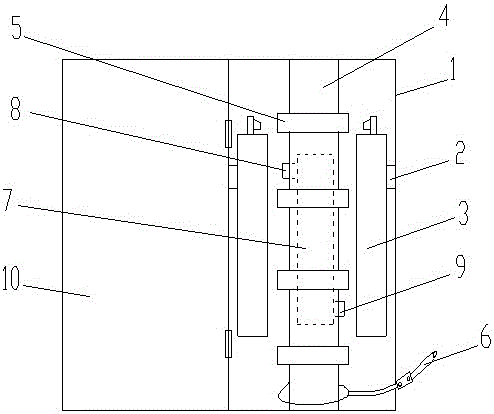

Point ring laser welding system and method under vacuum condition

PendingCN114643418AInhibition defectStrong penetrating powerLaser beam welding apparatusLaser processingSingle fiber

The invention discloses a point-loop laser welding system and method under a vacuum condition. The system comprises a solid laser, a point-loop laser optical fiber connected with the solid laser, a laser processing head and a vacuum cabin which are arranged at the end, away from the solid laser, of the point-loop laser optical fiber, and a moving platform arranged in the vacuum cabin. Light emitted by a solid laser directly outputs a point loop light source through a point loop laser fiber and a coaxial single fiber, outputs the point loop light source through a built-in fiber coupler of the laser, outputs the point loop light source through a built-in integrated optical shutter of the laser or outputs the point loop light source through a two-in-one fiber to form a composite point loop laser beam. The point ring laser power ratio is accurately adjusted according to different welding structure conditions, and the adaptability of point ring laser welding to welding joints of different sizes is improved; vacuum laser welding and point ring laser welding are combined, welding spatter is restrained, plasma plume is restrained through low-vacuum environment welding, the fusion depth is increased, and then the welding quality is improved.

Owner:哈尔滨工大焊接科技有限公司

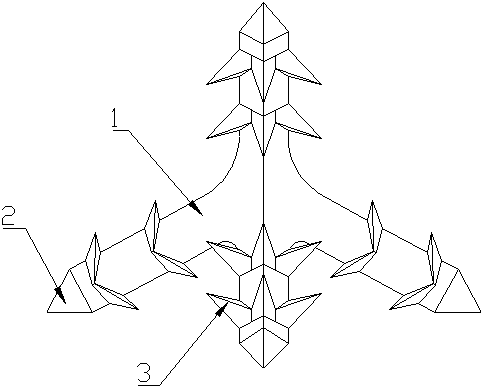

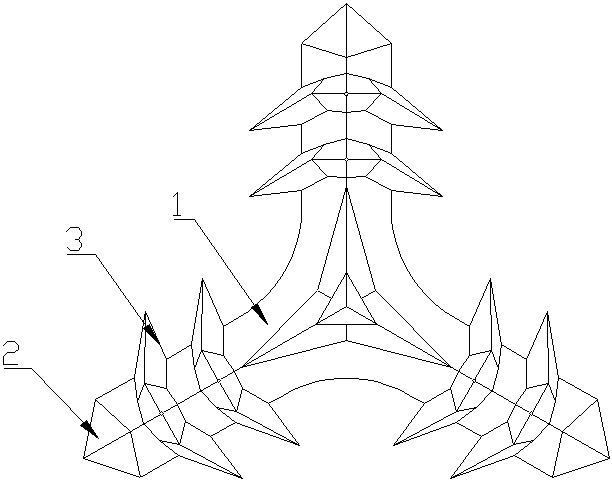

Portable car arrester

The invention relates to a portable car arrester. The arrester comprises a nail frame, wherein the nail frame is composed of four nail bodies of the same structures, the angle between any two adjacentnail bodies is the same, each nail body is in a shape of a regular triangular prism, the top end of each nail body is provided with a convex tip, and the outer wall of the middle of each nail body isprovided with a convex thorn group. The car arrester has the advantages of being simple in structure, convenient to carry, small in volume, light in weight, sturdy and durable.

Owner:党铮

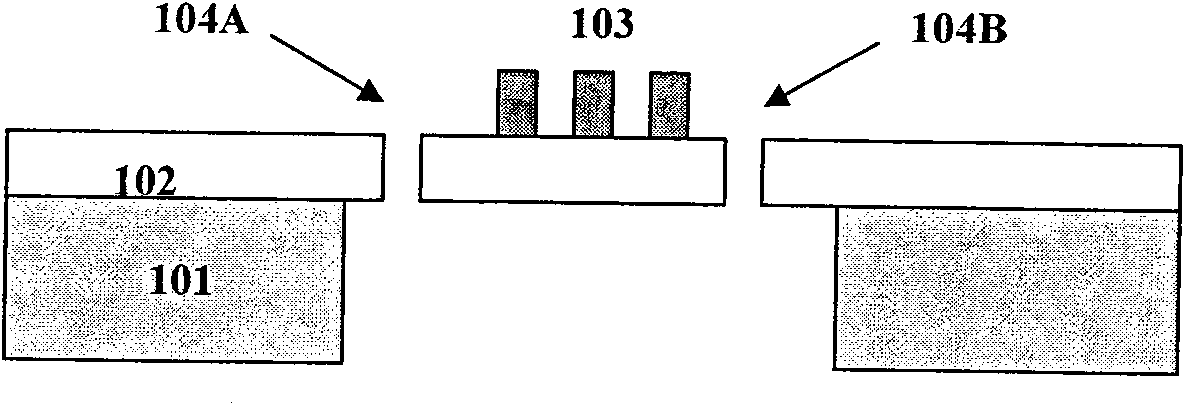

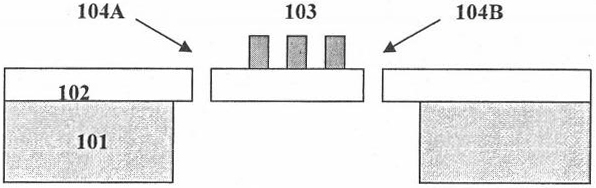

X-ray photolithographic mask with through hole

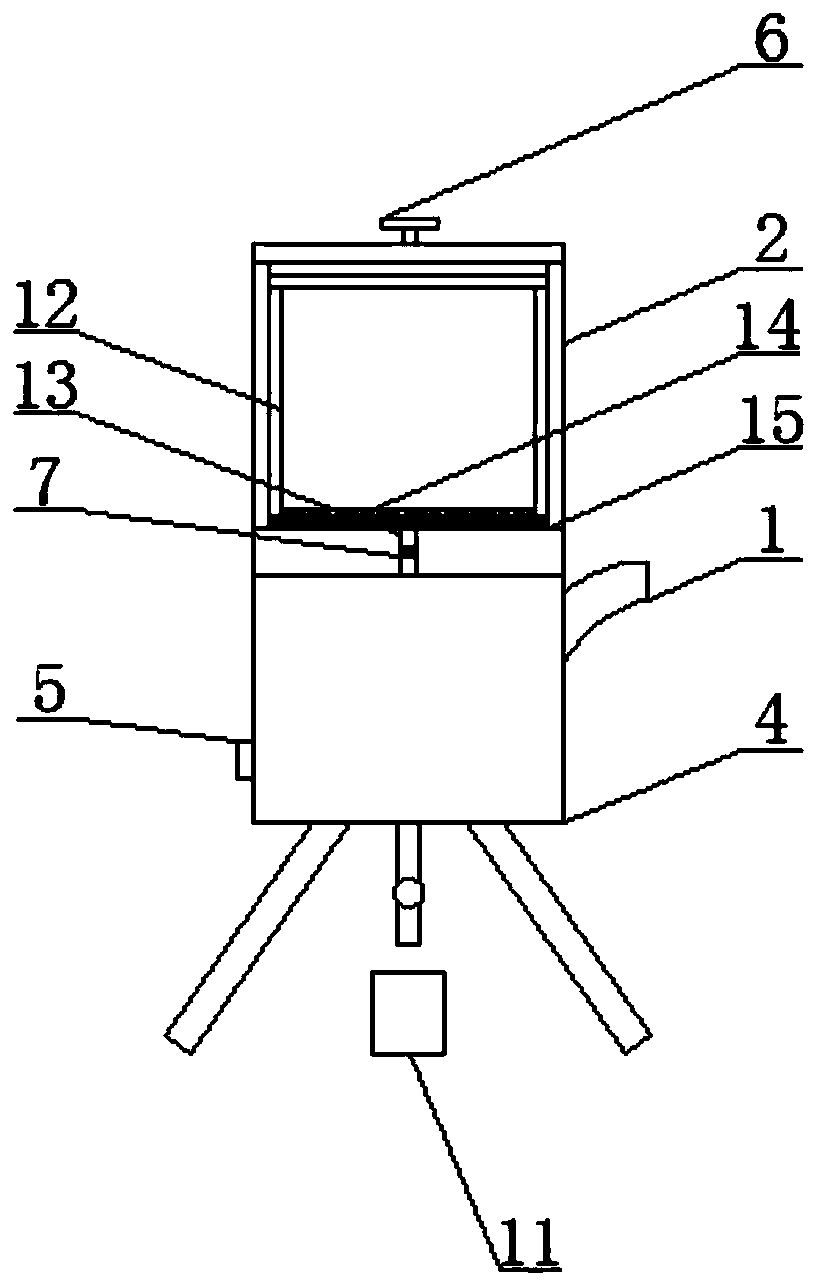

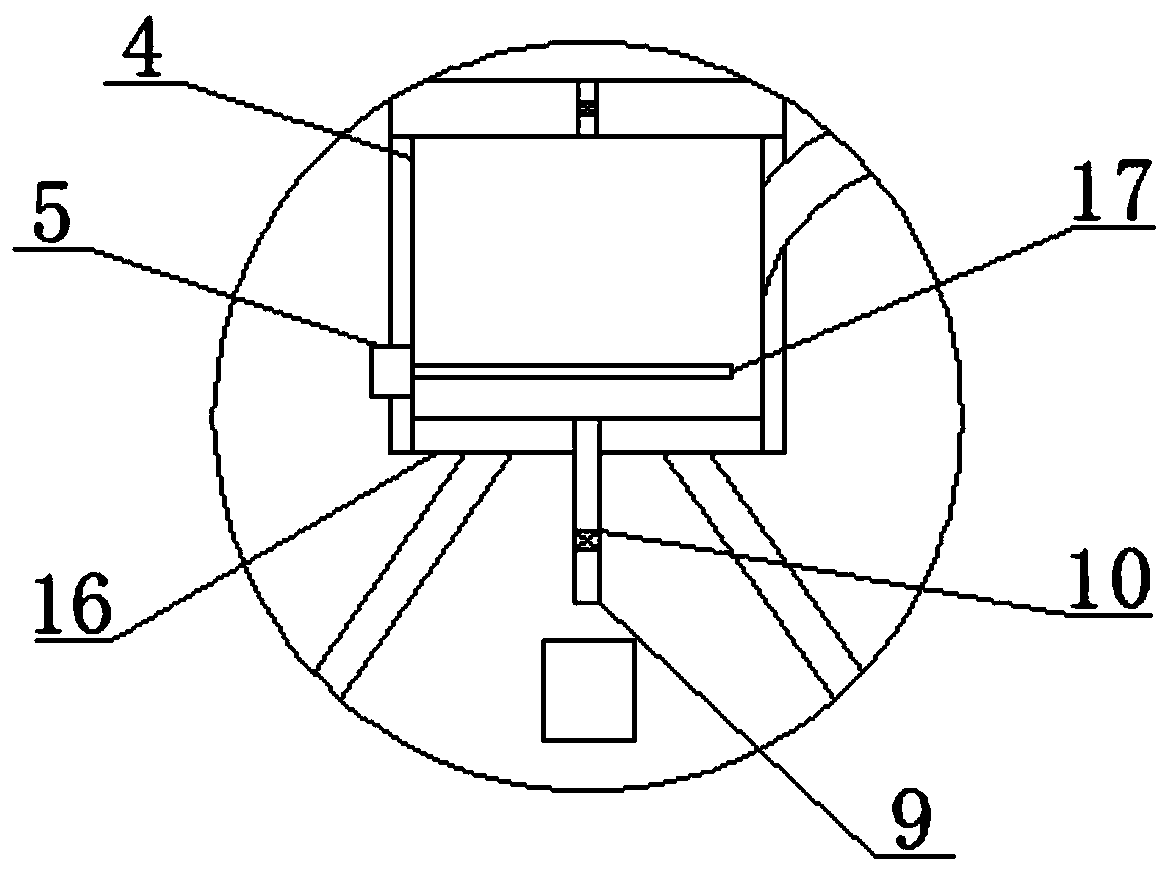

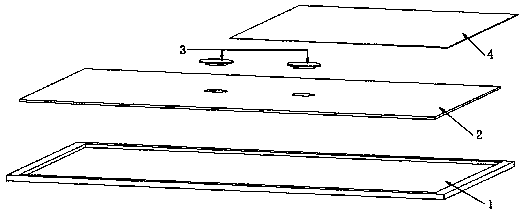

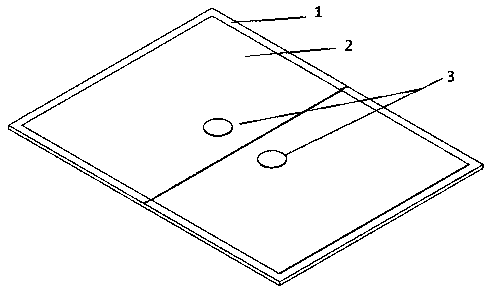

InactiveCN101846874AImprove performanceAvoid deformationOriginals for photomechanical treatmentX-rayOptoelectronics

The invention discloses an X-ray photolithographic mask with a through hole, which comprises a support frame, a layer of thin film with a through hole and a group of absorbers, wherein the support frame is provided with a smooth upper surface and used for fixing and supporting the thin film with the through hole; the thin film with the through hole is positioned on the smooth upper surface of the support frame; and the absorbers are adhered to the thin film with a through hole. By utilizing the invention, residual gas between a mask and a substrate can be effectively discharged by one or a plurality of through holes during vacuumization, thereby a smaller clearance between the mask and the substrate is maintained. Accordingly, on one hand, the mask breakage caused by gas expansion is prevented, and on the other hand, the reduction of an exposure clearance is beneficial to obtaining a more favorable exposure effect.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

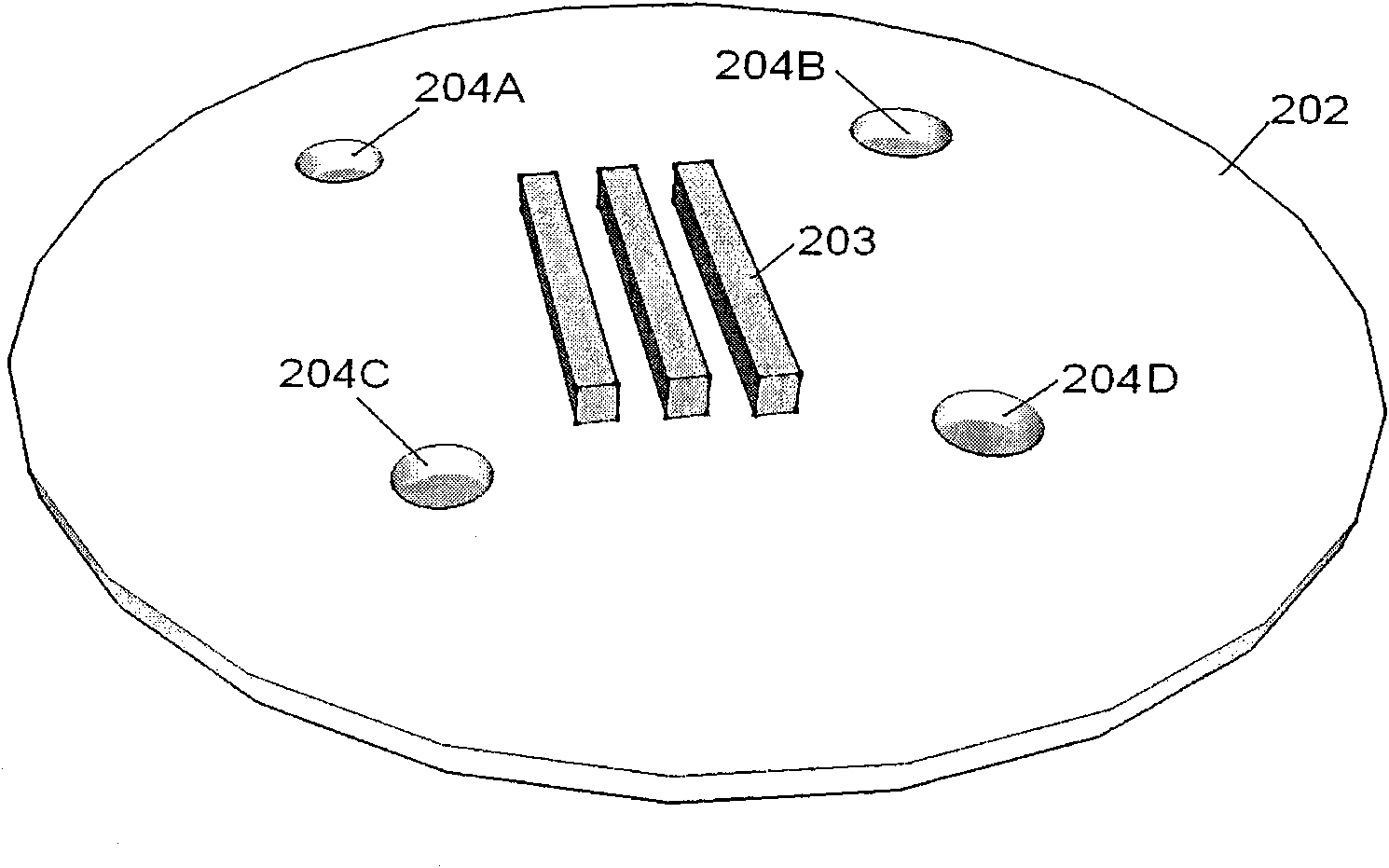

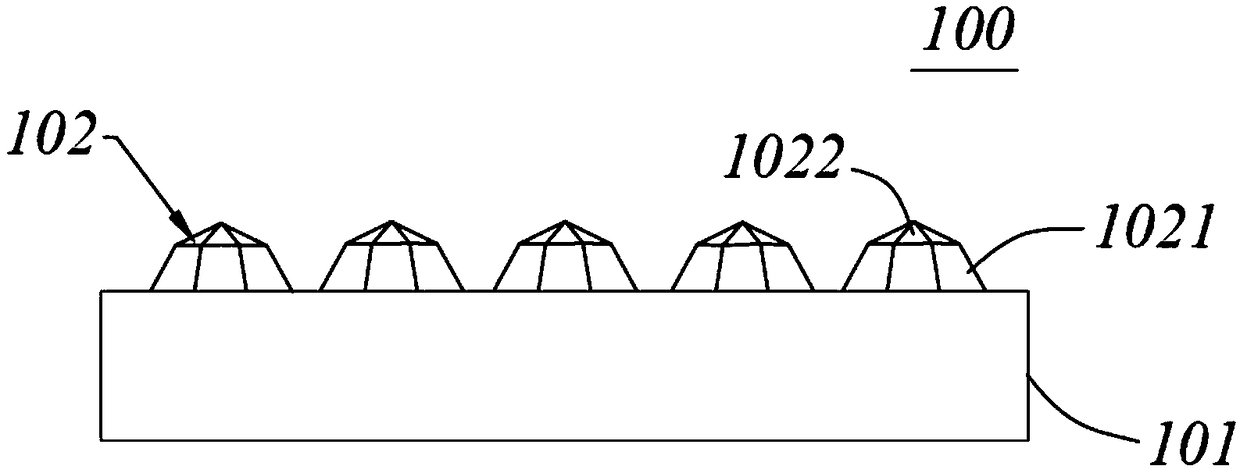

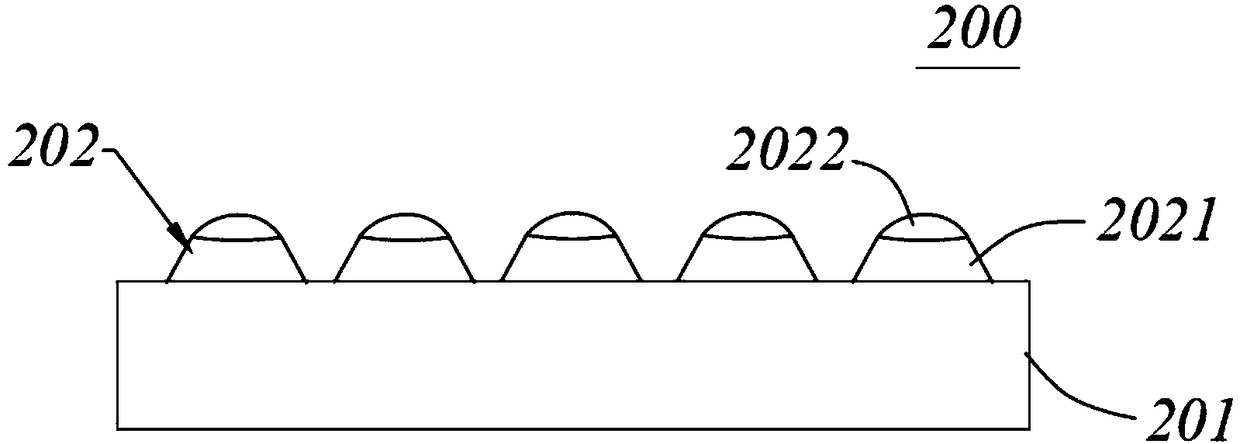

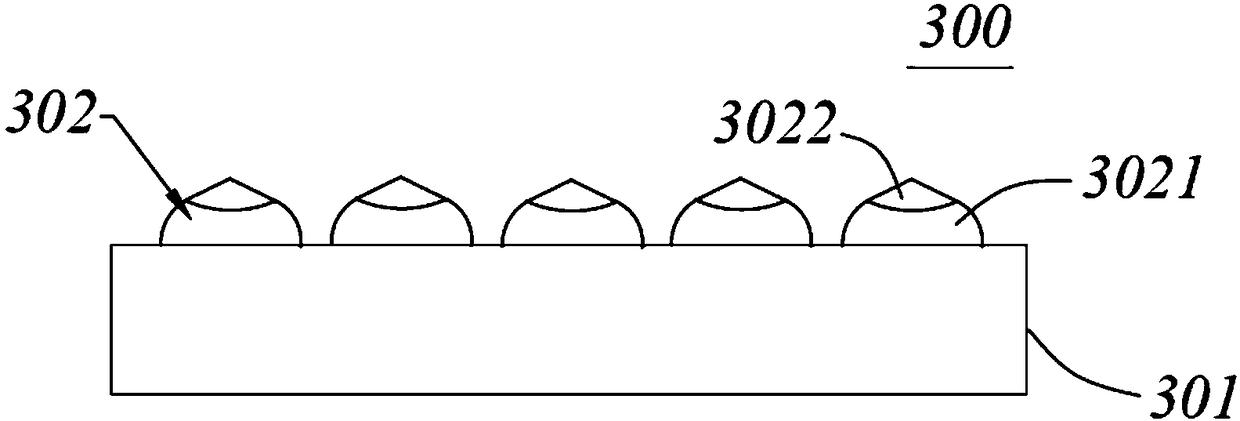

Stacked patterned LED substrate

InactiveCN108091738AImprove light extraction efficiencyEasy to escapeSemiconductor devicesLight reflectionEngineering

The invention discloses a stacked patterned LED substrate comprising a main substrate body and a plurality of stacked patterns formed on the main substrate body. The stacked patterns include first pattern blocks connected to the main substrate body and second pattern blocks stacked on the first pattern blocks. Each of the first pattern blocks and the second pattern blocks has at least one light reflection surface with different angles. Compared with the traditional pattern design, the stacked patterns can provide more light reflection surface, so that light is reflected at more angles and escaping of light out of a chip is realized and thus the luminous efficiency of the LED chip is improved.

Owner:苏州亿拓光电科技有限公司

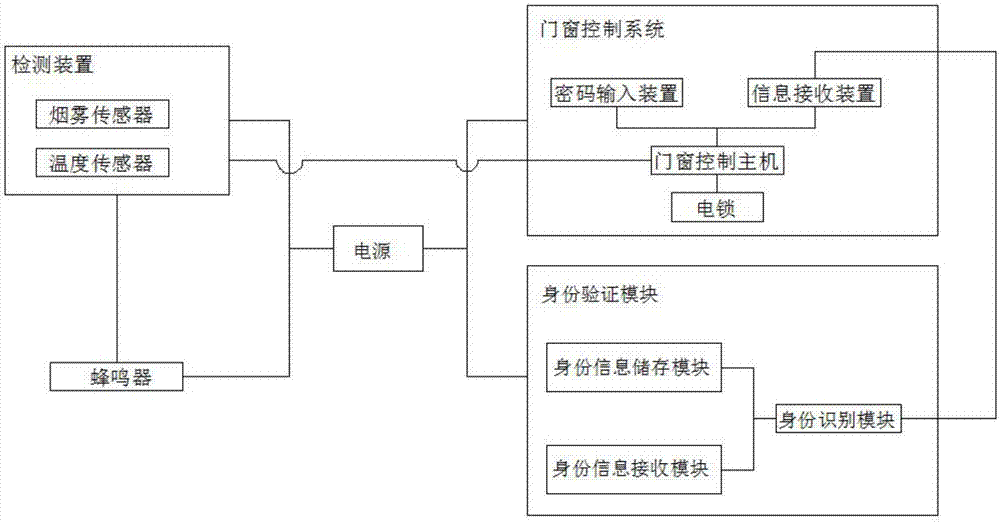

Door/window security and protection system and method thereof

InactiveCN107452107AEasy to escapePrevent random openingFire alarmsIndividual entry/exit registersFingerprintInformation storage

The invention discloses a door / window security and protection system which comprises a password input device, a door / window control host, an electric lock and an identity information storage module, wherein the password input device is used for manually inputting a password so that the door / window control host controls the electric lock to open; the door / window control host is used for controlling the opening and closing of the electric lock; the electric lock is used for finishing the opening and closing of a door / window finally; the identity information storage module is used for storing the fingerprint of a user in advance. According to the system disclosed by the invention, the opening and closing of the door / window are finished by a fingerprint identification technology, and foreign people are prevented from opening the door / window at will so as to realize an antitheft effect; moreover, the door / window also can be opened by inputting a digital password; in the case of fire, fire alarm can be realized, the door / window control host can directly control the electric lock to open without using other ways, and the door / window is opened during a fire, so that people can escape conveniently.

Owner:安徽普智智能科技有限公司

An aquatic plant inlaying combination system used for water body cleaning

PendingCN106904746ATake advantage ofLarge biomassSustainable biological treatmentBiological water/sewage treatmentAquatic animalWater flow

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

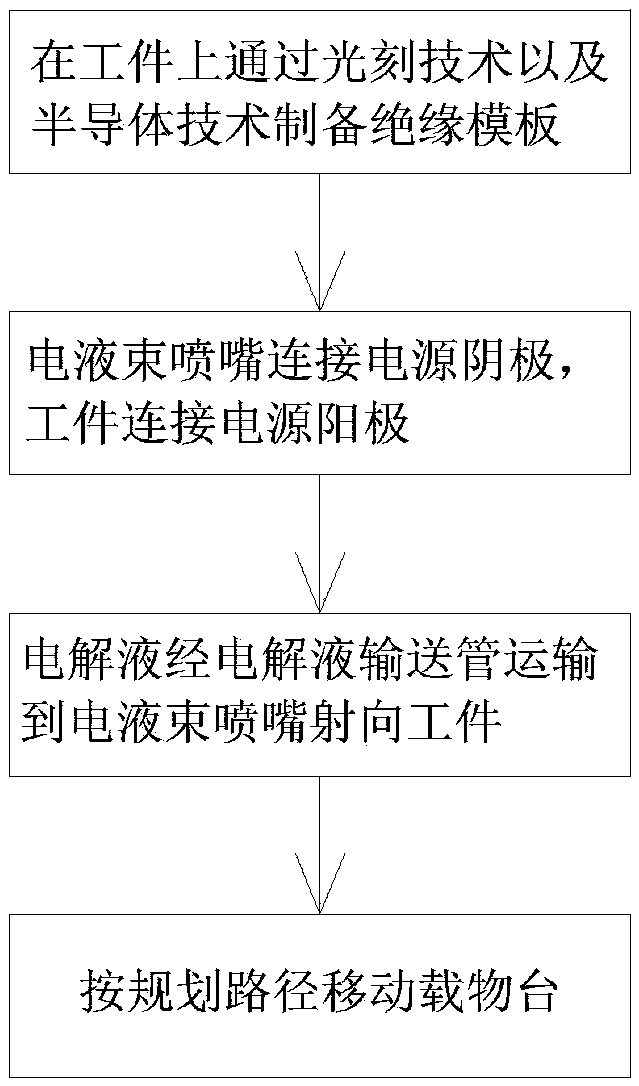

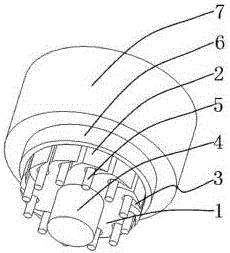

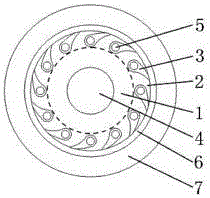

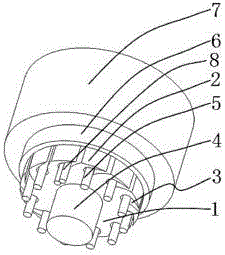

Device and method for processing metal surface microstructures through formwork electro-hydraulic beam

InactiveCN108115233AOvercome sizeOvercoming processabilityElectrochemical machining apparatusMaterial removalHydraulic brake

The invention provides a device and a method for processing metal surface microstructures through a formwork electro-hydraulic beam. The device comprises an electro-hydraulic beam nozzle, an insulating formwork, a workpiece, a carrying platform, electrolyte, a workpiece bin, an electrolyte jet pressure control system, a power source, an electrolyte conveying pipeline, a filtering system and a pressure pump, the power source comprises a power source anode and a power source cathode, the electro-hydraulic beam nozzle is connected with the power source cathode, the workpiece is connected with thepower source anode, and one end of the electrolyte conveying pipeline is connected with the electrolyte while the other end of the same is provided with the electro-hydraulic beam nozzle. The insulating formwork is made on the workpiece through photoetching technology and semiconductor technology, the electrolyte is ejected to the workpiece from the electro-hydraulic beam nozzle, and areas, not protected by the insulating formwork, of the workpiece are removed. The device has the advantages of zero stress and high material removal rate during electro-hydraulic beam processing and also has thecharacteristics of large batch and high accuracy of the photoetching process.

Owner:GUANGDONG UNIV OF TECH +1

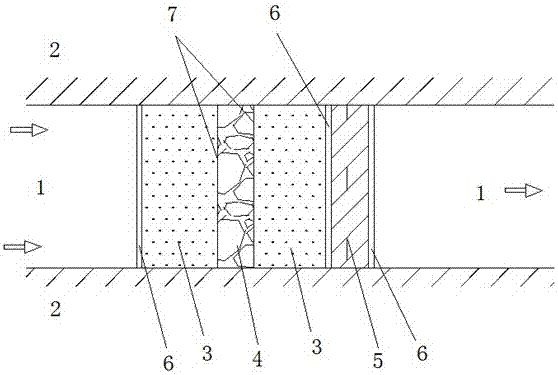

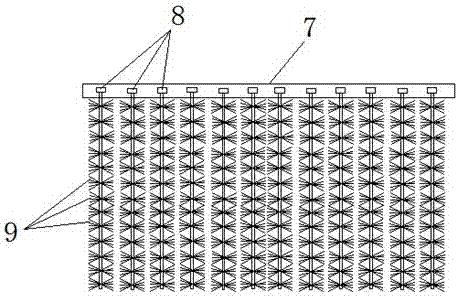

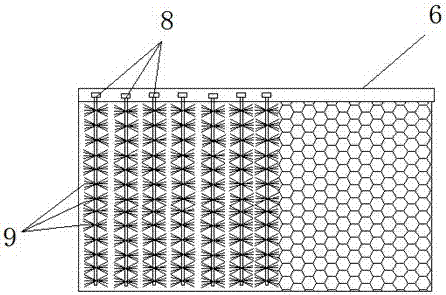

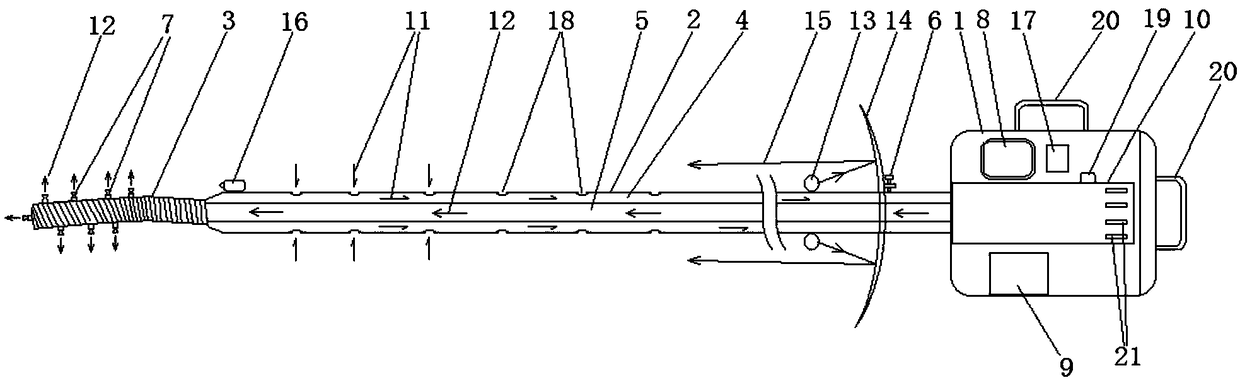

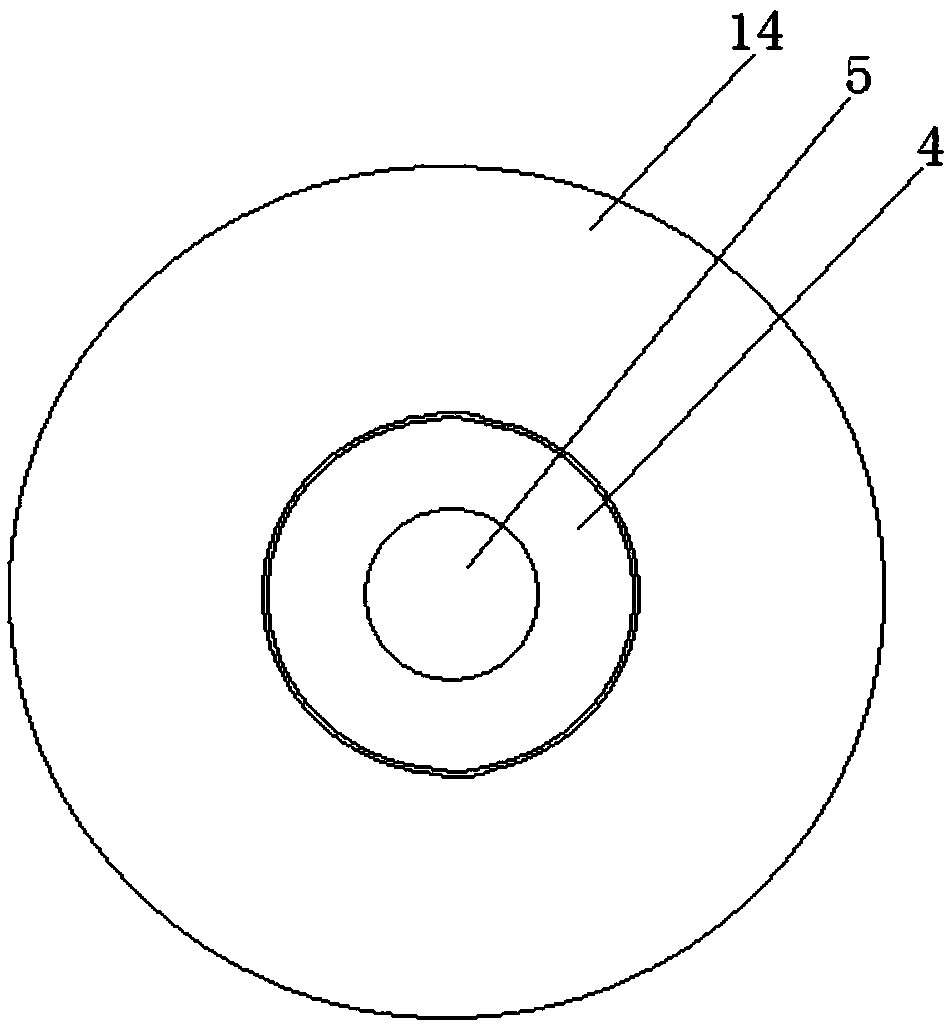

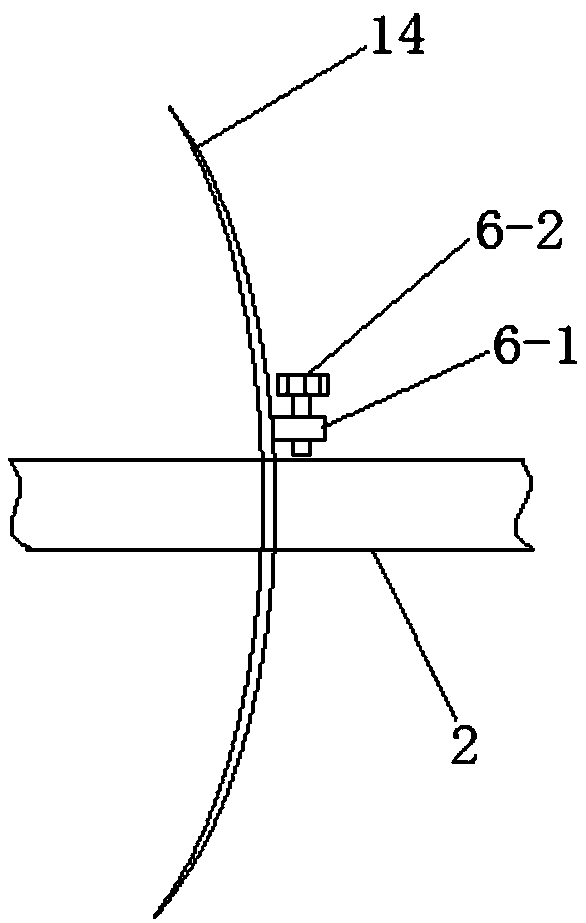

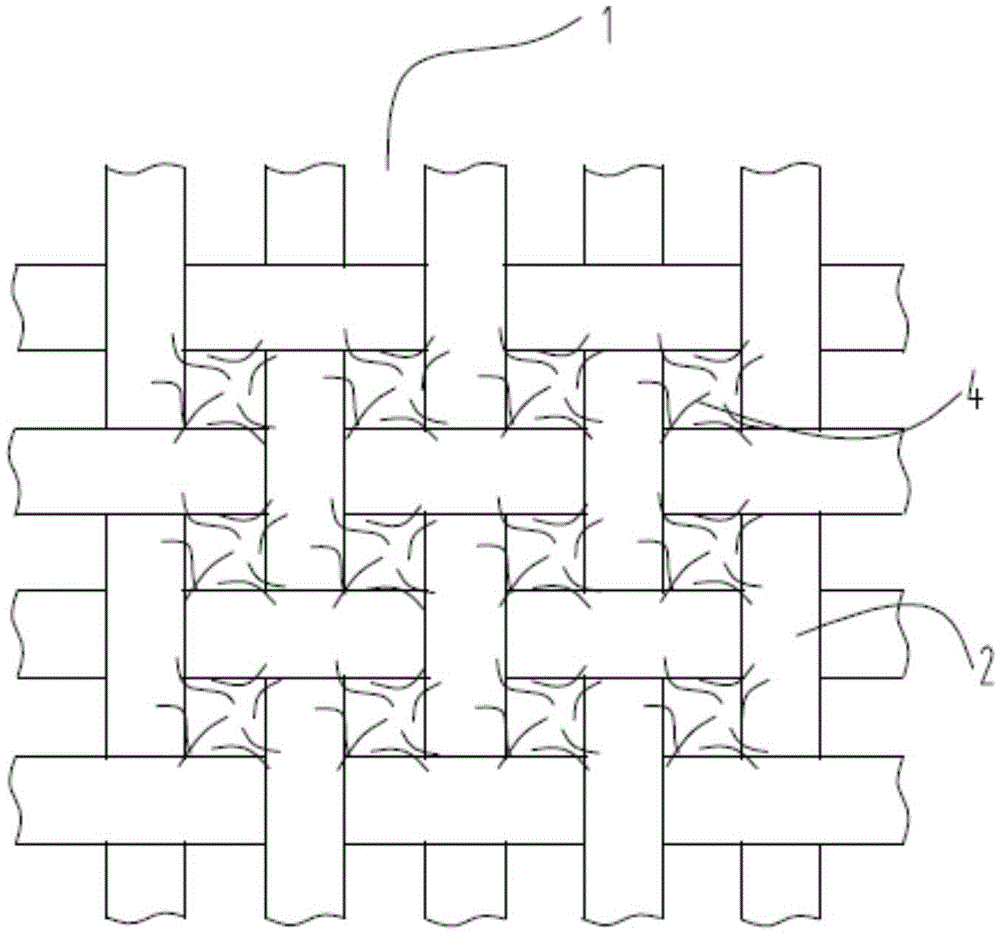

Microchannel structure cable used for electric power or communication

InactiveCN105655032ANot easy to escapeNot easy to escape, but easy to take out during constructionInsulated cablesInsulated conductorsElectric cablesElectric power

The invention belongs to the technical field of cables and relates to a microchannel structure cable used for electric power or communication. The microchannel structure cable used for the electric power or communication comprises a skeleton body, multiple bone blades, multiple skeleton channels, a reinforcer, multiple cable cores, a protective layer and a sheath layer, wherein the skeleton body, the bone blades and the skeleton channels are formed an integrated manner, the bone blades are arranged at the edge of the skeleton body, the reinforcer is arranged at the center of the skeleton body, the skeleton channels are formed between adjacent bone blades, the cable cores are arranged in the skeleton channels, the protective layer coats the outside of the bone blades, and the sheath layer coats the outside of the protective layer in an extrusion moulding manner. The microchannel structure cable used for the electric power or communication is characterized in that the outer edges of the bone blades and the outer edges of the skeleton channels are arranged on the side of one cylinder, one opening is formed in each skeleton channel, the openings are towards the sheath layer, width of each skeleton channel at the opening is smallest, and width is gradually increased from the opening to a position near the bottom of the corresponding skeleton channel. The microchannel structure cable used for the electric power or communication has the main beneficial effects of easy production, relatively high passing rate of finished products, low production equipment investment, less resource consumption, higher product density and more stable product quality.

Owner:珠海星光在线信息技术有限公司

Carbon-containing material as well as preparation method and application thereof

InactiveCN107698899AAffect uniformityImprove adsorption efficiencyPolyvinyl chlorideMaterials science

The invention discloses a carbon-containing material, which is characterized by being prepared from the following components in parts by weight: 15 to 30 parts of polyvinyl chloride, 48 to 72 parts ofasbestos and / or calcium carbonate, 3 to 12 parts of bamboo charcoal powder, 1 to 10 parts of stabilizer and 1 part of additive. The carbon-containing material provided by the invention is uniform tomix and high-efficiency in adsorption.

Owner:HEYUAN CITY NEBO NEW BUILDING MATERIALS CO LTD

Energy-saving environment-friendly deinsectization device

InactiveCN108849802ANot easy to drill outDisinfect and sterilizeHeatInsect catchers and killersElectricityLight pipe

The invention provides an energy-saving environment-friendly deinsectization device. A seat body is fixedly provided with a hot-air blower, the hot-air blower is connected with an airflow conveying pipe, the airflow conveying pipe comprises a hot airflow conveying passage and an air conveying passage, the hot airflow conveying passage is connected with a hot air outlet of the hot-air blower, the air conveying passage is communicated with an air inlet of the hot-air blower, the outer side wall of the air conveying passage is provided with a plurality of air input holes, the left end of the hotairflow conveying passage is connected with a flexible hose, the left end head and side wall of the flexible hose are both provided with hair airflow nozzles; the pipe body of the airflow conveying pipe is also provided with a light lamp, the pipe body, at the right side of the light pipe, of the airflow conveying pipe is also slidably connected with a concave reflecting mirror; the light lamp iselectrically connected with a power supply module through a light lamp switch, and the hot-air blower is electrically connected with the power supply module through a hot-air blower switch. The energy-saving environment-friendly deinsectization device can roast and kill cockroaches hidden in gaps through high-temperature heated airflow, and the inner portions of the gaps can also be disinfected and sterilized under the roasting action of the high-temperature airflow.

Owner:何德学

Wall-embedded fire extinguisher box with function of binding multiple escape ropes

InactiveCN106823206AEasy to escapeEasy to coverFire rescueBuilding rescueFire hazardWater storage tank

The invention discloses a wall-embedded fire extinguisher box with a function of binding multiple escape ropes. The wall-embedded fire extinguisher box comprises a fire extinguisher box body. A cavity is arranged inside the fire extinguisher box body, fire extinguisher racks are fixedly mounted on inner box walls of two sides of the fire extinguisher box body, fire extinguisher bottles are hung on the fire extinguisher racks, a binding column is fixedly arranged in the center of the fire extinguisher box body, a plurality of annular lugs are arranged on a column body of the binding column, a concave ring surface is formed between every two corresponding annular lugs, the escape ropes are arranged among the annular lugs in a connected manner, one end of each escape rope is bound on the binding column, the other end of each escape rope is led out of the binding column, safety buckles are arranged at led-out ends of the escape ropes, and a water storage tank is further arranged in the binding column. Owing to the mode, the wall-embedded fire extinguisher box has the advantages that the wall-embedded fire extinguisher box not only can be used as a storage box for fire extinguishers, but also can provide the escape ropes to be bound on people for escape; the water storage tank is further arranged in the binding column, and accordingly clear water can be poured out to dampen rag for muffling the mouths and the noses of people during fire hazards.

Owner:WUXI KDM MACHINERY TECH CO LTD

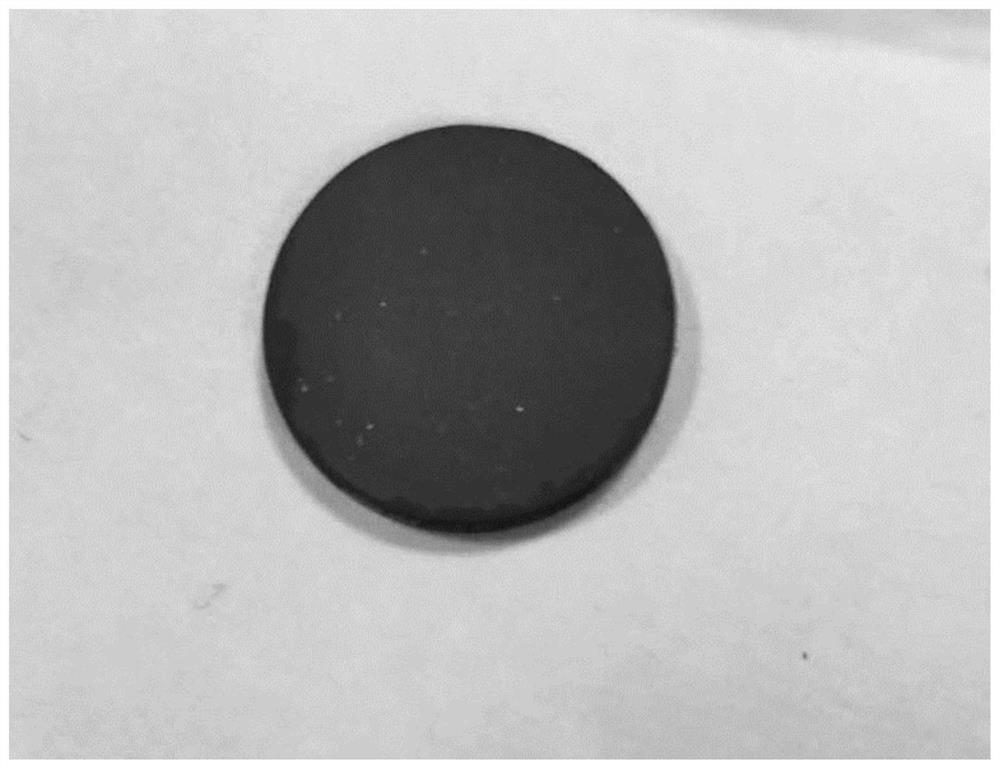

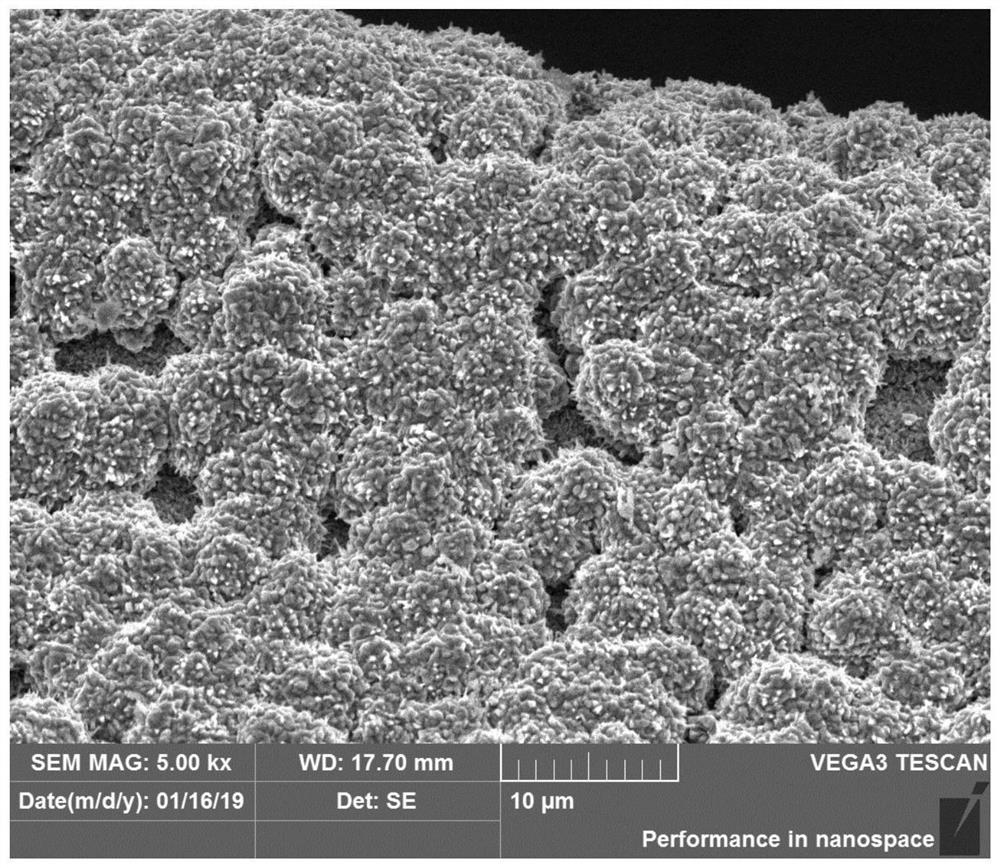

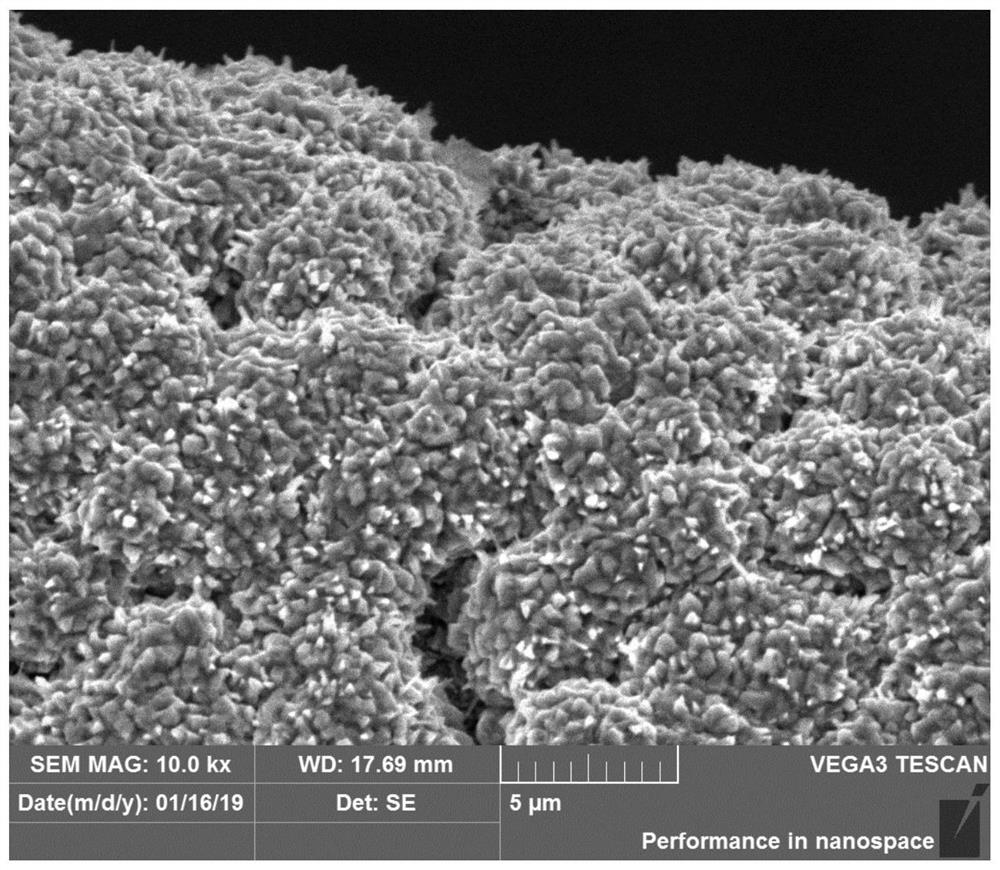

Preparation method of molybdenum-based composite material electrode plate

ActiveCN112831800AHigh catalytic activityIncrease contact areaNon-noble metal oxide coatingsTransportation and packagingPtru catalystTitanium tetrachloride

The invention relates to a preparation method of a molybdenum-based composite material electrode plate, which comprises the following steps: in a glove box filled with argon, pouring molybdenum powder and nickel powder into excessive titanium tetrachloride, fully stirring, filtering, putting mixed powder stained with the titanium tetrachloride into a quartz tube of a tube furnace, introducing oxygen, carrying out heat treatment, putting the mixed powder subjected to heat treatment into a graphite mold for spark plasma sintering, soaking a sintered sample into titanium tetrachloride again, filtering, taking out the sample, putting the sample into the quartz tube of the tubular furnace again, and sequentially introducing oxygen and hydrogen sulfide for heat treatment to obtain the molybdenum-based composite material electrode plate. The method is low in cost, convenient to operate and controllable in process. The obtained electrode plate has relatively high catalytic activity and good conductivity, also has certain mechanical properties and machinability, can be used as a catalyst, a current collector and an electrode directly to be applied to catalytic water decomposition, and has a wide large-scale industrial production prospect.

Owner:HENAN UNIV OF SCI & TECH

Dechlorination mechanism for filtering drinking water

InactiveCN111285529ASimple structureEasy to operateWater contaminantsTreatment involving filtrationPotable waterWater flow

The invention discloses a dechlorination mechanism for filtering drinking water. The mechanism comprises an upper cover and an upper cylinder, wherein the upper cover is mounted on the outer wall of the upper end of the upper cylinder; a handle is arranged on the outer wall of the upper end of the upper cover; a connecting seat is arranged on the outer wall of the lower end of the upper cylinder;drinking water flows into the lower cylinder through the connecting pipe, and the drinking water is further filtered through filtering holes; in this way, drinking water can be filtered in various filtering modes; drinking water is cleaner, a user can use the mechanism conveniently and directly; then, the drinking water is heated through a heating wire, through boiling for a period of time, chlorine in the drinking water mainly exists in the form of chlorine gas so that chlorine can be removed in the heating and boiling manner, chlorine gas can easily escape, and after the chlorine gas escapesfrom a kettle port, the drinking water can be used. The dechlorination mechanism is simple in structure, convenient to operate, suitable for a large number of common families, safe, effective and free of toxic and side effects.

Owner:浙江南方梦科技有限公司

Flexible mouse sticking board

PendingCN108835102AEasy to escapeSolve environmental problemsAnimal trapsMechanical engineeringNon-stick surface

The invention discloses a flexible mouse sticking board. The flexible mouse sticking board comprises a base plate and flexible adhesive film fixed on the base plate; the bottom surface of the flexibleadhesive film is a non-stick surface, and the top surface of the flexible adhesive film is a sticky surface. After a mouse sticks to the mouse sticking board, the struggling movement of the mouse makes the adhesive film roll around the body of the mouse, so that the contact surface of the adhesive film and the body of the mouse is further enlarged to achieve the function of preventing the mouse from escaping. The problem is solved that by means of existing mouse sticking boards, mice easily struggle to escape and glue of the mouse sticking boards is carried out.

Owner:GUANGDONG POWER GRID CO LTD +1

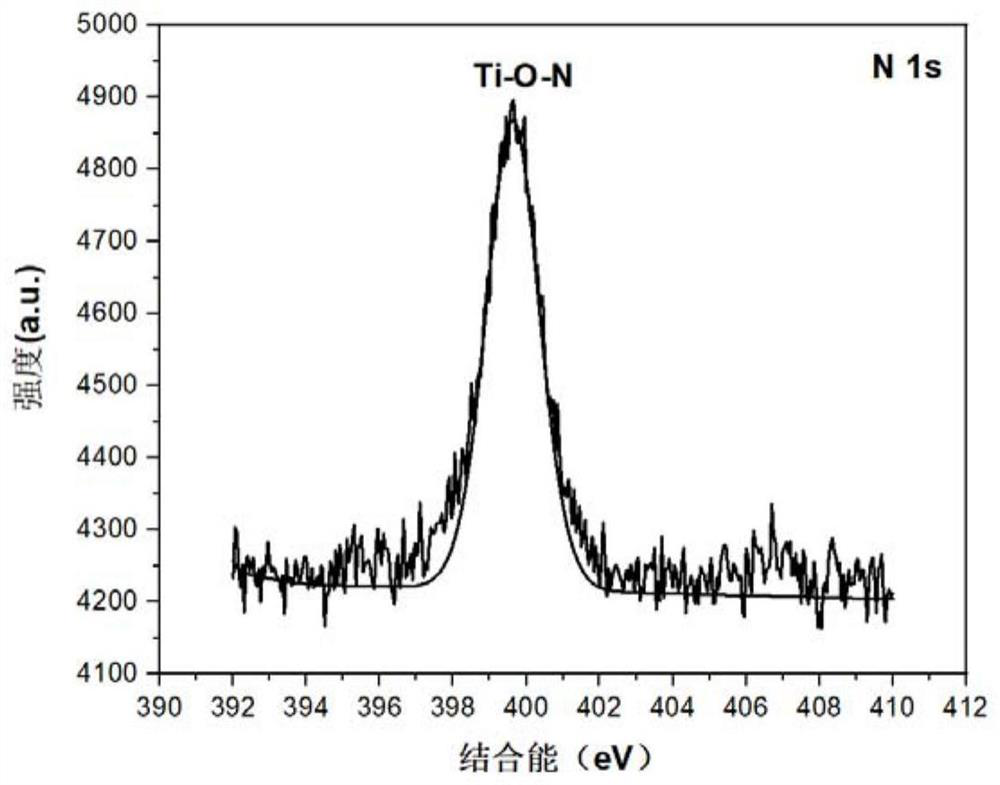

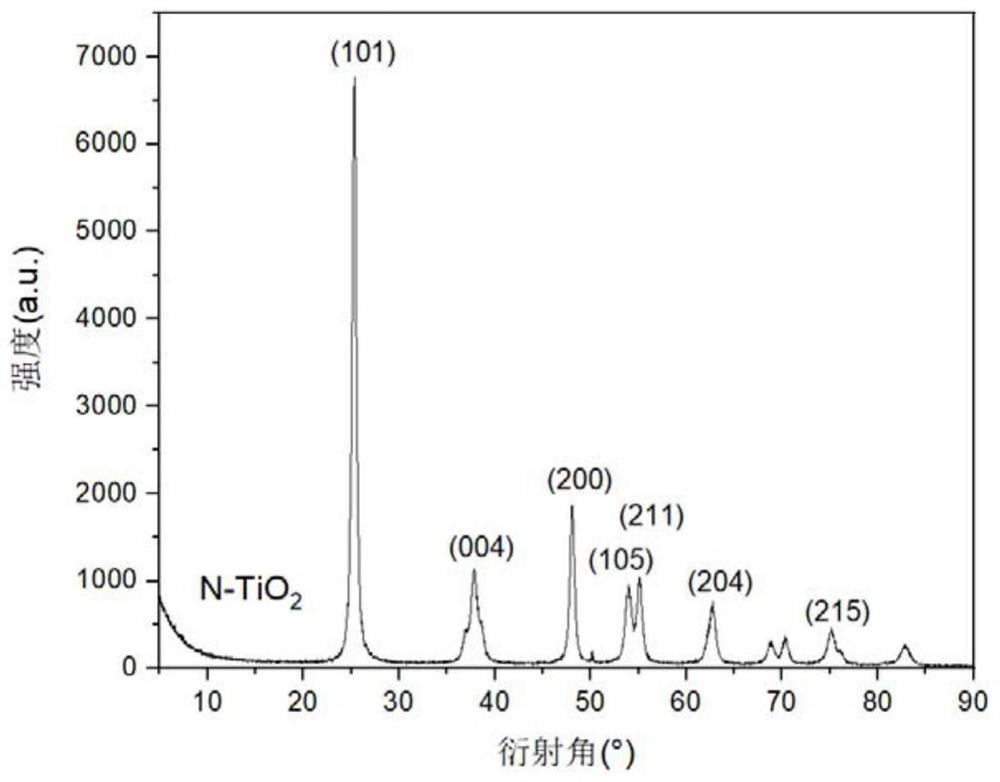

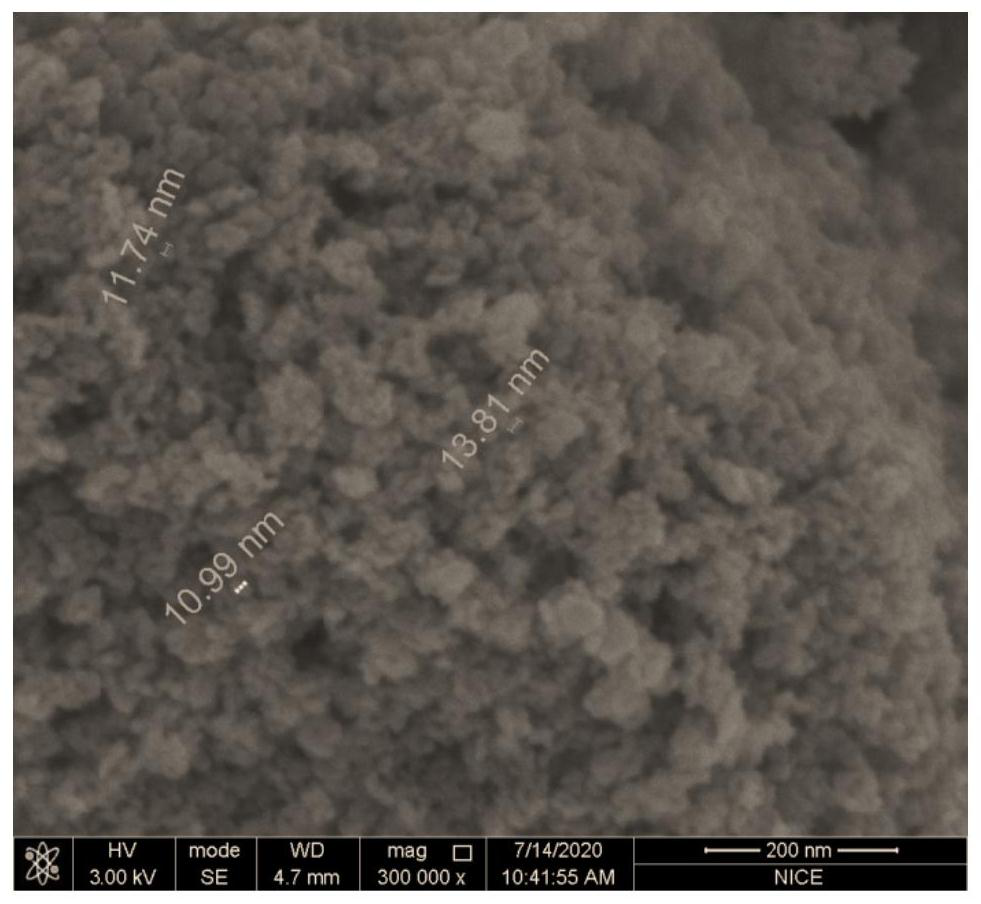

Preparation method and application of nitrogen-doped titanium dioxide denitration catalyst

PendingCN114247458AEasy to escapeImprove denitrification efficiencyGas treatmentPhysical/chemical process catalystsPtru catalystPhysical chemistry

The invention relates to the technical field of flue gas denitration catalysts, and discloses a preparation method and application of a nitrogen-doped titanium dioxide denitration catalyst. The preparation method of the nitrogen-doped titanium dioxide denitration catalyst comprises the following steps: (1) carrying out surface hydrogenation reduction on a titanium source to obtain black TiO2 powder; and (2) carrying out nitrogen doping on the black TiO2 powder to obtain the N-TiO2 catalyst. The crystal form of the N-TiO2 catalyst is an anatase type, and the N-TiO2 catalyst has oxygen vacancies and Ti < 3 + >; on the basis of the total weight of the N-TiO2 catalyst, the content of the nitrogen element is 0.4-0.5 wt%, and N atoms enter TiO2 crystal lattices in an interstitial doping (Ti-O-N) manner. The denitration efficiency of the nitrogen-doped TiO2 denitration catalyst at the temperature of 300-400 DEG C can reach 90% or above, the N2 selectivity can reach 92% or above, and the nitrogen-doped TiO2 denitration catalyst can be applied to NH3-SCR denitration.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

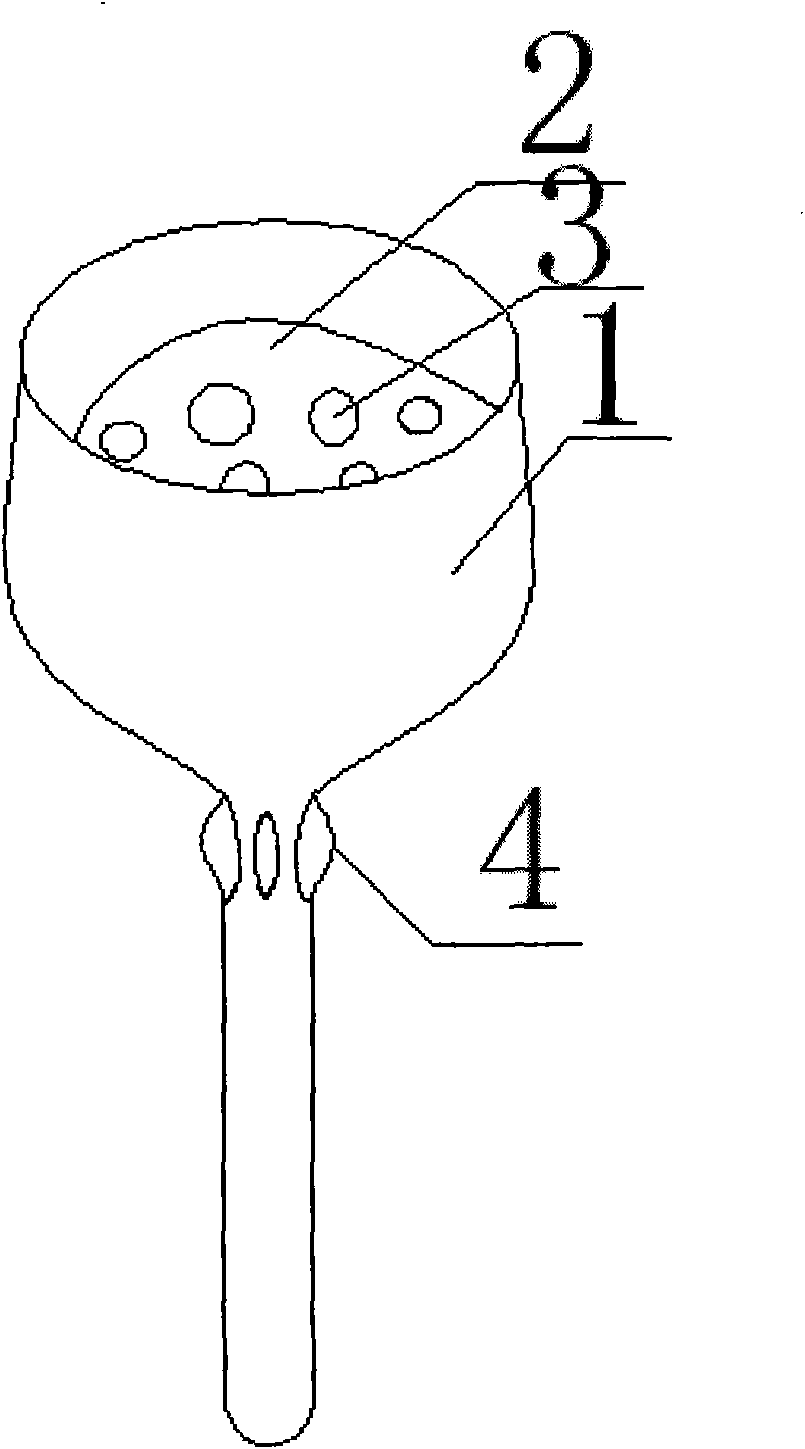

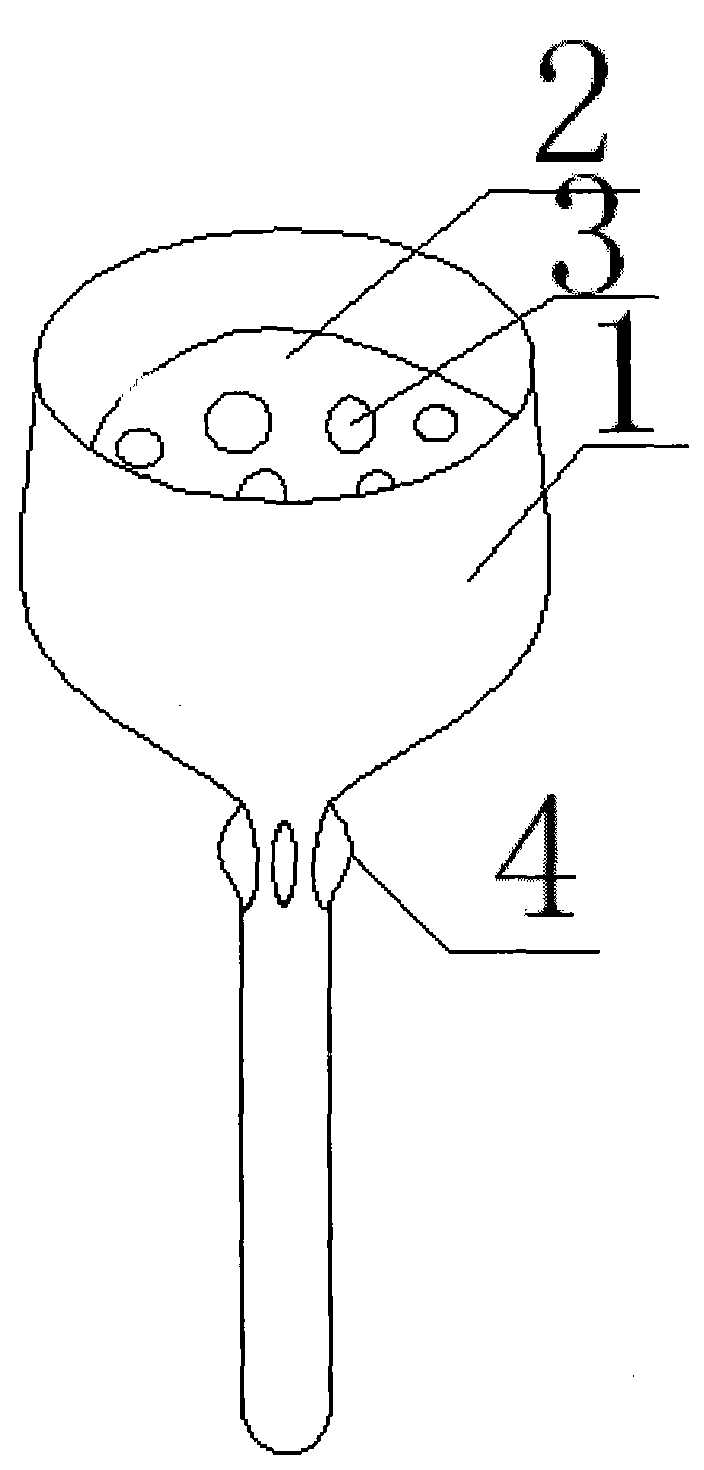

Novel hopper

The invention relates to an auxiliary tool for pouring water from a container, in particular relates to a novel hopper. The novel hopper comprises a funnel and is characterized in that an interlayer for separating the upper part and the lower part of the funnel is arranged at the middle of the funnel, dispersed small holes are arranged on the surface of the interlayer, and dispersed small bulges are arranged on the outer surface of the upper section of a stream tube at the bottom of the funnel. Therefore, the novel hopper has a simple structure and is convenient to use.

Owner:吕高晋

Textile fabric

ActiveCN105463667AEasy to escapeSpeed up the evaporation processWoven fabricsConjugated synthetic polymer artificial filamentsYarnTextile fiber

The invention relates to a textile fabric. The textile fabric comprises functional units, each functional unit comprises yarn and piles, and the yarn has the number of turns ranging from 100 T / m to 200 T / m; the yarn and the piles both comprise functional textile fibers capable of heating and dehumidifying; each functional textile fiber capable of heating and dehumidifying comprises 99.91%-99.95% by weight of crimped fiber materials capable of lowering the crimp ratio through water wetting and 0.05%-0.09% by weight of nano units; the crimped fiber materials are composed of a polyester resin component and a polyamide resin component of which the self elongation and the crimp ratio are different during water absorption according to the proportion of 1:1; each nano unit comprises microparticles of 8,500-9,000 nm, and the microparticles comprise, by weight, 300-500 parts of zinc, 350-450 parts of aluminum and 150-350 parts of iron. According to the textile fabric, by means of the effects of heating and heat accumulation and increasing of gaps of the fabric, the clothes drying efficiency is improved.

Owner:浙江东进新材料有限公司

Device and method for reducing ammonia nitrogen in PVDC resin production wastewater

ActiveCN113149284AStop pollutionPromote decompositionWater treatment parameter controlWater contaminantsAmmoniacal nitrogenHolding tank

The invention discloses a device and a method for reducing ammonia nitrogen in PVDC resin production wastewater. The device comprises a raw wastewater storage tank, an aeration tower, a fan, a wastewater temporary storage tank, an ammonia nitrogen detection system and an ammonia nitrogen remover storage tank, wherein the raw wastewater storage tank is communicated with a water inlet at the upper part of the aeration tower through a water inlet pipe; the fan is communicated with an air inlet at the lower part of the aeration tower, the wastewater temporary storage tank is communicated with a water outlet at the bottom of the aeration tower through a water outlet pipe, the ammonia nitrogen remover storage tank is communicated with a liquid inlet at the lower part of the aeration tower, and the ammonia nitrogen detection system is respectively communicated with the water inlet pipe and the water outlet pipe. The method has the advantages that the ammonia nitrogen content in the wastewater finally discharged by the factory can be effectively controlled within the discharge standard, and the method is more environment-friendly.

Owner:南通汇羽丰新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com