Microgroove cable

A cable and micro-groove technology, which is applied in the direction of power cables, insulated cables, cables, etc., can solve the problems of inconvenient construction and maintenance, easily damaged optical fiber performance, and easy loose shape of optical fiber ribbons, etc., and achieve high qualified rate of finished products and stable product quality , the effect of high product density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

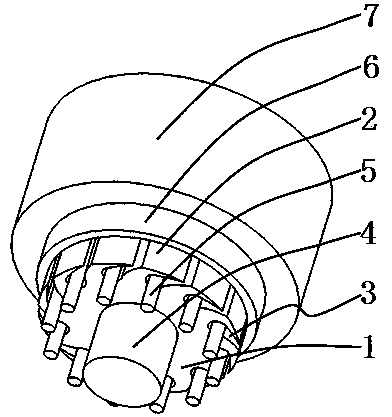

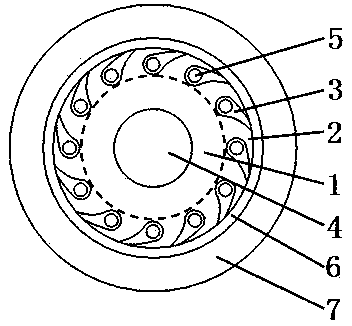

[0021] please see Figure 1 to Figure 2 A micro-groove cable, comprising a skeleton body 1, 12 bone leaves 2, 12 skeleton grooves 3, a reinforcement 4, a plurality of cable cores 5, a protective layer 6, a sheath layer 7, a skeleton body, and bone leaves 1. The skeleton groove is integrally formed, the bone leaf is located on the edge of the skeleton body, the reinforcement is located in the center of the skeleton body, the skeleton groove is formed between adjacent bone leaves, the cable core is located in the skeleton groove, and the protective layer is covered outside the bone leaf. The sheath layer is extrusion-coated outside the protective layer, and it is characterized in that: the outer edge of the bone leaf and the outer edge of the skeleton groove are located on the side of the same cylinder, each skeleton groove has an opening, and the opening is toward the shield In the direction of the jacket layer, the width of the skeleton groove at the opening is the smallest, a...

Embodiment 2

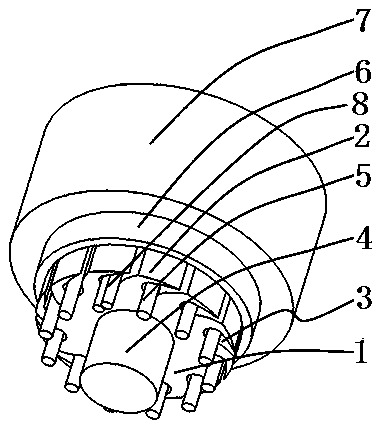

[0023] please see image 3 and Figure 4 , and refer to figure 1 and figure 2 , a micro-groove cable, comprising a skeleton body 1, 12 bone leaves 2, 12 skeleton grooves 3, a reinforcement 4, a plurality of cable cores 5, a protective layer 6, a sheath layer 7, the skeleton body, the bone leaves 1. The skeleton groove is integrally formed, the bone leaf is located on the edge of the skeleton body, the reinforcement is located in the center of the skeleton body, the skeleton groove is formed between adjacent bone leaves, the cable core is located in the skeleton groove, and the protective layer is covered outside the bone leaf. The sheath layer is extrusion-coated outside the protective layer, and it is characterized in that: the outer edge of the bone leaf and the outer edge of the skeleton groove are located on the side of the same cylinder, each skeleton groove has an opening, and the opening is toward the shield In the direction of the jacket layer, the width of the ske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com