Anti-aging nitrile rubber/o-phenylenediamine modified graphene oxide composite material

A technology of o-phenylenediamine and nitrile-butadiene rubber is applied in the field of aging-resistant nitrile-butadiene rubber/o-phenylenediamine-modified graphene oxide composite materials, and can solve the problems of high cost, complex process, low output and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] This embodiment provides a kind of anti-aging nitrile rubber / o-phenylenediamine modified graphene oxide composite material F 1 , in parts by weight, the composite material comprises the following raw material components: 100 parts of nitrile rubber raw rubber, 1 part of stearic acid, 3 parts of zinc oxide, 0.7 parts of accelerator TBBS, 1.5 parts of sulfur, 40 parts of carbon black, 3 parts of o-phenylenediamine modified graphene oxide.

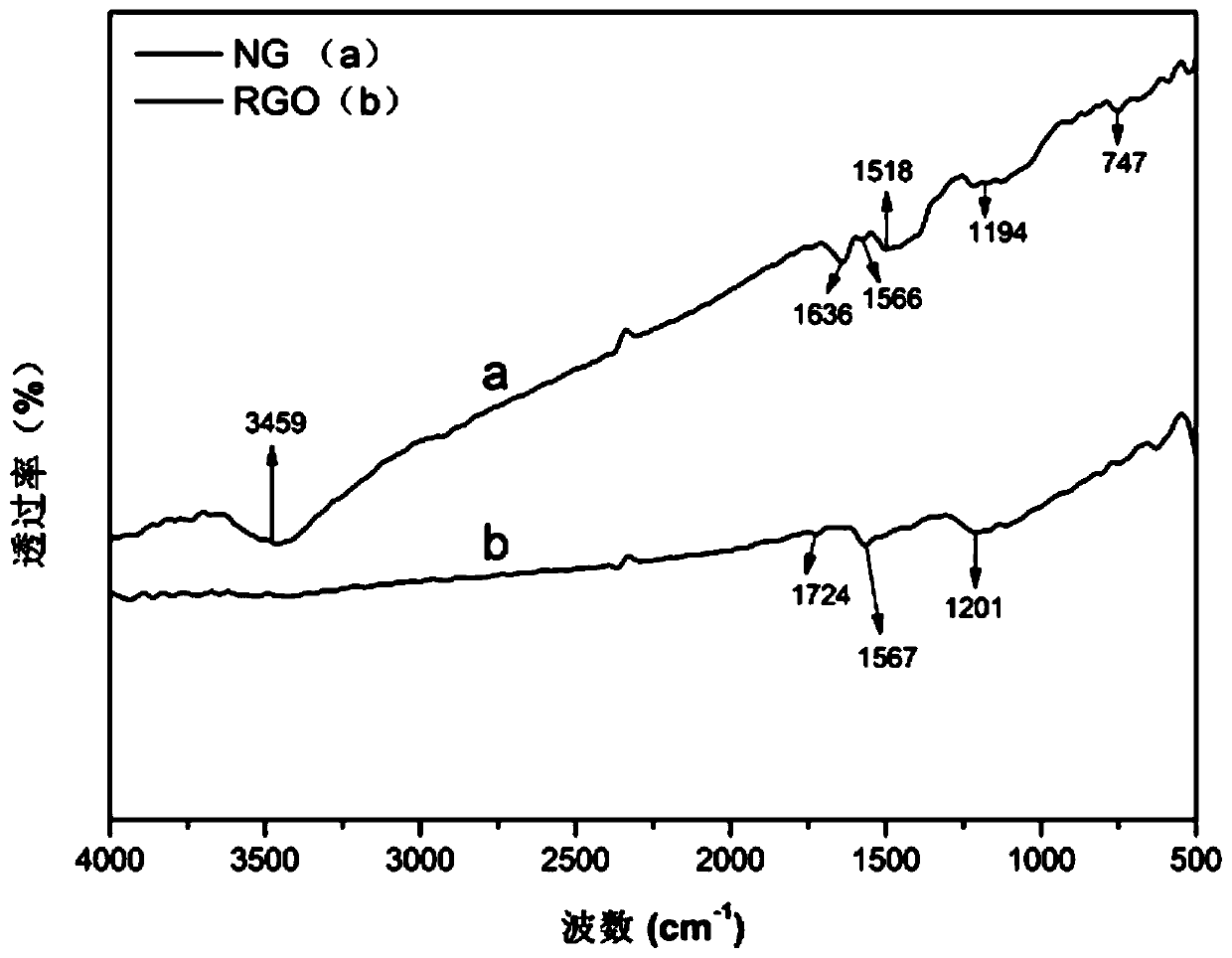

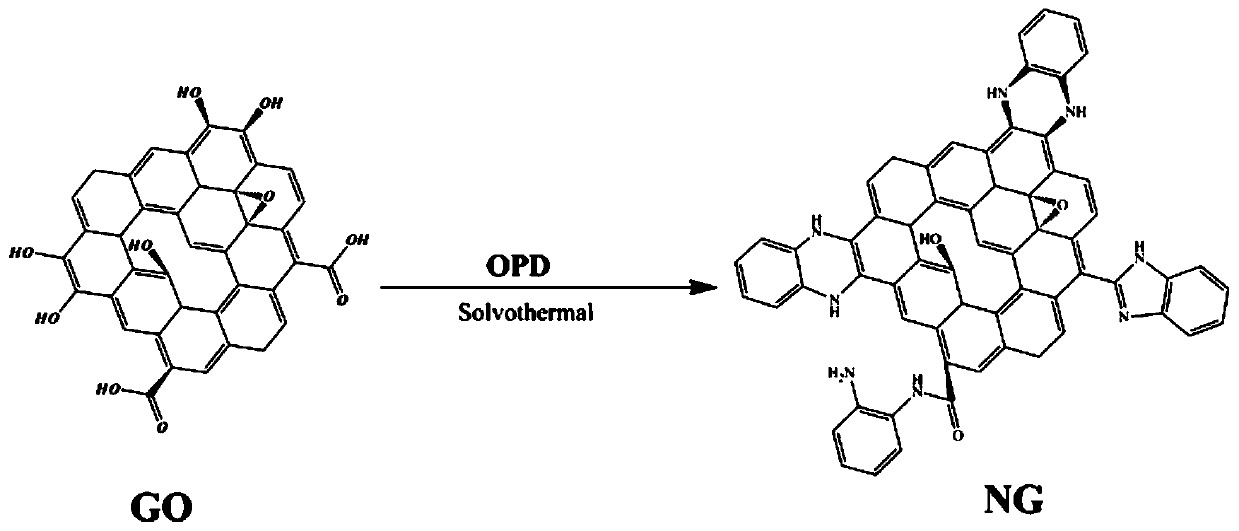

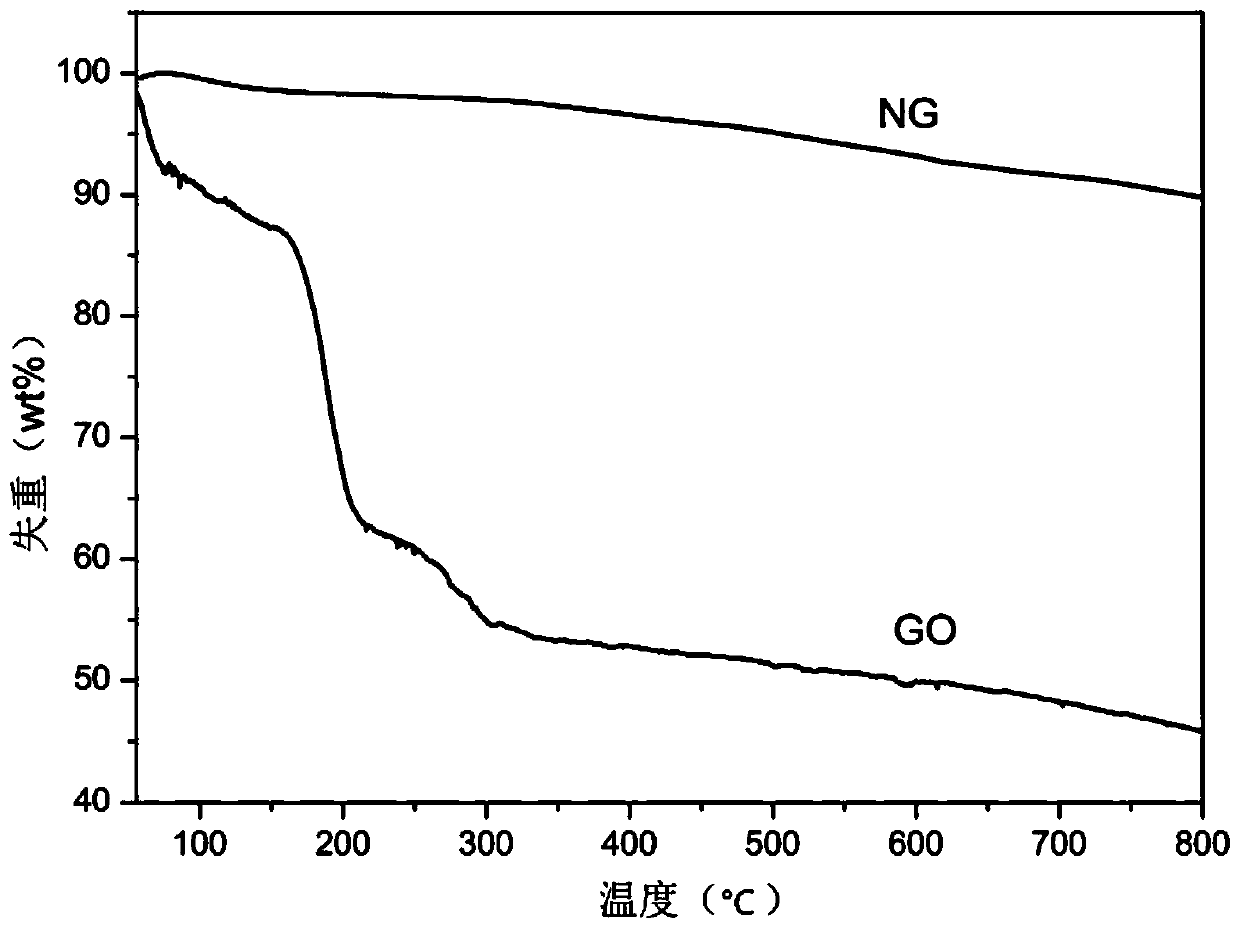

[0077] The preparation method of o-phenylenediamine-modified graphene oxide: Add 1 g of graphite oxide into 1000 mL of deionized water, and ultrasonicate for 1 h at a power of 800 W to obtain a graphene oxide dispersion liquid, which is designated as liquid A. Then, 1 g of o-phenylenediamine was dissolved in 500 ml of ethanol as liquid B. Mix liquid A and liquid B with ultrasound for 30 minutes to obtain a mixed dispersion. Finally, the mixed dispersion is reacted in a sealed hydrothermal reactor at 180°C for 12 hours. The product is ...

Embodiment 2

[0090] This embodiment provides a kind of anti-aging nitrile rubber / o-phenylenediamine modified graphene oxide composite material F 4 , in parts by weight, the composite material comprises the following raw material components: 100 parts of nitrile rubber raw rubber, 1 part of stearic acid, 3 parts of zinc oxide, 0.7 parts of accelerator TBBS, 1.5 parts of sulfur, 40 parts of carbon black, 1 part of o-phenylenediamine modified graphene oxide. The preparation method of o-phenylenediamine modified graphene oxide is shown in Example 1.

[0091] In this example, mechanical blending is used to prepare composite materials. The specific process is as follows: 100 parts of nitrile rubber raw rubber, 1 part of stearic acid, 3 parts of zinc oxide, 0.7 parts of accelerator TBBS, 1.5 parts of sulfur, carbon 40 parts of black and 1 part of o-phenylenediamine-modified graphene oxide were fully blended on a two-roll mill to obtain a rubber compound; then the rubber compound was vulcanized b...

Embodiment 3

[0094] This embodiment provides a kind of anti-aging nitrile rubber / o-phenylenediamine modified graphene oxide composite material F 5 , the raw materials are as follows: in parts by weight, 100 parts of nitrile rubber raw rubber, 1 part of stearic acid, 3 parts of zinc oxide, 0.7 parts of accelerator TBBS, 1.5 parts of sulfur, 40 parts of carbon black, o-phenylenediamine modified 4 parts of graphene oxide. The preparation method of o-phenylenediamine modified graphene oxide is shown in Example 1.

[0095] In this example, mechanical blending is used to prepare composite materials. The specific process is as follows: 100 parts of nitrile rubber raw rubber, 1 part of stearic acid, 3 parts of zinc oxide, 0.7 parts of accelerator TBBS, 1.5 parts of sulfur, carbon 40 parts of black and 4 parts of o-phenylenediamine-modified graphene oxide were fully blended on a two-roll mill to obtain a rubber compound; then the rubber compound was vulcanized by a flat vulcanizer at 145°C and 10M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com