Ton bag pressing device and feeding station

A technology of pressing bags and ton bags, which is applied in the field of material conveying and unloading equipment, can solve problems such as inconvenient operation, waste of materials, and bag openings, and achieve the effects of avoiding pollution, wide application range, and reducing health damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

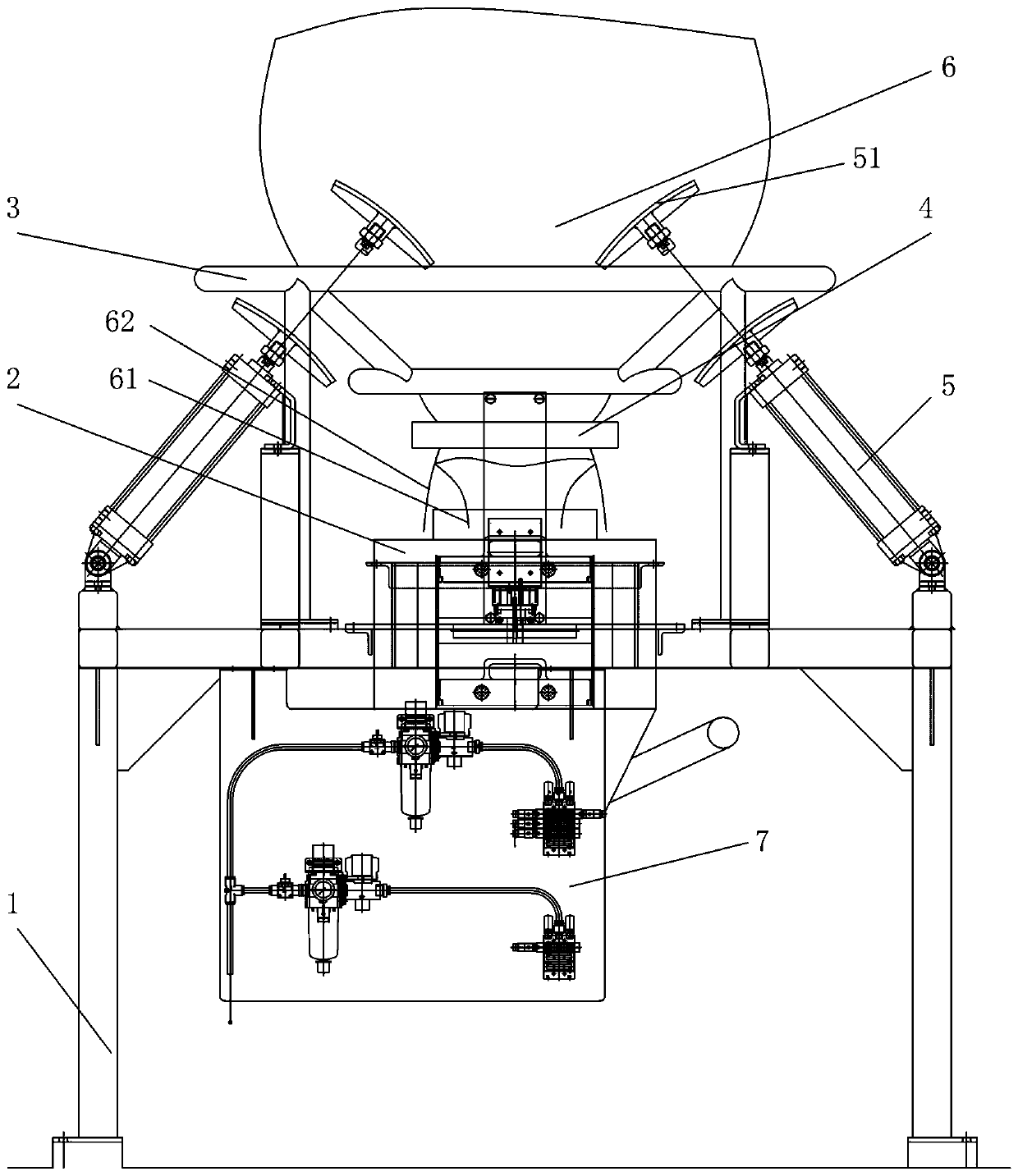

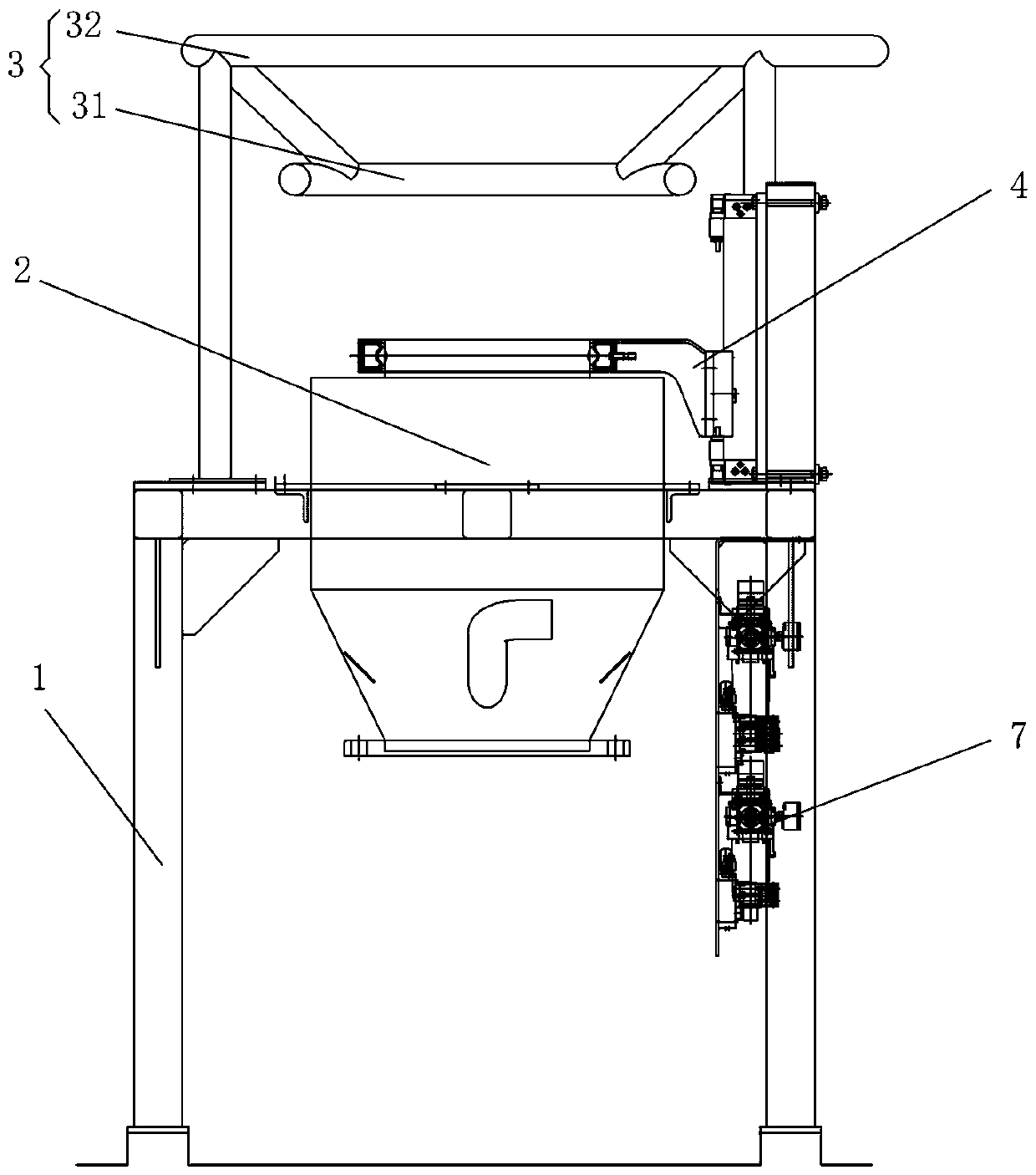

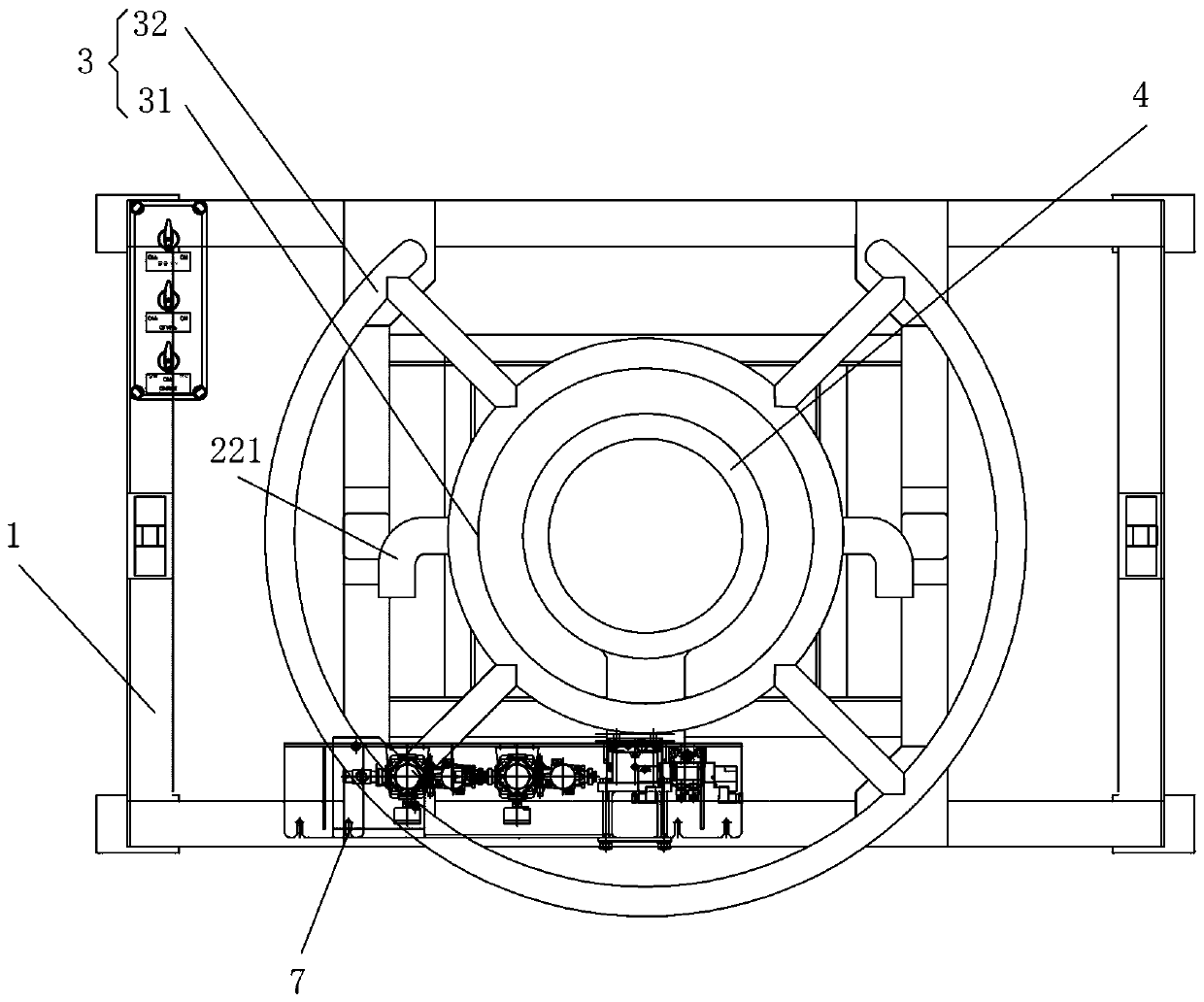

[0028] The big bag pressing device in this embodiment, such as figure 1 and Figure 5 As shown, the ton bag 6 includes an inner bag mouth 61 and an outer bag mouth 62, the length of the two bag mouths is relatively short, the bag pressing device 4 is arranged at the feed inlet 211 of the feeding chamber 2, and the inner pocket mouth 61 is placed In the mouth 211, the bag pressing device 4 includes a bag pressing member 41, which can directly compress the outer bag opening 62 to the outer wall of the feeding opening 211, without being limited by the length of the bag opening, and has a wide range of applications.

[0029] In this example, if Figure 5 As shown, an air bag 411 is installed inside the bag pressing member 41, the bag pressing member 41 presses the outer bag mouth 62 to the outer wall of the feed port 211, and the air bag 411 expands with air and compresses the outer bag mouth 62 to the feed port 211 ; The bag pressing part 41 is loosened, the air bag 411 deflate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com