Super-hybrid fireproof prepreg for new energy automobile battery box and preparation method

A new energy vehicle, ultra-hybrid technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems of poor fire and flame retardancy, low ignition point, and imperceptibility, so as to improve stiffness and damage tolerance , reduce residual porosity, and reduce overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

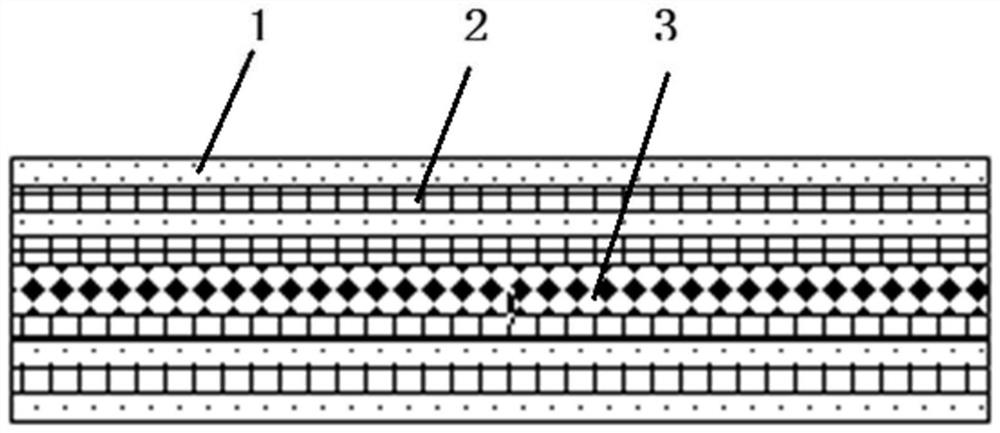

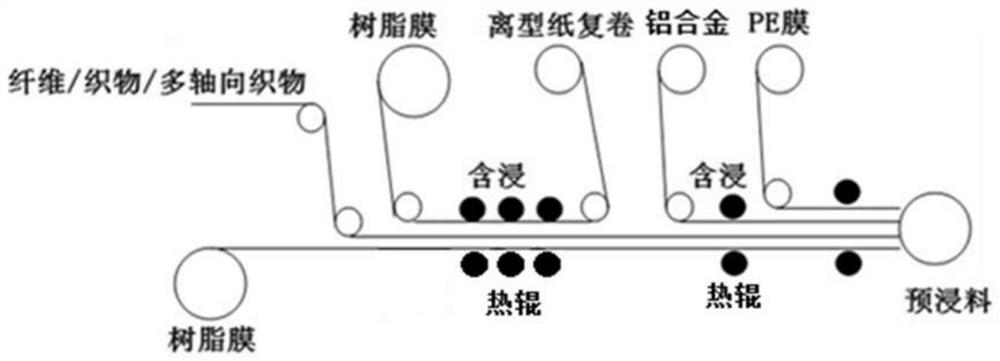

[0025] Embodiment one: refer to figure 1 and figure 2 As shown, a super-hybrid anti-fire impregnation material for new energy vehicle battery boxes and its preparation method are composed of a resin matrix, an aluminum alloy layer, and a fiber layer.

[0026] As a preference: the resin matrix is a thermosetting epoxy resin with flame retardant function, composed of epoxy resin E51: 10 parts, epoxy resin F51: 35 parts, nitrile rubber modified epoxy resin: 10 parts, modified containing Phosphorus epoxy resin: 15 parts, curing agent dicyandiamide: 6 parts, feed agent UR500: 1.5 parts, the resin is infiltrated in each layer of materials, and the resin content is 38%.

[0027] As a preference: the thickness of the aluminum alloy layer 1 is 0.06 mm, the surface of the aluminum alloy is anodized with phosphoric acid, and uniformly arranged circular holes with a diameter of 2 mm are processed.

[0028] As a preference: the fiber layer 2 is basalt fiber cloth with a surface densit...

Embodiment 2

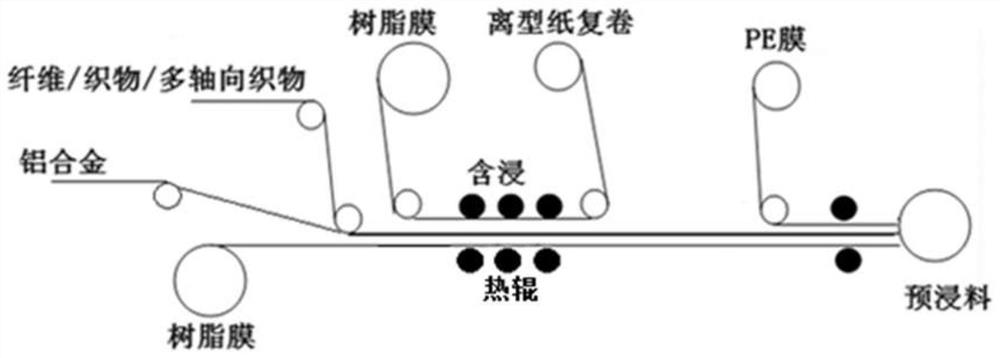

[0033] Example 2: A super-hybrid fireproof prepreg for new energy vehicle battery boxes and its preparation method, which consists of a resin matrix, an aluminum alloy layer, and a fiber layer.

[0034] As a preference: the resin matrix is a thermosetting epoxy resin with flame retardant function, composed of epoxy resin E51: 10 parts, epoxy resin F51: 35 parts, nitrile rubber modified epoxy resin: 10 parts, modified containing Phosphorus epoxy resin: 15 parts, curing agent dicyandiamide: 6 parts, feed agent UR500: 1.5 parts, the resin is infiltrated in each layer of materials, and the resin content is 45%.

[0035] As a preference: the thickness of the aluminum alloy layer 1 is 0.3 mm, the surface of the aluminum alloy is anodized with phosphoric acid, and evenly arranged circular holes with a diameter of 2 mm are processed.

[0036] As a preference: the fiber layer 2 is basalt fiber cloth with a surface density of 200g / m 2 . The fiber layer / aluminum alloy layer in the su...

Embodiment 3

[0040]Embodiment 3: The super-hybrid prepreg obtained in Embodiment 1 and 2 is made into a composite material plate and subjected to a fire performance test, and various performances are tested according to the national standard, and the test results are as follows:

[0041]

[0042] It can be seen from the above data that the hyper-hybrid prepreg prepared by the present invention has a higher oxygen index, refractoriness and fire resistance limit than the common flame-retardant prepreg, which can ensure the fireproof performance of the box.

[0043] Among them, the processing method of ordinary basalt flame-retardant prepreg is to soak the flame-retardant prepreg resin on the basalt fiber cloth on the prepreg production line to obtain the basalt flame-retardant prepreg. The material is composed of flame retardant resin and basalt fiber cloth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com