Vanadium-aluminum-iron intermediate alloy and preparation method thereof

A master alloy, vanadium-aluminum technology, which is applied in the field of vanadium-aluminum-iron master alloy and its preparation, can solve the problems of poor uniformity of vanadium-aluminum-iron alloy, increase process and equipment, increase production cycle, etc., achieve low melting point of metal, and facilitate production and operation , the effect of less heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing a vanadium-aluminum-iron master alloy, comprising the following steps:

[0023] Mix aluminum, vanadium pentoxide and iron to obtain a mixed material;

[0024] The mixed material is subjected to vacuum thermite reaction to obtain alloy liquid;

[0025] The alloy liquid is cooled to obtain a vanadium-aluminum-iron master alloy.

[0026] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0027] The invention mixes aluminum, vanadium pentoxide and iron to obtain a mixed material. In the present invention, the forms of the aluminum, vanadium pentoxide and iron are preferably powders, and the present invention has no special requirements on the particle size of the powders, and the corresponding conventional powders can be selected; the aluminum The purity is preferably ≥99.8%, the purity of vanadium pentoxide is ...

Embodiment 1

[0043] (1) The aluminum powder, vanadium pentoxide, and iron powder are dried separately at a drying temperature of 120° C. and a drying time of 12 hours.

[0044] (2) Proportion of raw materials: 2.46kg of aluminum powder, 3.59kg of vanadium pentoxide, and 0.30kg of iron powder. Put the raw materials into a V-shaped mixer and mix them well to ensure sufficient contact between the raw materials to obtain a mixed material.

[0045] (3) Put the mixed material into the corundum crucible in the vacuum reaction vessel, the charging temperature is 30°C, vacuumize to -0.08MPa, ignite, and carry out vacuum thermite reaction, the reaction temperature is 1550°C, the reaction time is 35s, and cool for 12h Finally, the crucible was dismantled, the alloy ingot was taken out, and weighed.

[0046] (4) Polishing and decontaminating the surface of the alloy ingot to obtain a vanadium-aluminum-iron master alloy.

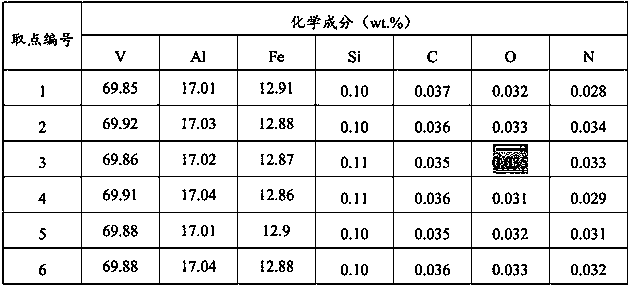

[0047] According to the conventional method, one position of the vanadium-alumi...

Embodiment 2

[0052] (1) The aluminum powder, vanadium pentoxide, and iron powder are dried separately at a drying temperature of 120° C. and a drying time of 12 hours.

[0053] (2) Proportion of raw materials: 2.43kg of aluminum powder, 3.64kg of vanadium pentoxide, and 0.33kg of iron powder. Put the raw materials into a V-shaped mixer and mix them well to ensure sufficient contact between the raw materials to obtain a mixed material.

[0054] (3) Put the mixed material into the corundum crucible in the vacuum reaction vessel, the charging temperature is 40°C, vacuumize to -0.10MPa, ignite, and carry out vacuum thermite reaction, the reaction temperature is 1580°C, the reaction time is 32s, and cool for 12h Finally, the crucible was dismantled, the alloy ingot was taken out, and weighed.

[0055] (4) Polishing and decontaminating the surface of the alloy ingot to obtain a vanadium-aluminum-iron master alloy.

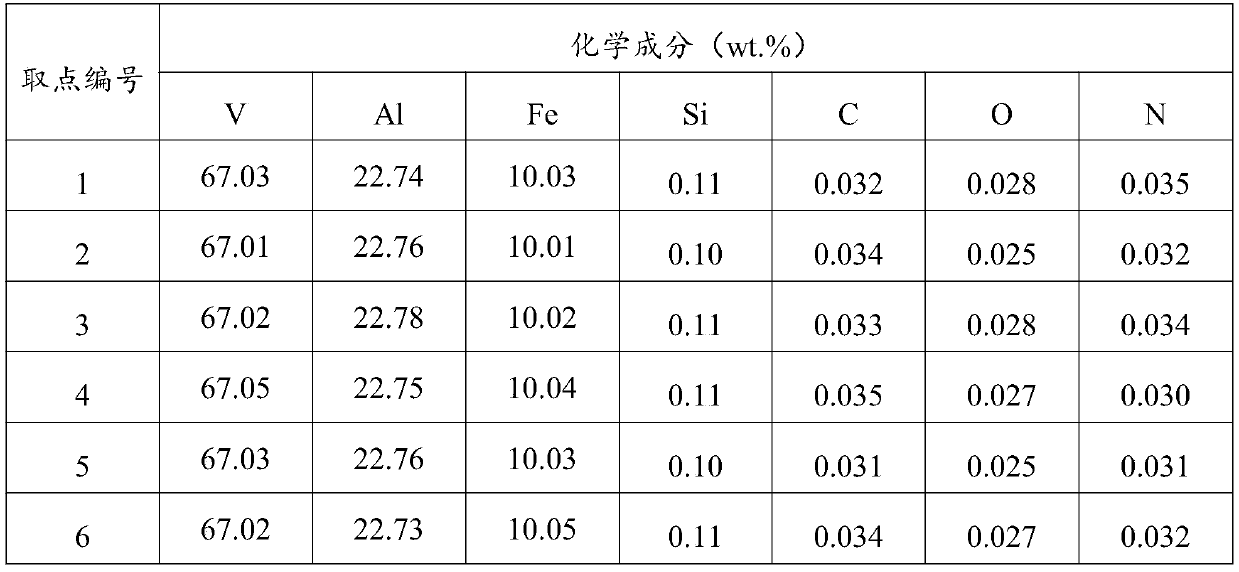

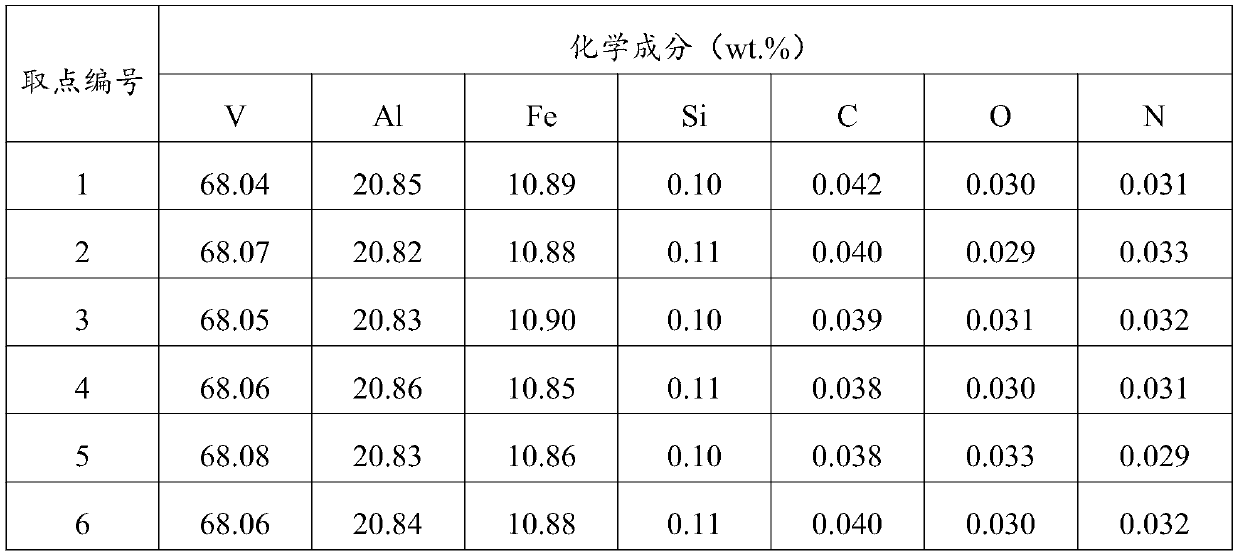

[0056] According to the method described in embodiment 1, a position (same as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com