Preparation method and application of nitrogen-doped titanium dioxide denitration catalyst

A denitration catalyst, titanium dioxide technology, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., to achieve the effects of strong controllability, low preparation temperature, and increased Fermi level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The first aspect of the present invention provides a method for preparing a nitrogen-doped titanium dioxide denitration catalyst, wherein the method includes: (1) performing surface hydrogenation reduction on a titanium source to obtain black TiO 2 powder; (2) the black TiO 2 The powder is doped with nitrogen to obtain N-TiO 2 catalyst.

[0025] In the present invention, step (1) is used to construct defects by surface hydrogenation of the titanium source, resulting in a large number of oxygen vacancies and Ti 3+ , so as to form an oxygen cycle with the reaction gas; step (2) is used to stabilize oxygen vacancies through nitrogen doping while increasing the Fermi level, making it easier for electrons to escape, N-TiO 2 Provides redox performance while enhancing N-TiO 2 denitrification efficiency.

[0026] In some embodiments of the present invention, the surface hydrogenation can realize that the hydrogenated titanium source has a certain number of oxygen vacancies ...

Embodiment 1

[0055] This example is used to illustrate the preparation method of nitrogen-doped titania catalyst

[0056] (1) First, carry out hydrogenation reduction on the surface of titanium dioxide, under normal pressure, 99.99% H 2 Under the atmosphere, the hydrogen flow rate is 200mL / min, hydrogenation is carried out in a tube furnace at 450°C, kept for 11h, and then lowered to room temperature to prepare black TiO 2 powder.

[0057] (2) Then, the black TiO 2 For nitrogen doping, under normal pressure, NH 3 / N 2 Under an atmosphere with a volume ratio of 1:99, purge in a fixed bed at 300 °C for 1 h, and then cool down to room temperature to obtain N-TiO 2 catalyst.

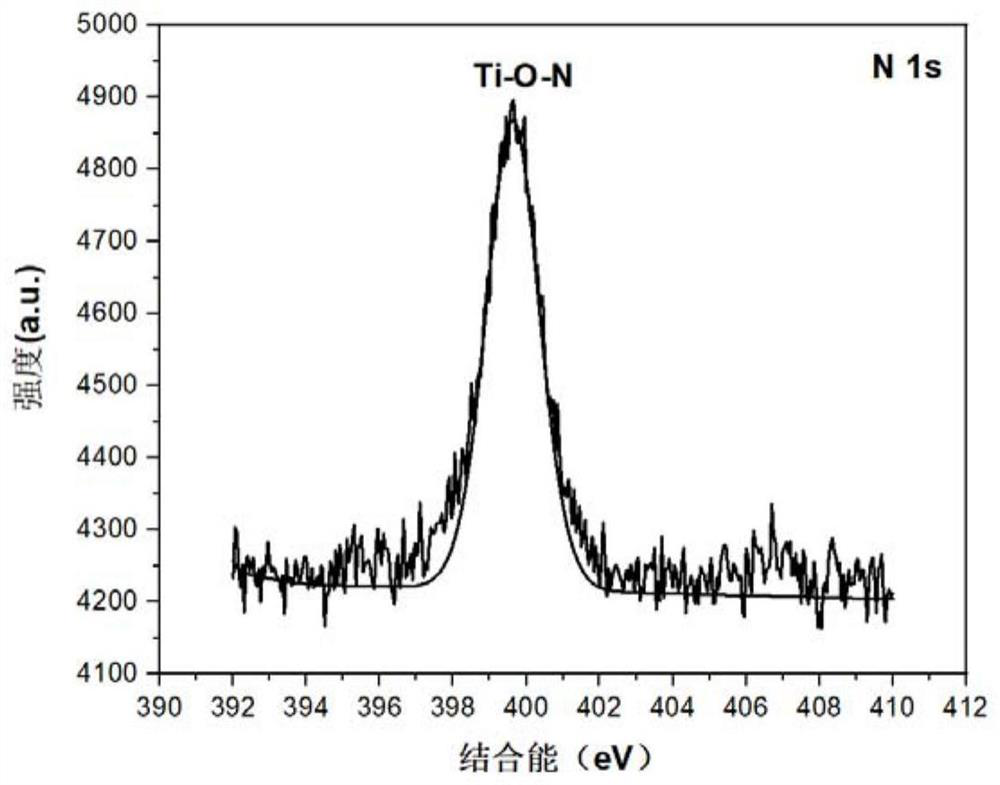

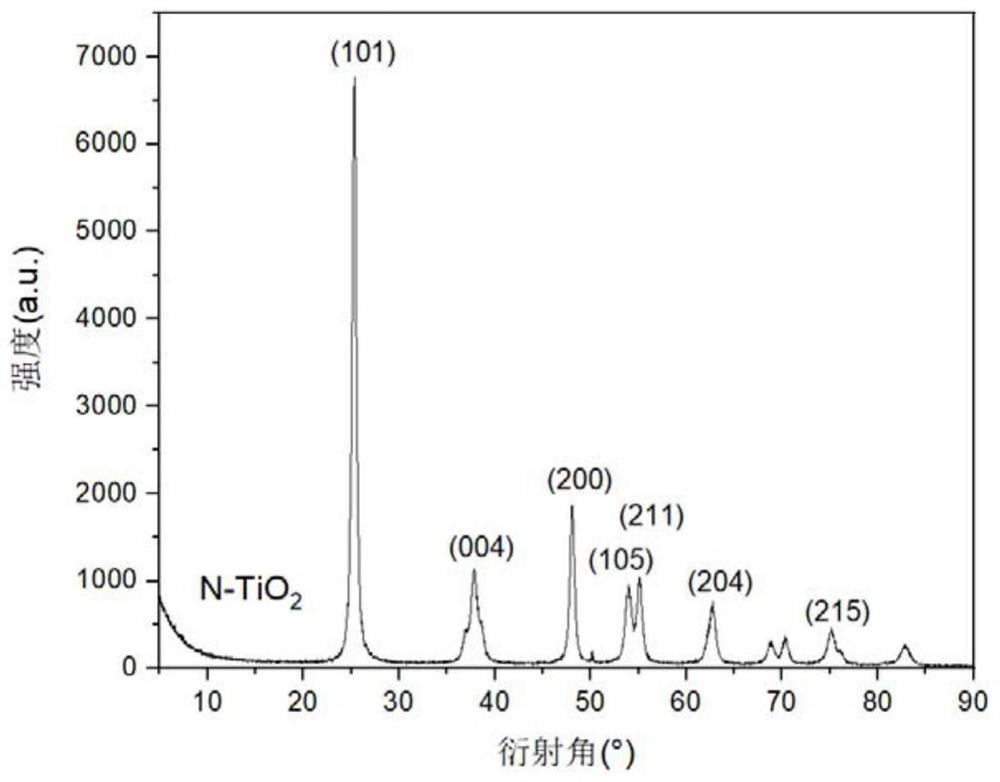

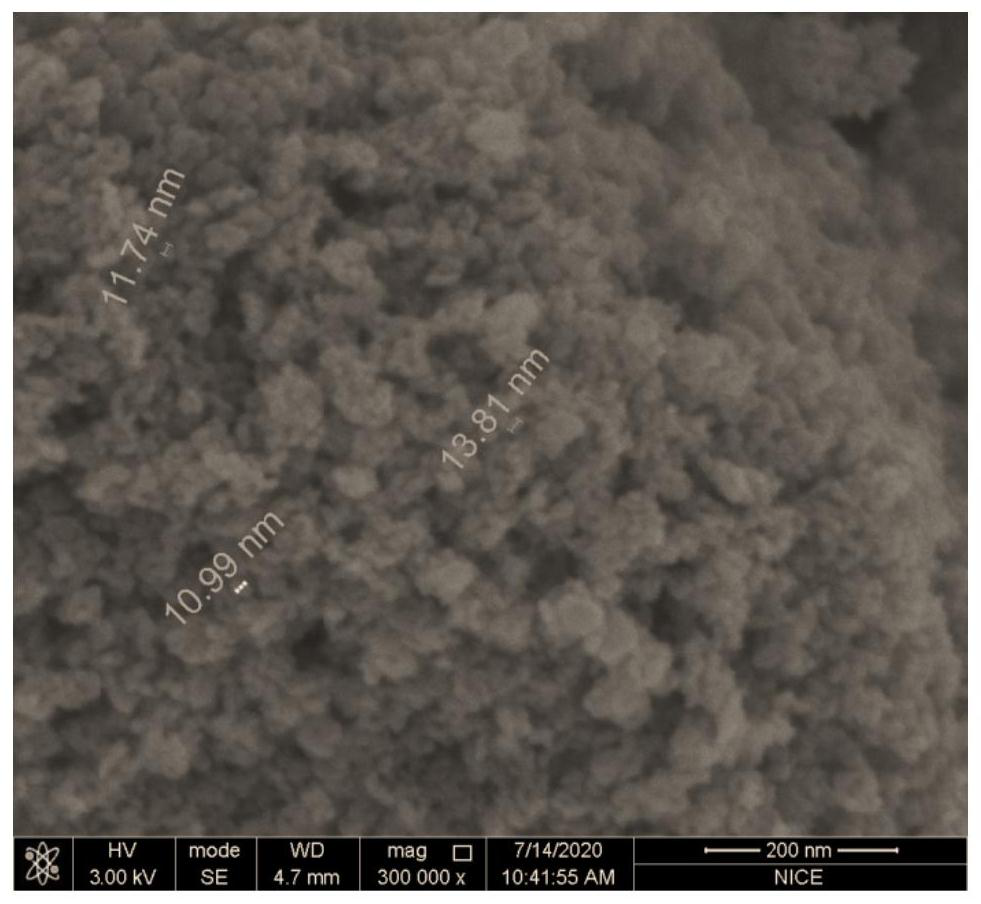

[0058] figure 1 N-TiO of the present invention 2 The XPS spectrum of the catalyst. From figure 1 It can be seen that in the high-resolution spectrum corresponding to N1s, the binding energy at 399.59eV corresponds to the gap N (Ti-O-N), which proves that the obtained product is nitrogen-doped titanium dioxide. ...

Embodiment 2

[0062] This example is used to illustrate the preparation method of nitrogen-doped titania catalyst

[0063] (1) First, carry out hydrogenation reduction on the surface of titanium dioxide, under normal pressure, 99.99% H 2 Under the atmosphere, the hydrogen flow rate is 100mL / min, hydrogenation is carried out in a tube furnace at 500°C, kept for 12h, and then lowered to room temperature to prepare black TiO 2 powder.

[0064] (2) Then, the black TiO 2 For nitrogen doping, under normal pressure, NH 3 / N 2 Under an atmosphere with a volume ratio of 1:99, purge in a fixed bed at 300°C for 1.5h, and then cool down to room temperature to obtain N-TiO 2 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com