Device and method for processing metal surface microstructures through formwork electro-hydraulic beam

A metal surface and microstructure technology, applied in electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to manufacture nozzles, difficult to control the stability of electrolyte jet, difficult to locate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Embodiment: A device and method for machining metal surface microstructures by template electrohydraulic beam.

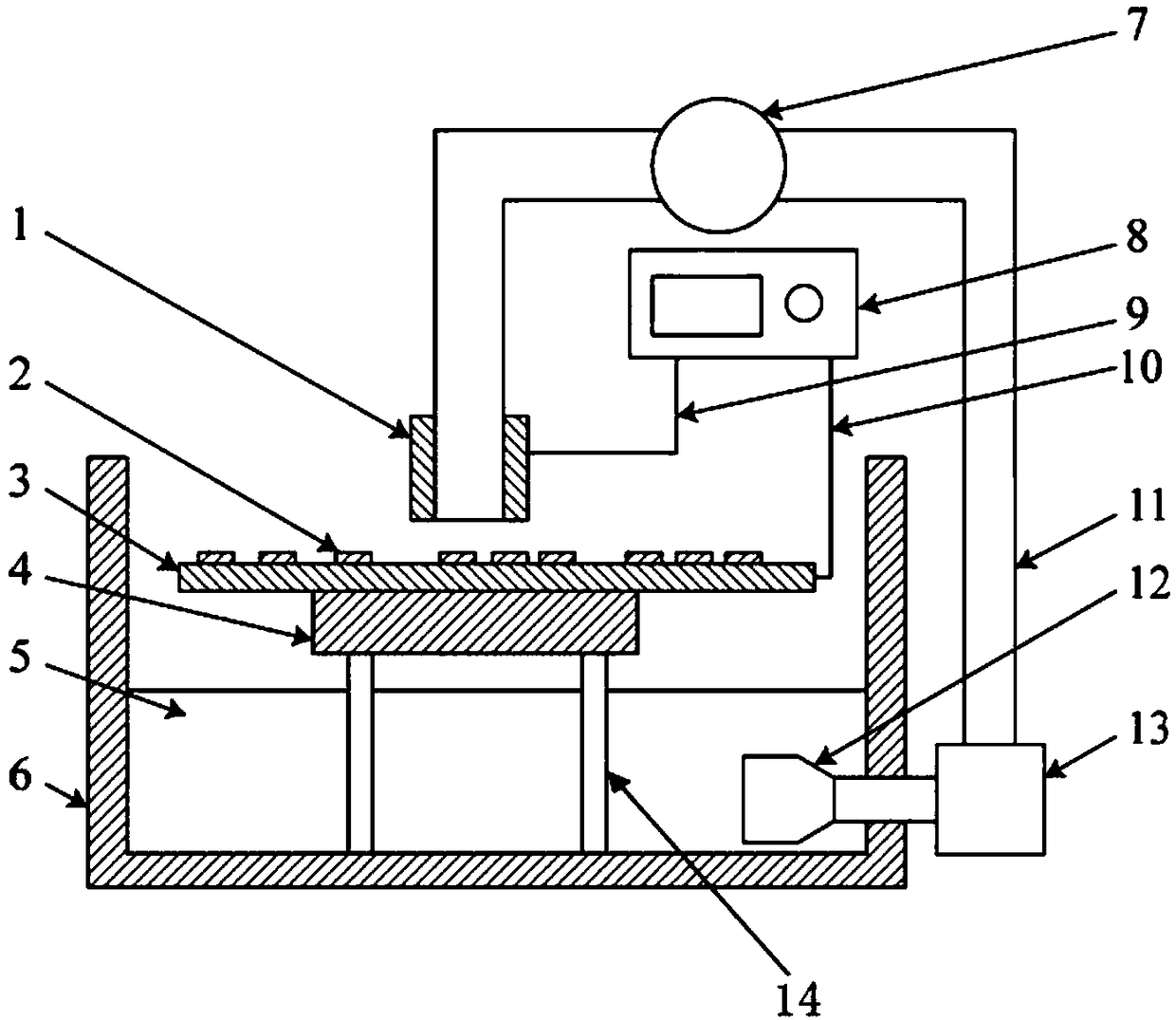

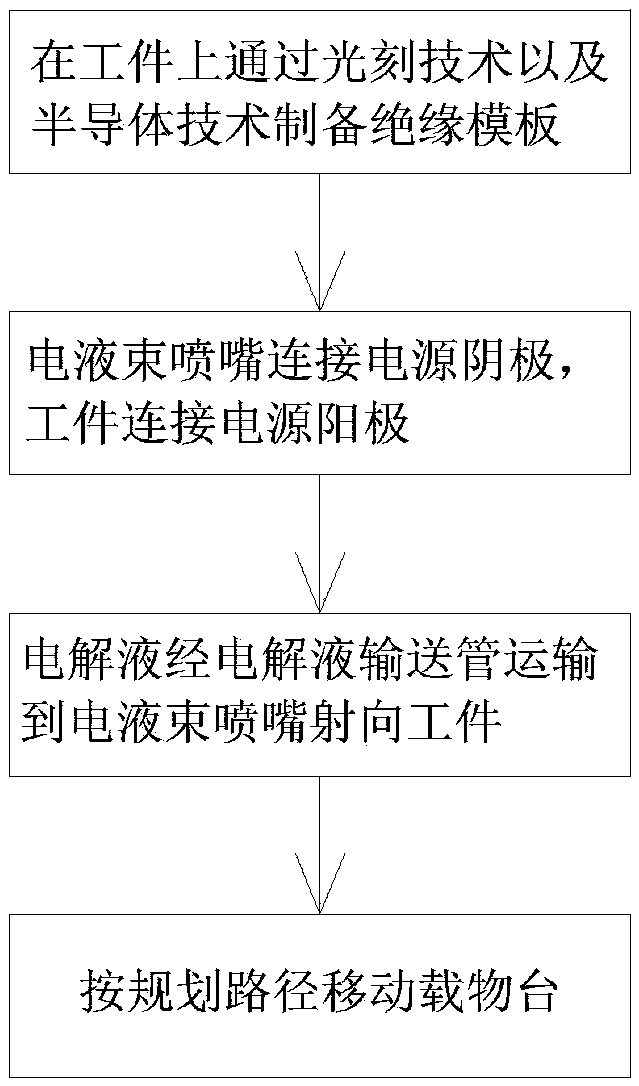

[0025] refer to figure 1 As shown, a device for template electrohydraulic beam machining metal surface microstructure, comprising: a workpiece compartment 6; an electrolyte solution 5 arranged at the bottom of the workpiece compartment 6; an object stage 4 installed in the workpiece compartment 6, the The stage 4 is connected to the bottom of the workpiece warehouse 6 through a bracket 14; the workpiece 3 installed on the stage 4 is provided with an insulating template 2; the electro-hydraulic beam nozzle 1 arranged above the workpiece 3; The electrolyte delivery pipeline 11 on the electro-liquid beam nozzle 1, the other end of the electrolyte delivery pipeline 11 is connected to the electrolyte 5, and the electrolyte delivery pipeline 11 is connected to the electrolyte solution 5. A filtration system 12 is installed, and the electrolyte delivery pipeline 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com