X-ray photolithographic mask with through hole

A photolithography mask, X-ray technology, applied in the field of masks, can solve problems such as cracking, loss of elasticity, permanent damage, etc., to achieve the effect of improving performance, preventing deformation, and preventing damage to the mask

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

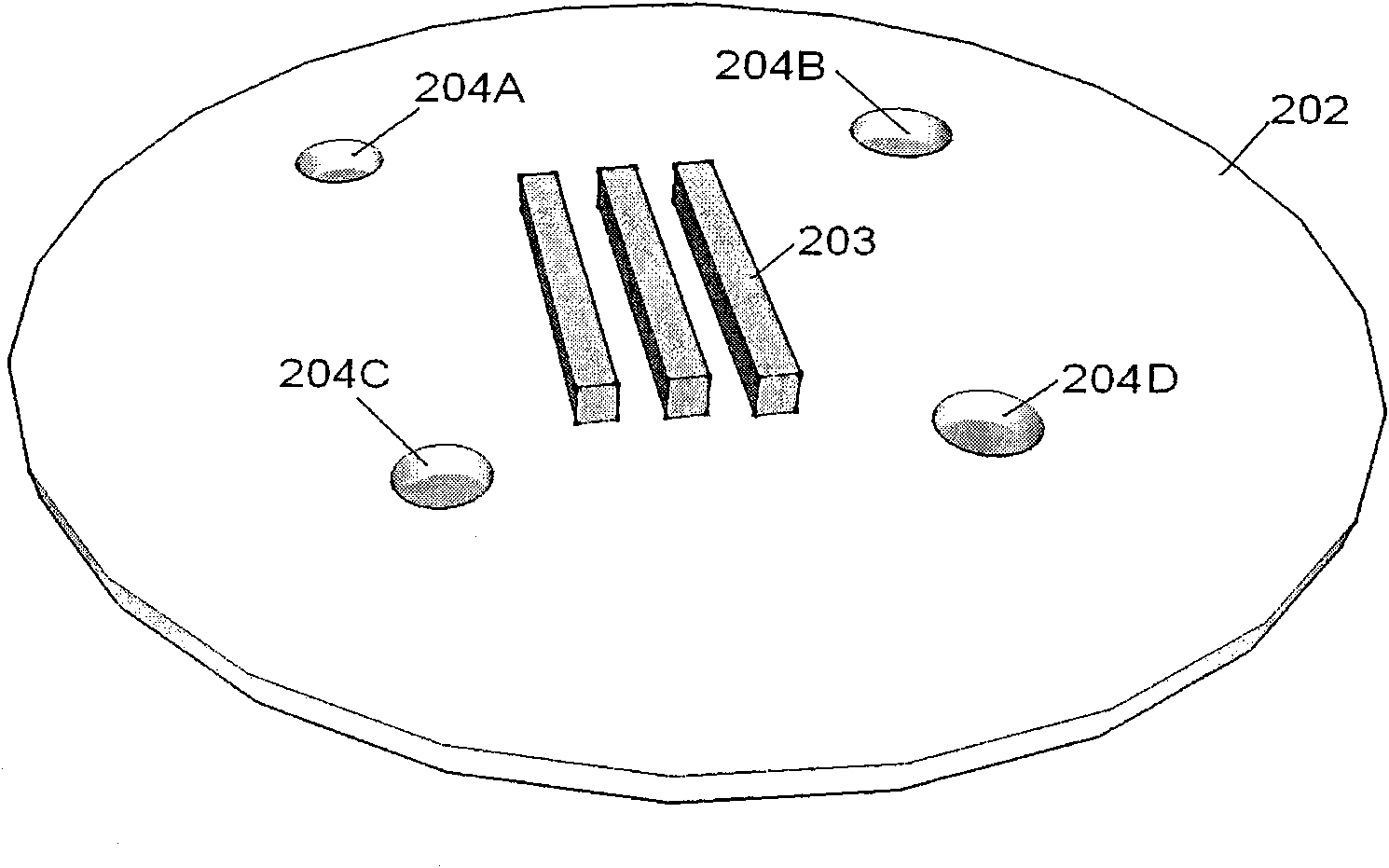

[0025] Refer below figure 1 and figure 2 , the specific embodiment of the present invention will be described in detail.

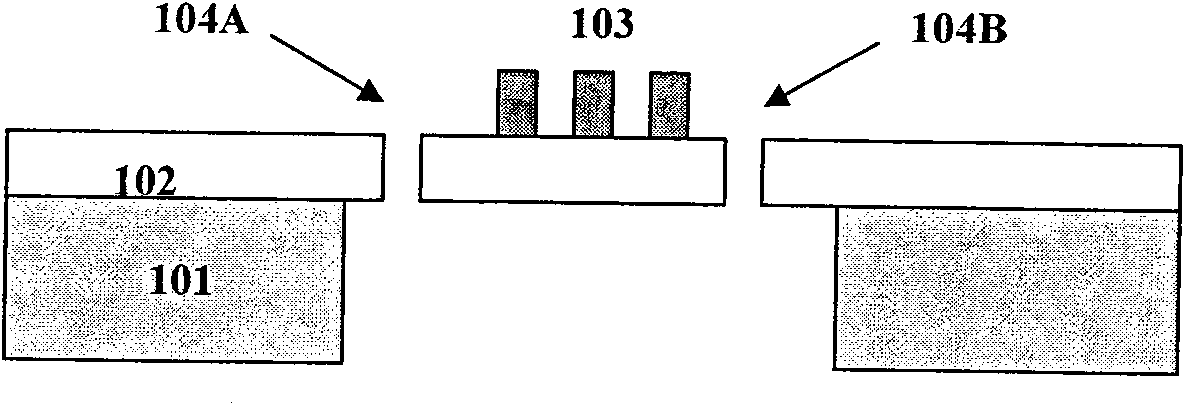

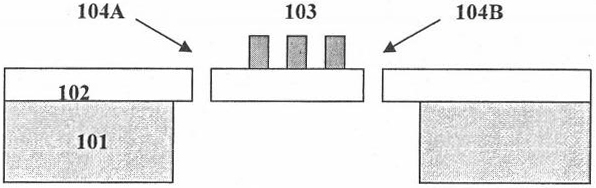

[0026] figure 1 is a cross-sectional view of an X-ray lithography mask with vias according to an embodiment of the present invention. Wherein 101 is a supporting frame of the X-ray mask according to the present invention. The frame is made of silicon, the frame is circular, the outer diameter of the frame is 50 mm, and the inner diameter of the frame is 10 mm, and the frame can be formed by etching the central area of a complete silicon wafer. 102 is a thin film of the X-ray mask according to the present invention, the thin film is made of polyimide material, and the thickness of the thin film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com