Point ring laser welding system and method under vacuum condition

A technology of laser welding and vacuum conditions, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of welding quality or penetration ability that cannot be compared with electron beam welding, and achieve the suppression of welding spatter, welding Suppression of slit pores and reduction of tendency to air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

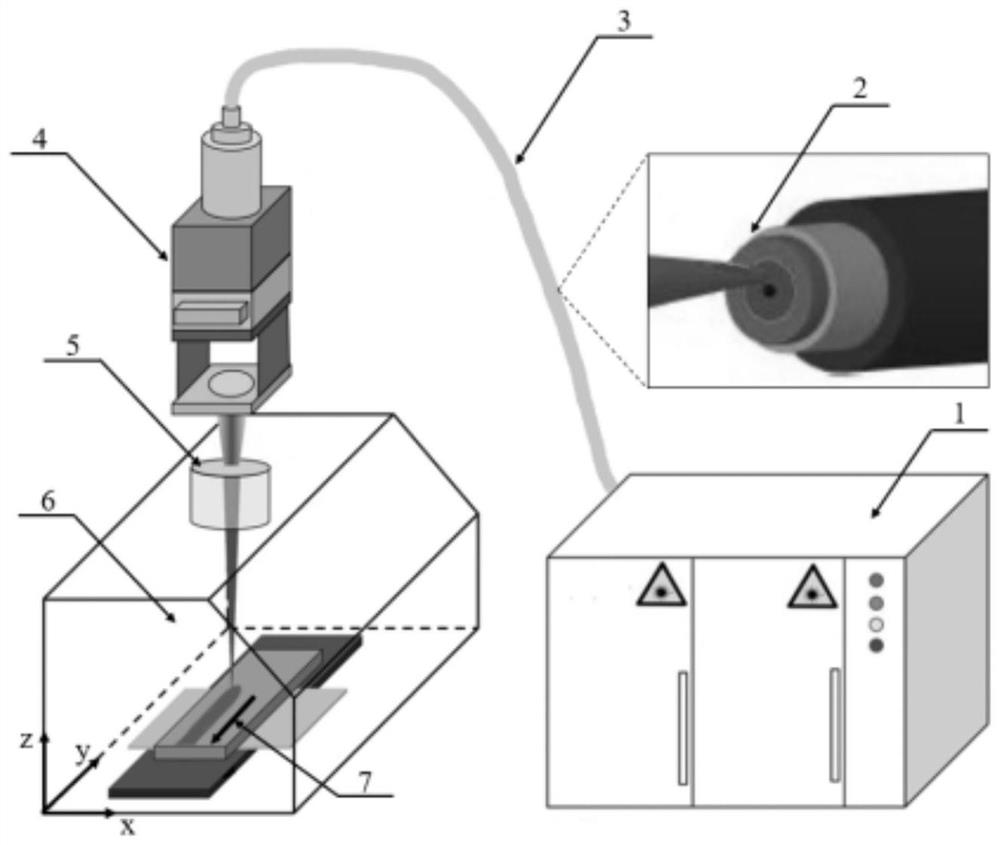

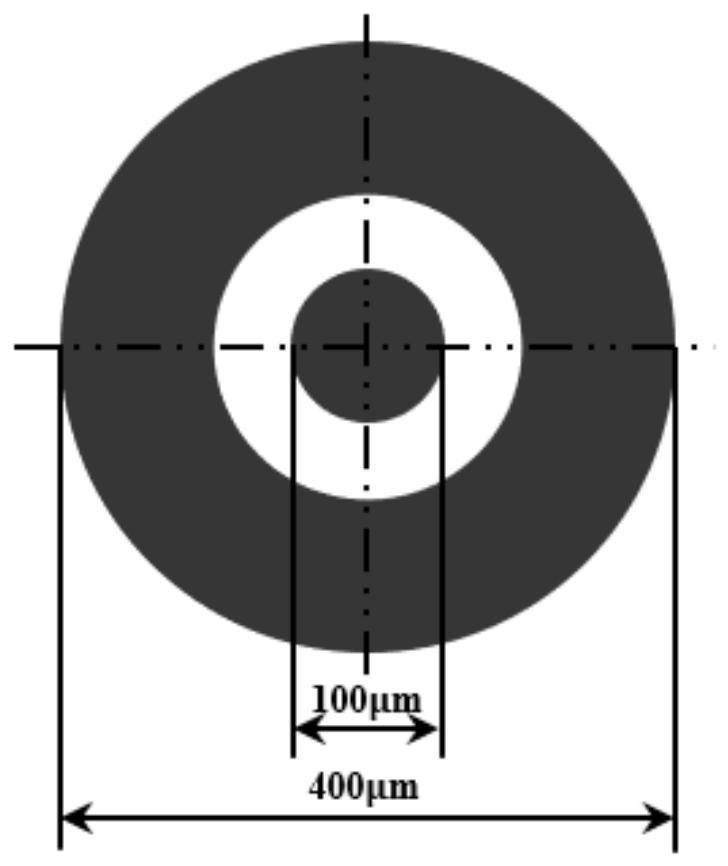

[0048] like figure 1 and Figure 3-Figure 7 As shown, one aspect of the present invention provides a spot-ring laser welding system under vacuum conditions, comprising a solid-state laser 1, a spot-ring laser fiber 3 connected to the solid-state laser 1, and a spot-ring laser fiber 3 disposed on the spot-ring laser fiber 3 away from the The laser processing head 4 at one end of the solid-state laser 1 , the laser coupling window 5 provided under the laser processing head 4 , the vacuum chamber 6 provided under the laser coupling window 5 , and the movement in the vacuum chamber 6 Platform 7; the point-ring laser fiber 3 can directly output a point-ring light source through a single coaxial single fiber, output a point-ring light source through a built-in fiber coupler in the laser, output a point-ring light source through a built-in integrated optical gate of the laser, or output through a two-in-one optical fiber A composite point ring laser beam is formed by various methods...

Embodiment 2

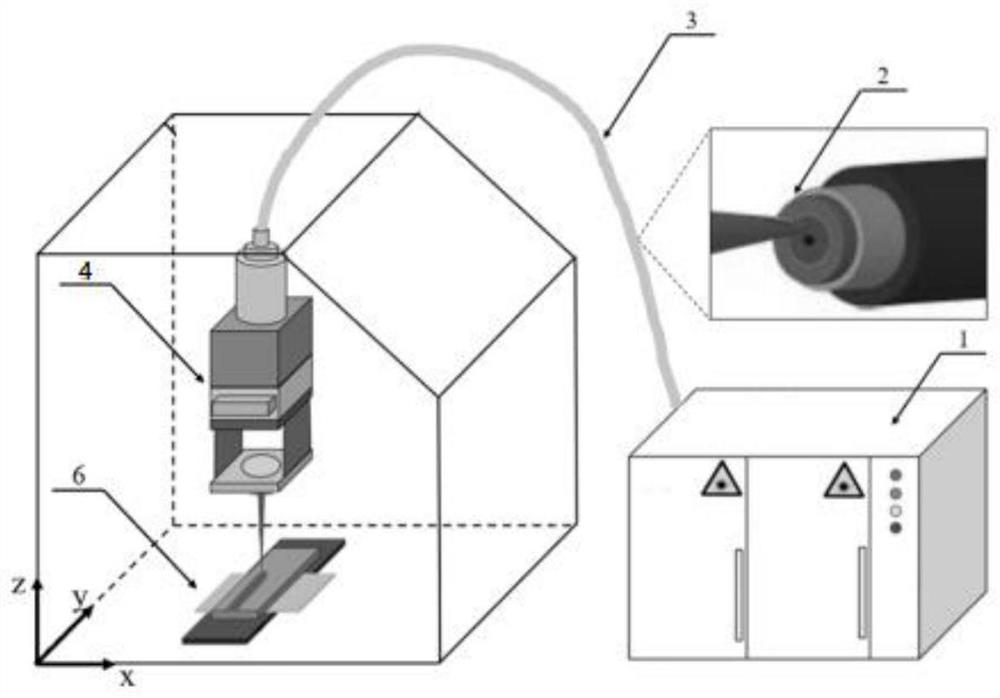

[0053] like Figure 2-Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the laser processing head of this embodiment is built into the vacuum chamber, and other conditions are the same, as follows:

[0054] An embodiment of the present invention provides a spot-ring laser welding system under vacuum conditions, including a solid-state laser 1, a spot-ring laser fiber 3 connected to the solid-state laser 1, and a spot-ring laser fiber 3 disposed on the spot-ring laser fiber 3 away from the solid state. The laser processing head 4 at one end of the laser 1, the vacuum chamber 6 arranged outside the laser processing head 4, and the mobile platform 7 arranged in the vacuum chamber 6; The solid-state laser 1 emits light, and the laser focused by the laser processing head in the vacuum environment of the vacuum chamber 6 is finally incident on the surface of the welding workpiece to complete the welding process; the point ring laser fiber 3 can pass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com