Automobile air conditioner compressor hollow piston and production method thereof

A technology of hollow piston and automobile air conditioner, which is applied in the direction of mechanical equipment, machine/engine, liquid displacement machinery, etc., can solve the problems that affect the performance and service life of hollow piston, small welding tension, unstable quality, etc., and achieve crystallization The effect of increasing the number of cores, improving elongation, and improving room temperature strength and high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

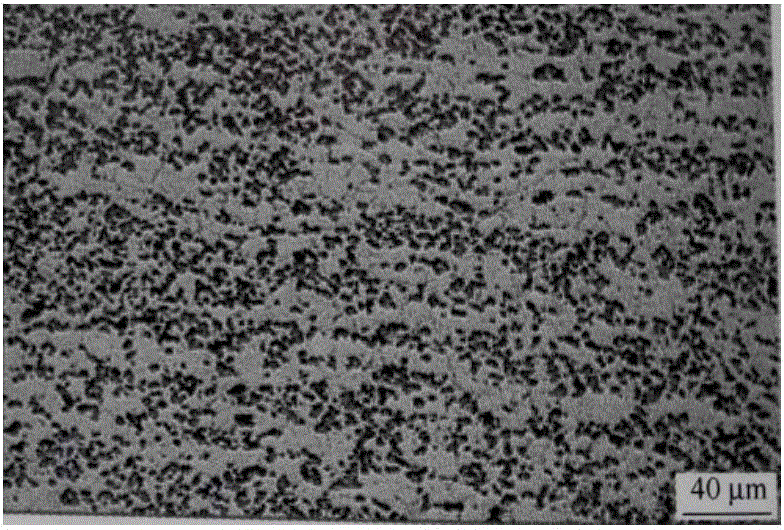

Embodiment 1

[0083] Add a certain quality of pure aluminum ingots into the crucible, heat to 780°C, melt the pure aluminum ingots into a melt, and then add Al-Cr master alloy, Al-Cu master alloy, Al -Ni master alloy, Al-Mn master alloy, Al-RE master alloy, Al-Si master alloy, Al-Zn master alloy, Al-Ti master alloy, heat up to 840°C, keep it warm for 6 hours, and wait until the solid alloy is completely melted Stir, turn on the electromagnetic stirrer, stir for 1 hour, and add 0.5% of the composite phosphorus modifier of the melt quality, then cool down to 760°C, add Al-C master alloy and Al-Mg master alloy according to the proportion, and start again Electromagnetic stirrer, stirring for 1 hour, degassing with nitrogen for 20 minutes, after the performance index is reached through the test, the melt is cast into an aluminum alloy ingot. The aluminum alloy ingot includes the following components in weight percentage: Si: 11%, Cu: 3.5%, Mg: 0.2%, Ni: 0.8%, Cr: 0.1%, C: 0.1%, Mn: 0.08%, Zn :...

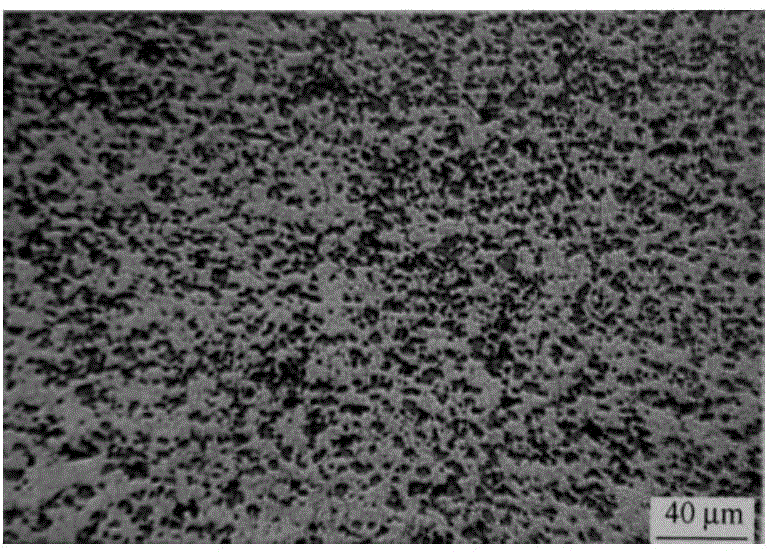

Embodiment 2

[0090] Add a certain quality of pure aluminum ingots into the crucible, heat to 785°C, melt the pure aluminum ingots into a melt, and then add Al-Cr master alloy, Al-Cu master alloy, Al -Ni master alloy, Al-Mn master alloy, Al-RE master alloy, Al-Si master alloy, Al-Zn master alloy, Al-Ti master alloy, heat up to 845°C, keep warm for 6 hours, after the solid alloy is completely melted Stir, turn on the electromagnetic stirrer, stir for 1 hour, and add a composite phosphorus modifier of 1% of the melt mass, then cool down to 765°C, add Al-C master alloy and Al-Mg master alloy according to the proportion, and start again Electromagnetic stirrer, stirring for 1 hour, degassing with nitrogen for 20 minutes, after the performance index is reached through the test, the melt is cast into an aluminum alloy ingot. The aluminum alloy ingot includes the following components in weight percentage: Si: 12%, Cu: 4.0%, Mg: 0.35%, Ni: 1.1%, Cr: 0.2%, C: 0.2%, Mn: 0.08%, Zn : 0.4%, Ti: 0.14%, ...

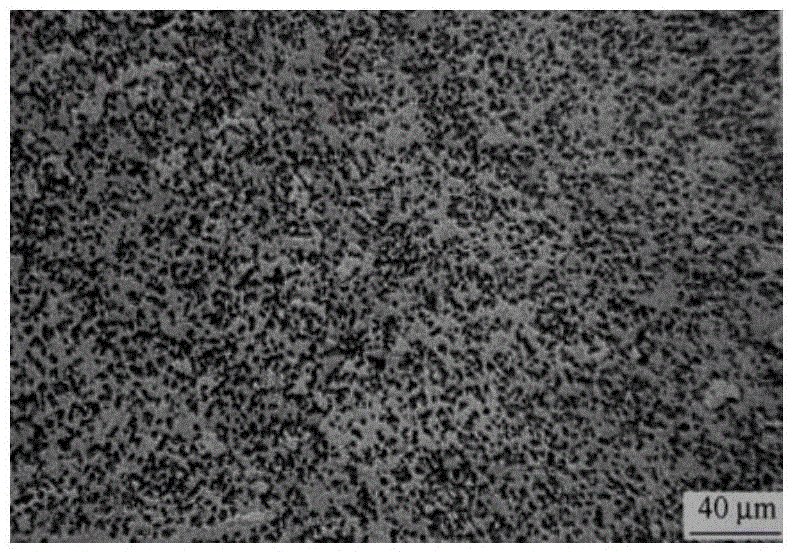

Embodiment 3

[0097]Add a certain quality of pure aluminum ingots into the crucible, heat to 790°C, melt the pure aluminum ingots into a melt, and then add Al-Cr master alloy, Al-Cu master alloy, Al -Ni master alloy, Al-Mn master alloy, Al-RE master alloy, Al-Si master alloy, Al-Zn master alloy, Al-Ti master alloy, heat up to 850°C, keep it warm for 6 hours, and wait until the solid alloy is completely melted Stir, turn on the electromagnetic stirrer, stir for 1 hour, and add 2% of the composite phosphorus modifier of the melt quality, then cool down to 770°C, add Al-C master alloy and Al-Mg master alloy according to the proportion, and start again Electromagnetic stirrer, stirring for 1 hour, degassing with nitrogen for 20 minutes, after the performance index is reached through the test, the melt is cast into an aluminum alloy ingot. The aluminum alloy ingot includes the following components in weight percentage: Si: 13%, Cu: 4.5%, Mg: 0.5%, Ni: 1.5%, Cr: 0.3%, C: 0.3%, Mn: 0.08%, Zn : 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com