Bowl type ornament manufacturing method

A production method and jewelry technology, which are applied in the directions of clothing, manufacturing tools, machine tools with surface polishing, etc., to achieve the effects of good effect, uniform polishing, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

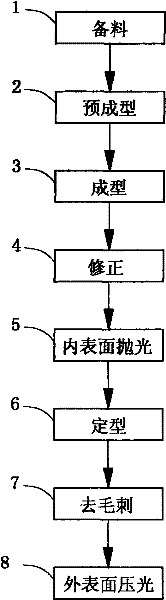

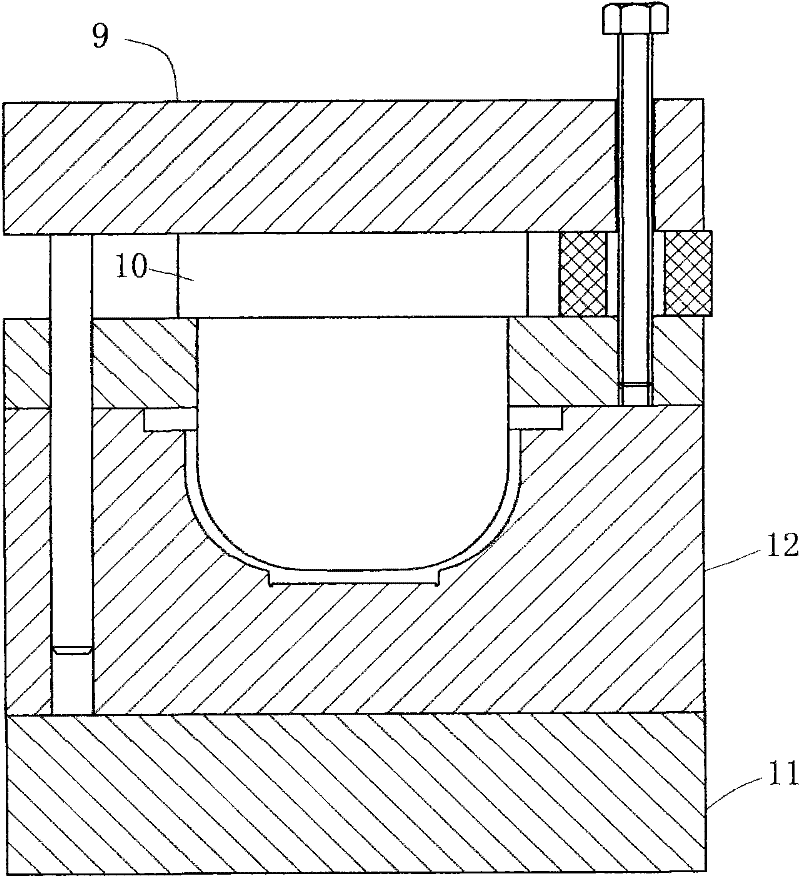

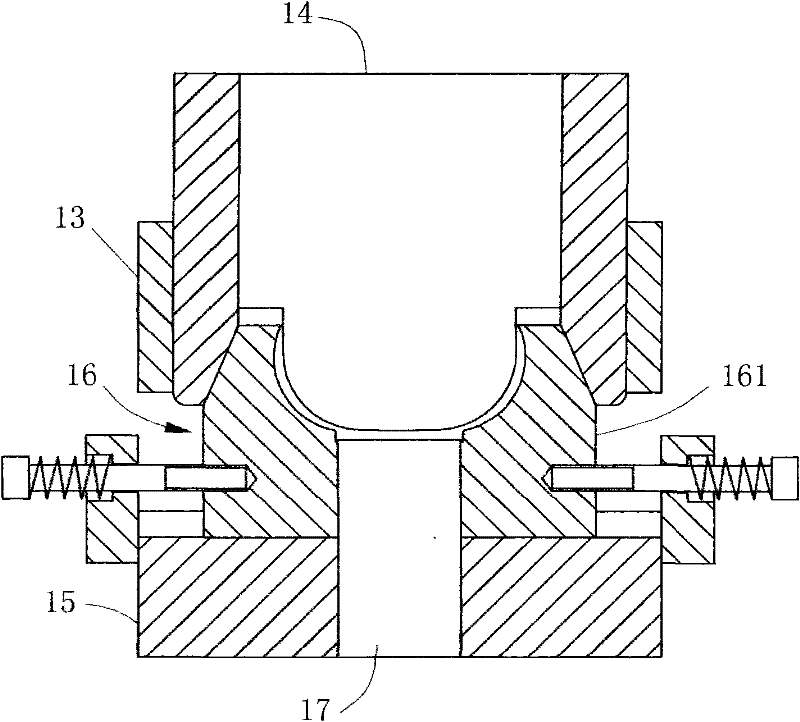

[0025] Such as figure 1 As shown, a method for making bowl-shaped ornaments mainly includes the following steps: material preparation 1, preforming 2, forming 3, correcting 4, inner surface polishing 5, shaping 6, deburring 7 and outer surface calendering 8. Polish the surface of the plate with the thickness required for the bowl-shaped ornament, and then obtain the blank required for the bowl-shaped ornament on a punching machine; draw the blank into a shape with an opening size greater than or equal to the cavity size through a preforming die Bowl-shaped semi-finished product; the semi-finished product is molded into a bowl-shaped workpiece with a maximum cavity size greater than the opening size through a sizing die; The supplementary weight of the standard weight is trimmed to the range required by the standard weight; after the bowl-shaped workpiece is annealed and pickled, the inner surface is polished, and the polishing of the inner surface includes placing the bowl-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com