Acceleration and deceleration look-ahead control method for high-speed machining of numerical control machine tool

A technology of CNC machine tools and control methods, which is applied in the directions of computer control, program control, general control system, etc., and can solve the problems of complicated calculation of S-shaped curve acceleration and deceleration planning and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

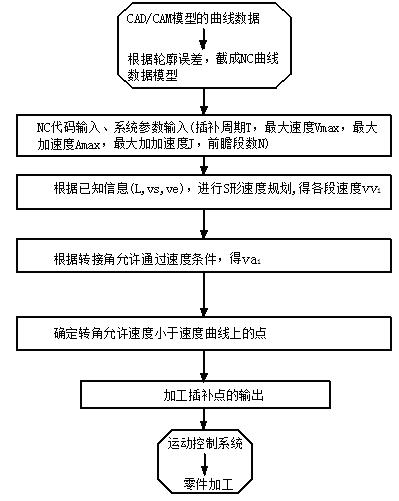

[0037] see figure 1 , the forward-looking control method of acceleration and deceleration for high-speed machining of CNC machine tools, including the following steps: the curve data of the CAD / CAM model is cut into an NC curve data model, and on the basis of the NC code, the overall calculation of the micro-segment is carried out to obtain its S S-shaped speed curve and the corresponding speed of each segment on the S-shaped speed curve (i=1:N, N is the number of forward-looking segments); determine the allowable passing speed of the transfer angle in the micro-segment (i=1:N); Determine the point where the allowable speed of the corner is less than the planned speed; thus obtain an S-shaped speed curve with the highest efficiency, and finally output the processing interpolation point to the motion control system.

Embodiment 2

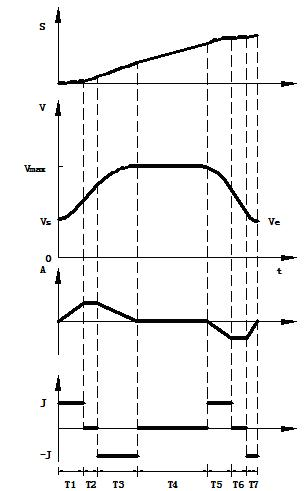

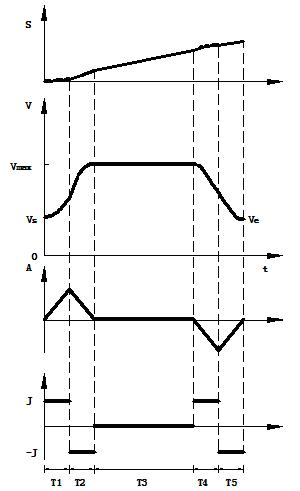

[0039] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present embodiment is the same as Embodiment 1, and the special innovations are as follows:

[0040] The overall S-shaped speed planning of the micro-segment and the corresponding speed of each segment on the S-shaped speed curve (i=1:N, N is the number of forward-looking segments) is determined based on the NC code generated by the numerical control system, according to the value of the data point on the model and the calculation formula for the segment length between two adjacent coordinate points to calculate the segment length L value, to get the segment length L between two adjacent coordinate points, and according to the overall segment length, initial velocity vs, and final velocity ve model, the overall calculation can be carried out in the forward-looking segment, and its S-shaped velocity curve can be obtained, and the phase of each segment can be obtained. The corresponding speed value ...

Embodiment 3

[0051] The acceleration and deceleration forward-looking control method for high-speed machining of CNC machine tools is based on the S-shaped acceleration and deceleration speed law curve model, and the corresponding speed of each segment on the S-shaped speed curve is considered comprehensively. (i=1:N, N is the number of forward-looking segments), the allowable passing speed of the micro-segment transfer angle (i=1:N), determine the reasonable speed that micro-segment machining can pass, and thus obtain an S-shaped speed curve with the highest efficiency. The present invention scheme such as figure 1 Shown:

[0052] According to the input workpiece processing data, on the basis of the NC code generated by the CNC system, firstly calculate the overall calculation in the forward-looking segment according to the known conditions (micro-segment segment length L, initial velocity vs, final velocity ve), and obtain its S-shaped velocity Curve, and at the same time, the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com