Automatic generation method of plunge milling toolpath for corner features

An automatic generation and plunge milling technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem that the processing method does not take into account the machining accuracy of the machining allowance, the processing of complex surfaces, the correctness of the generated tool path, The reliability and practicability are not strong, and the free-form surface of the corner surface is not considered, so as to achieve the effect of shortening the production cycle, high accuracy and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

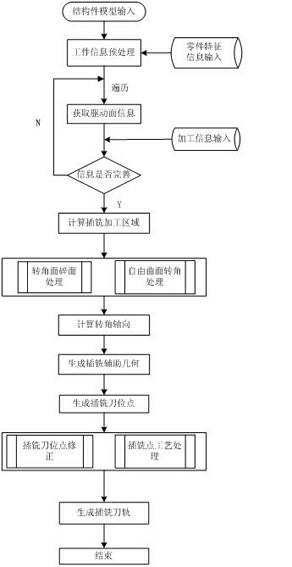

[0050] figure 1 It is a flow chart of the method for automatically generating corner feature plunge milling tool paths of the present invention. As shown in the figure, the following steps are included:

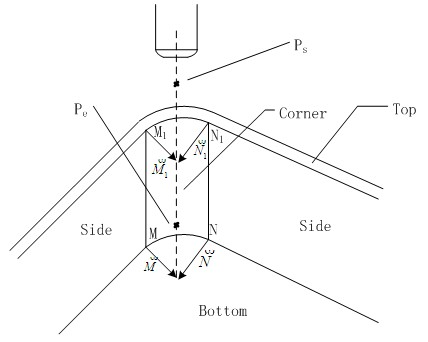

[0051] The processing feature involved in the invention is the cavity corner of the aircraft structure. Input the structural part model into the system to preprocess the parts. The input of part feature information can be automatically read into the feature information list of the part, or by manually selecting the feature of the part to obtain the driving geometry related to the corner. The relevant driving geometry of the plunge milling corner includes the corner surface, the side surface connected to the corner surface, the top surface, the web surface, such as figure 2 shown.

[0052] Input the plunge milling processing information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com