Patents

Literature

343 results about "Post processor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Post Processor is a unique "driver" specific to a CNC machine, robot or mechanism; some machines start at different locations or require extra movement between each operation, the Post-Processor works with the CAM software or off-line programming software to make sure the G-Code output or program is correct for a specific Trademark machine Control Cabinet (Fanuc, Siemens-Sinumeric, Mazak-Mazatrol, Heidenhein, Deckel-Maho, etc. ) CAM software uses geometry from a CAD model and converts it to G-code. The CAM software analyzes the CAD model, determines what tooling and toolpaths will be used to mill the desired features. Doing so requires a CAM post processor that generates the exact G-code dialect used by the machine Control Module (Sinumeric, Fanuc, Mazatrol, Heidenhein, Toshiba etc) that is being targeted. An instance of such a translation is often referred to as a "post". There will be a different “post” for each G-code dialect the CAM software supports. Post Processors (usually do not convert g-code from one dialect to the next), rather the “post” uses an intermediate format that captures the G-code commands in a dialect-independent form. Most CAM software accomplishes this with an intermediate format called "CL.Data."

Providing clients with services that retrieve data from data sources that do not necessarily support the format required by the clients

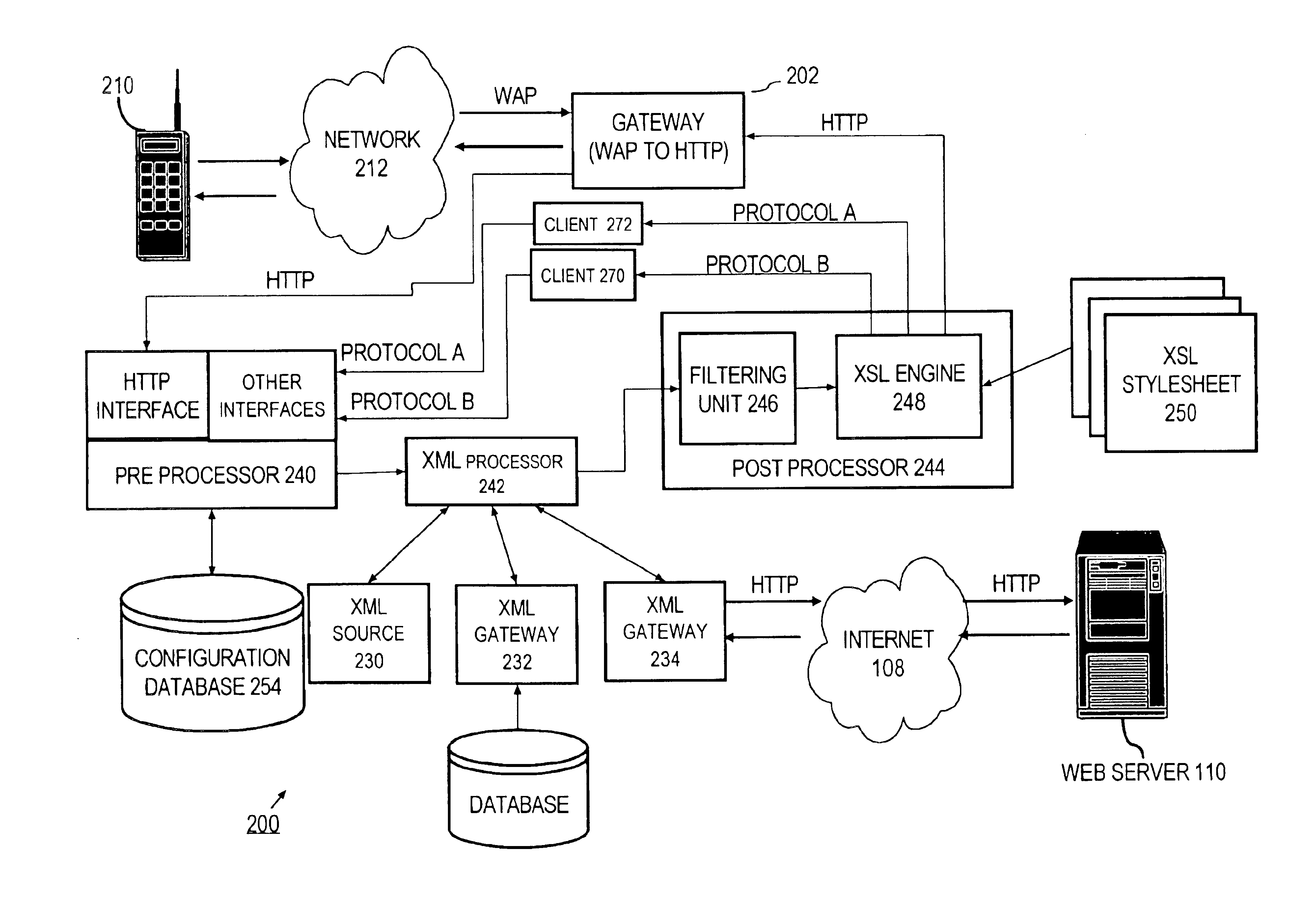

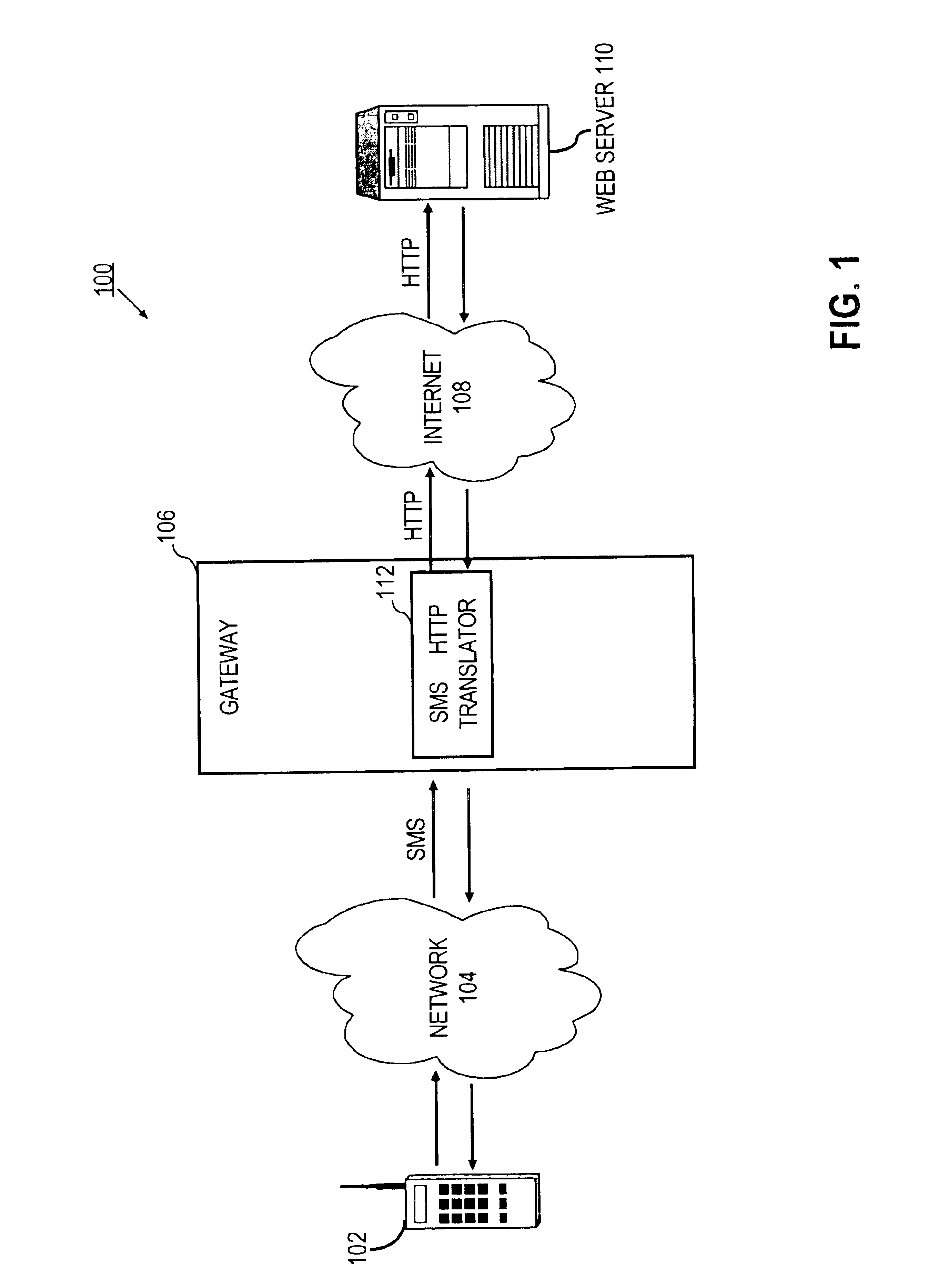

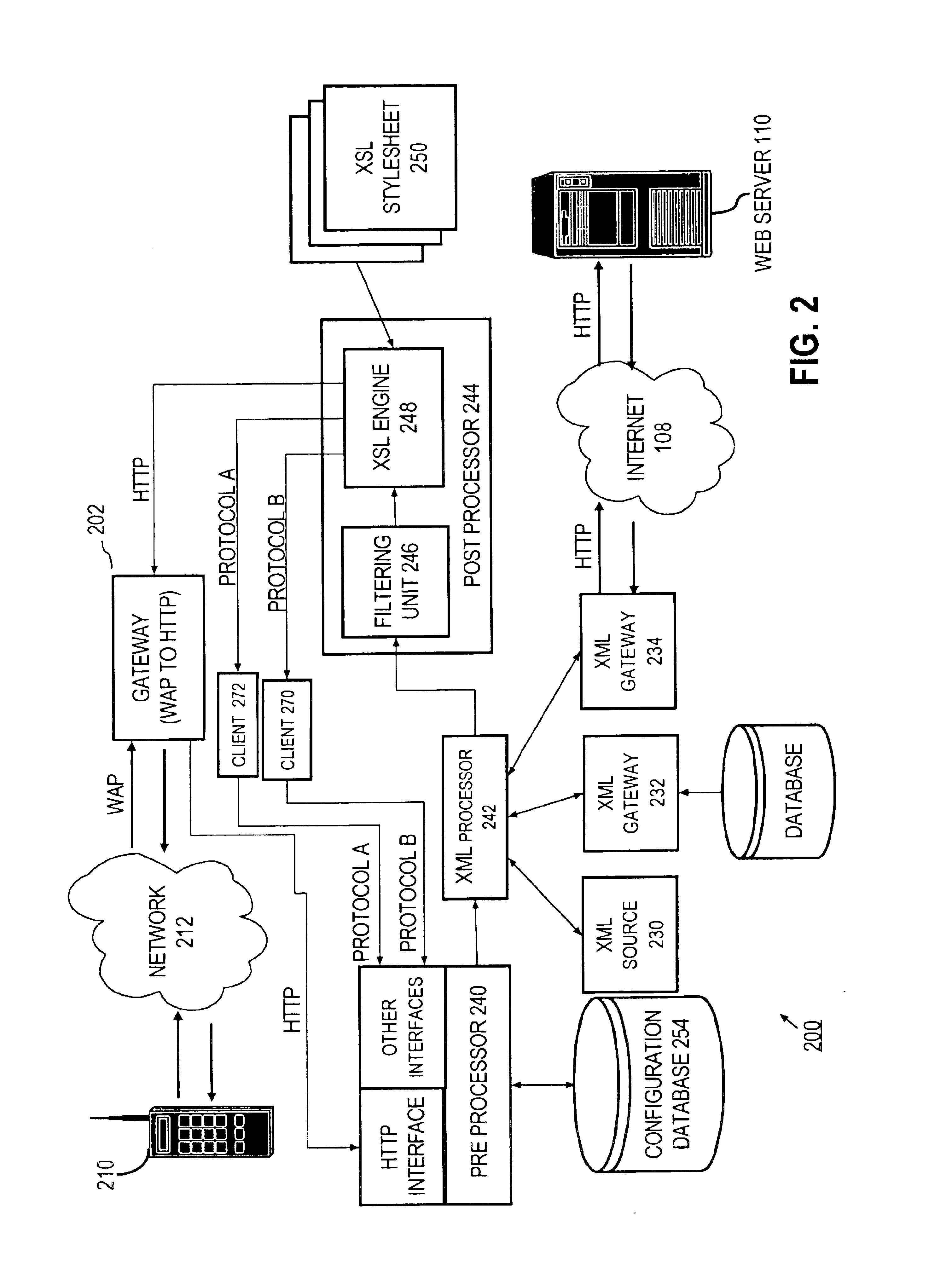

InactiveUS6826597B1Data processing applicationsDigital data information retrievalPost processorData source

A method and system for allowing clients to retrieve data from data sources that do not necessarily support the same protocols and formats as the clients. The clients issue service requests. A pre-processor responds to the requests by generating XML-structured request objects with unresolved links to the data sources that have information required by the clients. An XML processor resolves the links by issuing requests through one or more gateways. The gateways convert the responses received from the data sources into XML, which the XML processor uses to create XML composite response documents. A post-processor filters the XML response documents, and applies XSL stylesheets to transform the XML composite response documents into client-specific responses that conform to the format required by the clients. The client-specific responses are then sent to the clients.

Owner:ORACLE INT CORP

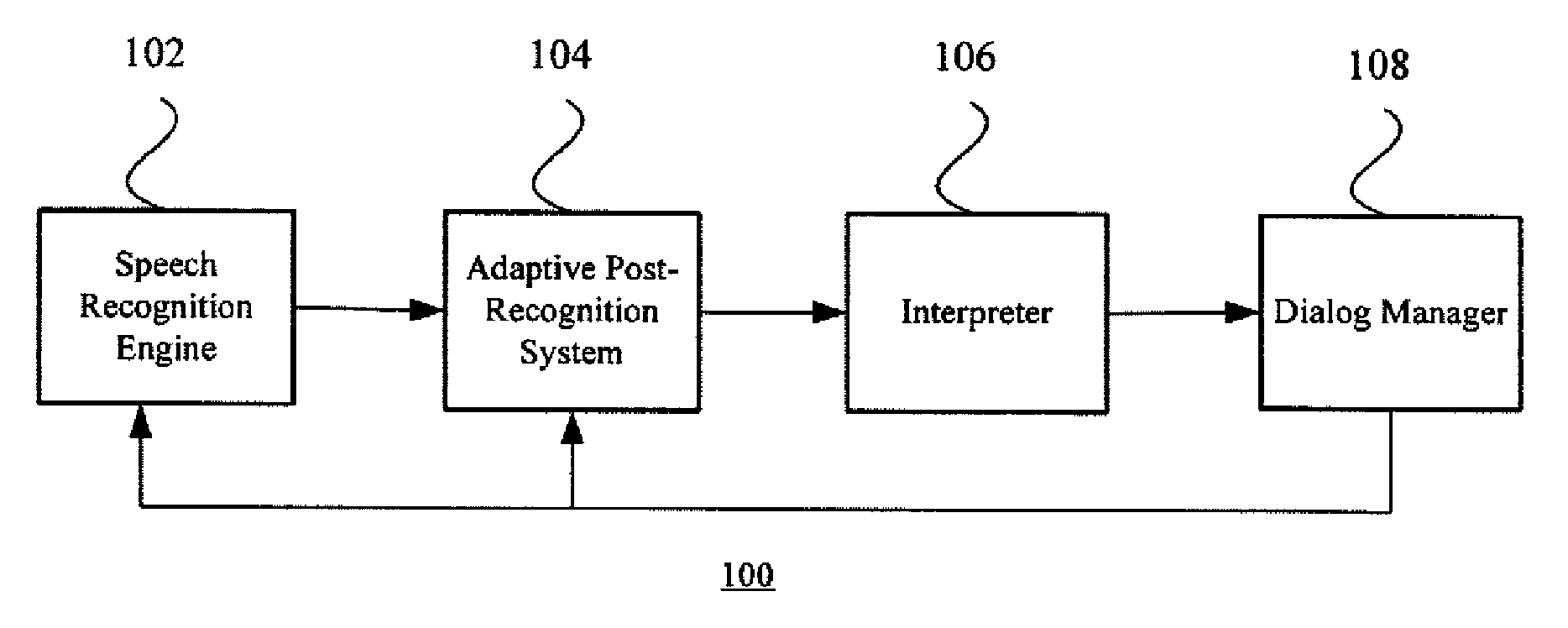

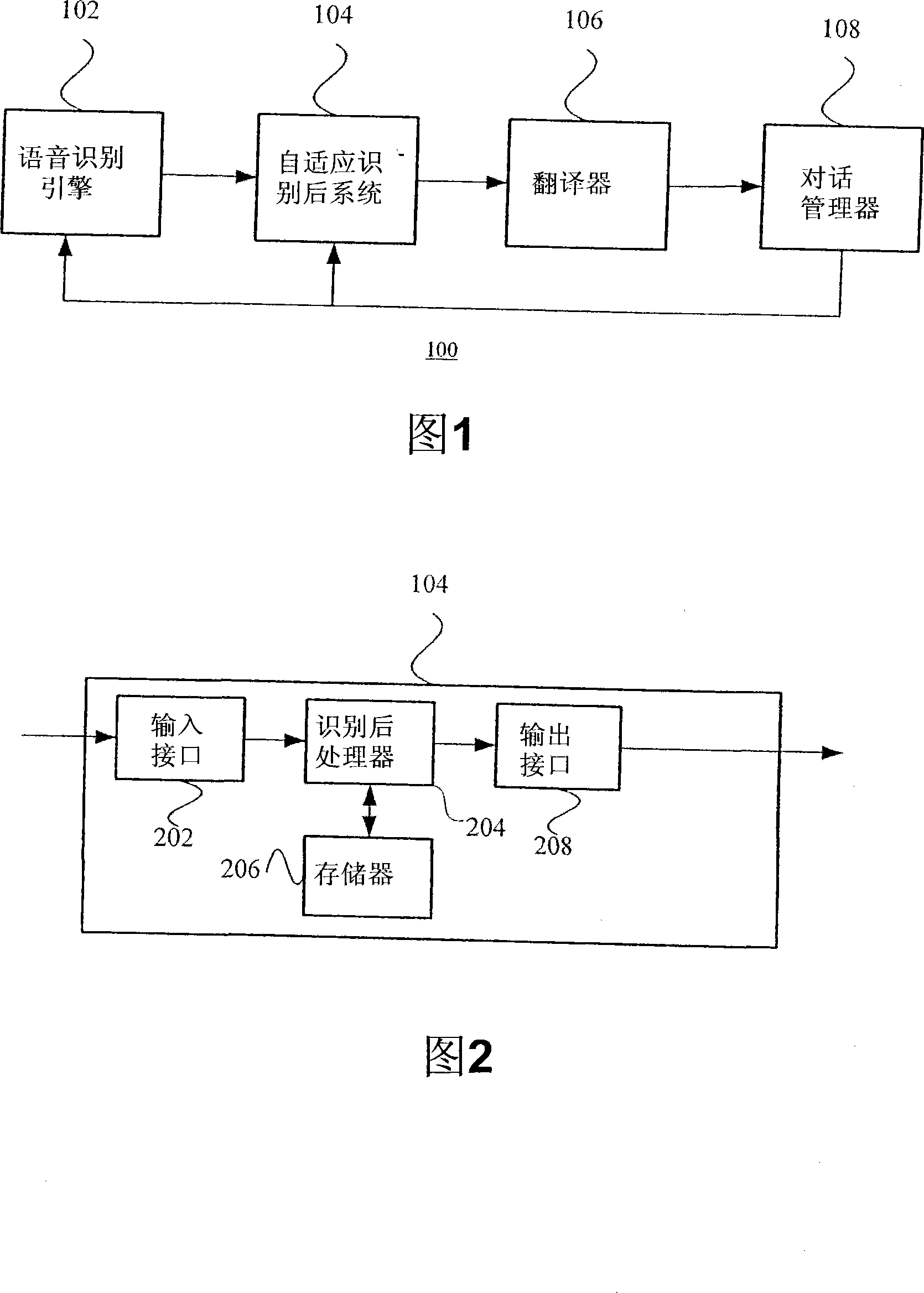

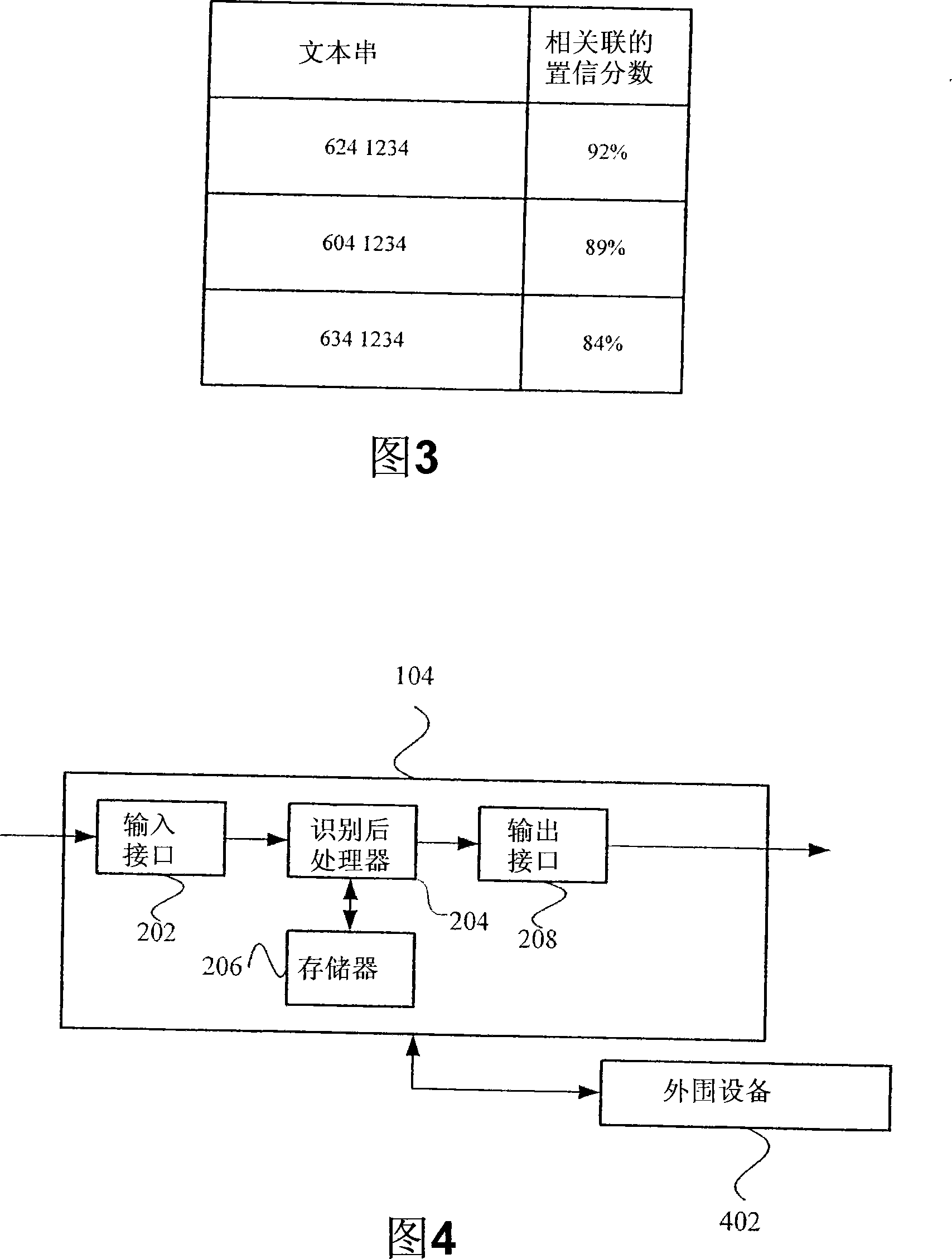

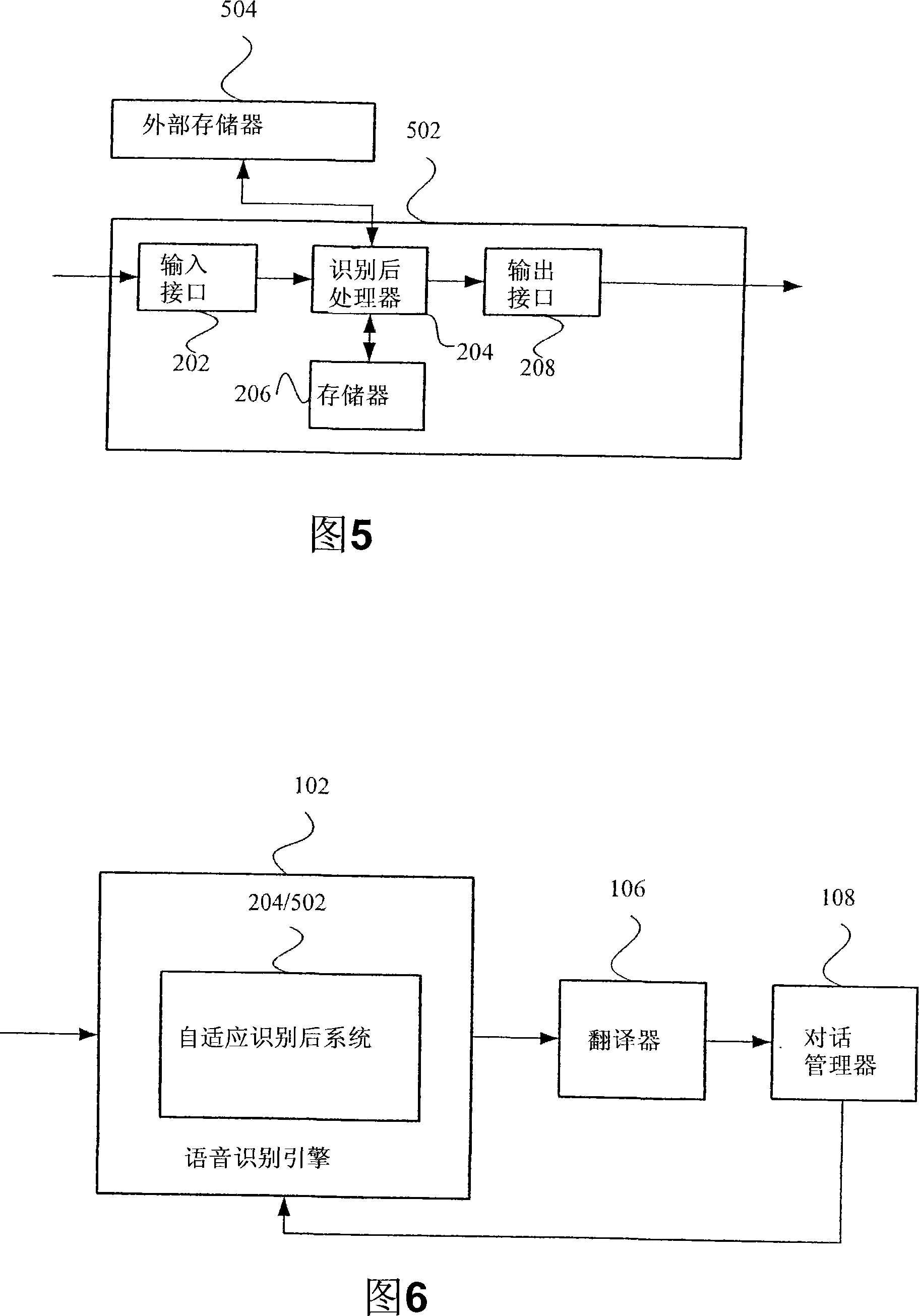

Adaptive context for automatic speech recognition systems

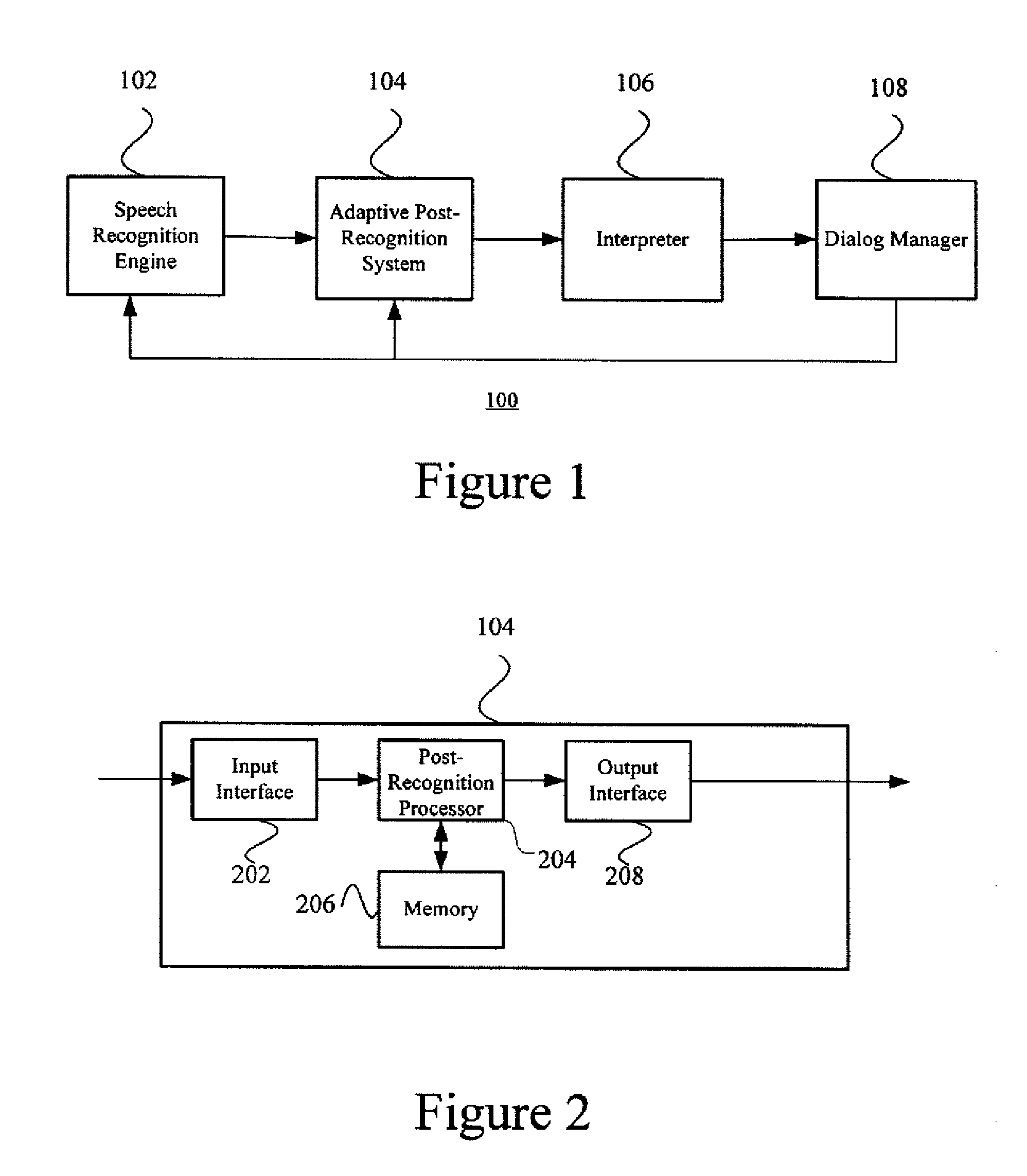

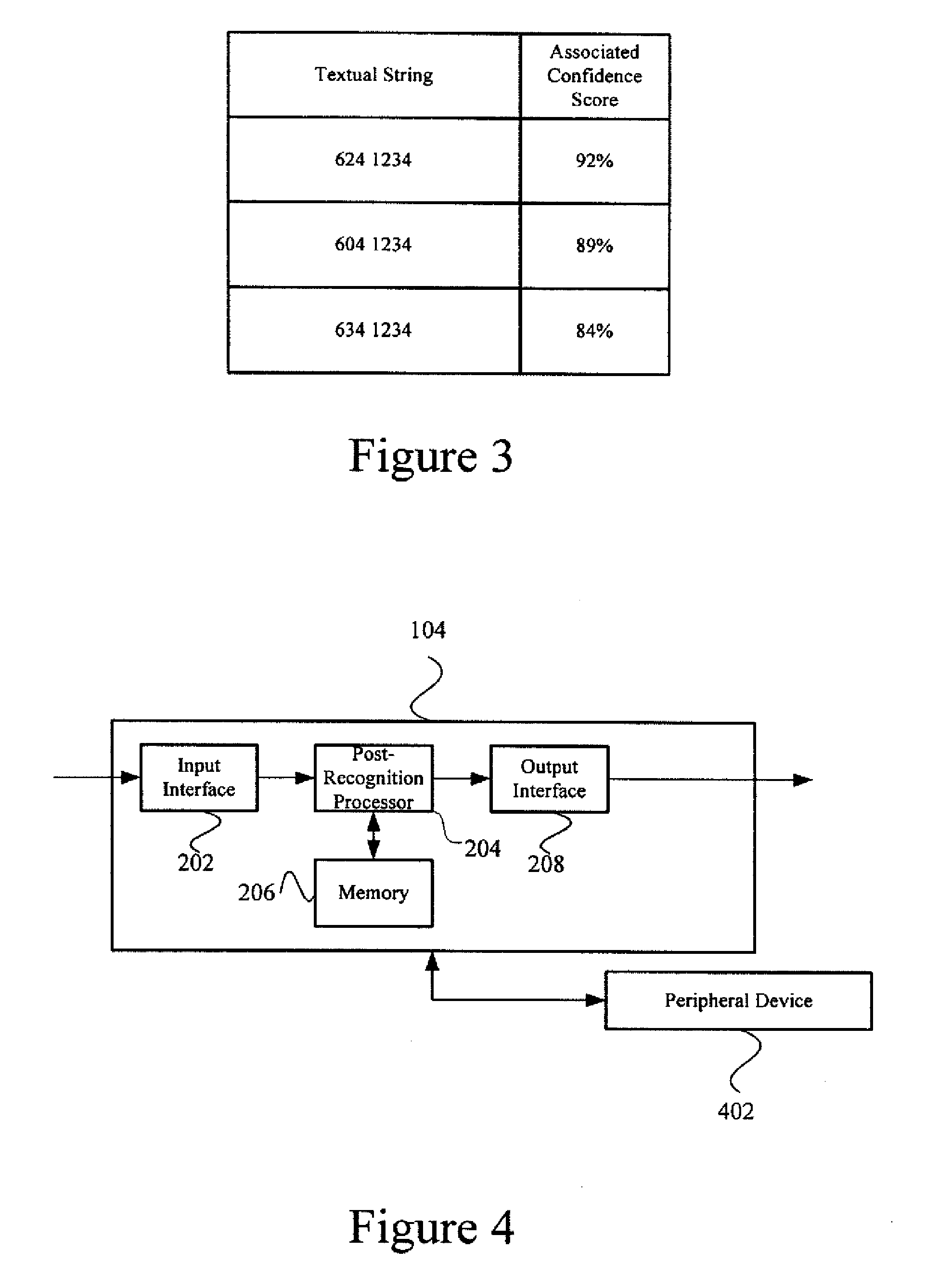

A system improves speech recognition includes an interface linked to a speech recognition engine. A post-recognition processor coupled to the interface compares recognized speech data generated by the speech recognition engine to contextual information retained in a memory, generates a modified recognized speech data, and transmits the modified recognized speech data to a parsing component.

Owner:NUANCE COMM INC +1

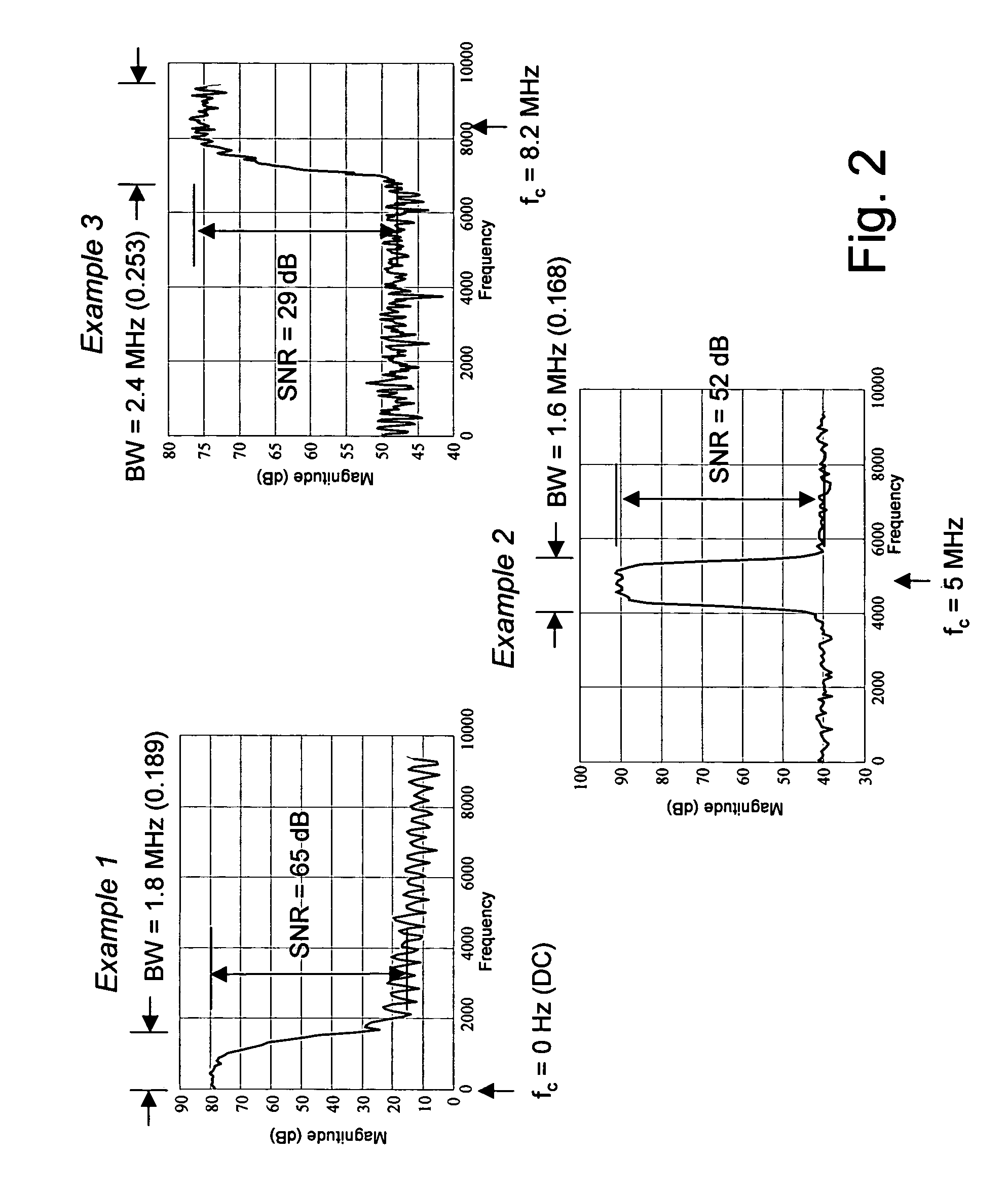

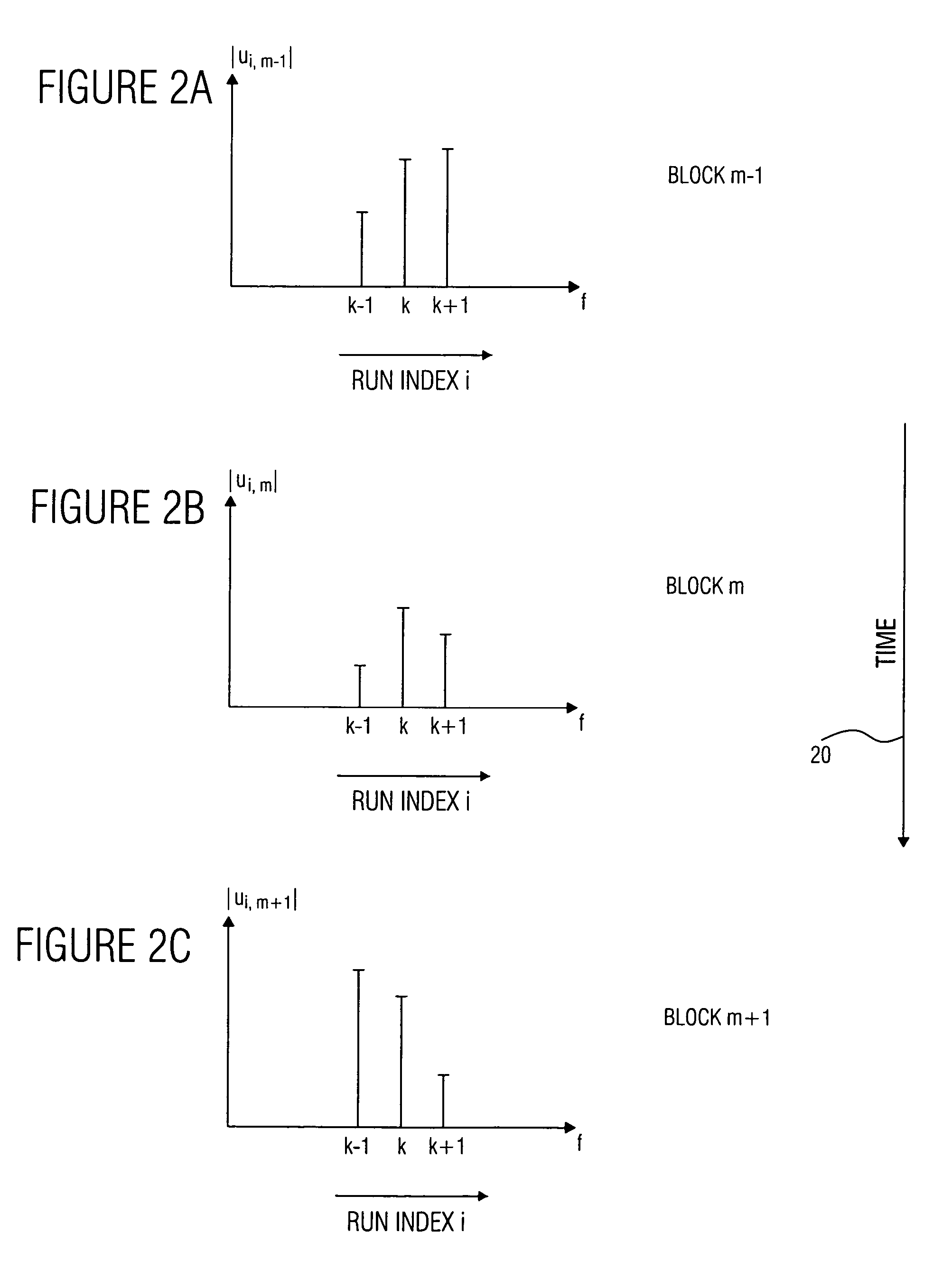

Adaptive compression and decompression of bandlimited signals

InactiveUS7009533B1Less bandwidthLess storageCode conversionPictoral communicationAdaptive compressionSpectrum analyzer

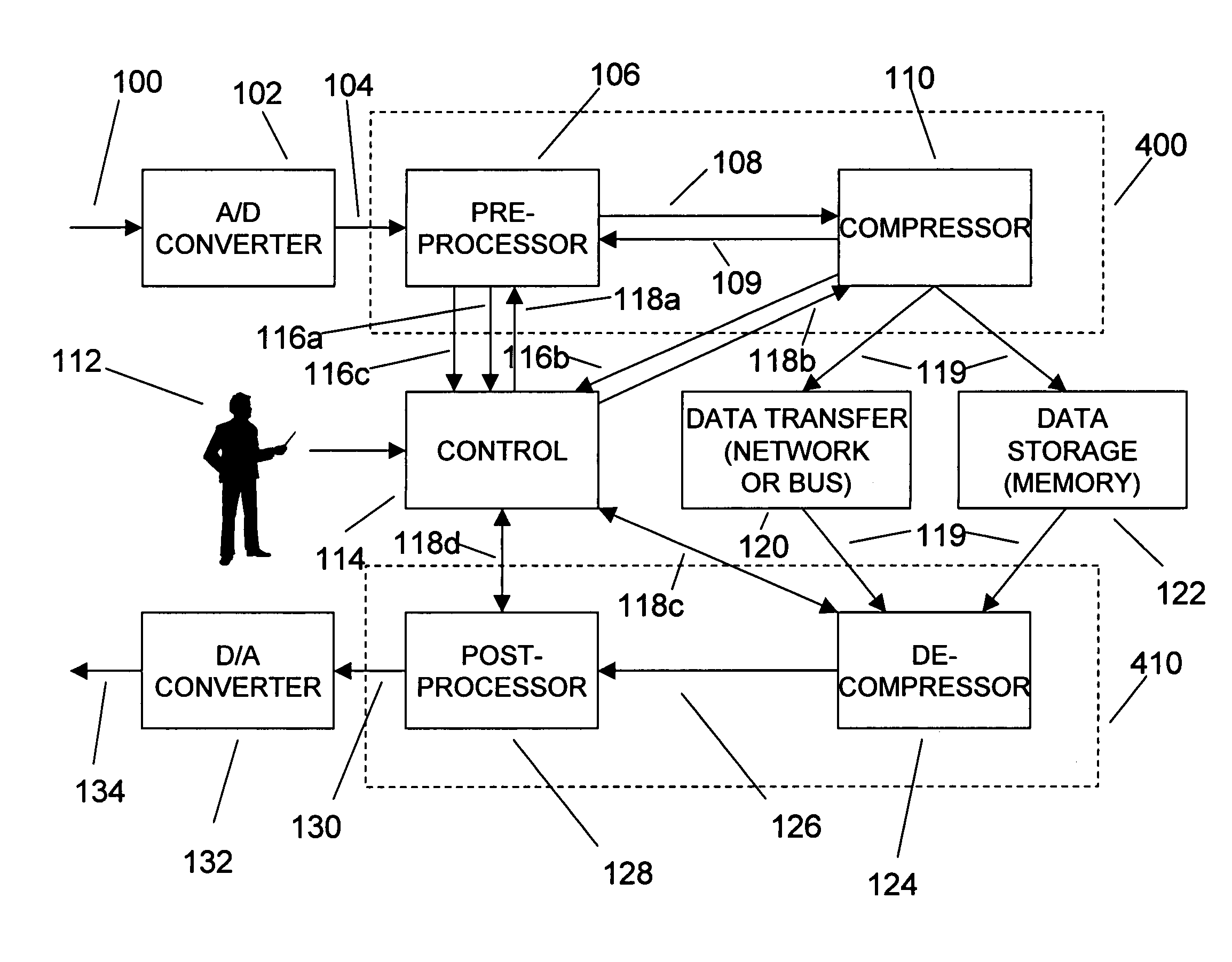

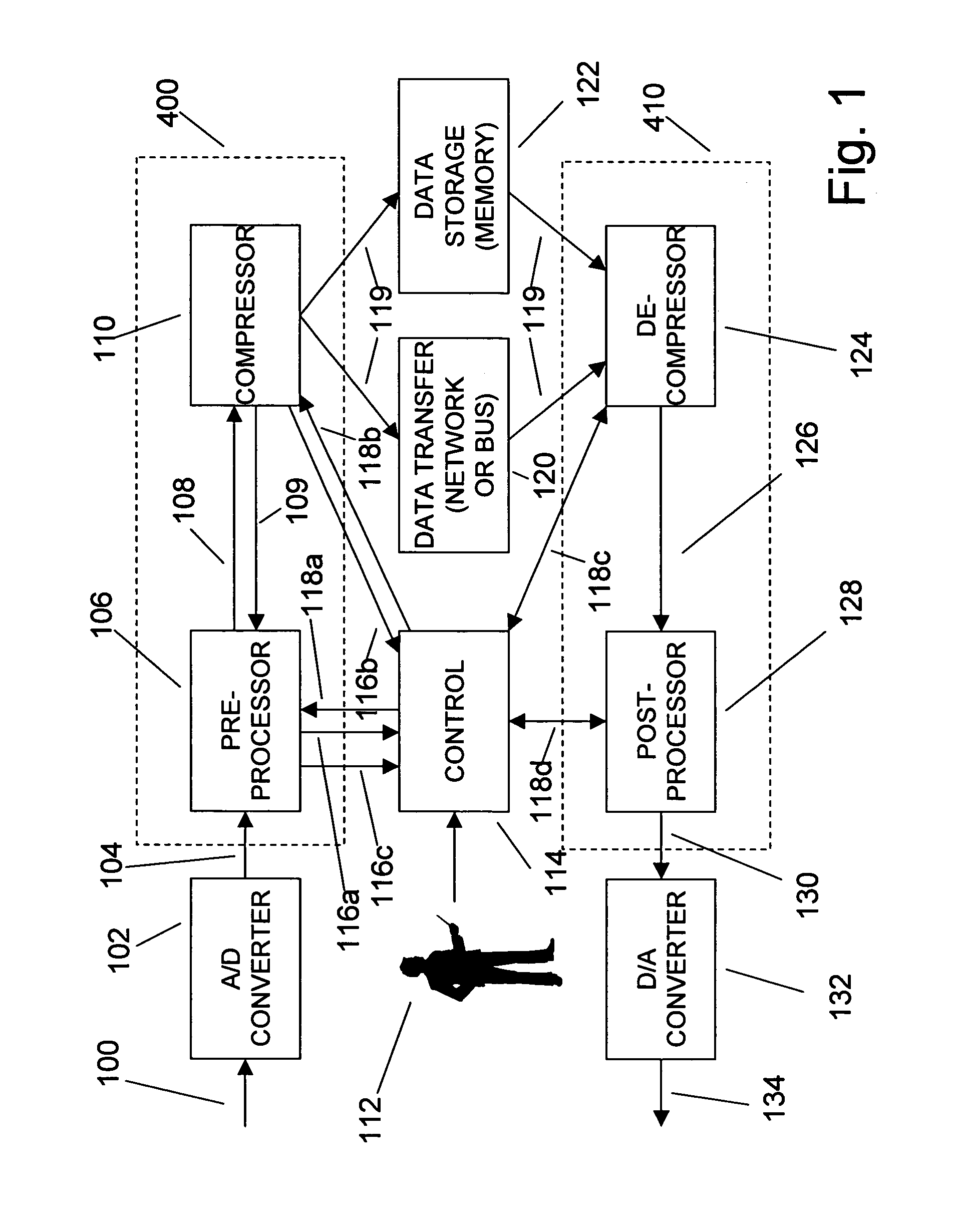

An efficient method for compressing sampled analog signals in real time, without loss, or at a user-specified rate or distortion level, is described. The present invention is particularly effective for compressing and decompressing high-speed, bandlimited analog signals that are not appropriately or effectively compressed by prior art speech, audio, image, and video compression algorithms due to various limitations of such prior art compression solutions. The present invention's preprocessor apparatus measures one or more signal parameters and, under program control, appropriately modifies the preprocessor input signal to create one or more preprocessor output signals that are more effectively compressed by a follow-on compressor. In many instances, the follow-on compressor operates most effectively when its input signal is at baseband. The compressor creates a stream of compressed data tokens and compression control parameters that represent the original sampled input signal using fewer bits. The decompression subsystem uses a decompressor to decompress the stream of compressed data tokens and compression control parameters. After decompression, the decompressor output signal is processed by a post-processor, which reverses the operations of the preprocessor during compression, generating a postprocessed signal that exactly matches (during lossless compression) or approximates (during lossy compression) the original sampled input signal. Parallel processing implementations of both the compression and decompression subsystems are described that can operate at higher sampling rates when compared to the sampling rates of a single compression or decompression subsystem. In addition to providing the benefits of real-time compression and decompression to a new, general class of sampled data users who previously could not obtain benefits from compression, the present invention also enhances the performance of test and measurement equipment (oscilloscopes, signal generators, spectrum analyzers, logic analyzers, etc.), busses and networks carrying sampled data, and data converters (A / D and D / A converters).

Owner:TAHOE RES LTD

Adaptive context for automatic speech recognition systems

Owner:QNX SOFTWARE SYST (WAVEMAKERS) INC (CA) +1

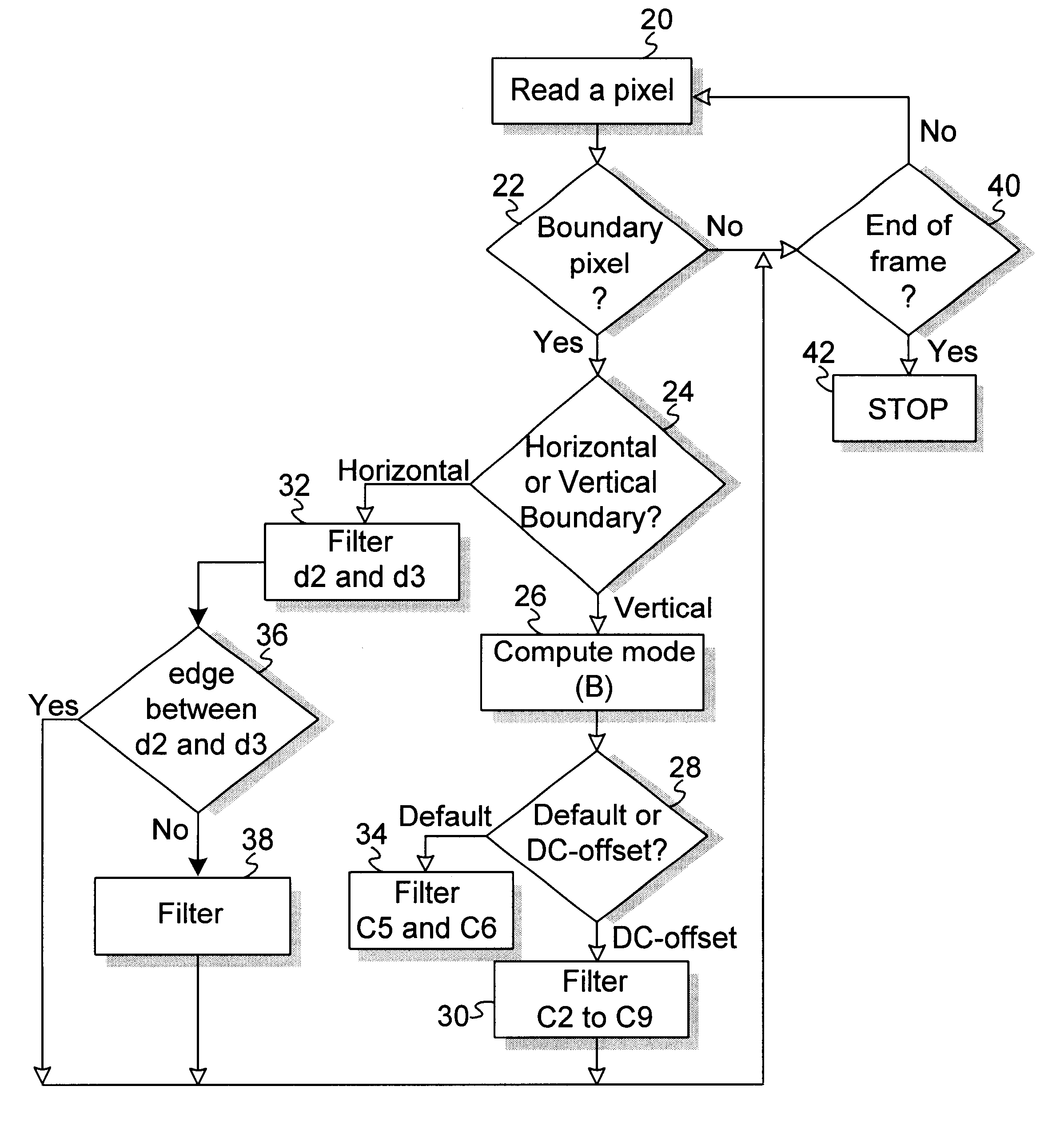

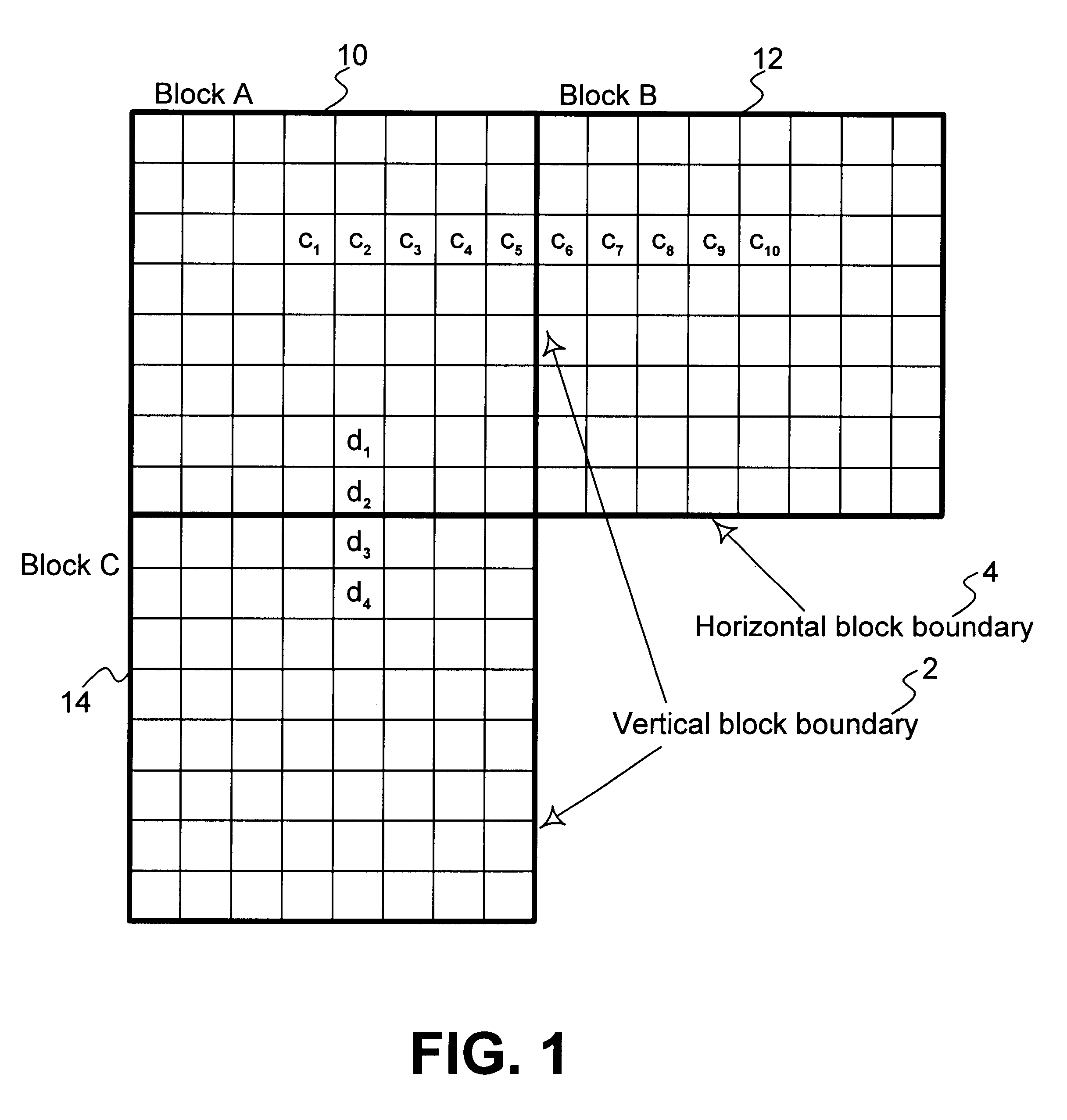

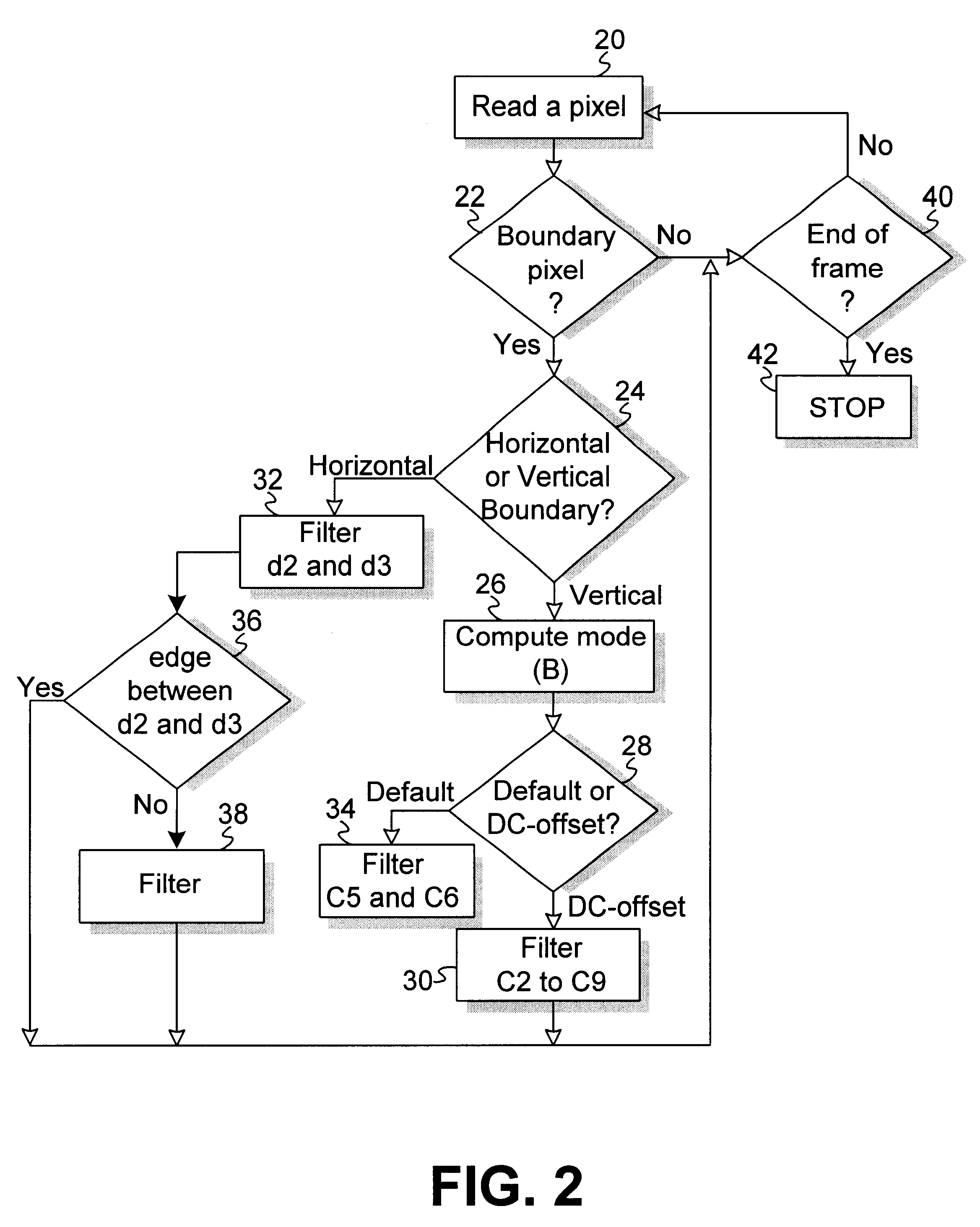

Postprocessing system for removing blocking artifacts in block-based codecs

InactiveUS6320905B1Color television with pulse code modulationColor television with bandwidth reductionPost processorImage edge

Video signal post-processor de-blocks signal by processing block edges, particularly vertical and / or horizontal neighboring pixels. Depending on boundary condition, received signal is filtered using smoothing LPF function. Low-memory post-processor system neither requires DCT block characteristics nor blurs image edges close to block boundary.

Owner:INTEGRATED DEVICE TECH INC

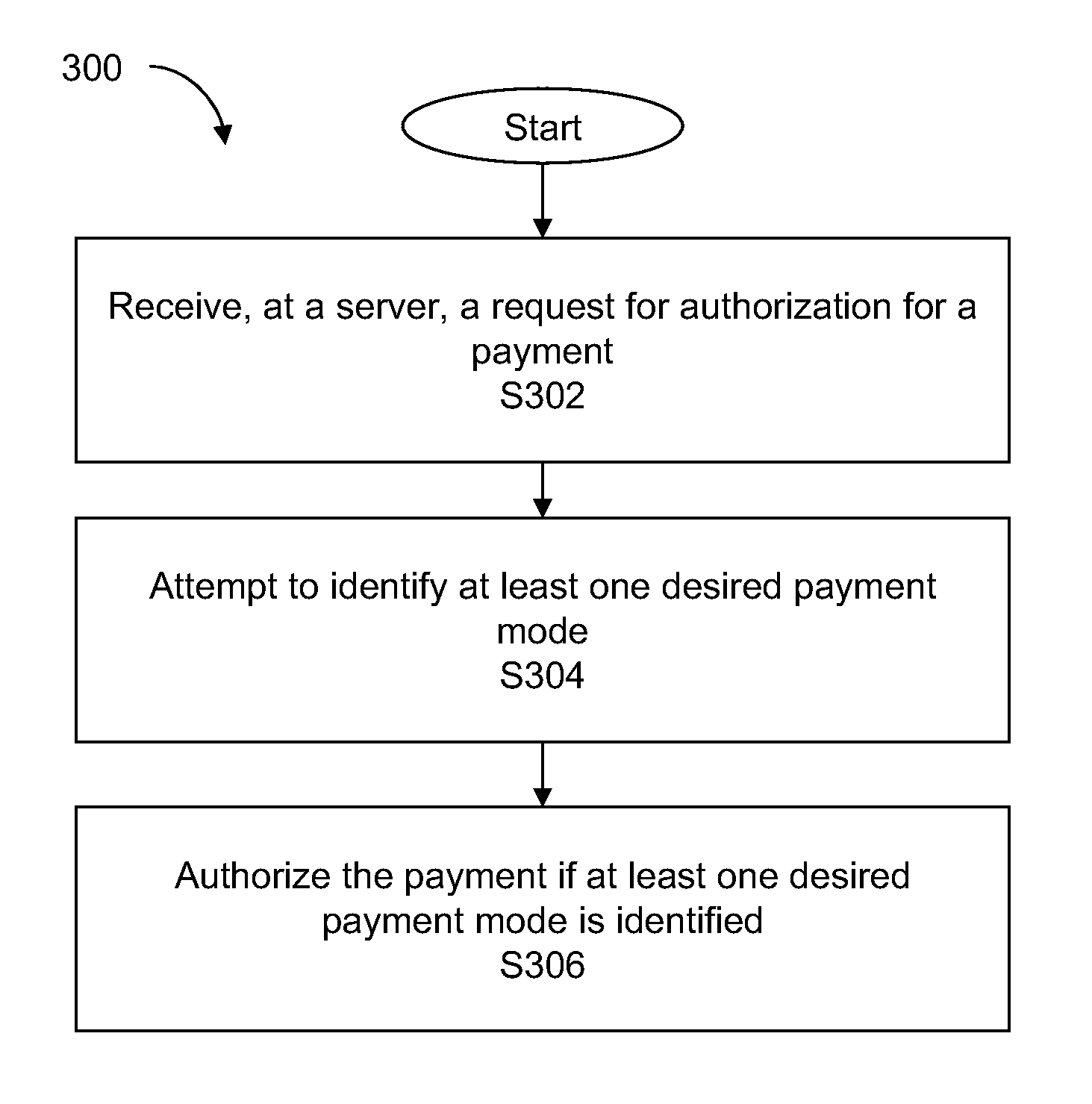

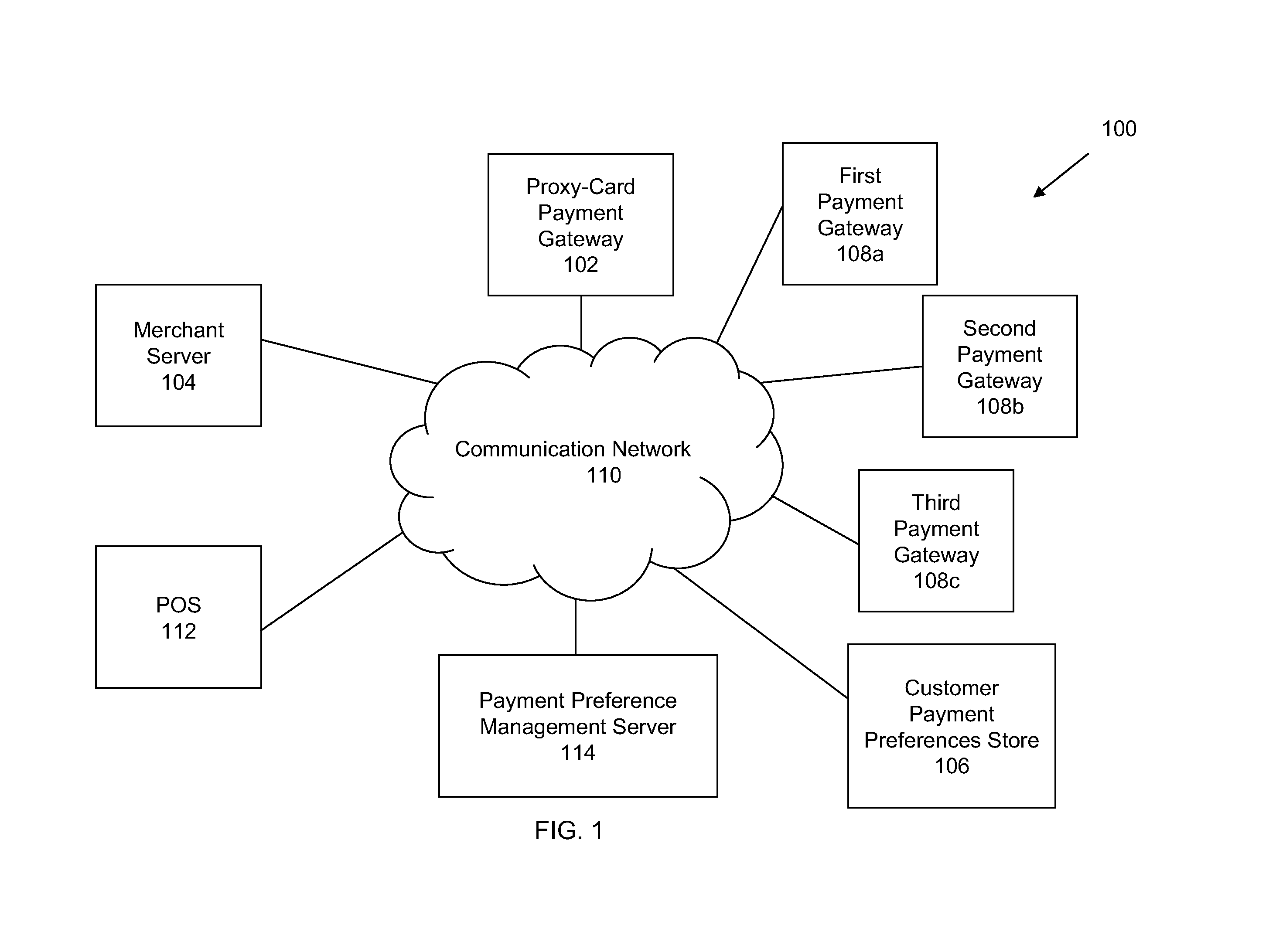

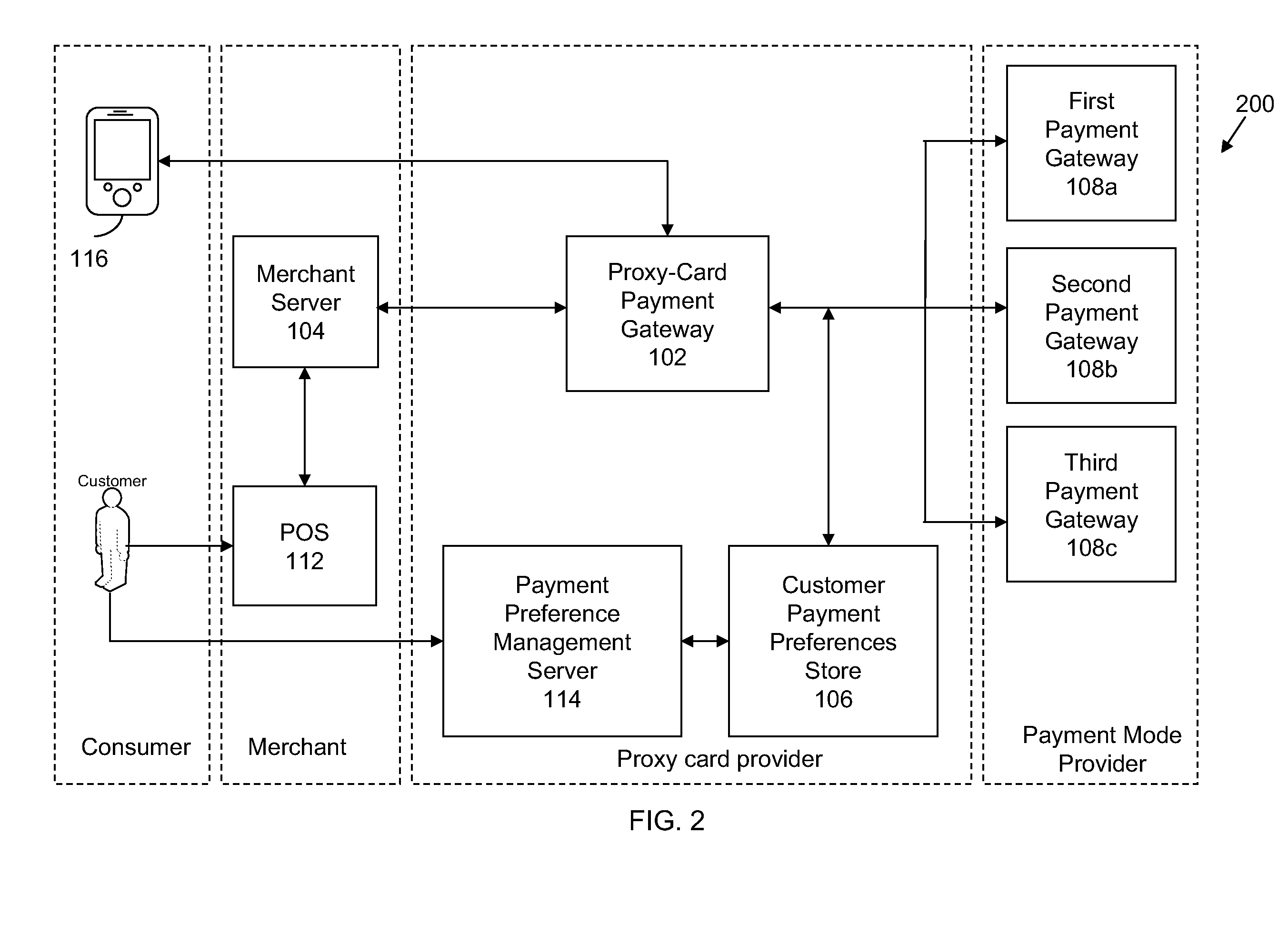

Systems, methods, and computer products for processing payments using a proxy card

Systems, methods and computer program products for processing payments for a proxy card are provided. Embodiments of the system include a processor, and a memory in communication with the processor. The memory may be configured to store processing instructions for directing the processor to receive a request for authorization of a payment. In various embodiments, the request is triggered at a merchant server, by the use of a proxy card of the customer. The processor attempts to identify at least one desired payment mode for making the payment, from among payment mode(s) associated with the proxy card. The processor first selects the payment modes based at least in part on one or more selection criteria, such as predefined customer goals, and then the processor performs an authorization check to identify the desired payment modes. Subsequently, the processor authorizes the payment if at least one desired payment mode is identified.

Owner:LIBERTY PEAK VENTURES LLC

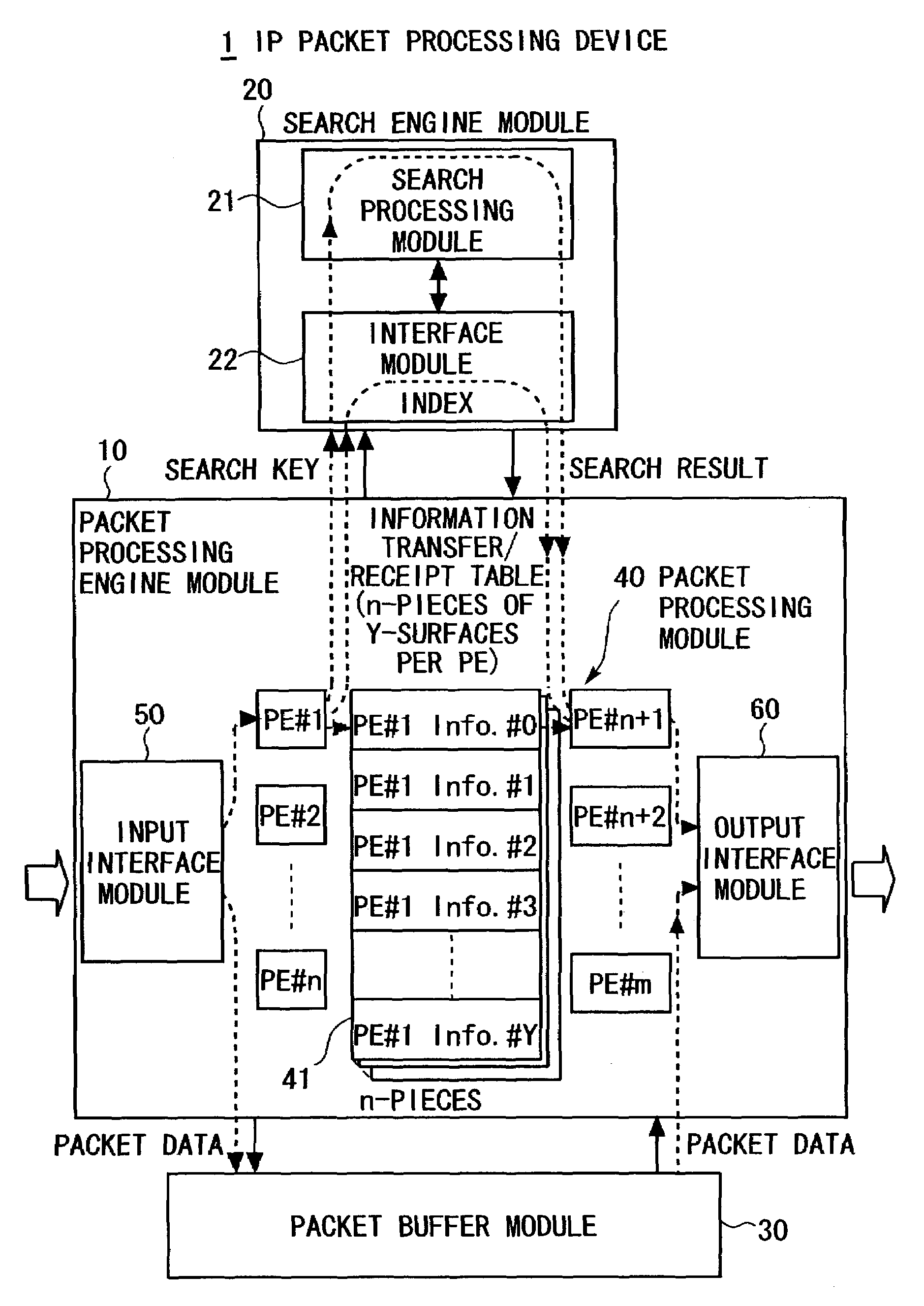

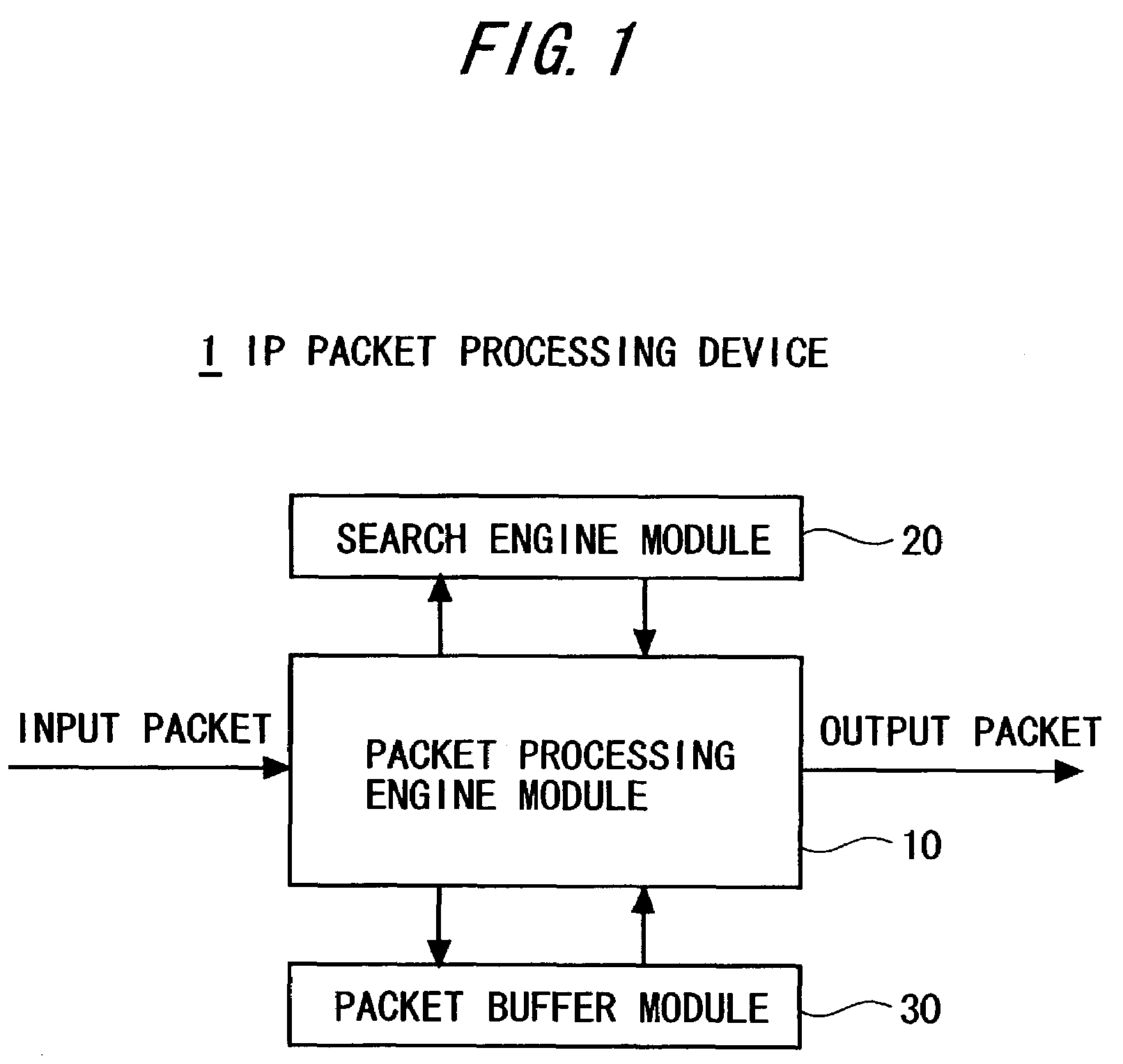

Packet processing device

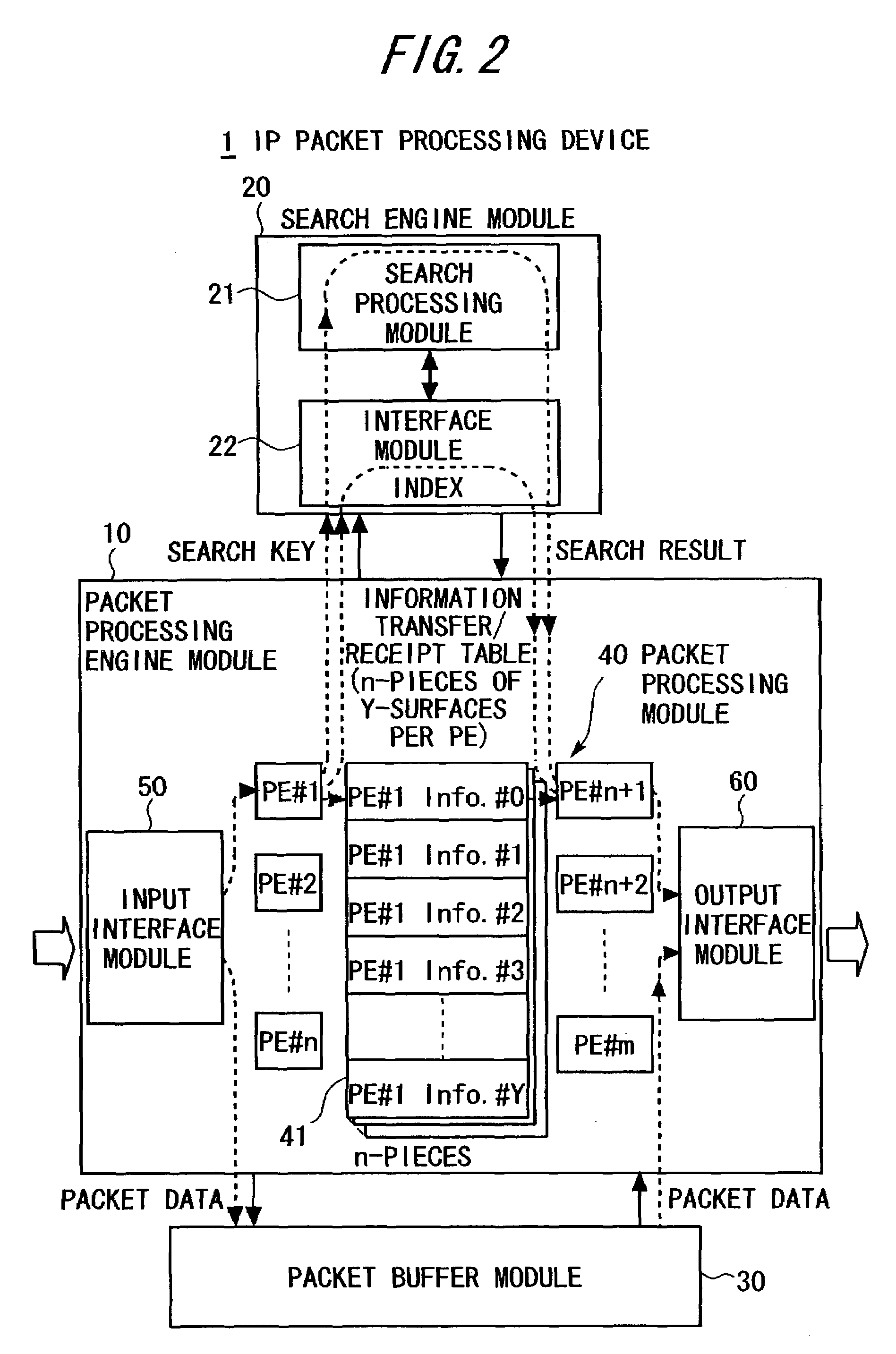

InactiveUS7313142B2Improve throughputAvoid timeData switching by path configurationStore-and-forward switching systemsPost processorPacket processing

A packet processing device has a search engine module including an associative memory for transferring a packet on the basis of an entry mapping to route information, a first processor taking charge of a pre-search process before a process of the packet to the search engine module, and a second processor taking charge of a post-search process for executing a process of routing the packet on the basis of a search result of the search engine module. In this architecture, the packet processing device further has a table used for transferring and receiving information between the first processor in charge of the pre-search process and the second processor in charge of the post-search processor, and identifying information in a specified field of the table is transferred through the search engine module as a transparent medium.

Owner:FUJITSU LTD

Telephony Device with Improved Noise Suppression

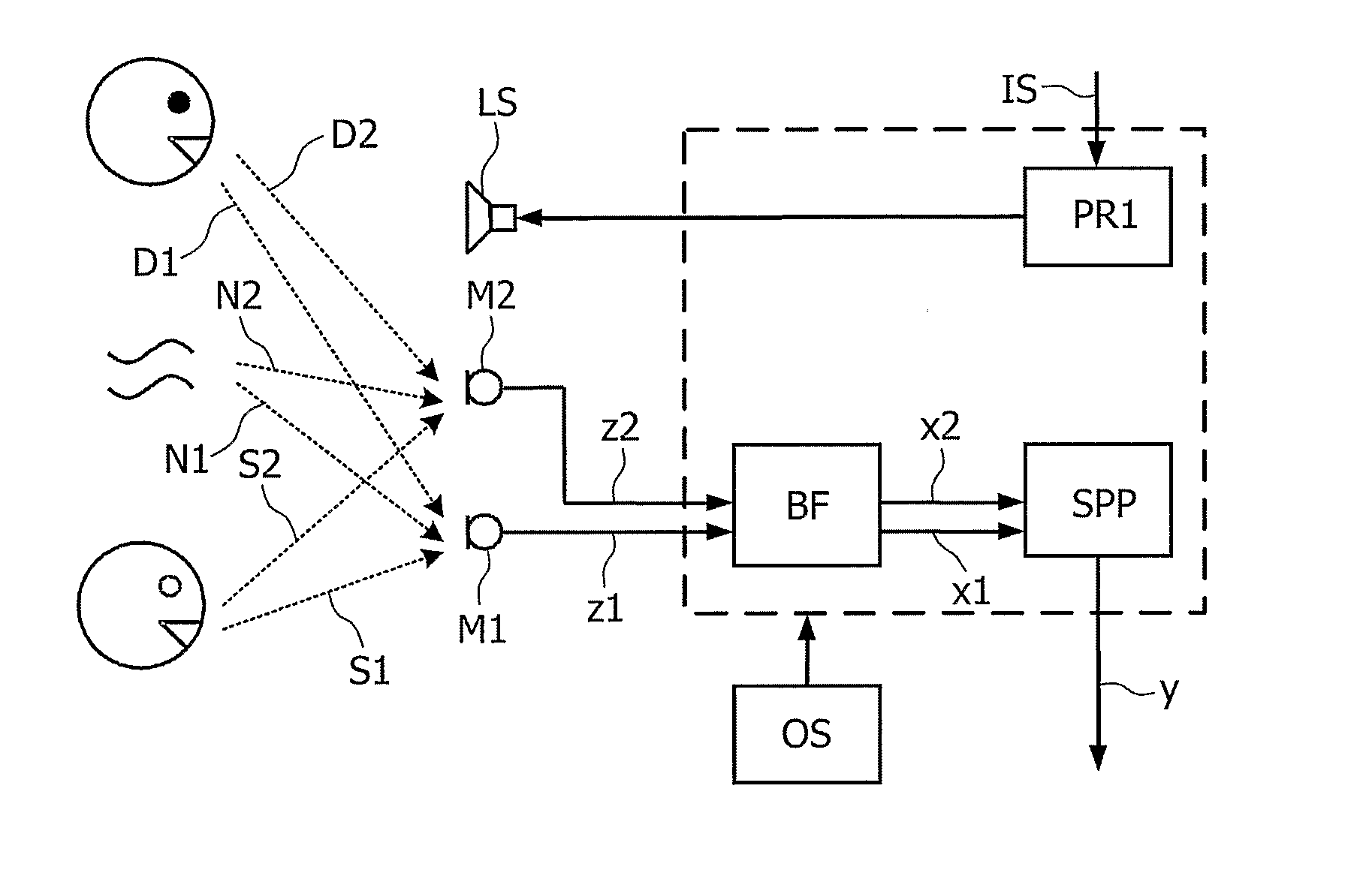

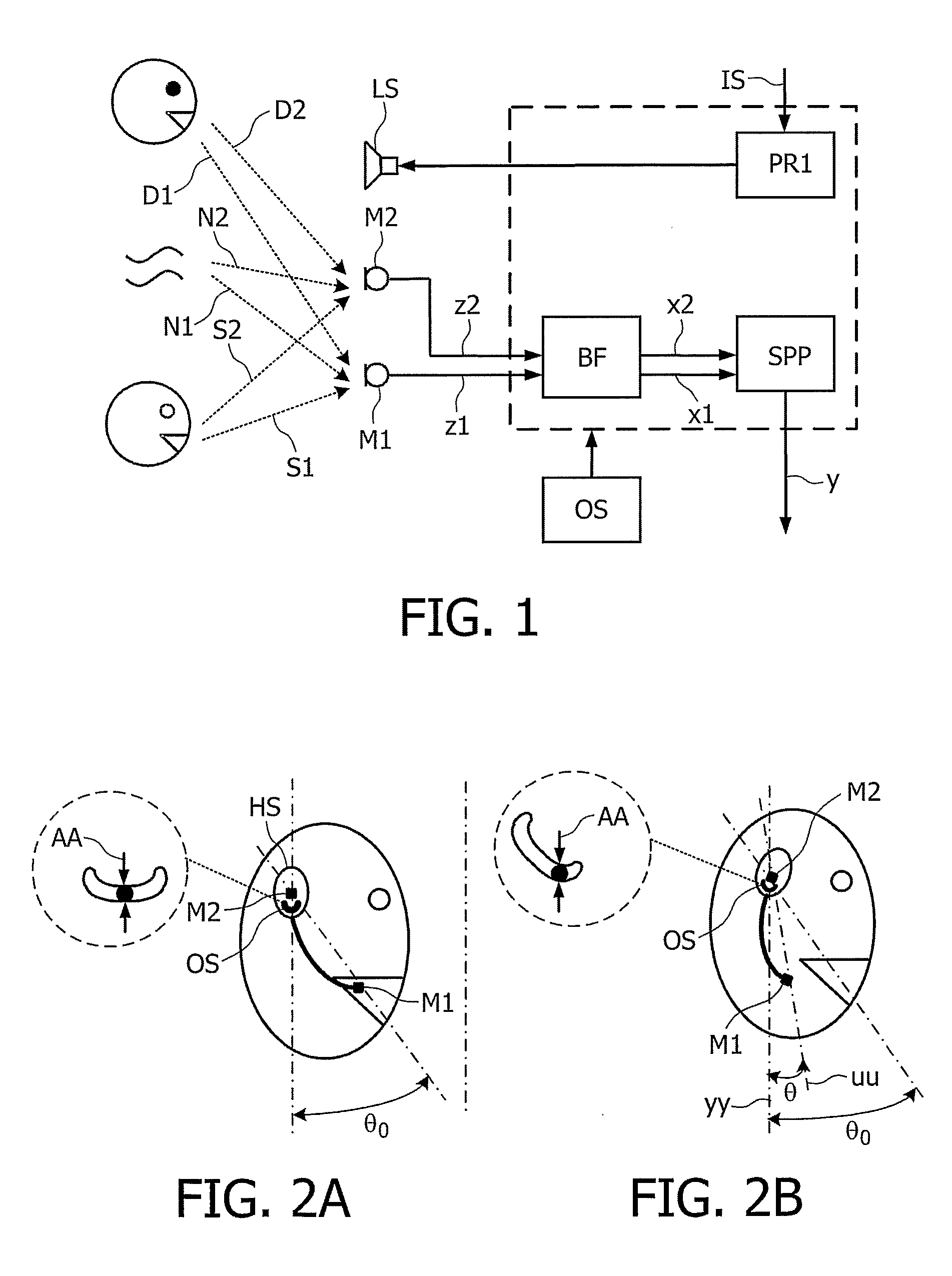

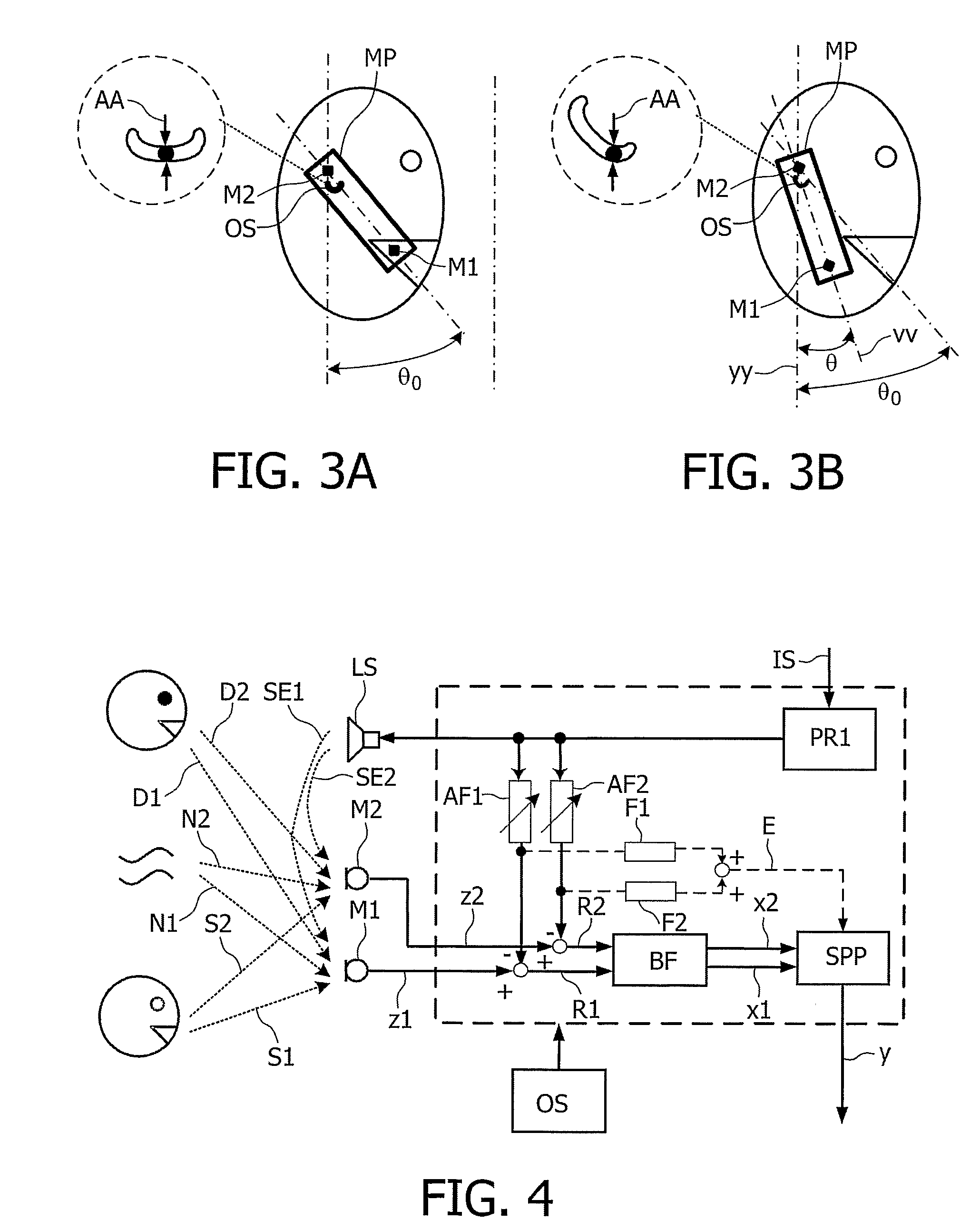

InactiveUS20070230712A1Unwanted noise signalMaximize qualityEar treatmentMicrophone structural associationFrequency spectrumPost processor

The present invention relates to a telephony device comprising a near-mouth microphone (M1) for picking up an input acoustic signal including the speaker's voice signal (S1) and an unwanted noise signal (N1,D1), a far-mouth microphone (M2) for picking up an unwanted noise signal (N2,D2) in addition to the near-end speaker's voice signal (S2), said speaker's voice signal being at a lower level than the near-mouth microphone, and an orientation sensor for measuring an orientation indication of said mobile device. The telephony device further comprises an audio processing unit comprising an adaptive beamformer (BF) coupled to the near-mouth and far-mouth microphones, including spatial filters for spatially filtering the input signals (z1,z2) delivered by the two microphones, and a spectral post-processor (SPP) for post-processing the signal delivered by the beam-former so as to separate the desired voice signal from the unwanted noise signal so as to deliver the output signal (y).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

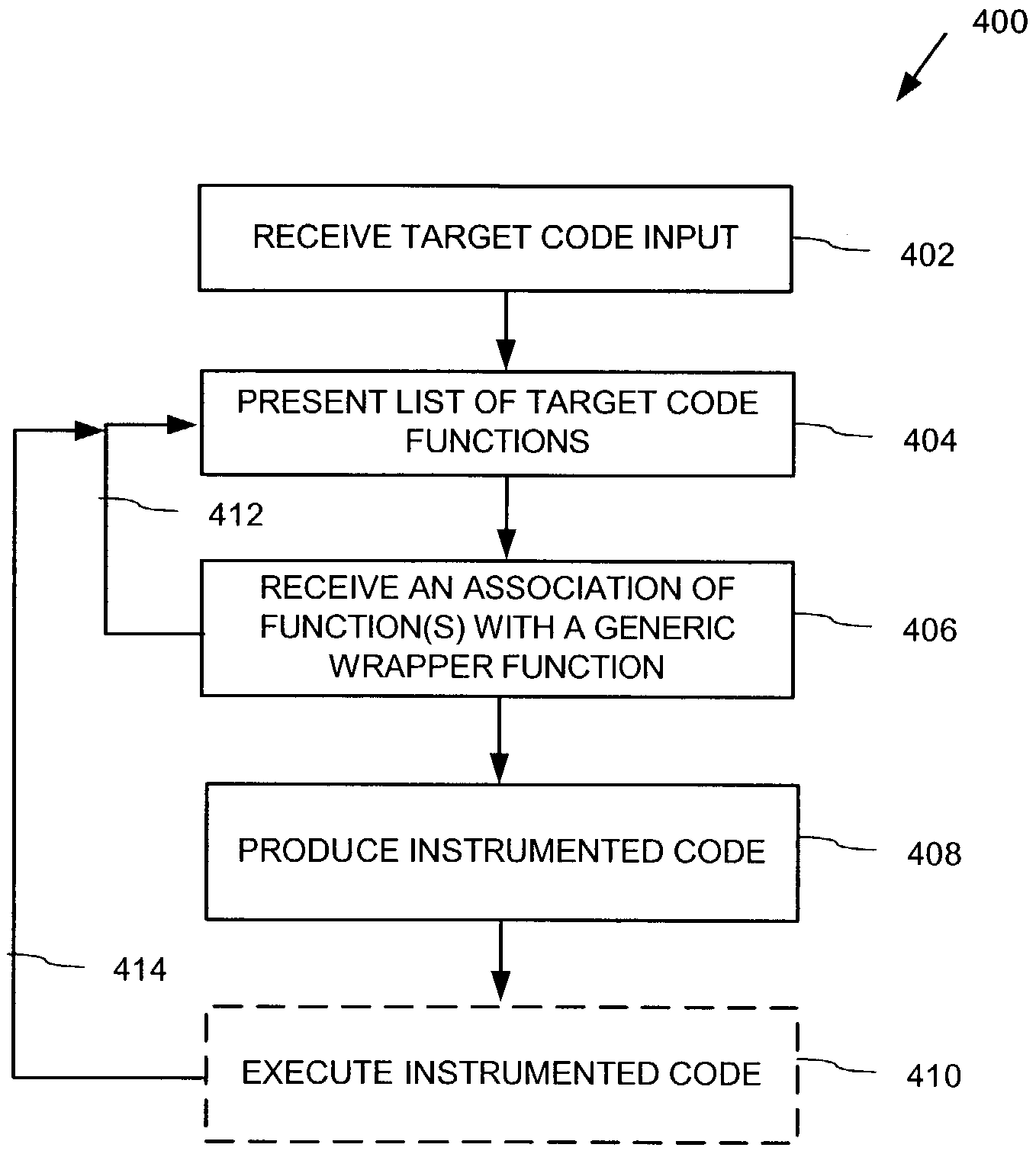

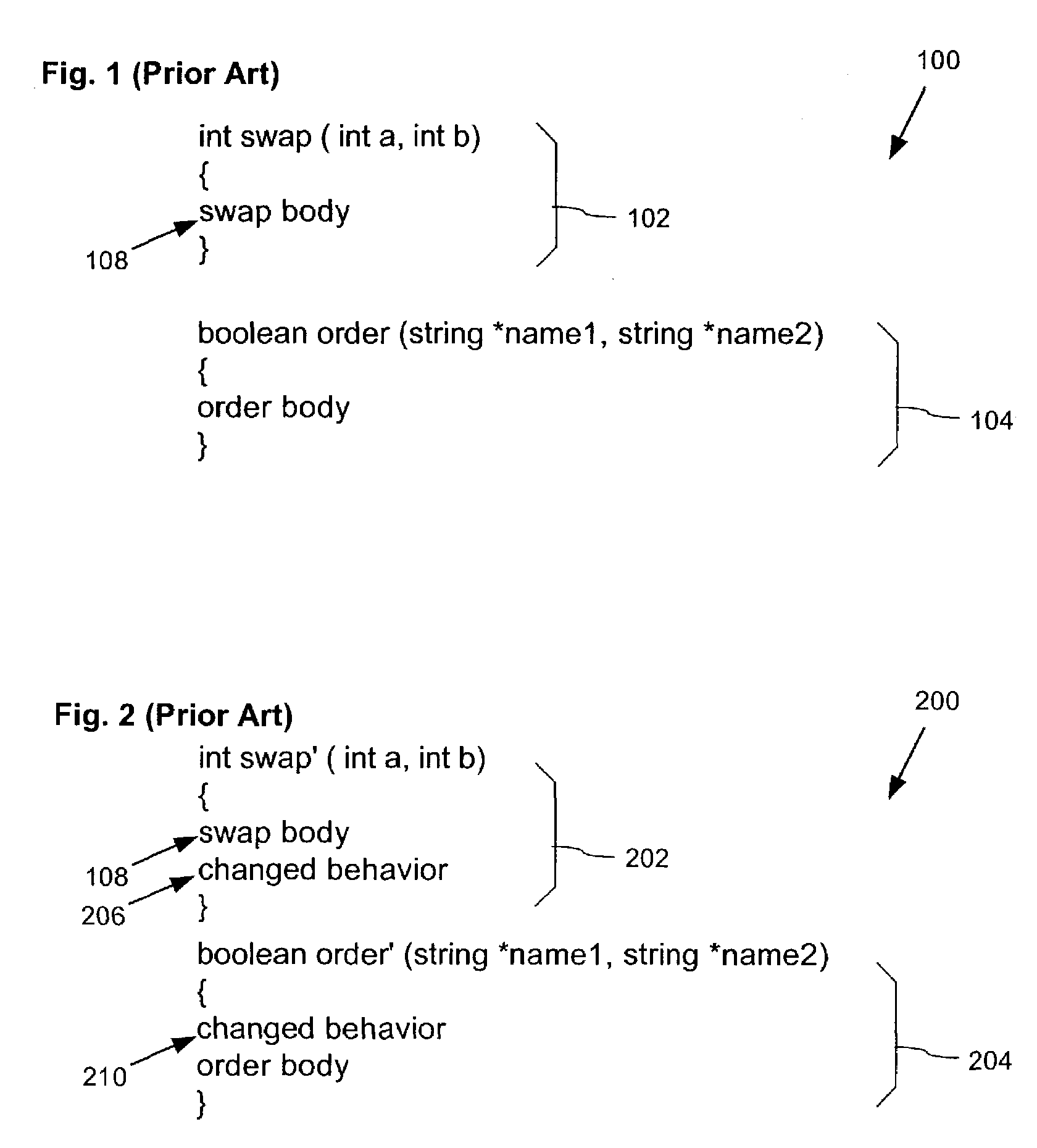

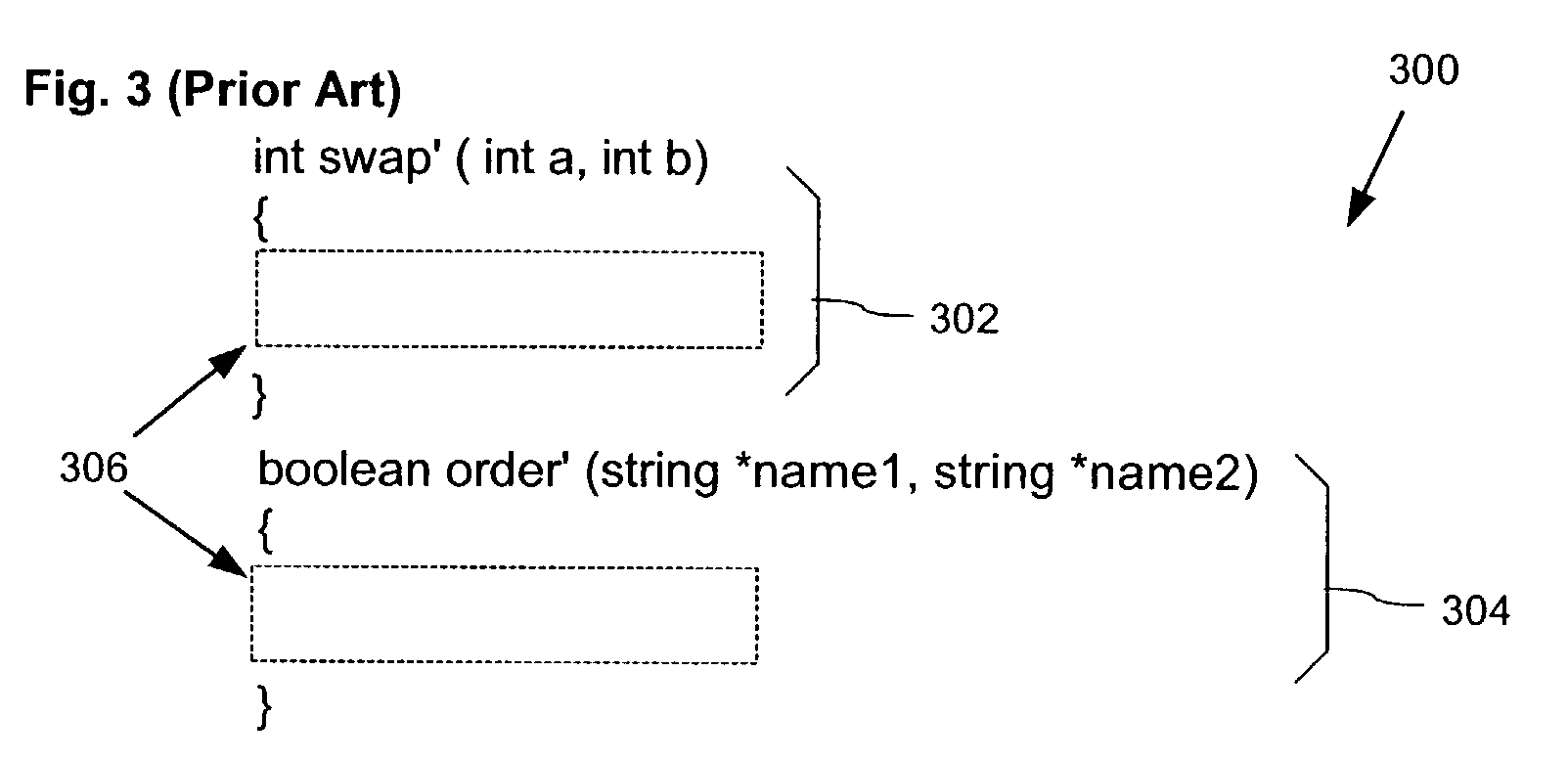

Generic wrapper scheme

InactiveUS7353501B2Improve programming performanceBehavior changeDigital computer detailsSoftware testing/debuggingInstrument functionParallel computing

A method instruments a function in an executable file so that the instrumented function calls a generic preprocessor prior to execution of the body of the function. After the preprocessor modifies the original function's incoming parameters, the body of the function itself is executed. Finally, execution is directed to a generic postprocessor prior to returning from the function. The postprocessor modifies the outgoing parameters and return value. In one implementation, the parameters of an instrumented function are described and packaged into a descriptor data structure. The descriptor data structure is passed to the generic preprocessor and postprocessor. A generic processor uses the descriptor to select changed behaviors based on the calling context.

Owner:MICROSOFT TECH LICENSING LLC

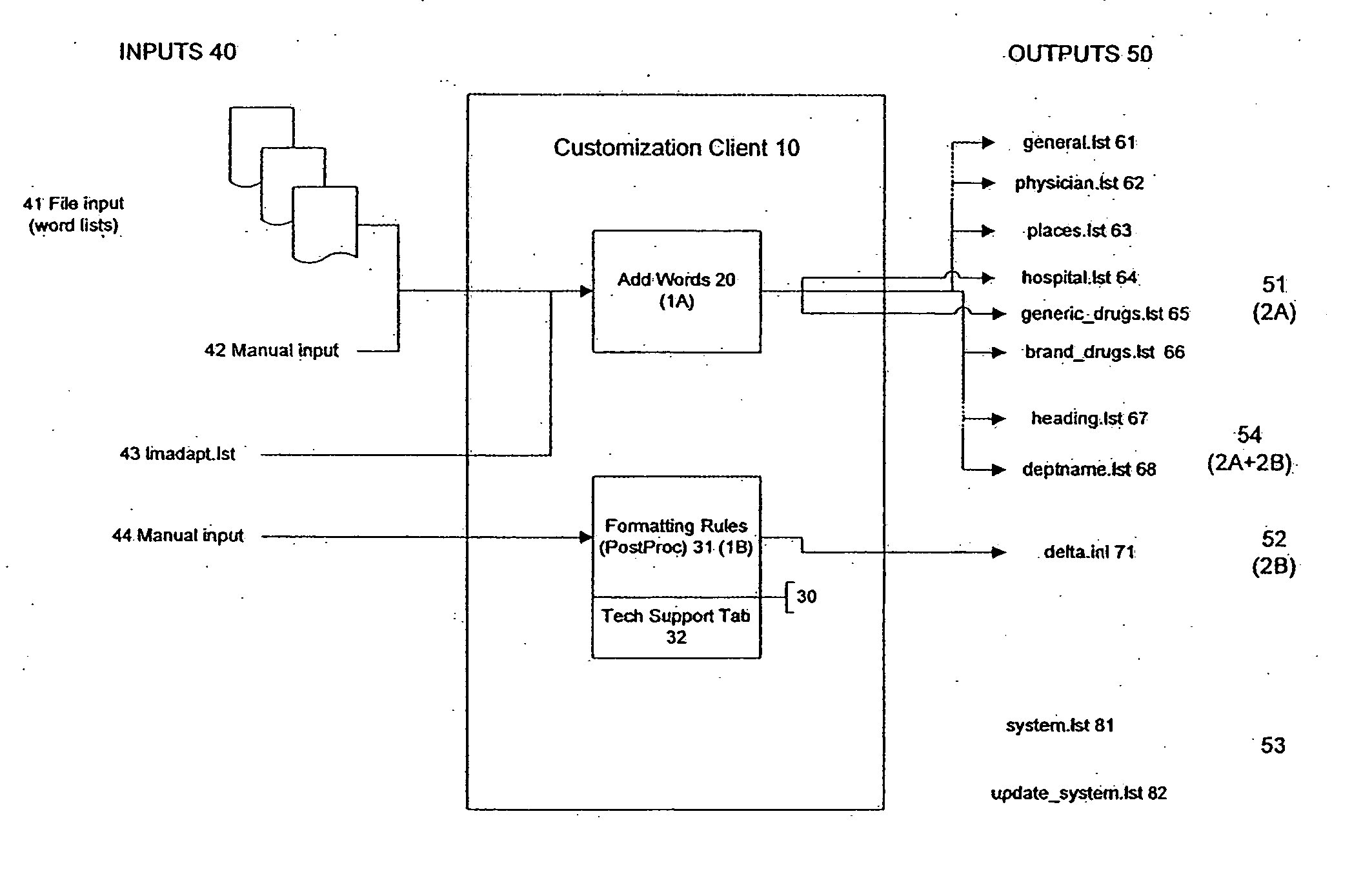

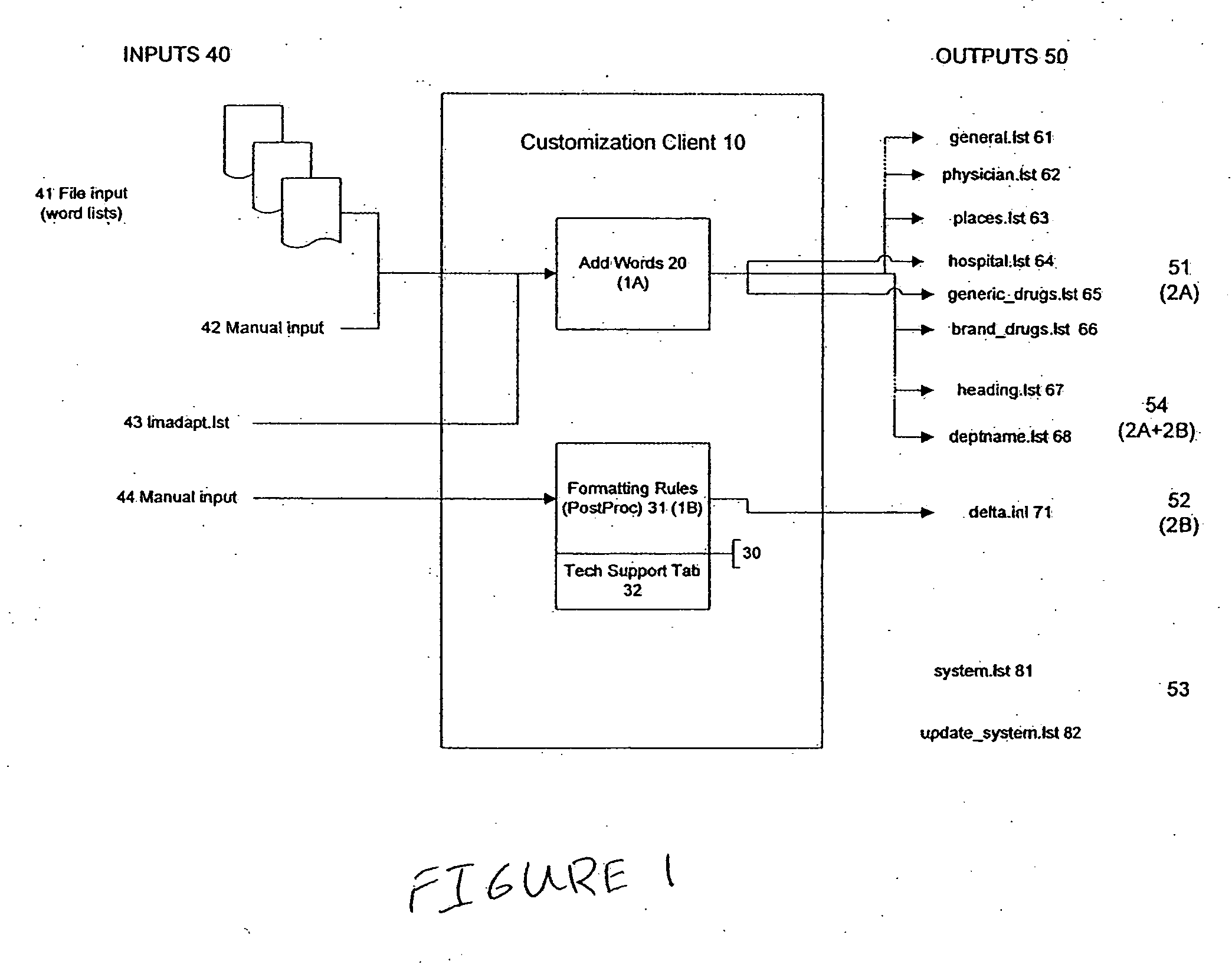

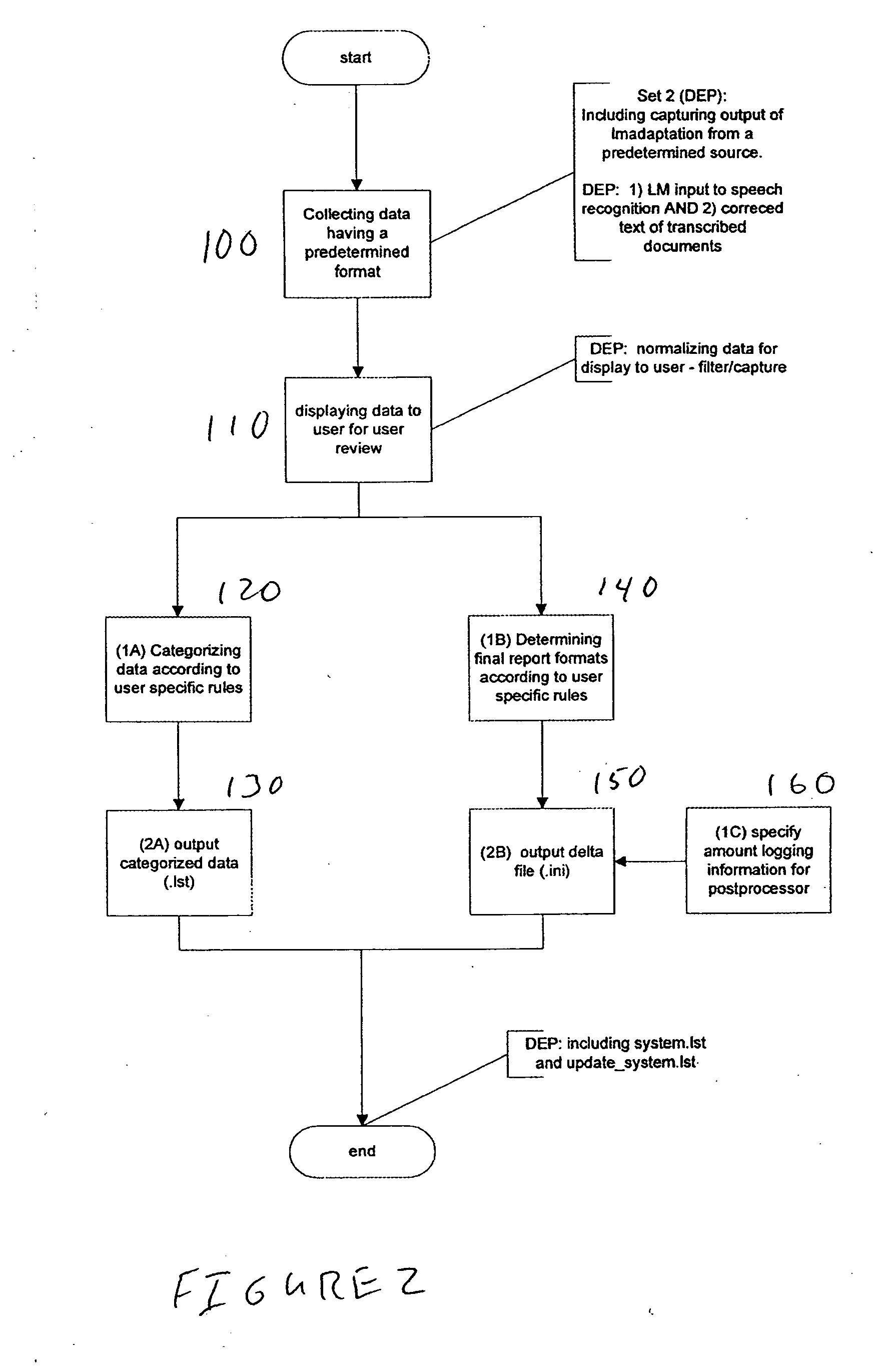

System and method for customizing speech recognition input and output

ActiveUS20050114122A1Easy to optimizeFacilitate automated speech recognition systemsNatural language data processingSpeech recognitionGraphicsGraphical user interface

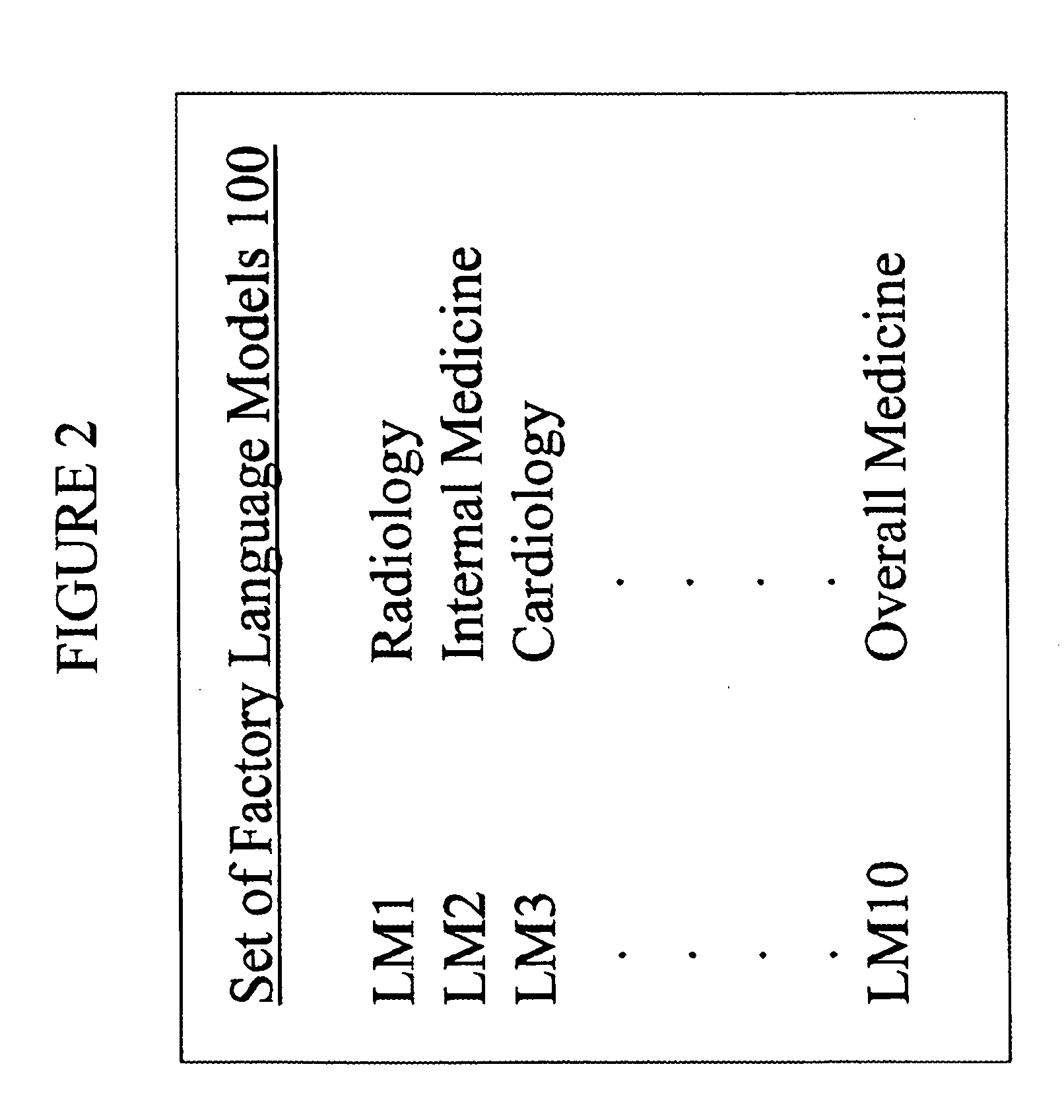

5 A system and method may be disclosed for facilitating the site-specific customization of automated speech recognition systems by providing a customization client for site-specific individuals to update and modify language model input files and post processor input files. In customizing the input files, the customization client may provide a graphical user interface for facilitating the inclusion of words specific to a particular site. The customization client may also be configured to provide the user with a series of formatting rules for controlling the appearance and format of a document transcribed by an automated speech recognition system.

Owner:NUANCE COMM INC

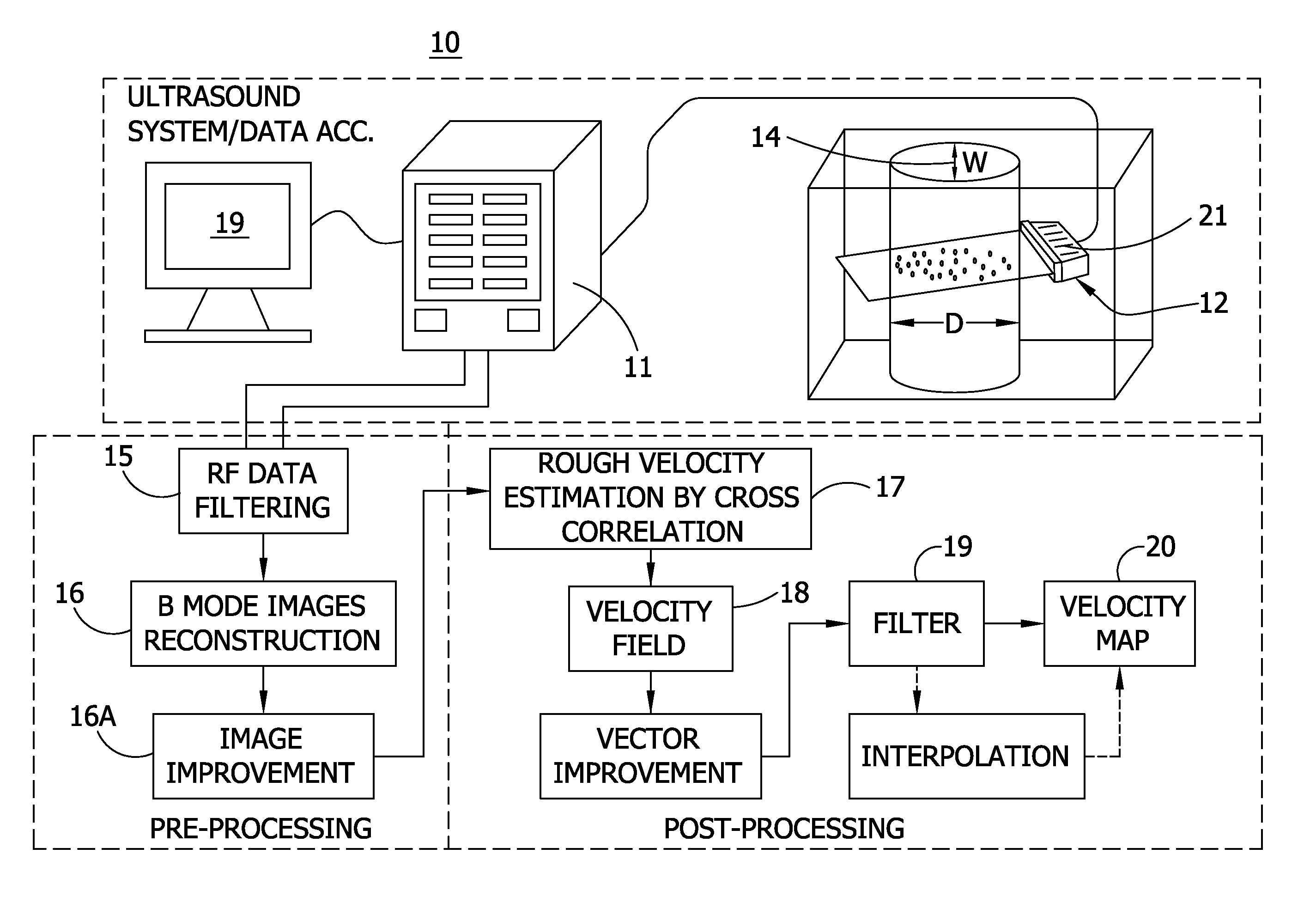

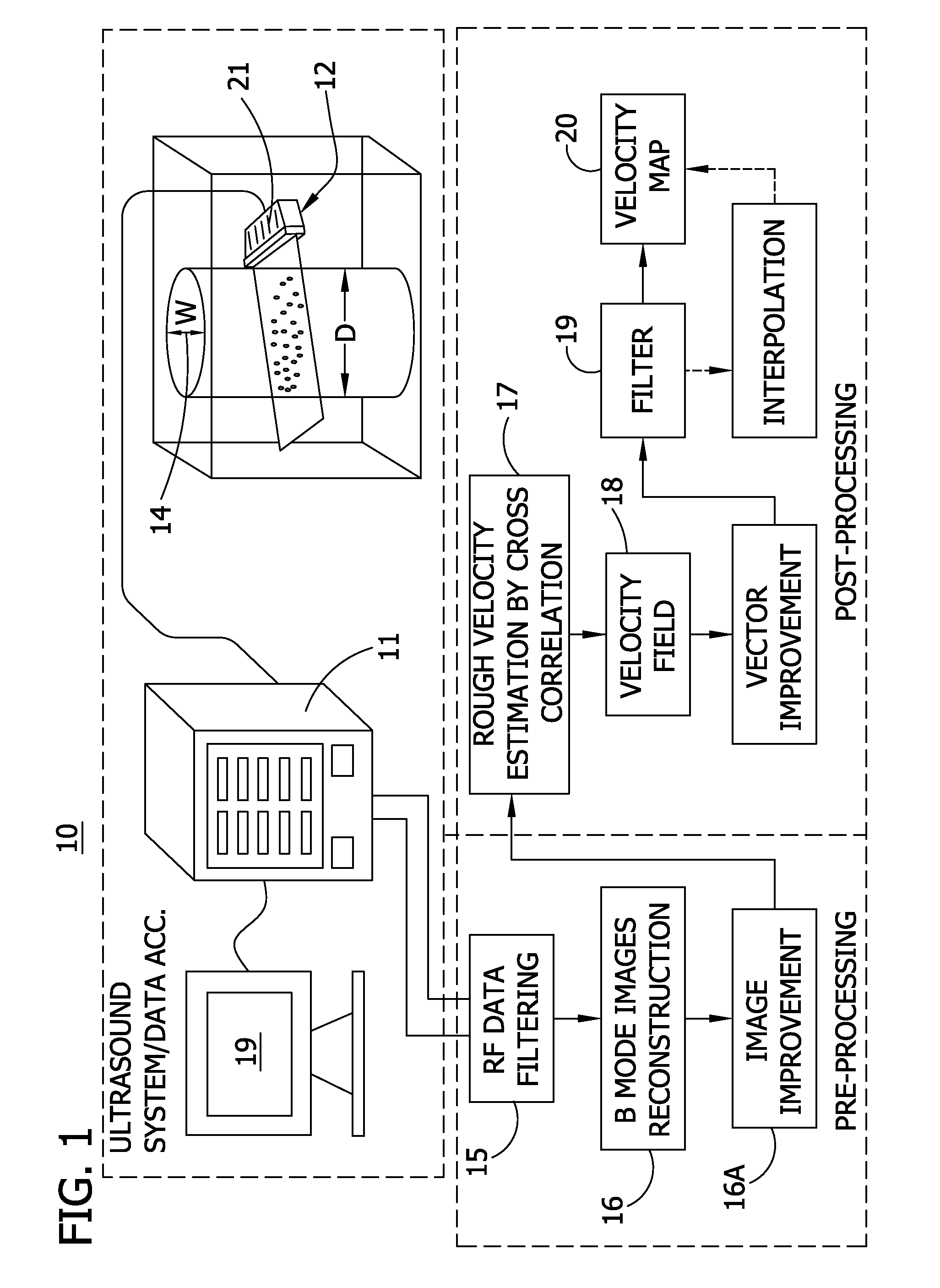

Echo particle image velocity (EPIV) and echo particle tracking velocimetry (EPTV) system and method

A system and method for detecting fluid flow. An ultrasound system comprises a signal generator providing ultrasound firing sequences applied to a linear array transducer. The transducer generating ultrasound energy applied to the fluid flow. A pre-processor comprises a digital RF data acquisition component receiving an RF signal from the transducer of back-scattered ultrasound energy and a B-mode image generation component for reconstructing images form the RF data. A post-processor executes particle image velocity (PIV) algorithms for generating velocity vectors indicative of the fluid flow. The sequences may have triangular waveforms.

Owner:UNIV OF COLORADO THE REGENTS OF

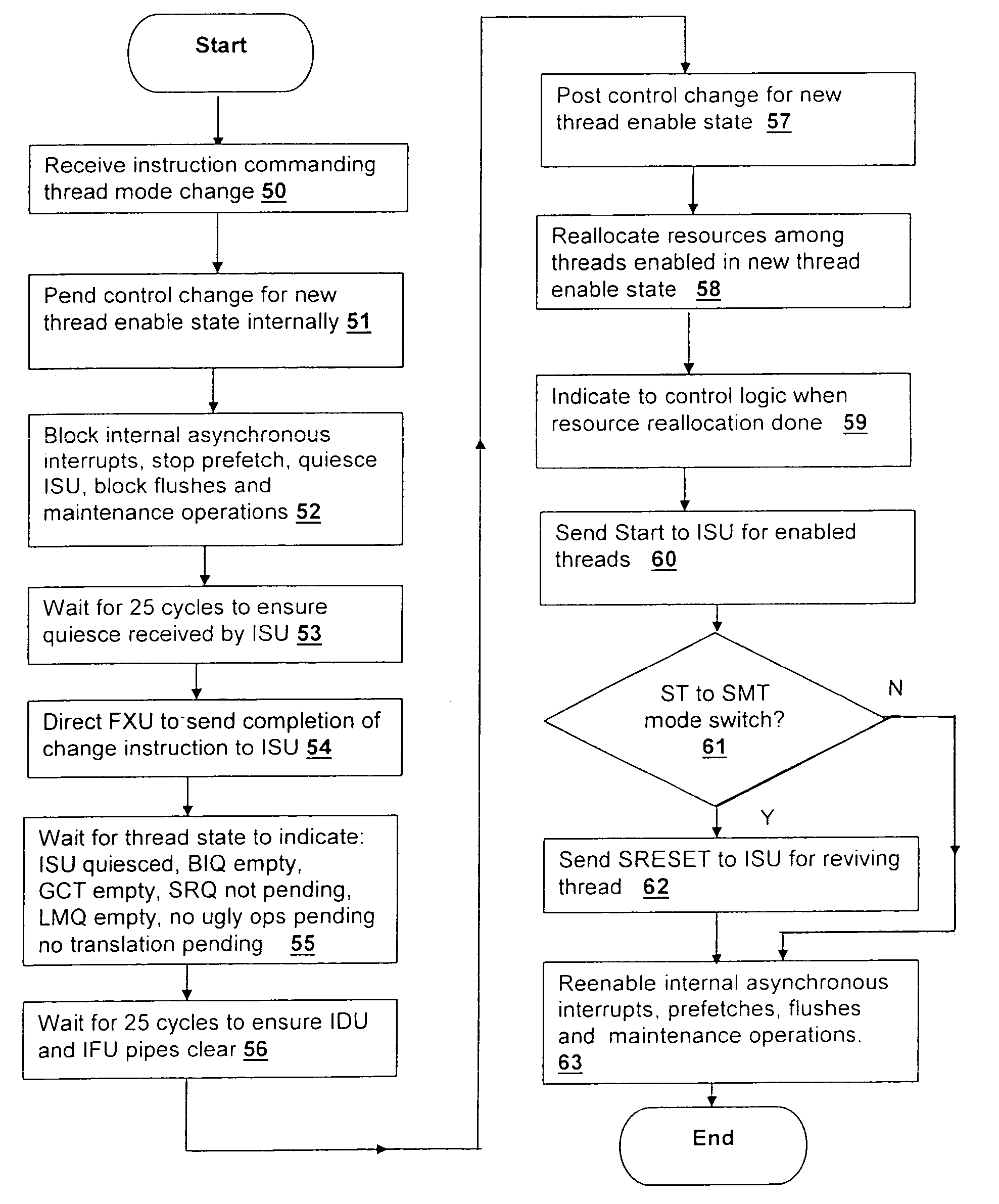

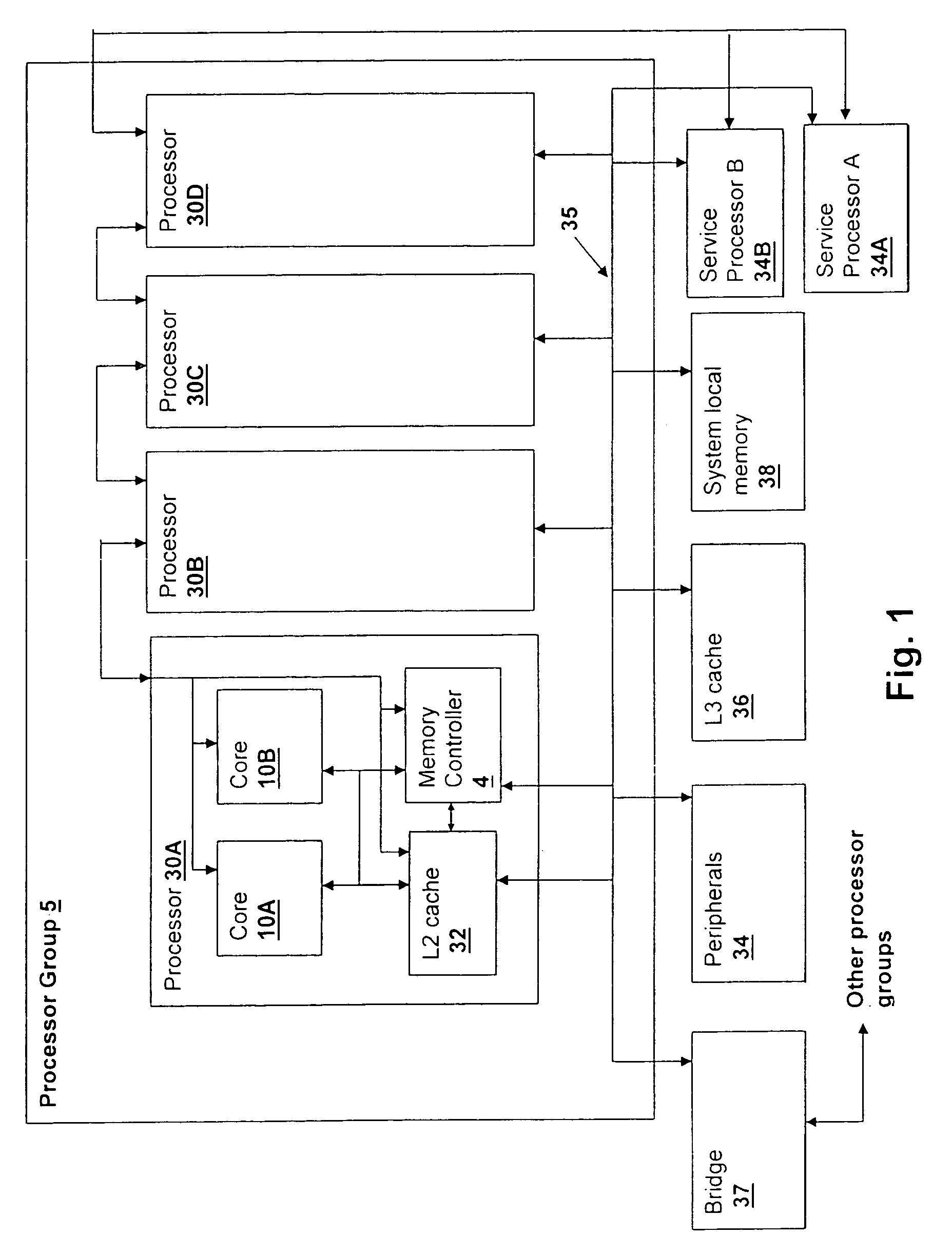

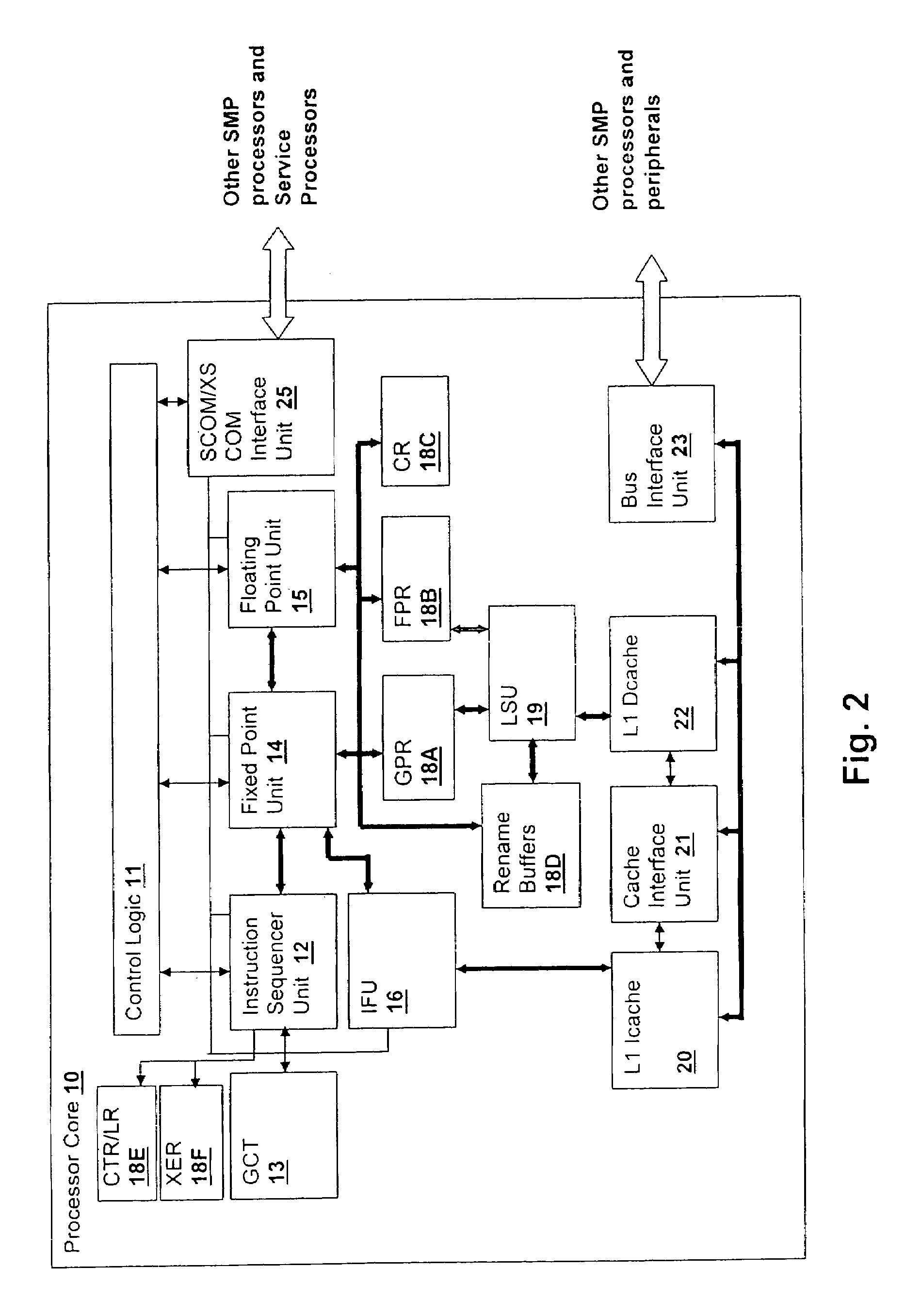

Method and logical apparatus for switching between single-threaded and multi-threaded execution states in a simultaneous multi-threaded (SMT) processor

InactiveUS7155600B2Program initiation/switchingGeneral purpose stored program computerPost processorControl logic

A method and logical apparatus for switching between single-threaded and multi-threaded execution states within a simultaneous multi-threaded (SMT) processor provides a mechanism for switching between single-threaded and multi-threaded execution. The processor receives an instruction specifying a transition from a single-threaded to a multi-threaded mode or vice-versa and halts execution of all threads executing on the processor. Internal control logic controls a sequence of events that ends instruction prefetching, dispatch of new instructions, interrupt processing and maintenance operations and waits for operation of the processor to complete for instructions that are in process. Then, the logic determines one or more threads to start in conformity with a thread enable state specifying the enable state of multiple threads and reallocates various resources, dividing them between threads if multiple threads are specified for further execution (multi-threaded mode) or allocating substantially all of the resources to a single thread if further execution is specified as single-threaded mode. The processor then starts execution of the remaining enabled threads.

Owner:INT BUSINESS MASCH CORP

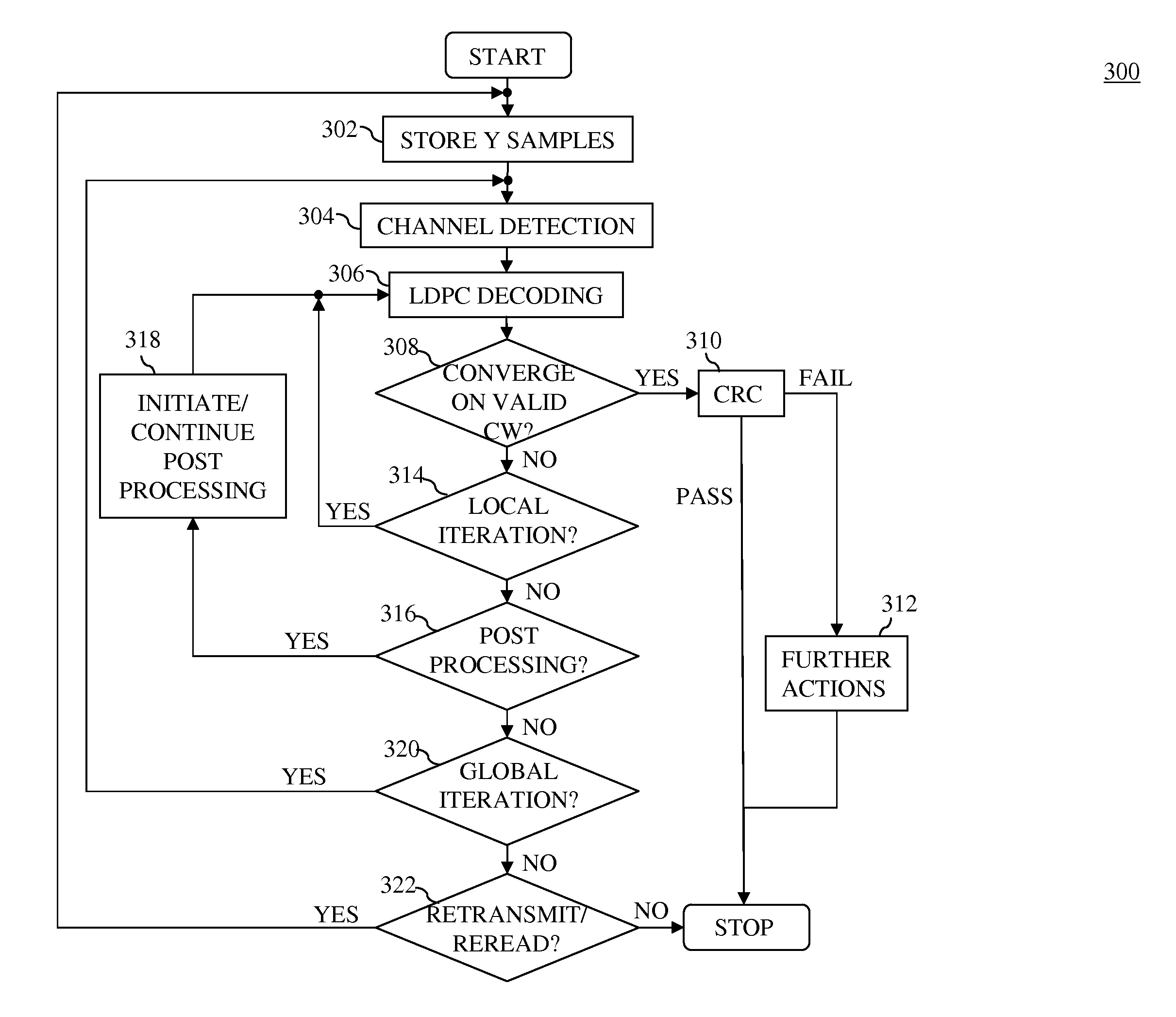

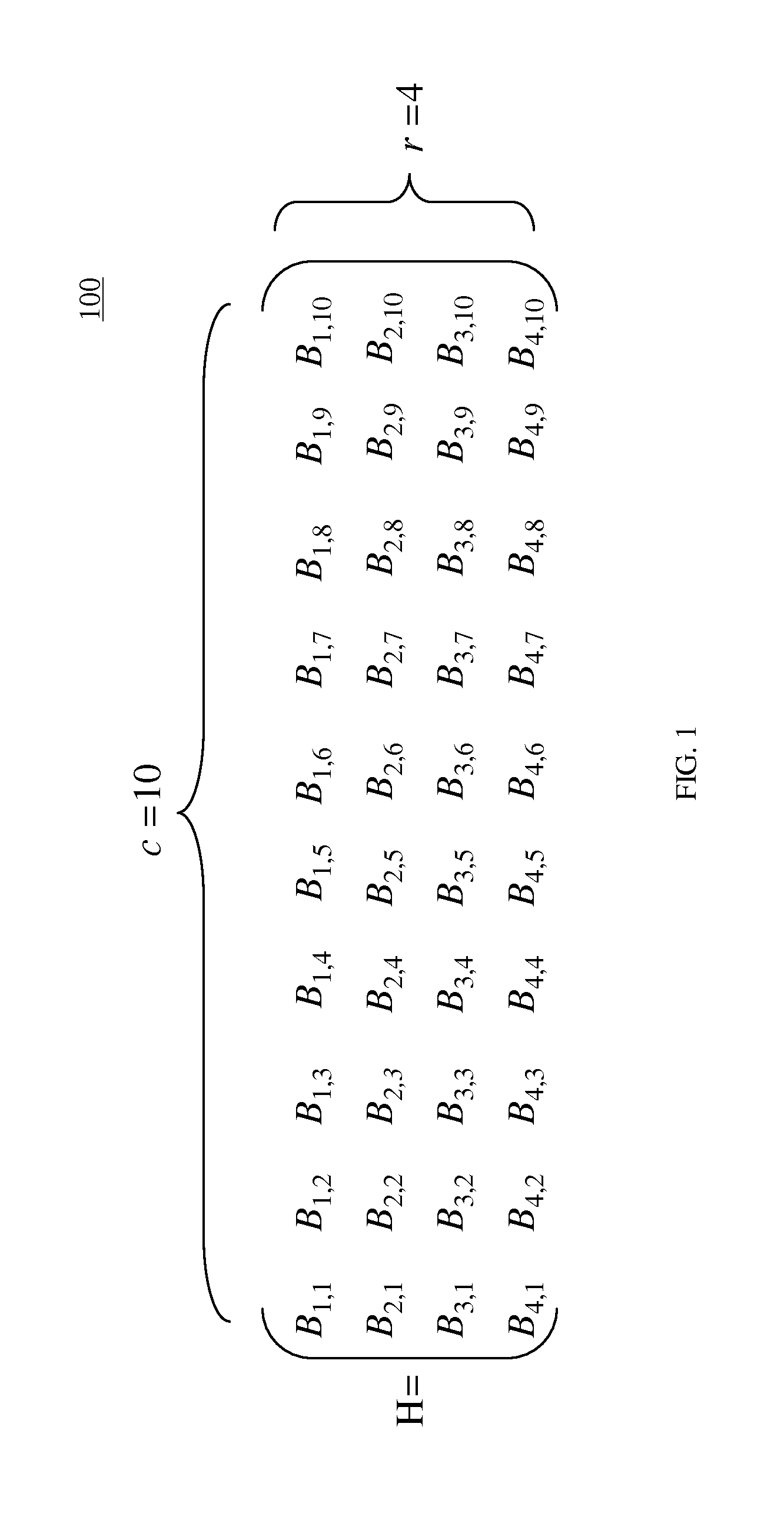

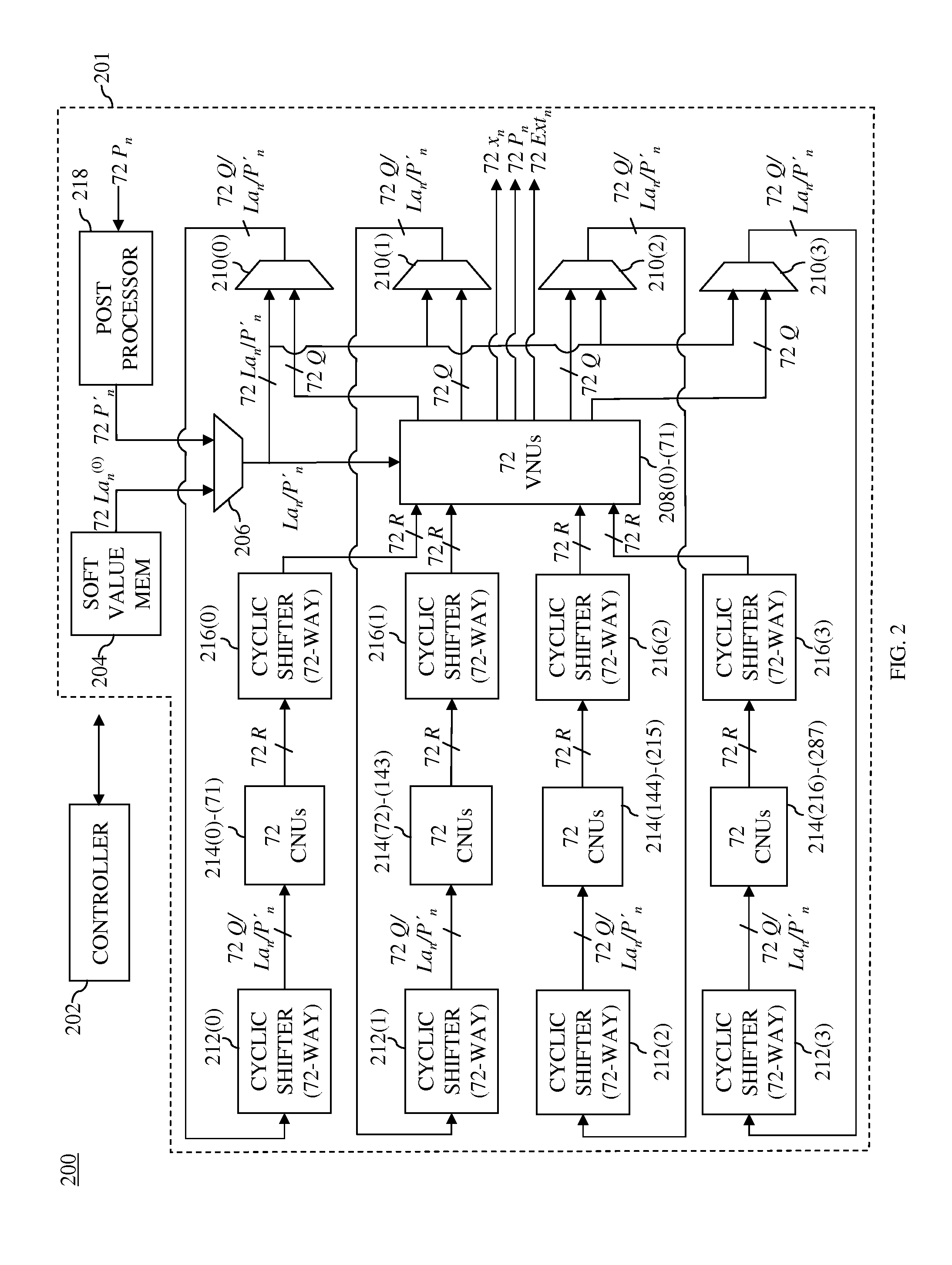

Breaking trapping sets using targeted bit adjustment

In one embodiment, an LDPC decoder performs a targeted bit adjustment method to recover a valid codeword after the decoder has failed. In a first stage, a post processor initializes the decoder by saturating LLR values output by the decoder during the last (i.e., failed) iteration to a relatively small value. Then, two-bit trials are performed, wherein LLR values corresponding to two bits of the codeword are adjusted in each trial. Decoding is performed with the adjusted values, and if the number of unsatisfied check nodes exceeds a specified threshold, then a second stage is performed. The post processor initializes the decoder by saturating the LLR values output by the decoder during the last (i.e., failed) iteration of the first stage to a relatively small value. The second stage then performs single-bit adjustment trials, wherein one LLR value corresponding to one bit of the codeword is adjusted in each trial.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

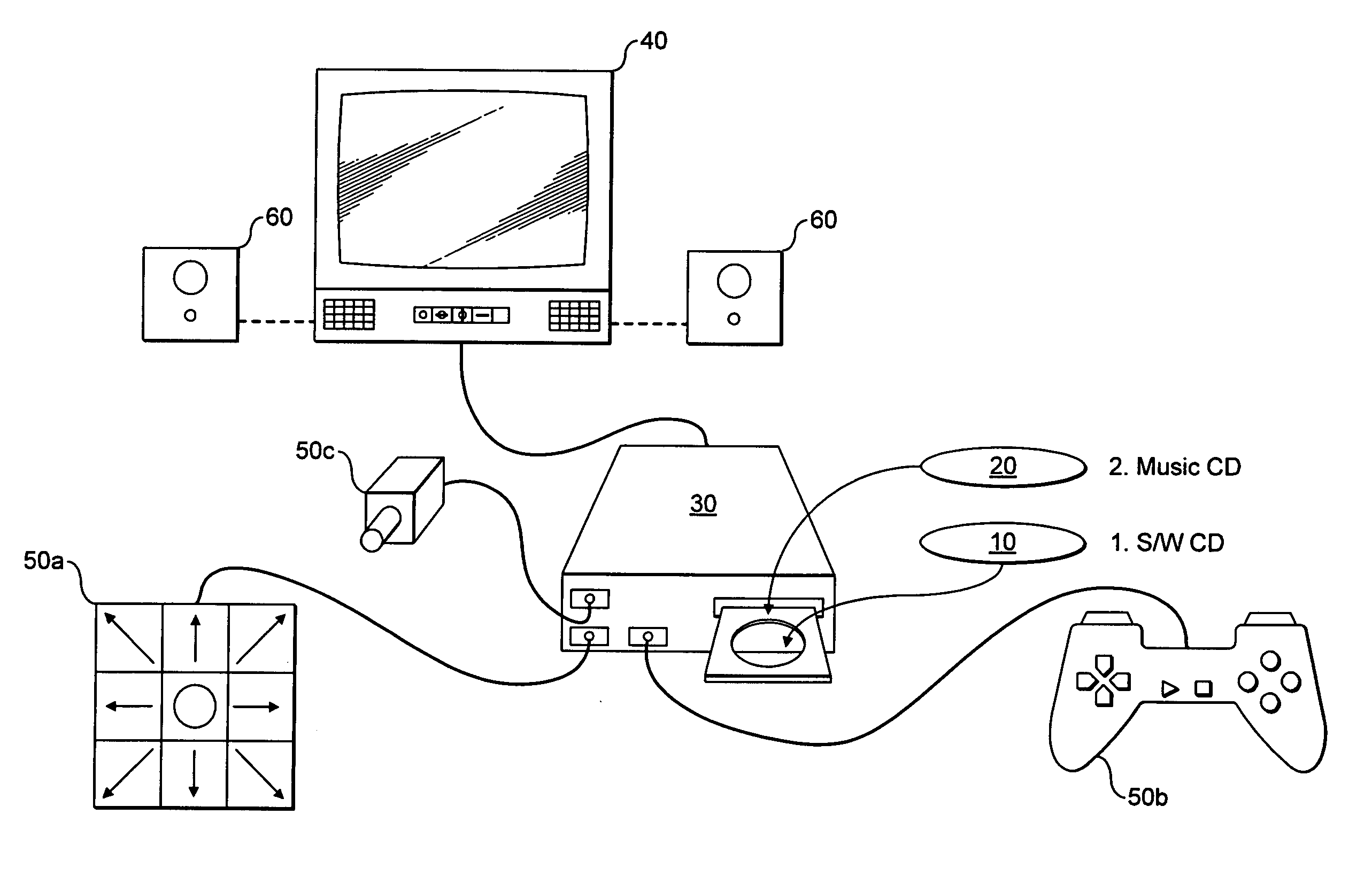

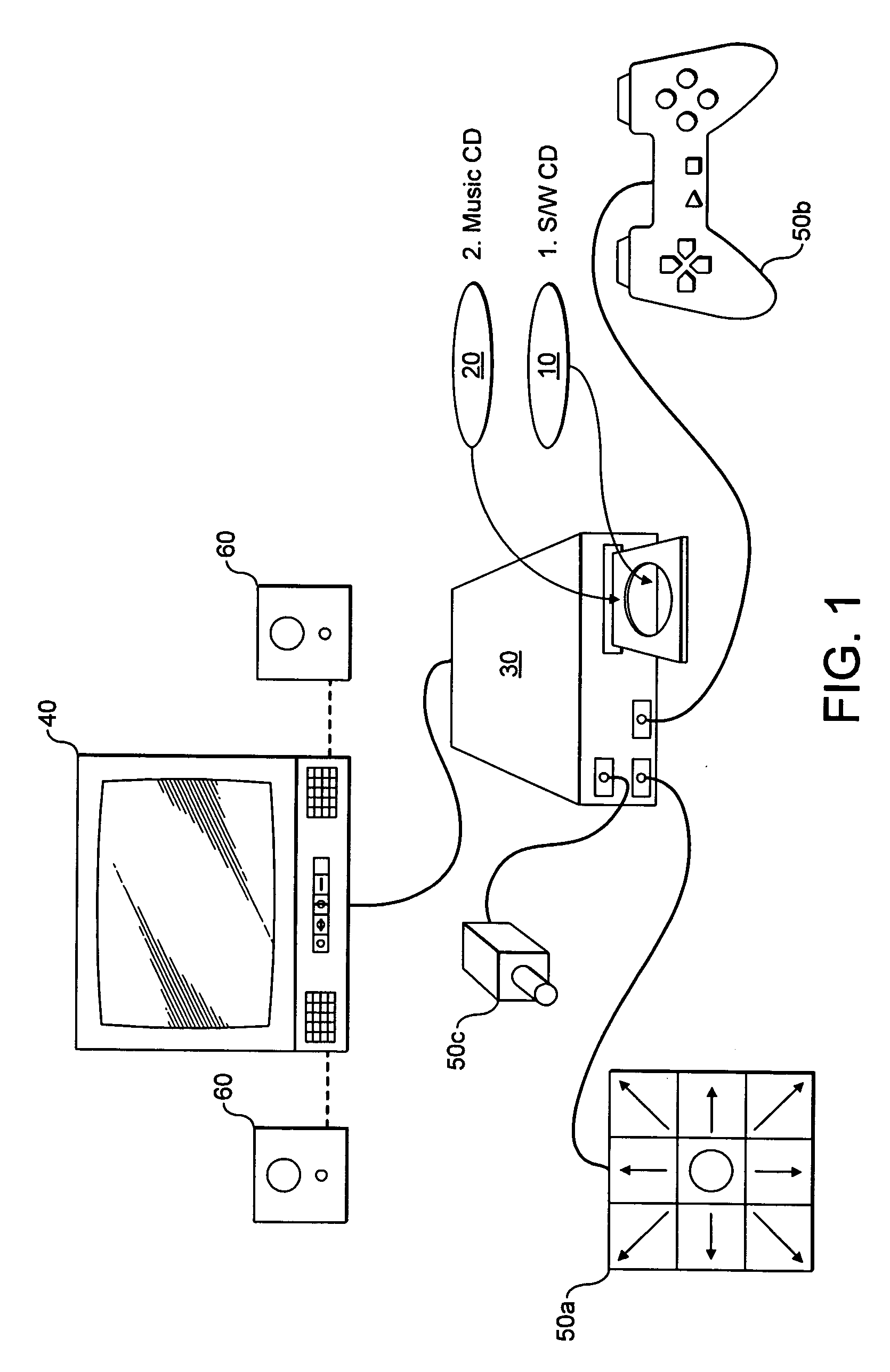

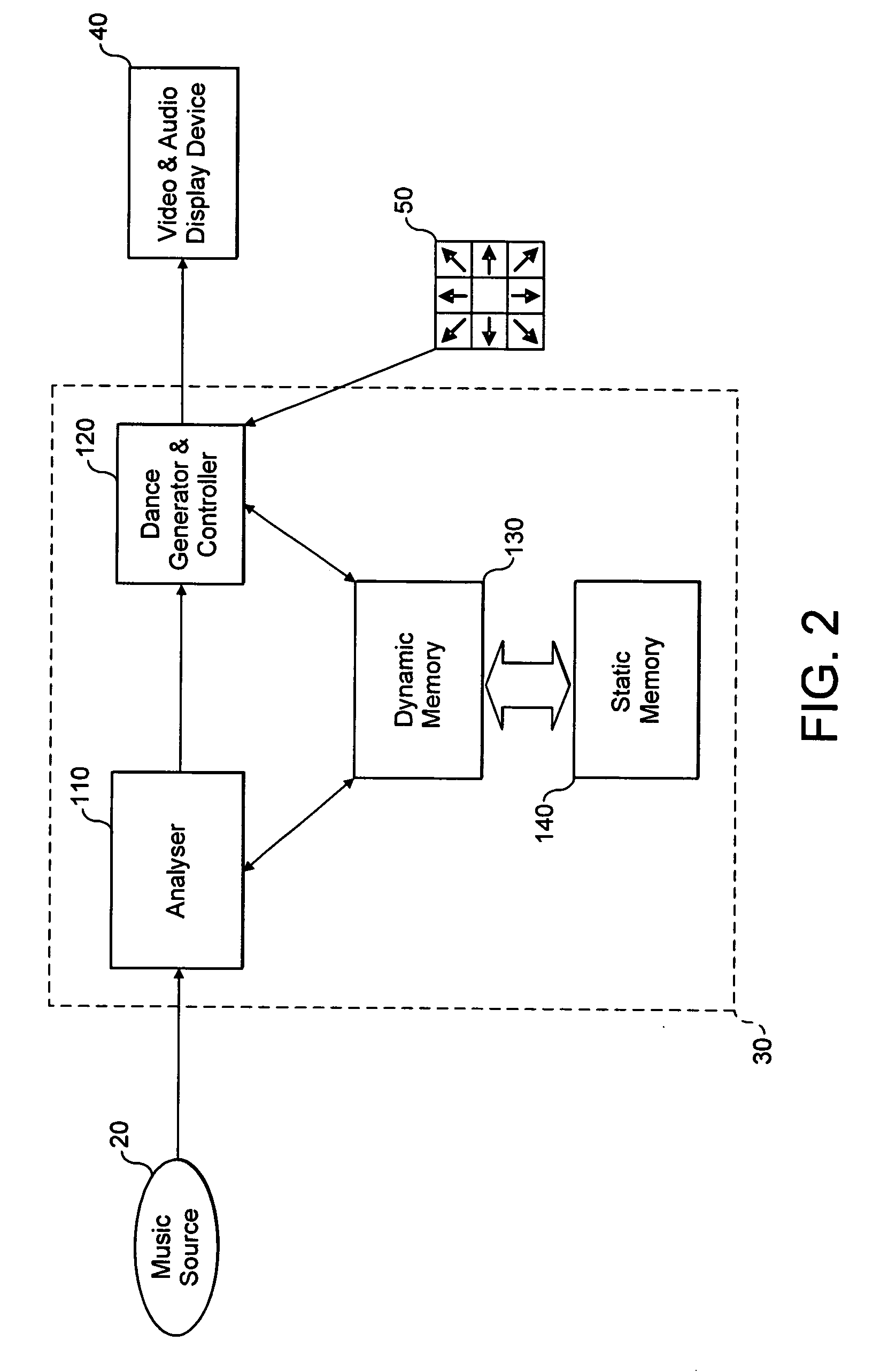

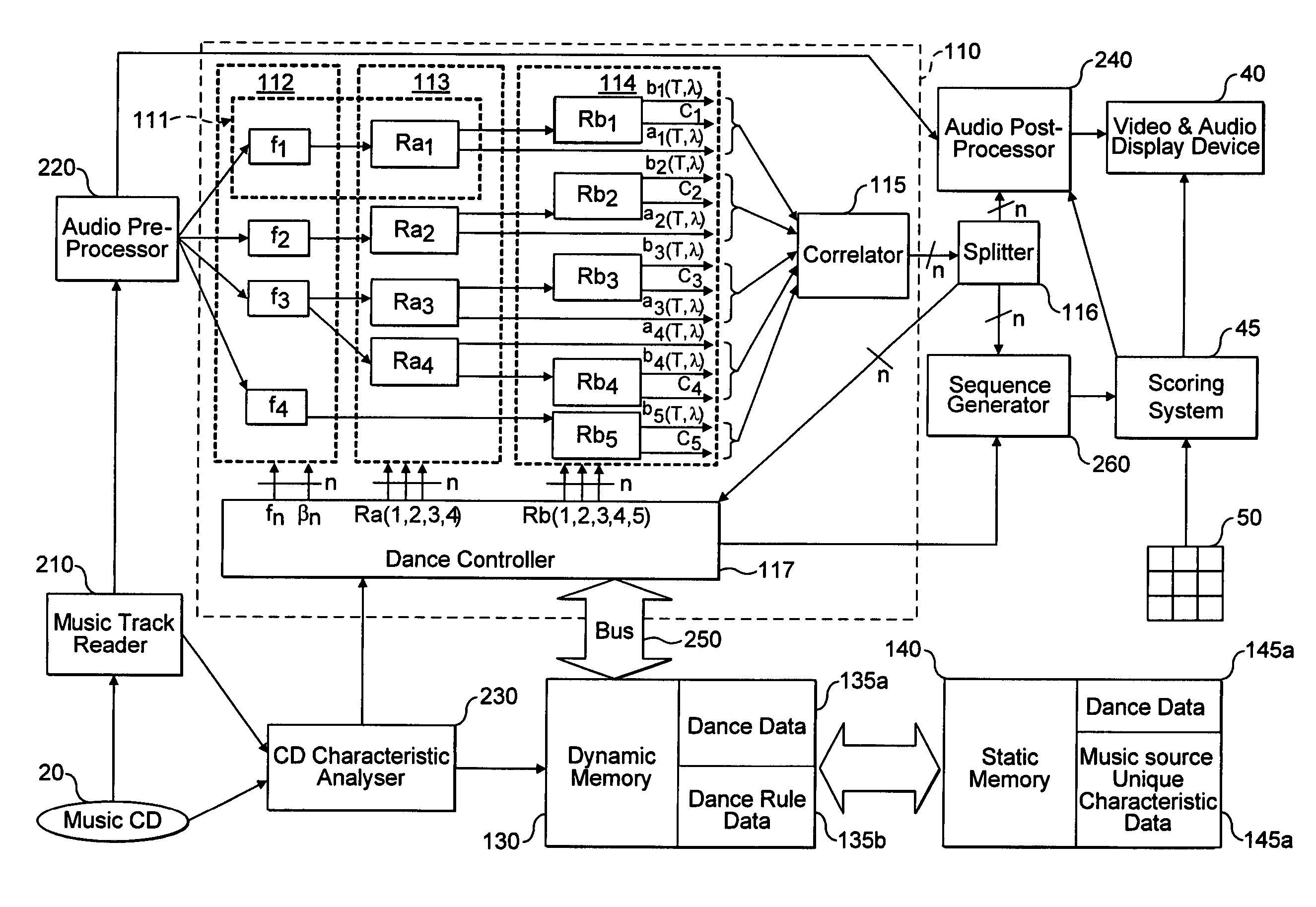

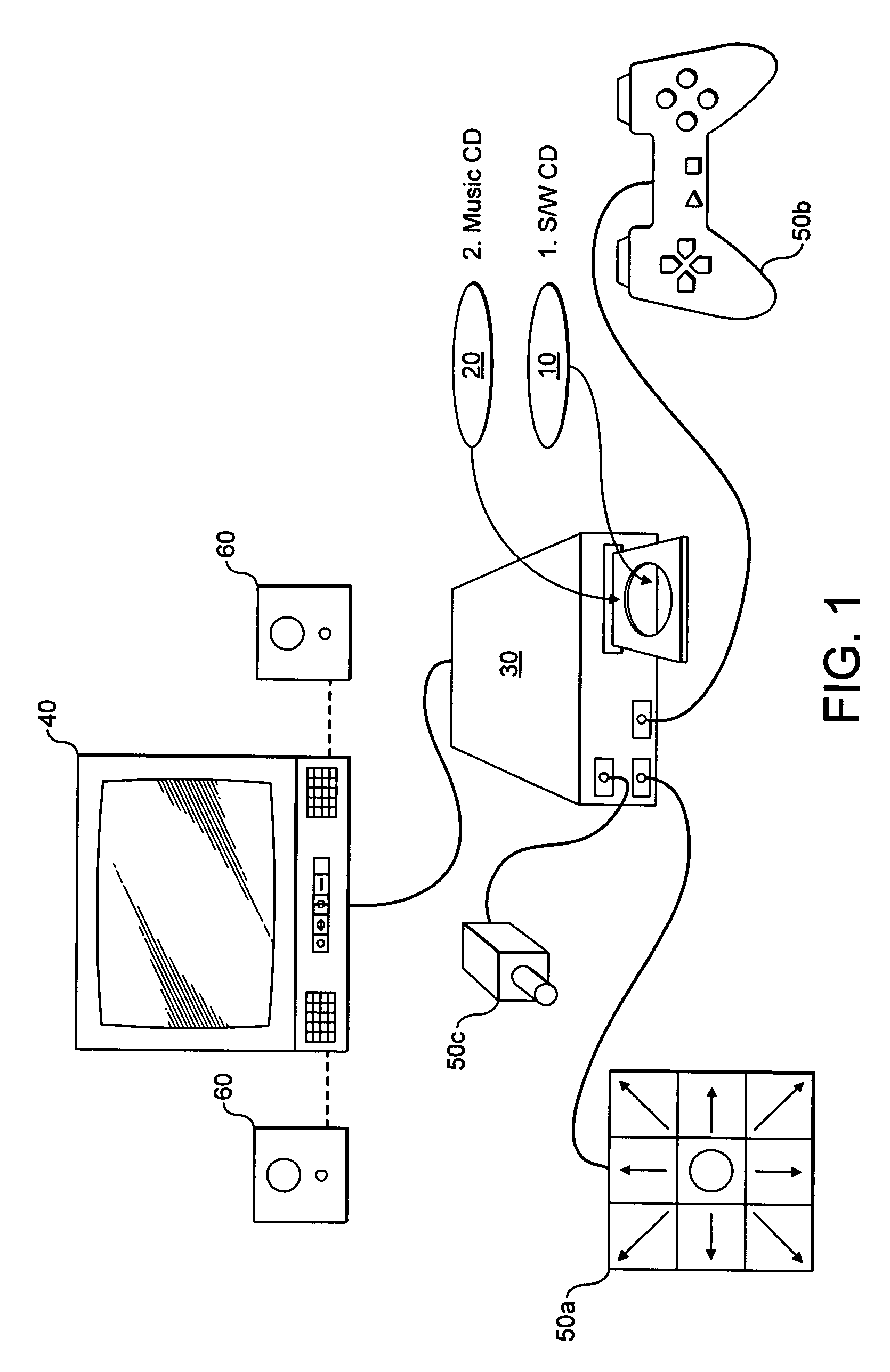

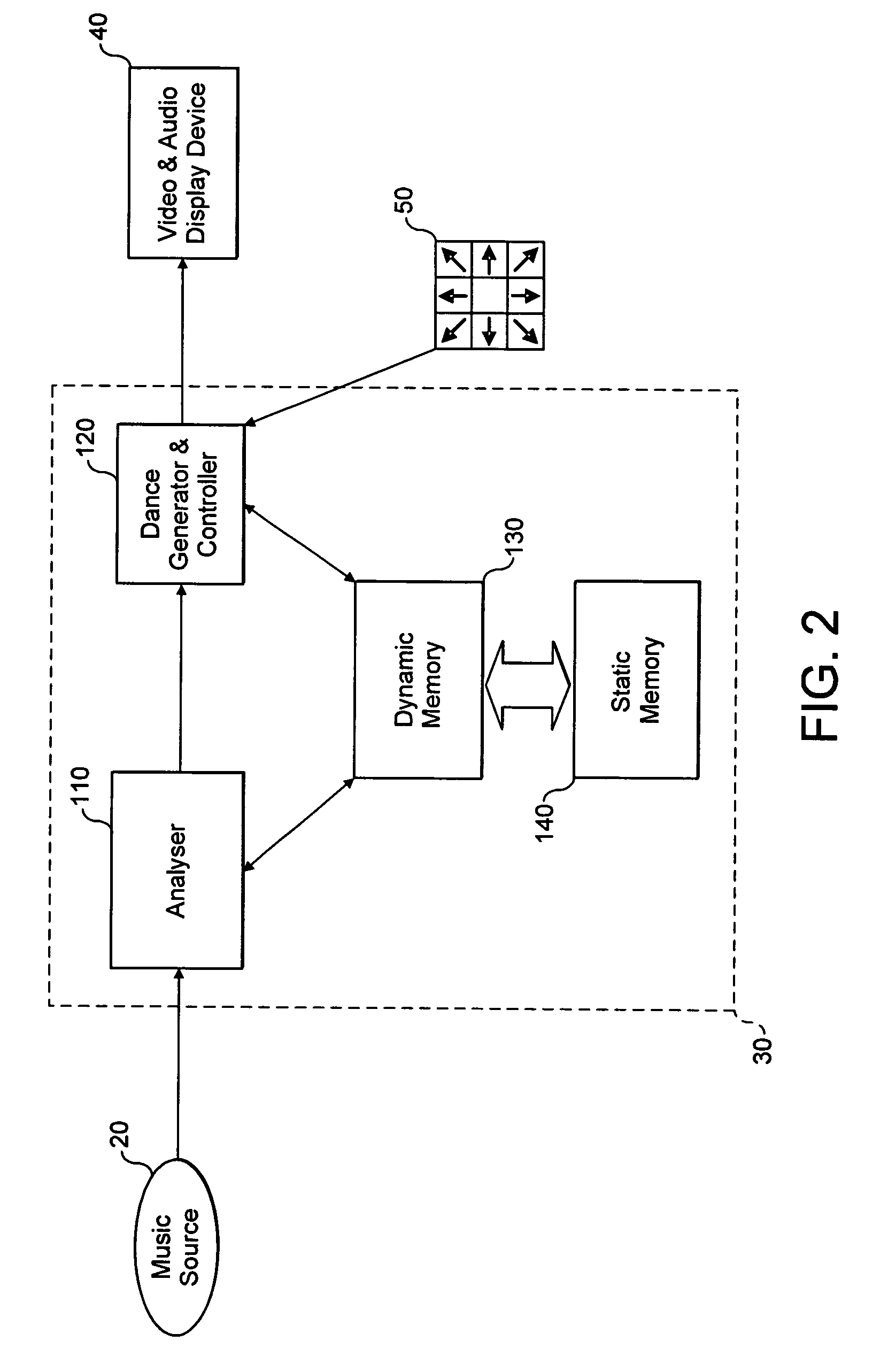

Rhythm action game apparatus and method

InactiveUS20060266200A1Increased complexityElectrophonic musical instrumentsVideo gamesPost processorAudio analyzer

A rhythm action game apparatus comprising an audio analyser adapted to analyze a music track and provide corresponding rhythm data, and a sequence generator adapted to generate game play cues according to said rhythm data. There is also disclosed a music processor comprising an audio analyser adapted to analyze a music track and provide corresponding rhythm data, and an audio post processor adapted to reconfigure the music track controlled by the rhythm data.

Owner:CODEMASTERS

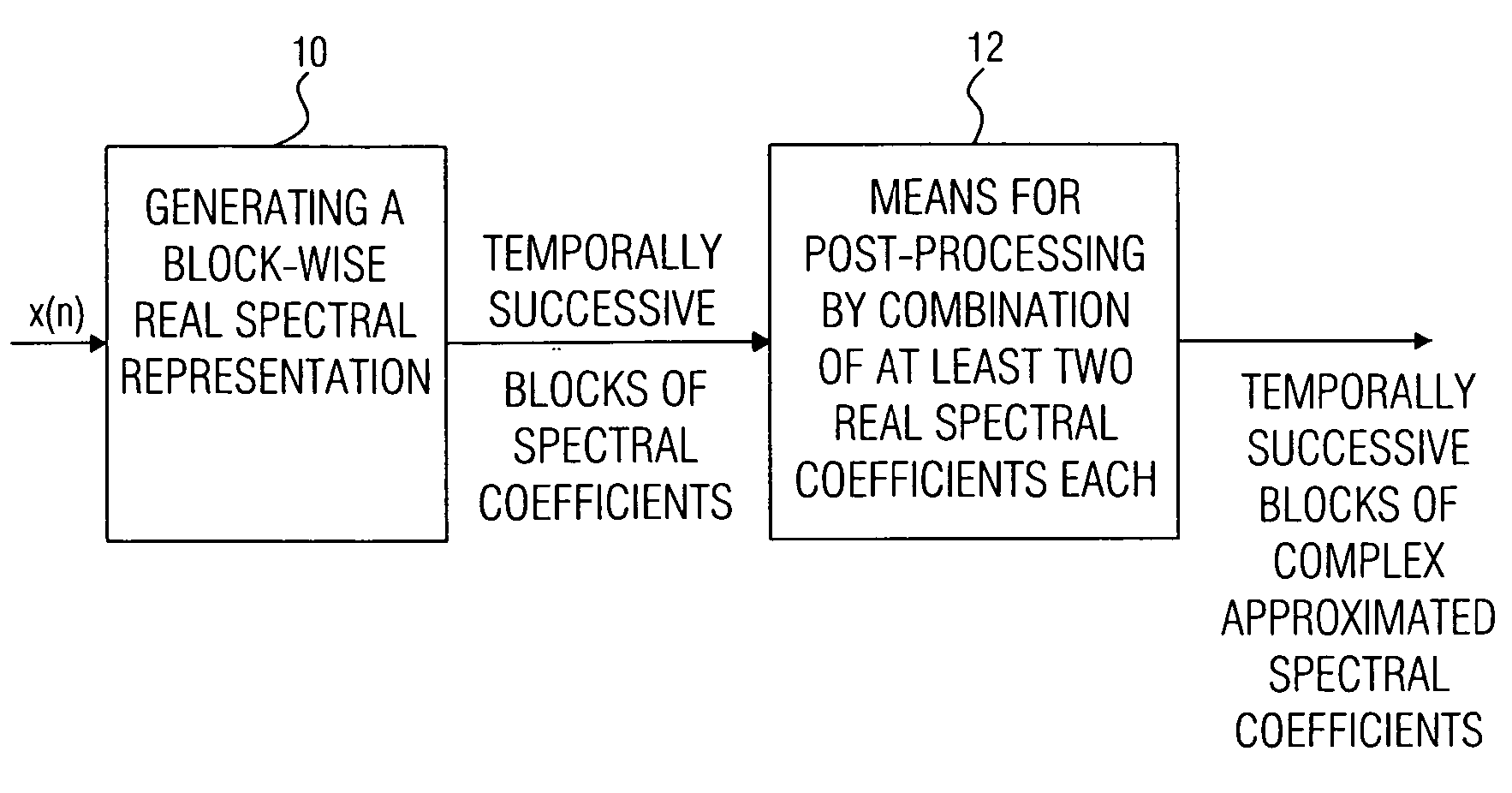

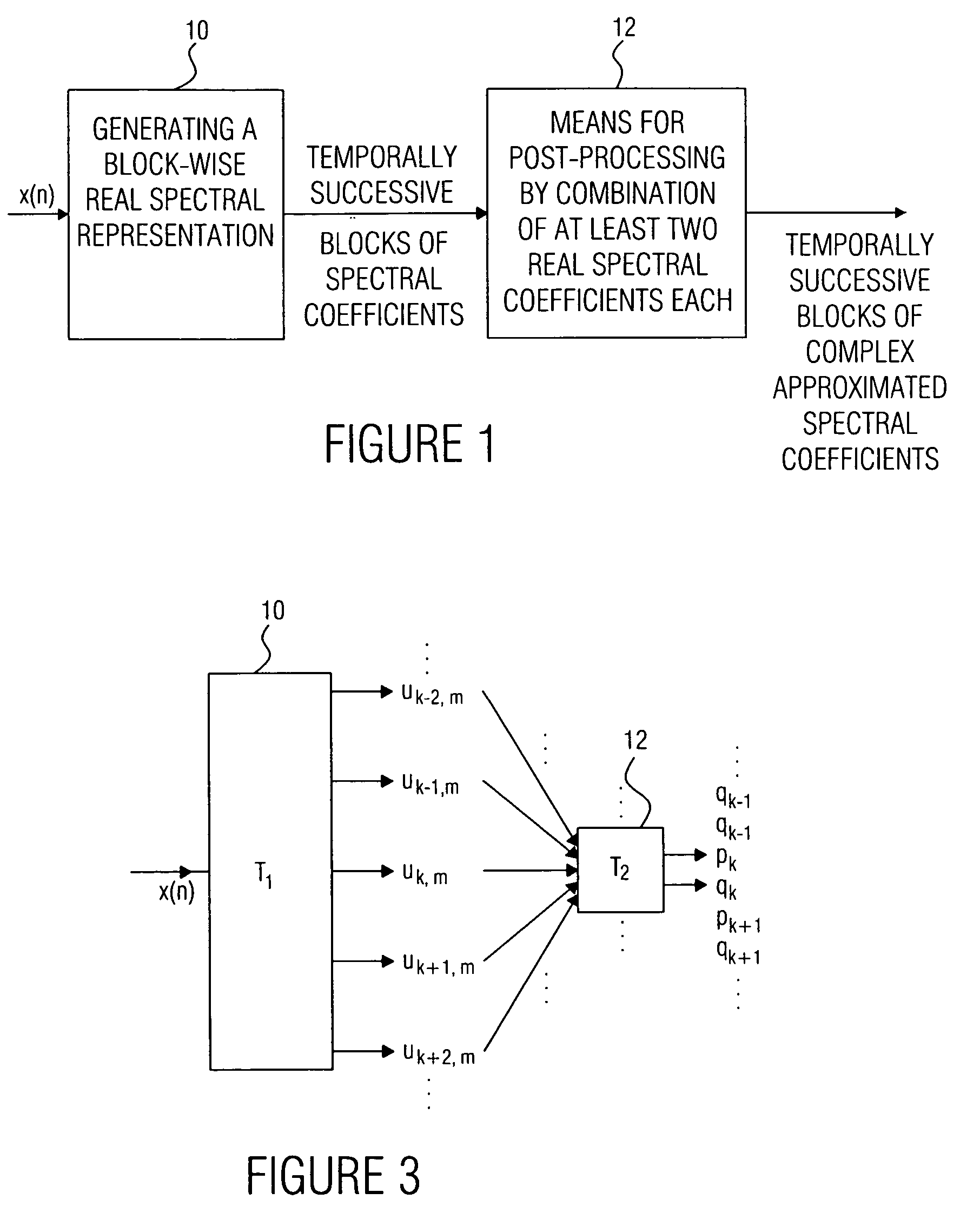

Device and method for generating a complex spectral representation of a discrete-time signal

ActiveUS20050197831A1Improve approximationSpeech analysisCode conversionFrequency spectrumPost processor

A filter bank device for generating a complex spectral representation of a discrete-time signal includes a generator for generating a block-wise real spectral representation, which, for example, implements an MDCT, to obtain temporally successive blocks of real spectral coefficients. The output values of this spectral conversion device are fed to a post-processor for post-processing the block-wise real spectral representation to obtain an approximated complex spectral representation having successive blocks, each block having a set of complex approximated spectral coefficients, wherein a complex approximated spectral coefficient can be represented by a first partial spectral coefficient and by a second partial spectral coefficient, wherein at least one of the first and second partial spectral coefficients is determined by combining at least two real spectral coefficients. A good approximation for a complex spectral representation of the discrete-time signal is obtained by combining two real spectral coefficients, preferably by a weighted linear combination, wherein additionally more degrees of freedom for optimizing the entire system are available.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

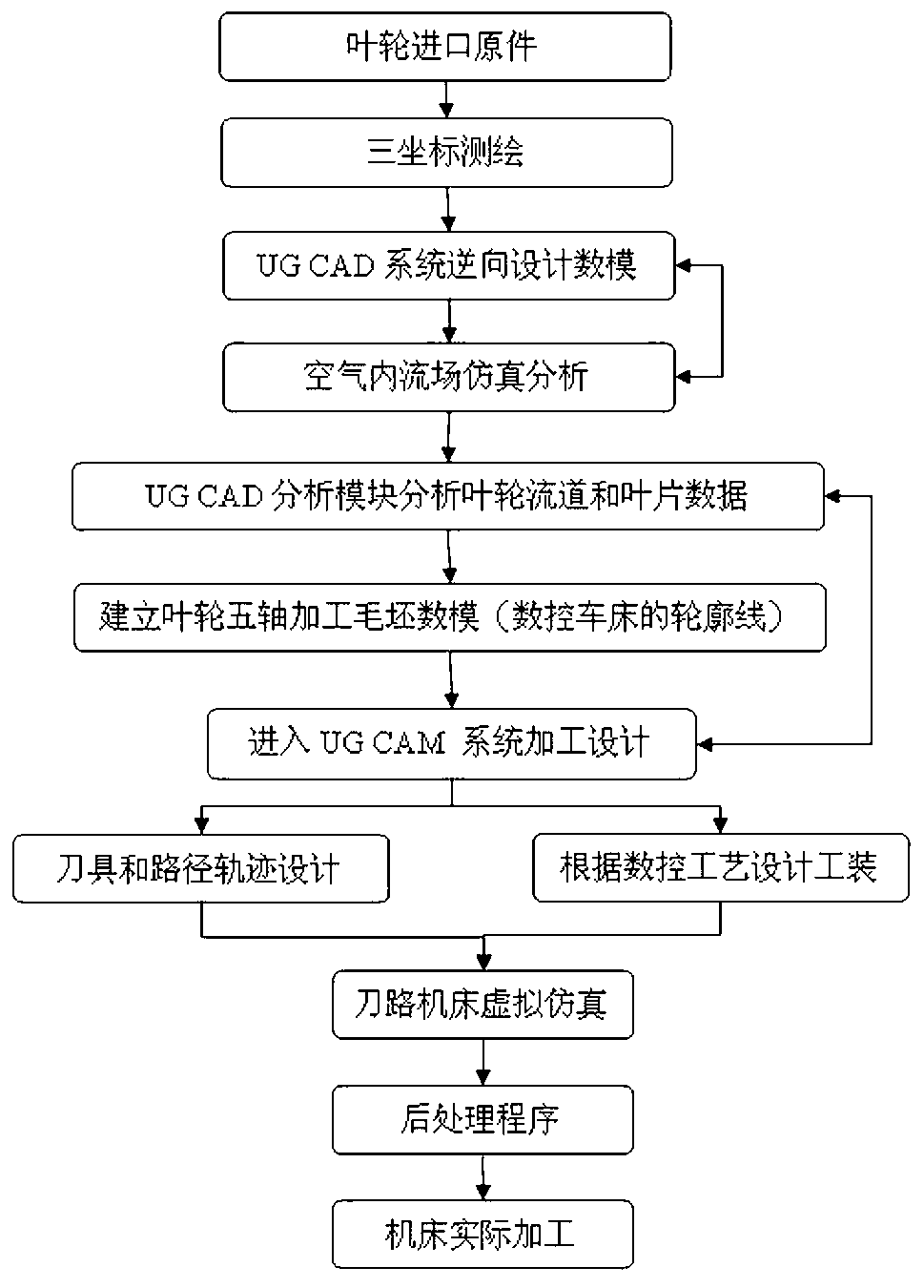

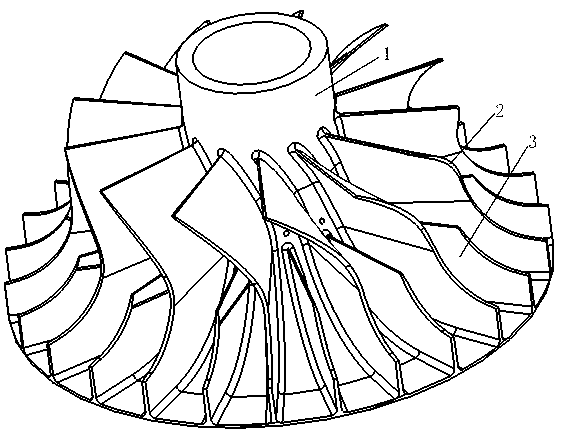

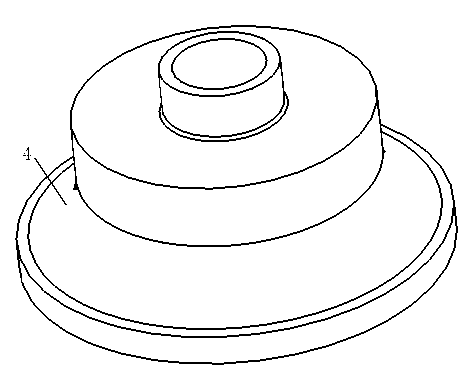

Integral impeller 5-axis machining method based on UG NX system platform

The invention discloses an integral impeller 5-axis machining method based on a UG NX system platform and relates to a technical scheme of a 5-axis numerical control processing technology for an integral impeller researched and developed under a UGNX 7.5 computer-aided design (CAD) system platform. The method comprises using a reversal design technique under the UGNX 7.5 CAD system platform to obtain compressor wheel digifax; acquiring corresponding data from the digifax to establish blank digifax on the digifax according to numerical control technology requirements; selecting a machine tool: using a 5-axis linkage machining center; selecting a cutter according to the geometrical shape and machining materials of an impeller and selecting the cutter with a diameter as large as possible as long as the passage dimension allows; and setting the impeller machining track: UGNX, selecting an appropriate machining method and selecting allowances for rough and finish machining, outputting 5-axis machining center machine tool machining codes for being called by the 5-axis linkage machining center.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

Method and system for stabilizing a series of intravascular ultrasound images and extracting vessel lumen from the images

InactiveUS20110033098A1Accurate and effective diagnosticsAccurate and effective and therapeuticUltrasonic/sonic/infrasonic diagnosticsImage enhancement3d shapesSonification

A method and system for generating stabilized intravascular ultrasonic images are provided. The system may include a probe instrument, such as a catheter, connected to a processor and a post-processor. The method of using the system to stabilize images and the method for stabilizing images involve the process by which the processor and post-processor stabilize the image. A computer readable medium containing executable instructions for controlling a computer containing the processor and post-processor to perform the method of stabilizing images is also provided. The probe instrument, which has a transmitter for transmitting ultrasonic signals and a receiver for receiving reflected ultrasonic signals that contain information about a tubular environment, such as a body lumen, preferably is a catheter. The processor and post-processor are capable of converting inputted signals into one or more, preferably a series of, images and the post-processor, which determines the center of the environment at each reflection position, detects the edges of the tubular environment and aligns the image center with the environment center thereby limiting the drift of images, which may occur due to movement of the environment, and stabilizing the images. The processor may also be programmed to filter images or series of images to improve the image stabilization and remove motion interference and / or may be programmed to extract the 3D shape of the environment. The method and device are of particular use where motion causes image drift, for example, the imaging a body lumen, in particular a vascular lumen, where image drift may occur due to heart beat or blood flow.

Owner:MEDINOL LTD

Directed Interpolation and Data Post-Processing

ActiveUS20120026288A1Picture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningMultiplexingSide information

An encoding device evaluates a plurality of processing and / or post-processing algorithms and / or methods to be applied to a video stream, and signals a selected method, algorithm, class or category of methods / algorithms either in an encoded bit-stream or as side information related to the encoded bitstream. A decoding device or post-processor utilizes the signaled algorithm or selects an algorithm / method based on the signaled method or algorithm. The selection is based, for example, on availability of the algorithm / method at the decoder / post-processor and / or cost of implementation. The video stream may comprise, for example, downsampled multiplexed stereoscopic images and the selected algorithm may include any of upconversion and / or error correction techniques that contribute to a restoration of the downsampled images.

Owner:DOLBY LAB LICENSING CORP

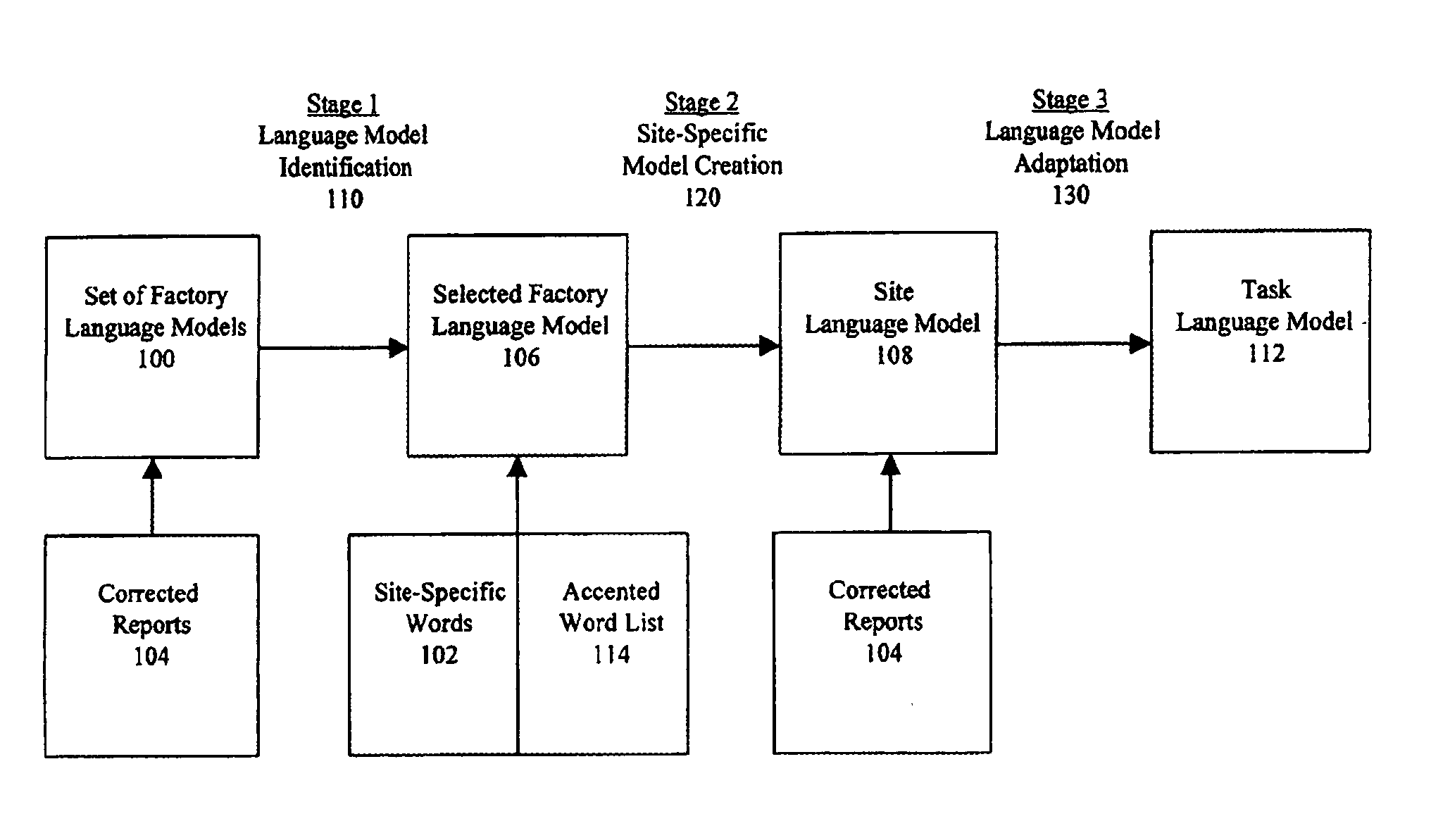

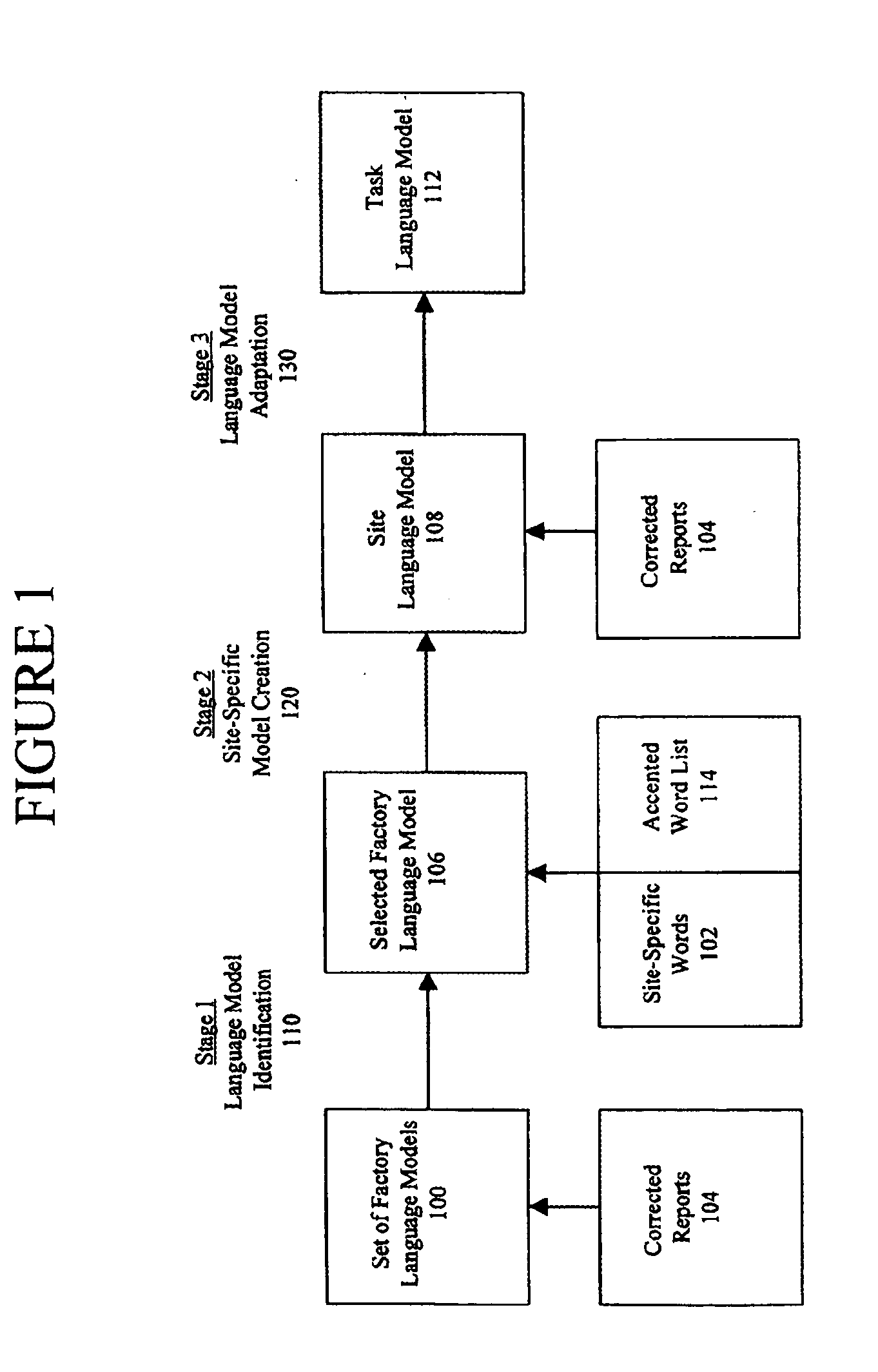

System and method for modifying a language model and post-processor information

A system and method for automatically modifying a language model and post-processor information is provided. The system includes the steps of language model identification, site-specific model creation, and language model adaptation.

Owner:NUANCE COMM INC

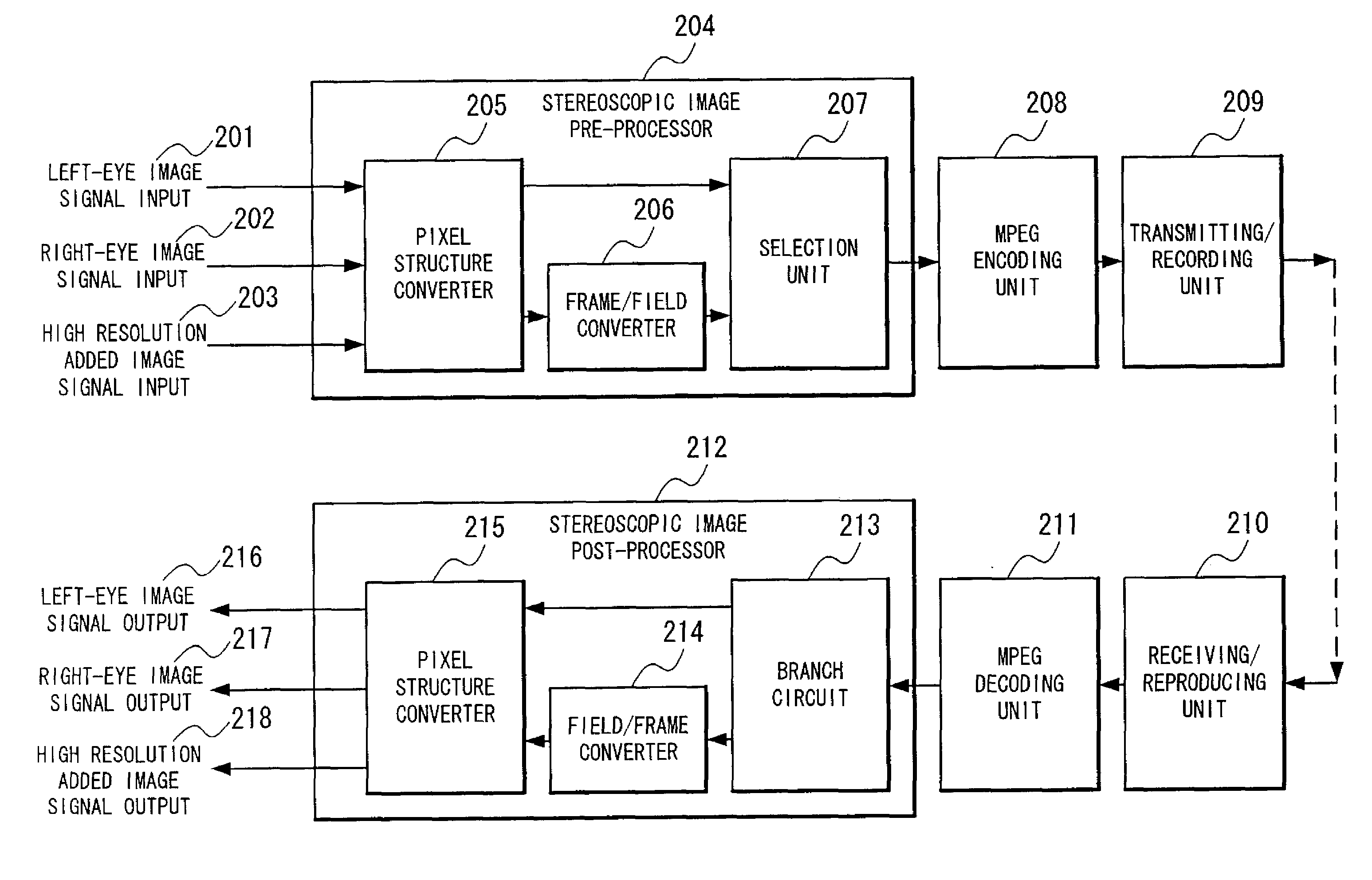

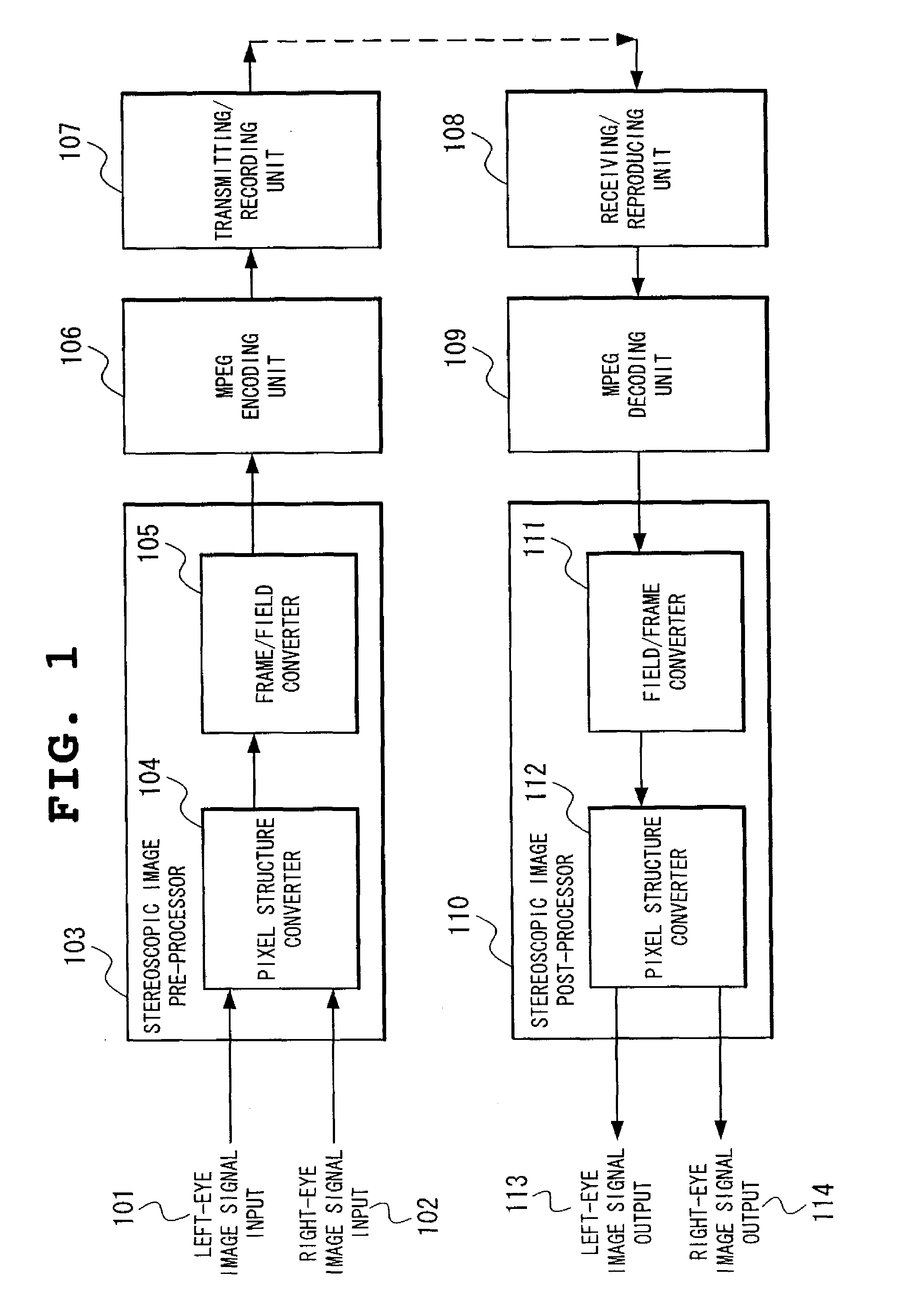

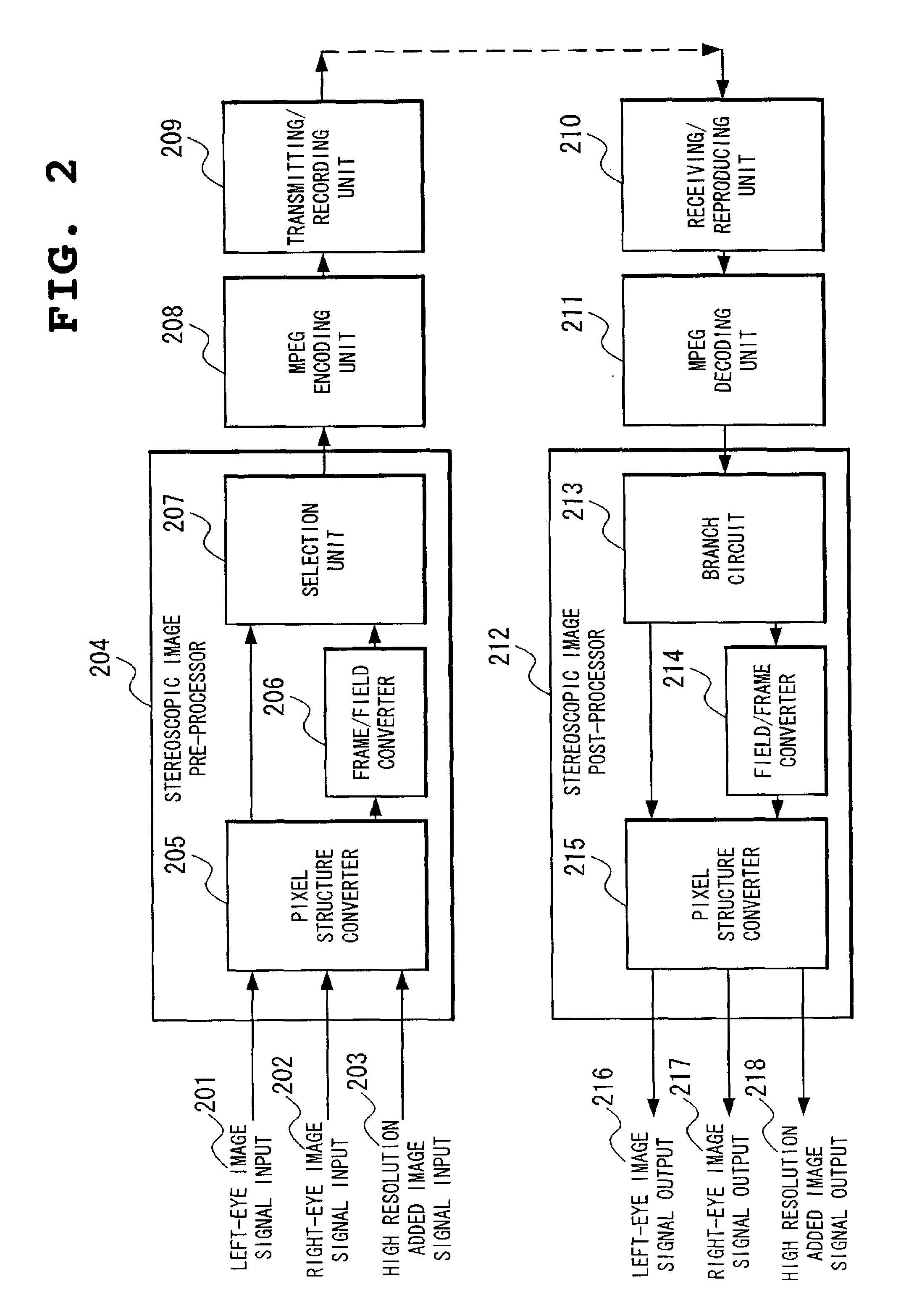

Stereoscopic image encoding and decoding device multiplexing high resolution added images

InactiveUS20080152241A1Efficiently encoding and transferring image dataEfficient codingCharacter and pattern recognitionImage codingMultiplexingComputer graphics (images)

A left-eye image signal and a right-eye image signal are supplied to a pixel structure converter of a stereoscopic image pre-processor, and multiplexed, so to form one image, an interlace image is formed by a frame / field converter, encoded in an MPEG format by an MPEG encoding unit, stored into a storage and transmitted outward by a transmitting / recording unit. The encoded stereoscopic image signal received from the outward and reproduced from the storage is decoded by am MPEG decoding unit after going through a receiving / reproducing unit, the interlace image is reproduced, returned to the frame image by a field / frame converter of a stereoscopic image post-processor, and reproduced as the left-eye image signal and the right-eye image signal and output by the pixel structure converter.

Owner:NEC CORP

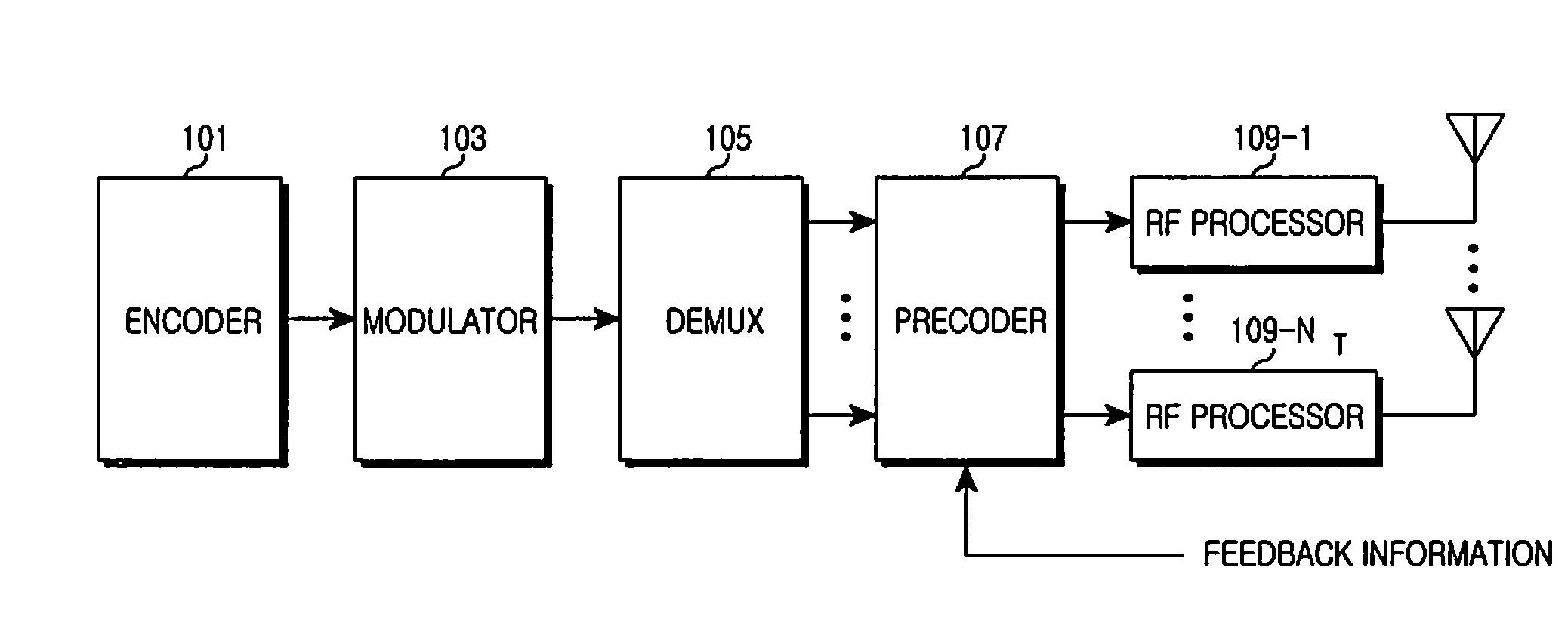

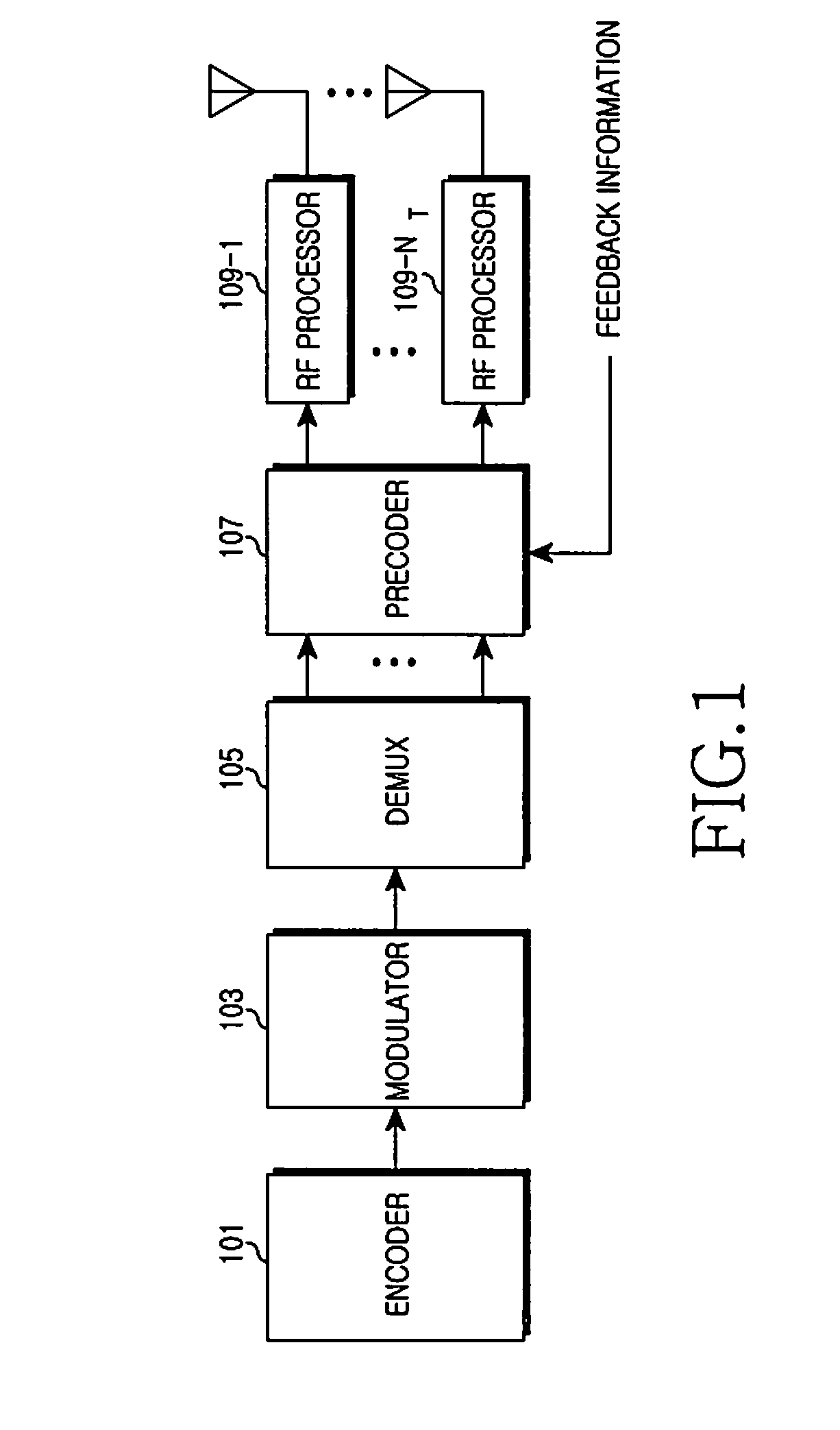

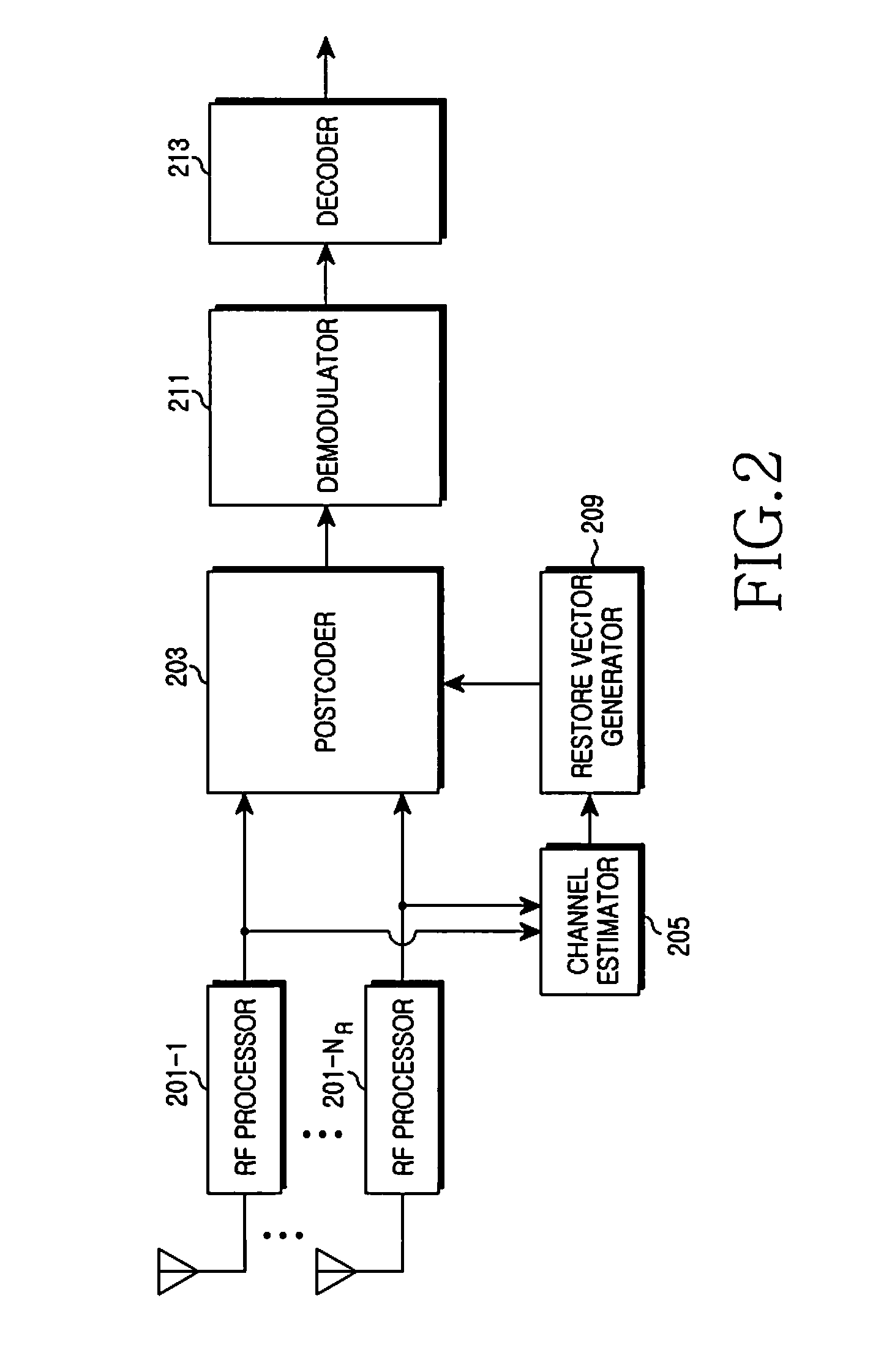

Apparatus and method for transmitting and receiving in a multi-antenna system

ActiveUS20100046655A1Reduce errorsReduce calculationModulated-carrier systemsPolarisation/directional diversityPost processorEngineering

Apparatuses and methods for transmitting and receiving in a multi-antenna system are provided. A receiver for reducing a quantization error of channel information feedback in a multi-antenna system includes a restore vector generator for selecting a codeword ck and d determining a real part wkreal and an imaginary part wkimag of a restore vector corresponding to the codeword; and a post-processor for performing post-processing by multiplying the real part wkreal of the restore vector by a first reception signal and multiplying the imaginary part wkimag of the restore vector by a second reception signal.

Owner:SAMSUNG ELECTRONICS CO LTD +1

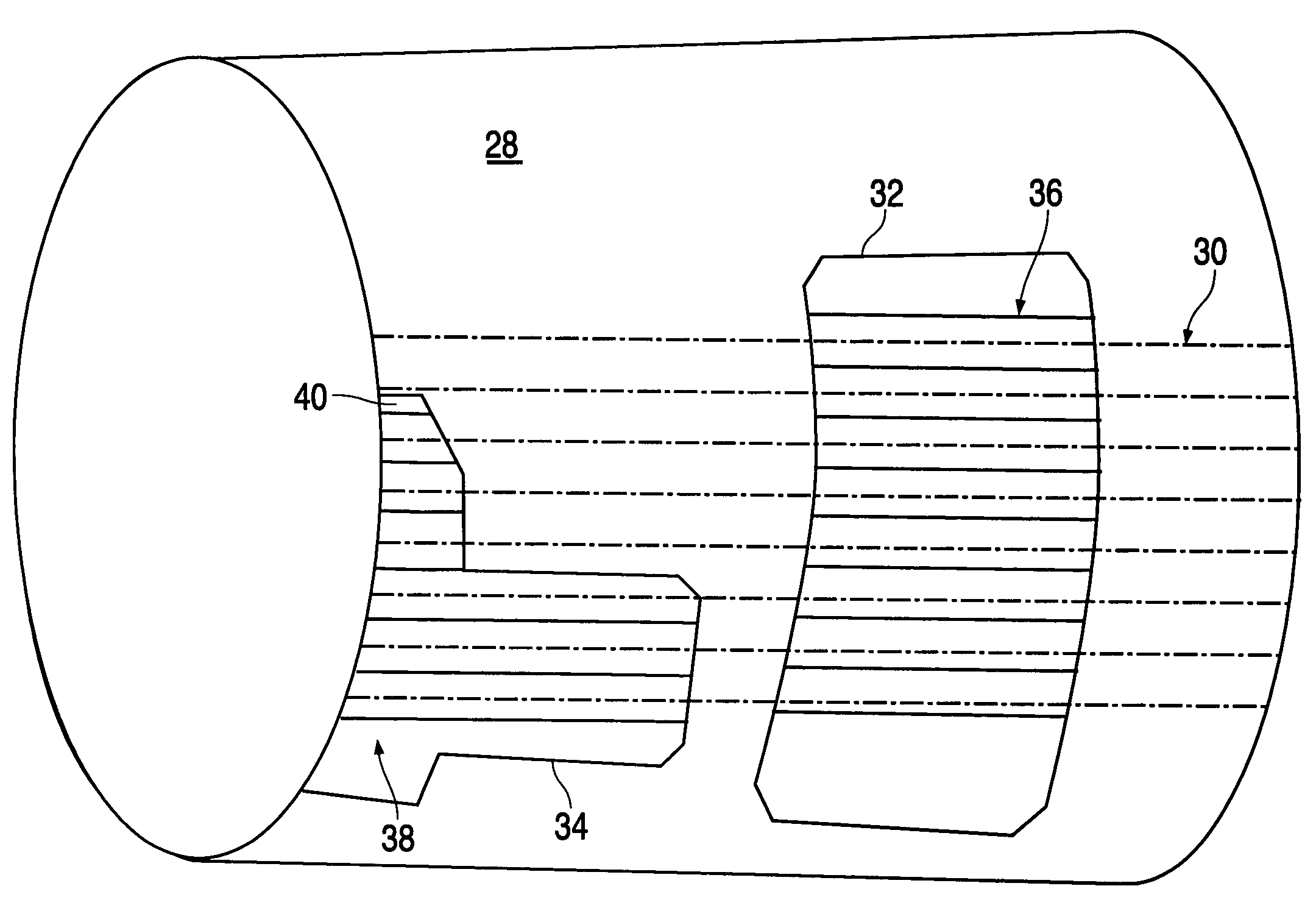

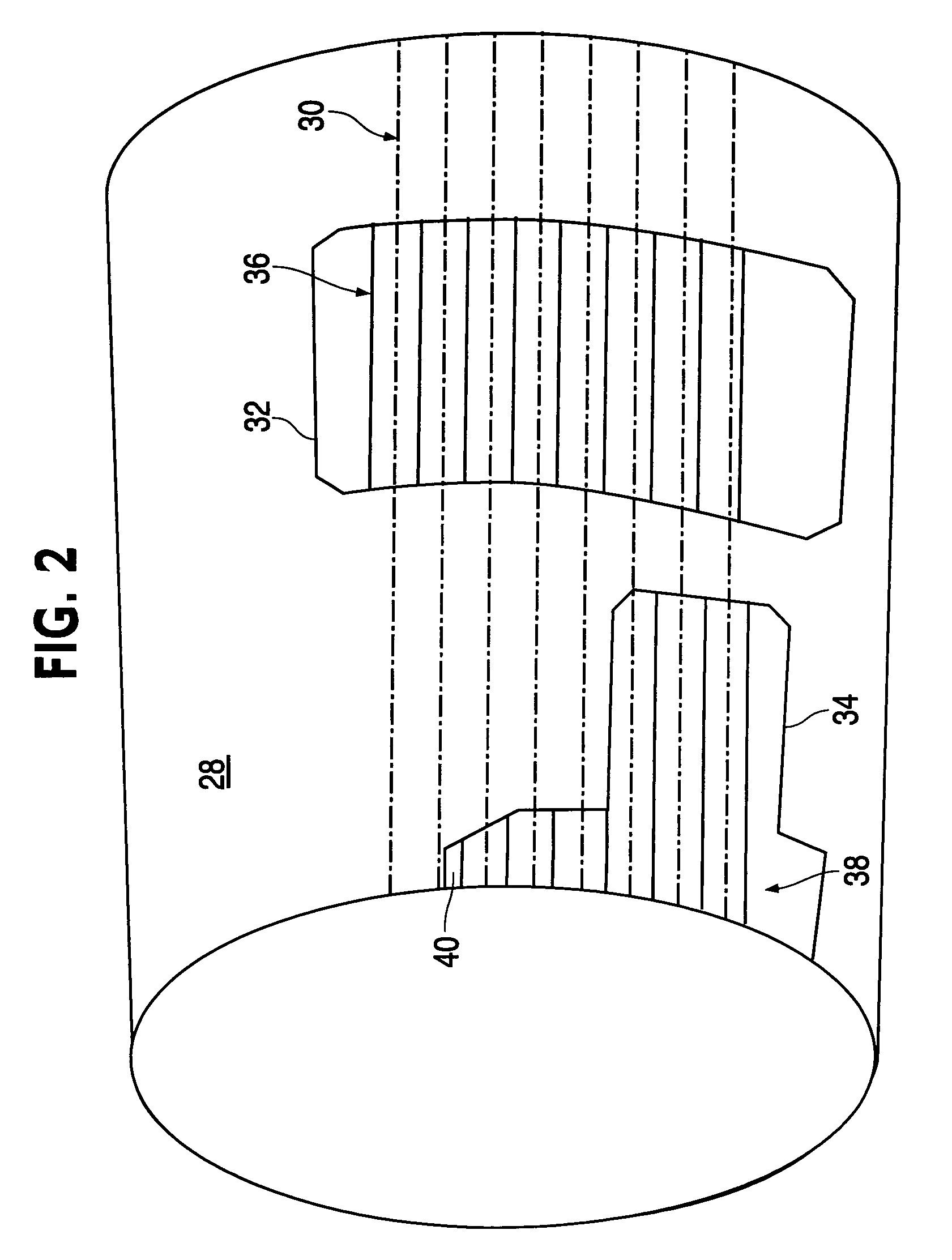

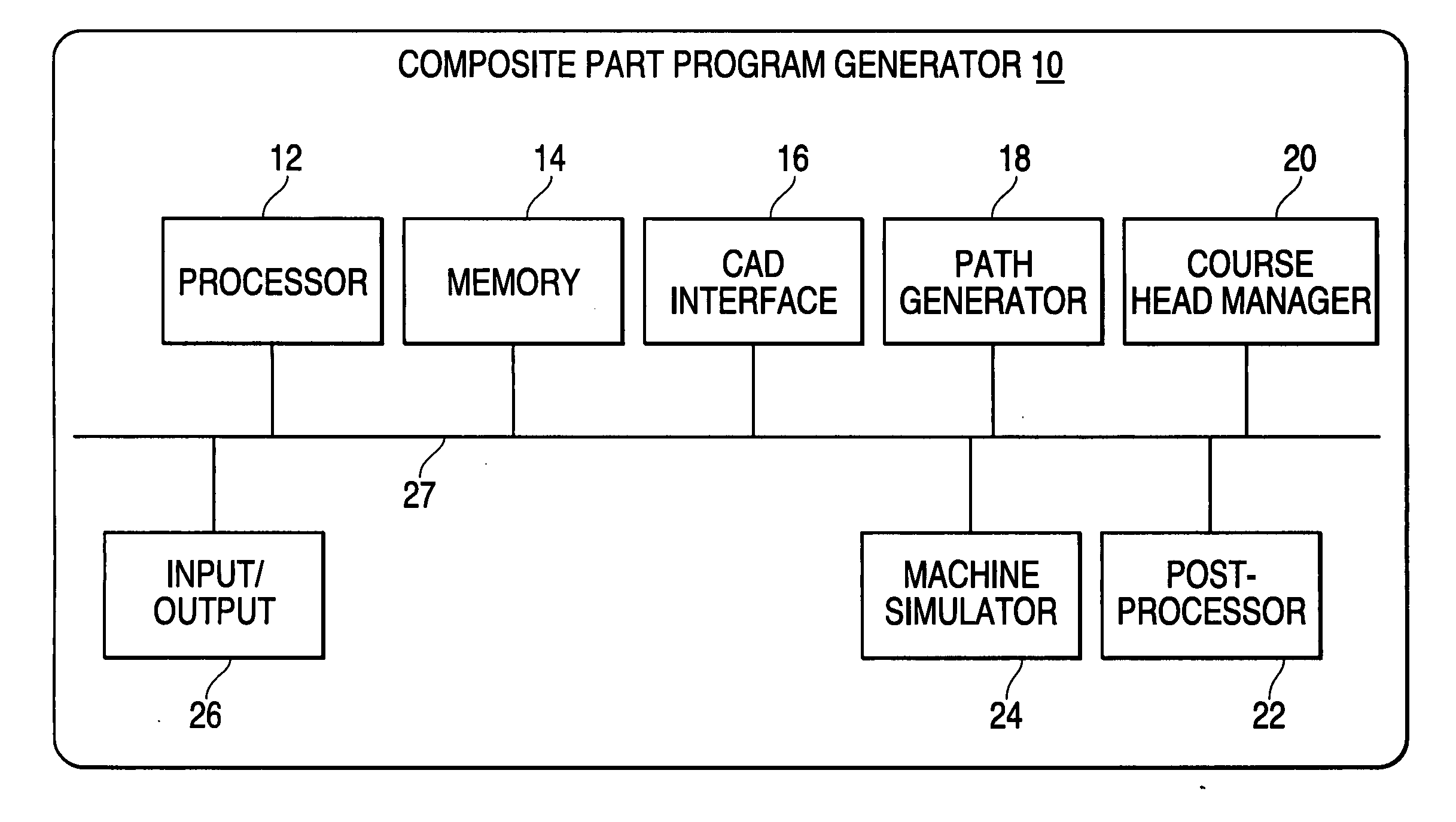

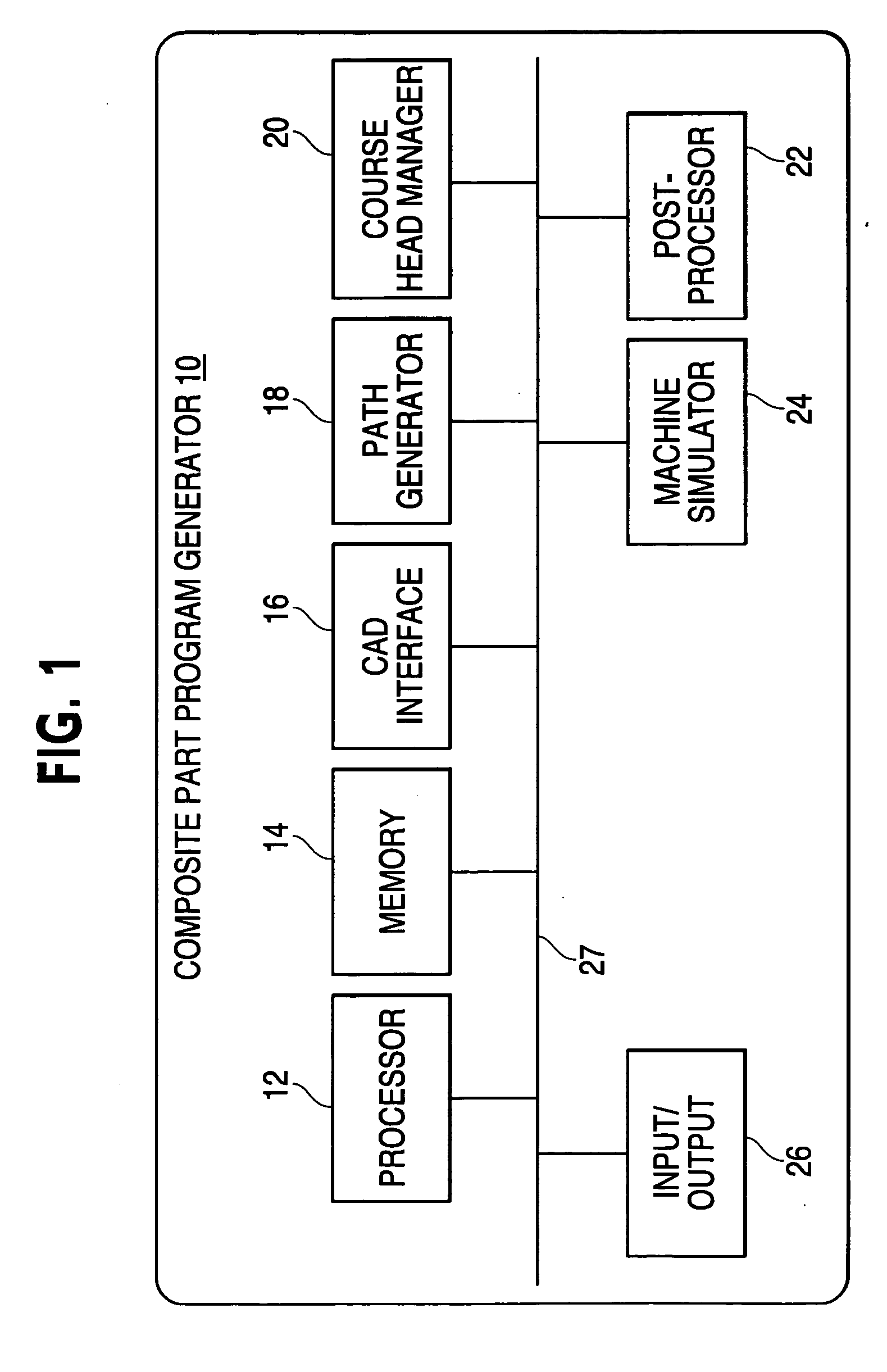

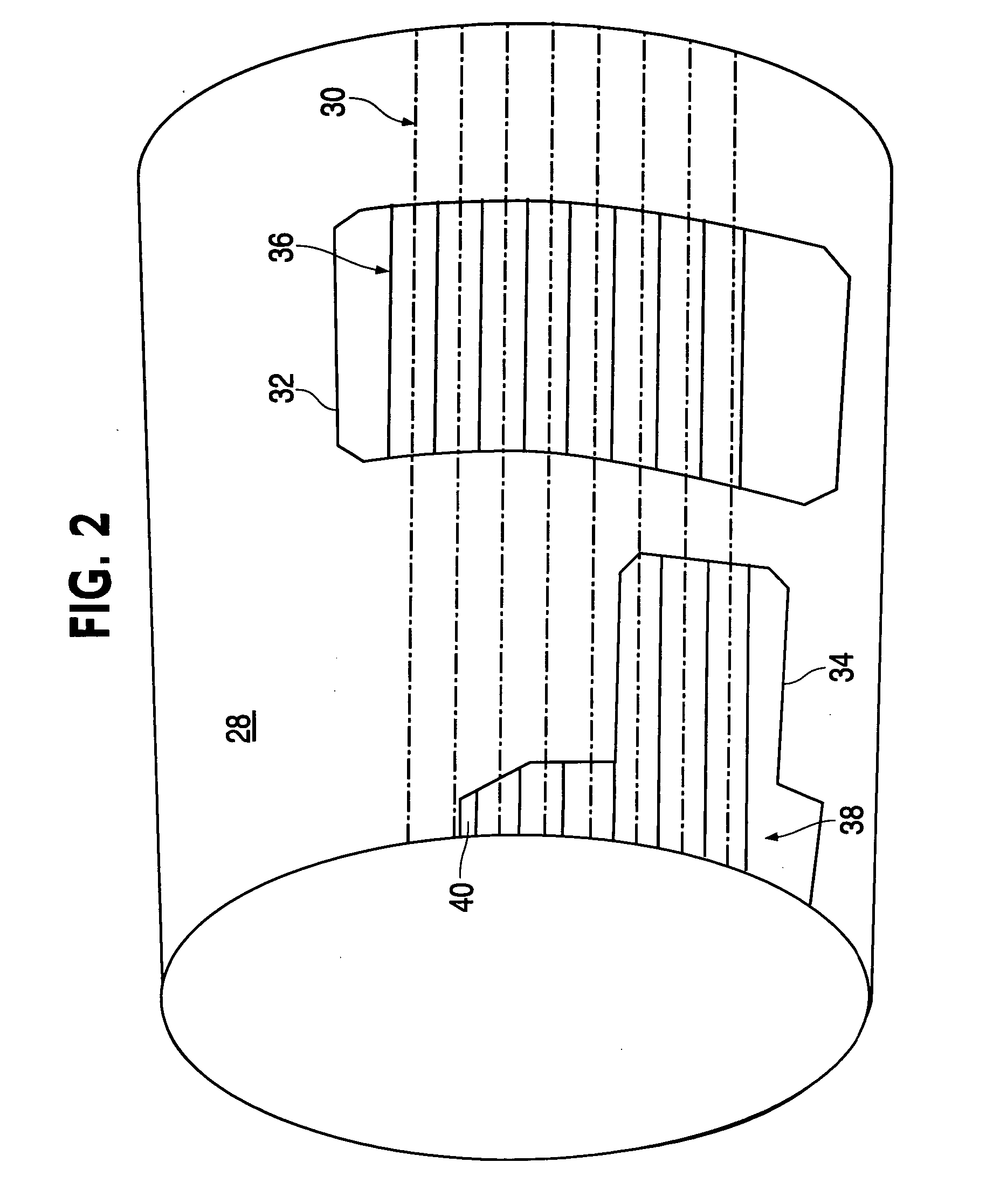

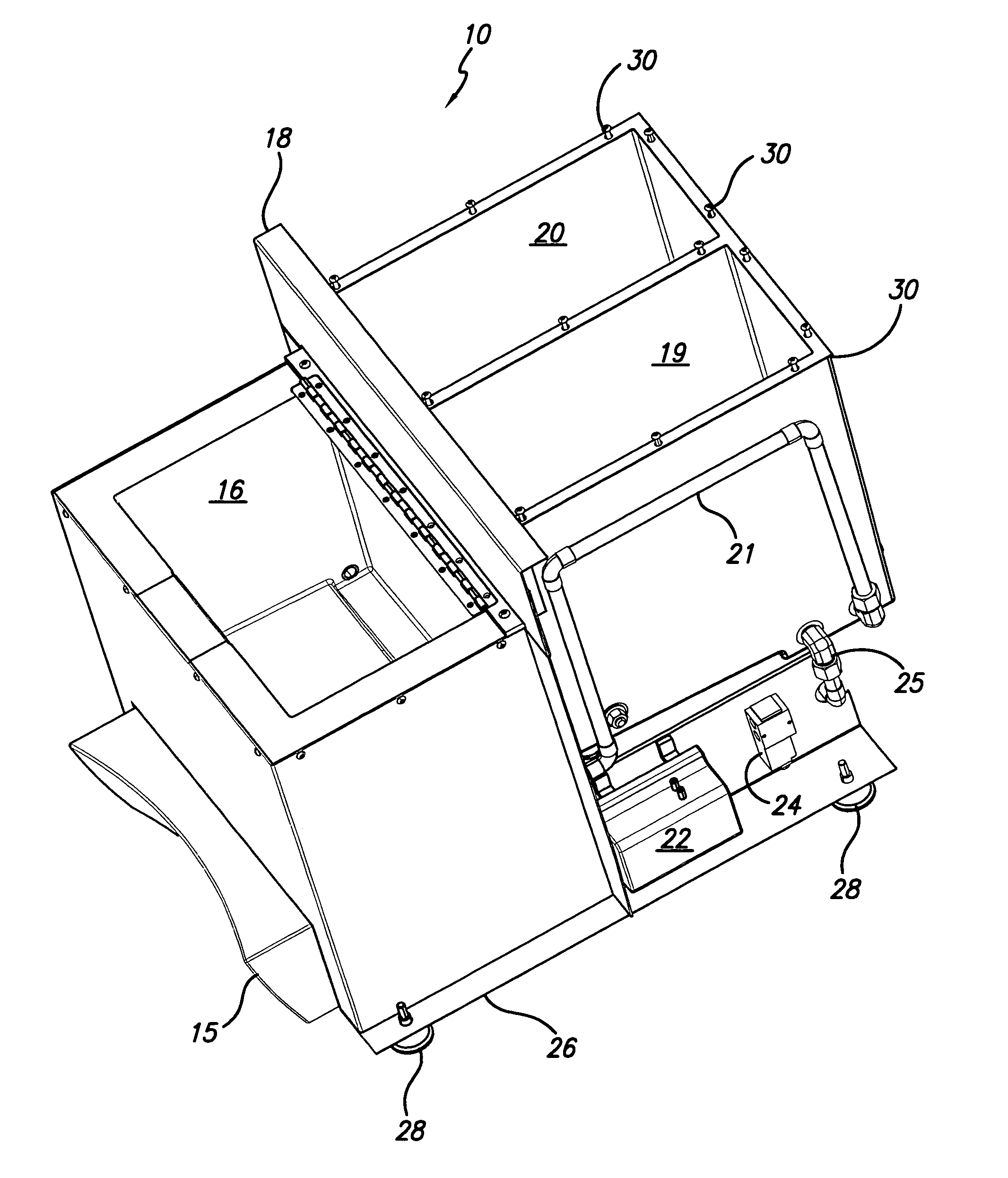

Multihead composite material application machine programming method and apparatus for manufacturing composite structures

ActiveUS7376480B2Efficient productionProgramme controlControlling laminationComputer Aided DesignFiber

A composite part program generator includes a computer-aided design (CAD) system interface, a path generator, a course head manager, a post-processor and a machine simulator. The composite part program generator produces composite part programs for use on a multihead composite material application machine, such as a composite tape lamination machine or an automated fiber placement (AFP) machine, to manufacture a complex composite parts, including relatively flat, contoured, or generally cylindrical composite parts. This programming method can reduce the labor and time required to produce a composite part program for a multihead composite material application machine by an order of magnitude with respect to manual or existing automated programming methods.

Owner:THE BOEING CO

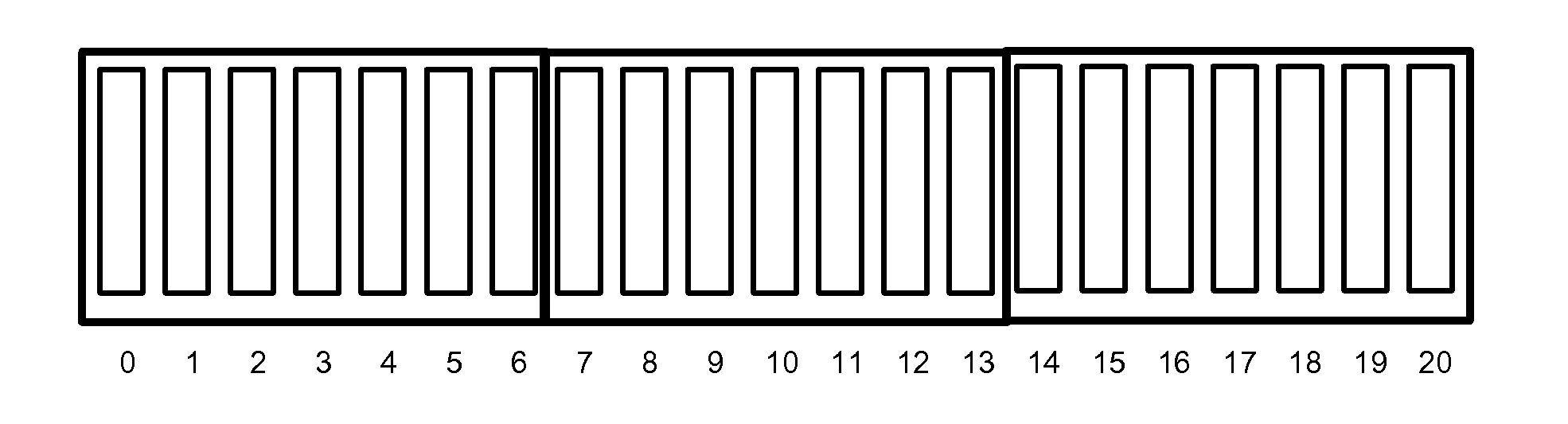

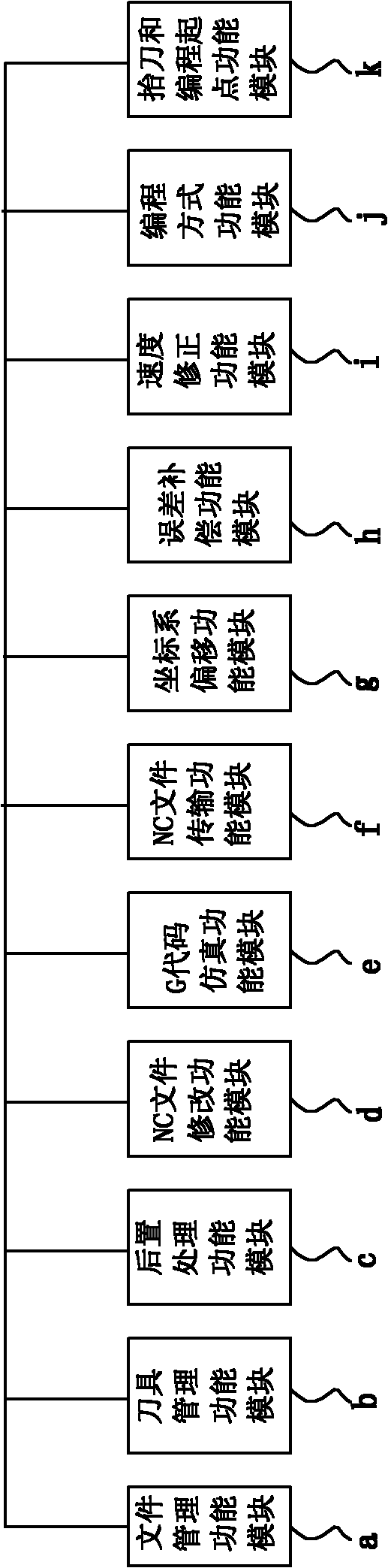

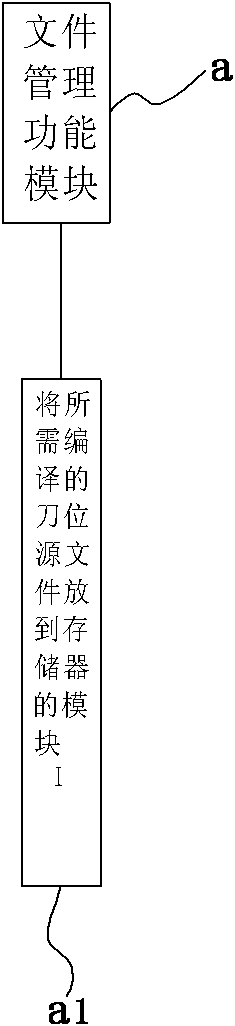

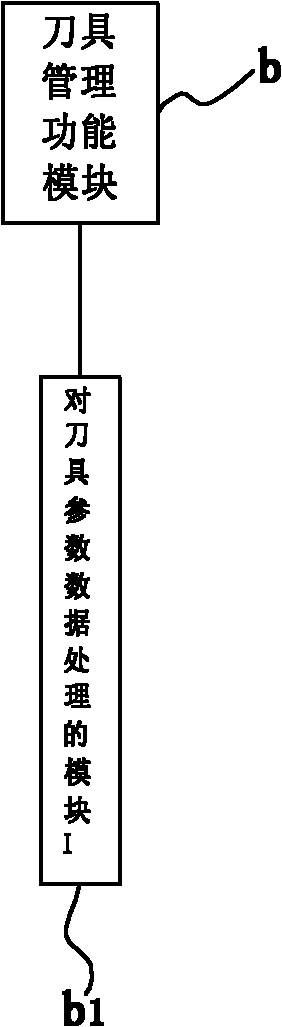

Five-axis linkage numerical control (NC) machining post processor and processing method thereof

InactiveCN102023613ARealize simulationRealize serial communicationProgramme controlComputer controlPost processorManagement functions

The invention discloses a five-axis linkage numerical control (NC) machining post processor and a processing method thereof, and relates to a post processor for an NC machining program and a processing method. The processor comprises computer program software which is used for processing a cutter location source file generated by a workpiece shape characteristic and a machining process, wherein the computer program software comprises a file management function module, a cutter management function module, a postprocessing function module, an NC file modification function module, a G code simulation function module, an NC file transmission function module, a coordinate system offset function module, an error compensation function module, a speed modification function module, a programming mode function module and a cutter-lifting and programming staring point function module. The processing method comprises the steps of setting a file, arranging a cutter, processing a programming mode, processing data of machine tool motion parameters, processing data of cutter dynamic cutting speed, outputting a G code file and the like. By the processor and the processing method, machining dynamic speed, speed compensation, non-linear error compensation and analog simulation of G code five-axis linkage can be realized.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY +1

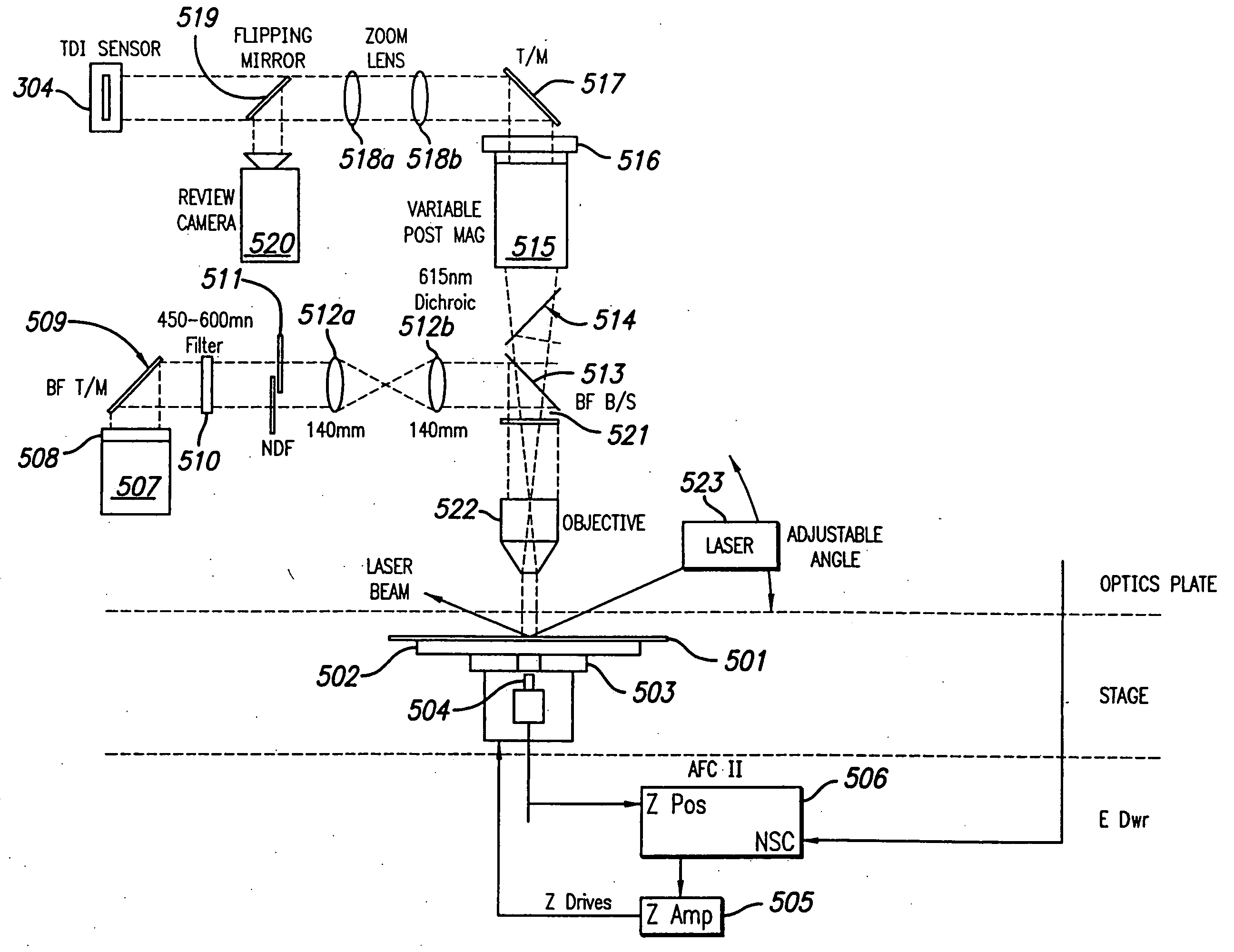

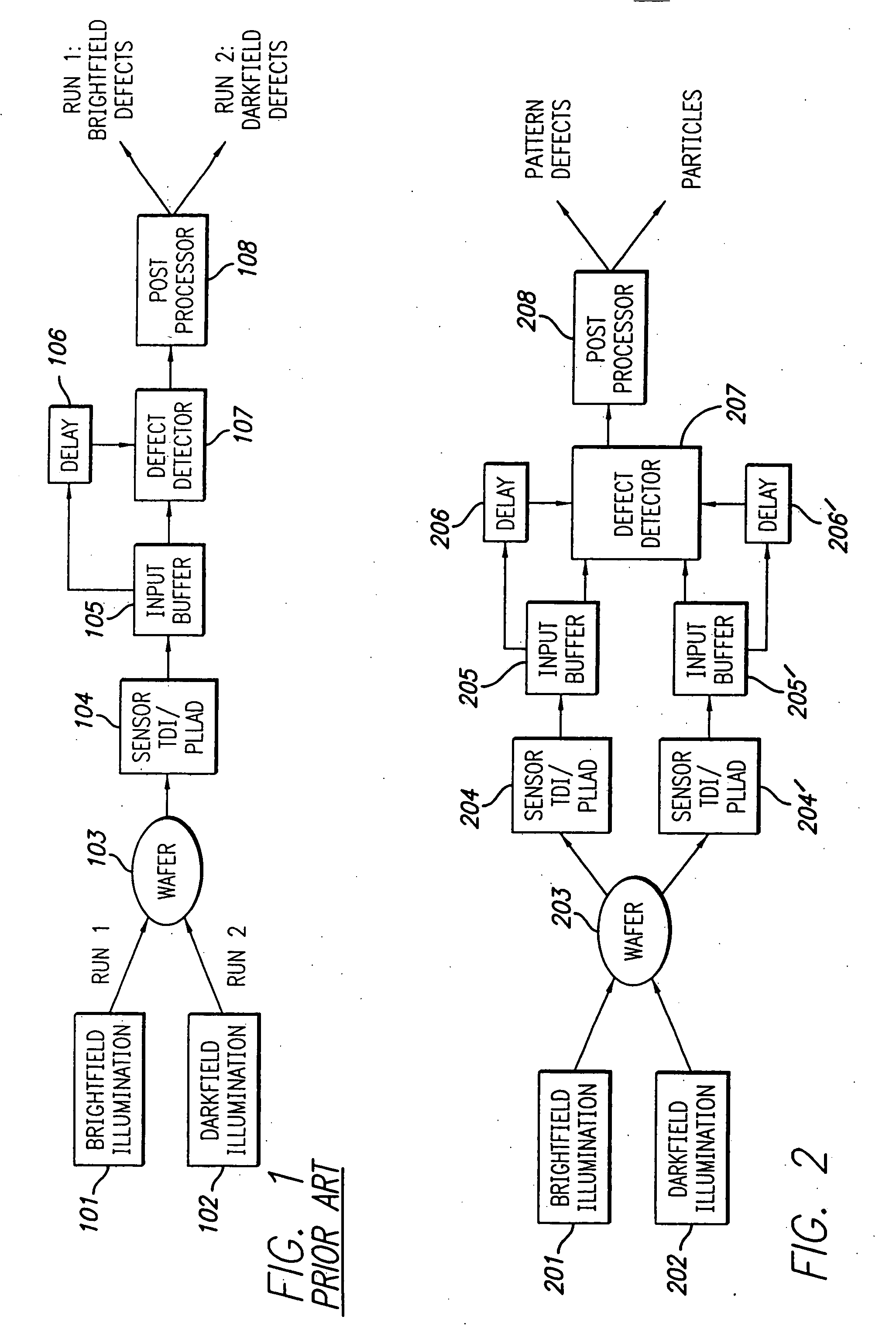

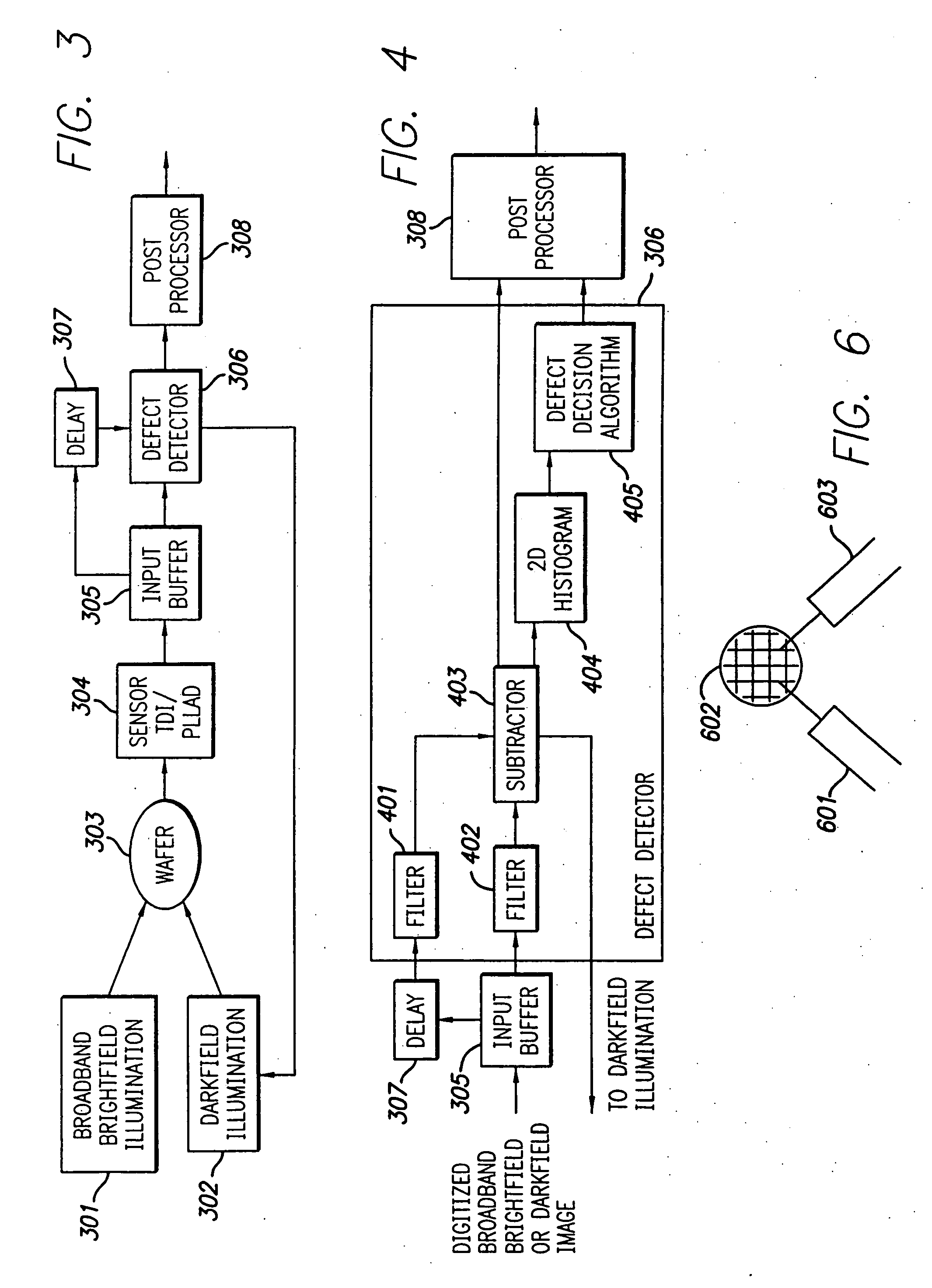

High throughput brightfield/darkfield wafer inspection system using advanced optical techiques

InactiveUS20050062962A1Great level of detectionImprove the level ofPolarisation-affecting propertiesOptically investigating flaws/contaminationDual modePost processor

The broadband brightfield / darkfield wafer inspection system provided receives broadband brightfield illumination information via a defect detector, which signals for initiation of darkfield illumination. The defect detector forms a two dimensional histogram of the defect data and a dual mode defect decision algorithm and post processor assess defects. Darkfield radiation is provided by two adjustable height laser beams which illuminate the surface of the wafer from approximately 6 to 39 degrees. Each laser is oriented at an azimuth angle 45 degrees from the orientation of the Manhattan geometry on the wafer, and 90 degrees in azimuth from one another. Vertical angular adjustability is provided by modifying cylindrical lens position to compensate for angular mirror change by translating an adjustable mirror, positioning the illumination spot into the sensor field of view, rotating and subsequently moving the cylindrical lens. A brightfield beamsplitter in the system is removable, and preferably replaced with a blank when performing darkfield illumination. Light level control for the system is provided by a dual polarizer first stage. Light exiting from the second polarizer passes through a filter which absorbs a portion of the light and comprises the second stage of light control. The beam then passes through a polarizing beamsplitter. The second channel is further reflected and polarized and both beams thereafter illuminate the substrate.

Owner:KLA TENCOR TECH CORP

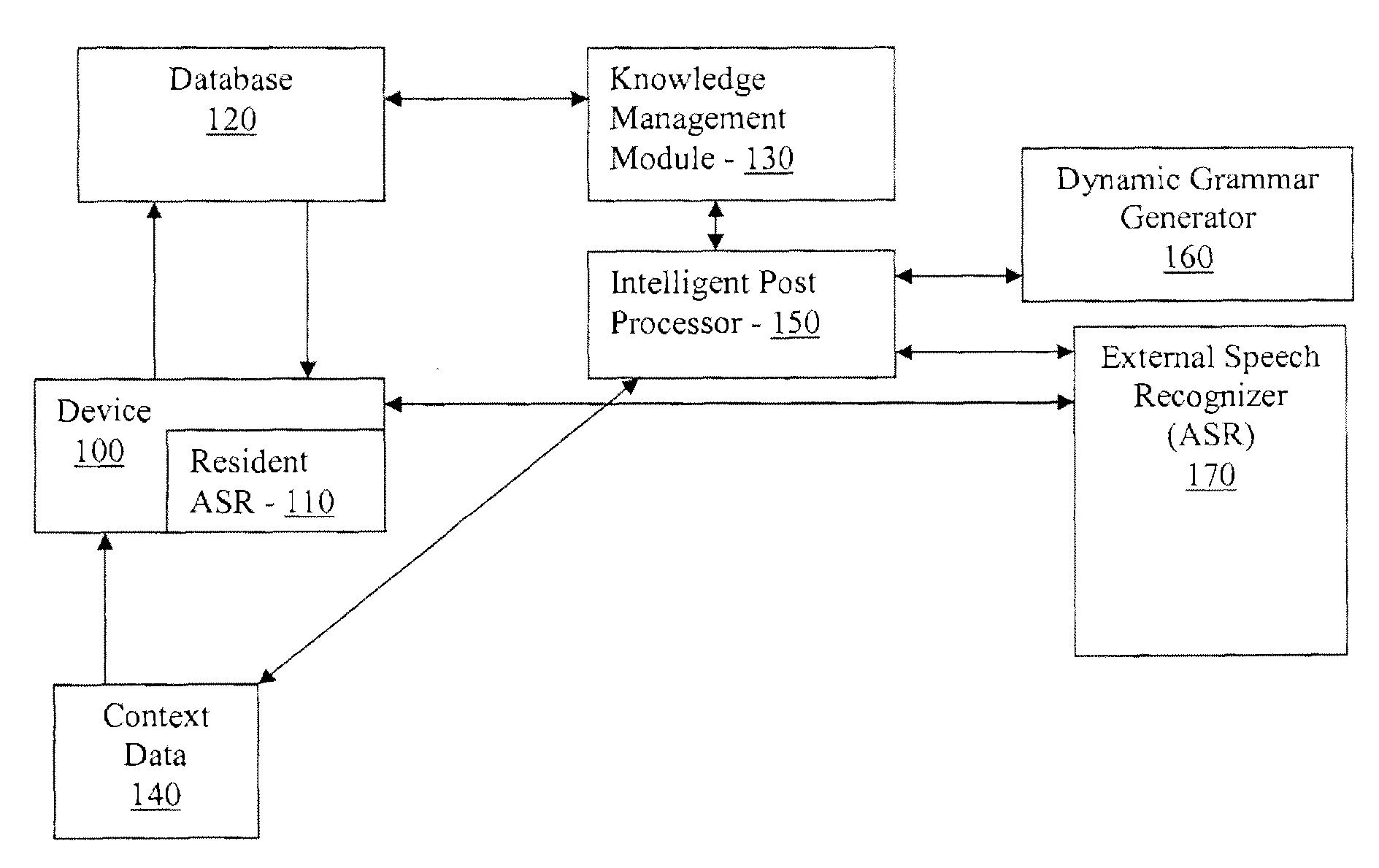

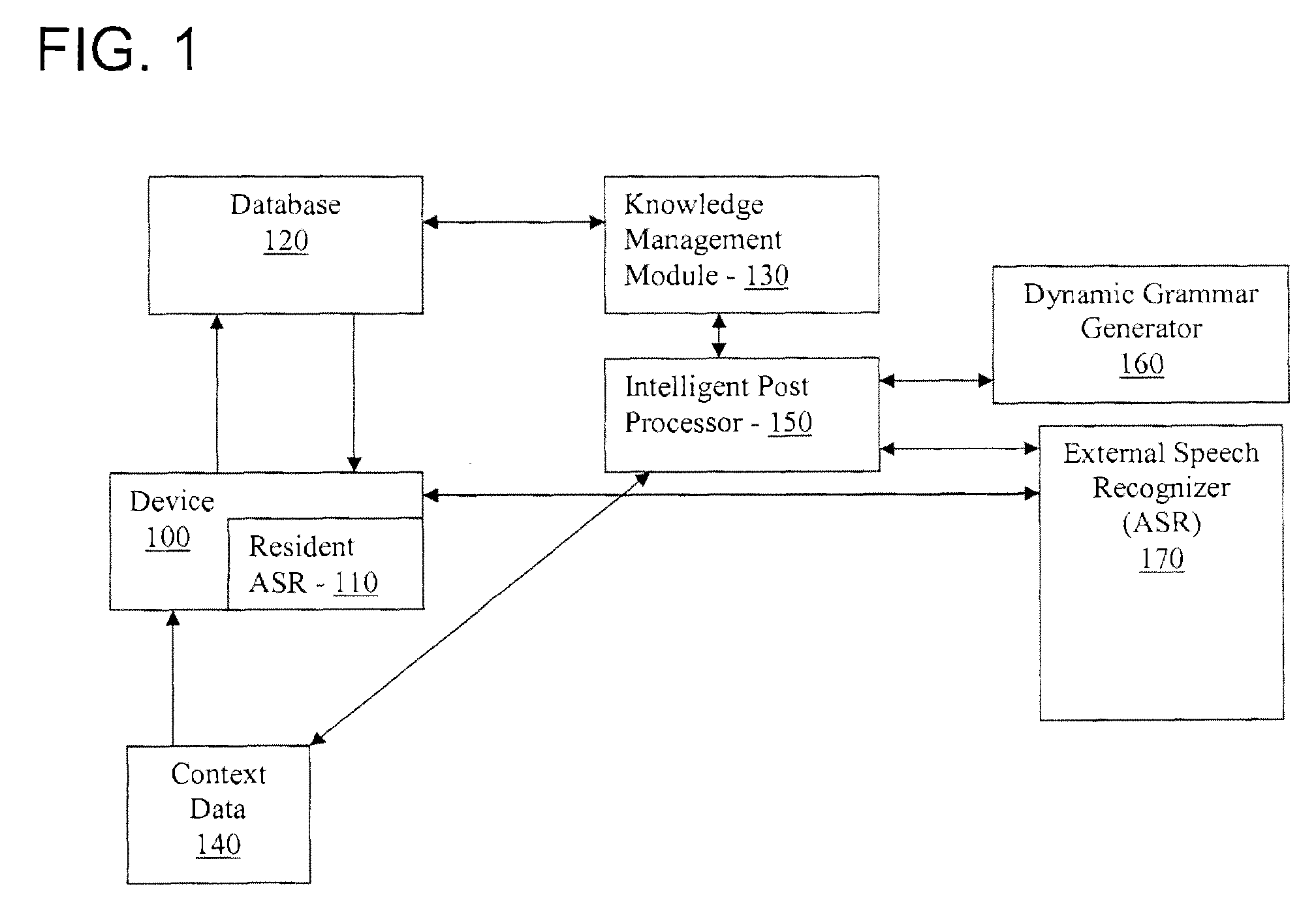

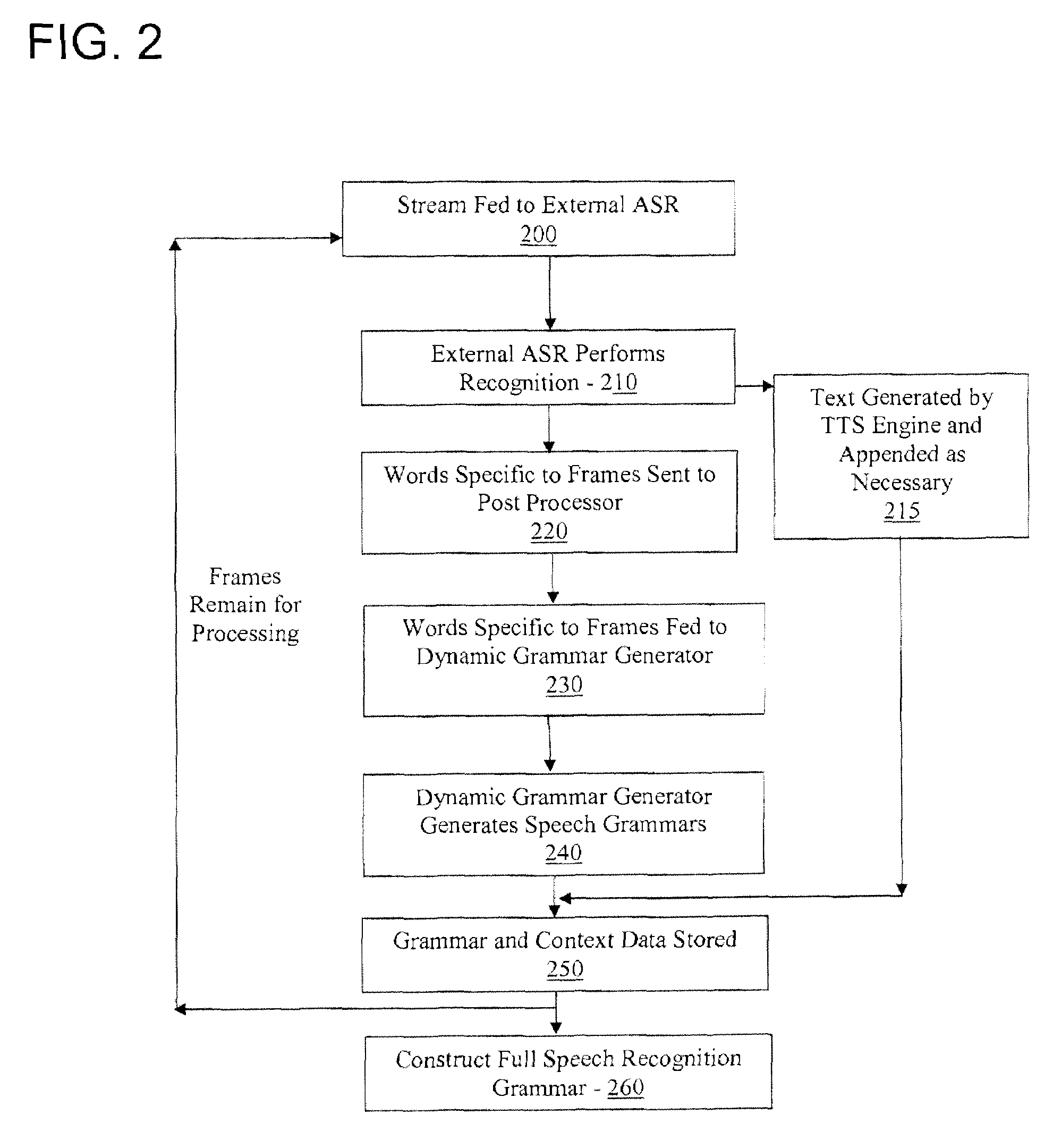

System and method for providing context-based dynamic speech grammar generation for use in search applications

A system and method for using a context-based dynamic speech recognition grammar generation system that is suitable for multimodal input when applied to context-based search scenarios. Dynamic context-based grammar is generated for a media stream during a post-processing period. The media stream is fed to an external automatic speech recognizer (ASR) for a specified number of frames. The ASR performs recognition of words that do not occur in common vocabulary that may be specific to those media frames. These words that are specific to the frames are sent back to the post processor, where they are fed to a dynamic grammar generator that generates speech grammars in some format, using the words that are fed to it. This grammar and other contextual information, form a new set of context data for those frames of media. The media, the grammar and other context data. is stored in a database. This is repeated for the entire stream of media, and a full speech recognition grammar can be constructed.

Owner:NOKIA CORP

Rhythm action game apparatus and method

InactiveUS7528315B2Increased complexityElectrophonic musical instrumentsVideo gamesPost processorAudio analyzer

A rhythm action game apparatus comprising an audio analyzer adapted to analyze a music track and provide corresponding rhythm data, and a sequence generator adapted to generate game play cues according to said rhythm data. There is also disclosed a music processor comprising an audio analyzer adapted to analyze a music track and provide corresponding rhythm data, and an audio post processor adapted to reconfigure the music track controlled by the rhythm data.

Owner:CODEMASTERS

Multihead composite material application machine programming method and apparatus for manufacturing composite structures

ActiveUS20070106418A1Efficient productionProgramme controlTotal factory controlFiberComputer Aided Design

A composite part program generator includes a computer-aided design (CAD) system interface, a path generator, a course head manager, a post-processor and a machine simulator. The composite part program generator produces composite part programs for use on a multihead composite material application machine, such as a composite tape lamination machine or an automated fiber placement (AFP) machine, to manufacture a complex composite parts, including relatively flat, contoured, or generally cylindrical composite parts. This programming method can reduce the labor and time required to produce a composite part program for a multihead composite material application machine by an order of magnitude with respect to manual or existing automated programming methods.

Owner:THE BOEING CO

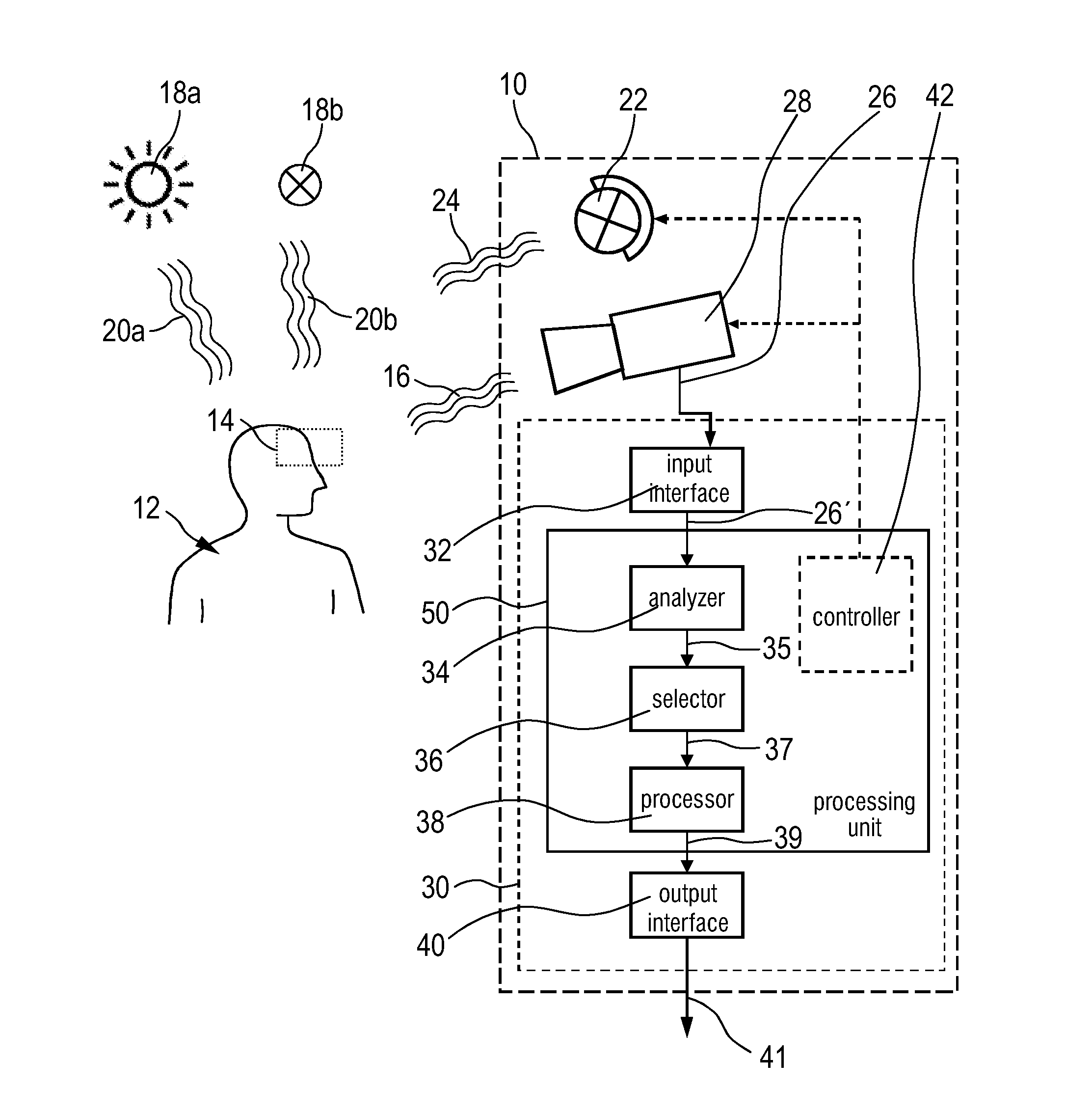

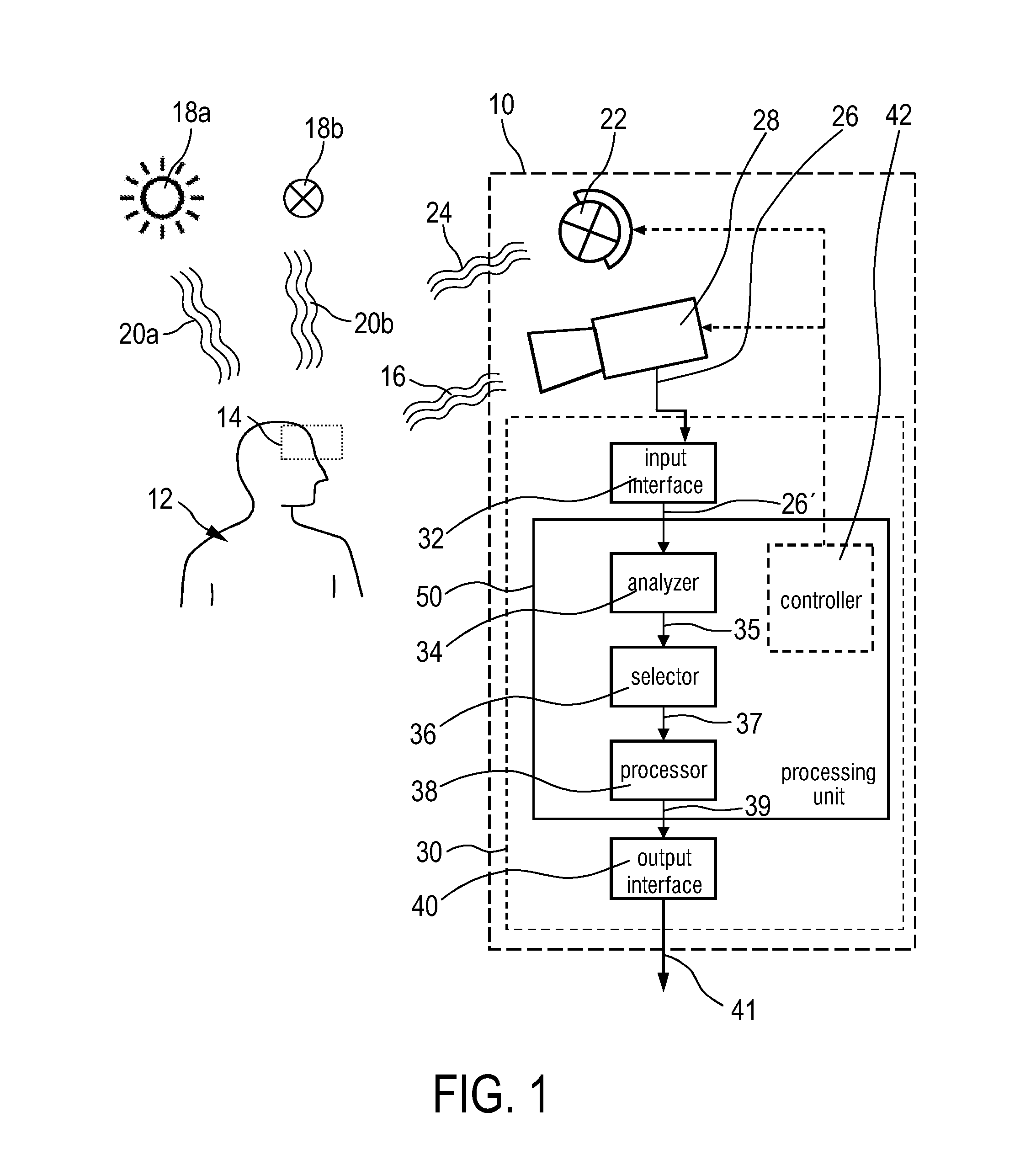

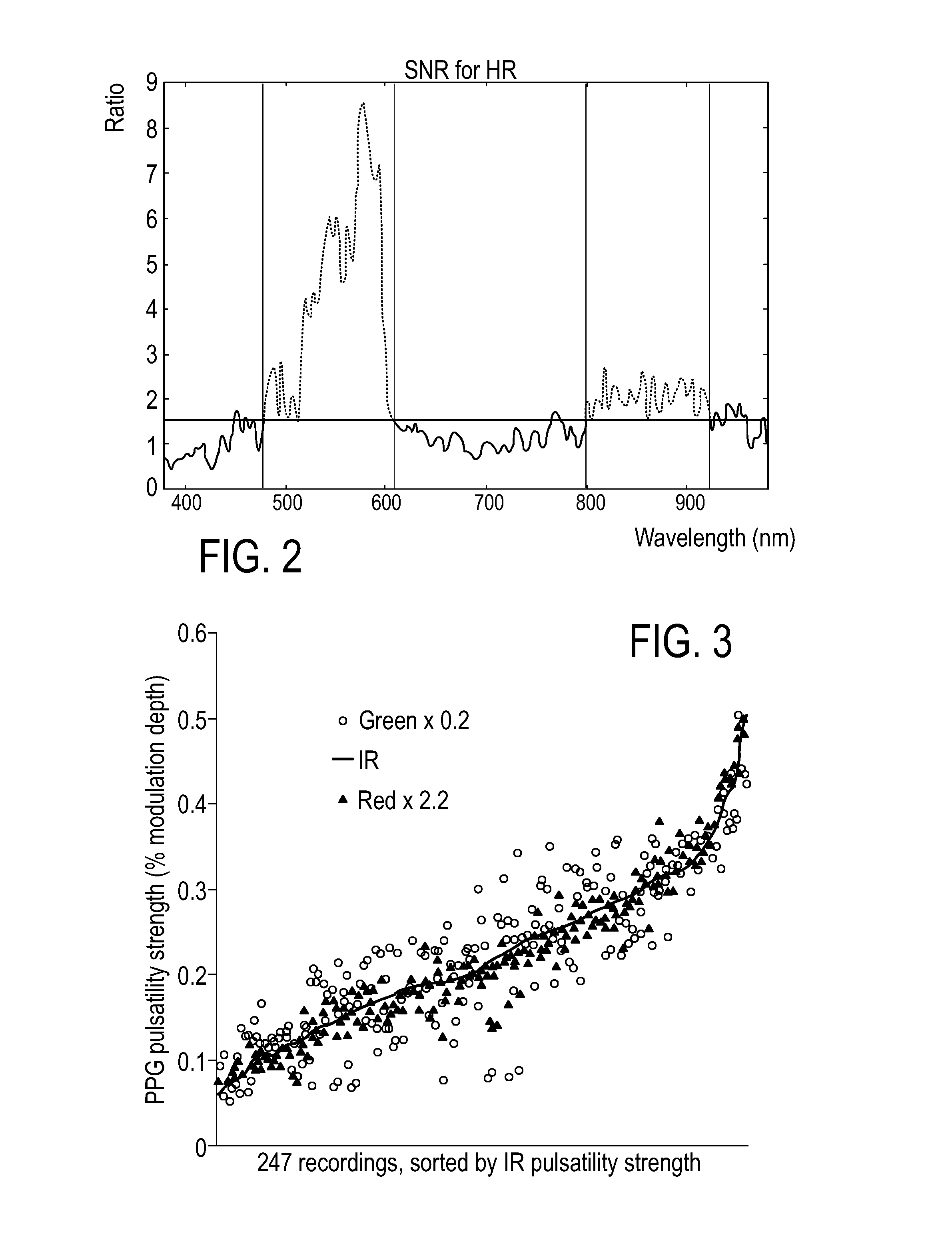

Device and method for determining vital signs of a subject

ActiveUS20140276089A1Improve signal-to-noise ratioReliable distinctionRespiratory organ evaluationSensorsOptical propertyData stream

A device for determining a vital sign of a subject comprises an interface for receiving a data stream derived from detected electromagnetic radiation reflected from a region of interest including a skin area of the subject, said data stream comprising a data signal per skin pixel area of one or more skin pixels for a plurality of skin pixel areas of said region of interest, a data signal representing the detected electromagnetic radiation reflected from the respective skin pixel area over time. An analyzer is provided for analyzing spatial and / or optical properties of one or more data signals in one or more wavelength ranges. A processor is provided for determining a vital sign information signal of the subject based on the data signals of skin pixel areas within the skin area, and a post-processor is provided for determining the desired vital sign from said vital sign information signal. The determined spatial and / or optical properties are used by the processor for determining the vital sign information signal and / or by the post-processor for determining the desired vital sign.

Owner:KONINKLJIJKE PHILIPS NV

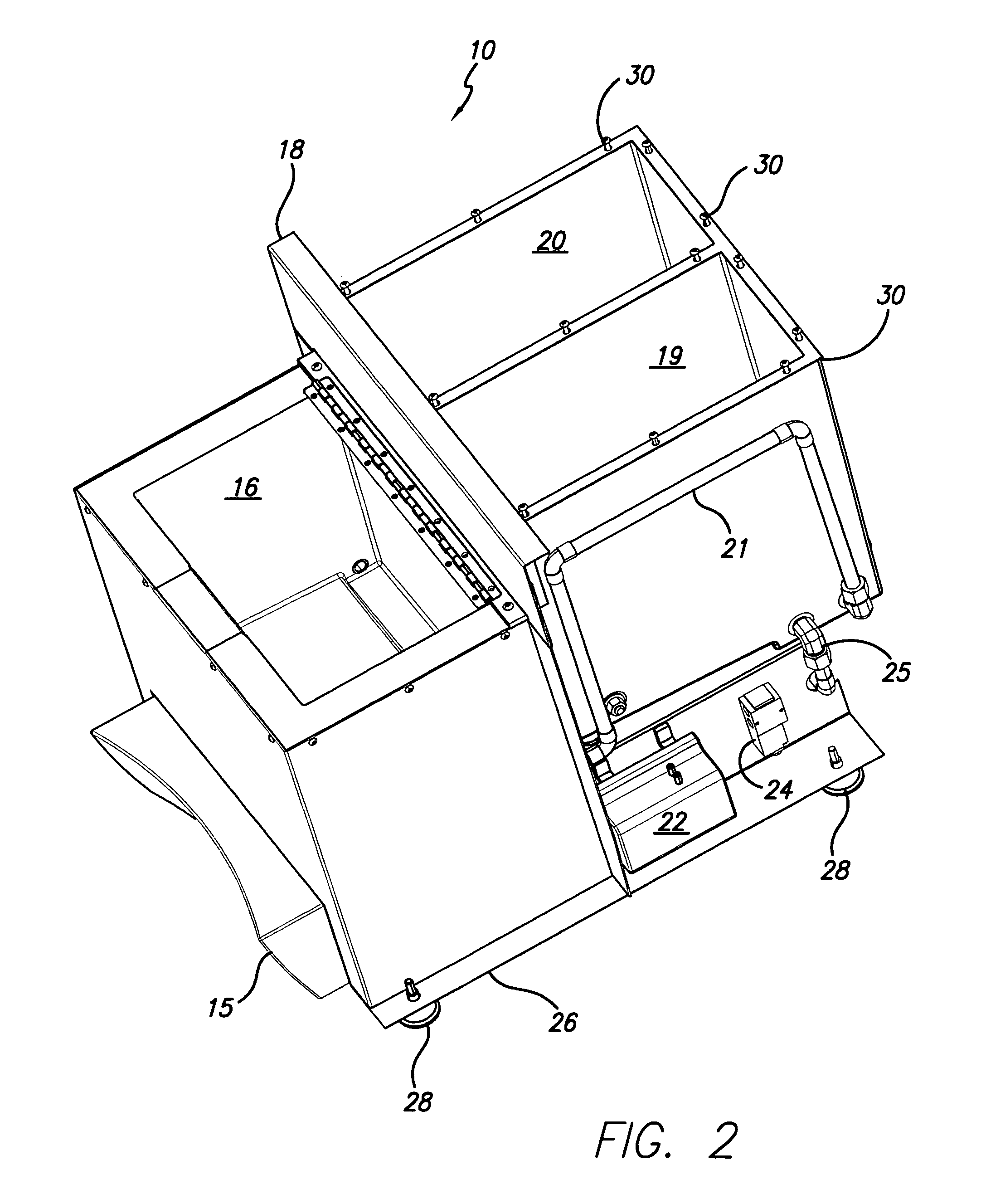

Post processor for three-dimensional objects

ActiveUS7114943B1Low costEfficient removalAdditive manufacturing apparatusConfectioneryPost processorEngineering

A post processing apparatus for automated removal of support material from a three-dimensional objected formed from a build material by selective deposition modeling is provided. The apparatus includes a heated main chamber into which is placed the three-dimensional object with the support material attached and first and second liquid heat transfer medium storage reservoirs. The storage reservoirs reversibly provide liquid heat transfer medium to the main chamber to immerse the three-dimensional object and the attached support material for desired periods of time to meltingly separate the support material from the object.

Owner:3D SYST INC

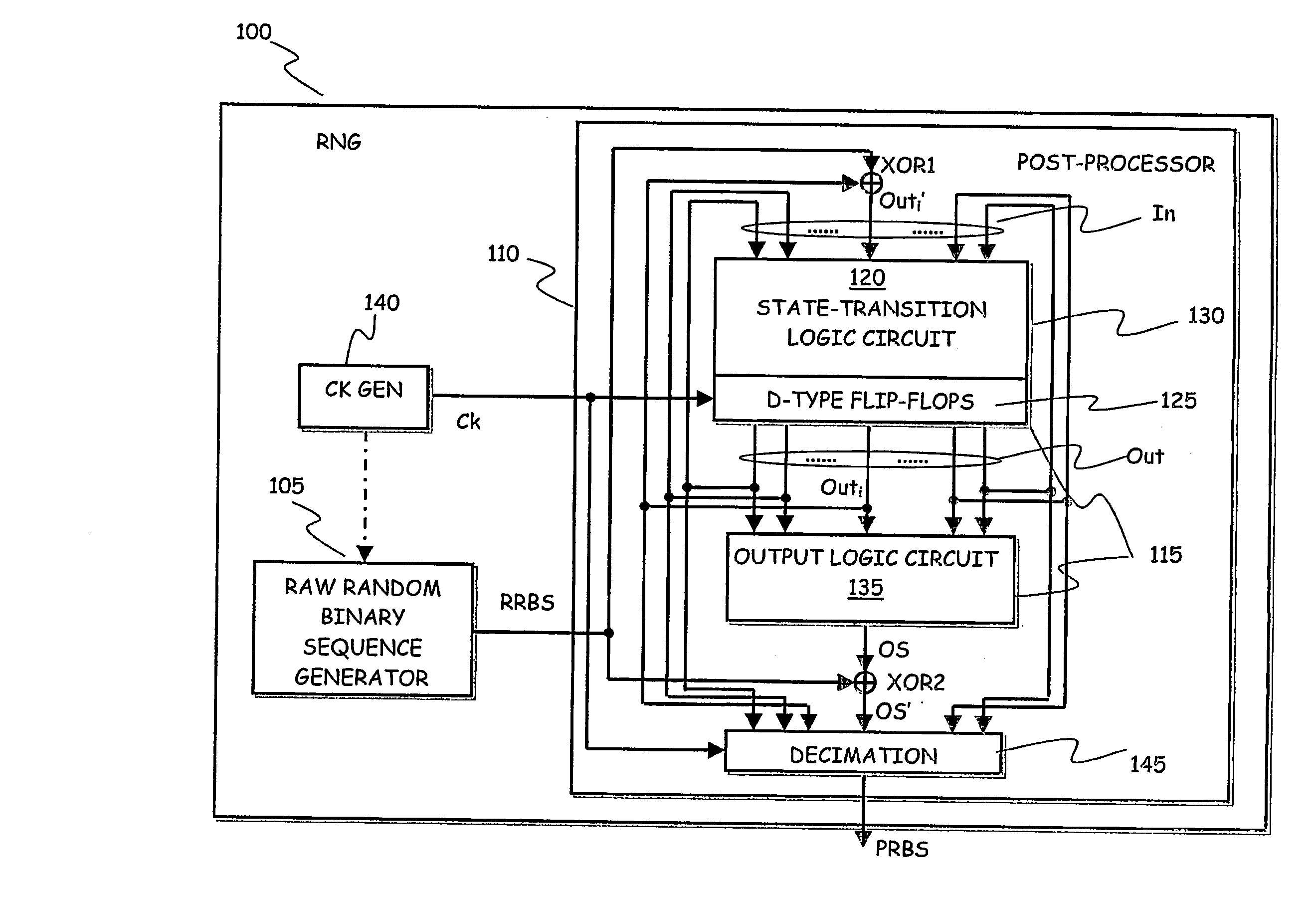

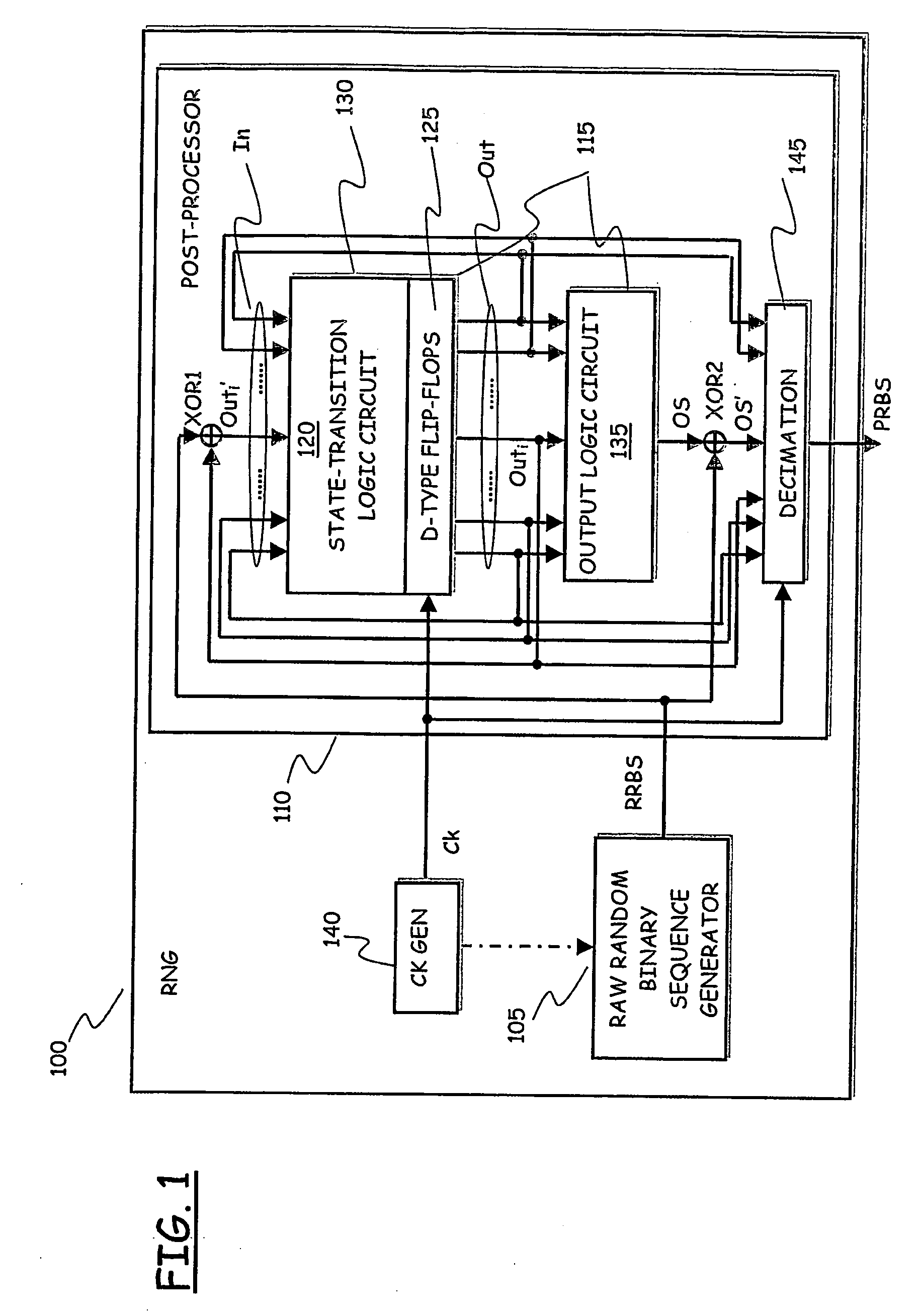

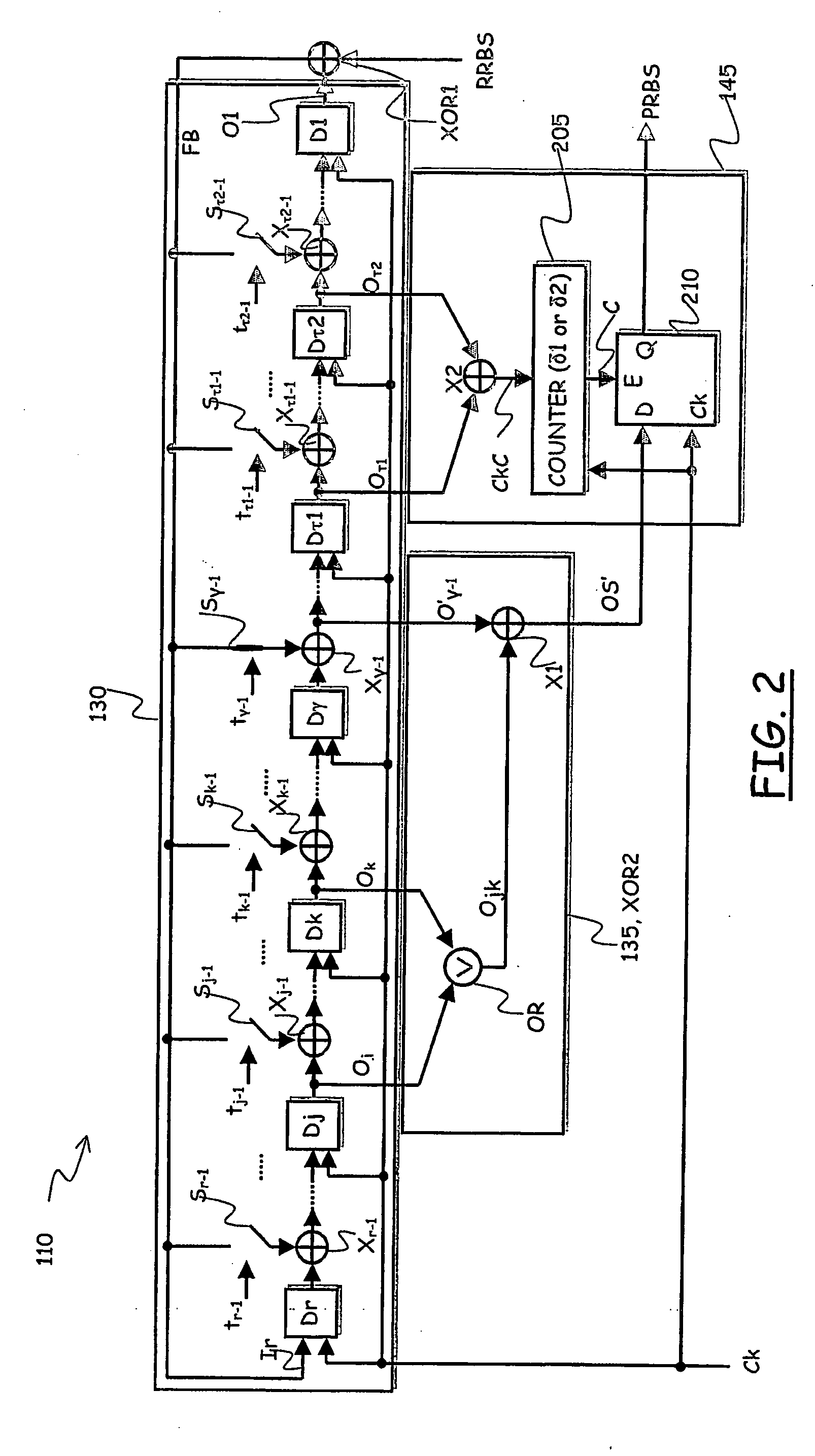

Method and Apparatus for Generating Random Data

ActiveUS20070244950A1Efficient implementationRandom number generatorsDigital function generatorsPost processorFinite-state machine

An apparatus for generating random data includes a raw random sequence source adapted to generate a raw random sequence and a digital post processor adapted to process the raw random sequence to generate the random data, wherein the digital post-processor includes a synchronous finite state machine having at least one input adapted to repeatedly receive a current value of the raw random sequence and at least one output to provide a current output value depending on previous values of the raw random sequence.

Owner:TELECOM ITALIA SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com