Integral impeller 5-axis machining method based on UG NX system platform

A system platform and processing method technology, applied in metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve problems such as complex geometry of the impeller, interference collision, large degree of distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

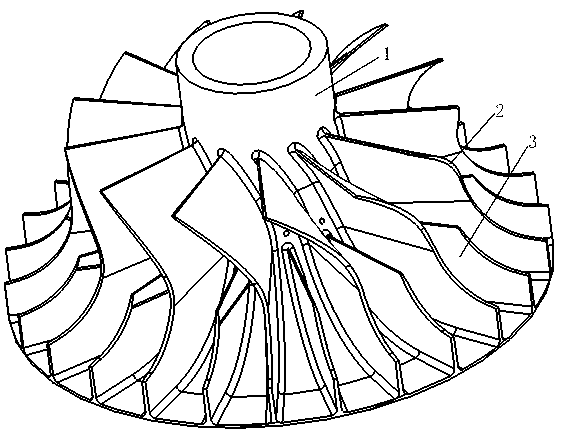

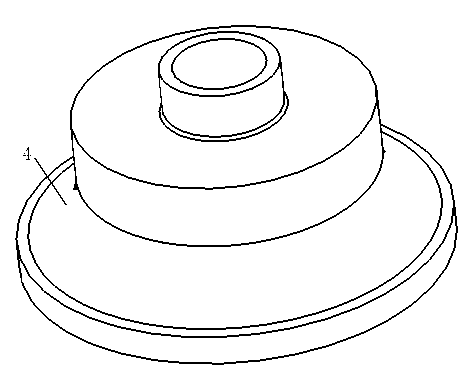

[0031] Refer to attached Figure 1-8 , the impeller that the present invention adopts is the compressor wheel rotor of CYS-150WP type turbojet engine. The diameter of the rotor outlet is 194mm, there are 13 primary blades 2, 13 secondary blades 3, the height of the outlet blades is 12.6mm, the diameter of the impeller 1 inlet is 136mm, the height of the inlet blades is 41mm, and the thinnest blade thickness is 0.8mm. The minimum distance between adjacent blades is 3mm. See the product digital model figure 1 .

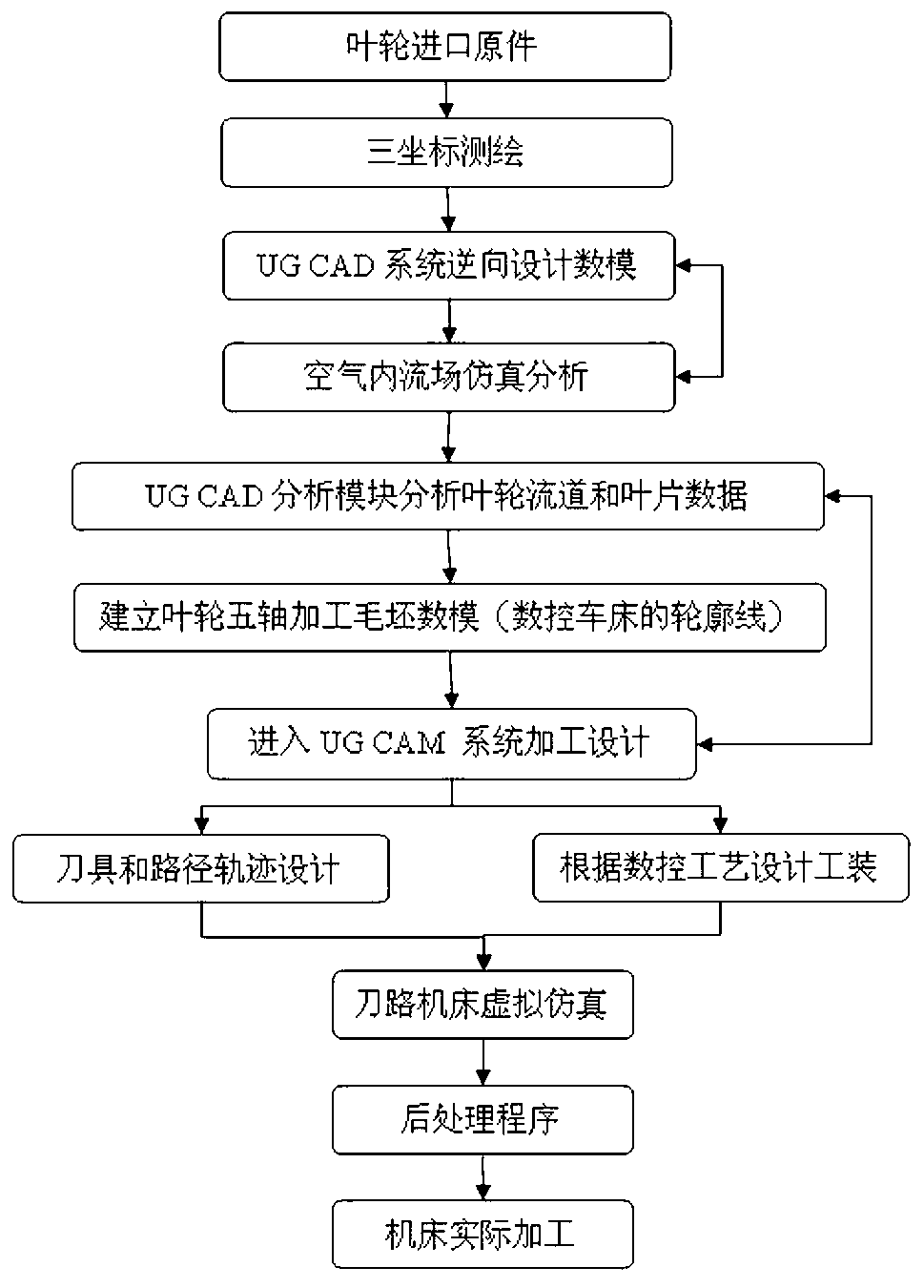

[0032] The steps of the five-axis machining method for the integral impeller based on the UG NX system platform are as follows:

[0033]1. Under the UG NX7.5 CAD system platform, reverse design technology is used to obtain the digital model of the compressor wheel. The reverse data of the compressor wheel is measured by the contact three-coordinate measuring instrument according to the given trajectory, and enters the modeling application environment in the UG progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com