Five-axis linkage numerical control (NC) machining post processor and processing method thereof

A post-processor, five-axis linkage technology, applied in the direction of instruments, simulators, program control, etc., can solve the problems of insufficiency of functions, difficult for users to handle, high cost, and achieve the effect of dynamic processing speed and speed compensation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

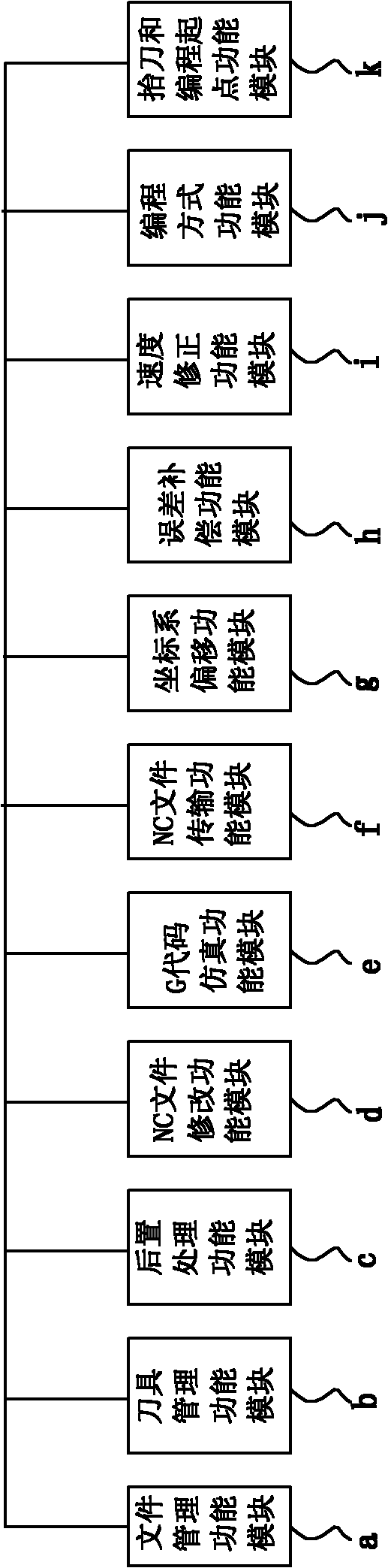

[0058] Such as Figure 1 to Figure 12 As shown, the post-processor of the five-axis linkage numerical control machining of the present invention includes computer program software for processing tool position source files generated by workpiece shape features and machining procedures, and the computer program software includes the following steps: Function modules: file management function module a, tool management function module b, post-processing function module c, NC file modification function module d, G code simulation function module e, NC file transmission function module f, coordinate system offset function module g , Error compensation function module h, speed correction function module i, programming mode function module j, tool lifting and programming starting point function module k.

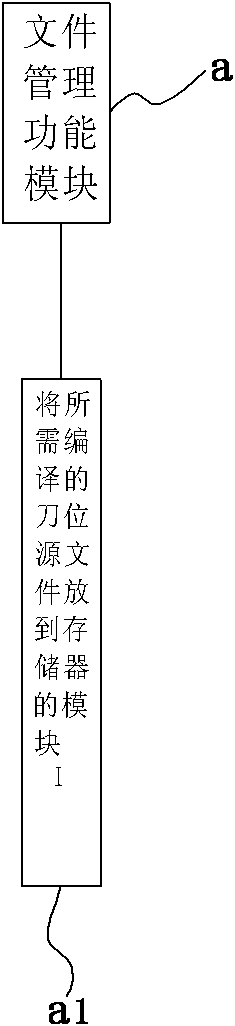

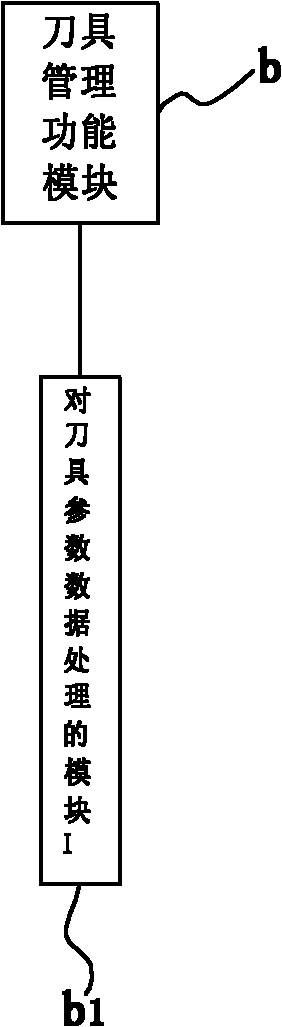

[0059] Such as figure 2 , image 3 As shown, the file management function module a includes a module I a1 that puts the tool position source file to be compiled into the memory, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com