Deep hole drill programming method and device

A technology for deep hole drilling and depth, which is applied in the field of deep hole drilling programming to achieve the effects of reducing programming workload, improving service life and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

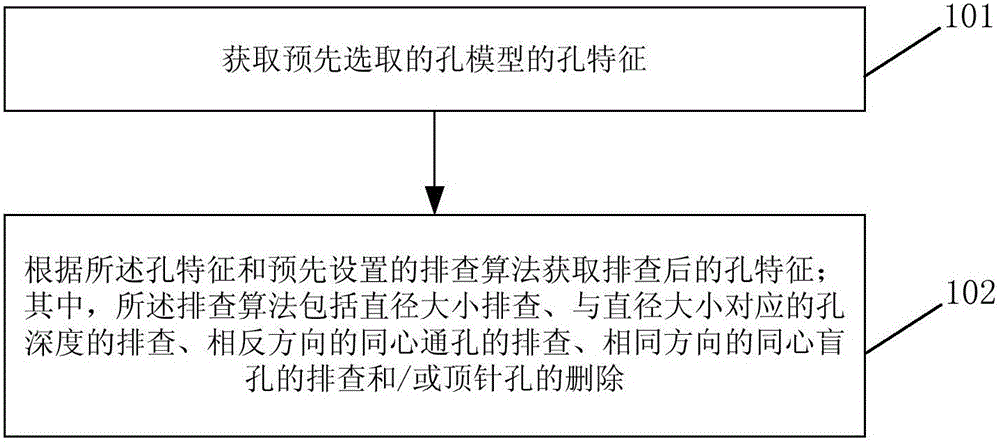

[0072] refer to figure 1 , figure 1 It is a schematic flowchart of the first embodiment of the deep hole drilling programming method according to the embodiment of the present invention.

[0073] In Embodiment 1, the method for deep hole drilling programming includes:

[0074] Step 101, obtaining the hole features of the pre-selected hole model;

[0075] Preferably, said obtaining the hole characteristics of the pre-selected hole model includes:

[0076] Obtain the coordinates of the normal direction of the six surfaces of the pre-selected hole model;

[0077] converting the data of the pre-selected hole model into the coordinates of the normal direction of the six curved surfaces;

[0078] A hole feature is obtained according to the data in the transformed coordinates.

[0079] Specifically, this application uses a three-dimensional digital model of a hole model generally generated by other CAD software. For example, a 3D digital model file containing hole elements is g...

Embodiment 2

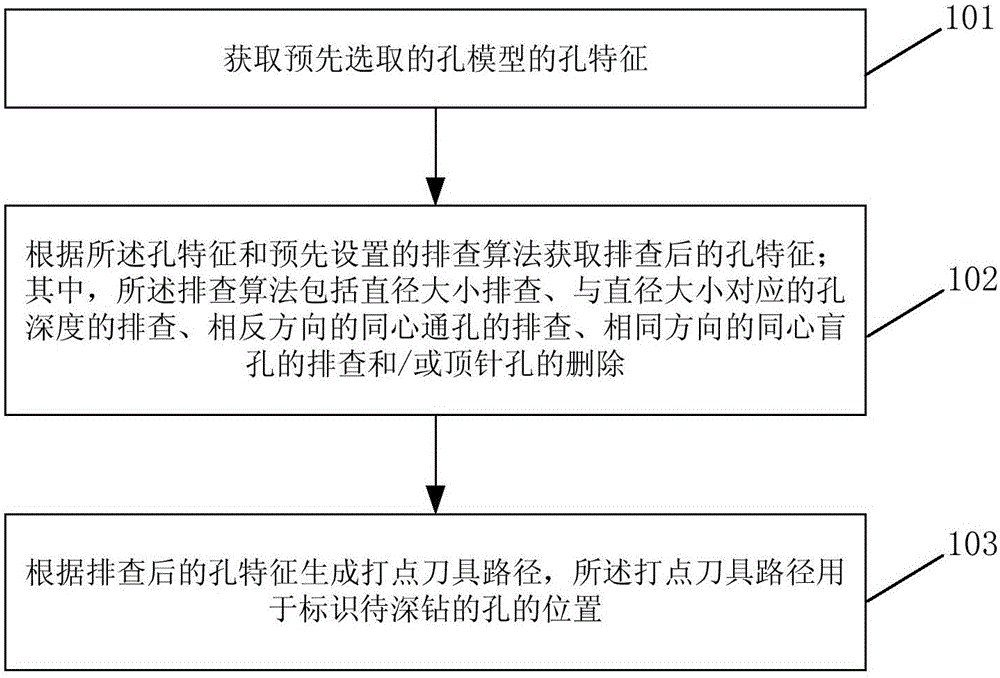

[0118] refer to figure 2 , figure 2 It is a schematic flowchart of the second embodiment of the deep hole drilling programming method according to the embodiment of the present invention.

[0119] On the basis of Embodiment 1, after obtaining the checked hole features according to the hole features and the preset checking algorithm, it further includes:

[0120] Step 103, generate a dotted tool path according to the checked hole features, and the dotted tool path is used to identify the position of the hole to be deep drilled.

[0121]Specifically, after the feature filtering of holes is completed, a dotted tool path must be generated before the deep hole drilling tool path is generated. The dotting toolpath here refers to all the hole features on the same surface, which are all generated as the same dotting toolpath.

Embodiment 3

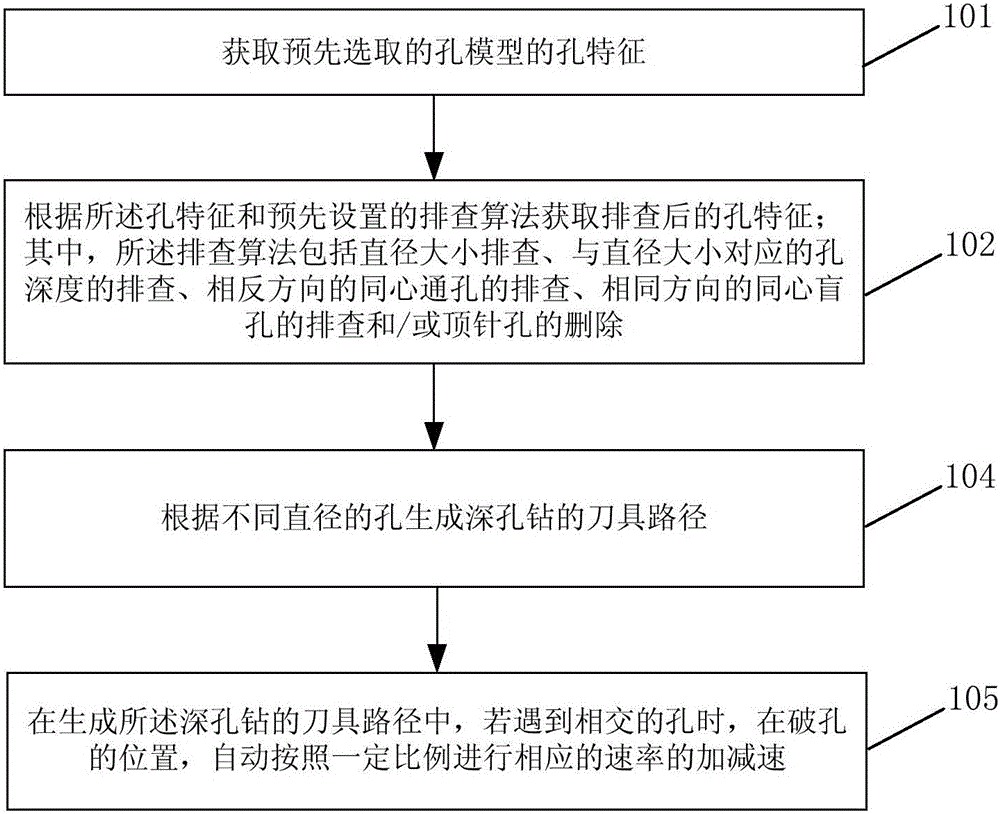

[0123] refer to image 3 , image 3 It is a schematic flowchart of the third embodiment of the deep hole drilling programming method according to the embodiment of the present invention.

[0124] On the basis of Embodiment 1, after obtaining the checked hole features according to the hole features and the preset checking algorithm, it further includes:

[0125] Step 104, generating a tool path for deep hole drilling according to holes of different diameters;

[0126] Step 105 , when generating the tool path for the deep hole drilling, if an intersecting hole is encountered, at the hole breaking position, the acceleration and deceleration are automatically performed at a corresponding rate according to a certain ratio.

[0127] Specifically, for the deep hole drilling process, after the dotting tool path is generated, the tool paths for deep hole drilling must be generated according to different diameters in the same normal direction of the surface. When generating the drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com