Vertical-type and connecting-rod-type intersecting line cutting head

A technology of intersecting wire cutting and connecting rods, applied in welding/cutting auxiliary equipment, auxiliary devices, auxiliary welding equipment, etc., can solve problems such as low reliability, small bevel angle, large mechanism size, etc., and achieve simple electrical control , Eliminate winding deviation, effect of compact rod structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

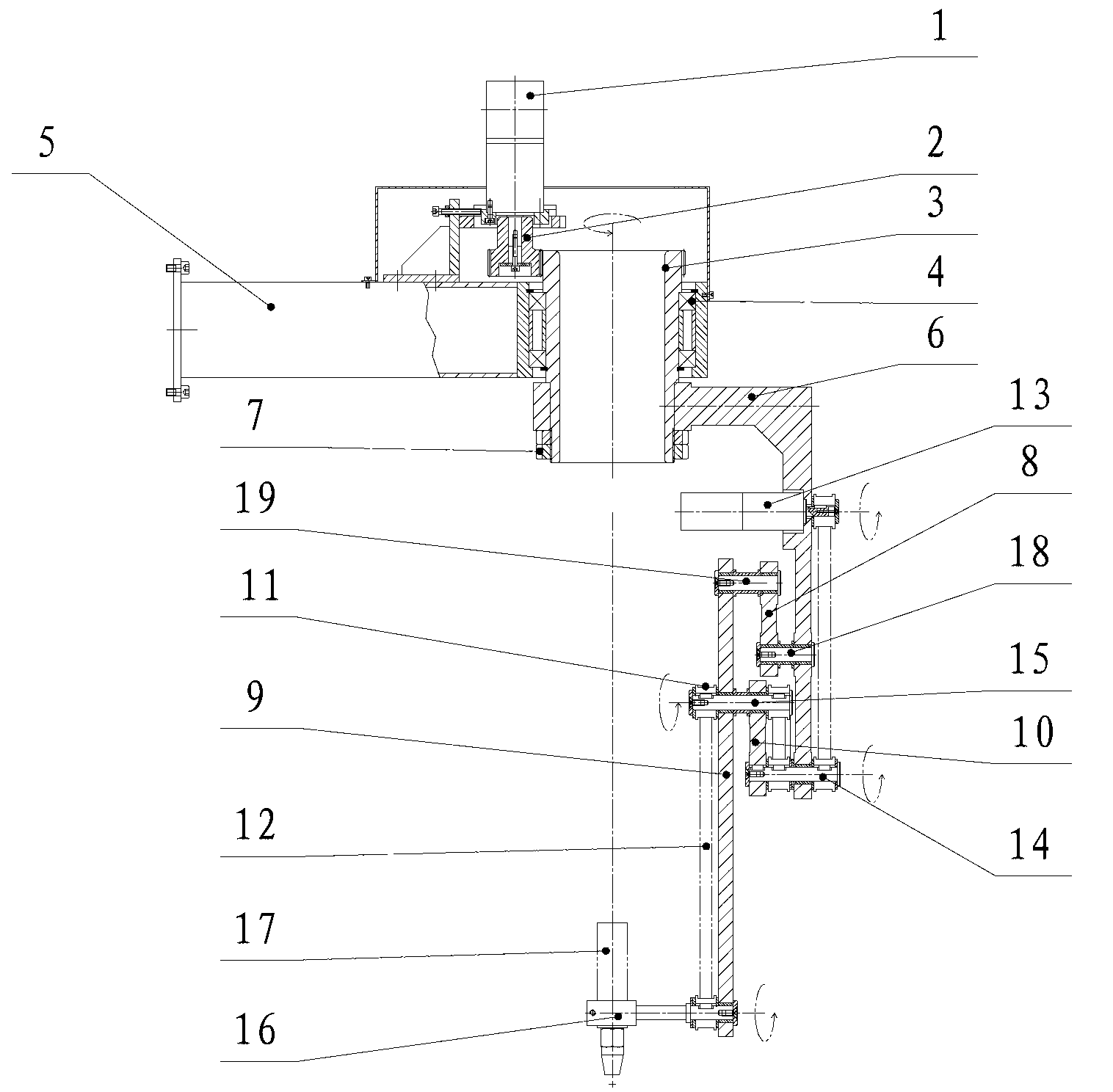

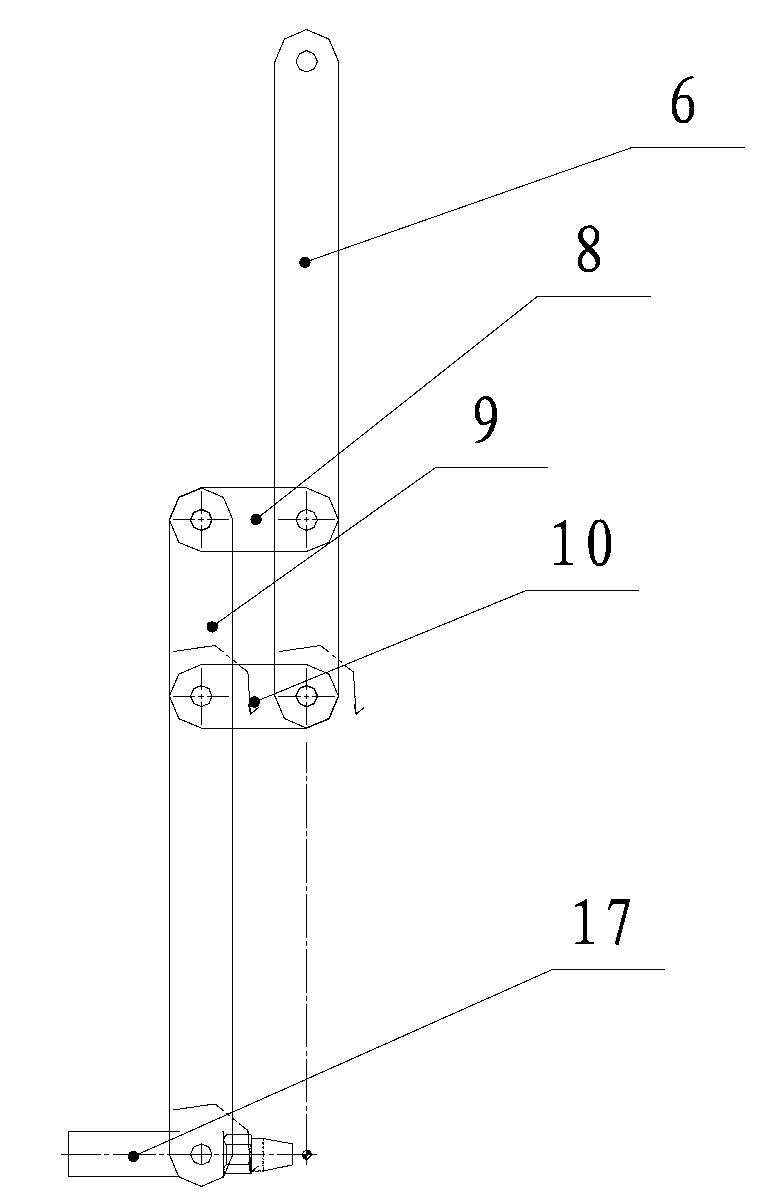

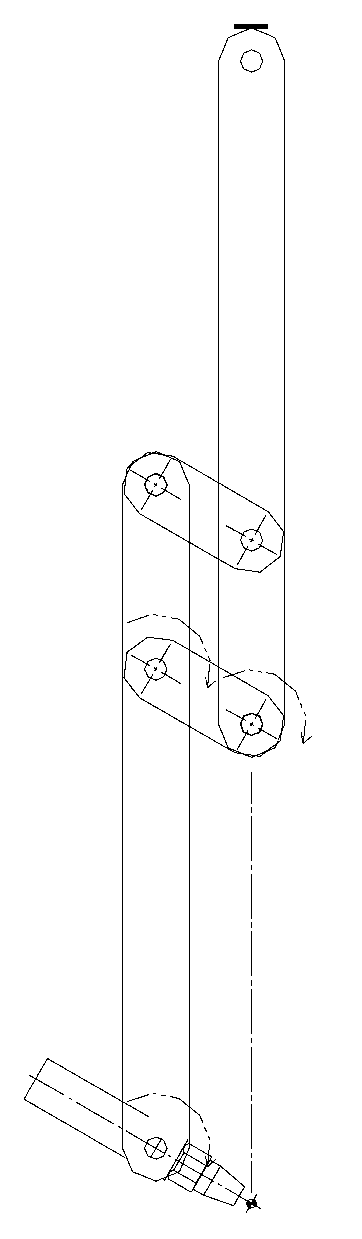

[0017] This embodiment is a vertical connecting rod type intersecting line cutting head, the structure is as follows figure 1 As shown, it includes the main arm 5, the driven gear shaft 3 and the swing angle assembly installed on the driven gear shaft. The driven gear shaft 3 is installed on the main arm 5 through the bearing 4, and the driven gear shaft is a hollow structure. There are air pipes and electric wires in the driven gear shaft 3; a rotary reduction motor 1 is installed on the main arm, and the driving gear 2 on the rotary reduction motor 1 is meshed with the driven gear on the driven gear shaft 3 to drive the driven gear The driven gear shaft rotates; the lower part of the driven gear shaft is fixed to the frame 6 through the round nut 7, and the swing angle assembly is installed on the frame 6. The swing angle assembly is mainly composed of a crank 8, a connecting rod 9, a rocker 10, and a four-link Geared motor 13, first transmission shaft 14, second transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com