Online turning electric transverse feeding device for four-roll crusher

A transverse feed, roller crusher technology, applied in feeding devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of complex electrical control, low work efficiency, high labor intensity, etc., to reduce the risk of safety management and control, The effect of constant and stable lateral feed and improved turning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Now, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. This invention may, however, be embodied in many different forms and should not be construed as limited to the exemplary embodiments set forth herein. In the drawings, like reference numerals will refer to like parts throughout.

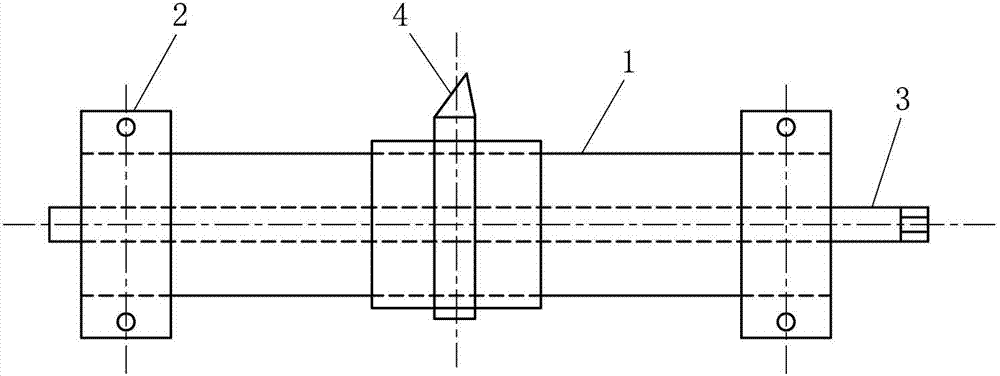

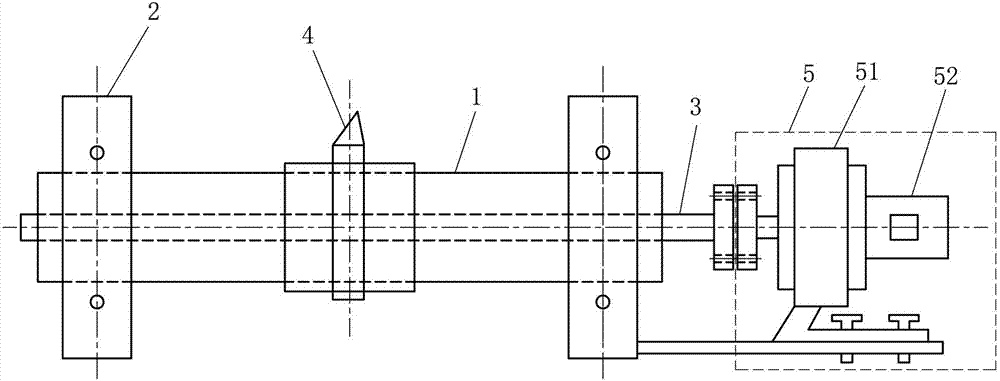

[0030] figure 2 It is a simplified schematic diagram of an electric transverse feed device for online turning of a four-roll crusher according to the present invention.

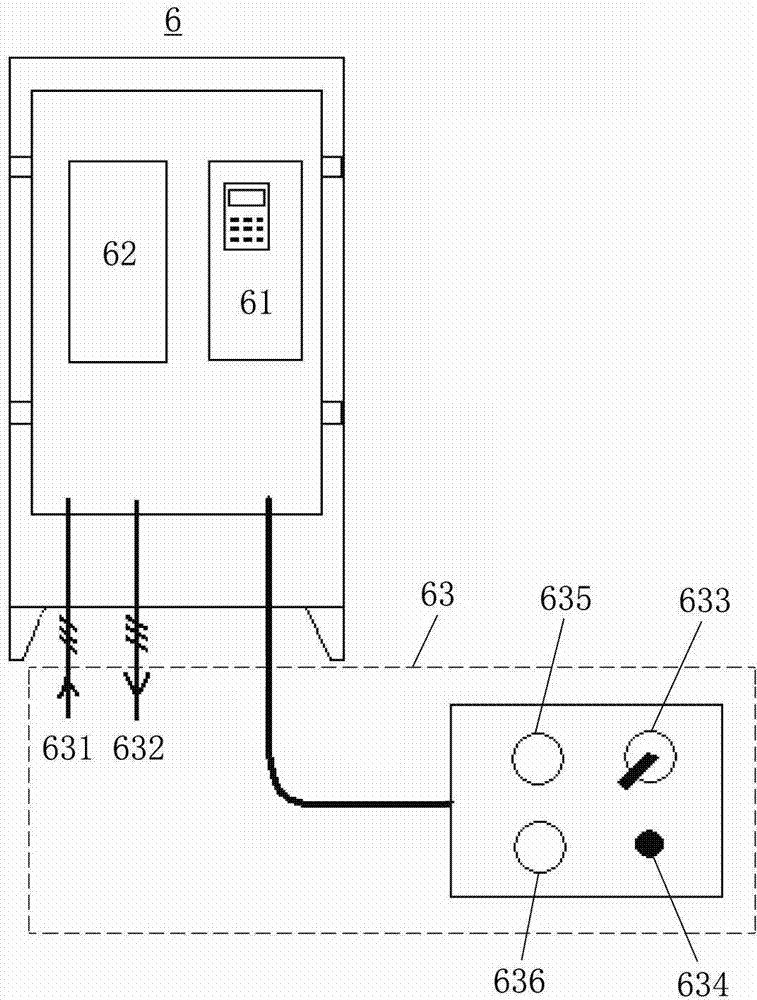

[0031] Such as figure 2 As shown in , the electric infeed device for online turning of a four-roll crusher according to an exemplary embodiment of the present invention includes a turning tool holder 1 on which a turning tool 4 is installed, and a turning tool holder fixing base 2 for fixing the turning tool holder 1 and the infeed screw 3 for realizing the infeed of the turning tool 4, the electric infeed device for online turning of the four-roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com