Plane rotational flow generator

A swirl generator and plane technology, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems of unable to form swirl, complex structure, etc., and achieve the effect of convenient manufacture, simple composition and structure, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

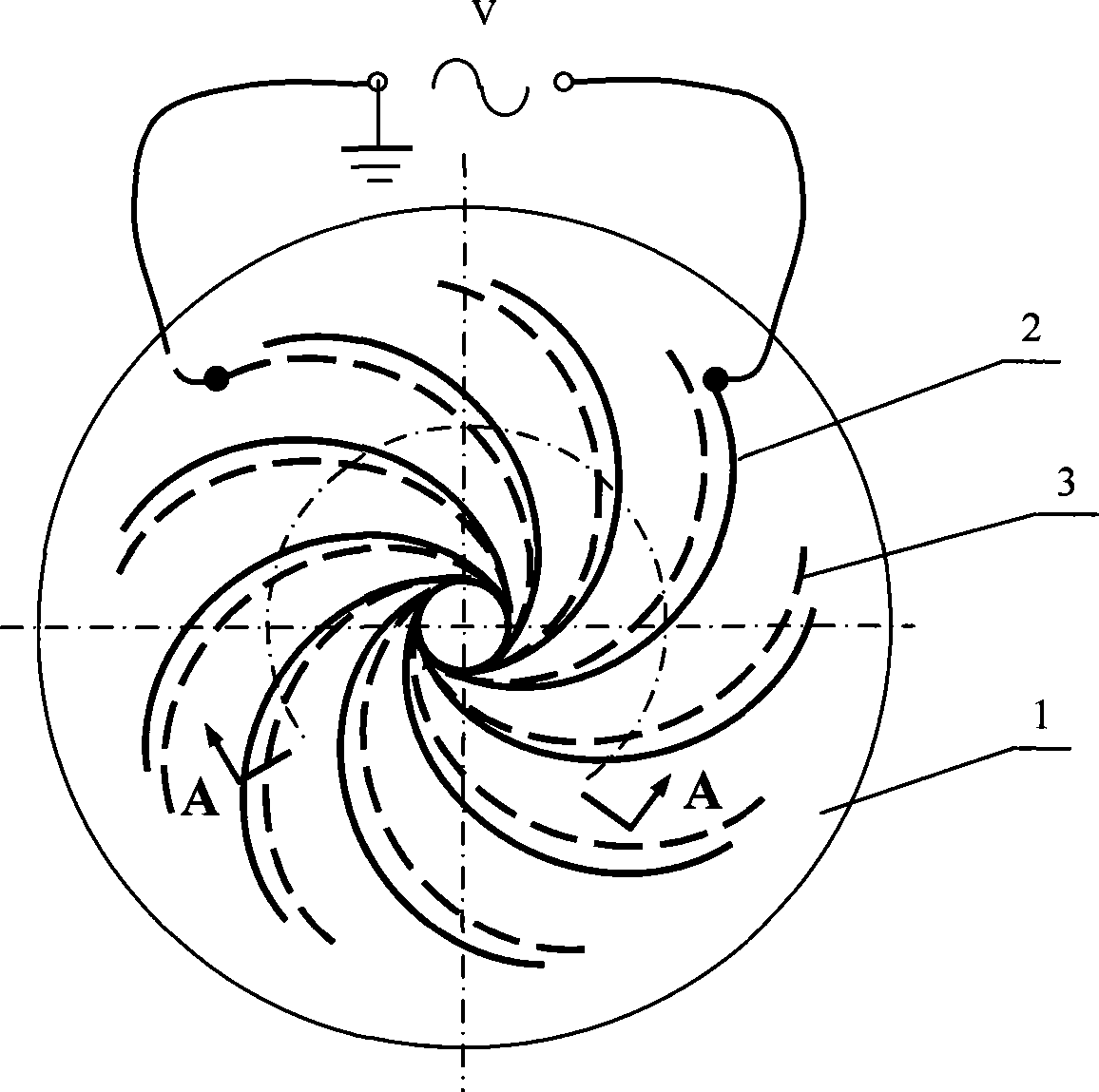

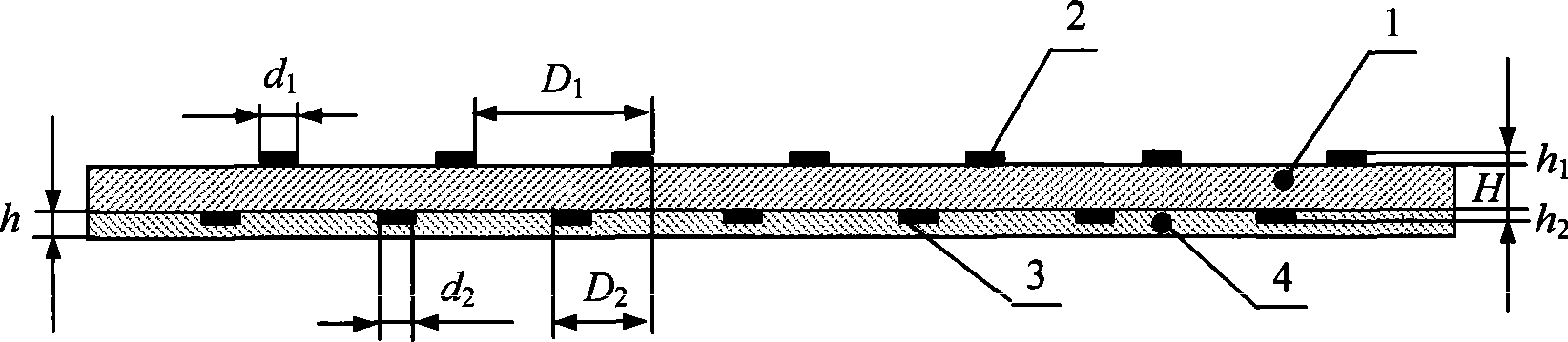

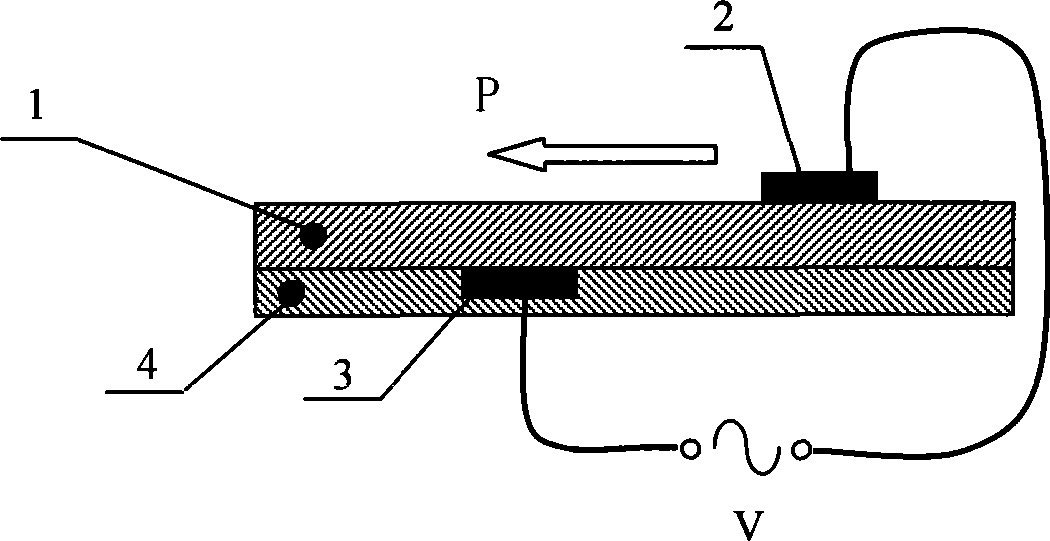

[0024] see Figure 1~4 , the present invention is provided with bottom plate 1 and high-voltage AC power supply V, and bottom plate 1 is an insulating dielectric flat plate, and 9 pairs of arc-shaped upper surface electrodes 2 and lower surface electrodes 3 are evenly covered on the upper surface and lower surface of bottom plate 1, and upper surface electrode 2 Both the electrodes 3 on the lower surface and the lower surface are arc-shaped, and are arranged radially in pairs at equal intervals along the circumferential direction. from figure 2 From above, the size of the upper surface electrode and the lower surface electrode of the same pair of arc-shaped electrodes is D 1 >D 2 , and D 2 >d 1 and D 1 —D 2 >D 2 —(d 1 +d 2 ), D 1 is the distance between adjacent upper surface electrodes 2, D 2 is the distance between the opposite sides of the upper surface electrode 2 and the lower surface electrode 3 of the same pair of arc-shaped electrodes, d 1 is the width of ...

Embodiment 2

[0031] see Figure 5 , the diameter of the bottom plate 1 is 100mm, and the thickness H≥0.5mm. Both the upper surface electrode 2 and the lower surface electrode 3 are arc segments, which are divided into three circles and evenly arranged on both sides of the bottom plate 1 . The upper surface electrodes 2 and the lower surface electrodes 3 of each ring are respectively electrically connected to a circular electrode. The upper surface electrodes 2 and the lower surface electrodes 3 on each circle are alternately arranged up and down along the circular electrodes. The inner diameter of the inner circular electrode 21 on the upper surface of the bottom plate 1 is 20mm, the inner diameter of the middle circular electrode 22 is 45mm, and the inner diameter of the outer circular electrode 23 is 70mm. The inner diameter of the inner circular electrode 31 on the lower surface of the bottom plate 1 is 10mm, the inner diameter of the middle circular electrode 32 is 35mm, and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com