Coal powder atomization electric ignition combustor

A technology of electric ignition and burner, which is applied in the direction of burner, burner for burning powder fuel, combustion method, etc., can solve the problems of pulverized coal condensation and heat, incomplete coal combustion, defire, etc., and achieve good regulation performance and efficient Facilitate combustion and avoid condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Specific embodiments of the present invention will be described in detail below.

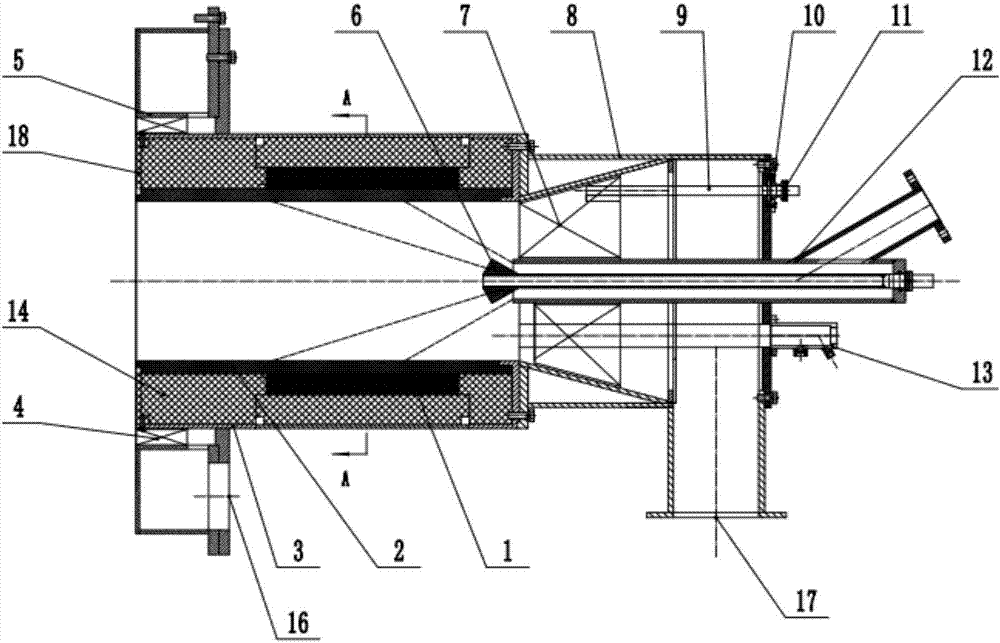

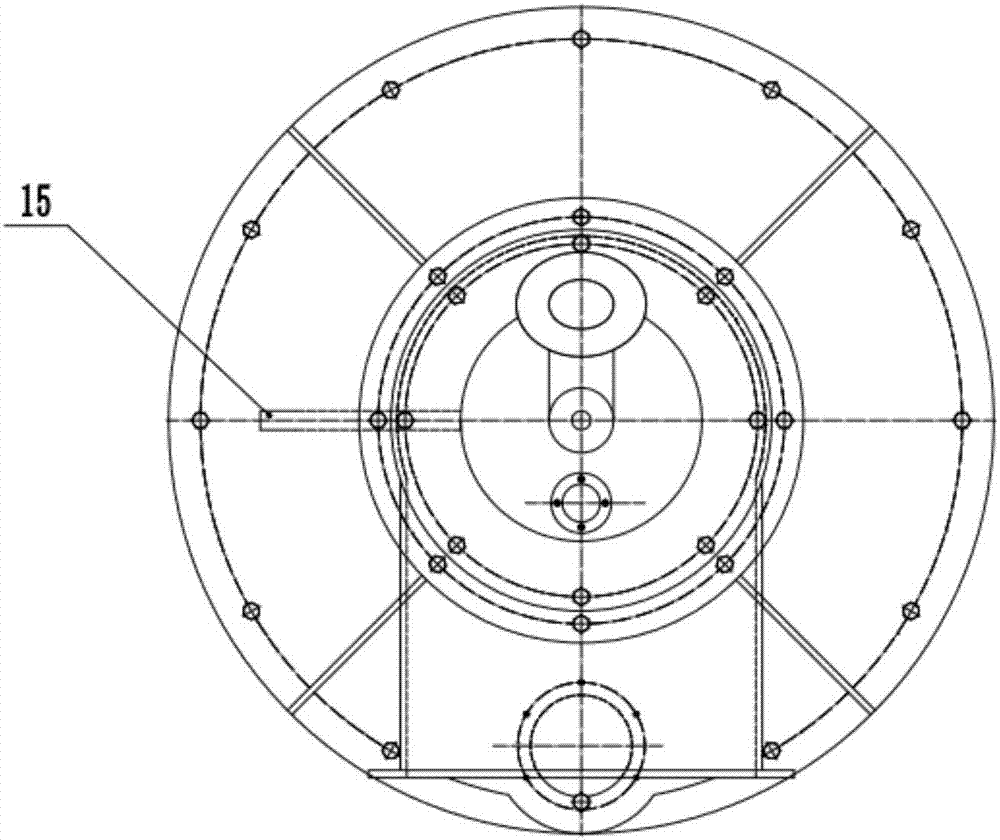

[0055] Such as Figure 1-9 As shown, a pulverized coal atomization electric ignition burner, including

[0056] Secondary air ring 3, its section is a ring,

[0057] The secondary air box body 8 is connected with the secondary air ring 3 by bolts, and the bottom of the secondary air box body 8 is provided with a secondary air inlet 17,

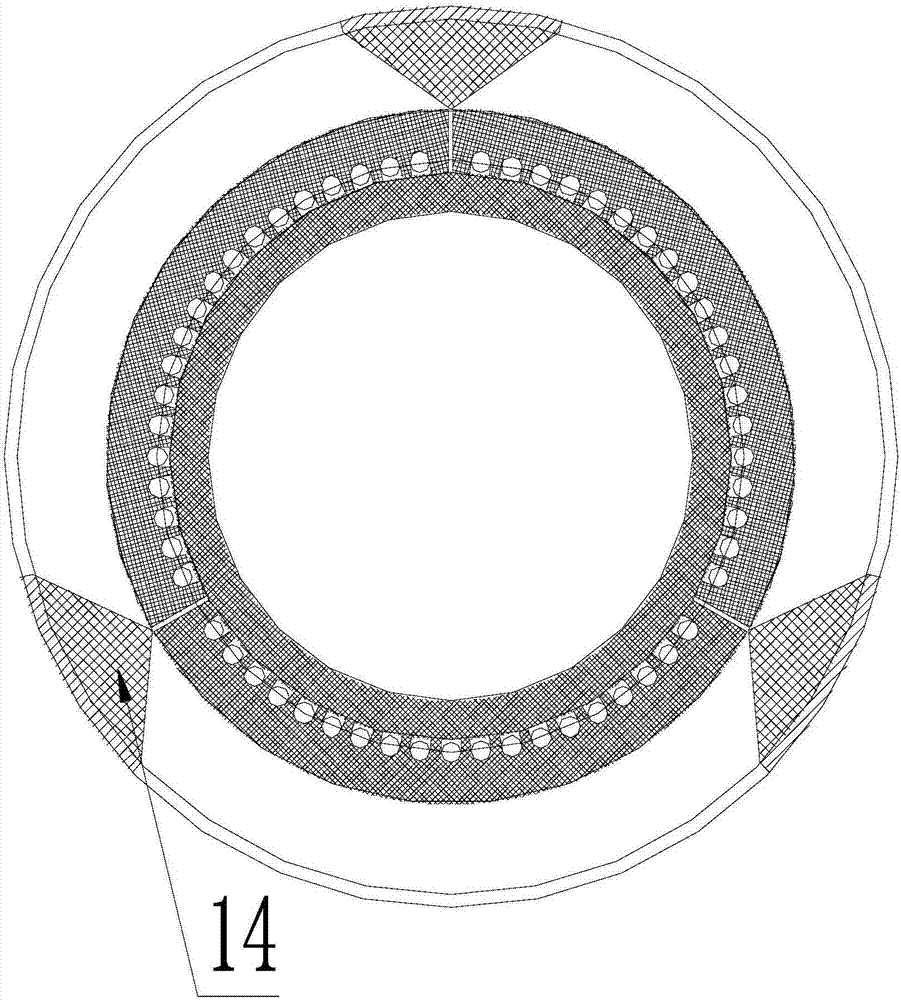

[0058] The thermal insulation body 14 is fixedly connected with the inner chamber of the secondary air ring 3 by bolts, and the outer side of the thermal insulation body 14 is provided with an annular groove,

[0059] The pulverized coal atomizing diffuser 6 is installed in the center of the primary air duct 12 by fastening nuts;

[0060] The secondary swirl body 7 is a hollow round platform including a large-caliber air inlet and a small-caliber air outlet. The secondary swirl body 7 is arranged in the secondary air box body 8 and is socketed with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com