Patents

Literature

51results about How to "Uniform flame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

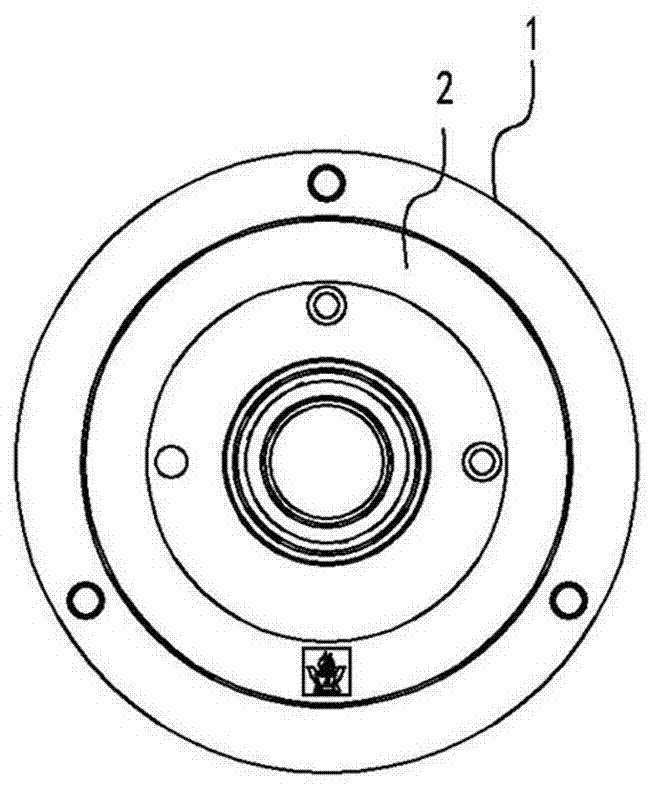

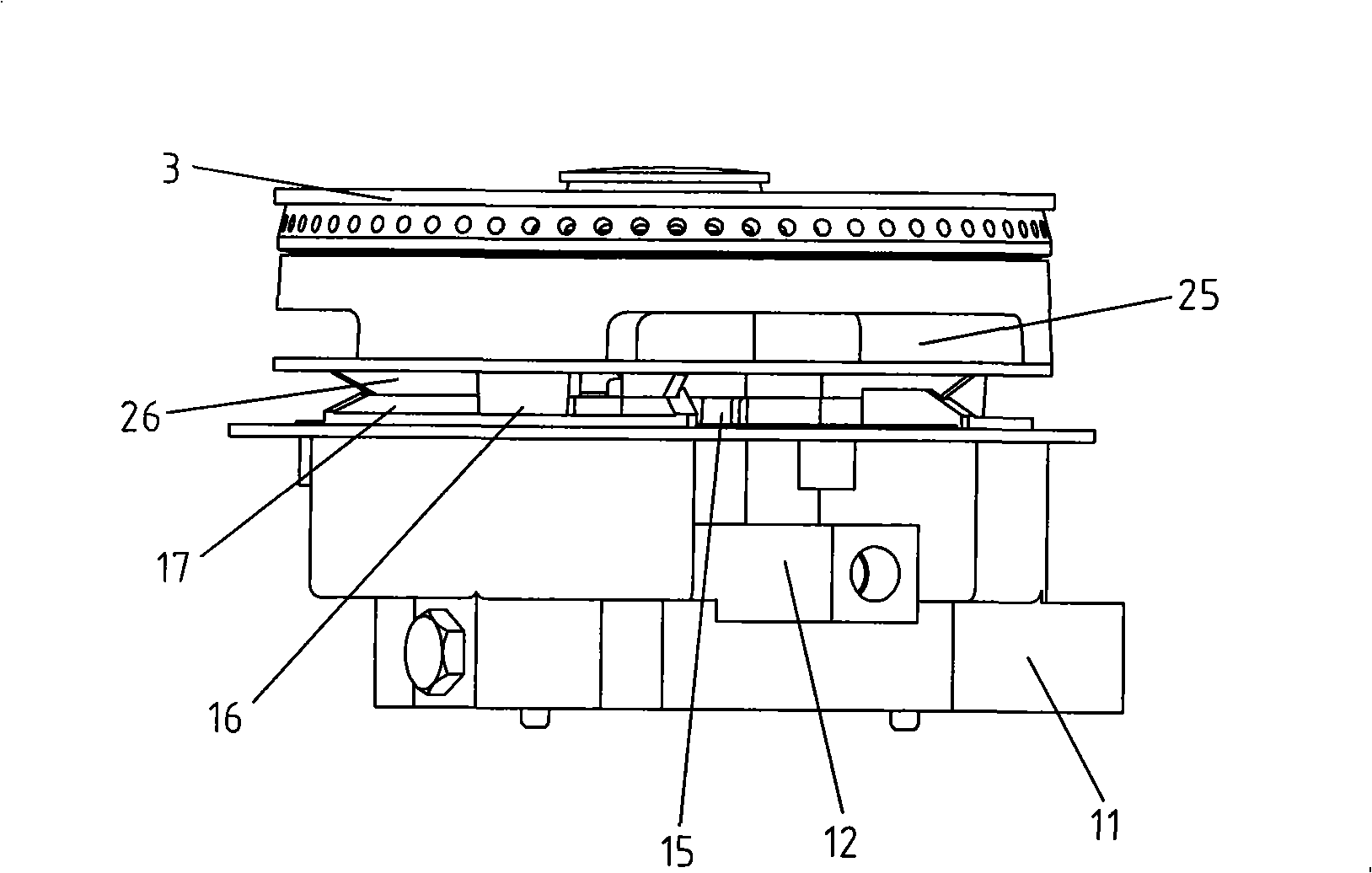

Household gas burner

The invention discloses a household gas burner, belonging to the part in the household gas kitchen range. The present household gas burner has the complex structure, poor processing precision and big accumulative error in assembling. The household gas burner comprises a nozzle, a gas distributing device, a gas mixing device and a fire lid, and characterized in that the gas distributing device and the gas mixing device are all the integrated structure, wherein the gas distributing device comprises a gas supplying pipe and a distributing chamber, a primary air inlet open is arranged on the distributing chamber, the nozzle is fixed on the orifice of the gas supplying pipe in the distributing chamber; the gas mixing device comprises a mixing pipe, a mixing chamber, a buffer baffle plate and a secondary air inlet slot, the mixing chamber is matched with the distributing chamber, the buffer baffle plate is arranged above the orifice of the mixing pipe in the mixing chamber, the secondary air inlet slot is arranged at the side surface of the gas mixing device. The gas distributing device and the gas mixing device in the invention have no accumulative error in assembling, simple assembling and safe and reliable use.

Owner:HANGZHOU DE&E ELECTRICAL CO LTD

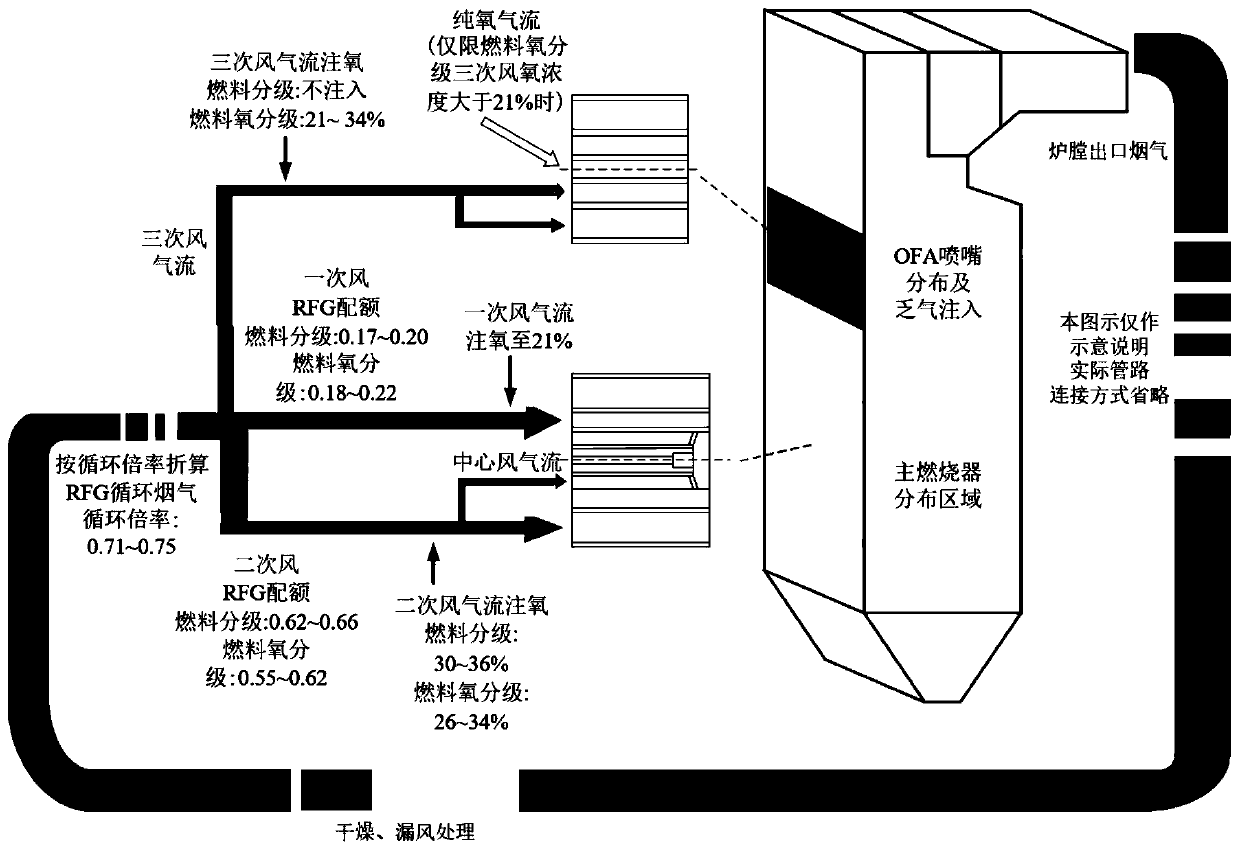

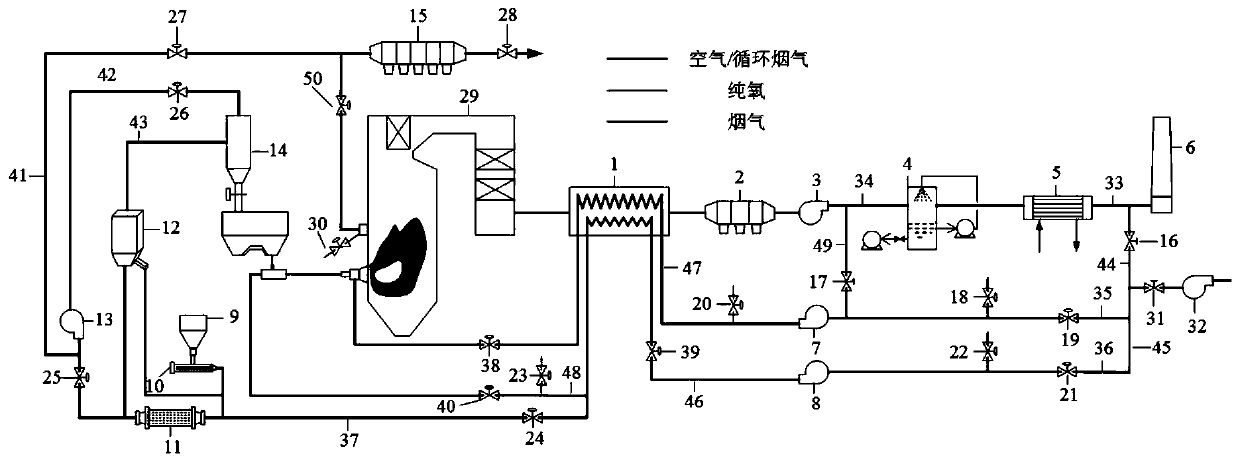

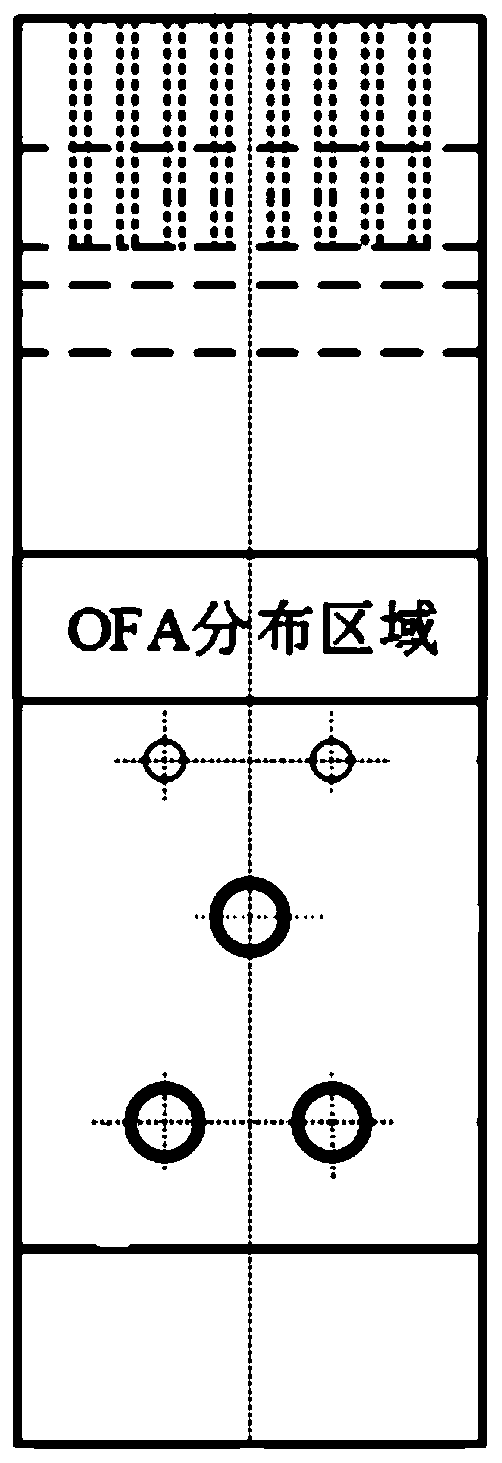

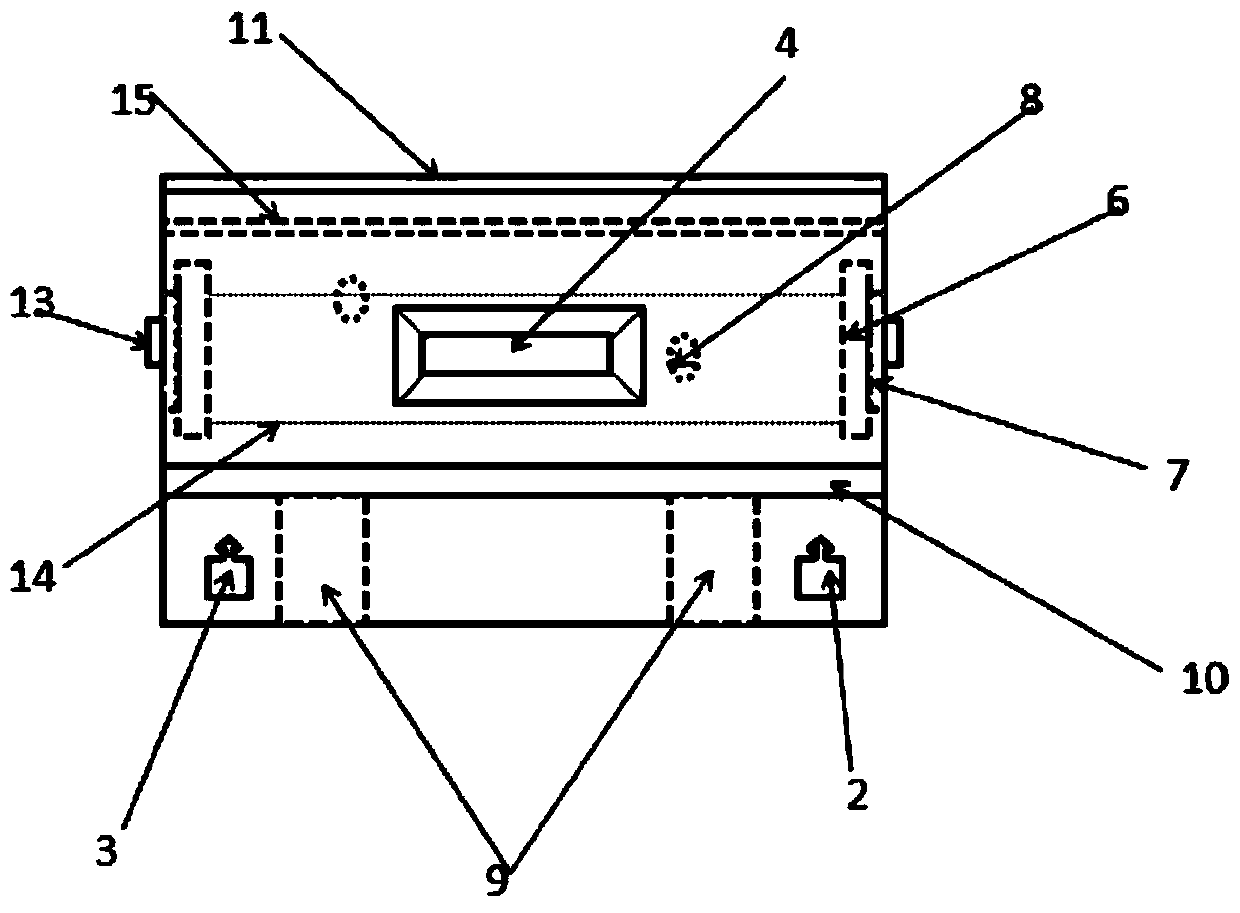

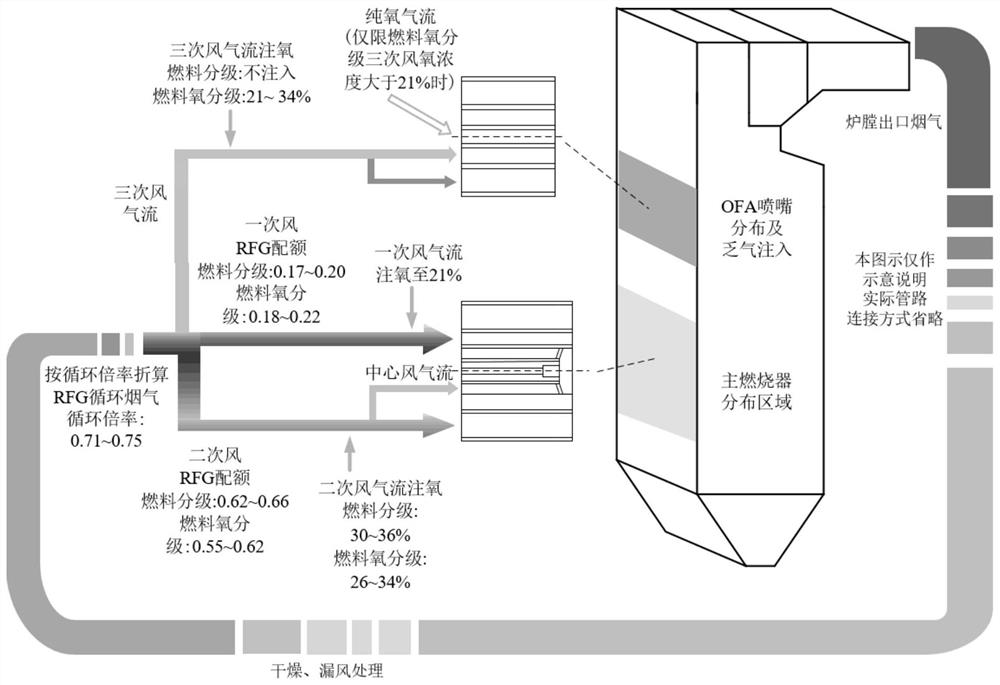

Flameless graded oxygen-enriched low-NOx combustion method and system

ActiveCN111006206AImprove heat utilization efficiencyNormal ignitionIndirect carbon-dioxide mitigationGrain treatmentsThermodynamicsFlue gas

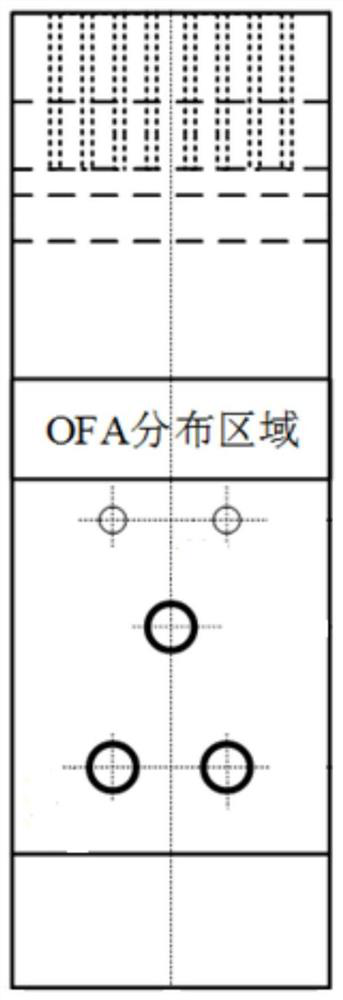

The invention belongs to the field of pulverized coal combustion and emission performance control, and particularly discloses a flameless graded oxygen-enriched low-NOx combustion method and system. The method comprises the following steps that smoke participating in circulation is divided into three paths, the fuel with the preset mass carried by a primary air pipeline, a secondary air pipeline and a tertiary air pipeline is introduced into a hearth through the primary air pipeline, the secondary air pipeline and the tertiary air pipeline to be combusted, wherein air outlets of the primary air pipeline and the secondary air pipeline are positioned in a main combustion area and an air outlet of the tertiary air pipeline is located in a re-combustion area, and the injection amounts and themass flows of oxygen in air in the air pipelines are controlled so as to control the peroxide coefficient range and the flow characteristic of the main combustion area and the re-combustion area so that a fuel staged oxygen-enriched combustion mode, a fuel-oxygen two-way staged oxygen-enriched combustion mode and a flameless oxygen-enriched combustion mode are achieved. The system comprises a boiler, a flue gas pretreatment module, a chimney, the primary air pipeline, the secondary air pipeline and the tertiary air pipeline. According to the invention, stable and efficient low NOx emission canbe achieved, the ignition characteristic of pulverized coal can be improved, and pulverized coal reburning is promoted.

Owner:HUAZHONG UNIV OF SCI & TECH

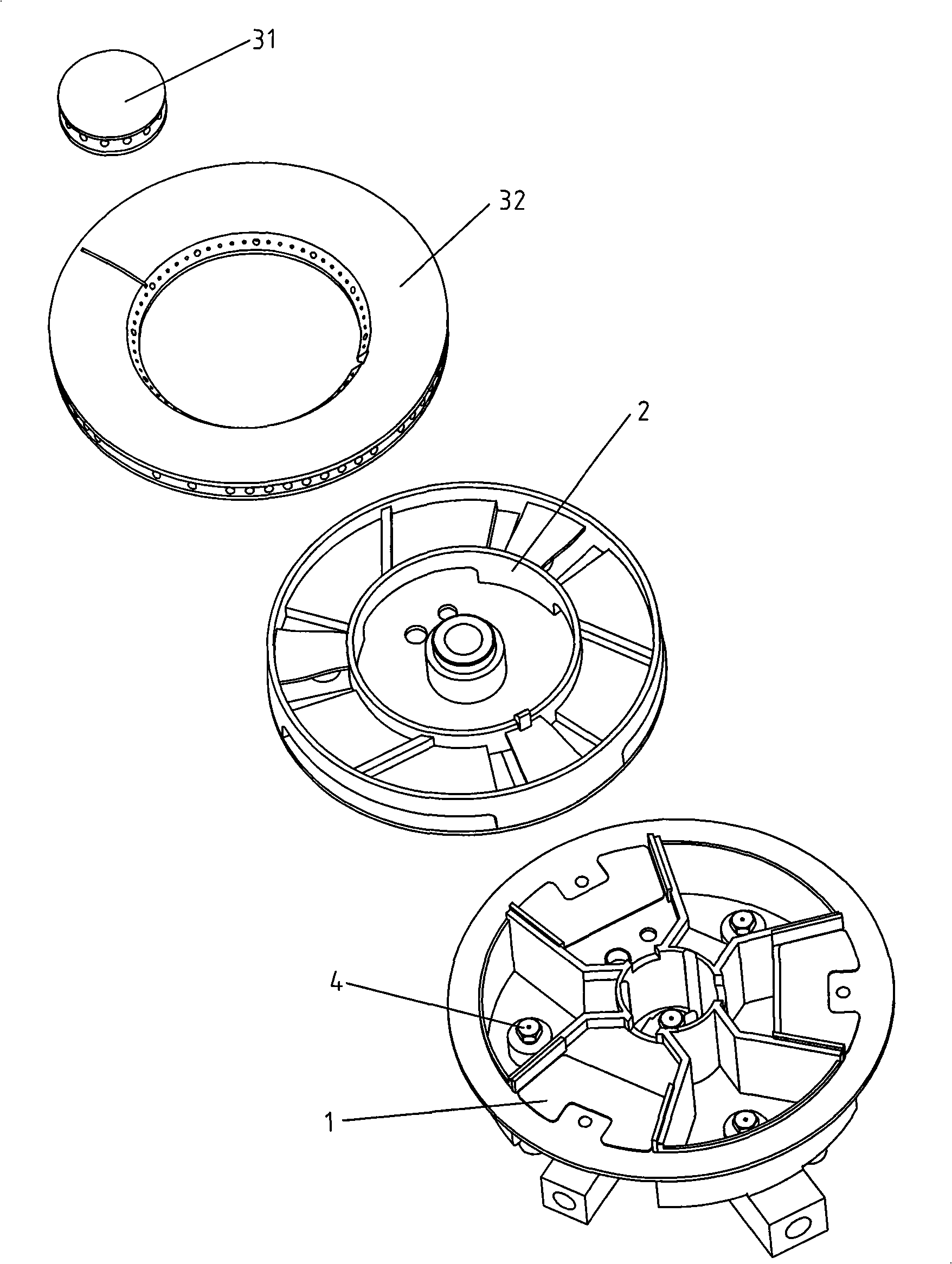

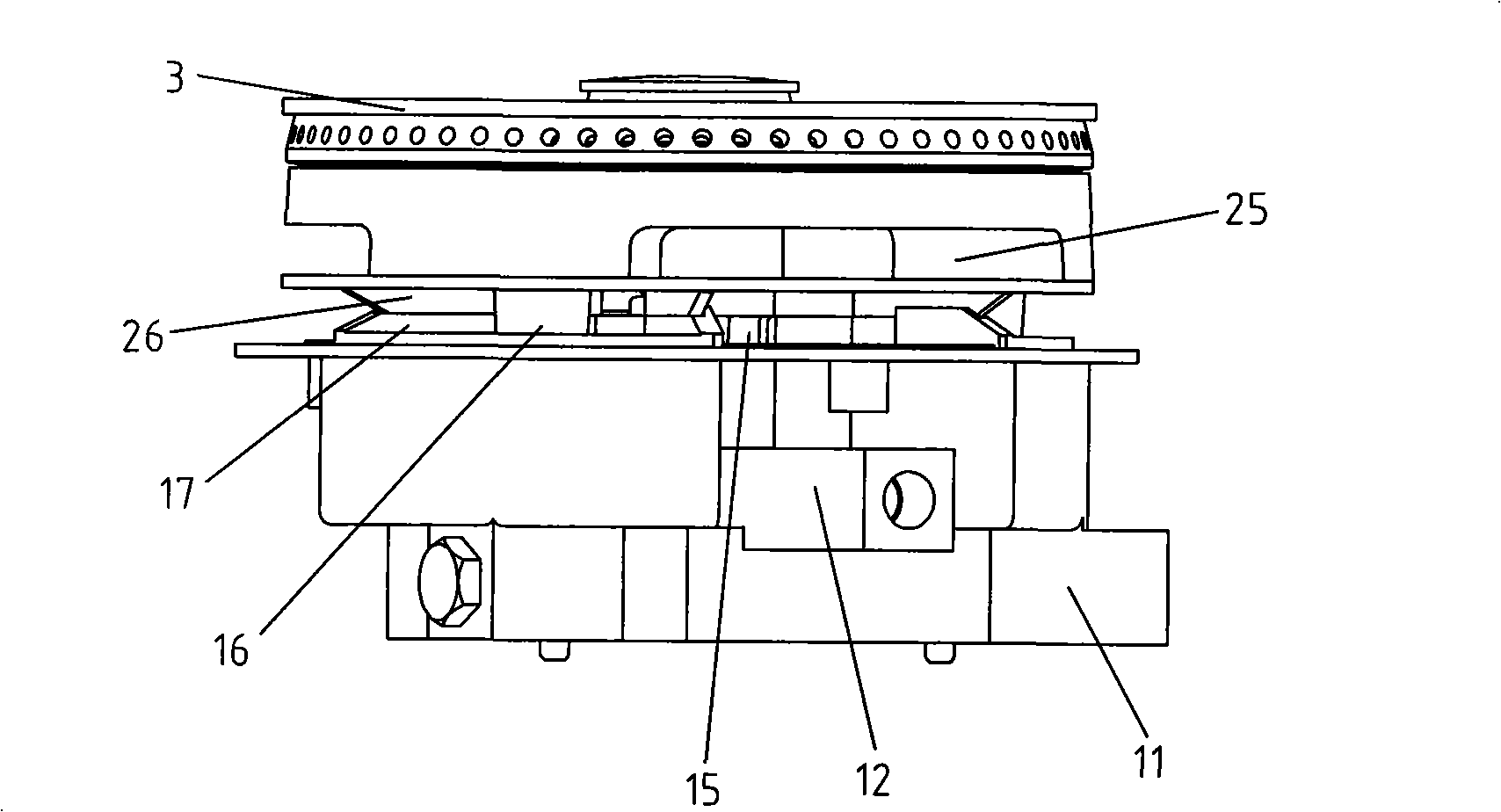

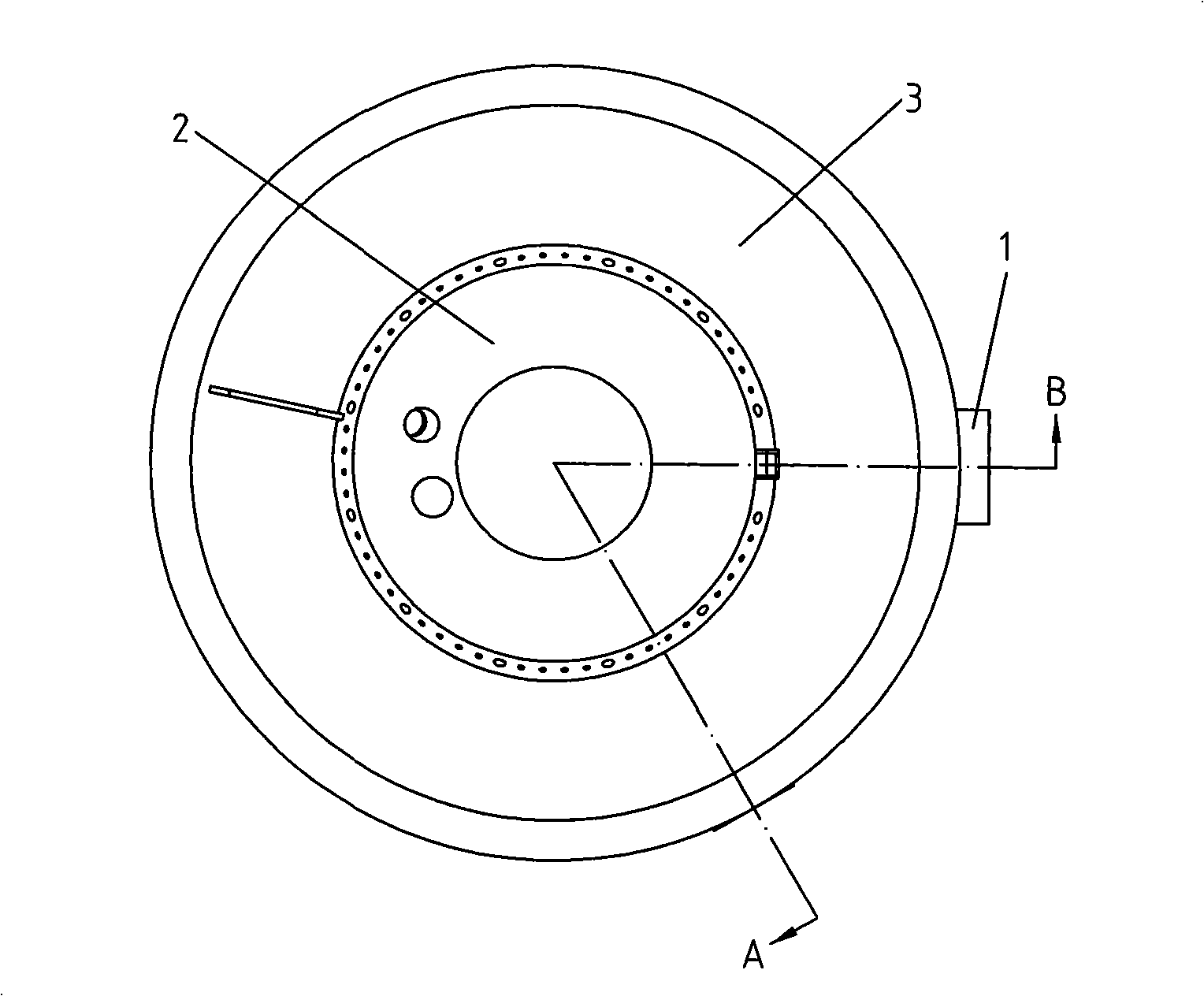

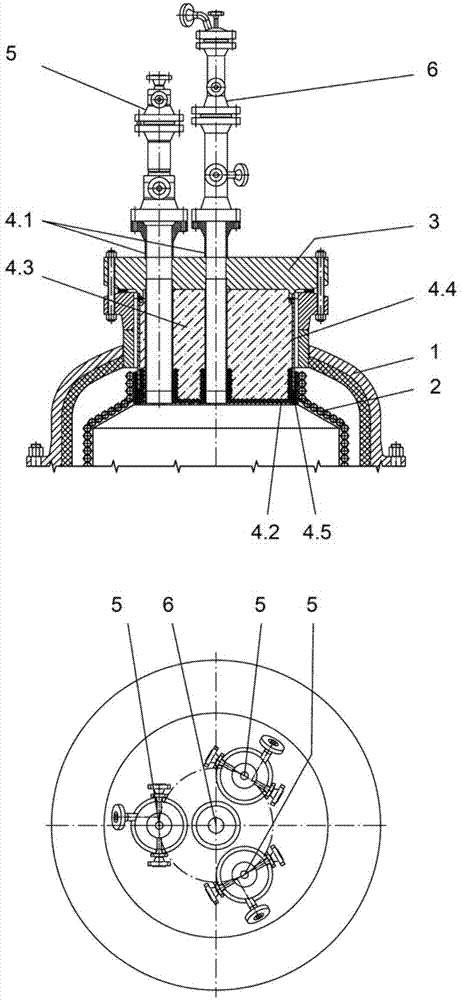

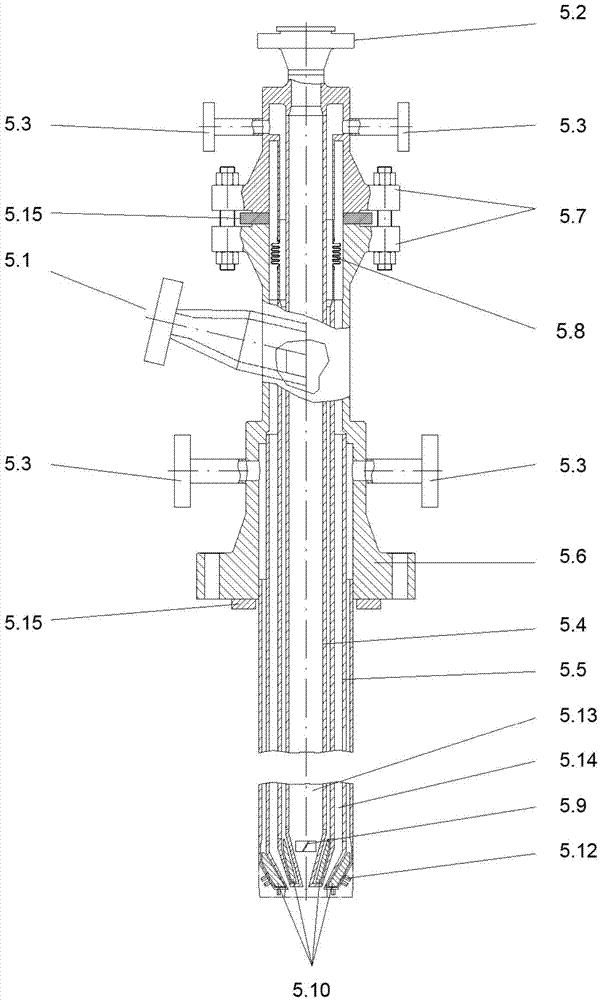

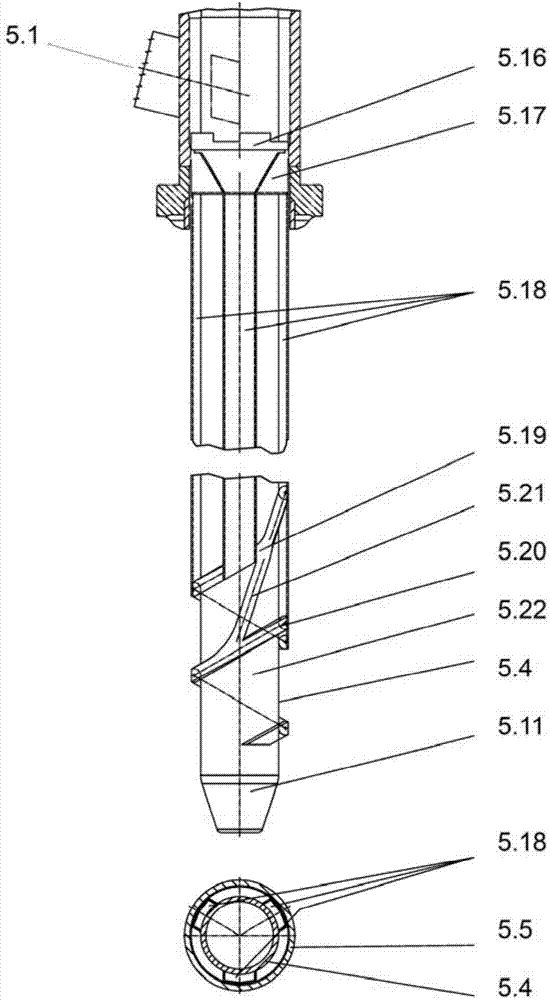

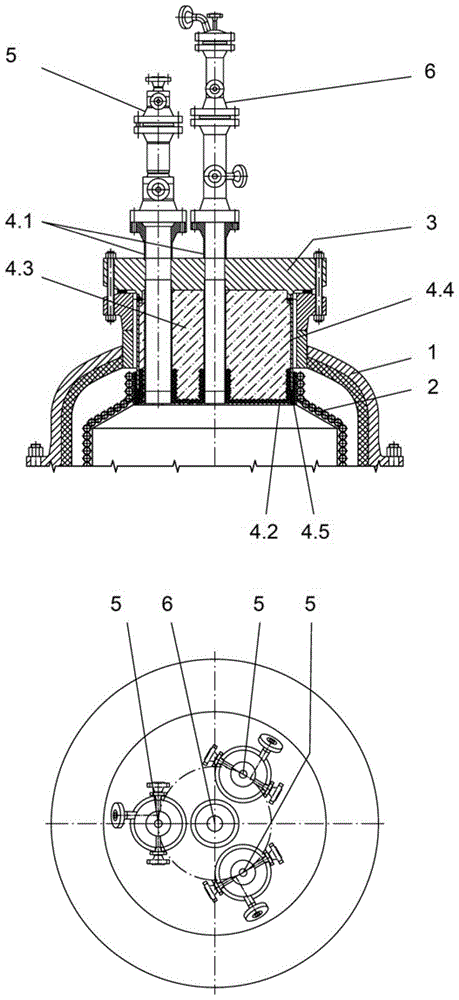

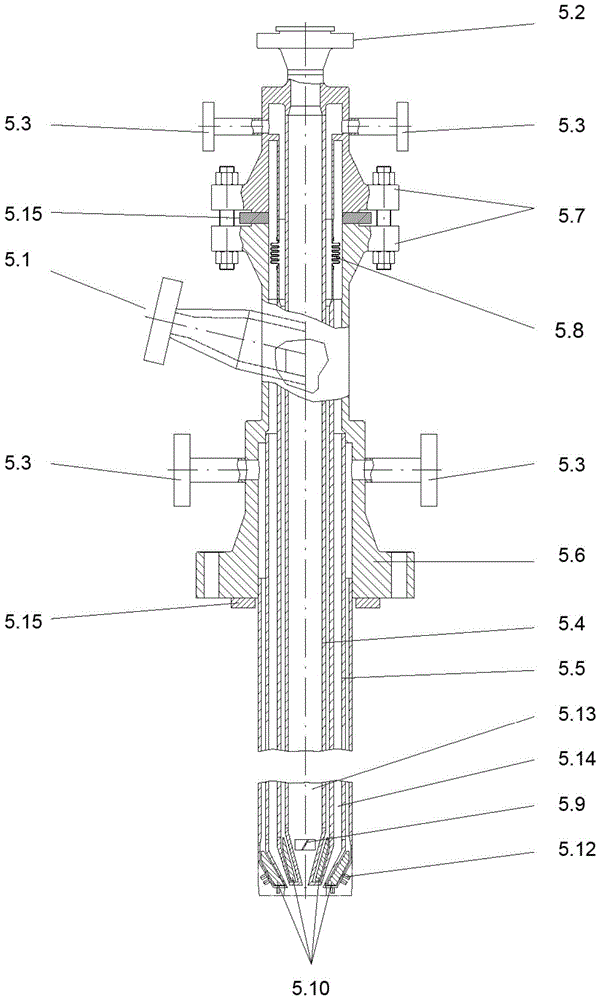

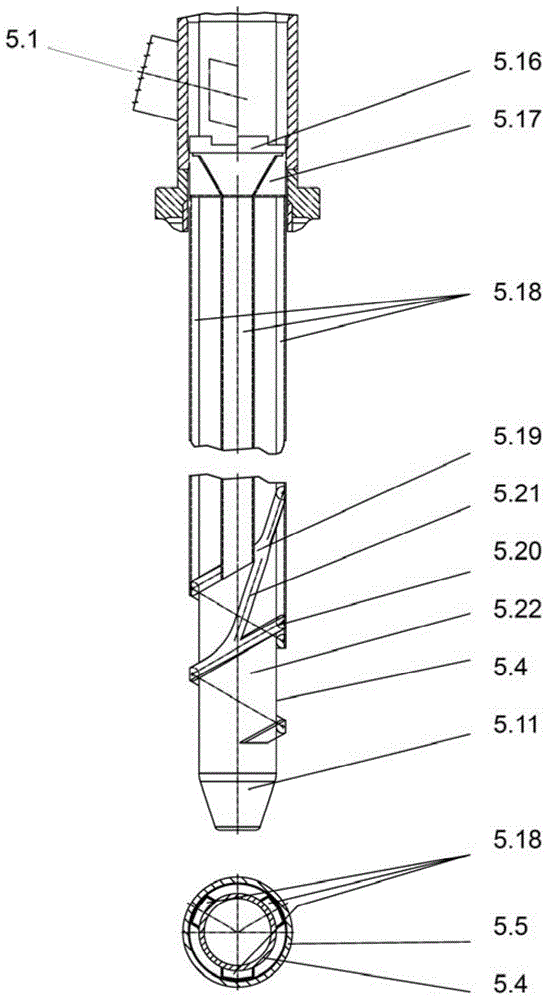

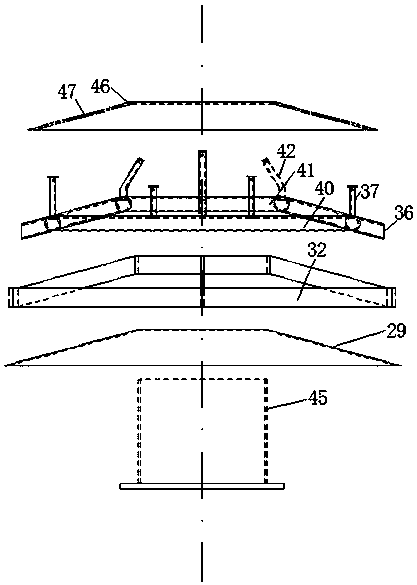

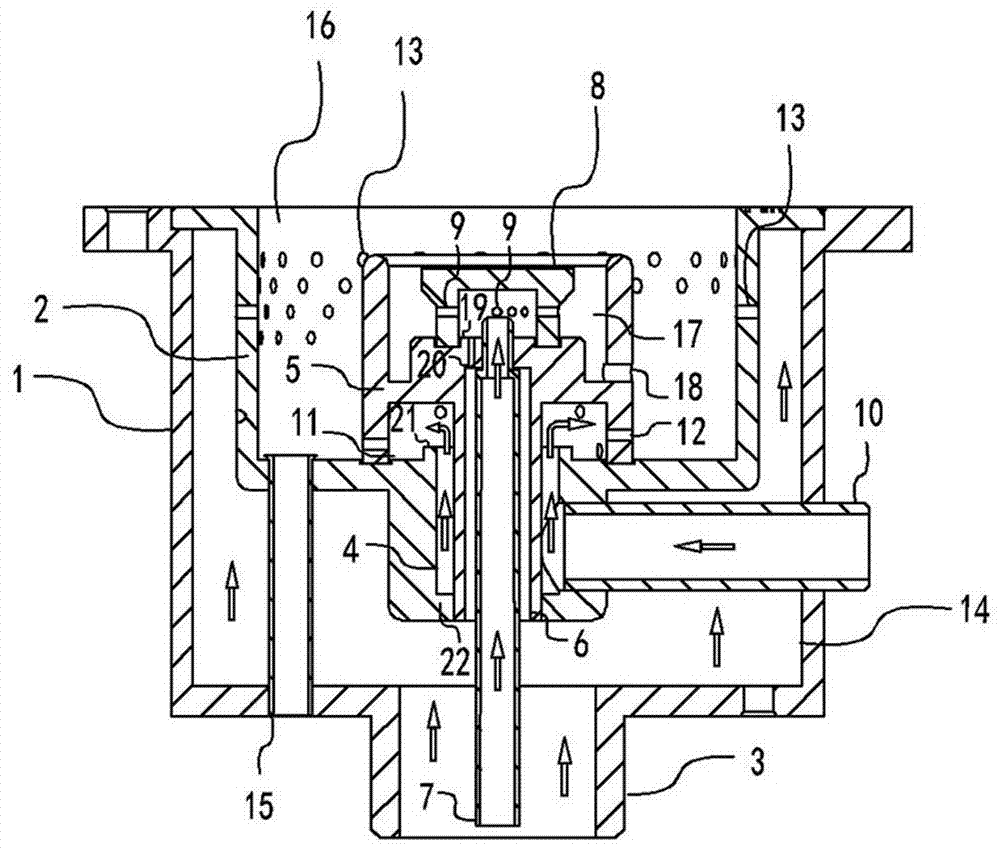

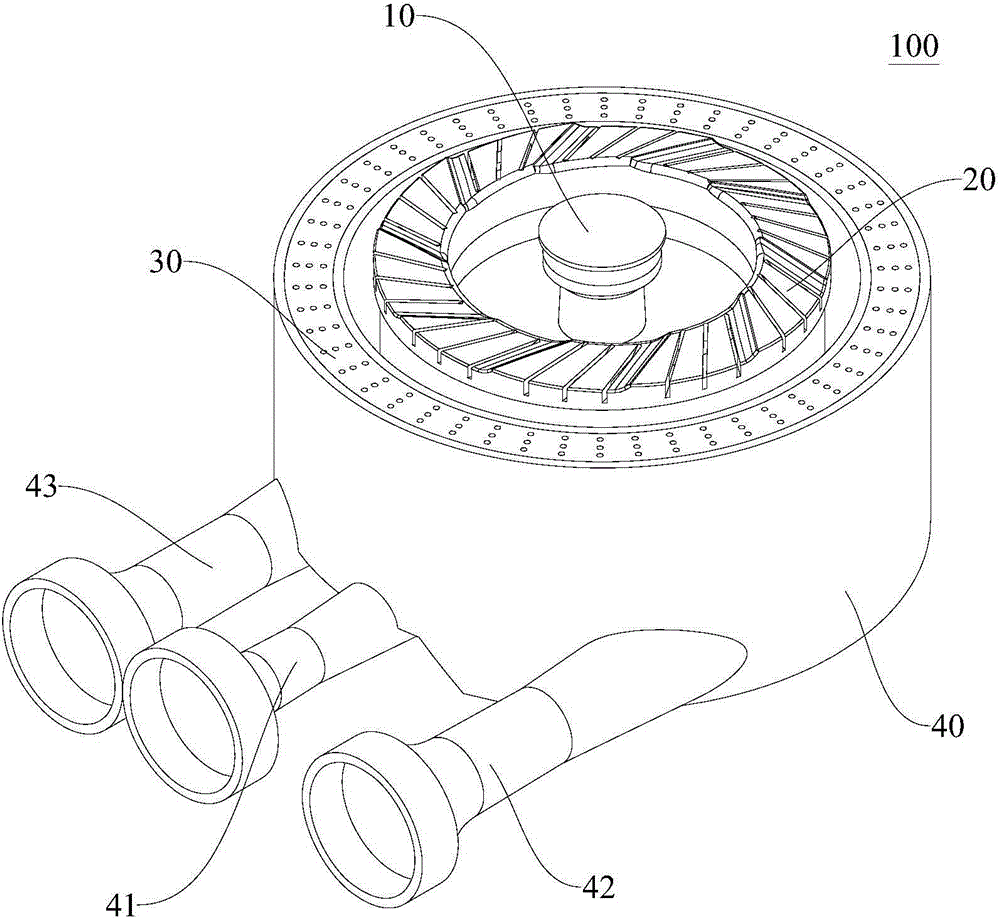

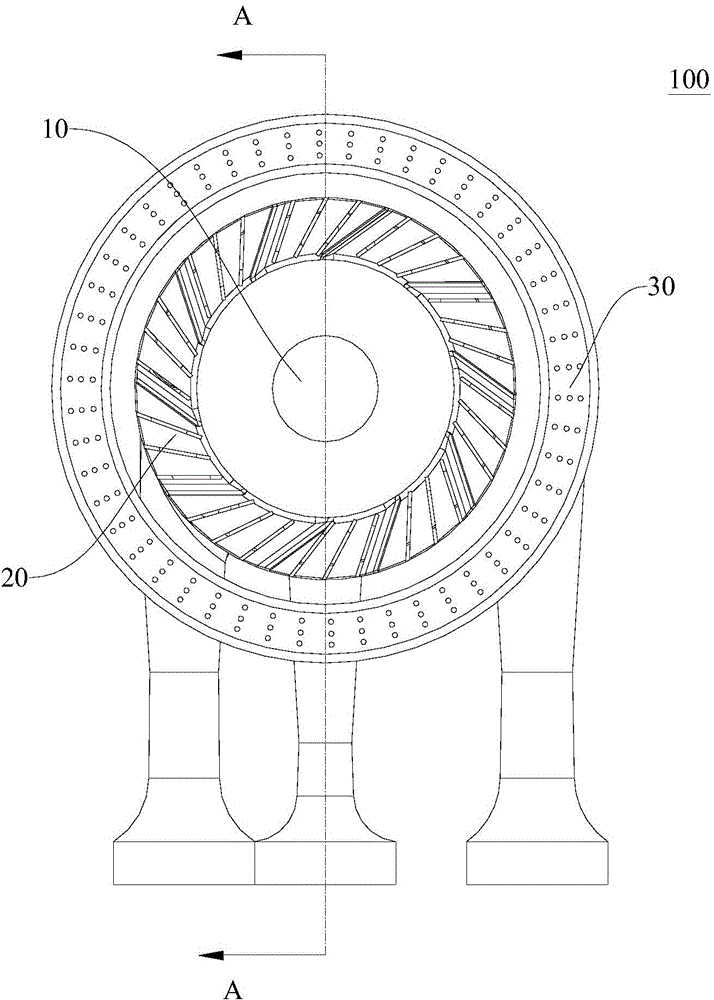

Pulverized fuel burner and entrained flow gasifier for the production of synthesis gas

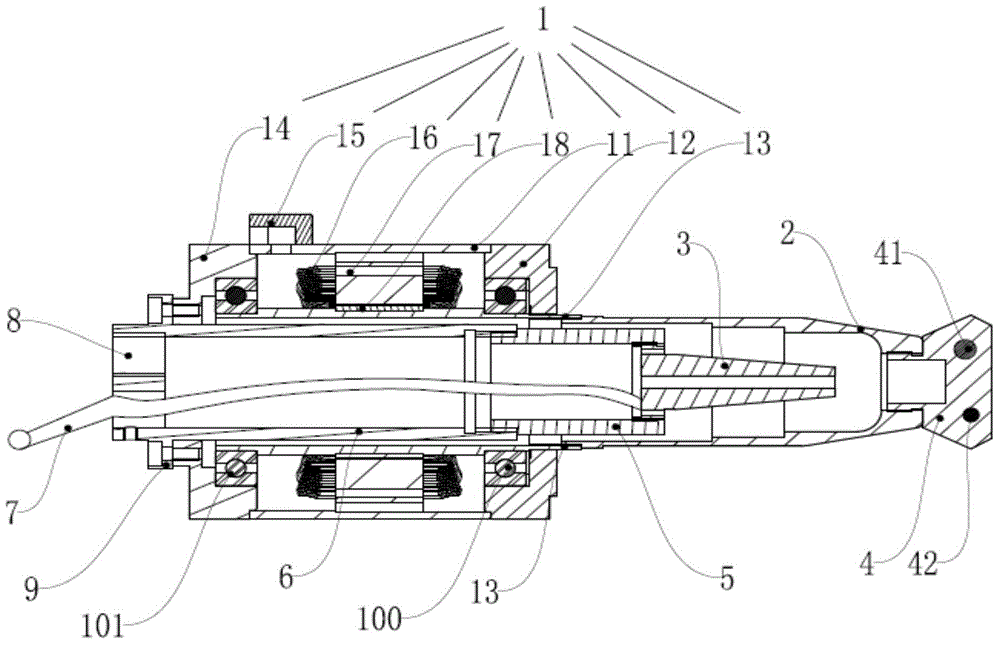

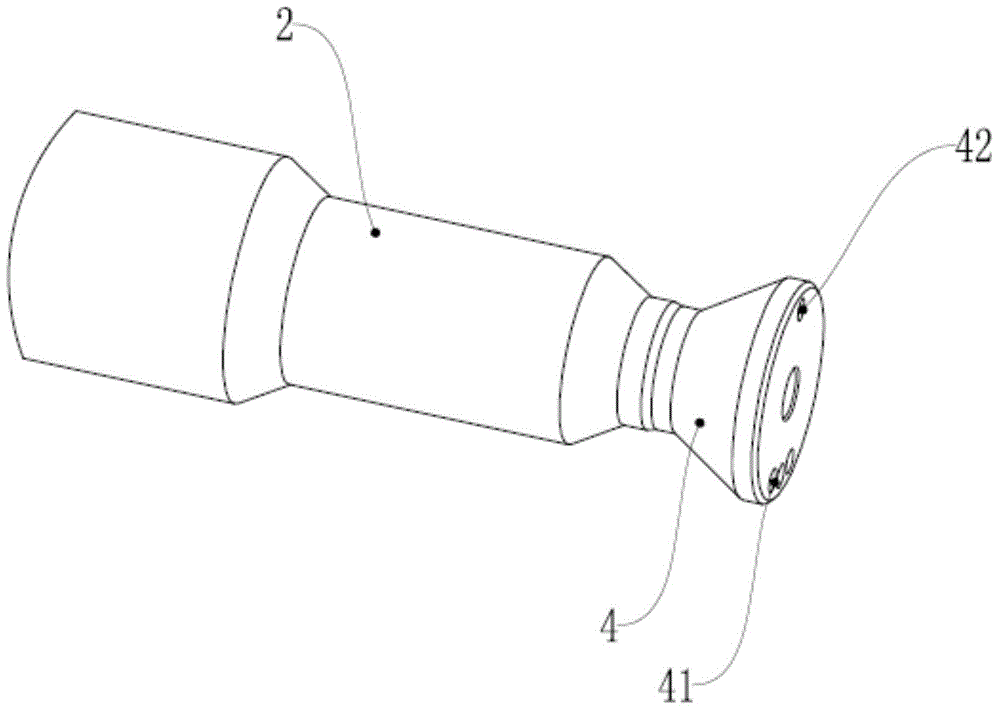

ActiveCN104713081AConstant flow rateEasy maintenanceBurner coolingGasification processes detailsCombustorEngineering

The invention relates to a pulverized fuel burner and an entrained flow gasifier with several such burners for the production of synthesis gas, the burner connecting pieces are arranged for the supply of fuel dust and coolant on an outer double-walled sleeve, the one a central tube in radial distance concentrically surrounding and to the central channel an annular channel for the promotion of the combustion dust forming the burner mouth, the burner has 1 connection port for an oxidizer, and for cooling water at double central tube for the promotion of the oxidizing agent to the burner mouth. The invention provides a pulverized fuel burner for the production of synthesis gas with a higher wear resistance, low tendency to clog and optimal mixing of pulverized fuel and oxidant to be created, which is suitable for use in an entrained flow gasifier. According to the invention of the pulverized fuel supply to the burner mouth underneath an opens tangentially inlet opening for the pulverized fuel in the annular channel a distributor with several annular sections circumferentially distributed funnel-like depressions with outlet available, each outlet opening in an axially parallel straight pulverized fuel channel with approximately rectangular cross-section within the annular channel opens, wherein the cross-sectional area of the pulverized fuel channels together corresponds to the cross-sectional area of the inlet opening for the pulverized fuel, said pulverized fuel channels open into a spiral plenum front of the burner mouth defined by an upper coil, which the spaces of the annular channel between the outlet openings of the pulverized fuel channels closes, a parallel to bottom coil to swirl generation in the pulverized fuel flow and a two helices interconnecting web is limited.

Owner:CHOREN INDTECHN

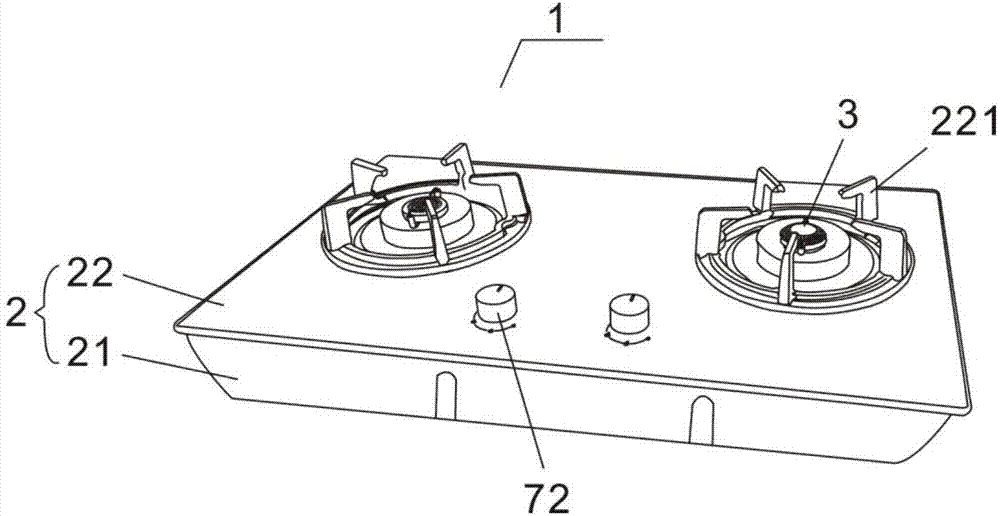

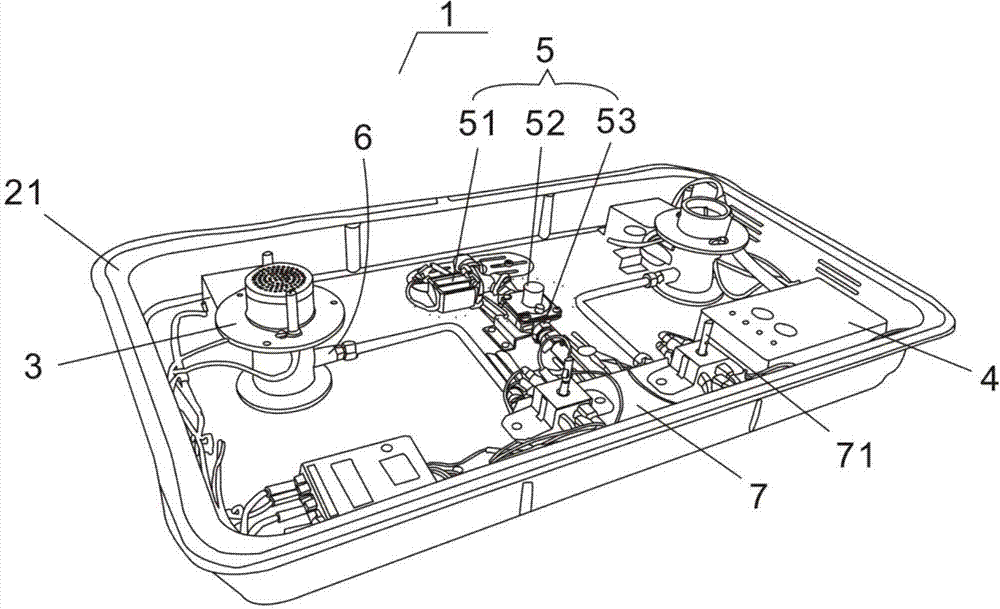

Gas stove

ActiveCN103398400AIncrease profitEmission reductionDomestic stoves or rangesGaseous fuel burnerEngineeringGas cooking stove

The invention provides a gas stove which comprises a shell, a combustor, a controller, an electromagnetic pressure maintaining valve, a gas pipe and a synchronizer. A blowing spray device realizes sufficient mixing of gas and air, a multi-level variable-pressure accelerating device realizes quick burning of gas, and the electromagnetic pressure maintaining valve avoids the defect of frequent fluctuation of gas, and therefore, the safety performance of the gas stove is improved. The gas stove is simple in structure, convenient to operate, carries out multiple times of mixing including coarse mixing and fine mixing on gas and air, and then pressurizes and accelerates, so that air and gas are sufficiently mixed, the combustion is sufficient and quick, emission of waste gas is reduced, and gas utilization rate is improved; the gas stove has energy-saving and environment-friendly effects, and is high in safety performance.

Owner:何梅顺

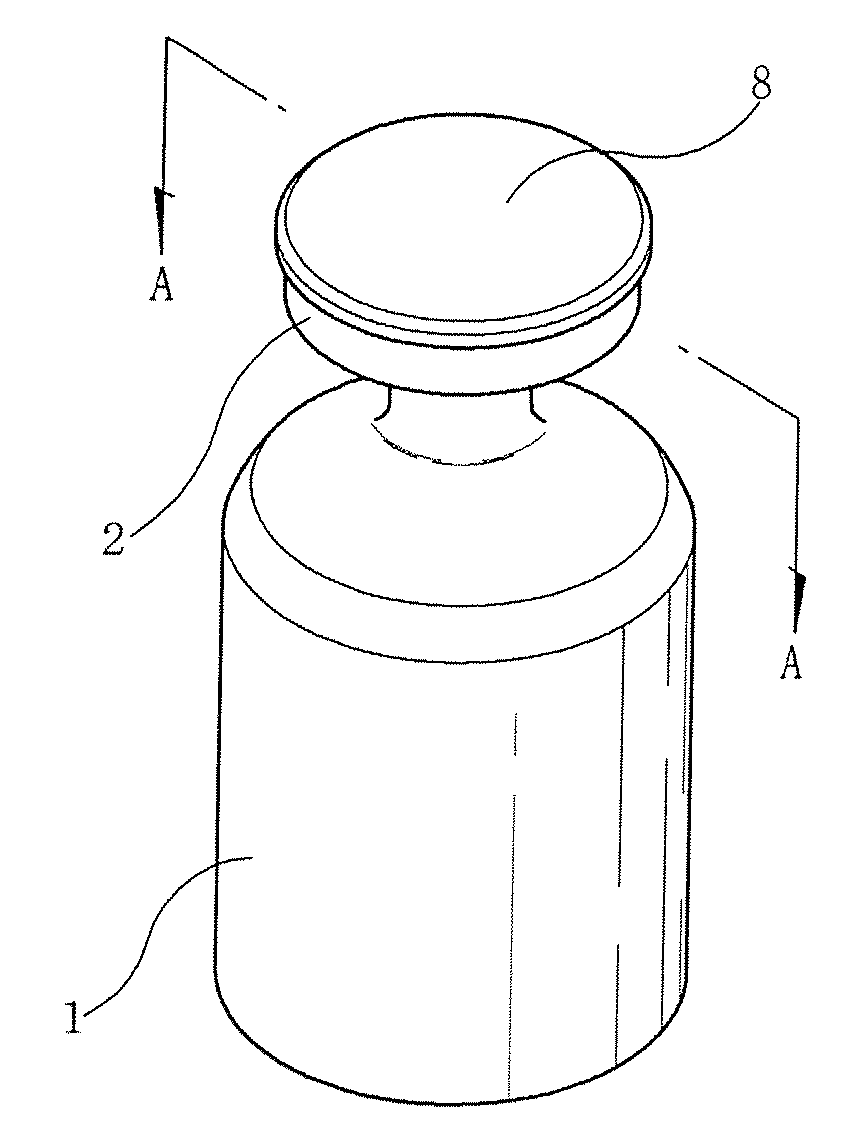

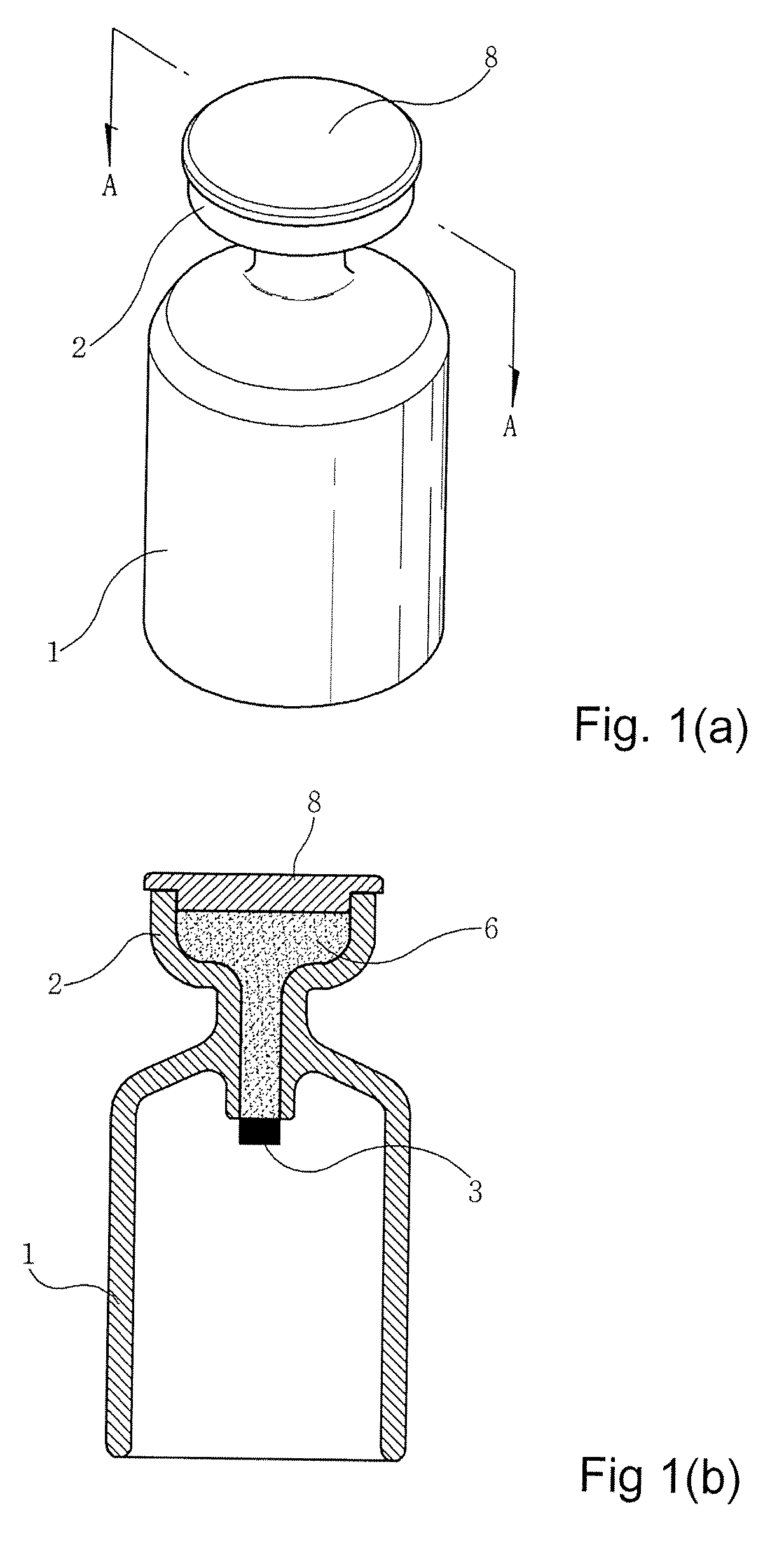

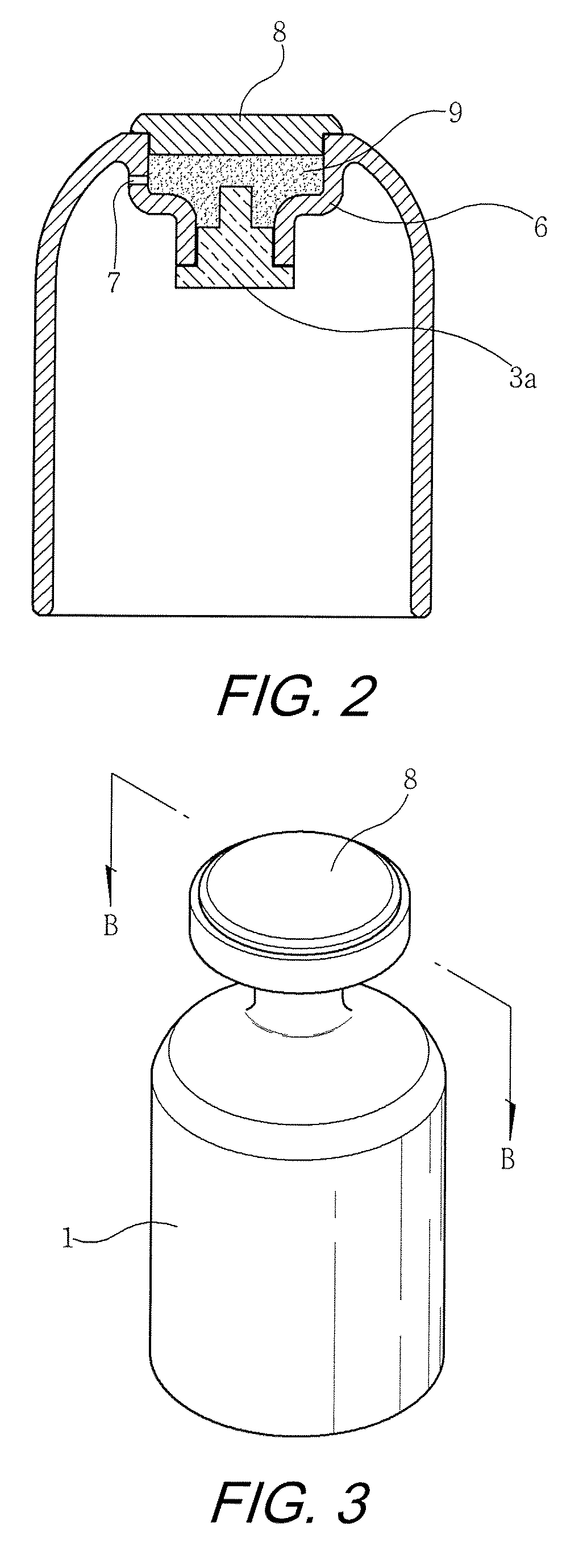

Cupping jar with lamp

InactiveUS20080051826A1The process is simple and convenientMaintaining flamePneumatic massageDiagnosticsEngineeringBottle

Owner:CHO YUN SANG

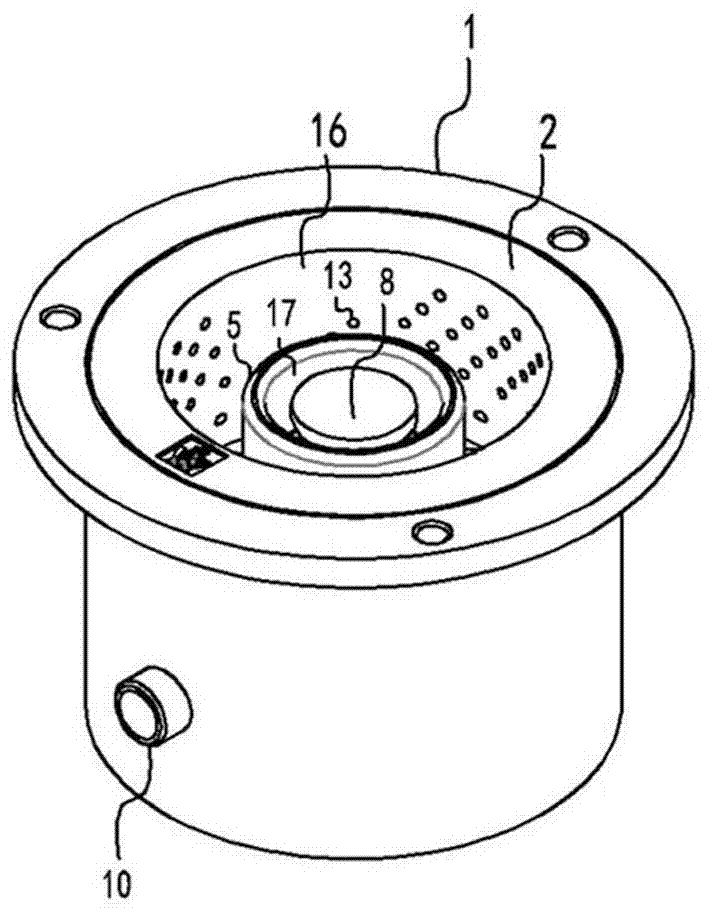

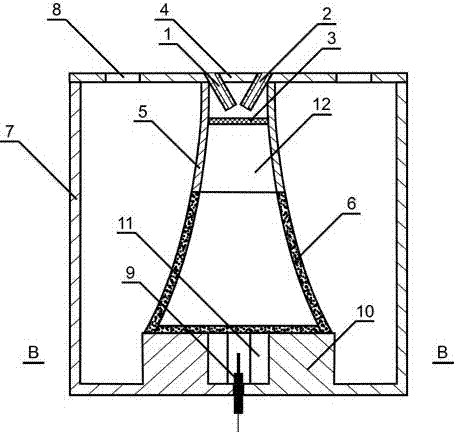

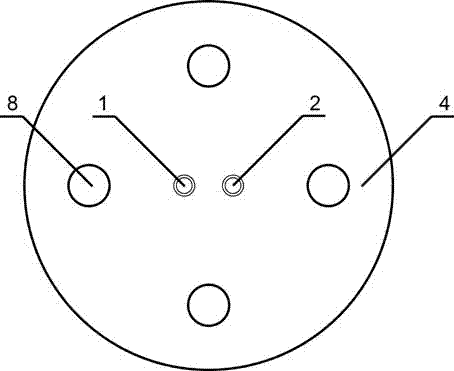

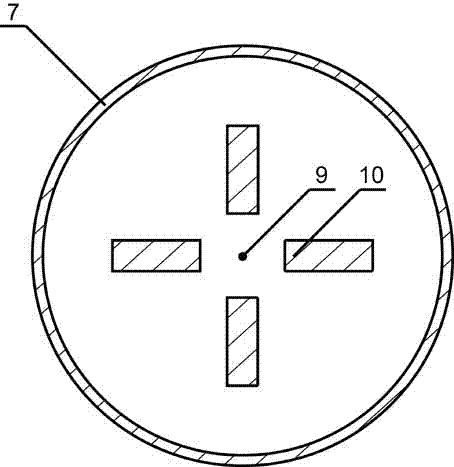

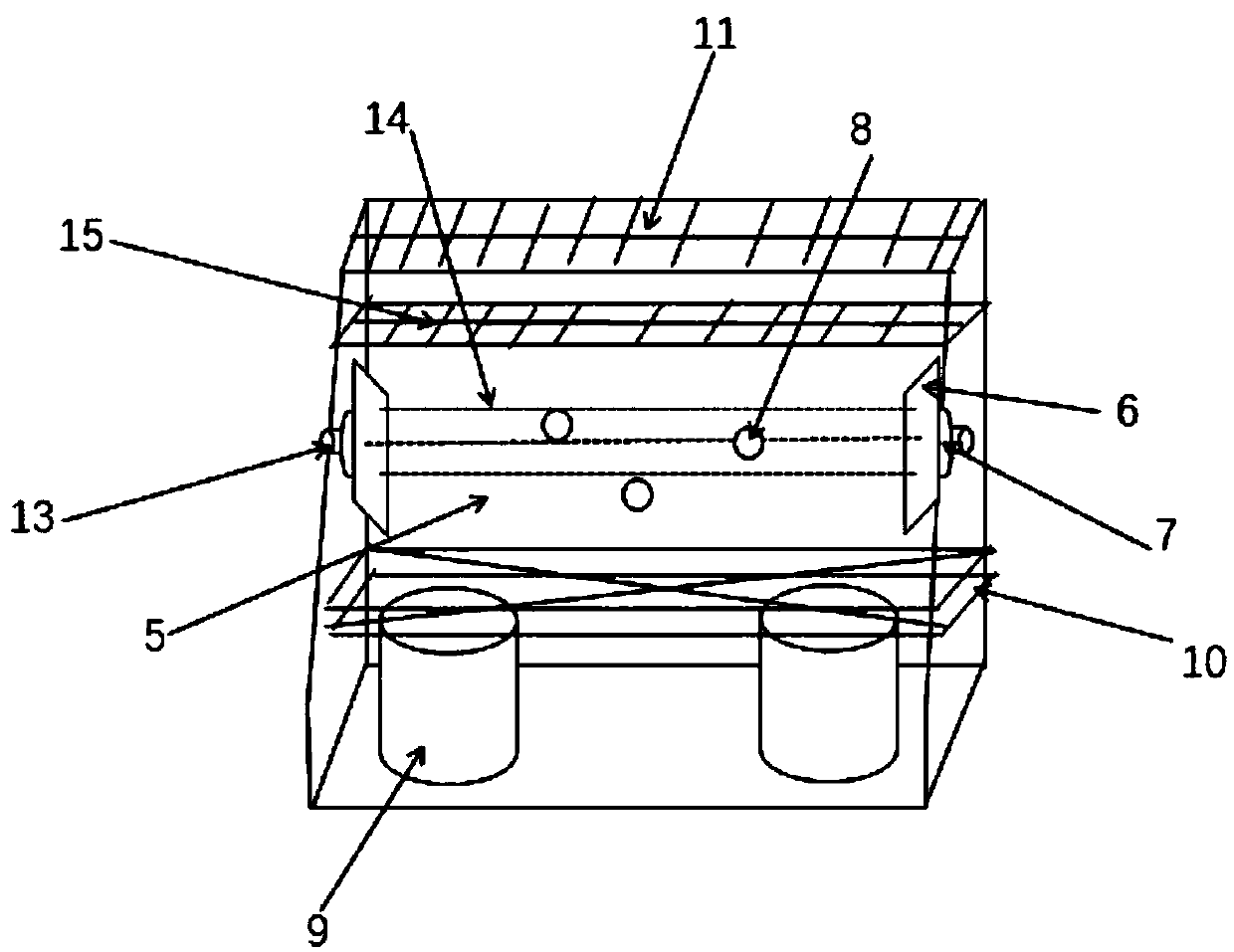

Micro diffuse type combustion apparatus for micro-thermphotoelectric system

InactiveCN105402725AReduce volumeImprove premix effectBurner material specificationsIndirect carbon-dioxide mitigationCombustion chamberEngineering

The invention provides a micro diffuse type combustion apparatus for a micro-thermphotoelectric system. The micro diffuse type combustion apparatus for the micro-thermphotoelectric system comprises an ignition device, an external sleeve, an internal sleeve and an upper panel, wherein the internal sleeve is positioned in the external sleeve; the upper panel is arranged at the top end of the external sleeve; the internal sleeve is a flared structure with big lower end; the lower end of the internal sleeve is provided with a porous bottom plate; the circumferential wall of the lower part of the internal sleeve; the interior of the internal sleeve is a preheating premixing chamber; a combustion chamber is formed between the internal sleeve and the external sleeve; the preheating premixing chamber is communicated with the combustion chamber through a porous wall and the porous bottom plate; and a gas exhaust opening, an air inlet and a fuel gas inlet are formed in the upper panel. According to the invention, as air enters the porous material from various surfaces, a temperature field is uniform and the combustion is enhanced to increase the device power; through the adoption of special combustion chamber wall surface design, heat obtained by the whole wall surface is much and uniform; the micro diffuse type combustion apparatus can stably respond to fine air inlet pulsation and combustion pulsation; and meanwhile, through the adoption of the porous material with reducing aperture, tempering and backflow problems of the porous material are also avoided.

Owner:CHONGQING UNIV

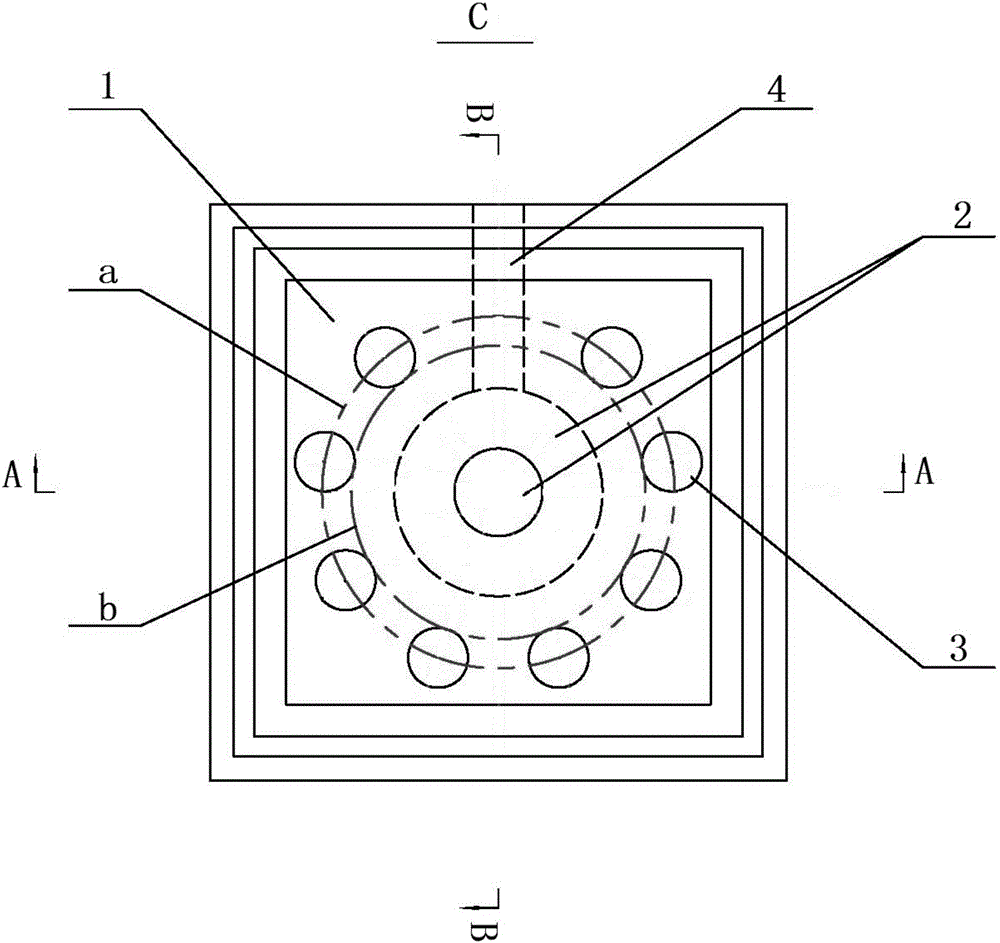

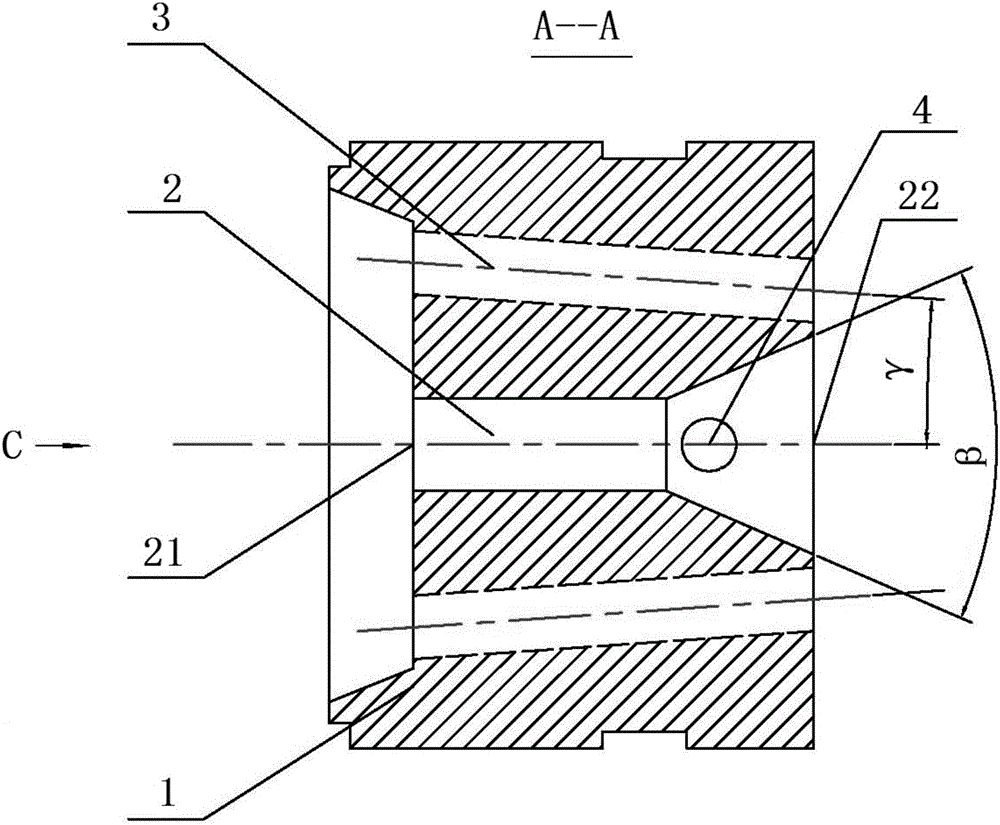

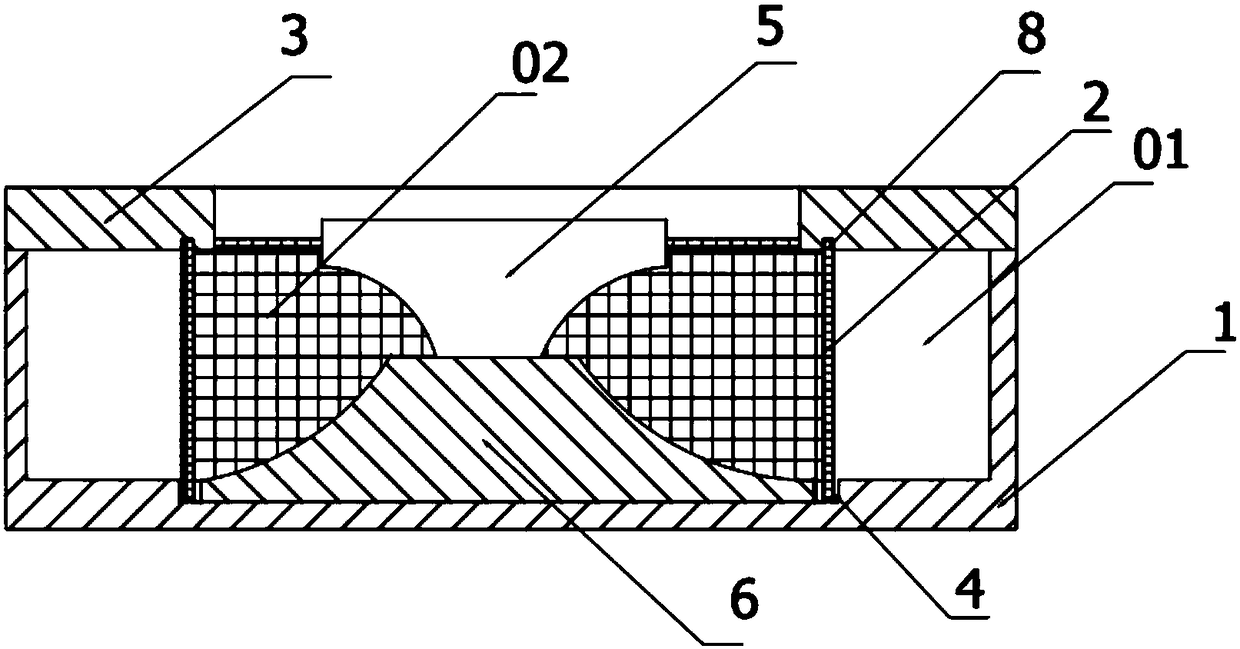

Nozzle and manufacturing method thereof

ActiveCN105889930AIncrease contact areaResolve Insufficient CombustionIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringGas burner

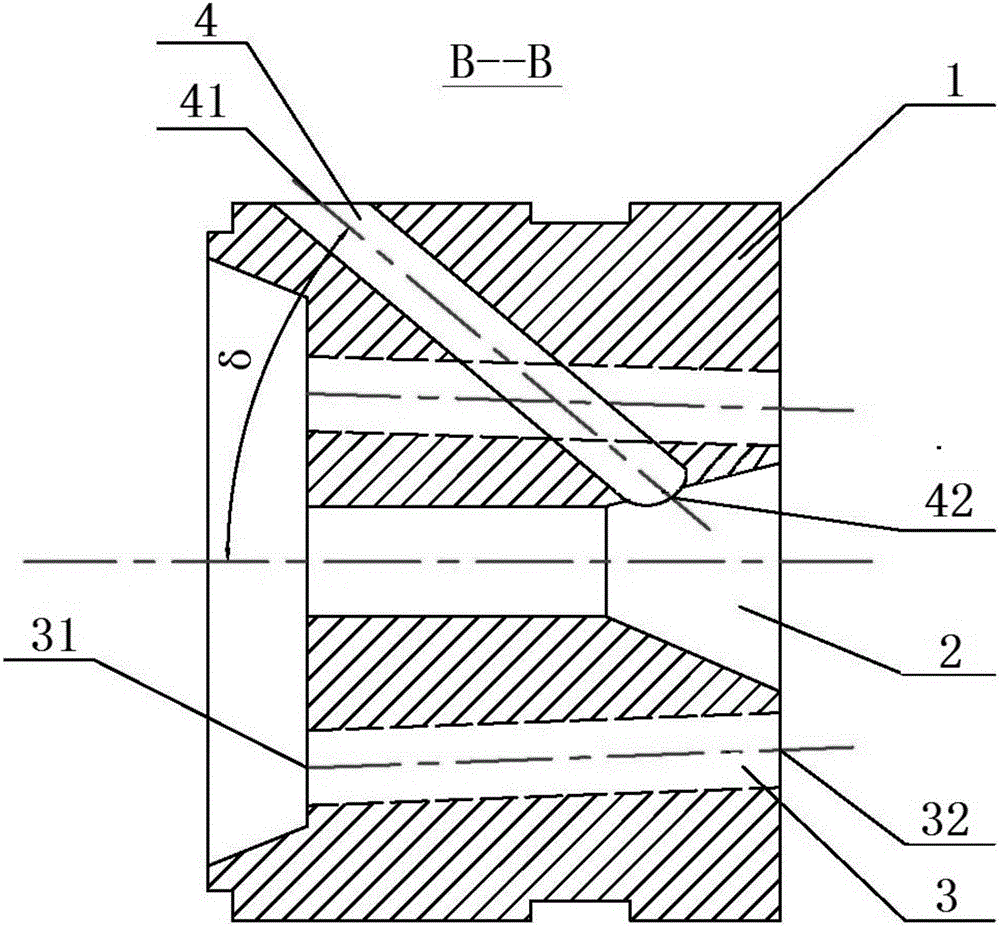

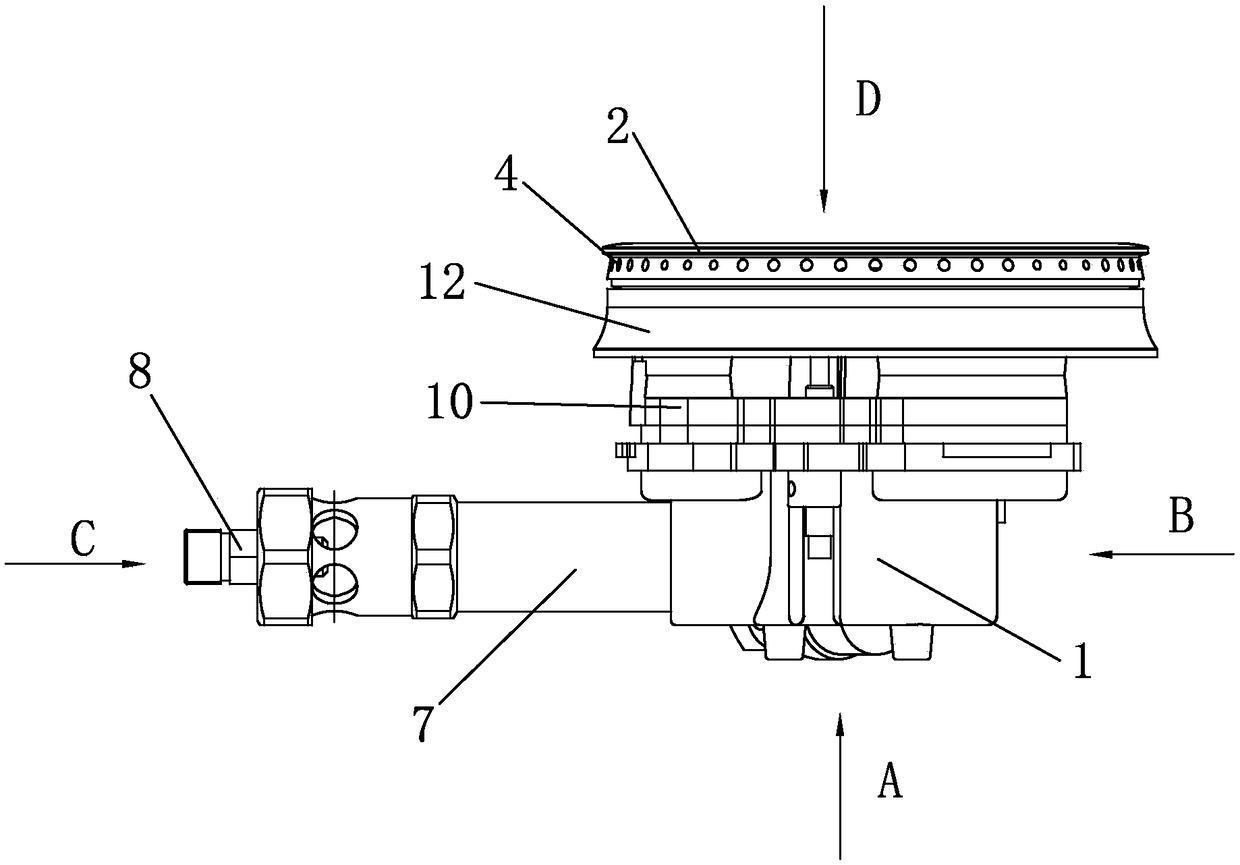

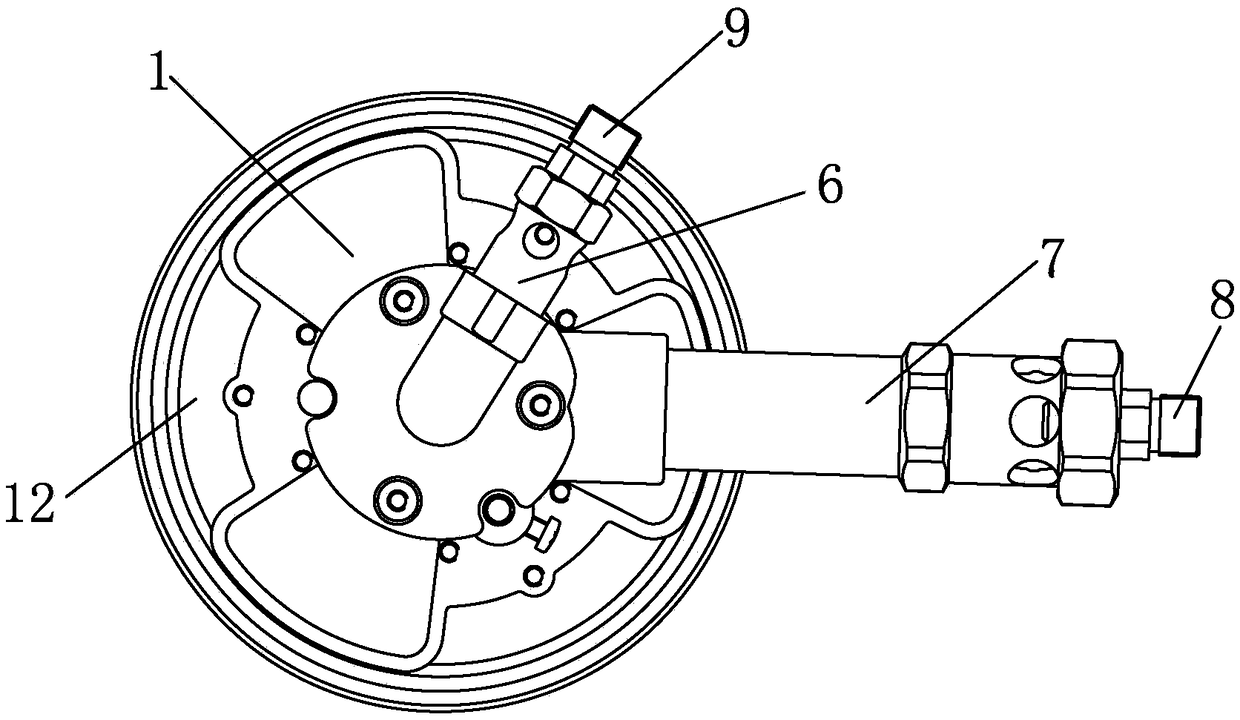

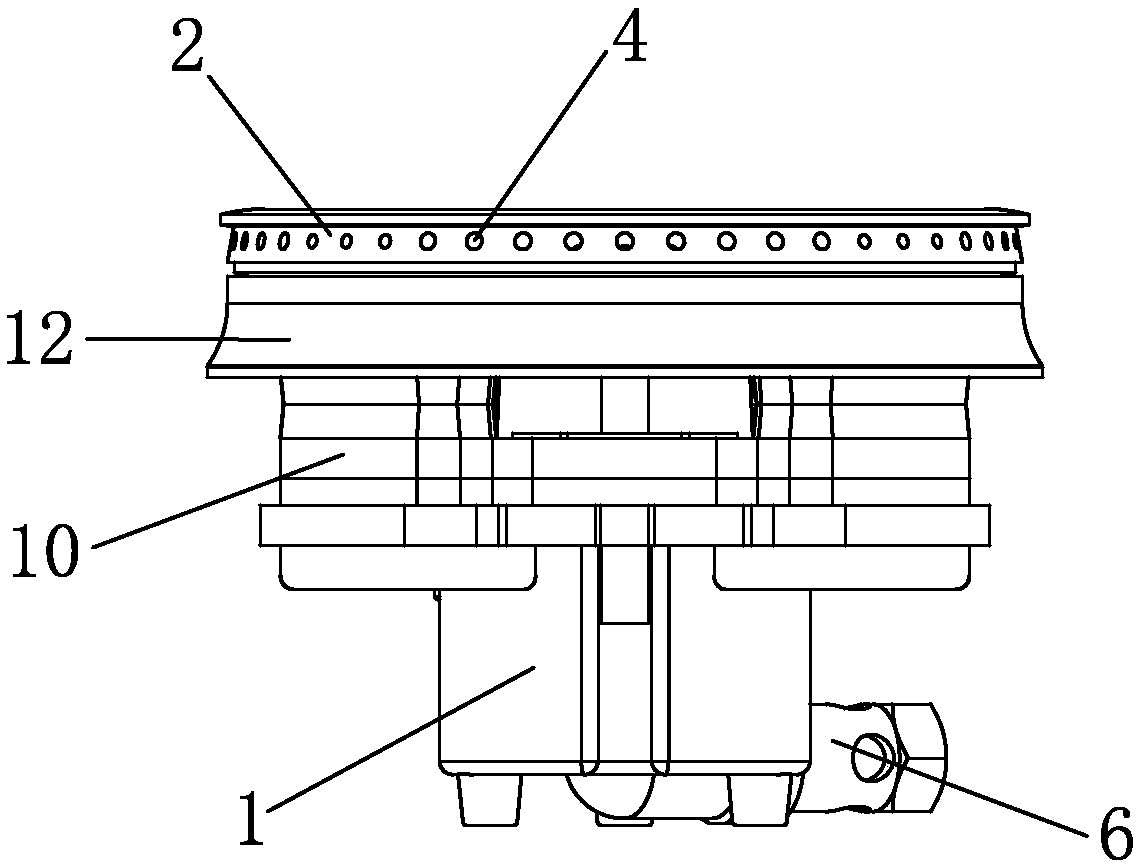

The invention discloses a nozzle and a manufacturing method thereof and belongs to the technical field of premixed gas burners. The nozzle comprises a primary air channel, secondary air channels and a natural gas channel which are located inside a nozzle body, the primary air channel comprises a uniform-section channel section and a gradually-wide channel section in sequence from a primary air inlet to a primary air outlet, three or more secondary air channels are distributed around the primary air channel, and a natural gas outlet of the natural gas channel is communicated with the gradually-wide channel section; the included angle delta between the natural gas channel and the central axis of the uniform-section channel section is greater than or equal to 30 degrees and less than or equal to 50 degrees; the included angle beta between two side edges on the axial cross section of the gradually-wide channel section is greater than or equal to 34 degrees and less than or equal to 60 degrees; the included angle gamma between each secondary air channel and the central axis of the uniform-section channel section is greater than or equal to 0 degree and less than or equal to 10 degrees. The nozzle is good in comprehensive combustion performance and used for gas combustion.

Owner:MAANSHAN TIANZHOU ENERGY SAVING ENG TECH

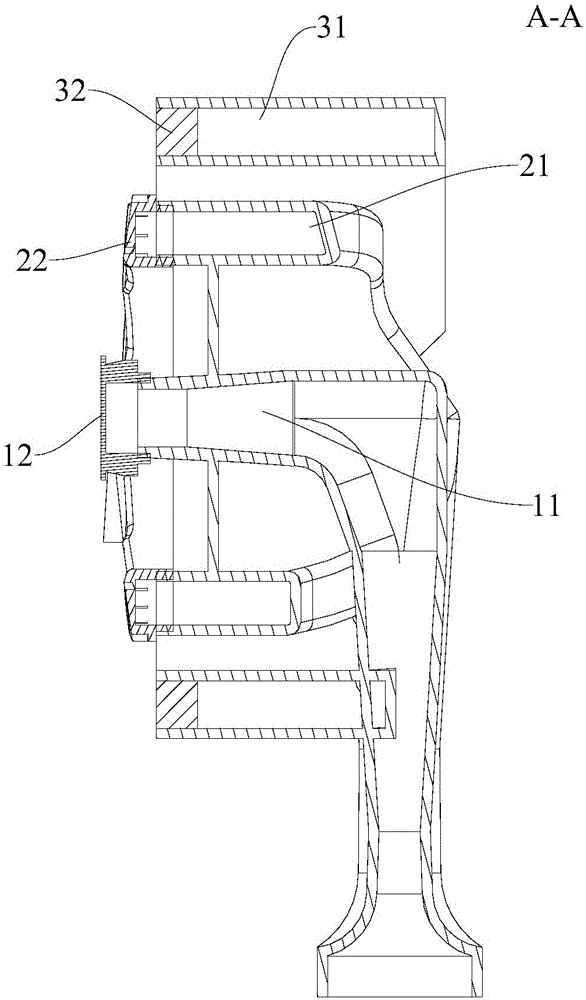

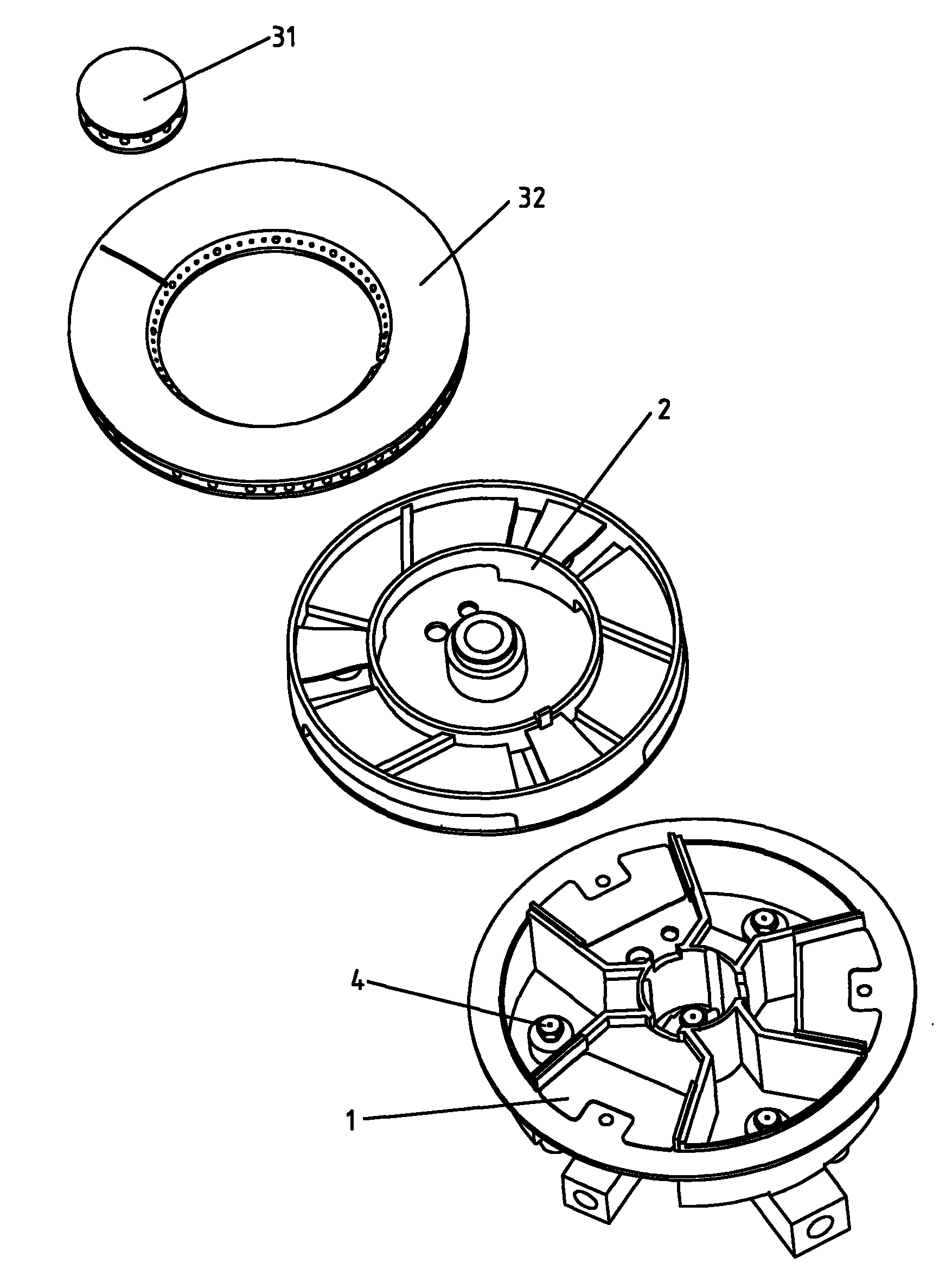

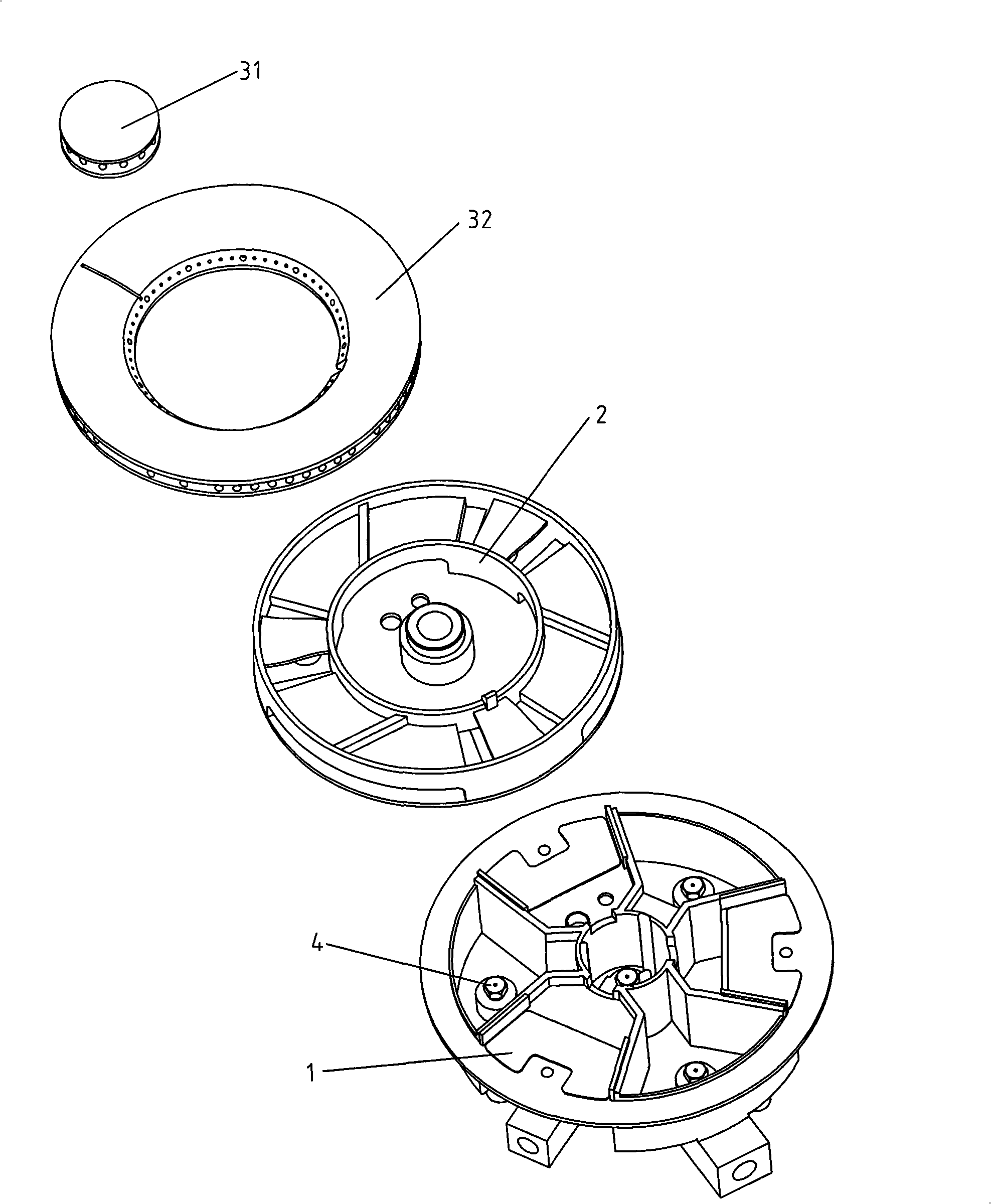

Lower air inlet gas burner for cooking appliance

PendingCN109340749AAchieve finishingFlat surfaceGaseous fuel burnerHome appliance efficiency improvementDie castingEngineering

The invention discloses a lower air inlet gas burner for a cooking appliance. The lower air inlet gas burner comprises a base and a fire cover, and the fire cover comprises an outer fire cover and aninner fire cover; the outer fire cover is provided with outer fire holes, and the inner fire cover is provided with inner fire holes; both the outer fire cover and the inner fire cover are arranged onthe base, and the base is provided with ejector pipes including an inner fire ejector pipe and an outer fire ejector pipe; the outer fire ejector pipe is provided with an outer fire nozzle, and the inner fire ejector pipe is provided with an inner fire nozzle; the base and the ejector pipes are of separate structures, and the ejector pipes are in threaded connection with the base; the base is manufactured through an aluminum die casting technology, and the ejector pipes are manufactured through a machining technology; finish machining of the ejector pipes is achieved, so that the surfaces ofthe inner walls of the ejector pipes are smooth, and the resistance of the ejector pipes to mixing flow is reduced; the ejection effect is improved, and the expected primary air coefficient can be achieved; and combustion is more sufficient.

Owner:浙江森歌智能厨电股份有限公司

Injection type metal burning torch

InactiveCN105643045AImprove high temperature resistanceWon't crackGas flame welding apparatusEngineeringTemperature resistance

The invention discloses an injection type metal burning torch. The injection type metal burning torch comprises a burning torch head and a burning torch handle. The burning torch head is rectangular and is connected with the burning torch handle. A nozzle is arranged under the burning torch head and is a cylindrical nozzle. The nozzle is connected with an air mixing component. The air mixing component is a mixing cavity which is connected with gas conveying channels. An adjusting rotary knob is arranged on the burning torch handle and provided with a scale adjusting gear. A shielding component is arranged around the nozzle, eyes of an operator can be further prevented from being burnt by hard light, and the personal safety of the operator is ensured. The nozzle is provided with a high-temperature-resistant coating so that the high-temperature resistance of the nozzle can be improved, the nozzle is prevented from cracking caused by the influence of high temperatures, and the replacement frequency of the nozzle is lowered.

Owner:扬州博泰冶金设备制造有限公司

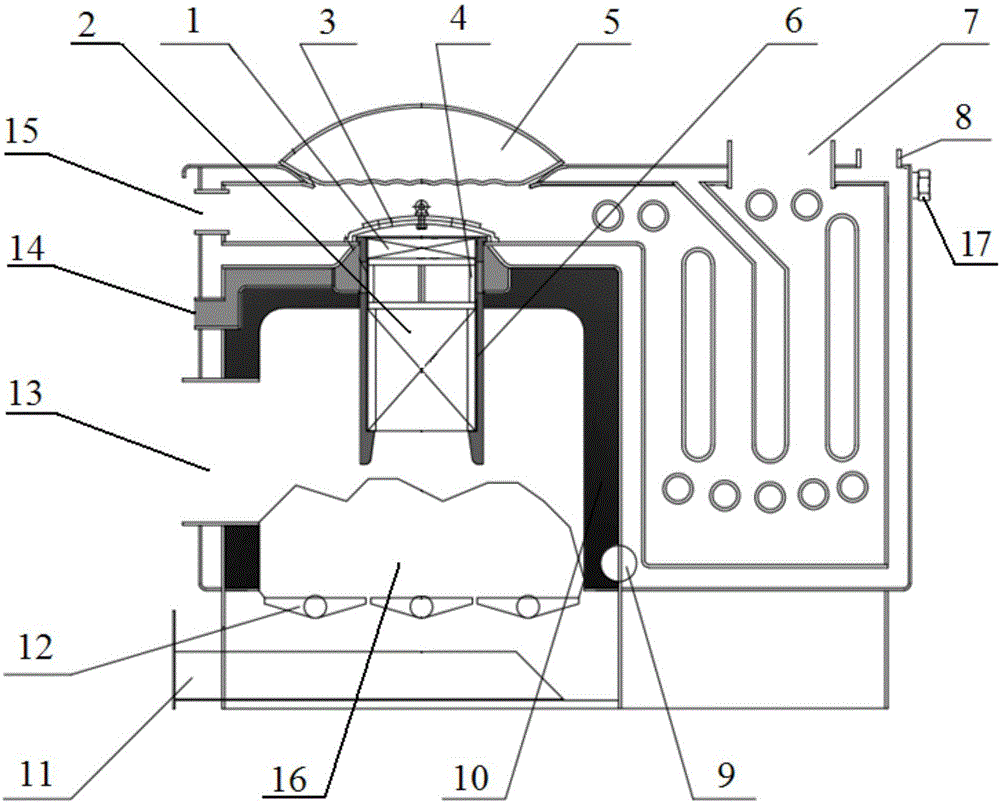

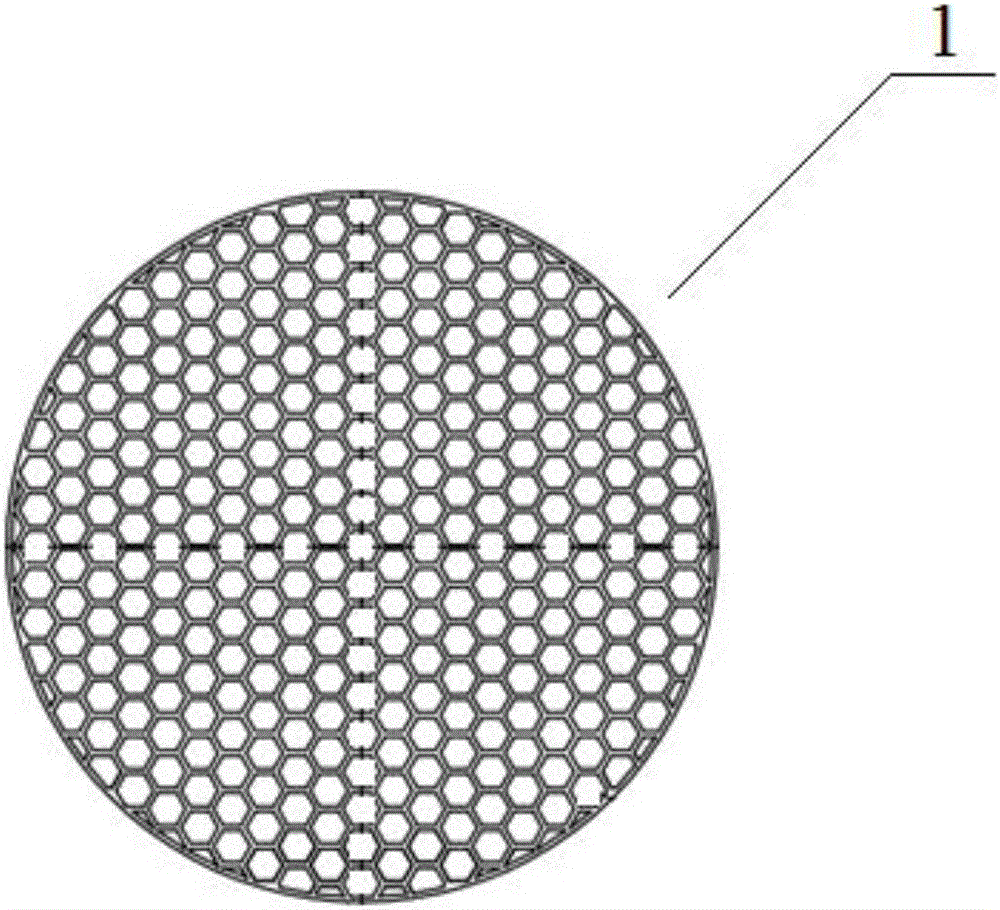

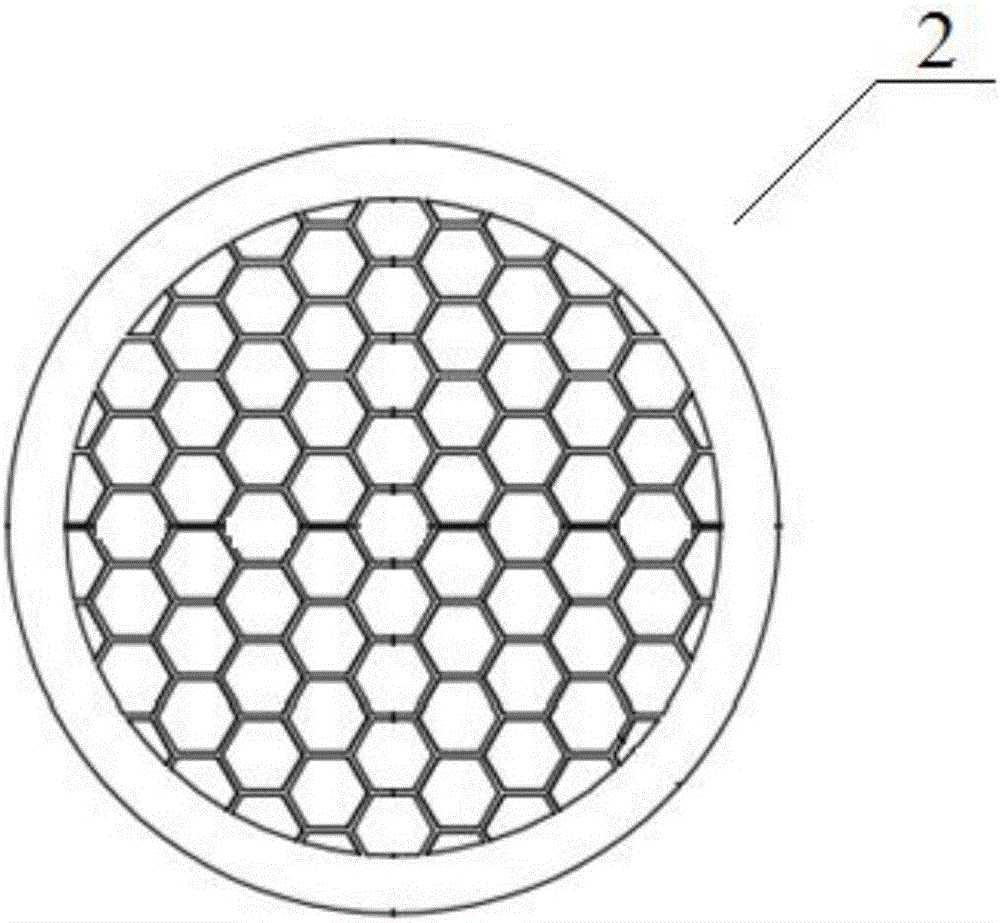

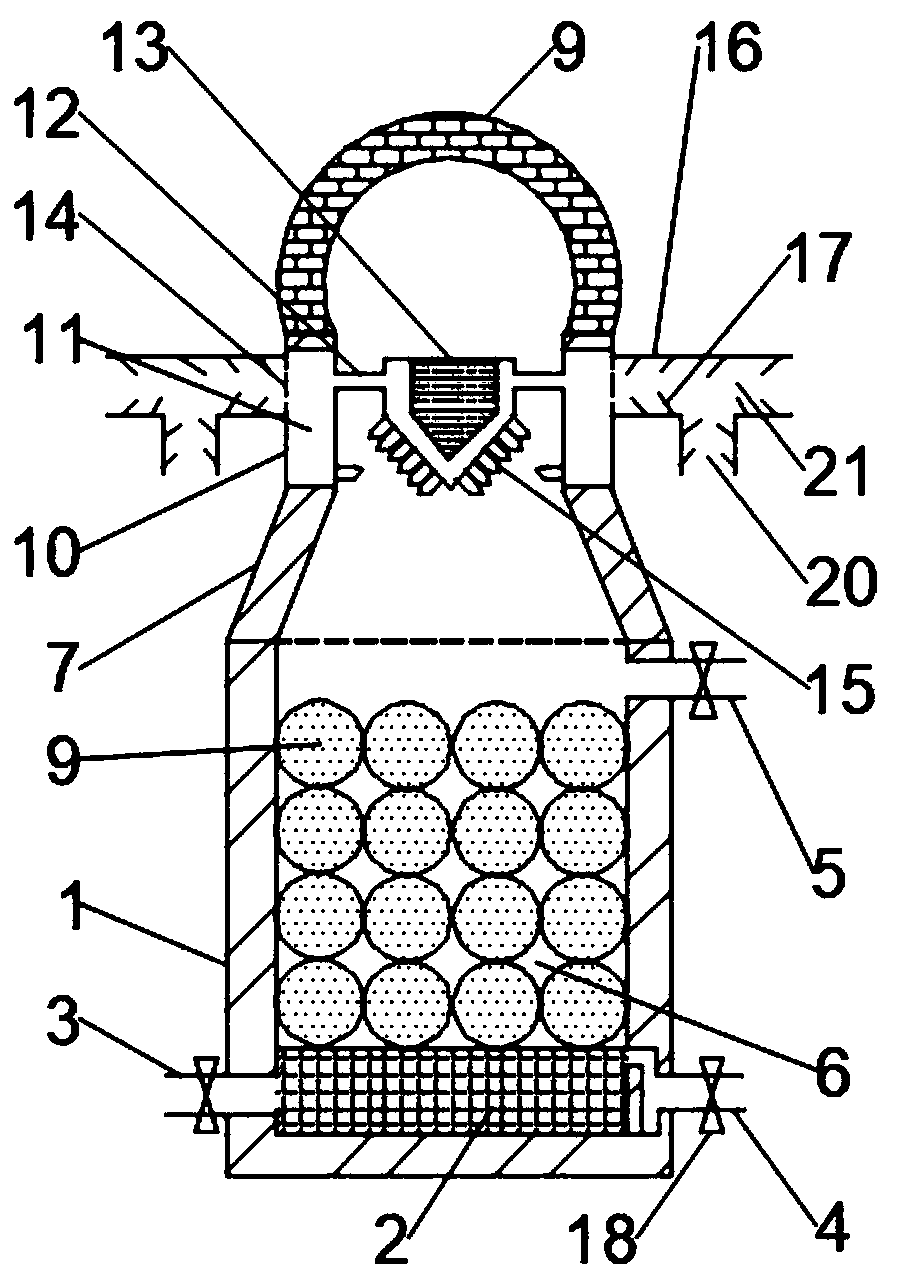

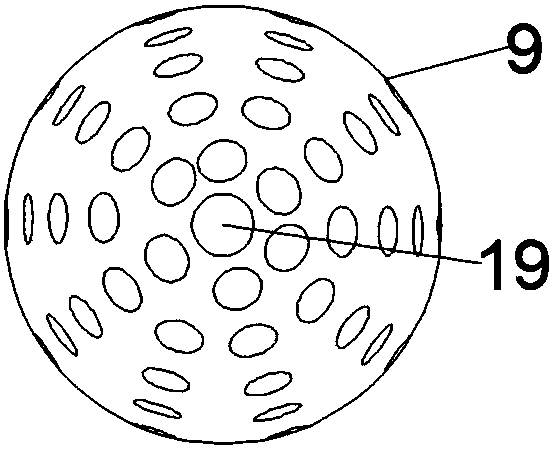

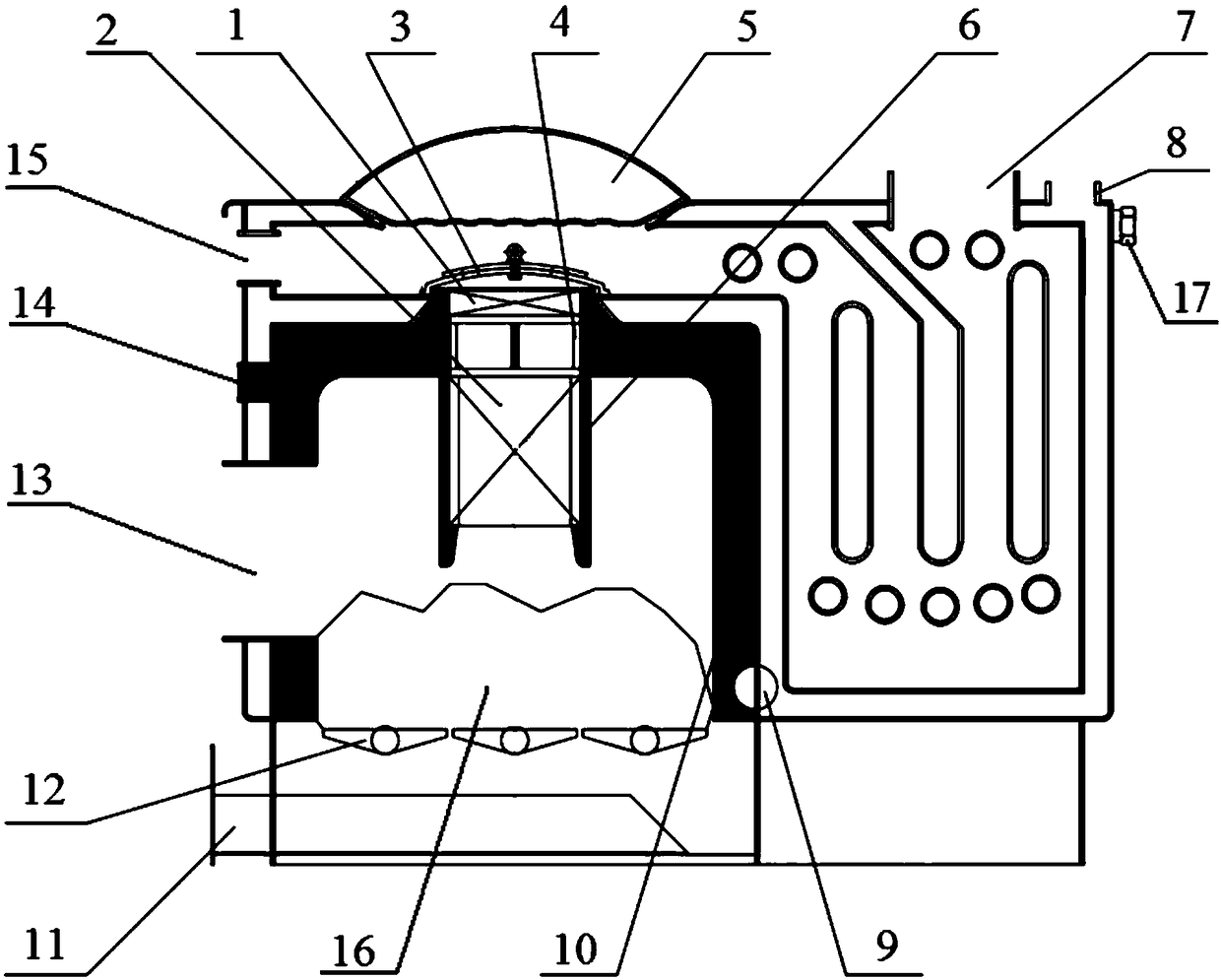

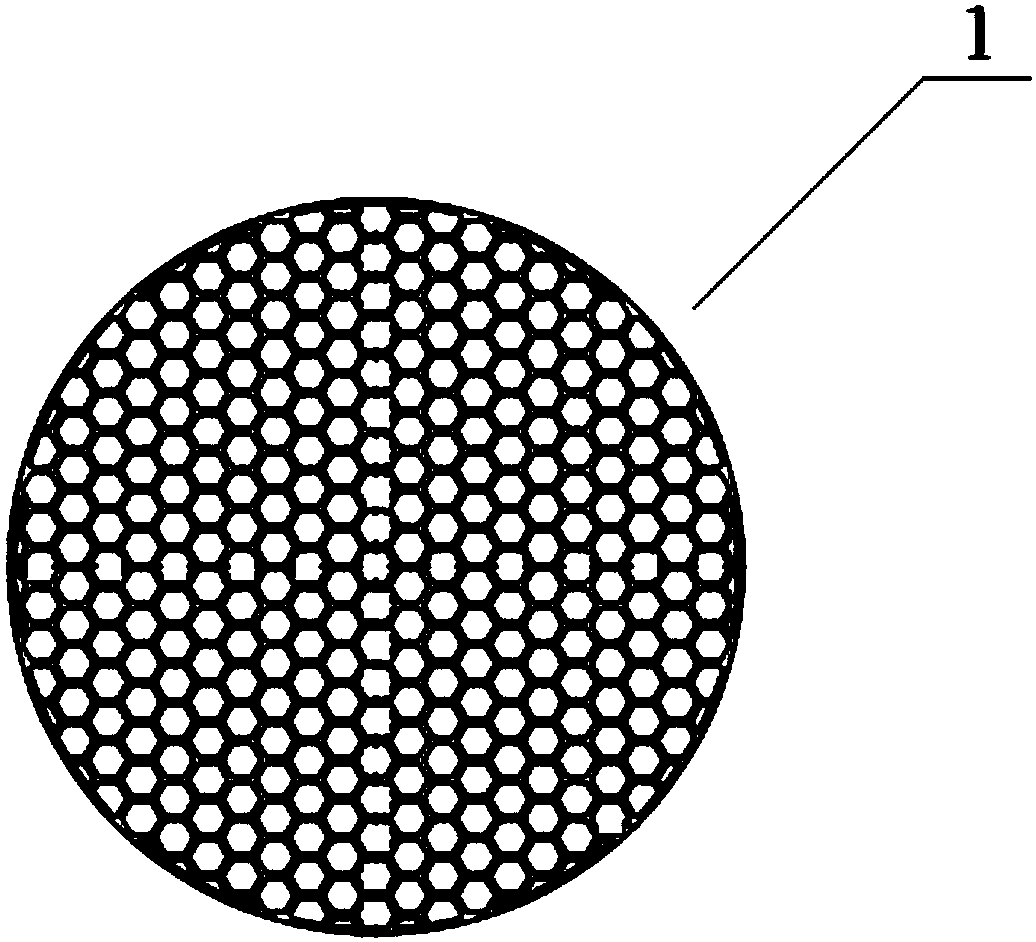

Heating stove based on honeycomb ceramic heat accumulators

ActiveCN105823090ALow ash contentBurn fullyLighting and heating apparatusStove/ranges for heating waterCombustion chamberMaterials science

The invention belongs to the technical field of heating stoves and relates to a heating stove based on honeycomb ceramic heat accumulators. The heating stove based on the honeycomb ceramic heat accumulators comprises a stove body. A stove chamber is formed in the stove body. A flame outlet is formed in the upper end of the stove chamber. A protective sleeve is arranged in the flame outlet in an embedded mode. The first honeycomb ceramic heat accumulator and the second honeycomb ceramic heat accumulator are arranged in the protective sleeve in an embedded mode. The first honeycomb ceramic heat accumulator is located above the second honeycomb ceramic heat accumulator. The first honeycomb ceramic heat accumulator and the second honeycomb ceramic heat accumulator are separated through a supporting body, and a secondary combustion chamber is formed. The first honeycomb ceramic heat accumulator and the second honeycomb ceramic heat accumulator are each provided with a plurality of through holes formed in the vertical direction. The cross section area of each through hole of the first honeycomb ceramic heat accumulator is smaller than that of each through hole of the second honeycomb ceramic heat accumulator. Fire bars used for supporting fuel are arranged at the bottom of the stove chamber. The lower end of the protective sleeve is suspended above the fuel. A fuel feeding and first air distribution port, a second air distribution port and a third air distribution port are formed in the stove body. By the adoption of the heating stove based on the honeycomb ceramic heat accumulators, the fuel utilization rate is increased, the pollutant discharge amount is decreased, energy is saved, and environmental friendliness is achieved.

Owner:SHIJIAZHUANG JINTONG MACHINERY CO LTD

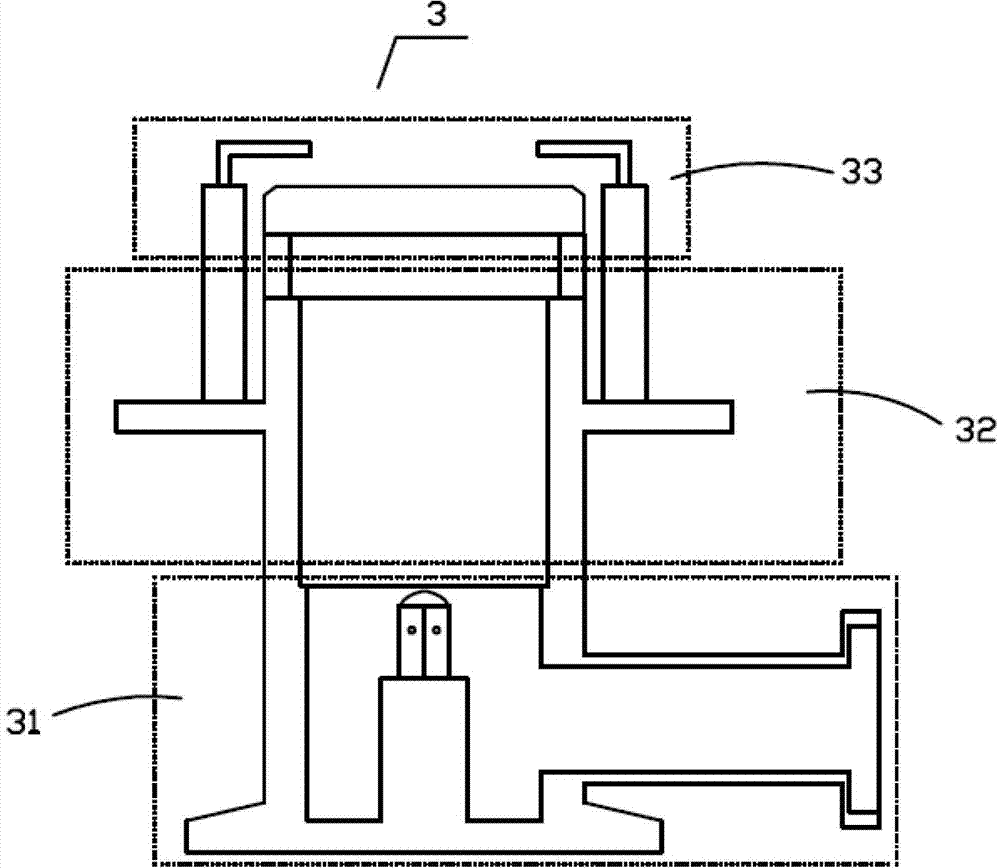

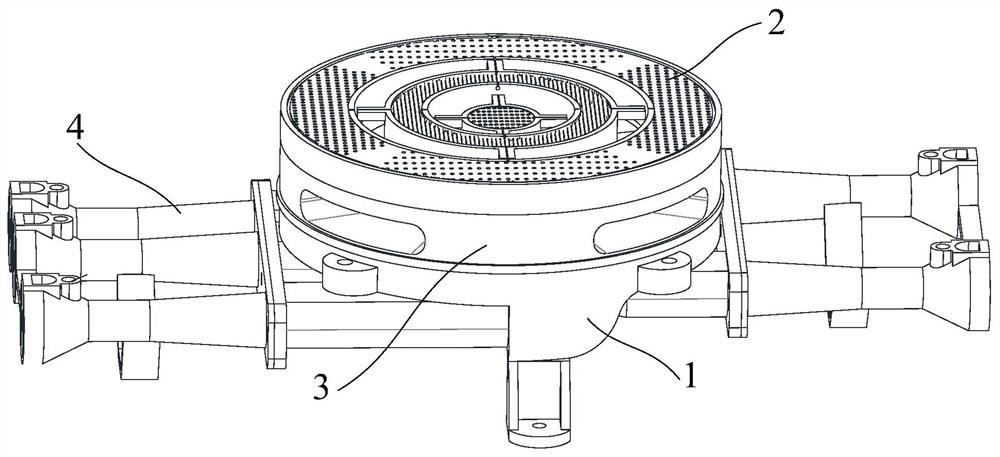

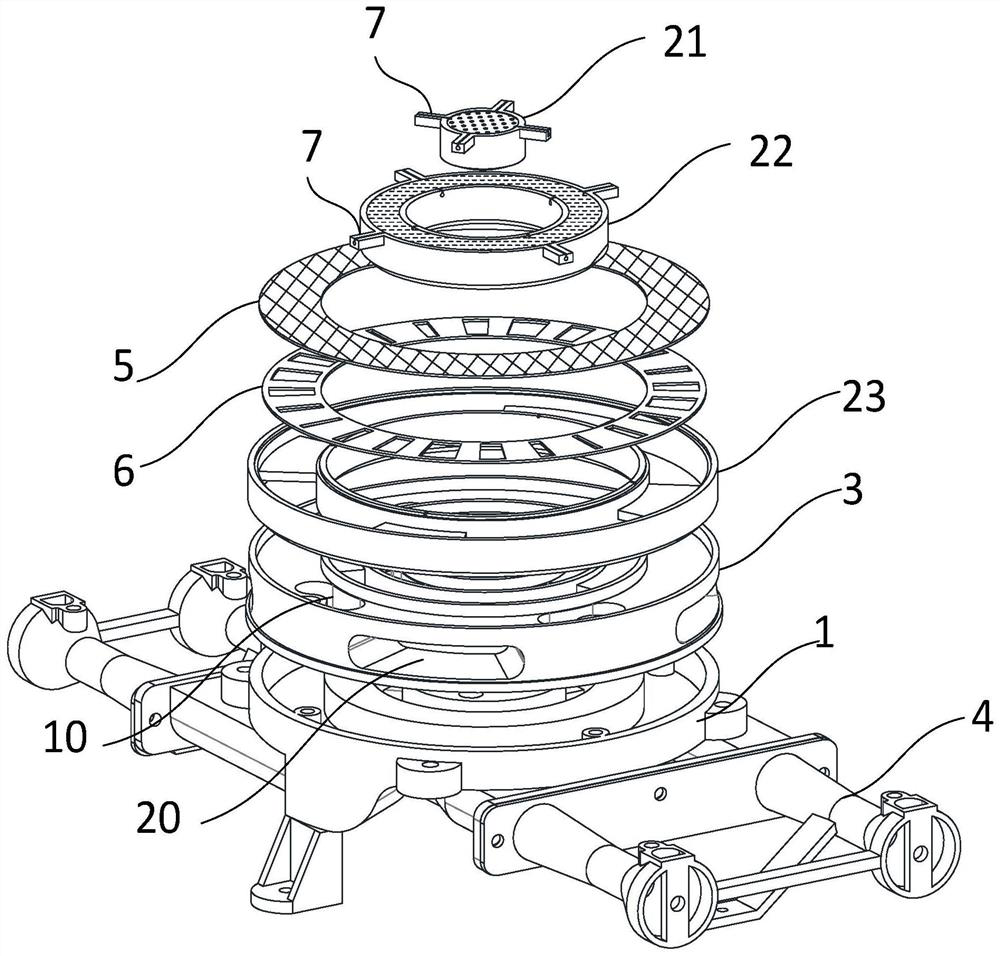

Stove burner

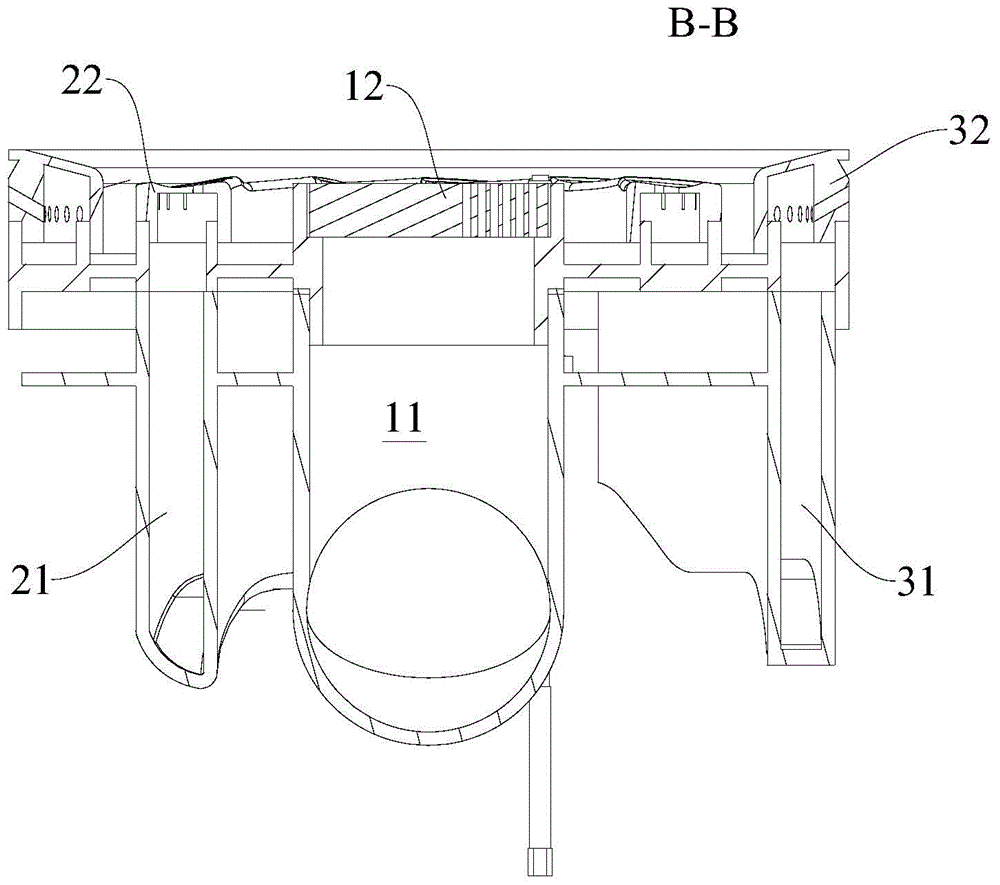

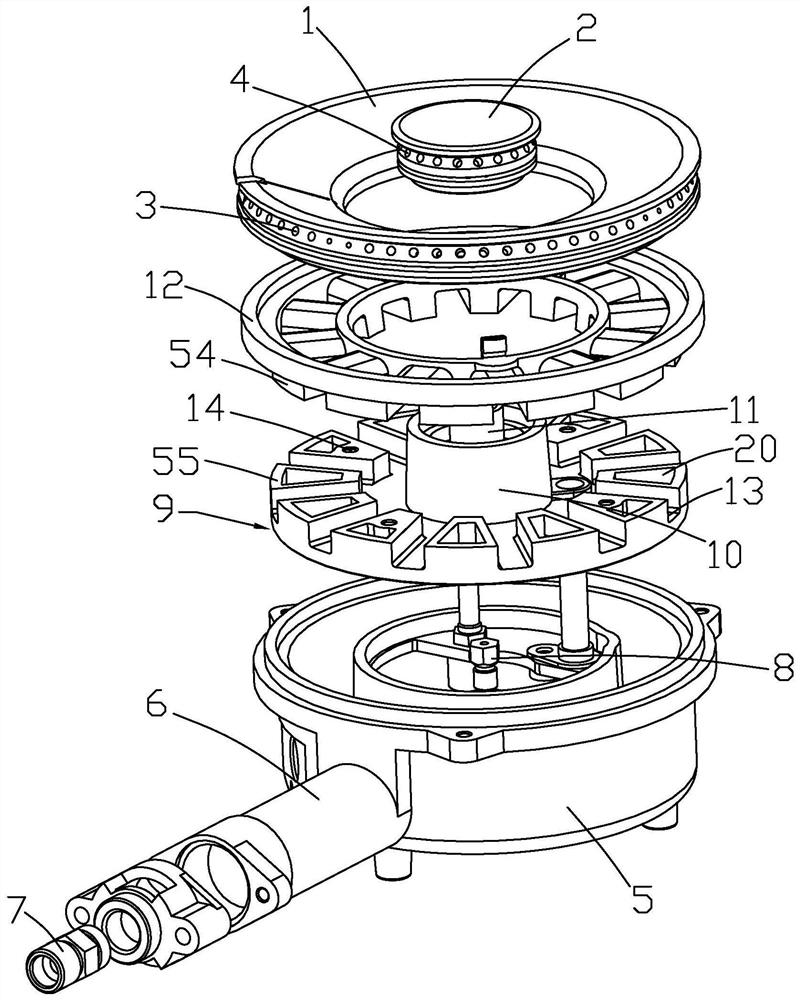

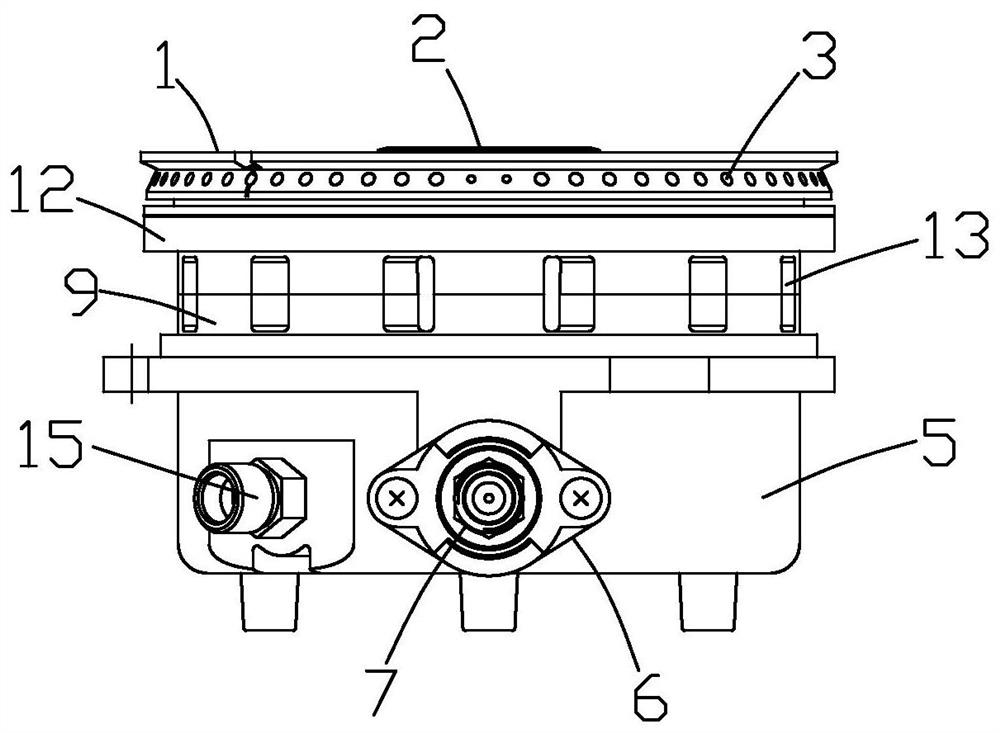

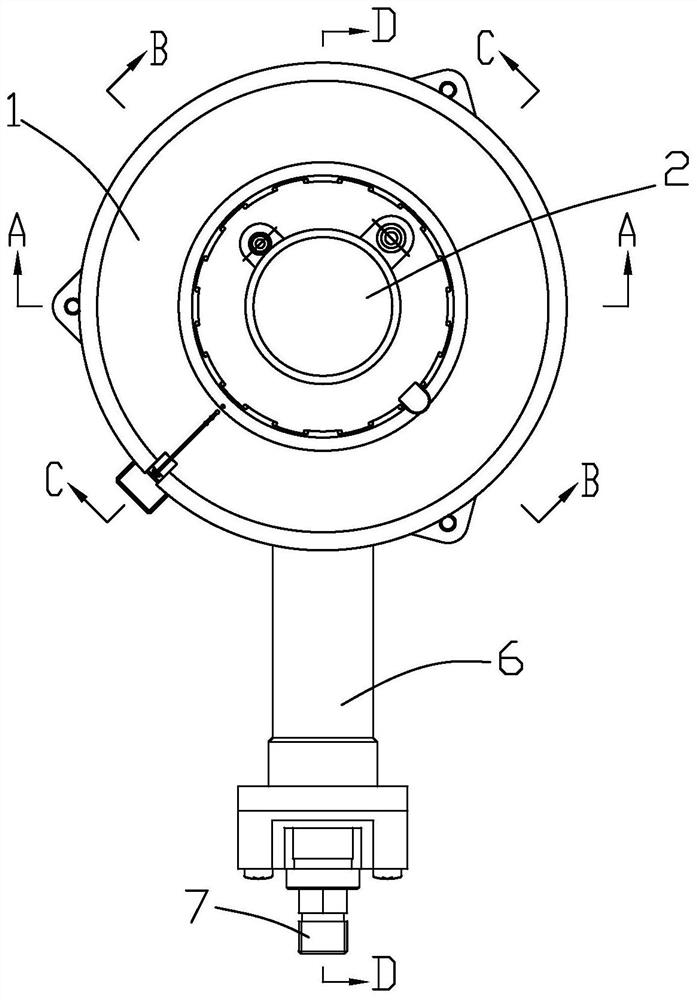

PendingCN112747316AUniform flameIncrease radiant energyDomestic stoves or rangesNon-combustible gases/liquids supplyCombustorEngineering

The invention discloses a stove burner. The stove burner comprises a base, a burner cap set, a gas mixing chamber and a plurality of injection pipes, wherein the top and the bottom of the gas mixing chamber are connected to the burner cap set and the base correspondingly and form three gas cavities, and the injection pipes are connected below the base and communicate with the three gas cavities; the burner cap set comprises an inner ring burner cap, a middle ring burner cap and an outer ring burner cap which are sequentially arranged from inside to outside, the inner ring burner cap uses an atmospheric combustion mode, and the strength of fire holes is 6-6.5 W / mm<2>; the outer ring burner cap uses an infrared combustion mode, and the strength of fire holes is 0.3-0.8 W / mm<2>; and the middle ring burner cap uses a half-atmosphere and half-infrared combustion mode, and the strength of fire holes is 2.5-3 W / mm<2>. According to the stove burner, burner cap structures with different three-ring burning modes are arranged, so that flame radiation energy of the burner is greatly increased, the defect that the temperature of a traditional stove with a single burning mode is not uniform is overcome, the heat efficiency of the burner is improved, and the heat loss is reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Burner and gas stove having same

InactiveCN104913305AHigh thermal efficiencyImprove thermal efficiencyGaseous fuel burnerInfraredCombustor

The invention discloses a burner and a gas stove having the same. The burner comprises an internal loop fire burner body having an internal loop mixing cavity and an internal loop cover plate covering the internal loop mixing cavity, a middle loop fire burner body surrounding the external side of the internal loop fire burner, and an external loop fire burner body, wherein the internal loop fire burner body is a full-premix burner; the internal loop cover plate is an infrared ray radiation plate with primary air coefficient no less than 1; and the external loop fire burner body surrounds the external side of the middle loop fire burner. The burner possesses high heat efficiency, strong fire power and low poisonous gas emission amount.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Energy-saving and high-efficiency lower air inlet gas burner and manufacturing method thereof

PendingCN111795384AUniform flameIncrease heat flowGrinding drivesCeramic shaping apparatusProcess engineeringMechanical engineering

The invention discloses an energy-saving and high-efficiency lower air inlet gas burner and a manufacturing method of the energy-saving and high-efficiency lower air inlet gas burner. The energy-saving and high-efficiency lower air inlet gas burner comprises an outer fire cover, an inner fire cover and a base, and further comprises an outer fire head part and a flame stabilizing fire ring. The outer fire head part and the flame stabilizing fire ring cooperate with each other to form a secondary air channel. The outer fire head part is provided with the inner fire head part. The secondary air channel faces the inner fire head part, so that the inner fire cover radially communicates with external air for air supplement. The method comprises the following steps of base processing, outer firecover and inner fire cover processing, flame stabilizing ring processing, outer fire head part processing and burner assembly. According to the energy-saving and high-efficiency lower air inlet gas burner and the manufacturing method of the energy-saving and high-efficiency lower air inlet gas burner, through the design of the secondary air channel, secondary air required for uniform pressure of the head portion of the burner and sufficient inner fire is ensured; an inner fire nozzle is convenient to replace by adopting a built-in vertical inner injection pipe; and the manufacturing method ofthe burner is simple, the processing efficiency and the processing quality of the burner are improved, disassembly and maintenance are convenient, and the manufacturing cost of a product is reduced.

Owner:浙江森歌智能厨电股份有限公司

Hot blast furnace device for blast furnace iron making

The invention discloses a hot blast furnace device for blast furnace iron making. The hot blast furnace device for blast furnace iron making comprises a furnace body. A fire grate is arranged at the bottom of the inner wall of the furnace body. A cold air pipe, a waste gas pipe and a hot air pipe are arranged on the side wall of the furnace body. A heat accumulation chamber is arranged in the middle of the furnace body. The top of the furnace body is connected with a vault through a connecting body. The heat accumulation chamber is internally filled with heat accumulation balls. The connectingbody comprises an annular wall. The inner wall of the annular wall is connected with a spraying burner through a connecting pipe. The outer wall of the annular wall is evenly provided with three-waypipes through gas ports. A plurality of nozzles are fixedly arranged on the side face of the spraying burner and the inner wall of the annular wall. A plurality of air deflectors are arranged on the inner walls of the three-way pipes. Gas is evenly scattered into the various nozzles through the three three-way pipes and the air deflectors, and the service life of the nozzles is longer. The spraying burner and the nozzles arranged on the annular wall are used for jointly spraying fire, the heat of the heat accumulation chamber is rapidly increased, and the heat accumulation time is saved. The nozzles downwards obliquely spray fire, the service life of the vault is longer, the heat accumulating balls are adopted in the heat accumulating chamber for heat accumulation, the heat accumulating efficiency is high, and hot air generation is faster.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

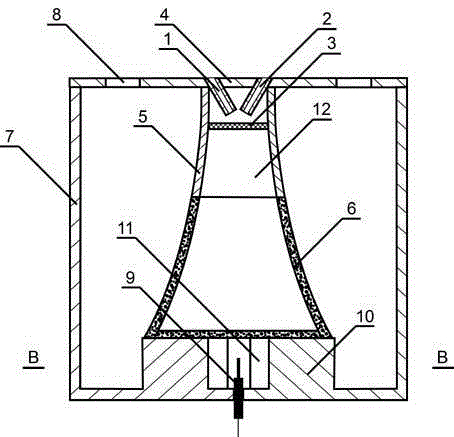

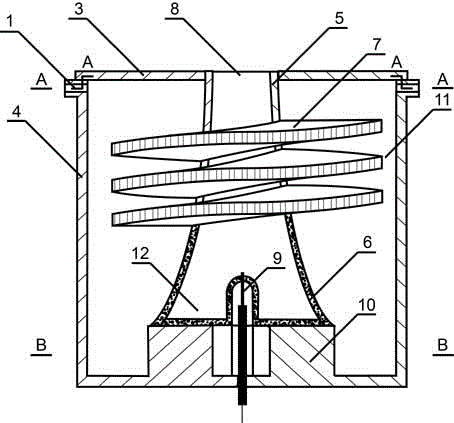

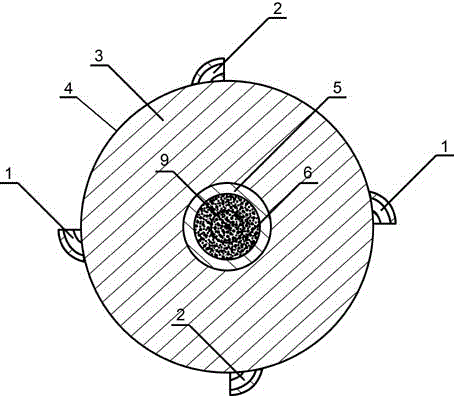

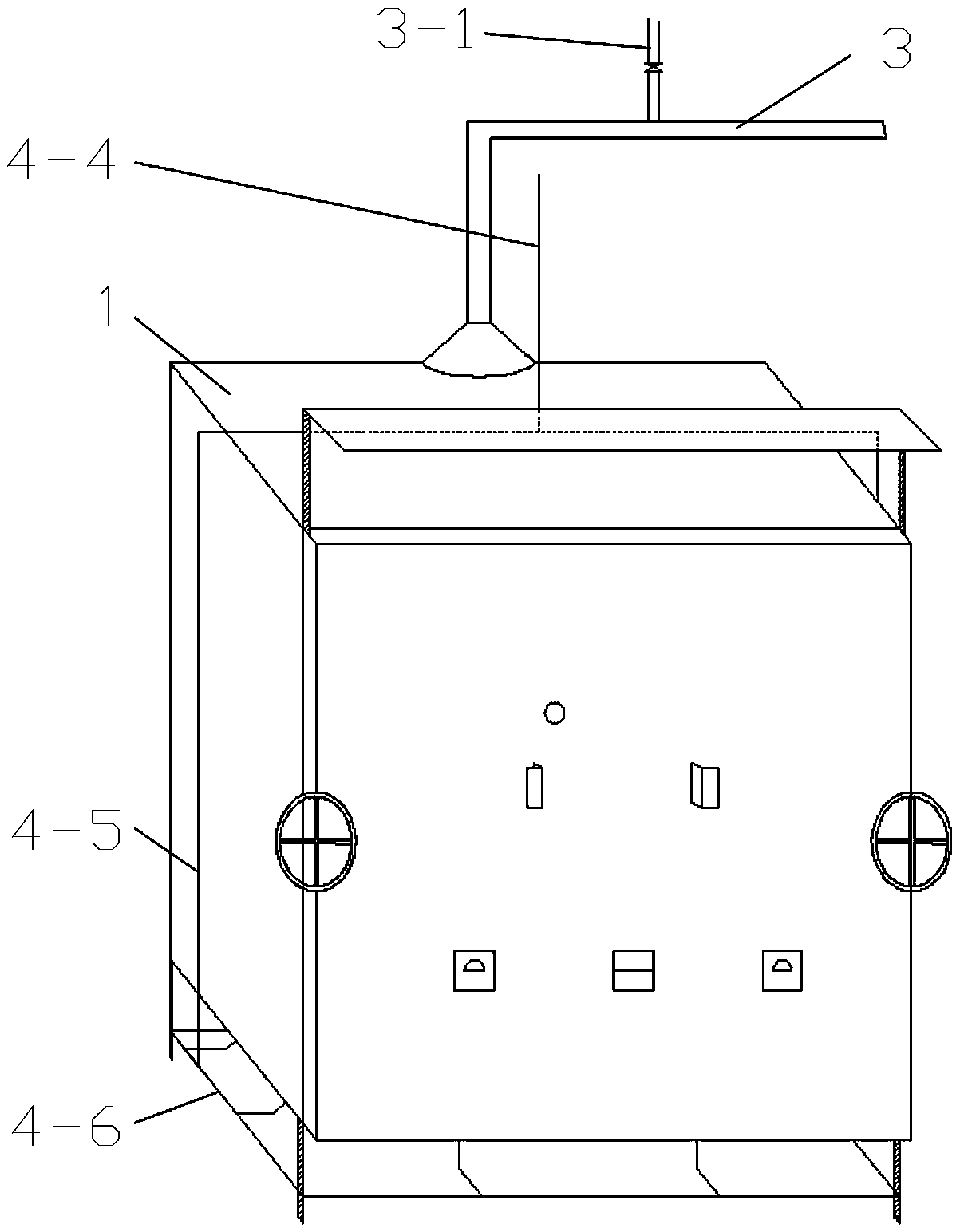

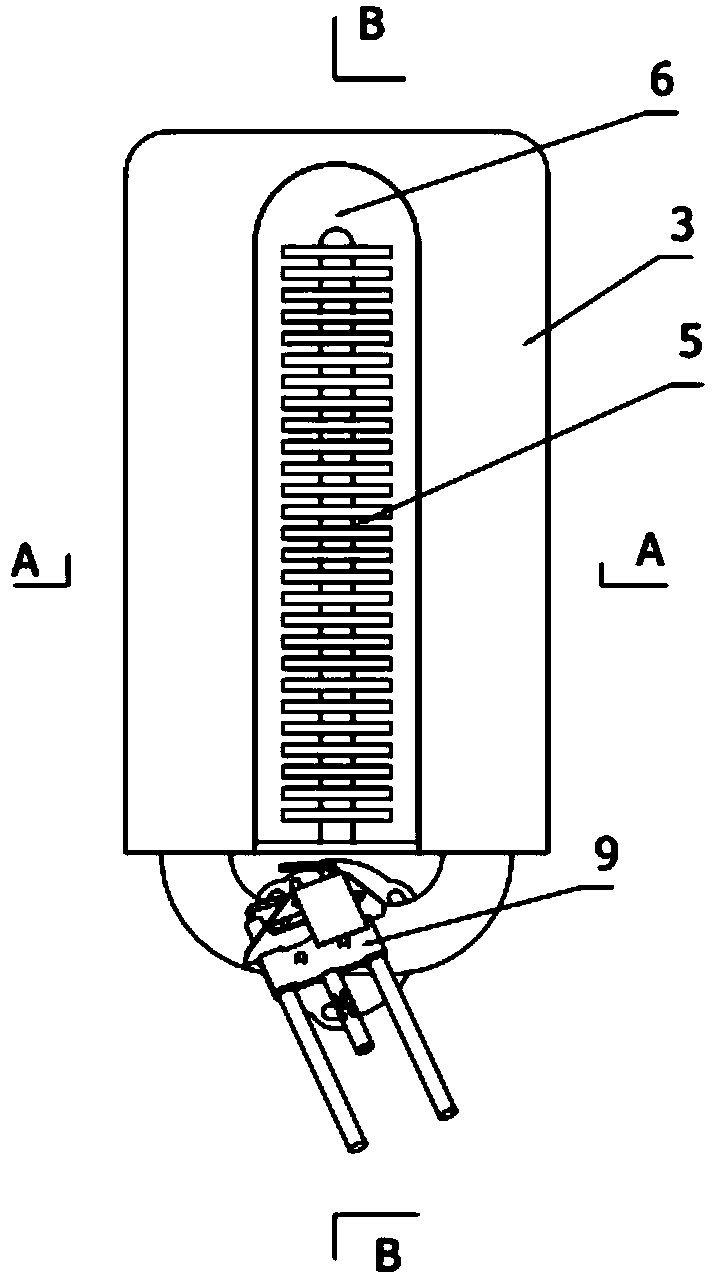

Miniature heat regeneration diffusion type uniform combustion device with combustion room shrunk gradually

InactiveCN105546583AExtend the motion pathImprove premix effectContinuous combustion chamberCombustion chamberEngineering

The invention provides a miniature heat regeneration diffusion type uniform combustion device with a combustion room shrunk gradually. The miniature heat regeneration diffusion type uniform combustion device comprises an ignition device, an outer sleeve, an inner sleeve and an upper panel. The inner sleeve is located in the outer sleeve. The combustion room is arranged in the inner sleeve. A preheating and premixing cavity is formed between the inner sleeve and the outer sleeve. The upper panel is arranged at the top end of the outer sleeve. A porous bottom plate is arranged at the lower end of the inner sleeve. The circumferential wall of the lower portion of the inner sleeve is a porous wall. An upper end opening of the inner sleeve serves as an exhaust opening. The combustion room communicates with the preheating and premixing cavity through the porous wall and the porous bottom plate. A plurality of air inlets and gas inlets are evenly distributed in the top end of the side wall of the outer sleeve in the circumferential direction. The combustion room of the miniature heat regeneration diffusion type uniform combustion device is in a reversely-buckled cylindrical inwards-concave horn shape so that fuel in the combustion room can be diffused, and inner combustion and temperature field distribution can be more uniform. According to the miniature heat regeneration diffusion type uniform combustion device, smoke waste heat is utilized, meanwhile, a porous material is adopted for multi-face air feeding, combustion is strengthened, a temperature field is more uniform, and therefore the power of the device is improved.

Owner:CHONGQING UNIV

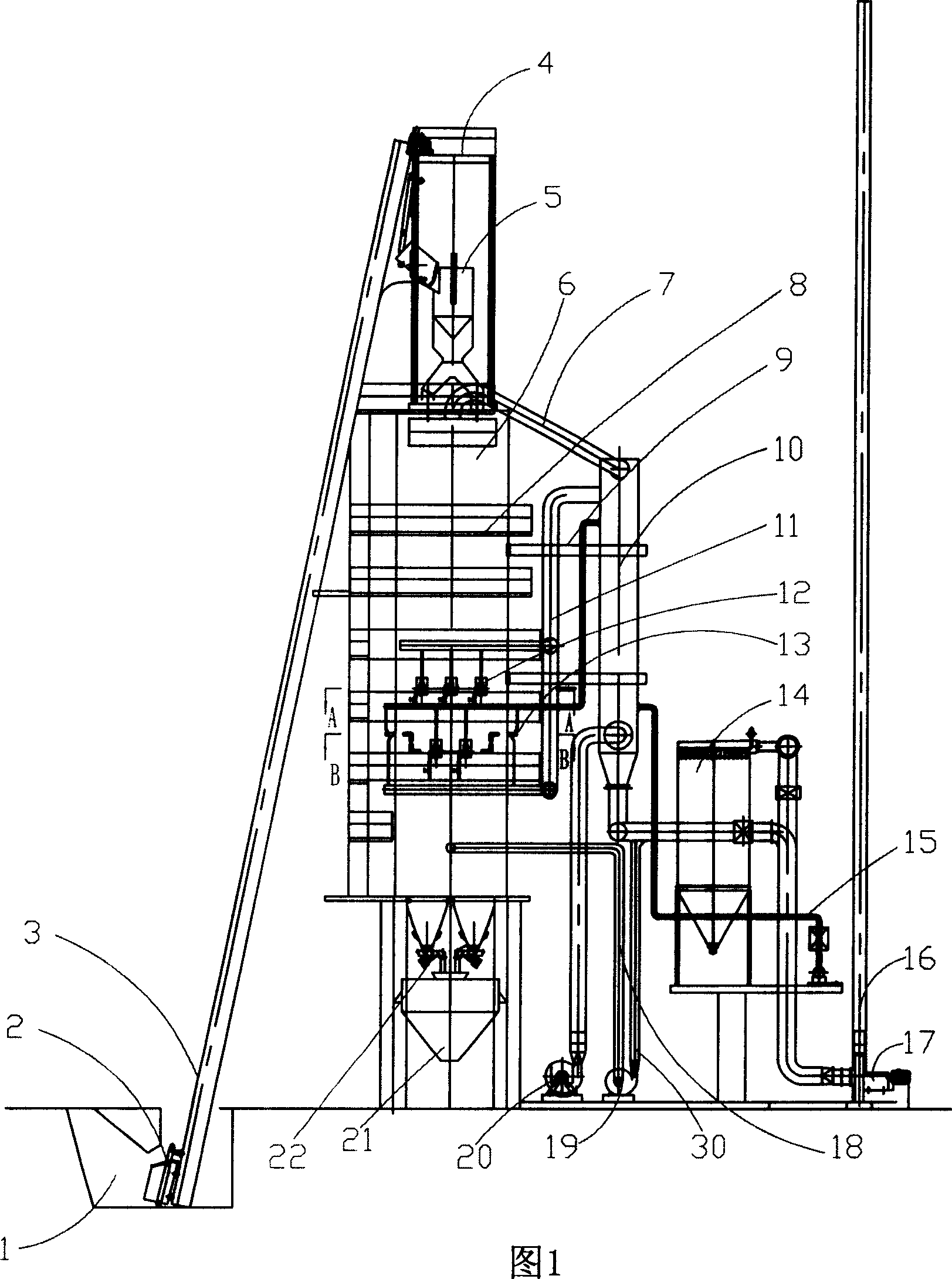

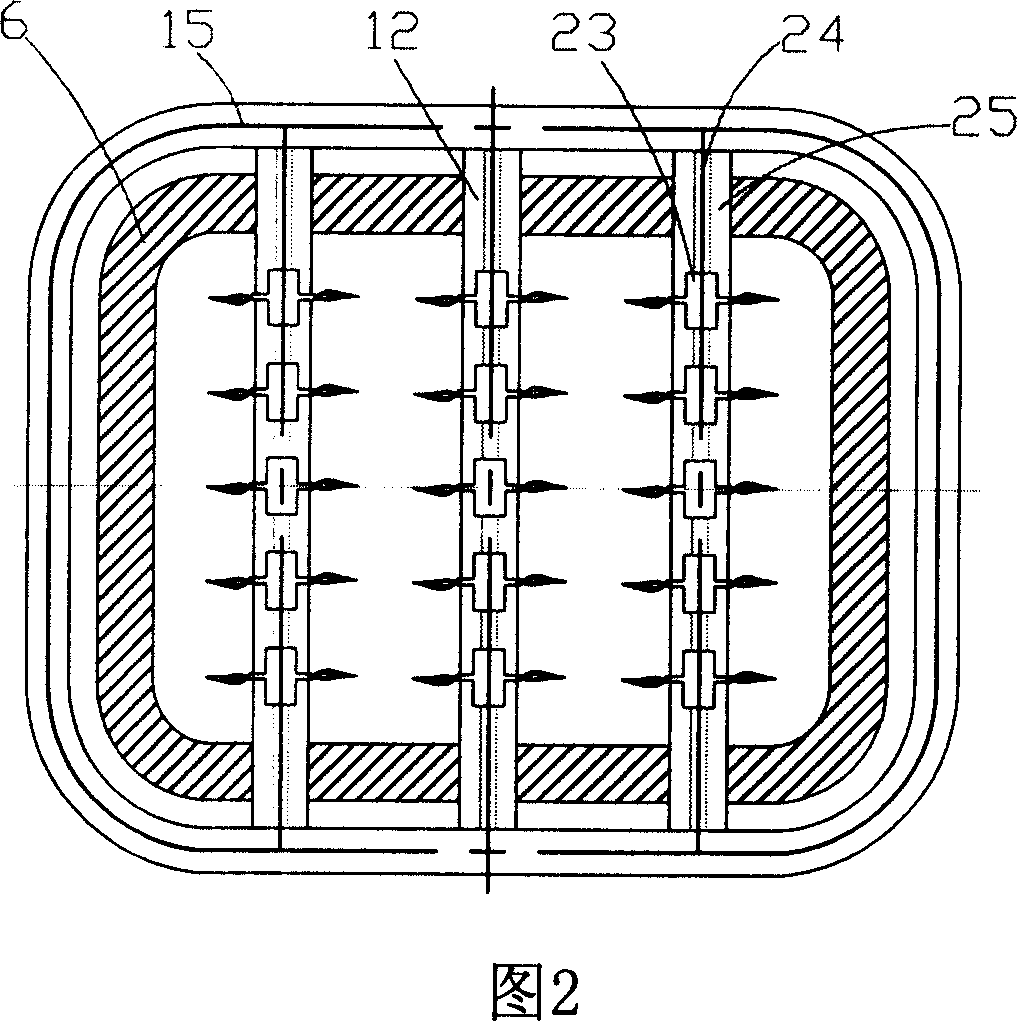

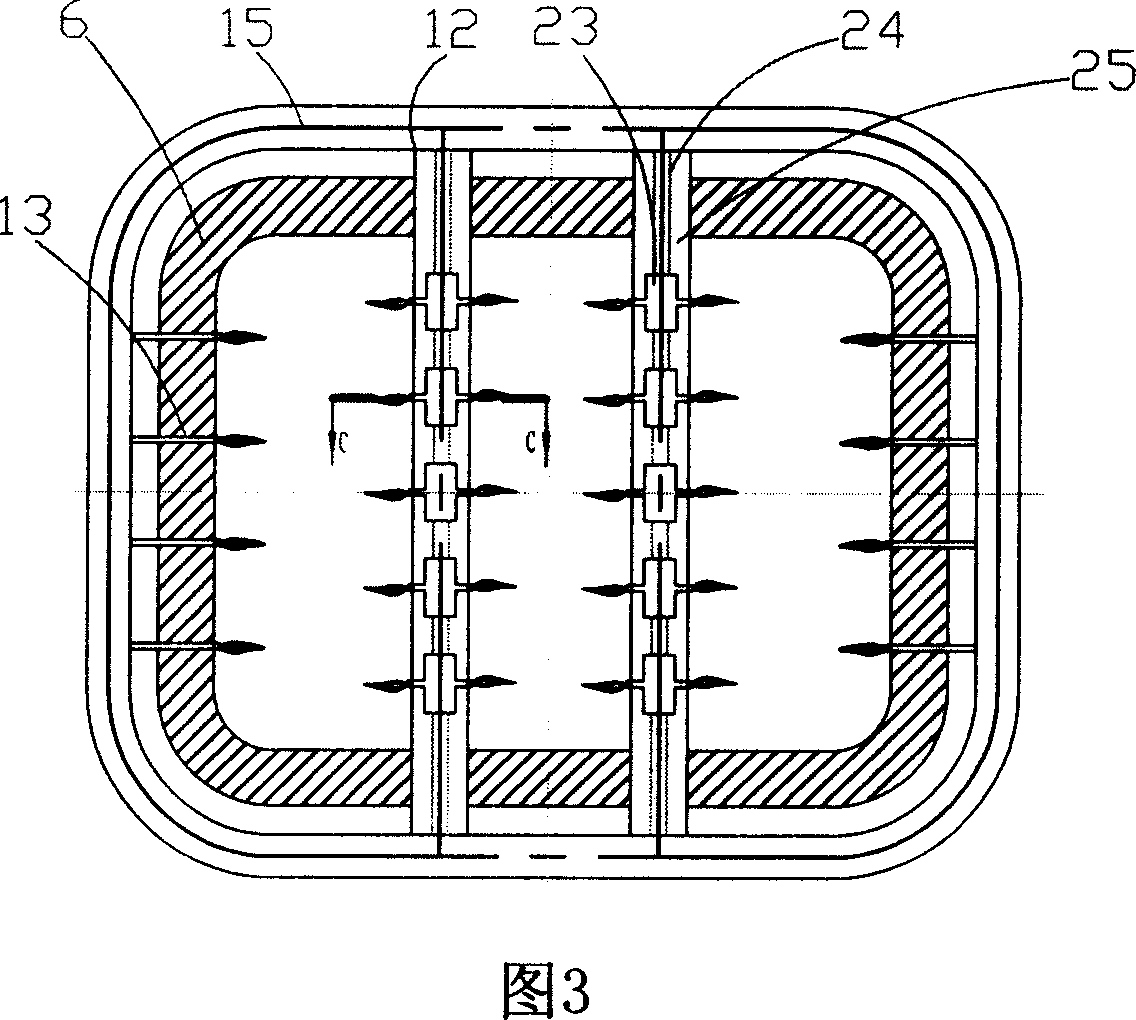

Gas heating type industrial vertical kiln with central burner

An industrial vertical kiln with central burning device in fuel-gas heating mode consists of kiln body, material supplying unit, fuel conveying unit, material output unit, smoke exhausting unit, burning unit and control unit. It is featured as preheating fuel gas and combustion-supporting air by heat exchanger, making casthouse pressure of mixed fuel gas and combustion supporting air be about 10Kpa with temperature being greater than 150deg.c under action of combustion-supporting air fan and then burning preheated- mixed fuel gas and combustion-supporting air in integrated burners.

Owner:贾会平

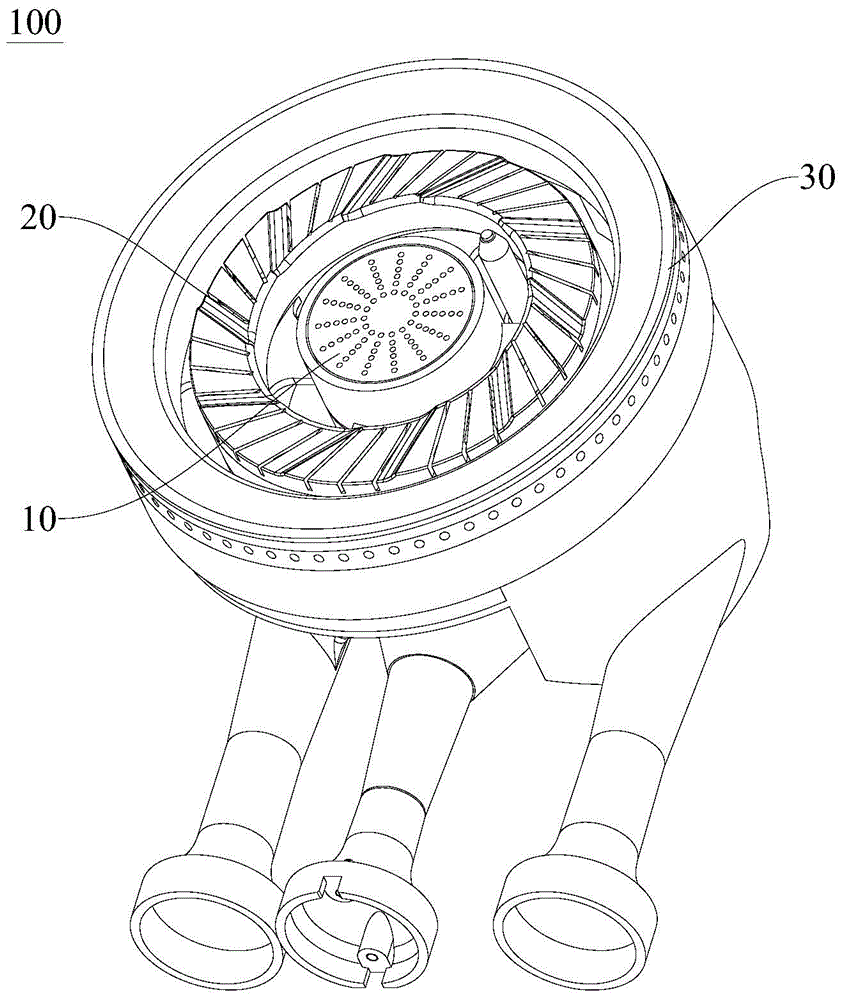

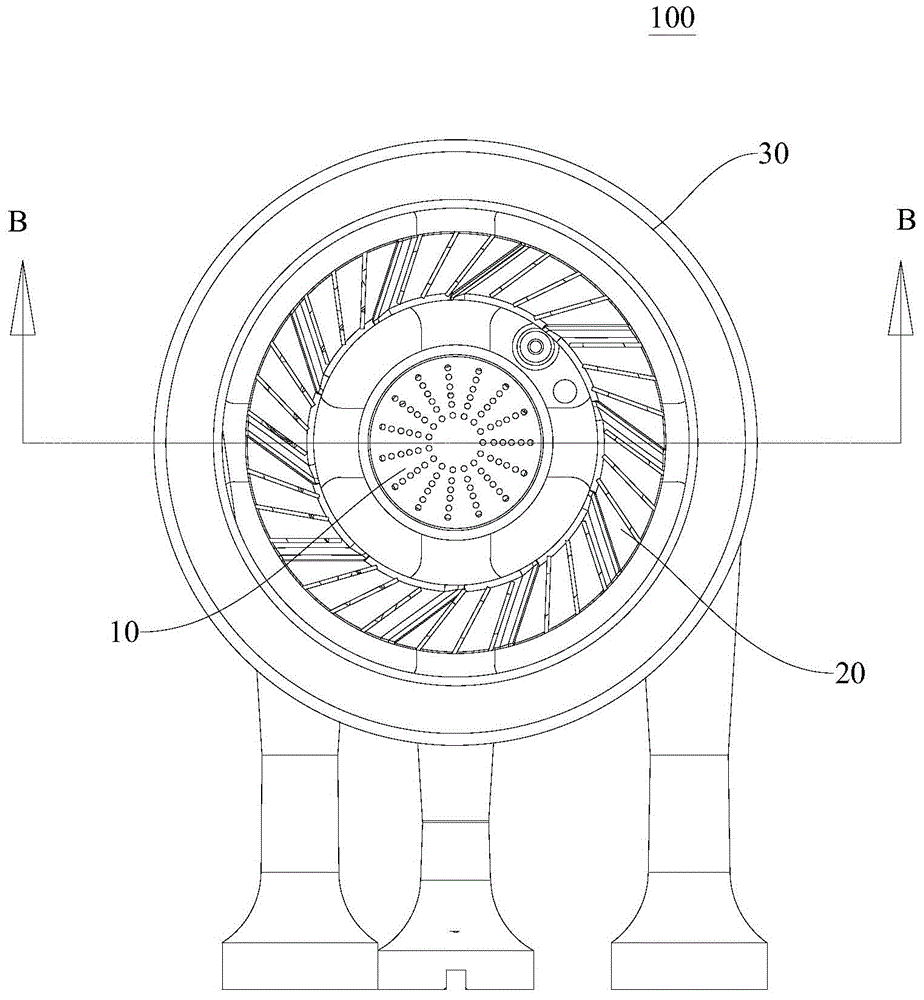

Dust fuel burners and entrained bed gasifiers for synthesis gas production

ActiveCN104713081BConstant flow rateEasy maintenanceBurner coolingPulverulent fuel combustion burnersCombustorEngineering

The invention relates to a pulverized fuel burner and an entrained flow gasifier with several such burners for the production of synthesis gas, the burner connecting pieces are arranged for the supply of fuel dust and coolant on an outer double-walled sleeve, the one a central tube in radial distance concentrically surrounding and to the central channel an annular channel for the promotion of the combustion dust forming the burner mouth, the burner has 1 connection port for an oxidizer, and for cooling water at double central tube for the promotion of the oxidizing agent to the burner mouth. The invention provides a pulverized fuel burner for the production of synthesis gas with a higher wear resistance, low tendency to clog and optimal mixing of pulverized fuel and oxidant to be created, which is suitable for use in an entrained flow gasifier. According to the invention of the pulverized fuel supply to the burner mouth underneath an opens tangentially inlet opening for the pulverized fuel in the annular channel a distributor with several annular sections circumferentially distributed funnel-like depressions with outlet available, each outlet opening in an axially parallel straight pulverized fuel channel with approximately rectangular cross-section within the annular channel opens, wherein the cross-sectional area of the pulverized fuel channels together corresponds to the cross-sectional area of the inlet opening for the pulverized fuel, said pulverized fuel channels open into a spiral plenum front of the burner mouth defined by an upper coil, which the spaces of the annular channel between the outlet openings of the pulverized fuel channels closes, a parallel to bottom coil to swirl generation in the pulverized fuel flow and a two helices interconnecting web is limited.

Owner:CHOREN INDTECHN

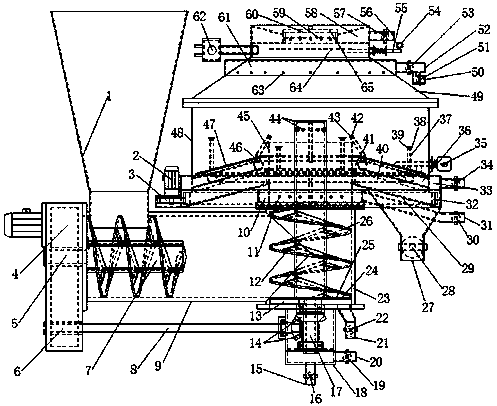

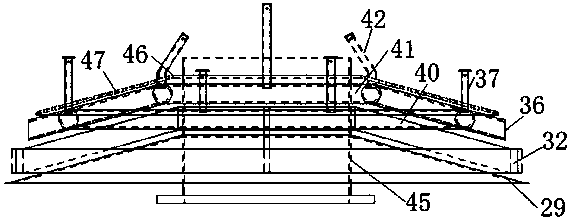

A Biomass Combustion Furnace with Steady Feed Wind and Less Sparks

ActiveCN105423350BSpread out steadilyStable burning planeDomestic stoves or rangesLighting and heating apparatusCombustionEmission channeling

The invention discloses a biomass combustion furnace with stable material air and few sparks. The biomass combustion furnace comprises a horizontal feeding device, a vertical feeding device, a hearth feeding pipe, an ash discharge device, a hearth, an upper hearth and various air ducts, wherein a hearth bottom of the hearth, an ash discharge gear of the ash discharge device, annular air duct air manifolds of the annular air ducts, and a vibrating screen are integrally in a circular table shaped annular shape, and the hearth bottom, the ash discharge gear and the annular air duct air manifolds and the vibrating screen are arranged from the bottom up sequentially. According to the biomass combustion furnace, the hearth bottom, the ash discharge gear, the annular air duct air manifolds and the vibrating screen that are integrally in a circular table shaped annular structure are assembled together, and a conical surface is formed at the hearth bottom, so that fuel can be dispersed towards the periphery easily and stably, and straight air pipes and bent air pipes can allow the air to be distributed in the same horizontal plane in the hearth more uniformly; and chip discharge grooves are uniformly formed in vane blade of a vertical screw, so that the sparks generated by combustion of chip-shaped objects are reduced, flue gas pressure of a flue gas emission channel is balanced, and the trends of the flames in the hearth are uniform.

Owner:FUZHOU SUNSHI XIONGDI IND

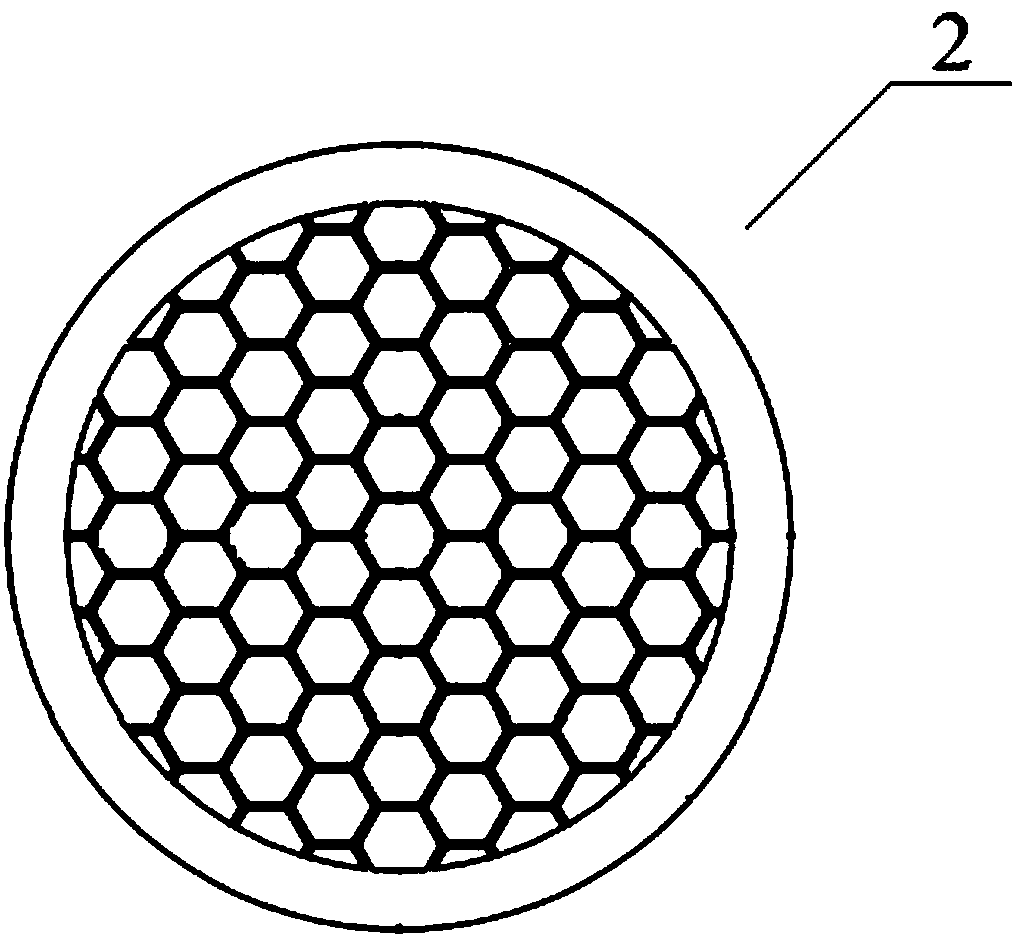

Gas energy saving burner

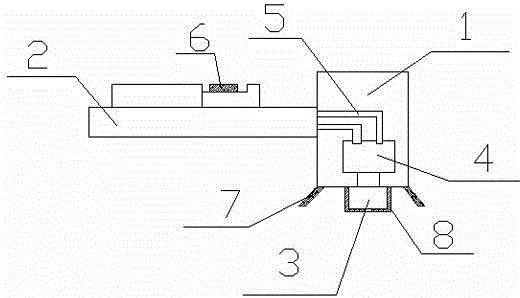

ActiveCN105674268BGood energy saving and environmental protection effectStrong wind resistanceDomestic stoves or rangesGaseous fuel burnerInlet channelCombustor

The invention belongs to the field of combustible gas burning stoves, and in particular relates to a gas energy-saving burner, which includes an outer stove (1) and an inner stove (2); an assembly channel opening (4) is provided at the bottom of the inner stove (2); A gas fire ring (5) is provided in the middle of the inner stove (2); a small gas supply pipe (7) is provided in the gas air inlet passage (6) and the blower pipe inlet (3); a small gas supply pipe (7) A dustproof cap (8) is provided at the end of the stove; a main gas inlet pipe (10) is arranged horizontally between the outer stove (1) and the inner stove (2); the gas supply port of the main gas inlet pipe (10) is connected with the gas inlet The annular gas distribution cavity (11) between the channel (6) and the assembly channel port (4) communicates; the outer wall of the annular gas distribution cavity (11) is provided with a main gas outlet (12). The invention has obvious energy saving and environmental protection effects, excellent wind resistance performance, high safety factor, waterproof, uniform flame, deflagration proof and wide application range.

Owner:鞍山科创燃气节能厨房电子设备有限公司

A Micro Dispersed Combustion Device for Micro-thermo-photovoltaic System

InactiveCN105402725BReduce volumeImprove premix effectBurner material specificationsIndirect carbon-dioxide mitigationCombustion chamberEngineering

The invention provides a micro diffuse type combustion apparatus for a micro-thermphotoelectric system. The micro diffuse type combustion apparatus for the micro-thermphotoelectric system comprises an ignition device, an external sleeve, an internal sleeve and an upper panel, wherein the internal sleeve is positioned in the external sleeve; the upper panel is arranged at the top end of the external sleeve; the internal sleeve is a flared structure with big lower end; the lower end of the internal sleeve is provided with a porous bottom plate; the circumferential wall of the lower part of the internal sleeve; the interior of the internal sleeve is a preheating premixing chamber; a combustion chamber is formed between the internal sleeve and the external sleeve; the preheating premixing chamber is communicated with the combustion chamber through a porous wall and the porous bottom plate; and a gas exhaust opening, an air inlet and a fuel gas inlet are formed in the upper panel. According to the invention, as air enters the porous material from various surfaces, a temperature field is uniform and the combustion is enhanced to increase the device power; through the adoption of special combustion chamber wall surface design, heat obtained by the whole wall surface is much and uniform; the micro diffuse type combustion apparatus can stably respond to fine air inlet pulsation and combustion pulsation; and meanwhile, through the adoption of the porous material with reducing aperture, tempering and backflow problems of the porous material are also avoided.

Owner:CHONGQING UNIV

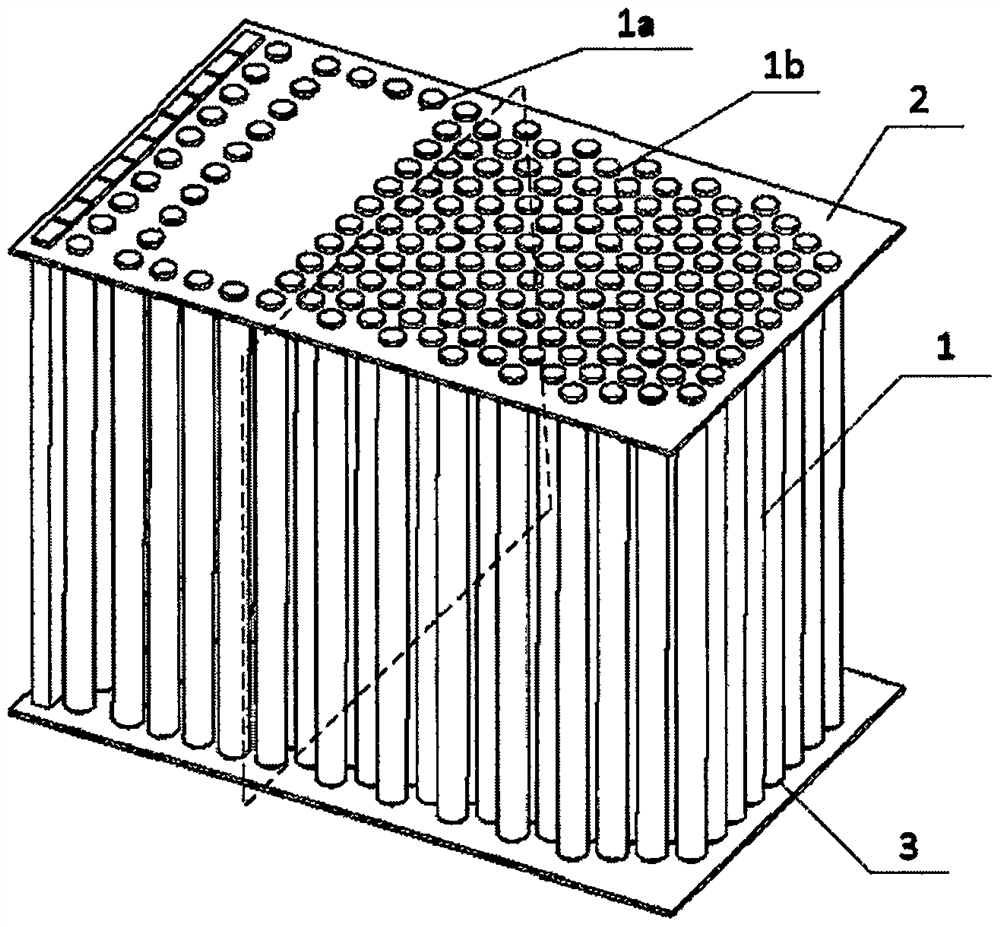

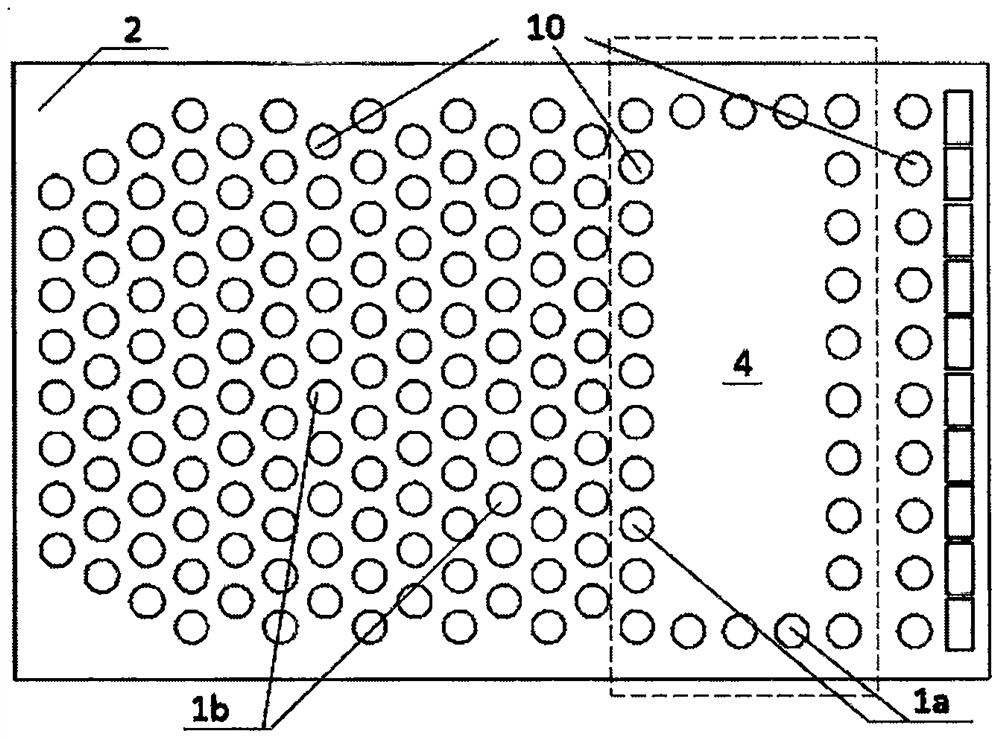

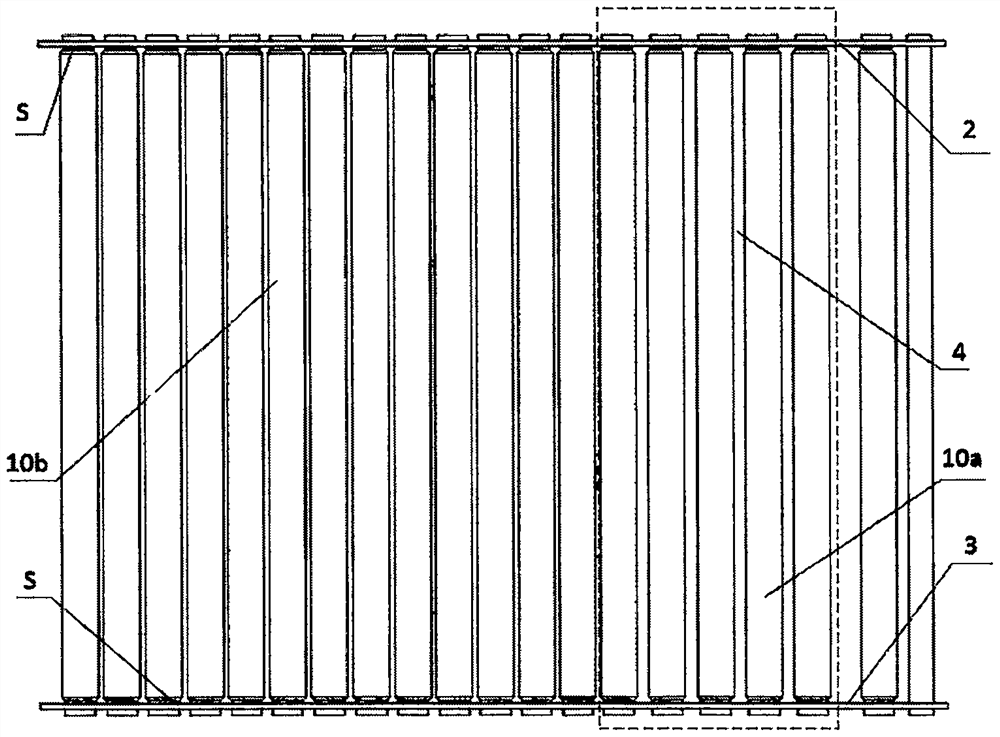

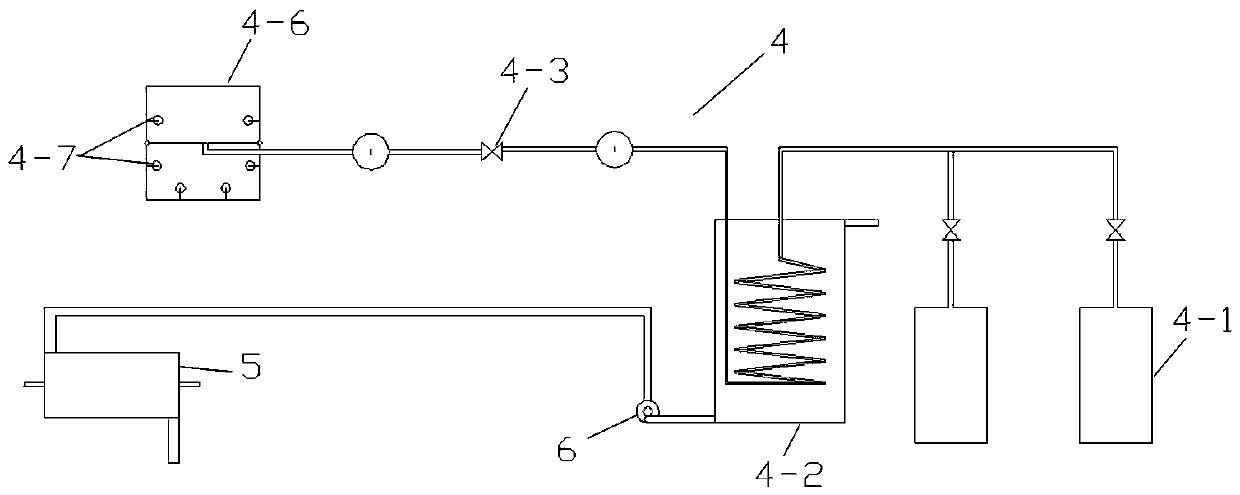

Water-cooling gas furnace core and vacuum hot water boiler comprising same

PendingCN114484435AFully stable combustionUniform flameCombustion technology mitigationWater heatersThermodynamicsFlue gas

The embodiment of the invention provides a water-cooling gas furnace core and a vacuum gas-fired hot water boiler comprising the same. The water-cooling gas furnace core comprises a first clamping flange, a heat exchange tube cluster and a second clamping flange, the heat exchange tube cluster is arranged between the first clamping flange and the second clamping flange to jointly form a wall face restraining smoke circulation, the heat exchange tube cluster at least comprises a first heat exchange tube cluster and a radiation heat dissipation tube cluster, and the first heat exchange tube cluster and the radiation heat dissipation tube cluster are arranged on the wall face. And a heat exchange medium is packaged in the heat exchange tube cluster. According to the embodiment, the average heat exchange coefficient can be increased, deep cooling of high-temperature flue gas is achieved, ultralow NOx emission is guaranteed, and meanwhile the heat utilization efficiency is greatly improved.

Owner:三木舜锅炉(江苏)有限公司

Discharge plasma assisted combustion energy-saving and environment-friendly oven

ActiveCN107928442AAvoid pollutionGreat tasteClimate change adaptationRoasters/grillsCo2 absorptionPollutant emissions

The invention discloses a discharge plasma assisted combustion energy-saving and environment-friendly oven which includes an insulating casing and a charcoal chamber. A baffle and a bracket are arranged on the lower portion of the charcoal chamber. The top of the charcoal chamber is provided with a tungsten net and a barbecue grill. High-voltage electrodes are arranged on both sides of an insulating shell in the charcoal chamber, and a sliding groove is formed between a lifting control device and the insulating shell. The high-voltage electrodes inside the charcoal chamber are connected with aregulating device through a high voltage wire. A carbon dioxide absorption and extinguishing device is connected with a gas inlet and outlet hole. The voltage is regulated to control charcoal flames,charcoal can also fully burn in oxygen-depleted areas, and carbon dioxide is absorbed. Electric energy is fully utilized, a fire is uniform, smoke-free barbecue is achieved, the discharge plasma assisted combustion energy-saving and environment-friendly oven enables foods to be rich in active materials and better in taste; the pollutant emission is less, and the oven is safe and reliable.

Owner:ANHUI UNIV OF SCI & TECH

A flameless graded oxygen-enriched low NOx combustion method and system

ActiveCN111006206BImprove heat utilization efficiencyNormal ignitionIndirect carbon-dioxide mitigationGrain treatmentsEngineeringMechanical engineering

The invention belongs to the field of pulverized coal combustion and emission performance control, and specifically discloses a flameless graded oxygen-enriched and low NOx combustion method and system. The method is as follows: the flue gas participating in the circulation is divided into three paths, and the fuel of a preset quality carried by the primary air duct, the secondary air duct and the tertiary air duct are passed into the furnace for combustion. The air outlet of the secondary air duct is located in the main combustion area, and the air outlet of the tertiary air duct is located in the re-combustion area. The injection amount and mass flow of oxygen in each secondary air are controlled to control the range and the oxygen peroxide coefficient of the main combustion area and the re-burning area. Flow characteristics to realize fuel staged oxyfuel combustion mode, fuel-oxygen two-way staged oxyfuel combustion mode and flameless oxyfuel combustion mode. The system includes a boiler, a flue gas pretreatment module, a chimney, a primary air duct, a secondary air duct and a tertiary air duct. The invention can achieve stable and efficient low NO x emission, and can improve the ignition characteristics of coal powder, and promote the reburning of coal powder.

Owner:HUAZHONG UNIV OF SCI & TECH

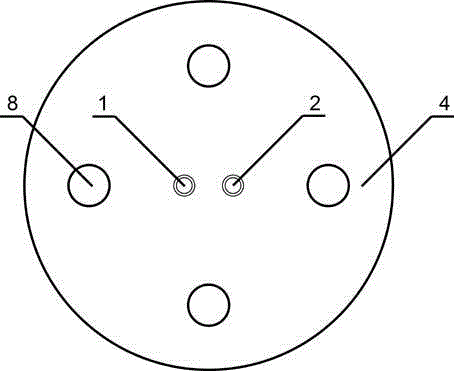

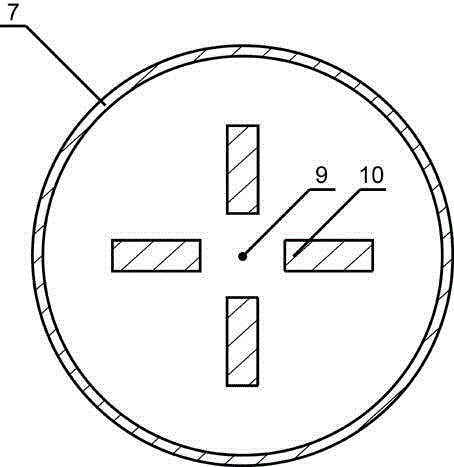

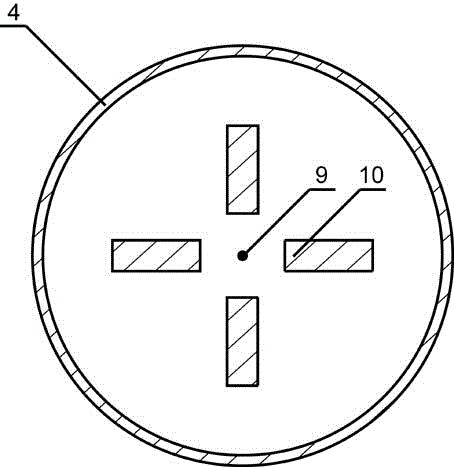

Electromagnetic plasma rotary processing device

InactiveCN104619107AAvoid damageFew partsSupports/enclosures/casingsPlasma techniqueSpray nozzleEngineering

The invention discloses an electromagnetic plasma rotary processing device. The electromagnetic plasma rotary processing device comprises a motor, an electrode, a plasma gun head and an inner core; the output shaft of the motor is a hollow shaft, and the shell of the motor is a shell with openings in the front and back; the rear opening of the motor is provided with a flange, and the inner core is fixed at the flange and located in the hollow shaft; an air pipe is connected into the inner core; a power cord is connected with the electrode through the inner core; the plasma gun head is located at the front opening of the shell and connected with the hollow shaft, and moreover, the plasma gun head covers the electrode, and the nozzle position of the plasma gun head is provided with a flame hole and three counterweight holes. The electromagnetic plasma rotary processing device directly uses the hollow shaft to drive the plasma gun head to rotate, the damage due to transmission can be reduced, and moreover, the structure is simple, the spare part is less, and the cost is low; by means of the nozzle, the blown flame is uniform, large in range, high in intensity and more obvious in processing effect; the possible product surface scratch due to the pointed end of an old nozzle can be avoided.

Owner:广东韦达尔传媒有限公司

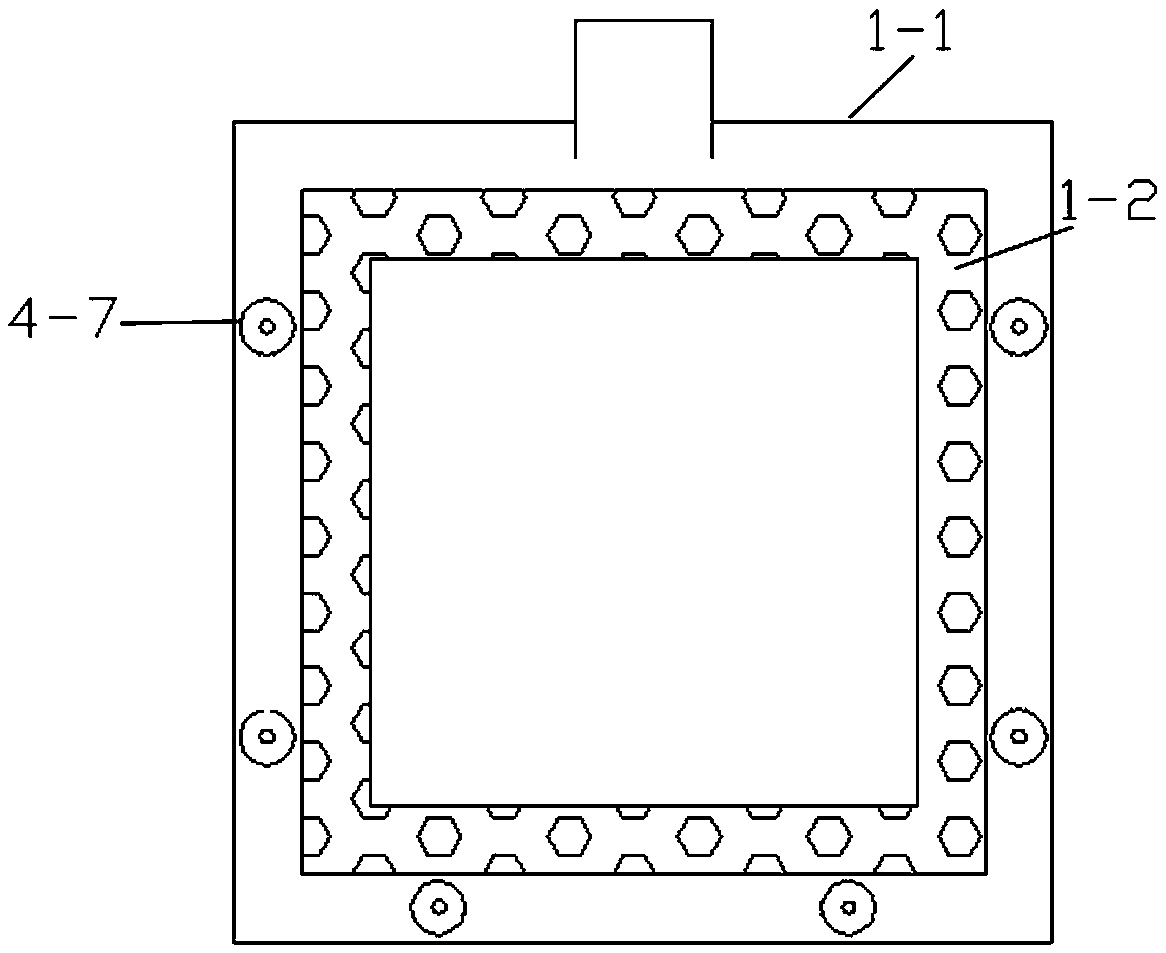

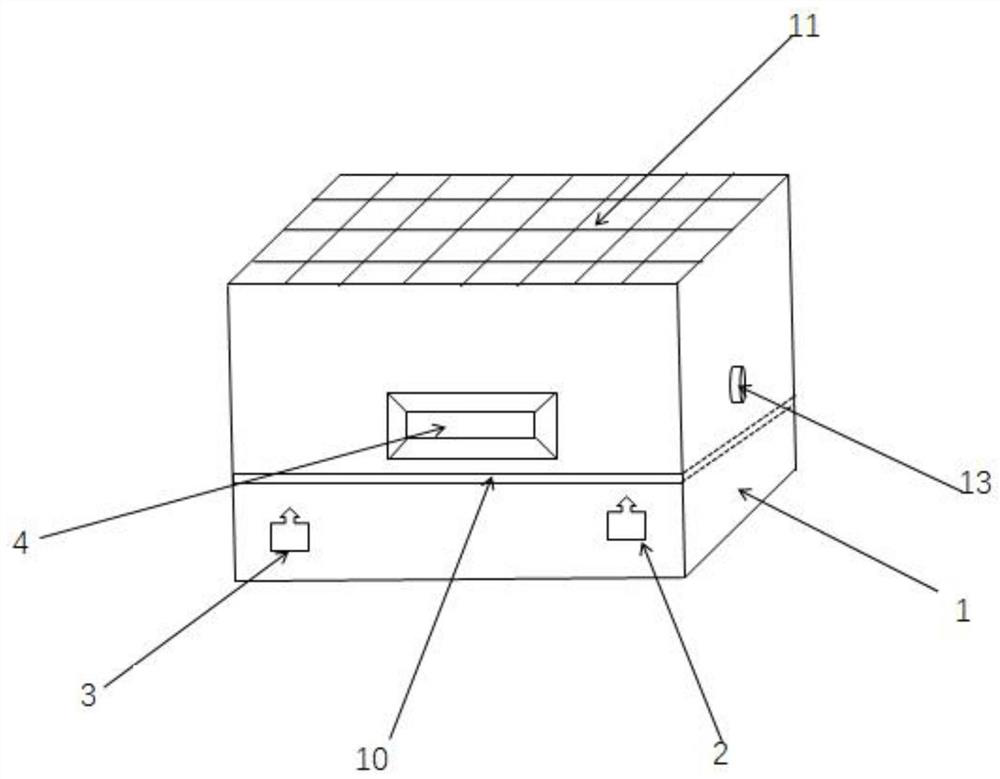

Multi-spark-plug fuel gas jun porcelain kiln

PendingCN111059901AAdd artistryImprove yieldCharge composition/stateCharge treatment typeFire brickReducing atmosphere

The invention discloses a multi-spark-plug fuel gas jun porcelain kiln which comprises a kiln body, wherein the kiln body comprises an outer kiln body and an inner kiln body; each of the outer kiln body and the inner kiln body is of a cuboid structure; the inner kiln body is a hollow structure built from refractory bricks; an interlayer space for mounting a spark plug component is formed between the inner kiln body and the outer kiln body; the spark plug components are arranged on the obverse side and the two sides of the inner kiln body; a smoke discharging pipeline stretches out of the backside face of the interlayer space from inside to outside and communicates with an external chimney; the chimney is mounted above the smoke discharging pipeline in a sleeving manner; an inverted funnelshaped structure is arranged at the lower part connecting end of the chimney; and the spark plug components are connected with a fuel air inlet system. Through improving the structure of the multi-spark-plug fuel gas jun porcelain kiln, arrangement of the spark plug is more reasonable; and in addition, the chimney structure is improved, so that the multi-spark-plug fuel gas jun porcelain kiln isfilled with flames to form a reducing atmosphere with negative pressure, and the yield and the appearance artistry of ceramics fired by the multi-spark-plug fuel gas jun porcelain kiln can be improved.

Owner:张晓兵

Burner and gas stove provided with burners

InactiveCN104964280AHigh thermal efficiencyUniform firepowerGaseous fuel burnerEngineeringGas stoves

The invention discloses a burner and a gas stove provided with the burners. The burner comprises an inner-ring fire burner body, a middle-ring fire burner body and an outer-ring fire burner body; the middle-ring fire burner body surrounds the outer side of the inner-ring fire burner body, the outer-ring fire burner body surrounds the outer side of the middle-ring fire burner body and comprises an outer-ring mixing cavity and an outer-ring cover plate arranged on the outer-ring mixing cavity in a covering mode, the outer-ring fire burner body is a full premixing burner, the outer-ring cover plate is an infrared radiation plate, and a primary air coefficient a is larger than and equal to 1. According to the burner, the heating efficiency is high, the fire power is even, and the emission quantity of noxious gases is low.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

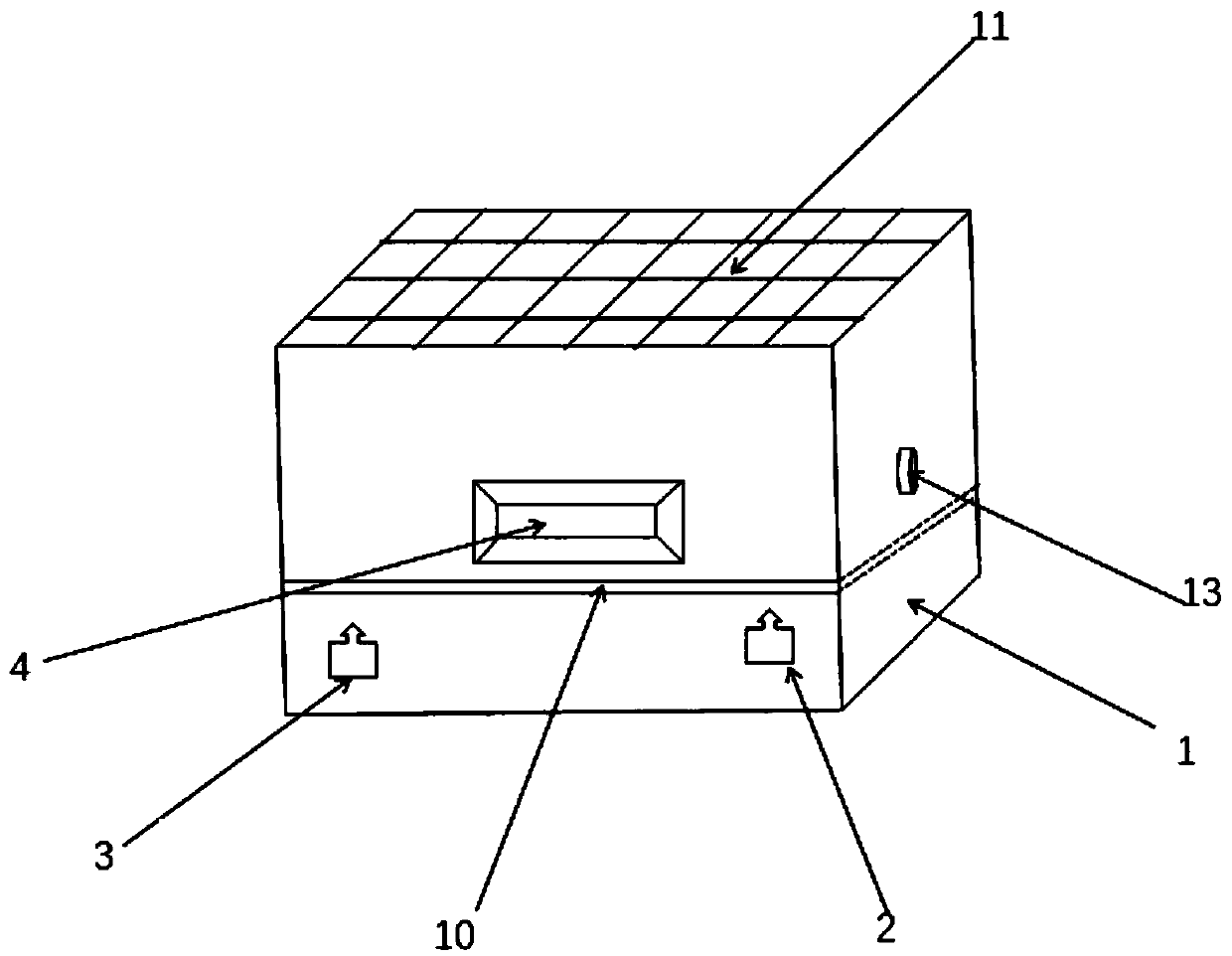

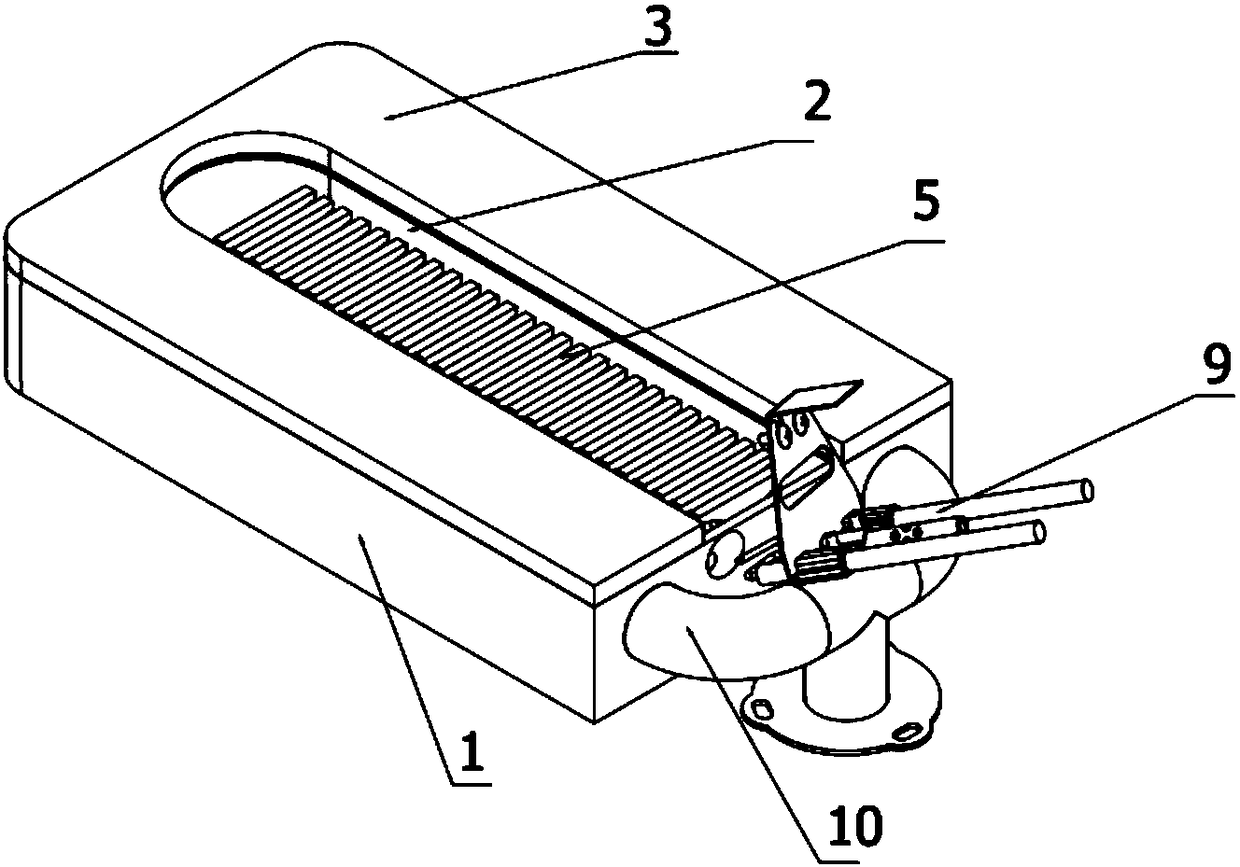

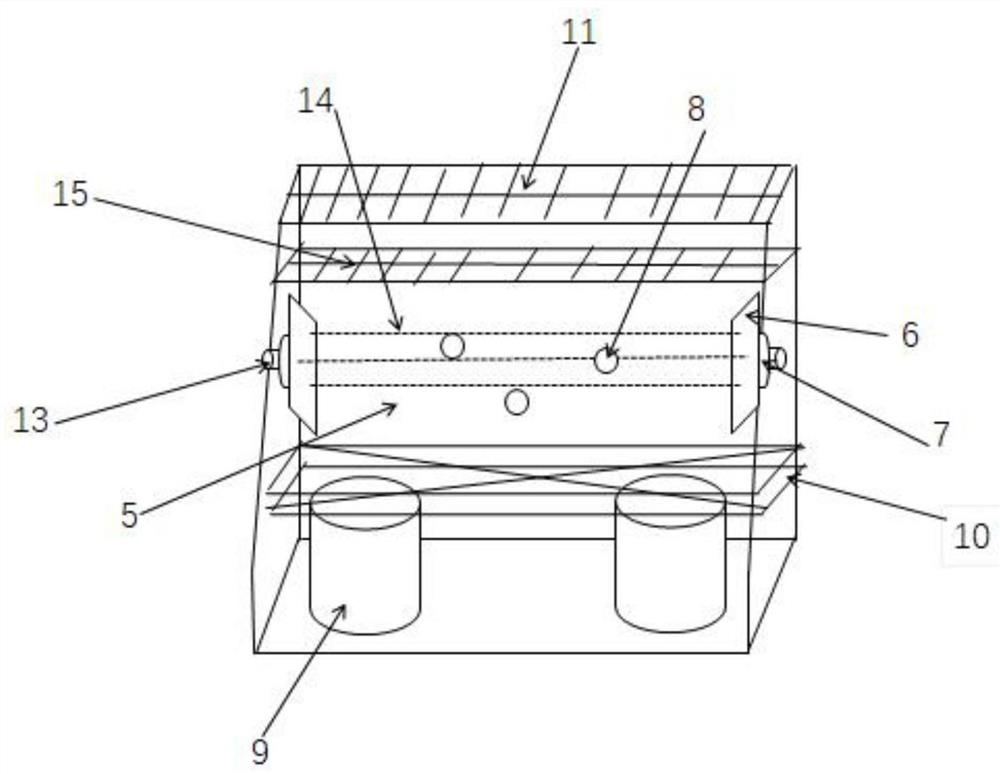

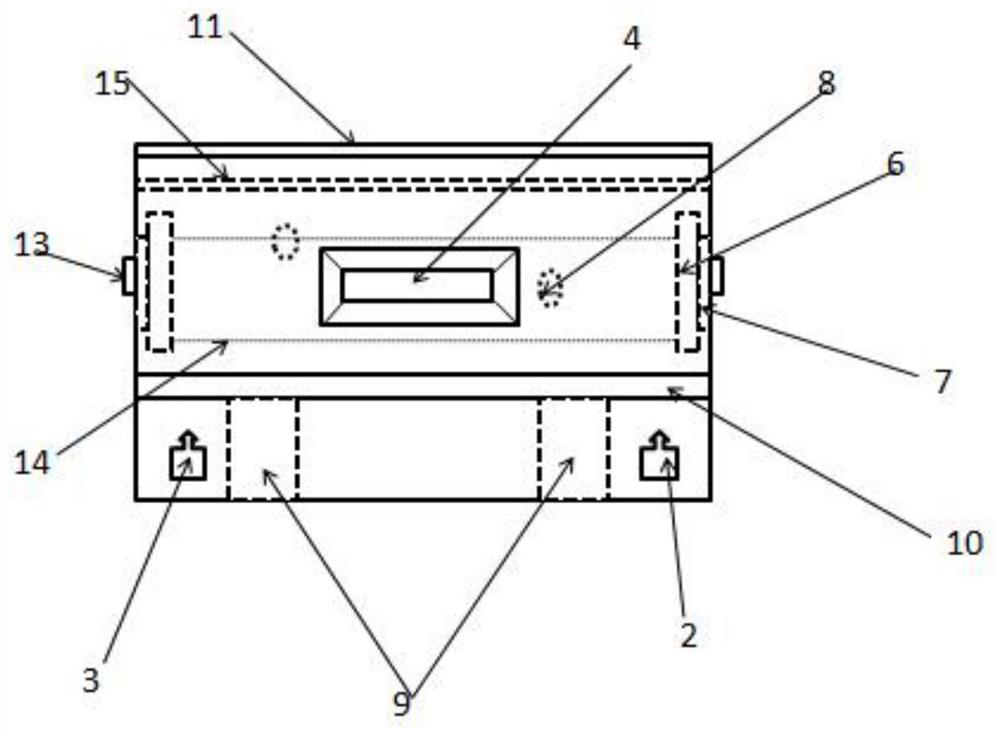

Gas burner and gas steam generator thereof

InactiveCN108375069AEasy to replacePlay a role in gathering energyBurner safety arrangementsSteam generation heating methodsCombustion chamberButt joint

The invention relates to the technical field of gas devices, in particular to a gas burner. The gas burner comprises a rectangular chamber, a gas mesh enclosure, a U-shaped cover plate and a combustion chamber base, wherein the top of the rectangular chamber is open, the bottom of the rectangular chamber is provided with a mounting recess, the combustion chamber base is inserted in the mounting recess, the gas mesh enclosure is of a U-shaped trough structure, the front end of which is open, the bottom edge of the gas mesh enclosure is inserted between a bottom flat surface and the mounting recess, heat-uniforming rib plates are also evenly distributed in parallel on a top flat surface of the combustion chamber base, and the cover plate is mounted on the top of the rectangular chamber. Theinvention further discloses a gas steam generator, which comprises a stove body and heat exchange smoke tubes, wherein the heat exchange smoke tubes are symmetrically arranged on the left and the right in the stove body, the middle of the lower part of the stove body is provided with a long chamber type combustion chamber along a front-rear direction, and the gas steam generator further comprisesthe gas burner in butt joint to the lower part of the combustion chamber. The gas burner has the beneficial effects as follows: the heat gathering performance of the gas mesh enclosure is sufficientlyutilized, burning is stable, flame is stable, and the thermal efficiency is high.

Owner:赵乐

A heating furnace based on honeycomb ceramic regenerator

ActiveCN105823090BLarge heat capacityBurn fullyLighting and heating apparatusStove/ranges for heating waterCombustion chamberHeating furnace

The invention belongs to the technical field of heating stoves and relates to a heating stove based on honeycomb ceramic heat accumulators. The heating stove based on the honeycomb ceramic heat accumulators comprises a stove body. A stove chamber is formed in the stove body. A flame outlet is formed in the upper end of the stove chamber. A protective sleeve is arranged in the flame outlet in an embedded mode. The first honeycomb ceramic heat accumulator and the second honeycomb ceramic heat accumulator are arranged in the protective sleeve in an embedded mode. The first honeycomb ceramic heat accumulator is located above the second honeycomb ceramic heat accumulator. The first honeycomb ceramic heat accumulator and the second honeycomb ceramic heat accumulator are separated through a supporting body, and a secondary combustion chamber is formed. The first honeycomb ceramic heat accumulator and the second honeycomb ceramic heat accumulator are each provided with a plurality of through holes formed in the vertical direction. The cross section area of each through hole of the first honeycomb ceramic heat accumulator is smaller than that of each through hole of the second honeycomb ceramic heat accumulator. Fire bars used for supporting fuel are arranged at the bottom of the stove chamber. The lower end of the protective sleeve is suspended above the fuel. A fuel feeding and first air distribution port, a second air distribution port and a third air distribution port are formed in the stove body. By the adoption of the heating stove based on the honeycomb ceramic heat accumulators, the fuel utilization rate is increased, the pollutant discharge amount is decreased, energy is saved, and environmental friendliness is achieved.

Owner:SHIJIAZHUANG JINTONG MACHINERY CO LTD

A discharge plasma assisted combustion energy-saving and environment-friendly oven

ActiveCN107928442BAvoid pollutionGreat tasteClimate change adaptationRoasters/grillsCo2 absorptionPollutant emissions

The present invention is an energy-saving and environment-friendly oven with discharge plasma assisted combustion, which comprises an insulating shell and a charcoal chamber. A high-voltage electrode is provided on the side, and a chute is provided between the lifting control device and the insulating shell; the high-voltage electrode inside the charcoal chamber is connected to the control device through a high-voltage wire; the carbon dioxide absorption and fire extinguishing device is connected to the gas inlet and outlet holes. catch. Adjust the voltage to control the charcoal flame, and make the charcoal fully burn in oxygen-poor areas and absorb carbon dioxide; make full use of electric energy, make the fire even, realize smokeless barbecue, make the food rich in active substances, and taste better; and less pollutants emissions, safe and reliable.

Owner:ANHUI UNIV OF SCI & TECH

Household gas burner

The invention discloses a household gas burner, belonging to the part in the household gas kitchen range. The present household gas burner has the complex structure, poor processing precision and big accumulative error in assembling. The household gas burner comprises a nozzle, a gas distributing device, a gas mixing device and a fire lid, and characterized in that the gas distributing device andthe gas mixing device are all the integrated structure, wherein the gas distributing device comprises a gas supplying pipe and a distributing chamber, a primary air inlet open is arranged on the distributing chamber, the nozzle is fixed on the orifice of the gas supplying pipe in the distributing chamber; the gas mixing device comprises a mixing pipe, a mixing chamber, a buffer baffle plate and asecondary air inlet slot, the mixing chamber is matched with the distributing chamber, the buffer baffle plate is arranged above the orifice of the mixing pipe in the mixing chamber, the secondary air inlet slot is arranged at the side surface of the gas mixing device. The gas distributing device and the gas mixing device in the invention have no accumulative error in assembling, simple assembling and safe and reliable use.

Owner:HANGZHOU DE&E ELECTRICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com