Patents

Literature

109results about How to "Burning safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processed solid burnable fuel composition

A solid burnable fuel composition which contains a major proportion of spent dried coffee grounds is described. The fuel composition includes at least 50% dried spent coffee grounds and a combustible wax which are mixed together and compressed into a suitable shape for combustion. The fuel composition may further include a small amount, 10% or less, of a coking agent useful to control burn rate and to prevent cracking of compressed fuel during combustion. Small amounts of cellulosic material may also be incorporated to improve the structural properties of the composition. Due to its superior heat and flame production, dried spent coffee grounds are an excellent fuel source for processed fuel products such as fire-logs and fuel pellets. The advantage is a hotter, cleaner burn which produces less soot and smoke, releases fewer harmful pollutants and provides a brighter flame over a longer period of time.

Owner:ROYAL OAK ENTERPRISES

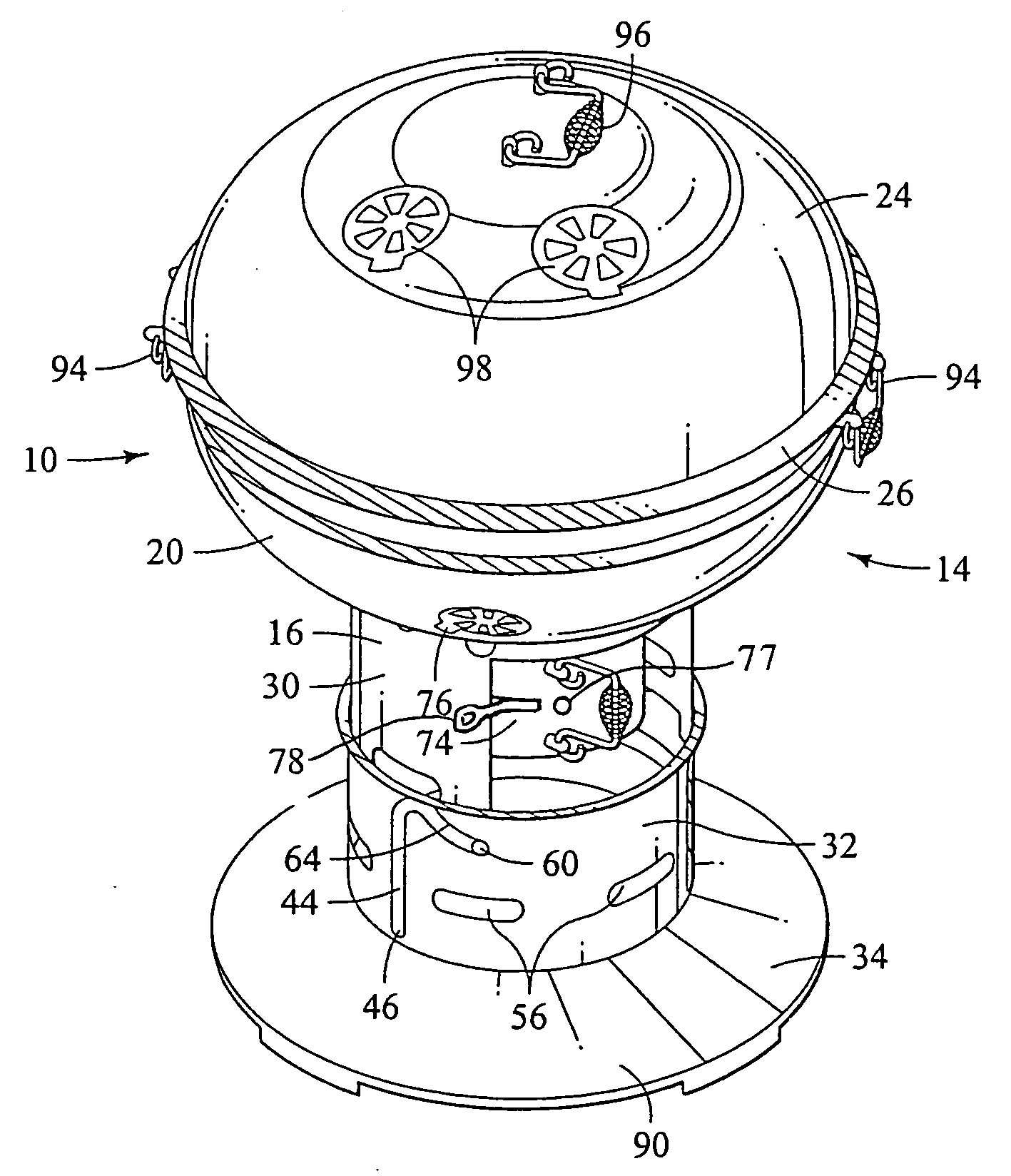

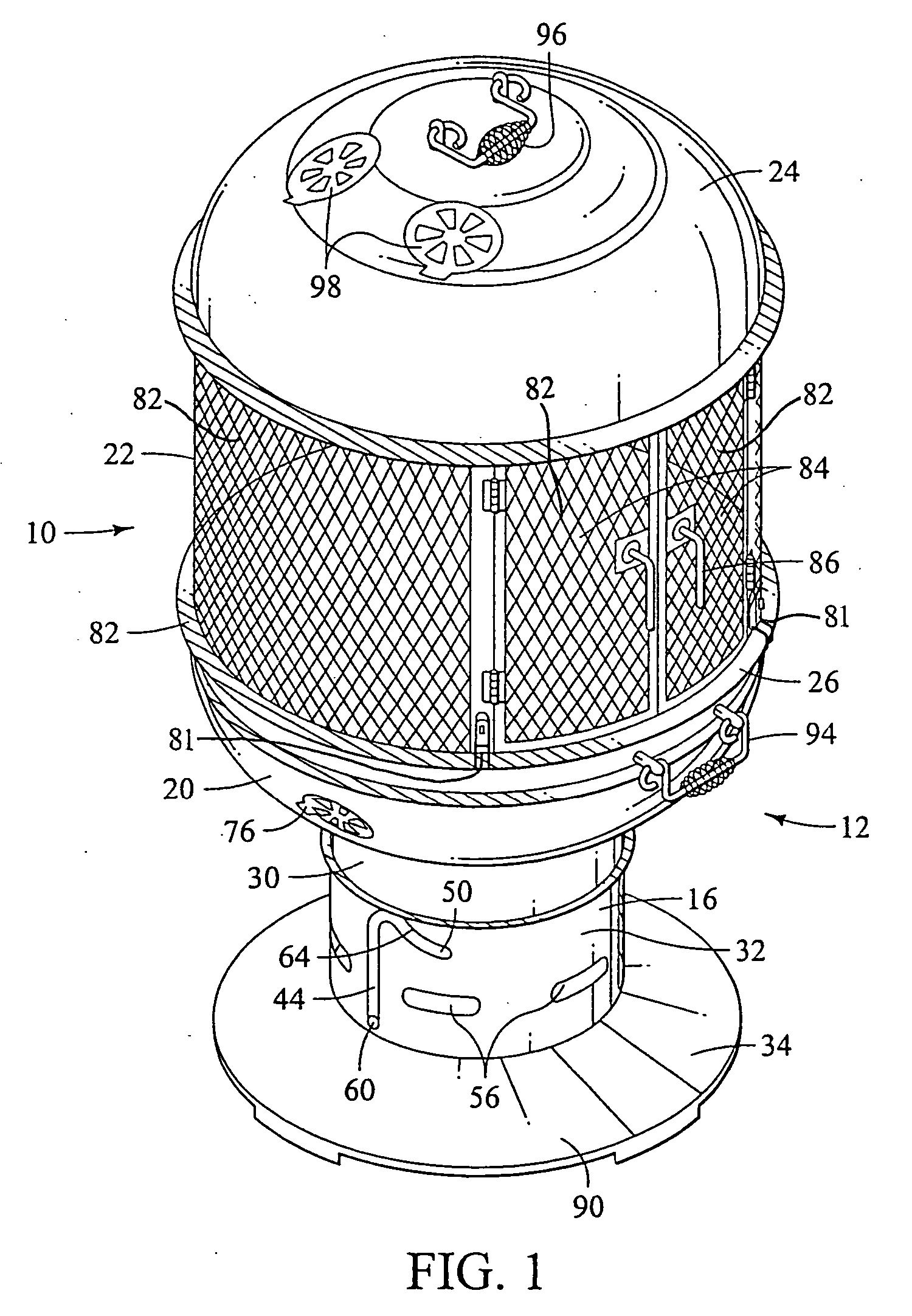

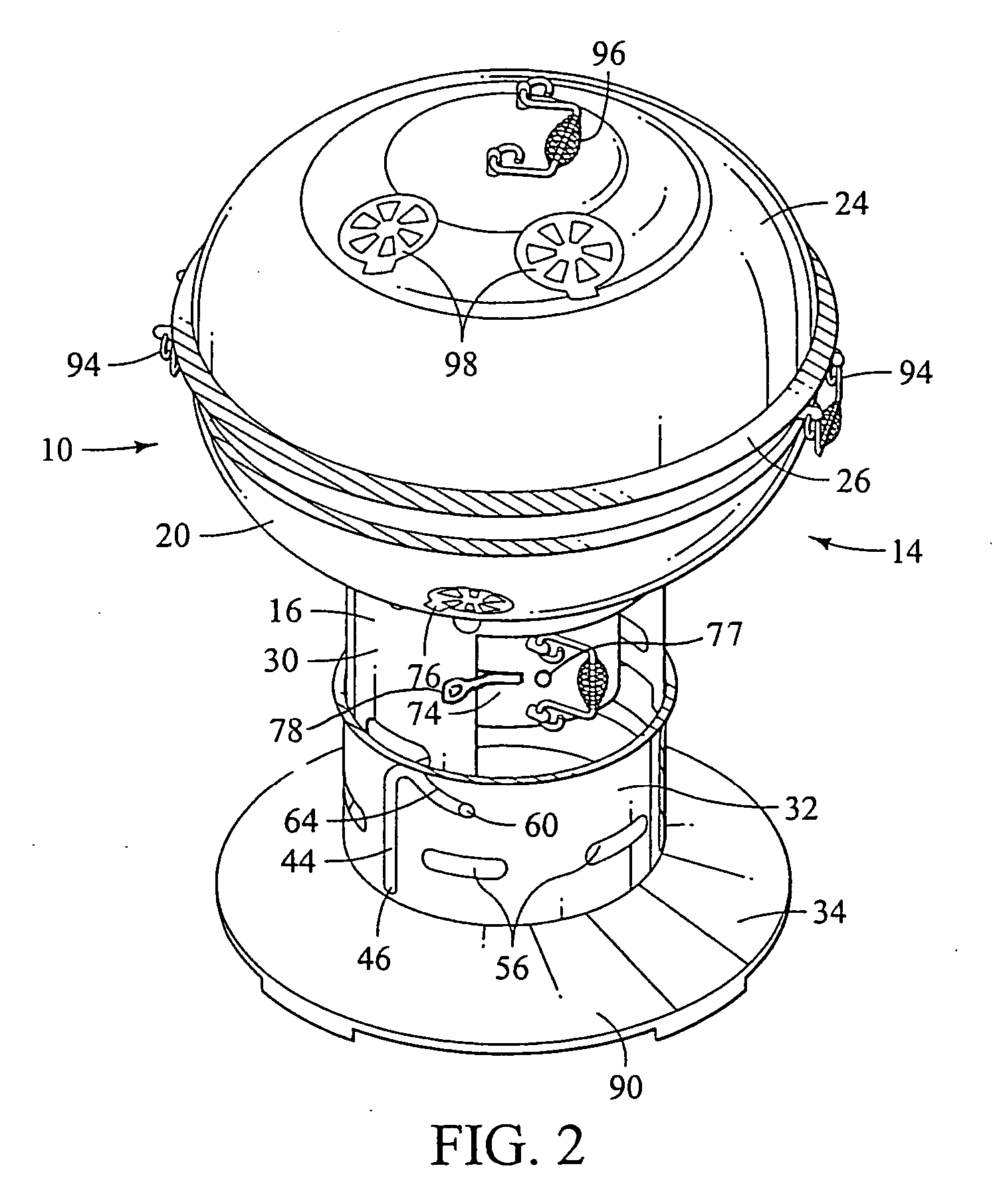

Convertible outdoor appliance

InactiveUS20050126556A1Easy to adjustBurn wood safelyDomestic stoves or rangesWater heatersEngineeringFireplace

A convertible outdoor appliance features a bowl that is configured to burn solid fuel and is mounted to at least one leg or pedestal. One or more screen sidewalls are removably supported by the bowl. The height of the bowl is adjustable between a barbecue grill position and a fireplace position. A lid is configured to fit atop the bowl and the sidewalls, whereby a barbecue grill is formed when the pedestal is in the barbecue grill position, said sidewalls are removed and said lid removably covers said bowl; and an outdoor fireplace is formed when the pedestal is in the fireplace position, and the sidewalls are releasably supported by the bowl.

Owner:BLUE RHINO GLOBAL SOURCING

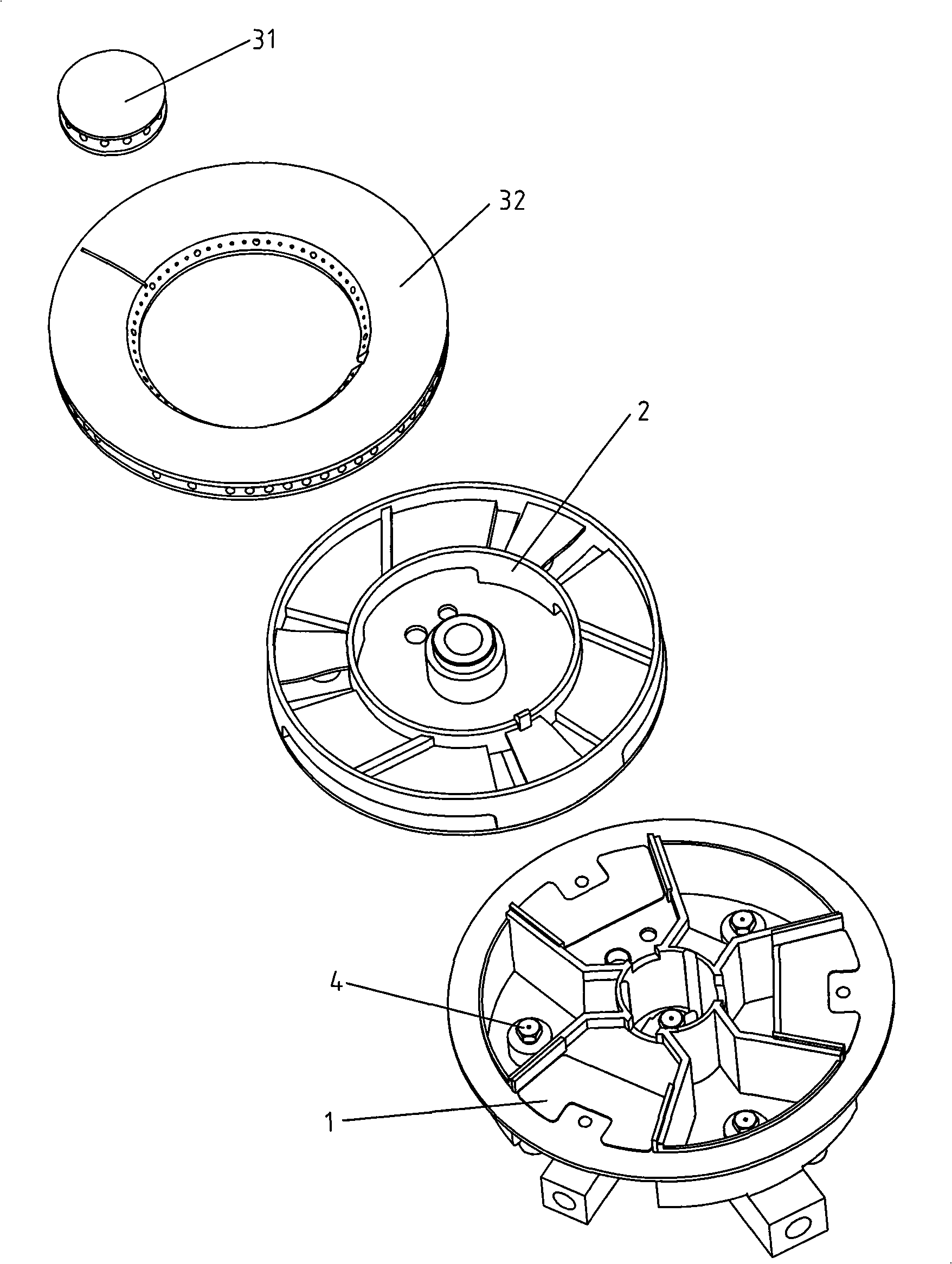

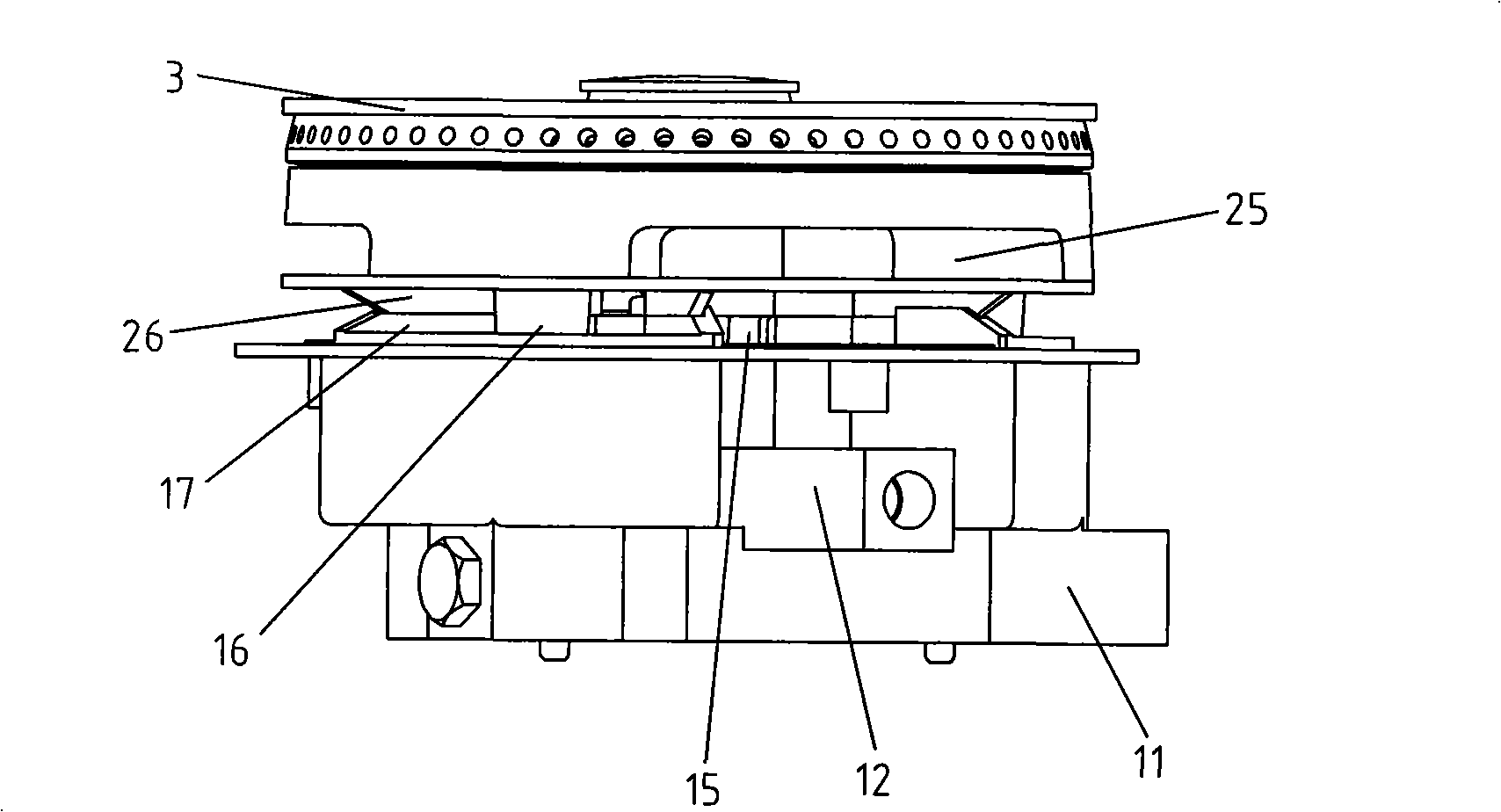

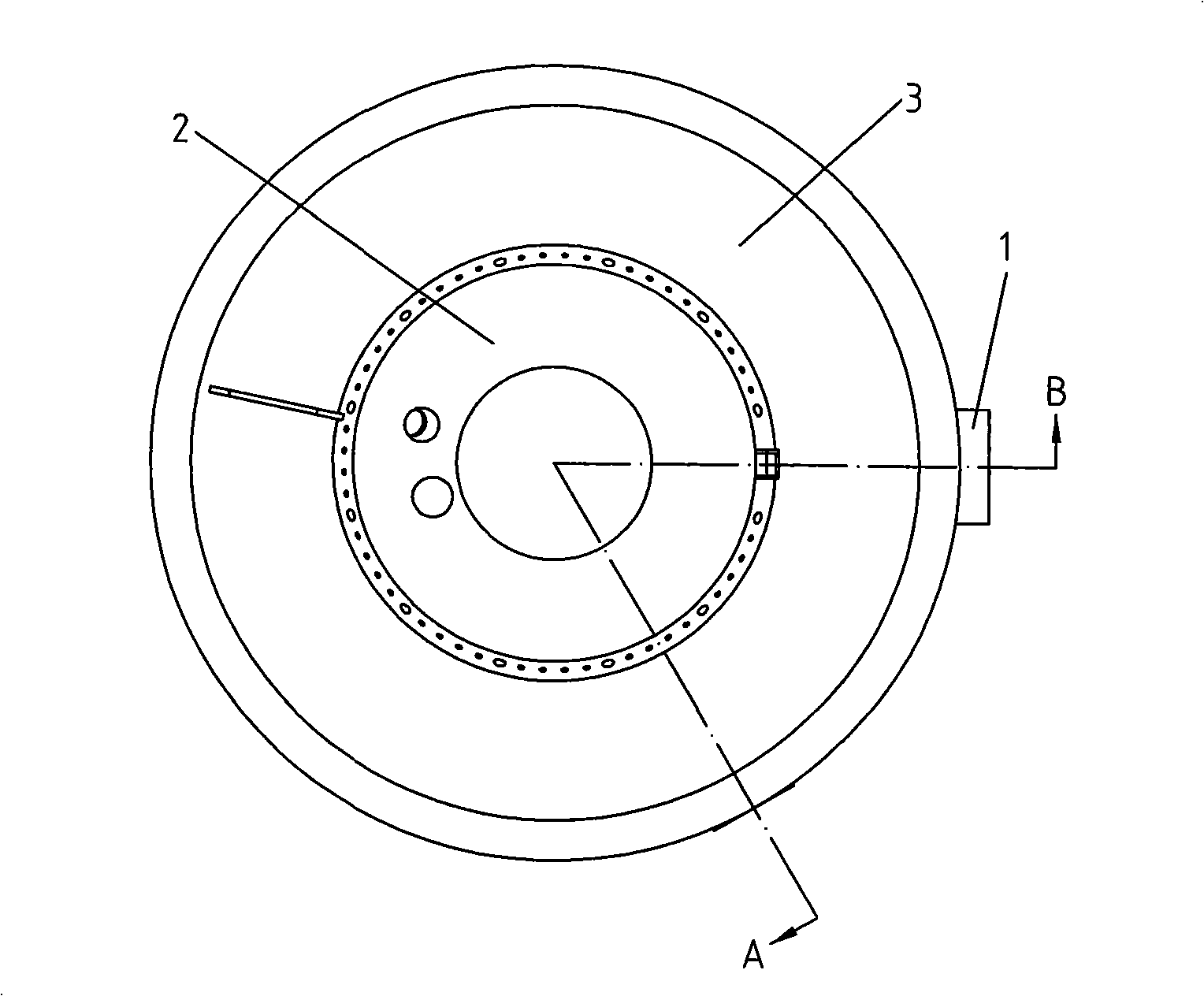

Household gas burner

The invention discloses a household gas burner, belonging to the part in the household gas kitchen range. The present household gas burner has the complex structure, poor processing precision and big accumulative error in assembling. The household gas burner comprises a nozzle, a gas distributing device, a gas mixing device and a fire lid, and characterized in that the gas distributing device and the gas mixing device are all the integrated structure, wherein the gas distributing device comprises a gas supplying pipe and a distributing chamber, a primary air inlet open is arranged on the distributing chamber, the nozzle is fixed on the orifice of the gas supplying pipe in the distributing chamber; the gas mixing device comprises a mixing pipe, a mixing chamber, a buffer baffle plate and a secondary air inlet slot, the mixing chamber is matched with the distributing chamber, the buffer baffle plate is arranged above the orifice of the mixing pipe in the mixing chamber, the secondary air inlet slot is arranged at the side surface of the gas mixing device. The gas distributing device and the gas mixing device in the invention have no accumulative error in assembling, simple assembling and safe and reliable use.

Owner:HANGZHOU DE&E ELECTRICAL CO LTD

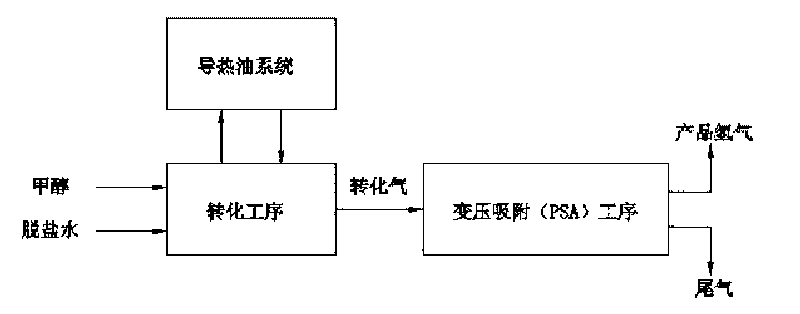

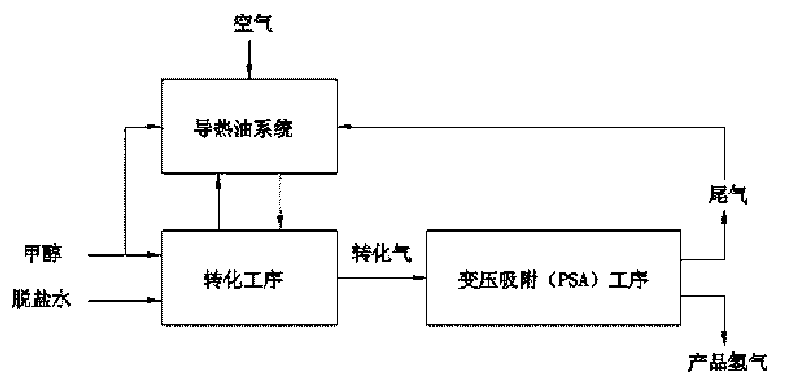

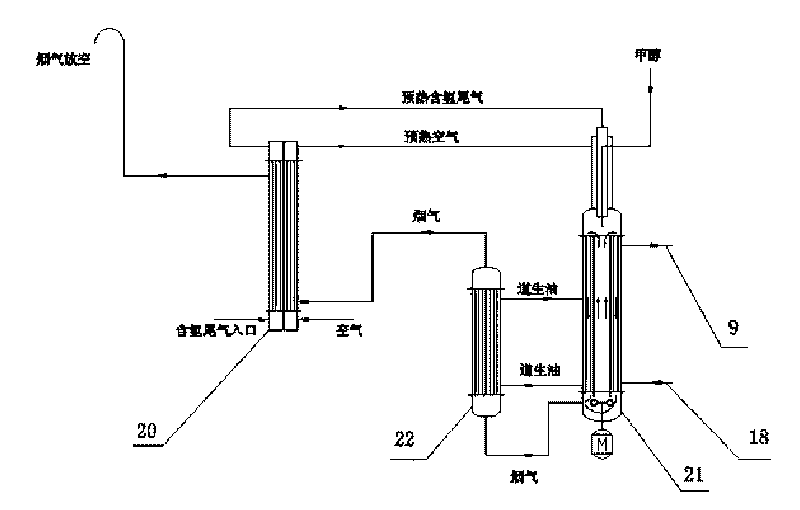

Methanol steam hydrogen production technology by using catalytic combustion flue gas as heat source

The invention discloses a methanol steam hydrogen production technology by using catalytic combustion flue gas as a heat source, relating to a hydrogen production technology, and aiming to solve the problem that tail gas is discharged but is not utilized to result in resource waste in the traditional methanol steam hydrogen production technology. Methanol and desalted water as raw materials are orderly preheated, gasified, overheated and converted to obtain converted gas; then the converted gas is adsorbed at variable pressure, the product hydrogen is obtained, and tail gas is discharged, wherein the heat quantity is supplied by heat conducting oil in the converting procedure, the tail gas generates the heat quantity through catalytic combustion and conducts the heat quantity to the heat conducting oil in a heat conducting system.

Owner:四川亚联氢能科技股份有限公司

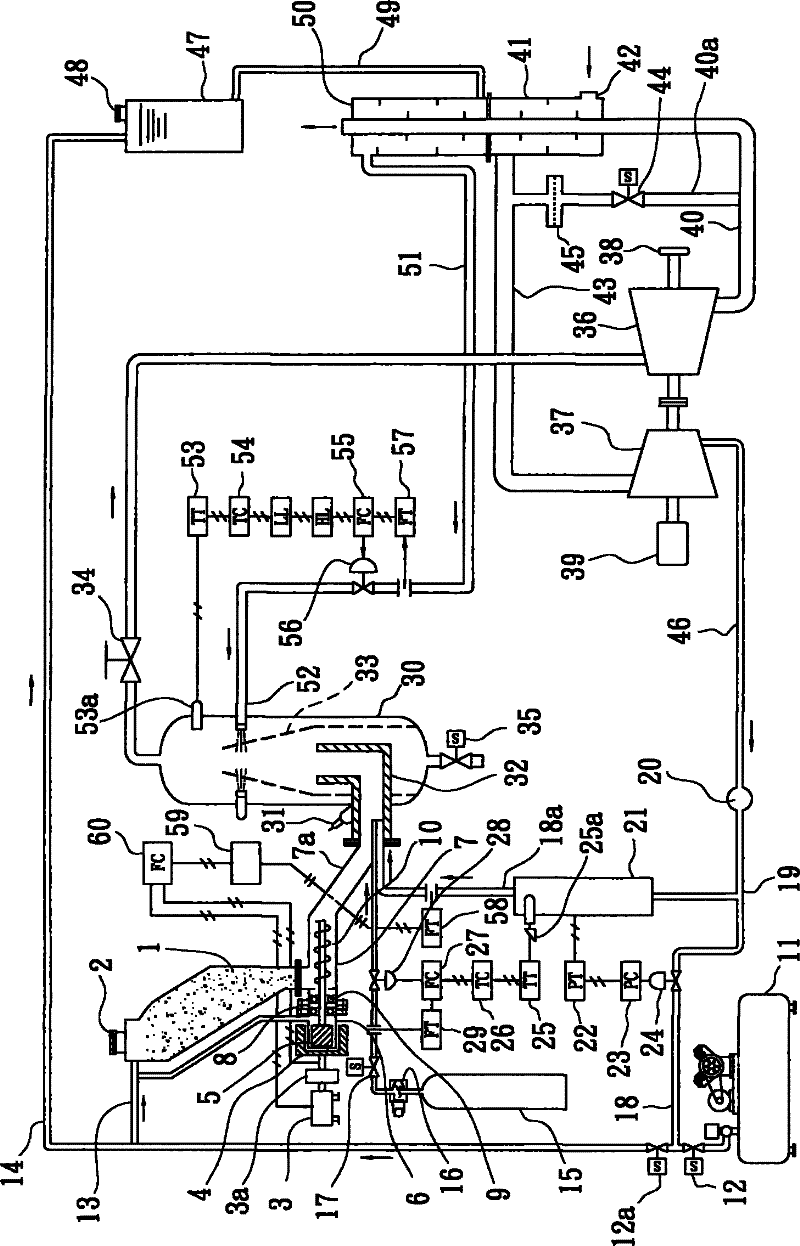

Industrial waste gas combustion apparatus and method

InactiveCN101457936AImprove fullnessImprove stabilityAir/fuel supply for combustionIncinerator apparatusCombustionExhaust fumes

The invention discloses an industrial waste gas combustion device and a method thereof. The invention comprises an industrial waste gas channel, at least one primary air channel, and at least one ignition device which is arranged at the terminal end of the industrial waste gas combustion device by extension, wherein, the industrial waste gas combustion device further comprises at least one secondary air channel; the industrial waste gas channel, the primary air channel and the secondary air channel are all ring-shaped channels; the industrial waste gas channel is arranged at the outer side of the primary air channel in a rotating way; and the secondary air channel is arranged at the outer side of the industrial waste gas channel in a rotating way. As the invention uses a structure that the industrial waste gas channel, the primary air channel and the secondary air channel are mutually separated, the combustion is safe and reliable; as a trumpet-shaped ring-shaped channel is used by each channel, the fullness of the flame can be enhanced, the length of the flame can be reduced, and the combustion efficiency can be improved.

Owner:刘武标

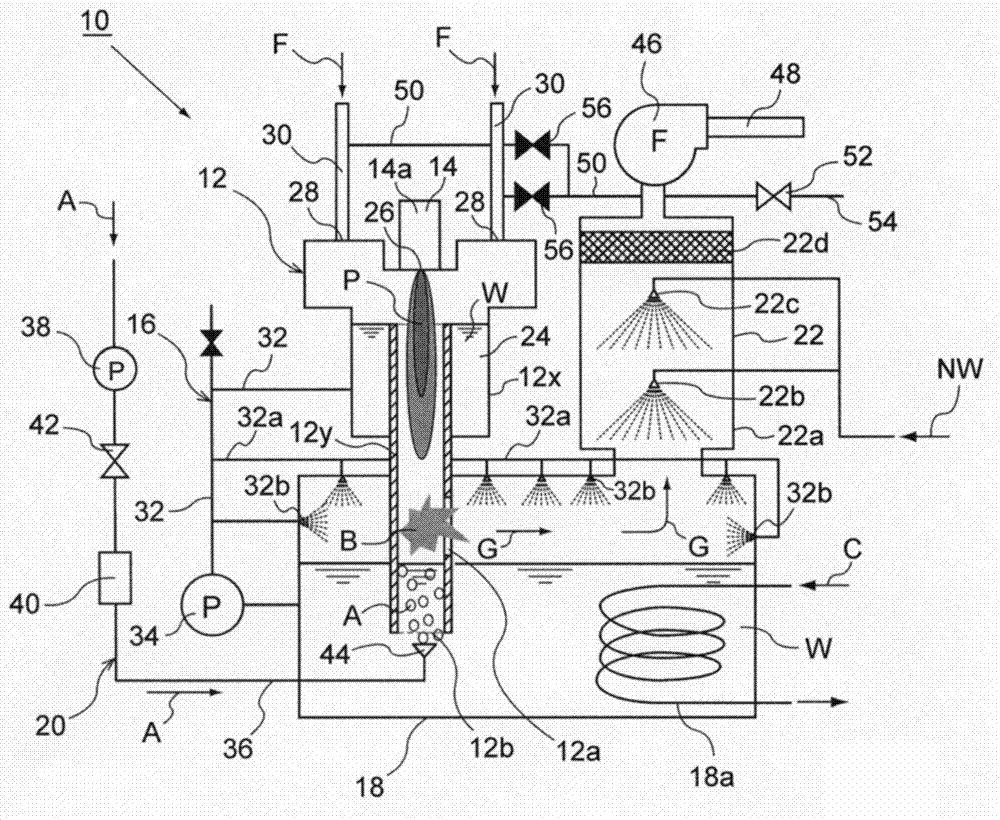

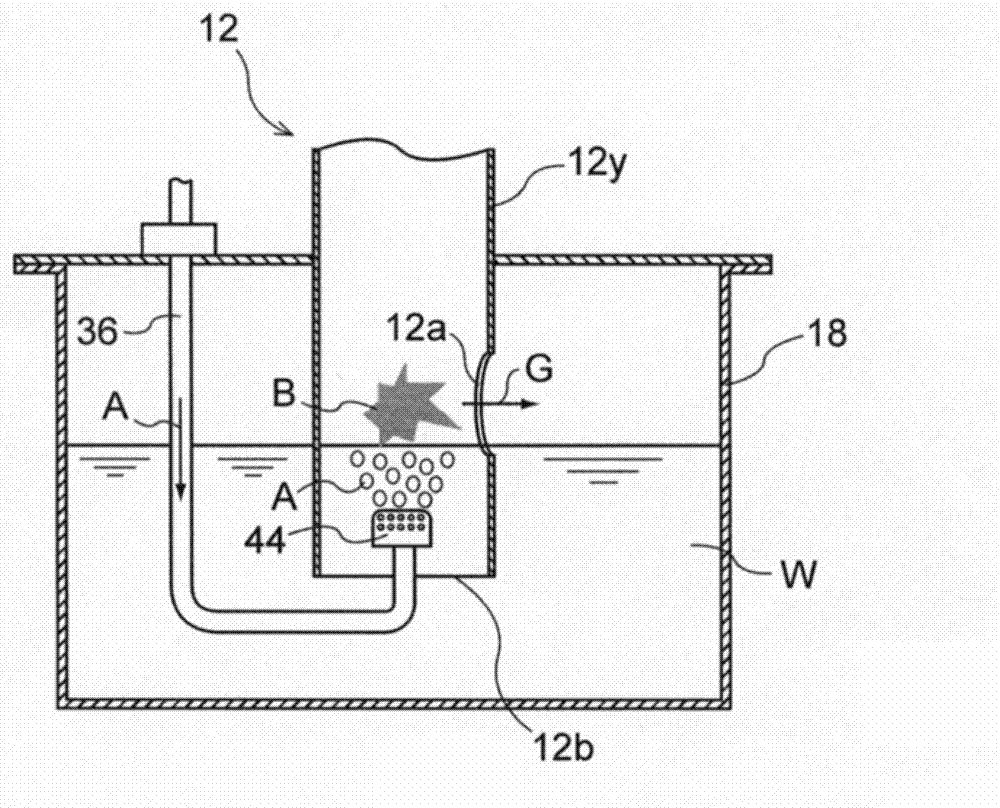

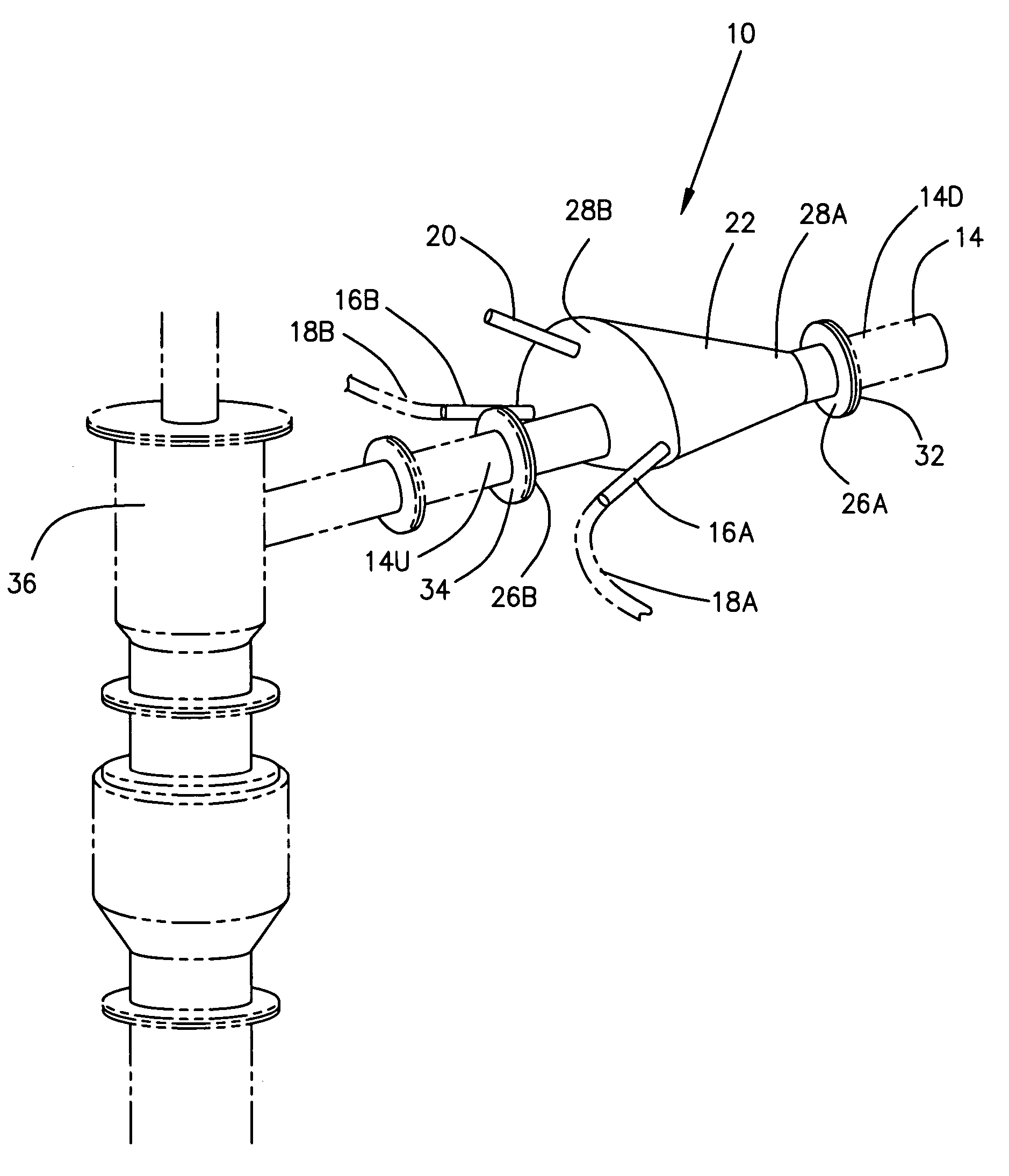

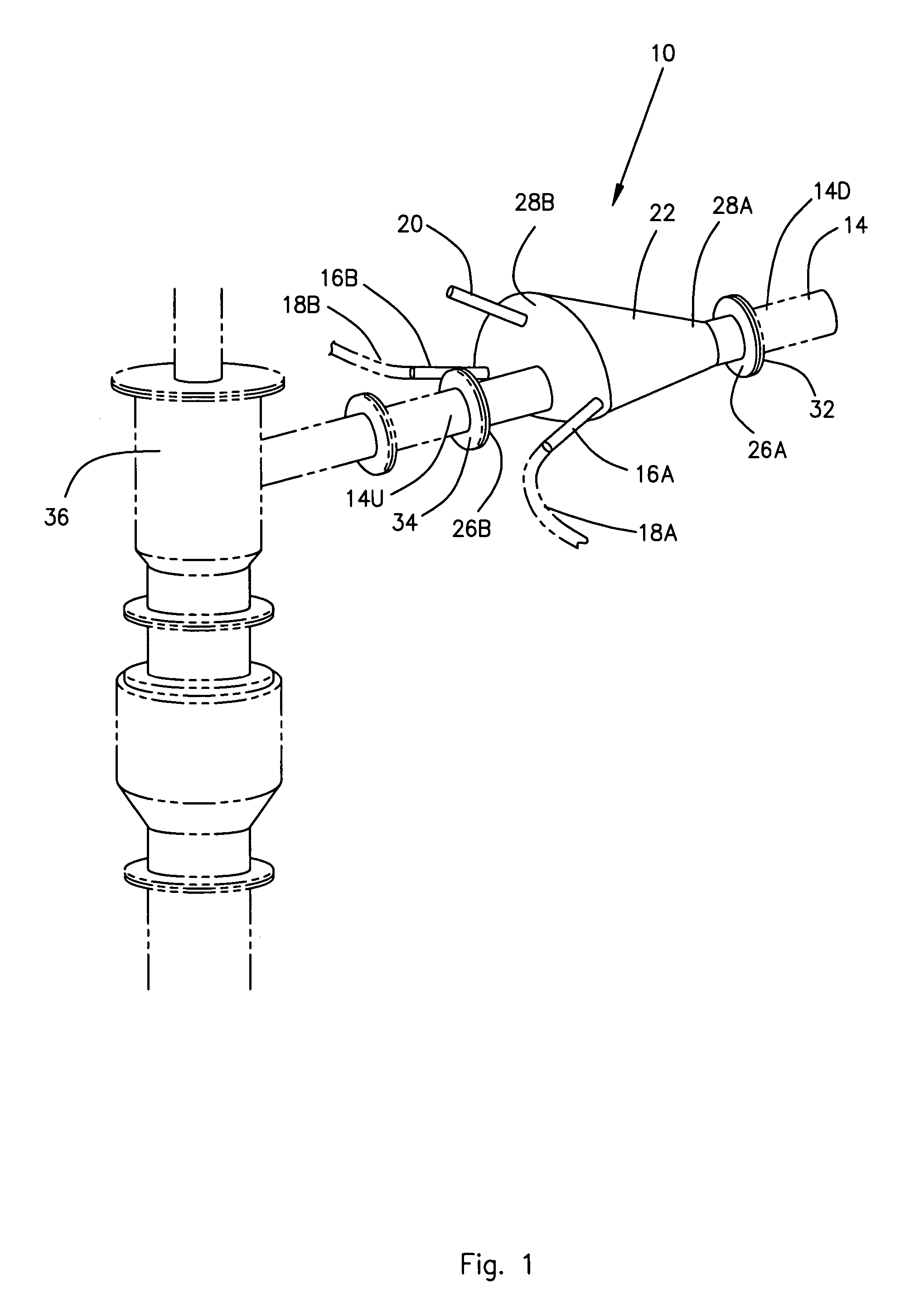

Gas treating apparatus

ActiveCN103316561ABurning safetyWon't backfireDispersed particle separationIncinerator apparatusHigh concentrationHydrogen

The invention provides a gas treating apparatus. Hydrogen and other combustible gases with high concentrations flow into the apparatus, various gases are treated safely and reliably. According to the gas treating apparatus (10), gases (F) to be treated are supplied from the inlet (28) at the upper portion of the cylindrical reactor (12) vertically arranged on a water tank (18), thermal decomposition of the gases (F) to be treated is carried out in the reactor (12), and gases (G) to be discharged generated after thermal decomposition are discharged from the outlet (12a) arranged at the lower part of the relactor (12). The lower end surface of the relactor (12) is provided with an opening, the oxidizing gas (A) transmitted from water (W) in the water tank (18) is conducted to the reactor (12) through a lower opening (12b).

Owner:KANKEN TECHNO

Fully-premixing full-automatic ignition burner

InactiveCN101871656ABurning safetyStable and reliable combustionElectric spark ignitersChemical industryFlame detection

The invention discloses a fully-premixing full-automatic ignition burner which combines ignition with flame detection into a whole. An ignition system and a flame monitoring system are arranged in a pipe of which the maximum inner diameter is only phi 52mm; the ignition burner has stable, safe and reliable operation, can be combined with a warming ignition burner for use and has superior ignition reliability, safety, stability, installation and disassembly than a common ignition burner. The fully-premixing full-automatic ignition burner is used for majority of chemical industry furnaces, comprising heating furnaces, hot coal furnaces, gasification furnaces, reforming furnaces and the like.

Owner:西安拓沃能动科技有限公司 +3

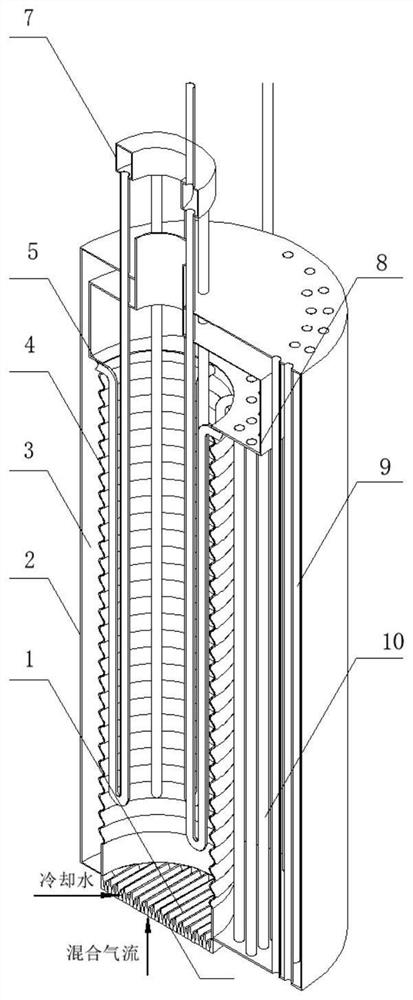

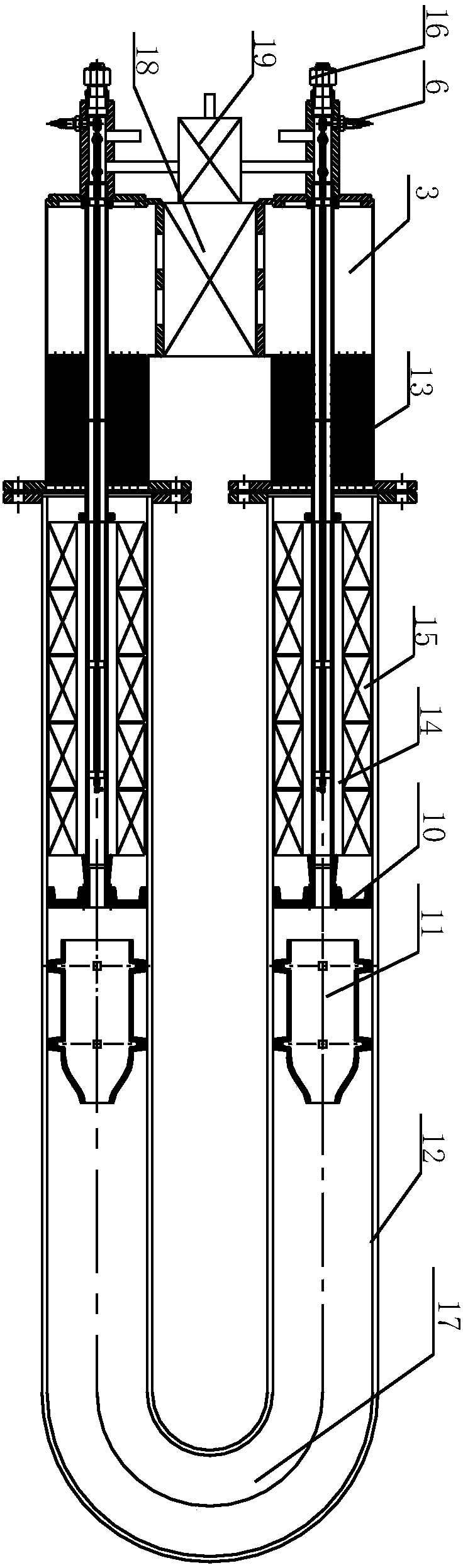

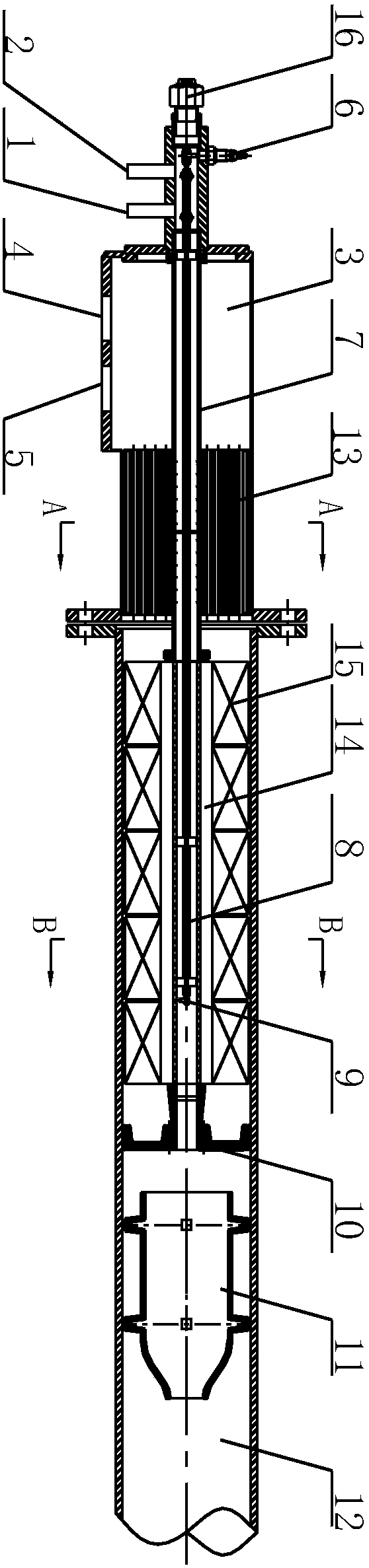

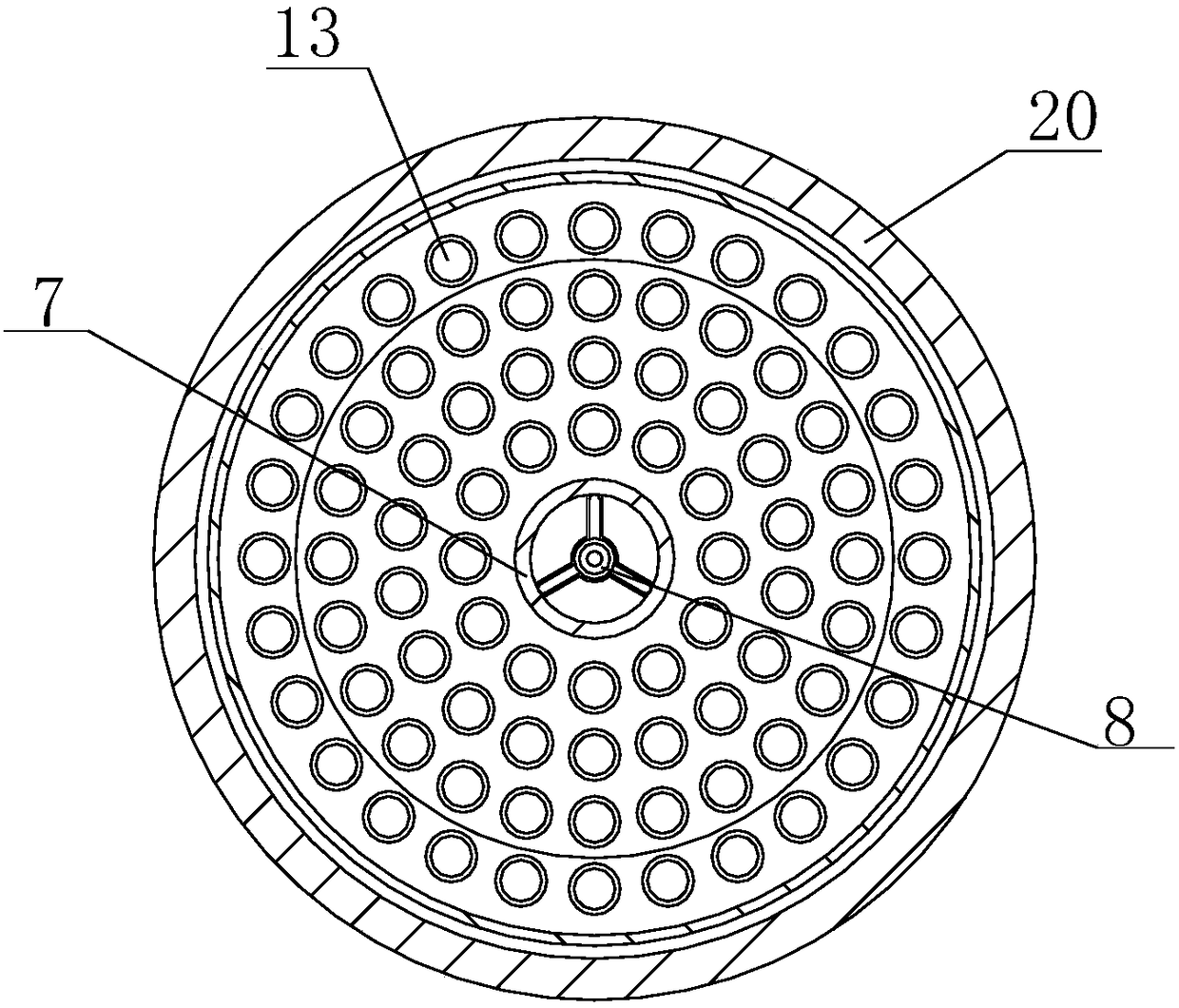

Hearth and combustor cooling type surface cold flame premixing gas boiler

The invention discloses a hearth and combustor cooling type surface cold flame premixing gas boiler. The boiler comprises a hearth, a water cooling combustor is installed at the position of an inlet of the hearth, an outlet of the hearth is connected to a reversal chamber, U-shaped water cooling components are evenly arranged in the hearth in the circumferential direction, inlets of the U-shaped water cooling components are evenly connected to an annular pipeline in the circumferential direction, and water outlets of the U-shaped water-cooling components and a water outlet of the water coolingcombustor are connected to a boiler water tank. According to the hearth and combustor cooling type surface cold flame premixing gas boiler, by the adoption of the water cooling combustor, uniform gascombustion can be achieved, the flame root combustion temperature is reduced while a local high-temperature area is not generated, generation of thermal NOx at the flame root is reduced, and meanwhile, a hearth cooling system is adopted, a U-shaped pipeline cooling structure is arranged, the compact structure and manufacturing economy of the boiler are achieved while the uniform low-temperature atmosphere in the boiler is guaranteed, and generation of the NOx during gas fuel combustion is further remarkably reduced.

Owner:XI AN JIAOTONG UNIV

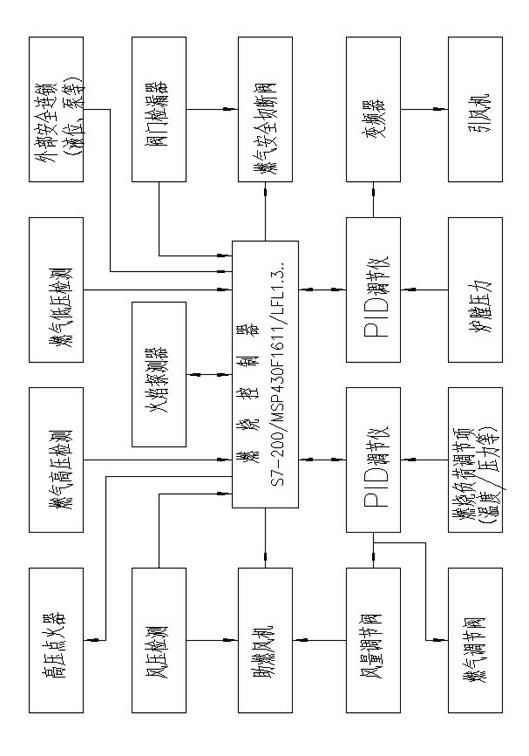

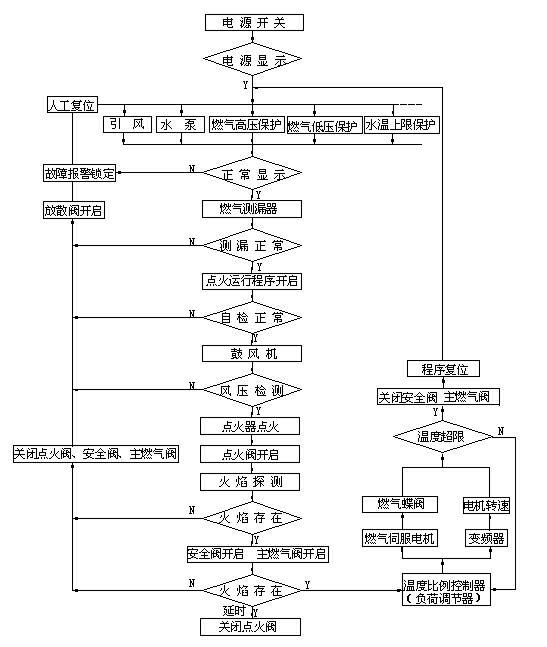

Coking plant VOCs treatment system

ActiveCN108592054AWill not dischargeReduce concentrationIncinerator apparatusChemical industryCombustion

The invention relates to a coking plant VOCs treatment system. The coking plant VOCs treatment system comprises a control system, a combustion treatment system and a negative pressure recovery system.The coking plant VOCs treatment system is capable of effectively treating VOCs and reducing the environment pollution caused by the VOCs to the greatest extent, and accords with the stipulation of Emission Standard of Pollutants for Coking Chemical Industry GB1617-2012.

Owner:山东东尊华泰环保科技有限公司

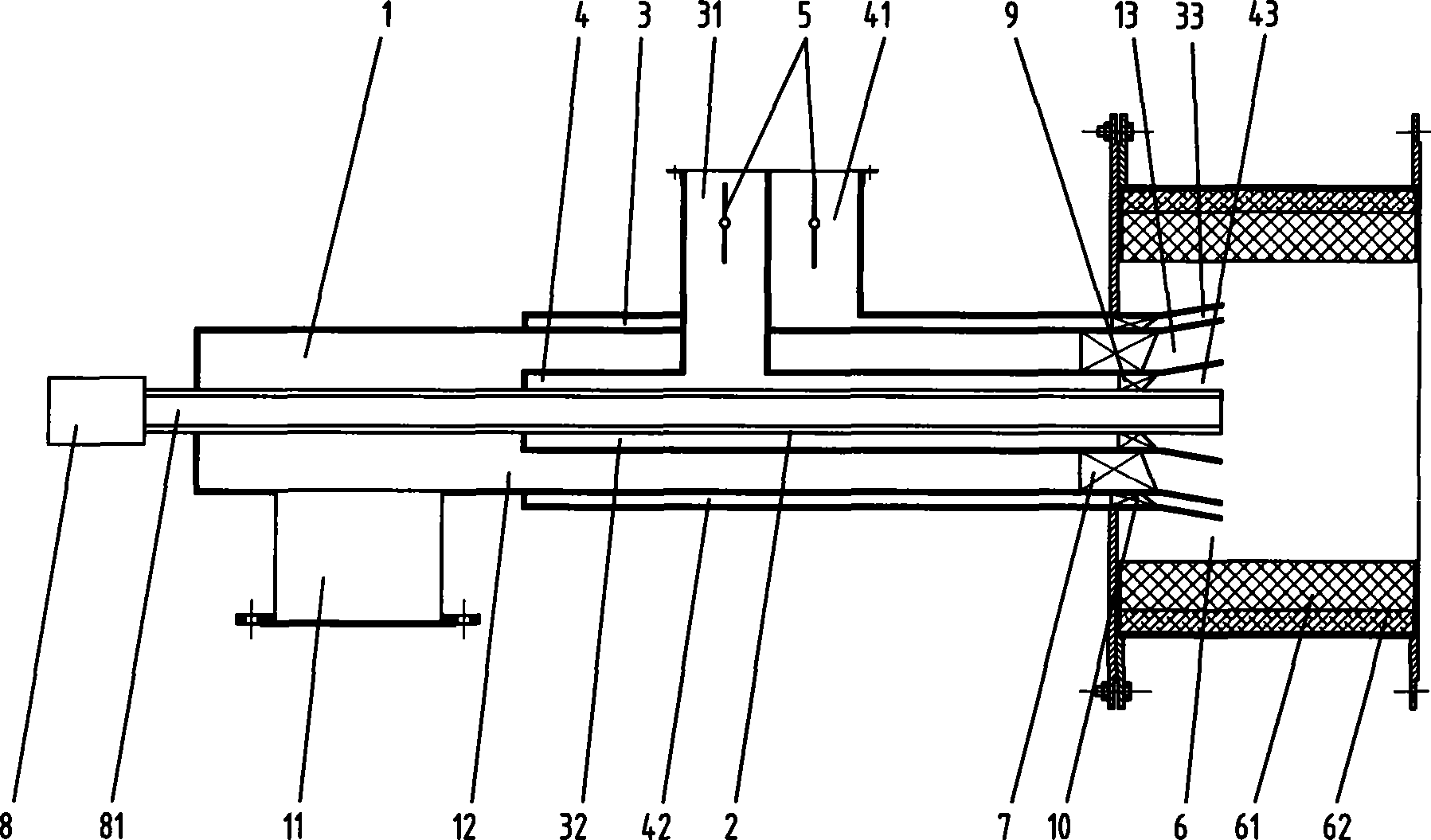

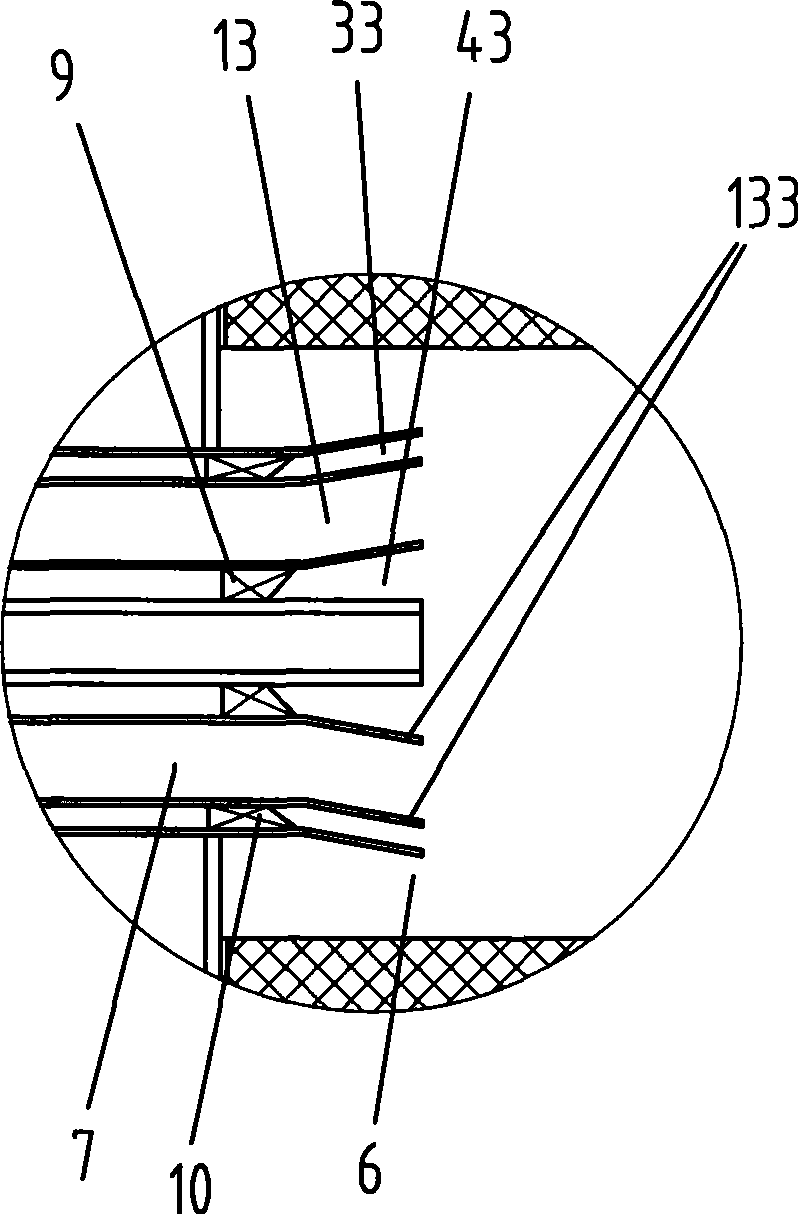

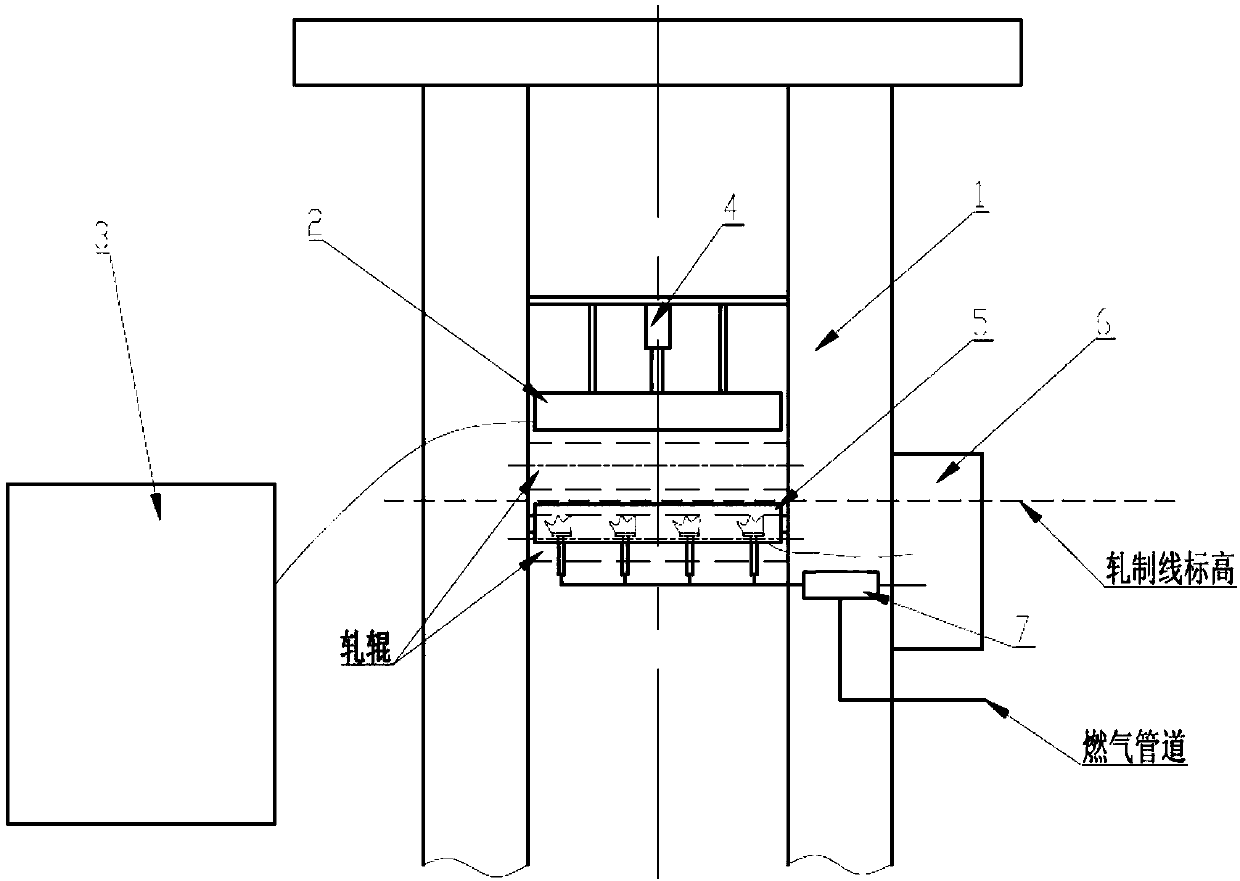

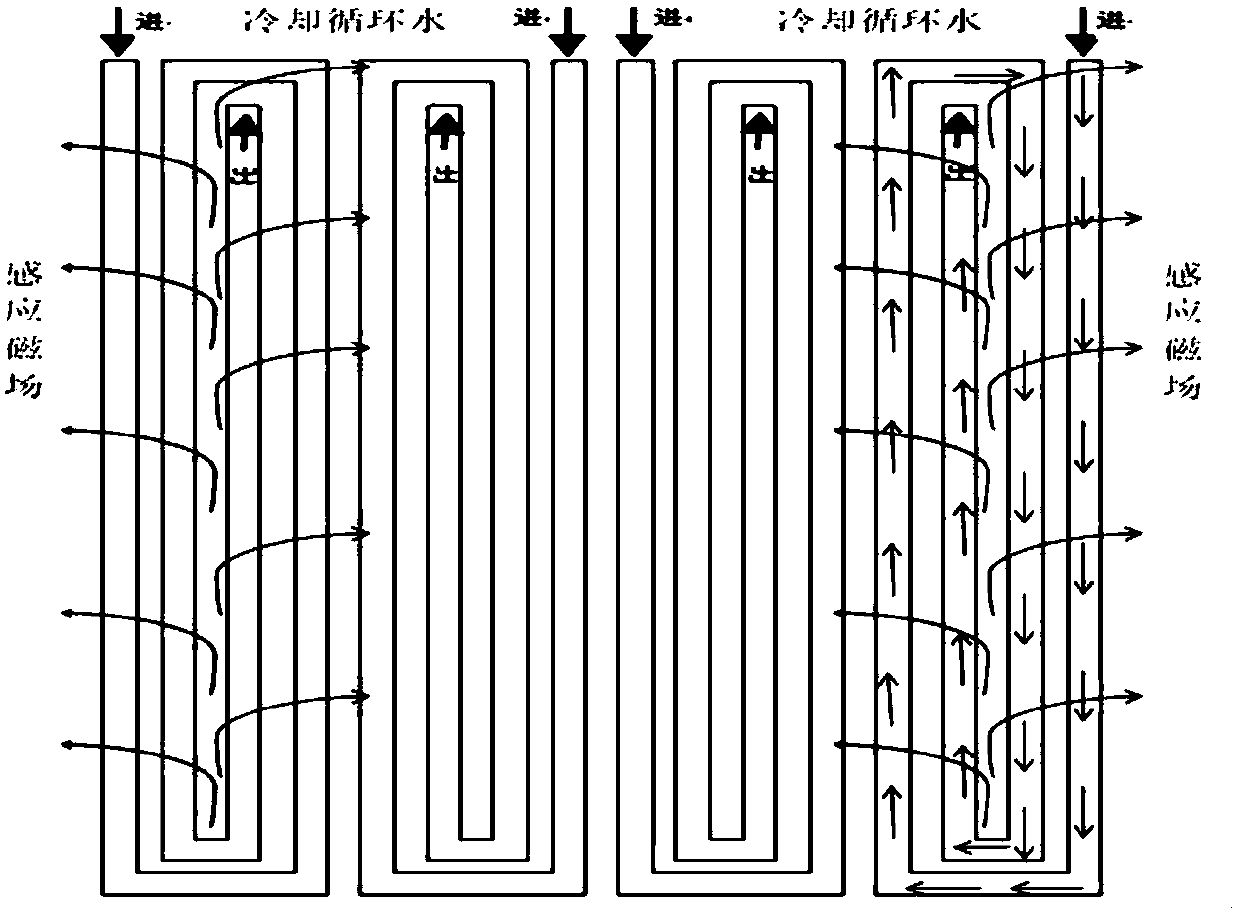

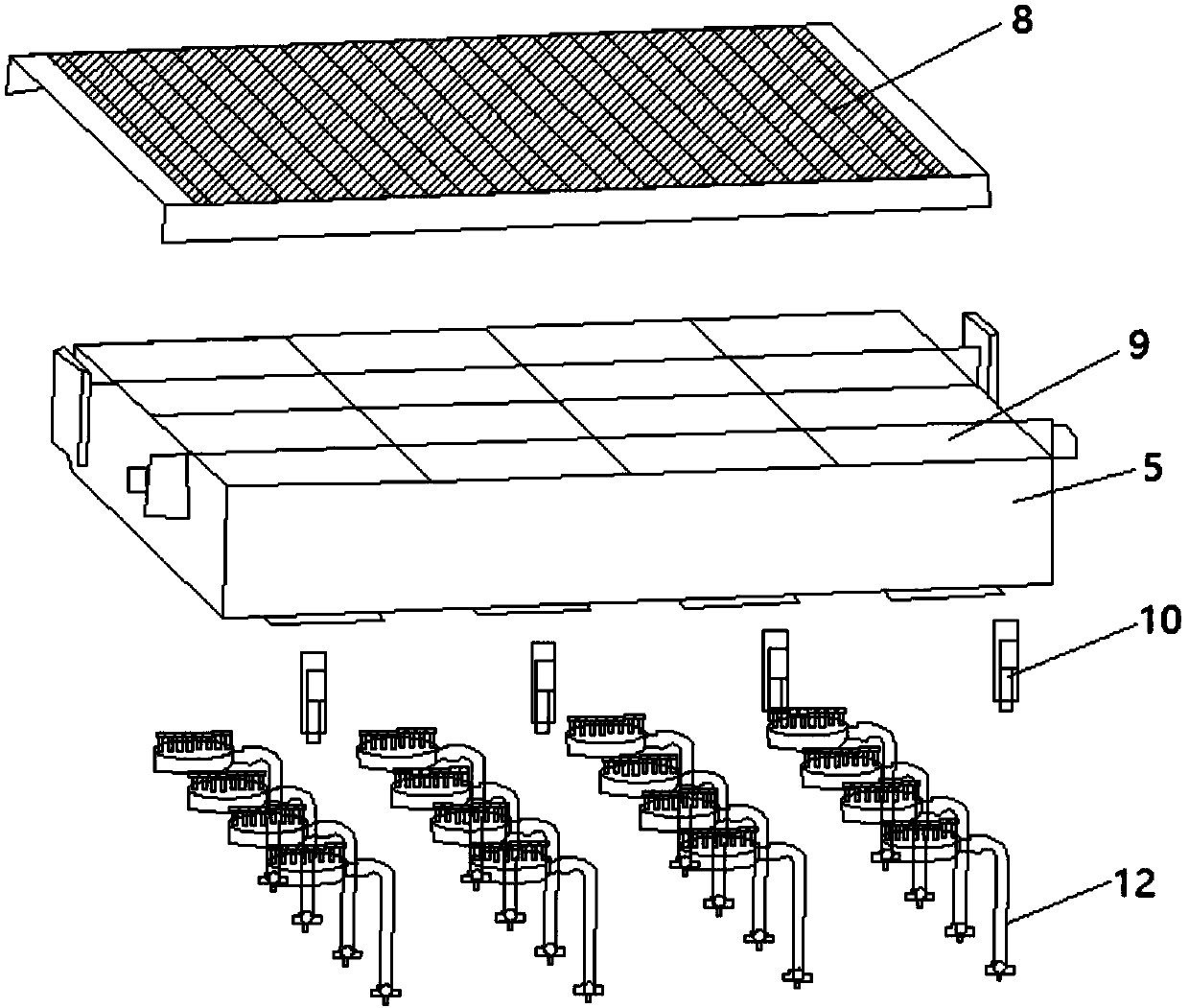

Plate-and-strip online heating device used in rolling process of magnesium alloy

PendingCN107866443AAchieve reversible rollingSimple mechanical structureTemperature control deviceInduction heatingCombustion chamberIntermediate frequency

The invention discloses a plate-and-strip online heating device used in the rolling process of magnesium alloy. The plate-and-strip online heating device comprises an induction heating device, a gas heating device and infrared thermometers which are installed at the rolling inlet and outlet positions of the magnesium alloy. The infrared thermometers are used for monitoring the online temperature of the magnesium alloy in real time and are further connected with a control system of the induction heating device and the gas heating device. The whole heating system can achieve closed-loop controlby setting a target temperature. The medium-frequency induction heating mode is adopted in the induction heating device, and the induction heating device comprises a frequency conversion device, an induction heating furnace body and a furnace front control device. The gas heating device comprises a combustion chamber, an ignition electrode, an ignition control system and a gas distributing cylinder. The induction heating furnace body and the gas heating combustion chamber are distributed up and down. Magnesium alloy plates and strips to be rolled penetrate through the gap between the inductionheating furnace body and the combustion chamber and further enter rollers for rolling. By means of the plate-and-strip online heating device, the magnesium alloy temperature can be controlled withinthe optimal rolling temperature range quickly and efficiently; and meanwhile, the temperature uniformity of the magnesium alloy plates and strips to be rolled can be improved, and the purpose of plateshape control is achieved.

Owner:SHANGHAI LIZHENG SATELLITE APPL TECH CO LTD

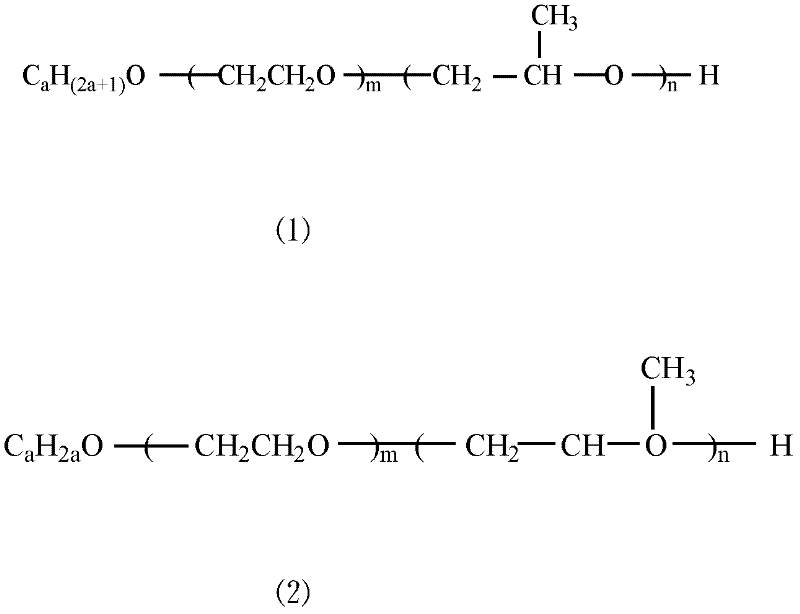

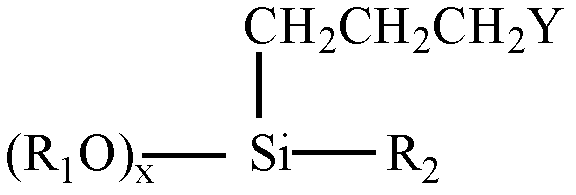

Polymeric functional additive used in coal combustion and preparation method thereof

Aiming to provide an additive with low use cost and its preparation method, the invention discloses a polymeric functional additive used in coal combustion and a preparation method thereof. An additive, with the surface modified by a functional polymer material, can have improved stability, activity and dispersity, and can be easier to be absorbed on the surface of coal to boost combustion, thus making the coal combustion more complete and securer, increasing coal burnout rate and fixing harmful substances of coal into the ash content of coal to realize clean combustion. The additive of the invention is prepared through the following steps: subjecting the functional polymer material and a dispersion stabilizer into a reaction at a temperature of 40-120DEG C in a reaction kettle, adding a catalyst with stirring, and leaving the mixture reacting for 1-6 hours; conducting shearing, grinding, homogenizing, filtration and separation, thus realizing the particle size control of an end product; adding an auxiliary surfactant, and cooling the mixture to room temperature, thus obtaining the polymeric functional additive used in coal combustion.

Owner:铜陵市绿源复合材料有限责任公司

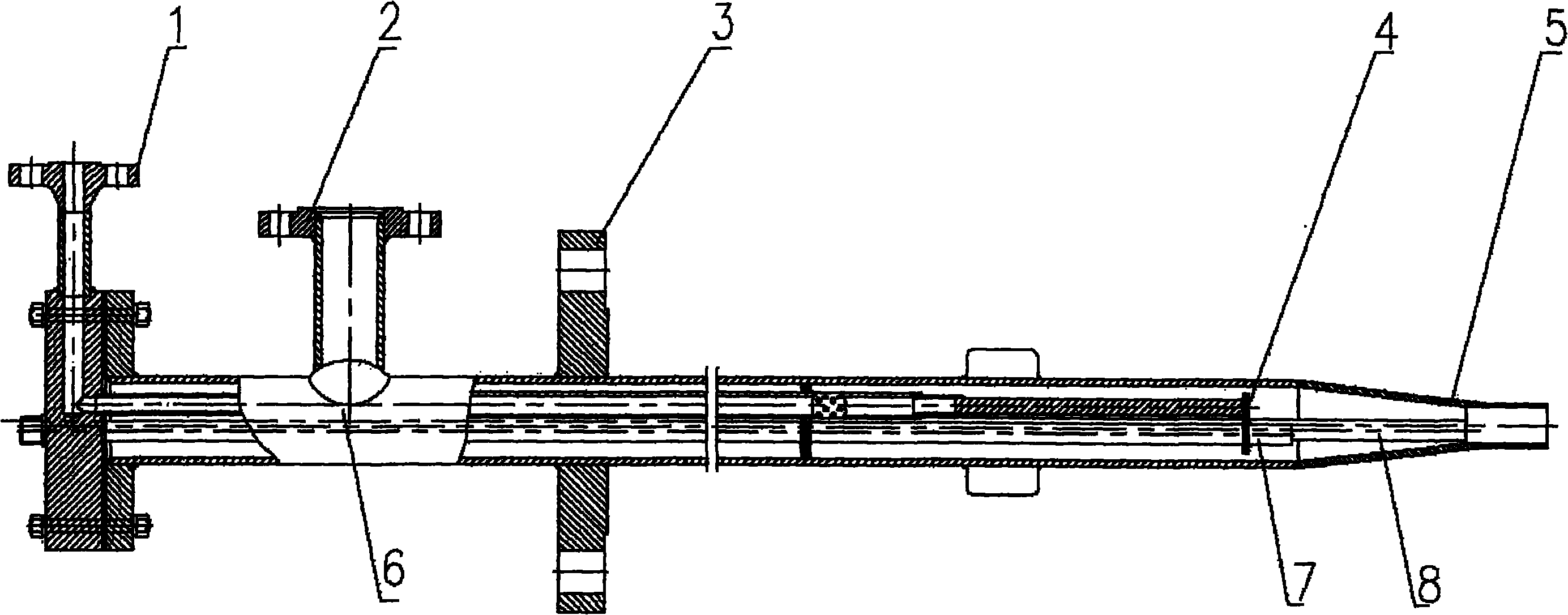

Combustion device for gaseous fuel with low heating values

ActiveCN102563646AStable and reliable combustionPrevent flashback from happeningGaseous fuel burnerCombustion regulationAutomotive engineeringEngineering

Owner:唐山亿昌热能科技有限公司

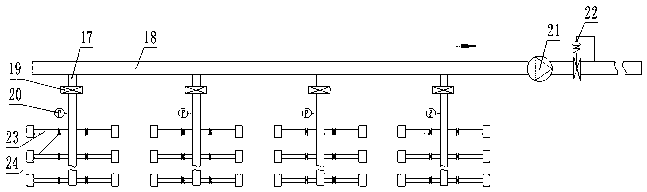

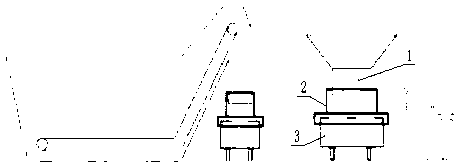

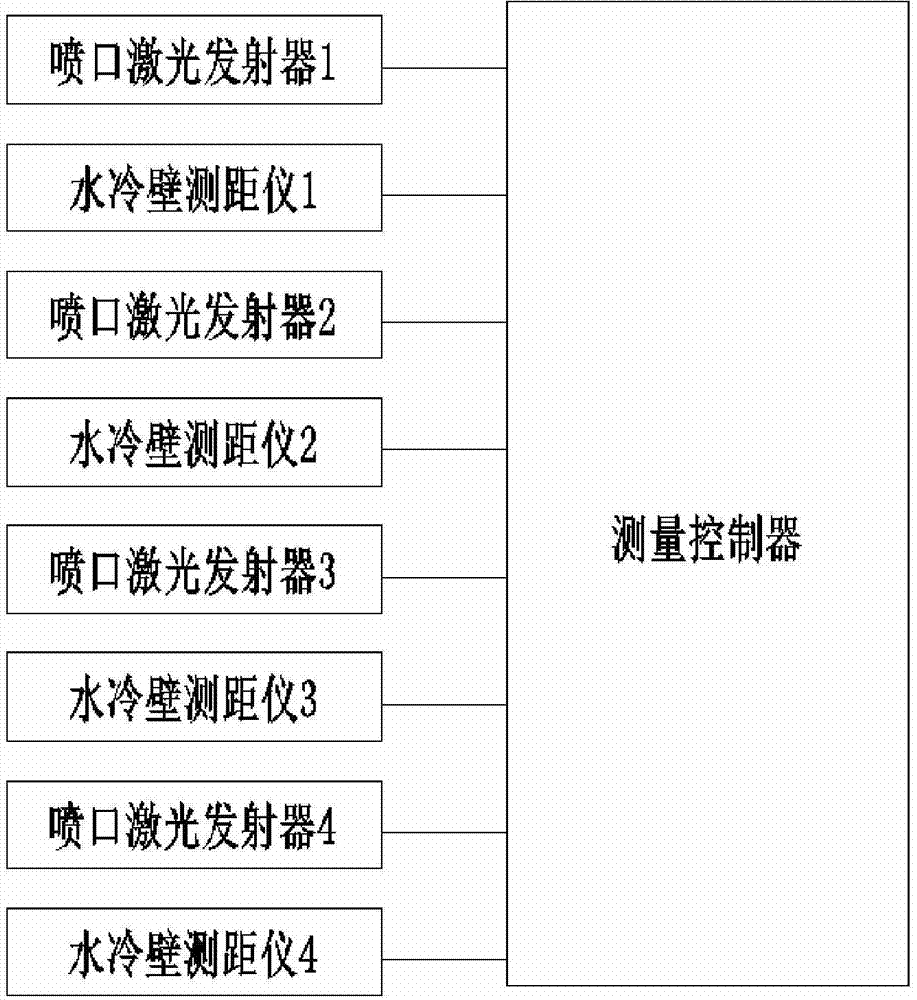

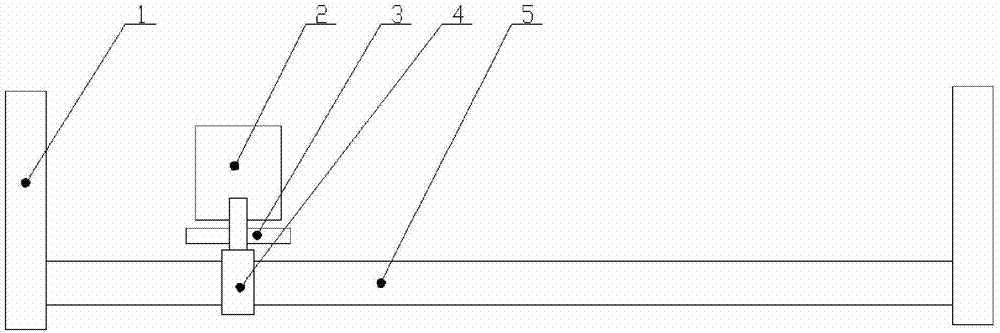

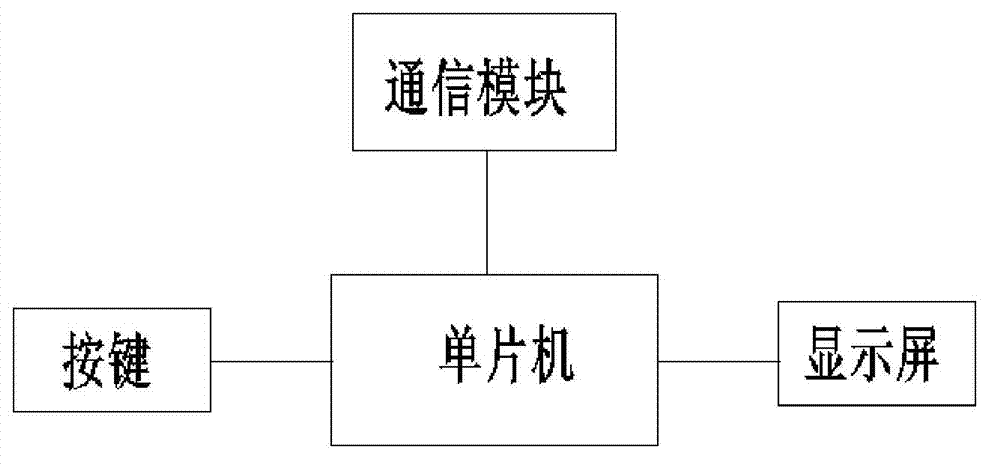

Device for measuring nozzle angles and tangent circles of quadrangular tangential injection burning boiler

The invention relates to a device for measuring nozzle angles and tangent circles of a quadrangular tangential injection burning boiler. The device is characterized by comprising a measurement controller, four nozzle laser transmitters and four water-cooling wall range finders, wherein nozzle laser transmitters are installed at injector nozzles to be measured, water-cooling wall range finders are horizontally installed on water-cooling walls corresponding to injector nozzles, and the four nozzle laser transmitters and the four water-cooling wall range finders are connected with the measurement controller in a wireless mode or a wired mode to implement a measurement function. The device has the advantages of being reasonable in design, capable of measuring nozzle angles and calculating combustion tangent circle positions through a laser ranging principle and an optical electronic sensor principle, measuring nozzle angles and sizes of tangent circles of the quadrangular tangential injection burning boiler quickly and accurately, reducing measurement errors and guaranteeing the safety and the reliability of boiler combustion, fast to install, convenient and easy to carry, and simultaneously, nozzle angles and sizes of tangent circles can be directly displayed through a display screen on the controller.

Owner:STATE GRID CORP OF CHINA +1

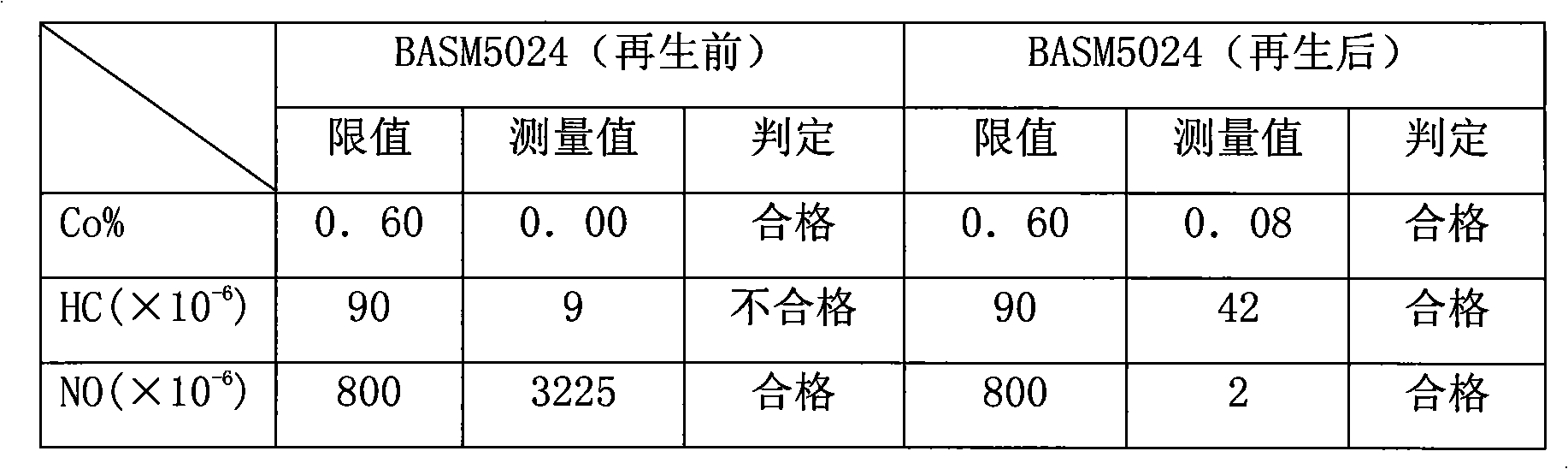

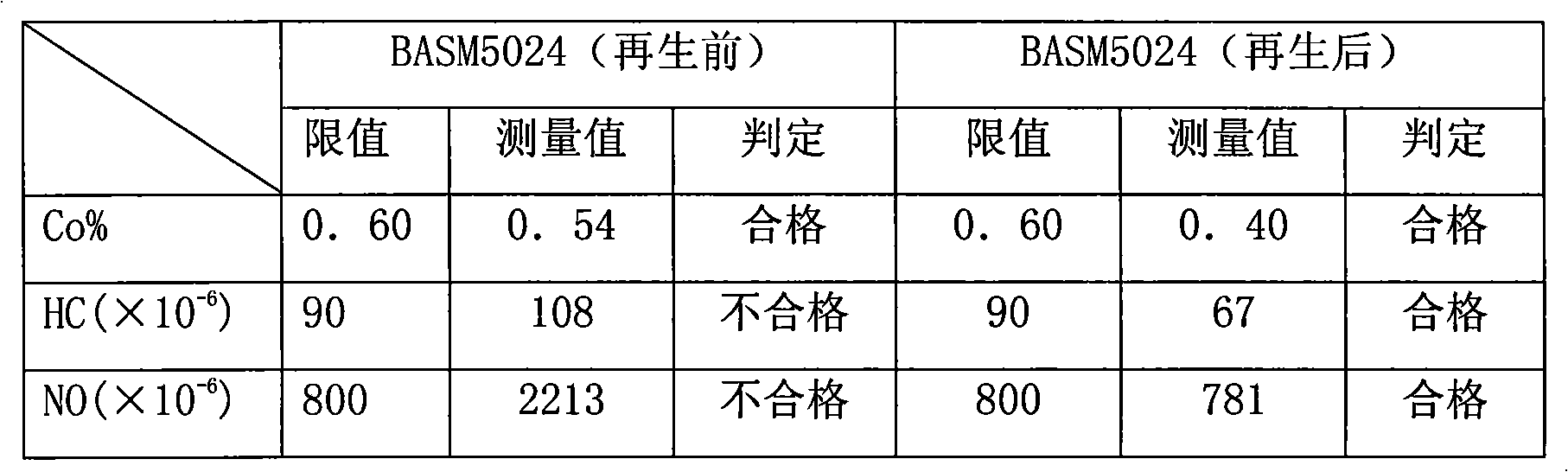

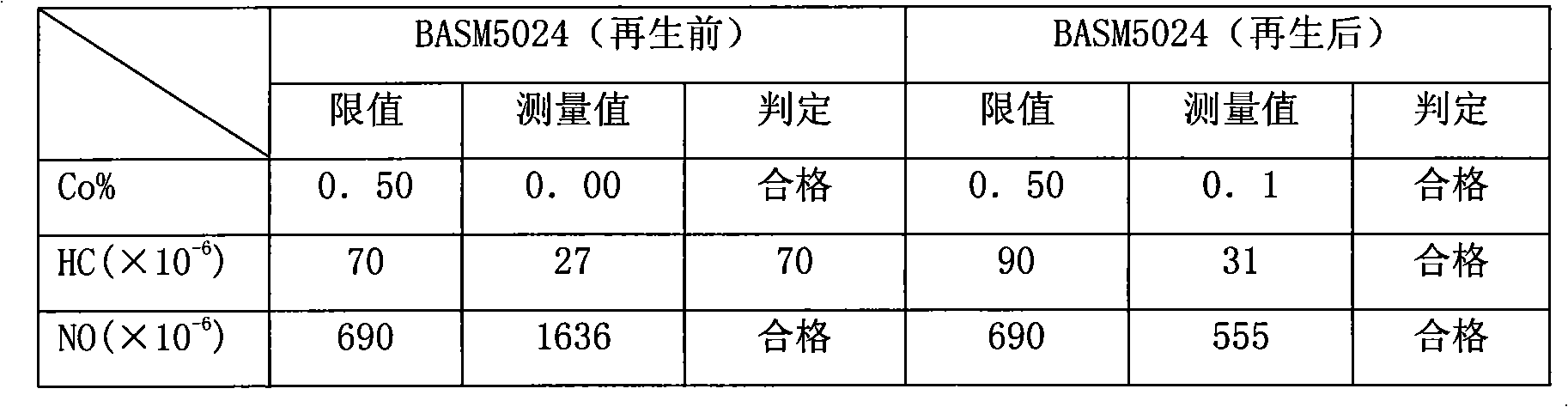

Regenerant and processing method of three-way catalytic converter of gasoline automobile

InactiveCN101884940AReduce pollutionRestore exhaust gas purification functionInternal combustion piston enginesExhaust apparatusCombustion chamberSolvent

The invention discloses a regenerant and a processing method of a three-way catalytic converter of a gasoline automobile. The regenerant comprises the following raw materials in mass percent: 0.006-0.03% of chlorine-containing solvent, 0.01-0.04% of hydrogen peroxide and 99.96-99.954% of methanol. The chlorine-containing solvent and the hydrogen peroxide in the raw materials are added into the methanol to be mixed to obtain the regenerant of the three-way catalytic converter of the gasoline automobile. The regenerant can be input into a burning chamber of an automobile engine for fully burning, then a high-temperature oxidation environment containing chlorine ions can be established in an exhaust system, the high-temperature oxidation environment can be used for removing deposited carbon and sulfur-phosphorus chemical complexes covering on the three-way catalyst in the three-way catalytic converter, and simultaneously, chlorine is replenished for the three-way catalyst which is deactivated caused by chlorine loss and grain accumulation to enable the grown grains accumulated on the surface thereof to be dispersed again, thereby realizing the regeneration of the three-way catalyst in the three-way catalytic converter.

Owner:倪初宁

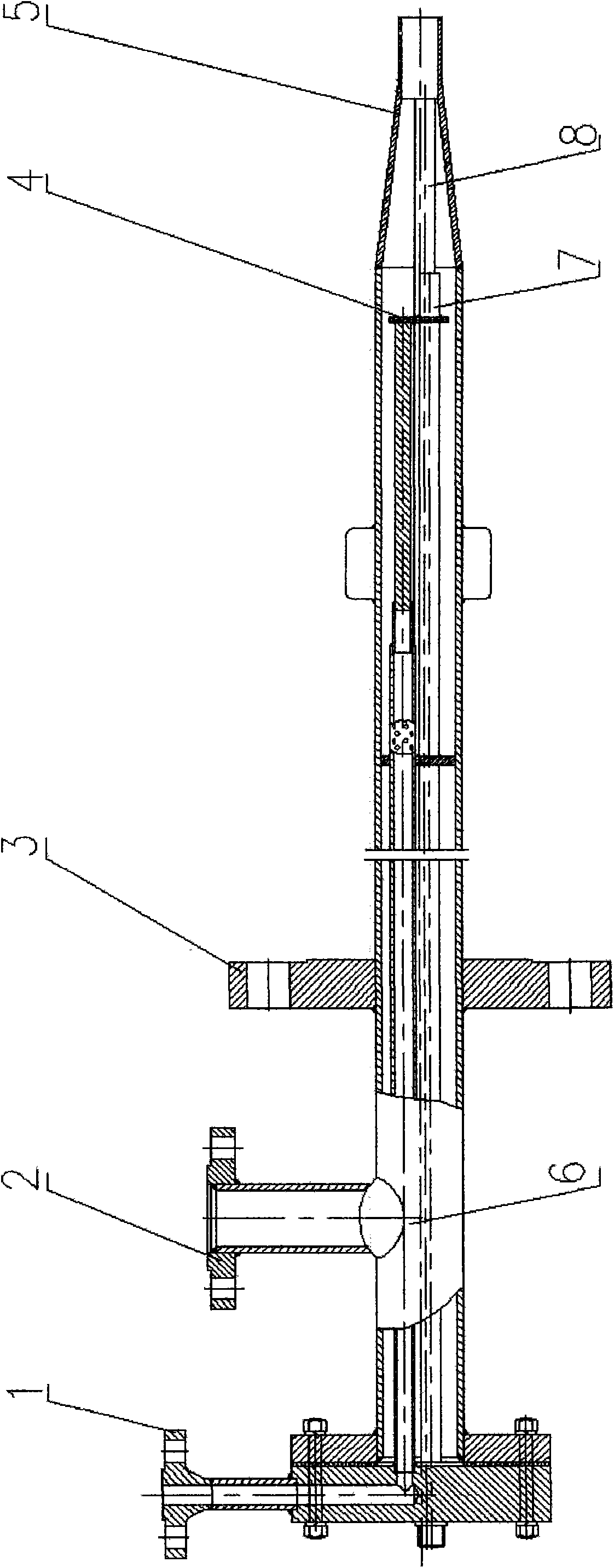

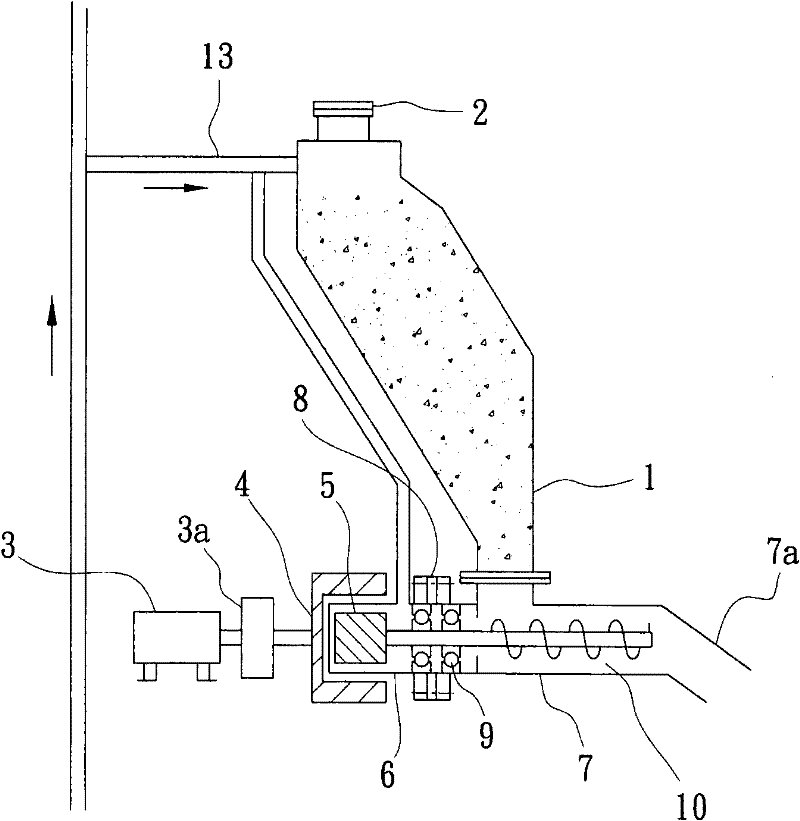

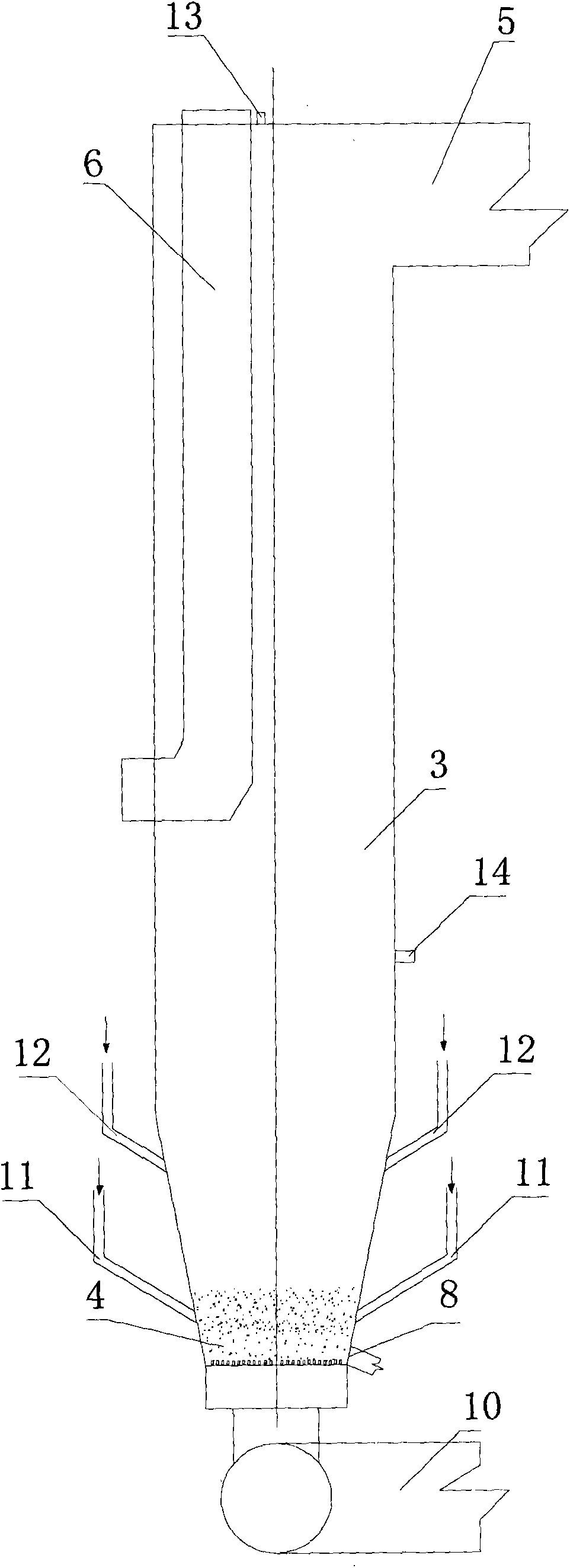

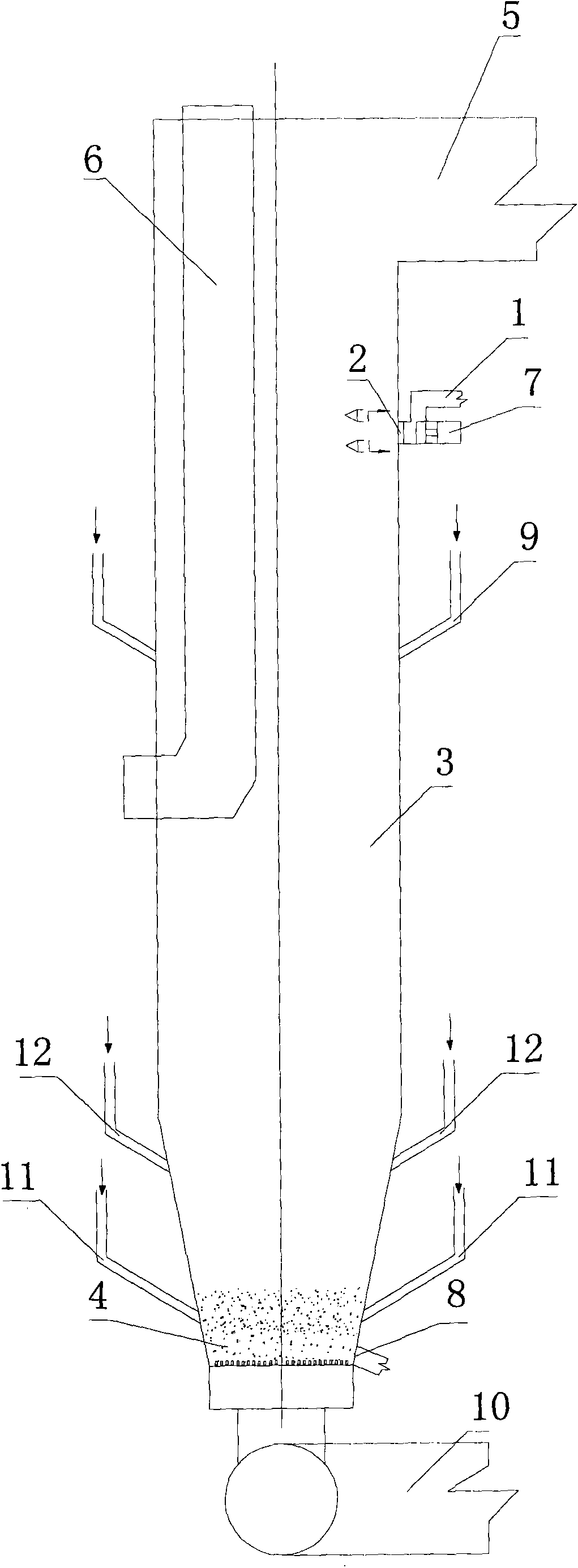

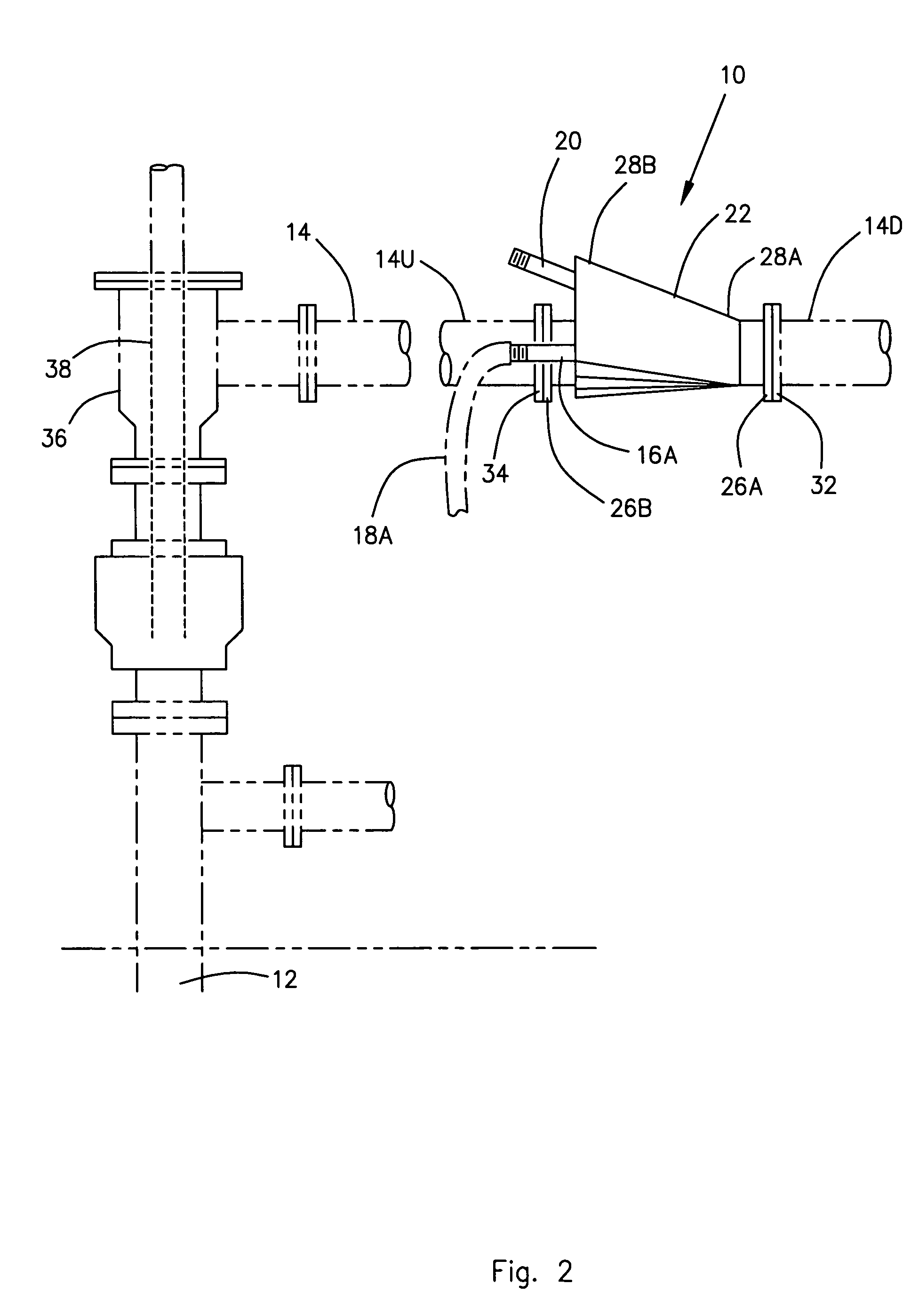

Method and device for solid fuel powder combustion and work

InactiveCN102278204APromote combustionBurning safetyGas turbine plantsTurbine/propulsion fuel controlCombustorSolid fuel

The invention discloses a powdery solid fuel combustion and work application method and a powdery solid fuel combustion and work application device. Powdery solid fuel is input into an open cycle gas turbine system for combustion by utilizing an airtight helical feeder, and enters a gas turbine to be expanded and apply work to generate power, wherein the airtight helical feeder is provided with a device which prevents a high-pressure combustion gas from being leaked outwards from a combustor along a rotating shaft of a helical fin in an airtight shell.

Owner:郭聪贤

Heat storage type vertical metal magnesium reducing furnace

InactiveCN101093140AExtended service lifeUniform temperatureCrucible furnacesControl systemEngineering

This invention relates to a Mg recovery furnace with a vertical recovery tank composed of a hearth, a roof, a wall, burners, a recovery tank, bottom storage chambers and a fan charactering in arranging several pairs of double-storage burners along the bottom of two ends on the furnace width direction, forming storage chamber1 and 2 on the bottom of the two ends, installing two directional valves at either end, the directional valves, the storage chamber 1 and 2 and the fan are connected with a directional control system by exterior pipelines, applying a vertical mode to arrange the recovery tank in the hearth and feeding from the top and discharging from the bottom, which costs less energy, temperature in the furnace is the uniform and burning mode is exclusive.

Owner:宁夏华源冶金实业有限公司 +1

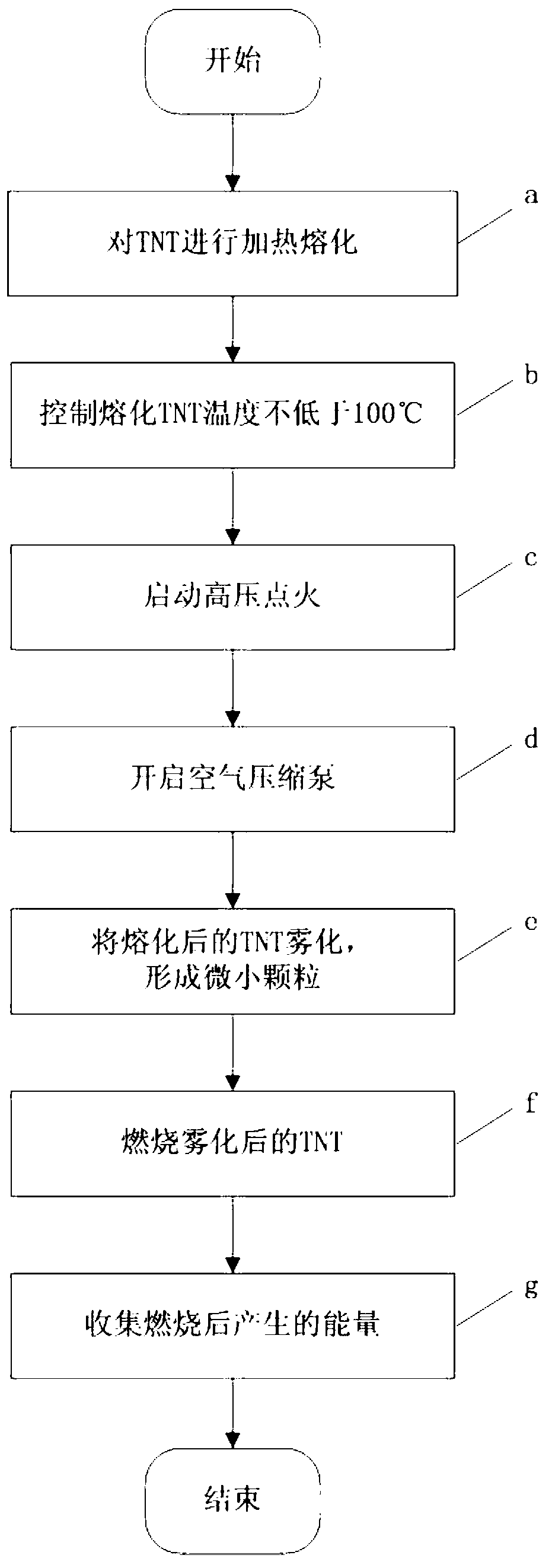

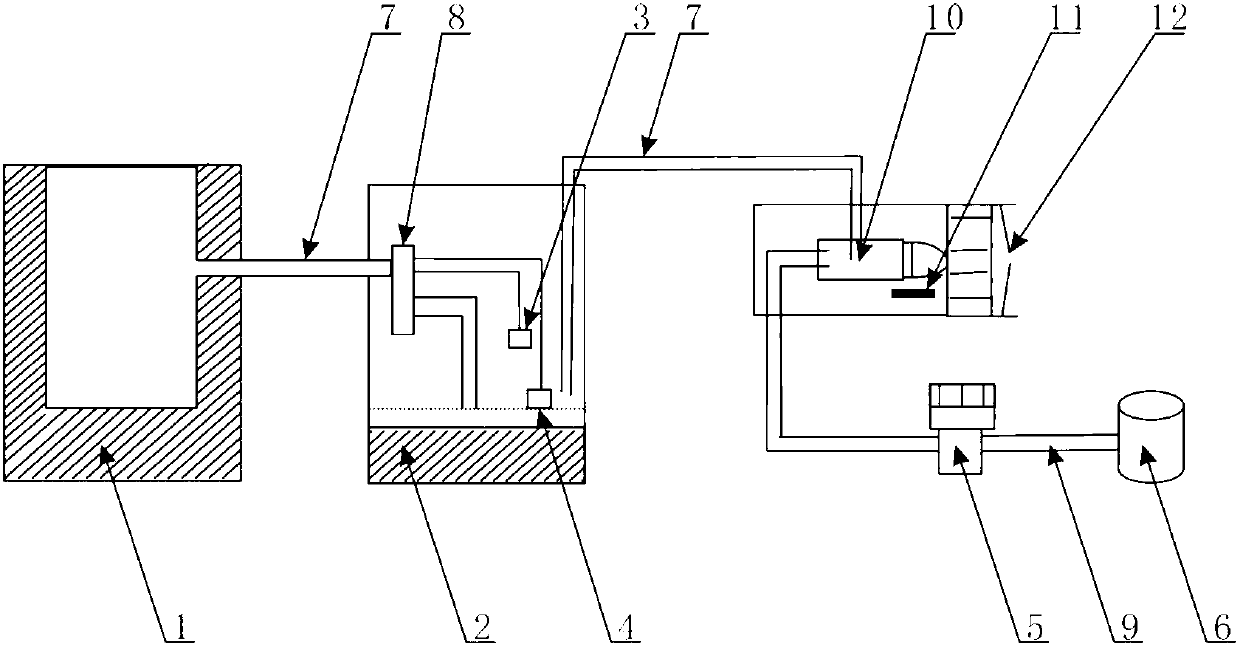

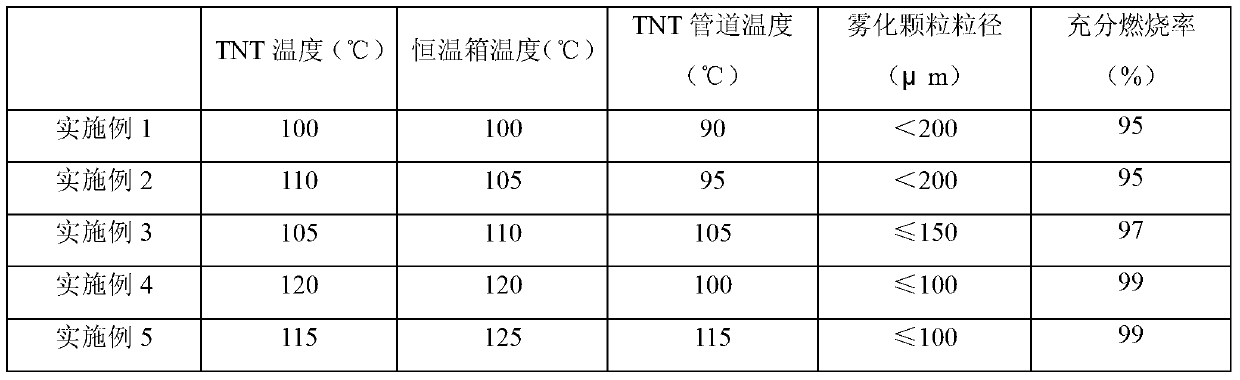

Method and device for melting, atomization and combustion of TNT

The invention discloses a method for melting, atomization and combustion of TNT. The method for melting, atomization and combustion of the TNT comprises the following steps of (1) carrying out heating and melting on the TNT, (2) controlling the temperature of the melted TNT to be no smaller than 100DEG C, (3) starting high-pressure ignition, (4) starting an air compressor pump, (5) carrying out atomization on the melted TNT to form micro particles, (6) carrying out combustion on the atomized TNT, and (7) collecting produced energy after combustion. In addition, the invention discloses a device for melting, atomization and combustion of the TNT. The device for melting, atomization and combustion of the TNT comprises a melting box, the air compression pump and an air atomization nozzle, wherein the melting box is connected with the air atomization nozzle through a TNT pipeline, the air compression pump is connected with the air atomization nozzle through a gas pipeline, and an ignition device is arranged outside the air atomization nozzle. The method and device for melting, atomization and combustion of the TNT can achieve efficient and clean combustion of the TNT. Due to the fact that ignition is carried out before atomization of the TNT, the fact that combustion can be timely, safely and reliably carried out on the atomized TNT can be ensured. The energy obtained through combustion is recycled, and the purpose of saving energy and the purpose of protecting the environment can be achieved.

Owner:郝俊修

High-temperature-resistant and corrosion-resistant conveying belt and preparation method thereof

PendingCN111154191AEasy to prepareHigh preparation efficiency and yieldBuilding insulationsCorrosion resistantEther

The invention provides a high-temperature-resistant and corrosion-resistant conveying belt. The high-temperature-resistant and corrosion-resistant conveyor belt is prepared from, by weight, 15-25 parts of fluorinated phosphazene rubber, 100 parts of ethylene-propylene-diene monomer rubber, 5-10 parts of polyisoprene, 10-15 parts of 3,3-diphenylacrylonitrile / [2-(triethoxysilyl)ethyl]vinyl ether / allyl 1H,1H-heptafluorobutyl ether / propenyl adamantyl triazine copolymer, 10-20 parts of black phosphorene, 1-4 parts of asphalt powder, 10-20 parts of zircon powder, 1-3 parts of a coupling agent, 1-2 parts of an initiator and 0.5-1.5 parts of a vulcanizing agent DTDM. The invention further provides a preparation method of the high-temperature-resistant and corrosion-resistant conveying belt. The high-temperature-resistant and corrosion-resistant conveying belt is excellent in high-temperature resistance, flame retardance and wear resistance, remarkable in corrosion resistance effect, good in fatigue resistance, impact resistance and aging resistance, high in mechanical strength, good in performance stability, long in service life, safe during combustion and environmentally friendly.

Owner:浙江环能传动科技有限公司

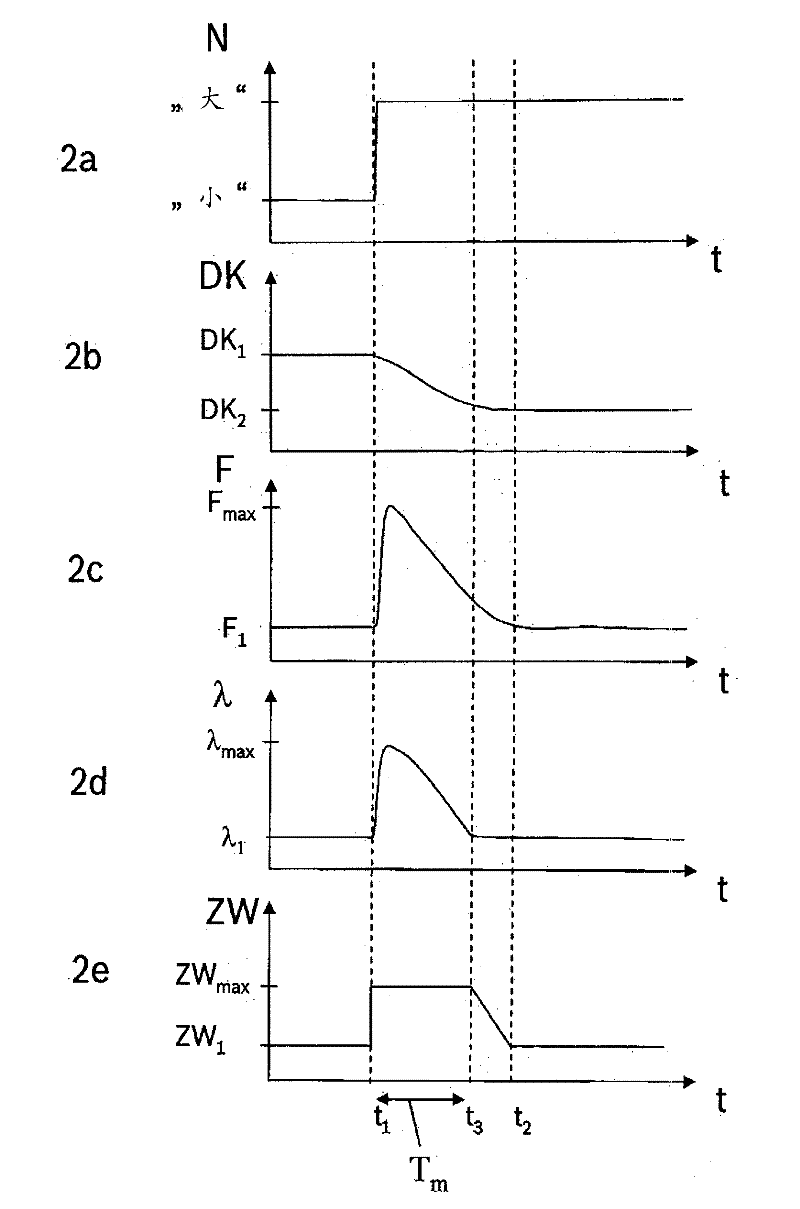

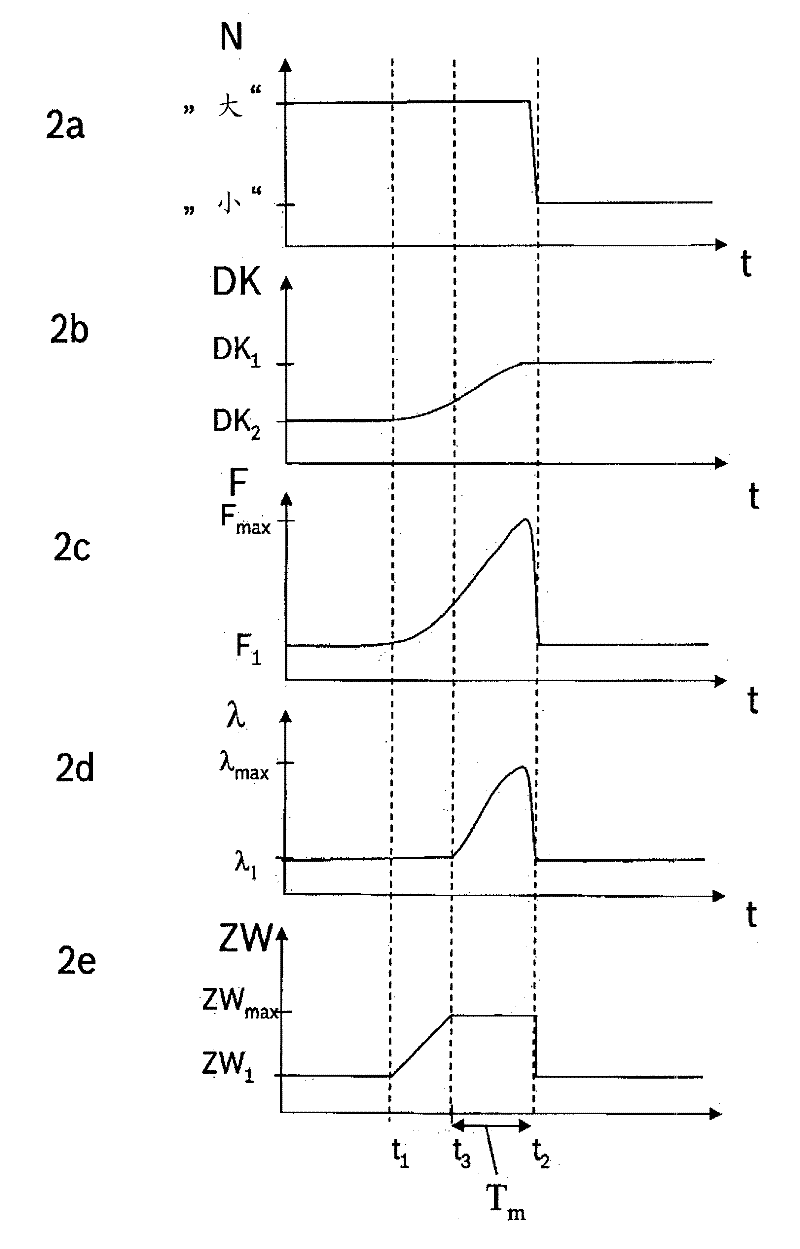

Method and device for controlling an internal combustion engine

InactiveCN102269074AEmission reductionShort lean phaseElectrical controlInternal combustion piston enginesExternal combustion engineInlet valve

The method involves changing a switching phase of a stroke (200) and an inlet valve (160) i.e. butterfly valve, of a valve stroke changing device (220) with lean-burn phase when air-fuel ratio exhibits a value larger than one and a firing angle exceeds a maximum firing angle. A filling change device (100) is controlled such that filling at beginning of the switching phase and filling at end of the switching phase are equal. The filling change device changes size of the filling according to valve position. Independent claims are also included for the following: (1) an electrical memory medium comprising a computer program for controlling torque curve of a lean executable internal combustion engine (2) a control and / or regulating device for controlling torque curve of a lean executable internal combustion engine.

Owner:ROBERT BOSCH GMBH

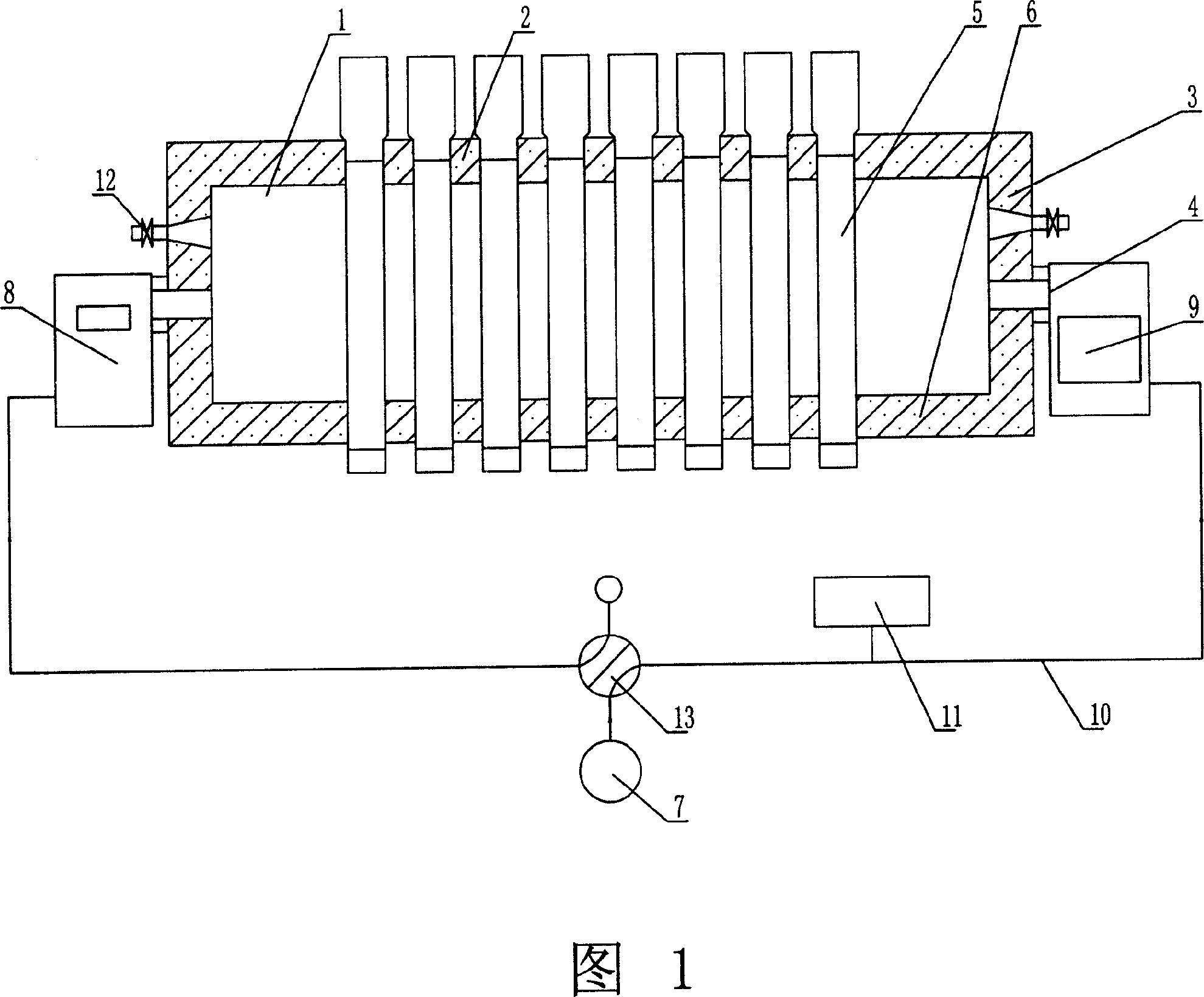

Method for coal slime combustion of circulating fluidized bed boiler

InactiveCN103697467AGood dispersionEasy to burn throughFluidized bed combustionApparatus for fluidised bed combustionAir volumeCombustion

The invention discloses a method for coal slime combustion of a circulating fluidized bed boiler. A cellular coal slime pipe orifice is designed to split a stream of coal slime into a plurality of streams, and is positioned below an outlet of a hearth and in the upper part of the hearth in a height direction, the coal slime is horizontally thrown by a reciprocating mechanism leaning against a coal slime pipe section after entering the hearth of the boiler, a layer of upper primary air is arranged on the upper part of the hearth, the thickness of a material layer is properly regulated and controlled to be 450mm to 550mm during the running of the boiler, the volumes of primary air and secondary air are properly regulated and controlled to ensure that the oxygen content of flue gas is 2 to 3 percent, and the negative pressure of the flue gas at the outlet of the hearth is regulated and controlled to be 0 to 50Pa. The method has the advantages that the coal slime flow is prevented from getting close to the outlet of the hearth and a screen type heated surface, the point of fall of the coal slime flow is prevented from being close to a deslagging hole, the concepts of low air volume, low oxygen content, low hearth outlet negative pressure, proper material layer thickness and the like are used for guiding running and regulation, and the operation method is innovative.

Owner:BEIJING XINGQIAO INT ENG TECH

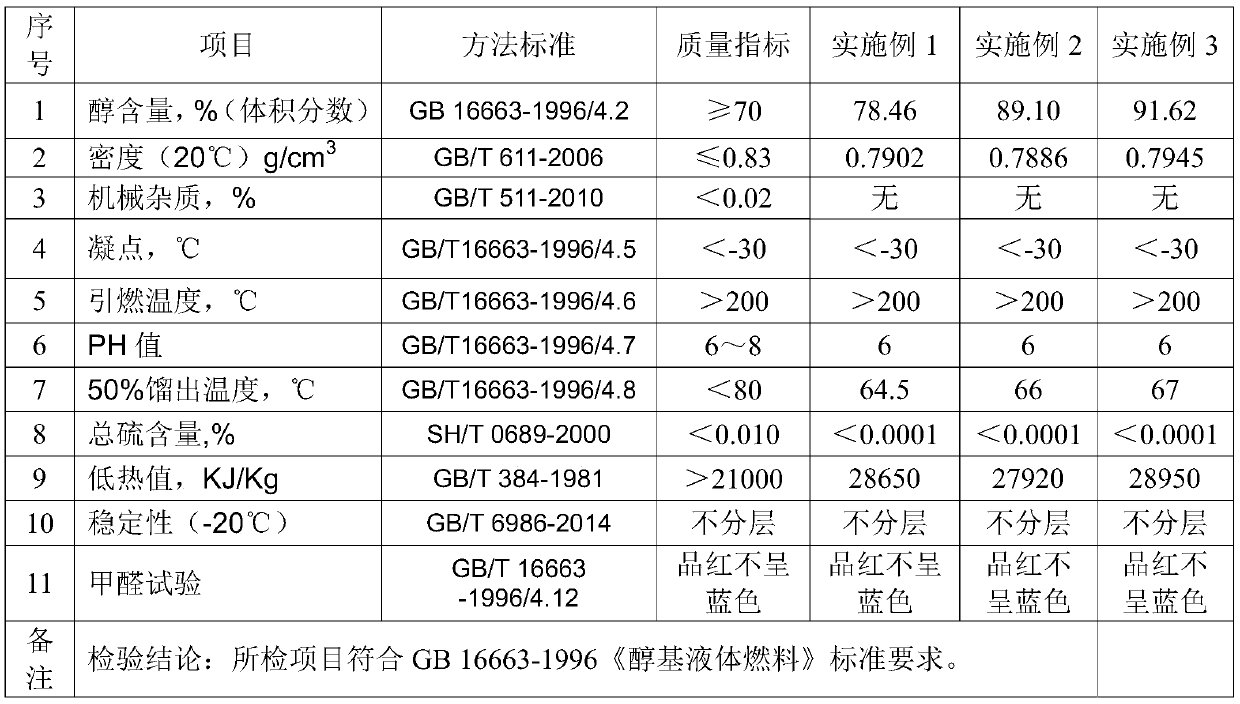

High-energy alcohol-based liquid fuel and preparation method thereof

PendingCN110003959ATransparent and clear textureGood miscibilityLiquid carbonaceous fuelsFuel additivesAlcoholHigh energy

The invention discloses a high-energy alcohol-based liquid fuel and a preparation method thereof, and belongs to the technical field of alcohol-based liquid fuels. The high-energy alcohol-based liquidfuel comprises an alcohol-based liquid, an auxiliary fuel and a composite additive. The preparation method comprises the following steps: compounding and blending a plurality of chemical raw materials to form the composite additive, compounding and denaturing the alcohol-based liquid with the composite additive, and blending with the matched high-energy stable auxiliary fuel to prepare the high-energy alcohol-based liquid fuel with a high combustion efficiency, a high calorific value, strong power, a good intersolubility, a low energy consumption and a low pollution discharge. The preparationmethod of the high-energy alcohol-based liquid fuel has the advantages of simplicity, no large devices, safe production process, no environmental pollution and wide sources of the raw materials; andthe product has the advantages of safety in storage and transportation, fullness in combustion, high effective heat value, reduction of air pollution, effectiveness in alleviation of energy shortage,great social and economic benefit, suitableness for large-scale quantitative production, and universal promotion values.

Owner:刘安平 +2

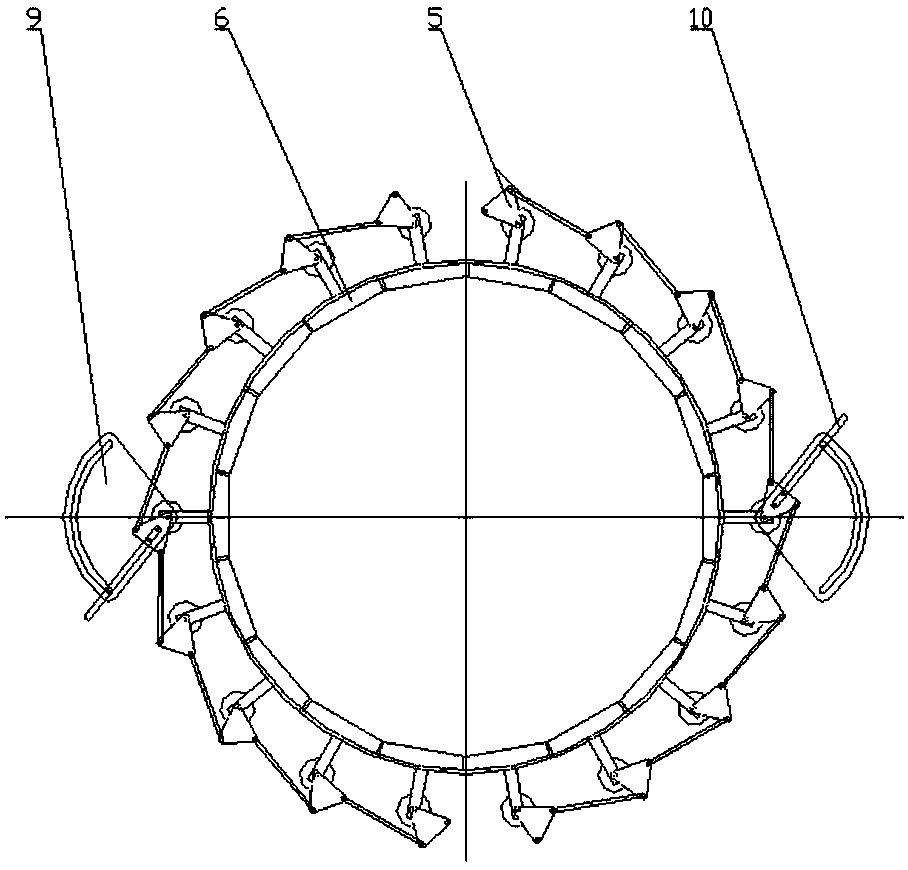

Device for preventing burner nozzle from bonding slag, with axial adjustable blades

PendingCN108167823ADecreased swirl intensityIncrease swirl intensityCombustion apparatusIndirect carbon-dioxide mitigationCombustorBoiler furnace

The invention discloses a device for preventing a burner nozzle from bonding slag, with axial adjustable blades. The device comprises a precombustion chamber, a burner body and a furnace, wherein theouter wall of the precombustion chamber is provided with remote over-fire air ducts distributed annually, and the burner body communicates with an inlet of the precombustion chamber; a nozzle of the precombustion chamber and outlets of the remote over-fire air ducts communicate with a boiler furnace; and the remote over-fire air ducts are internally provided with a plurality of axial blades used for regulating the swirling intensity of remote over-fire air, and the outer wall of each remote over-fire air duct is provided with a linkage regulating device which is composed of an angle regulatinghandle, a dial, a linkage device and a transmission device and used for regulating the angle of the axial blades. The device can be used for preventing the burner nozzle from bonding the slag, and the safe, efficient and stable combustion in the furnace is ensured.

Owner:XI AN JIAOTONG UNIV

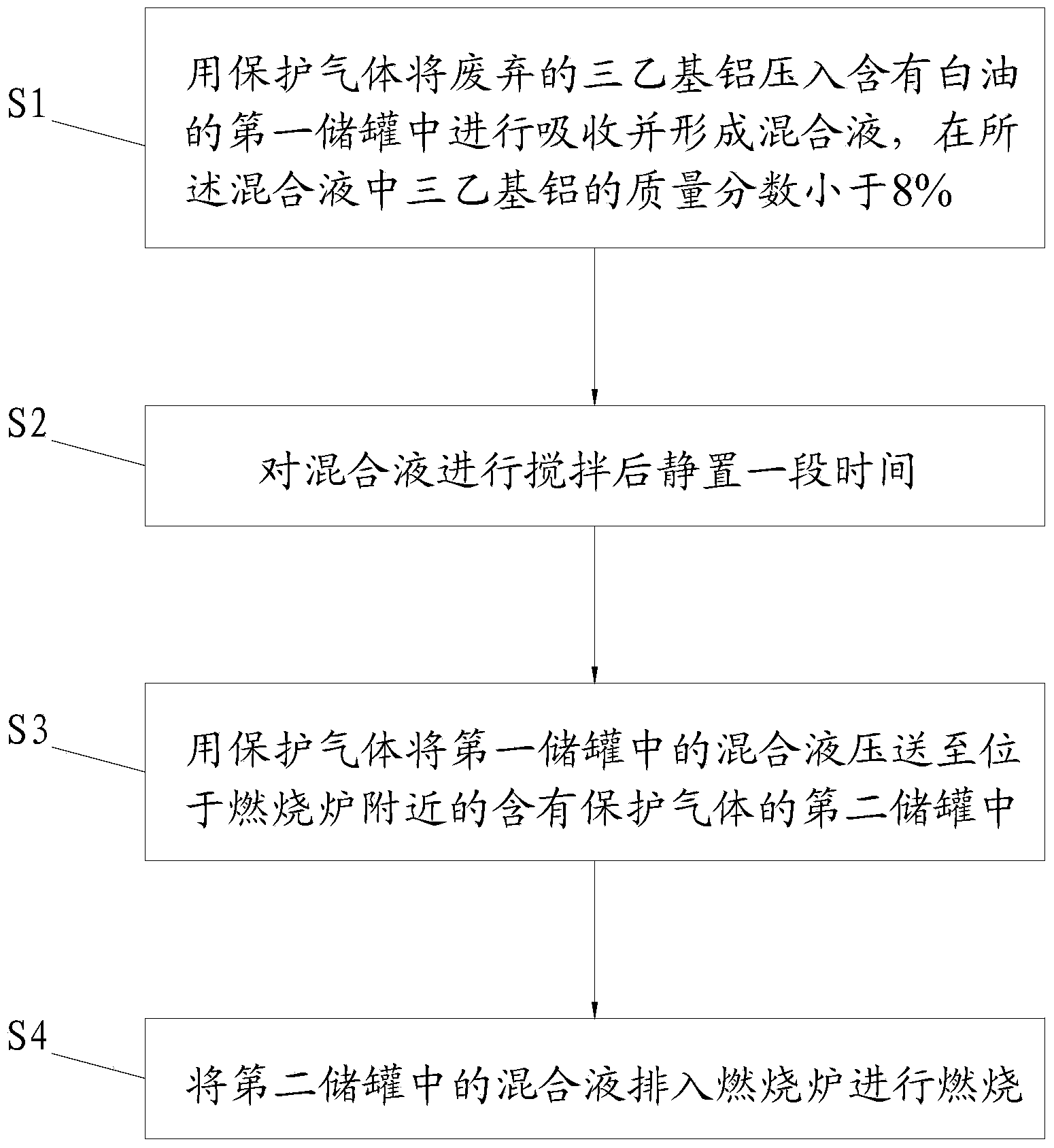

Method for treating waste triethyl aluminum

The invention discloses a method for treating waste triethyl aluminum. The method comprises the following steps: S1, pressing waste triethyl aluminum to a first storage tank with white oil by protection gas, and absorbing waste triethyl aluminum to form a mixed solution, wherein the mass percent of waste triethyl aluminum in the mixed solution is less than 8%; S2, stirring the mixed solution and standing for a period of time; S3, pressing the mixed solution in the first storage tank to a second storage tank with the protection gas near a combustion furnace by the protection gas; S4, discharging a mixed solution in the second storage tank to the combustion furnace for combusting. The method has the benefits that triethyl aluminum is absorbed through the white oil to obtain diluted triethyl aluminum for guaranteeing the safety of a triethyl aluminum transport process; the protection gas is adopted as a gas pressure source in the transport process, so that triethyl aluminum can be prevented from reacting with air; diluted triethyl aluminum is completely combusted in the combustion furnace, the combustion process is safe, carbon dioxide generated in combustion is harmless, and aluminum oxide generated after the combustion is discharged together with slag and fly ash.

Owner:福建省环境工程有限公司

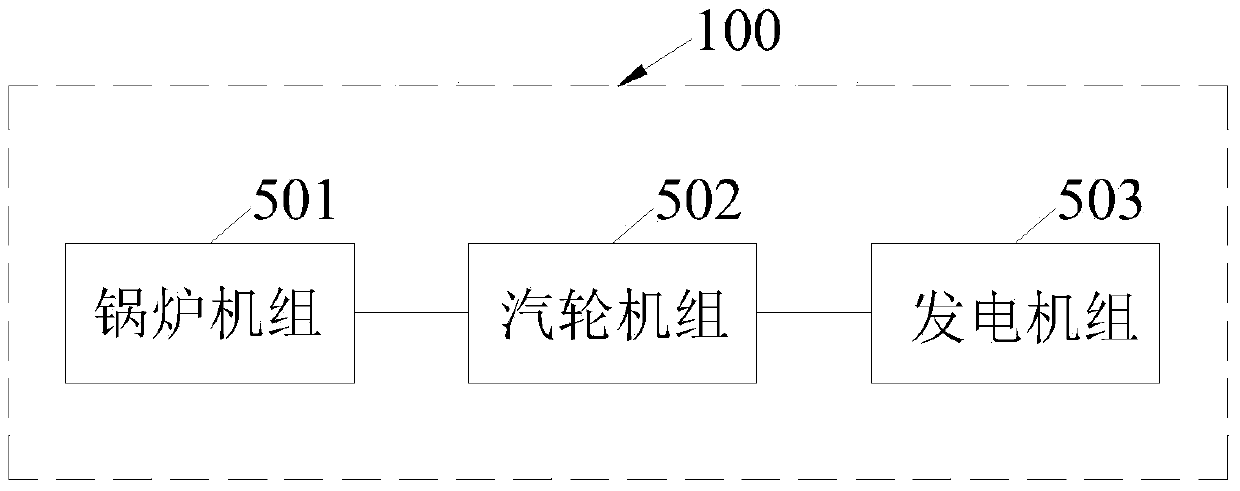

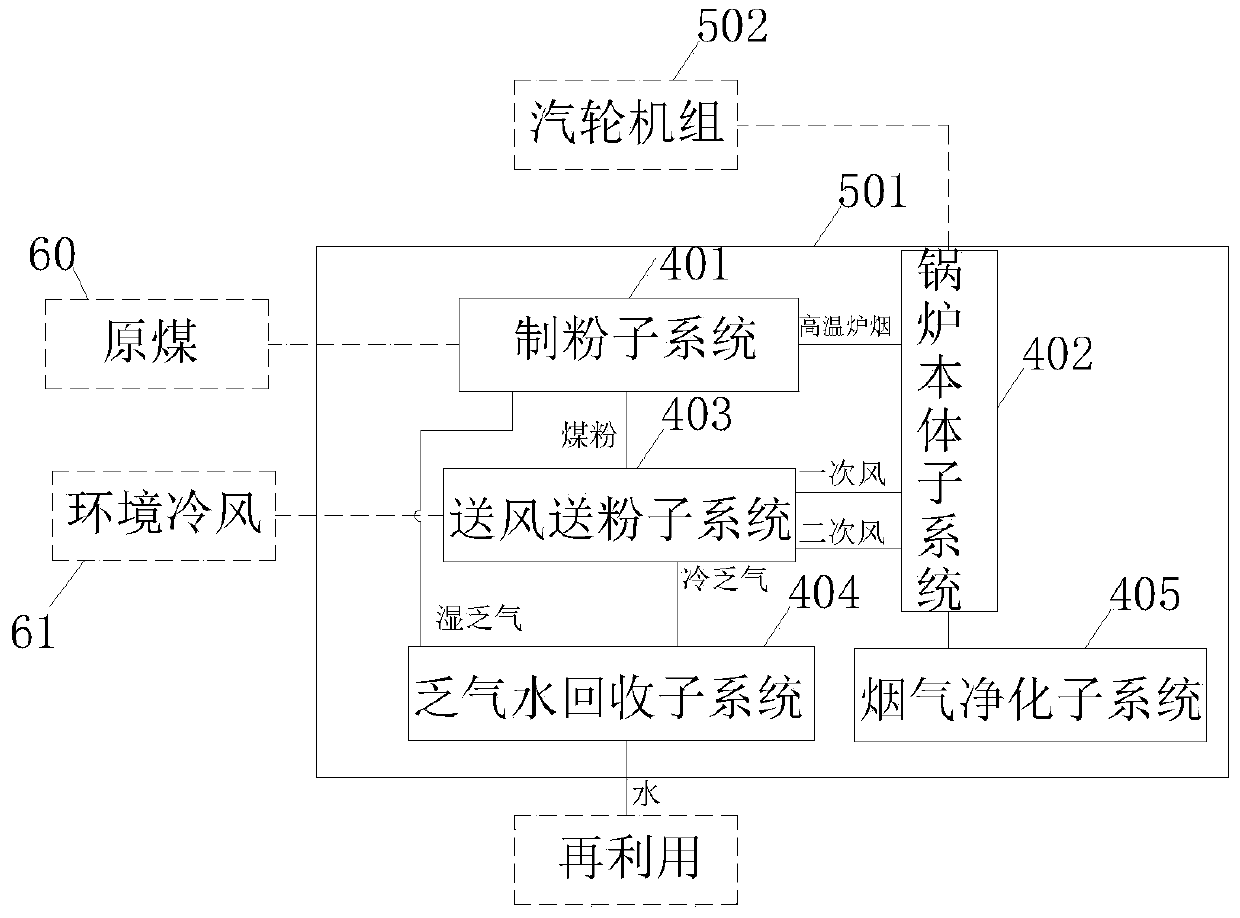

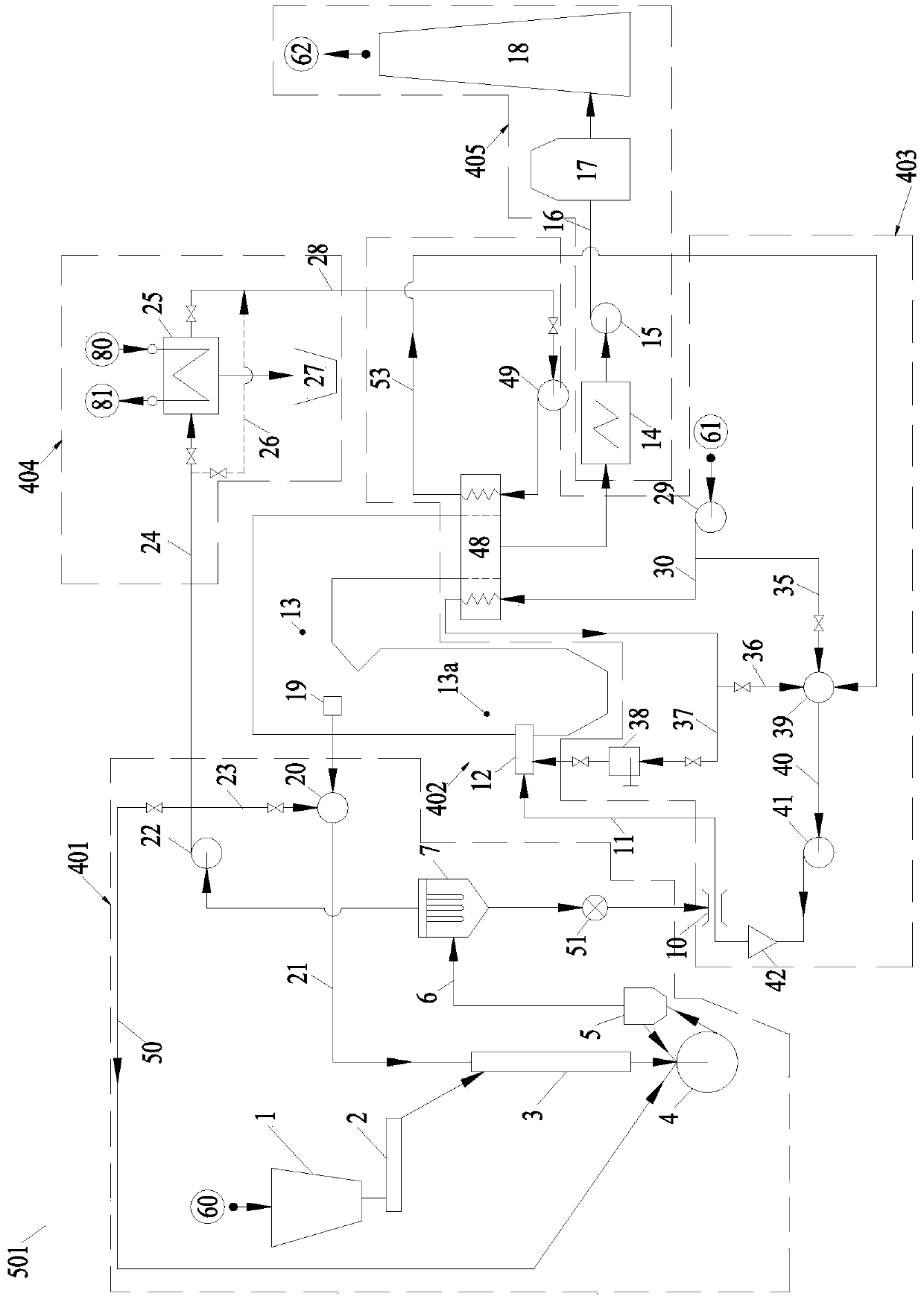

Fume-dried closed pulverization coal-fired boiler unit with function of exhaust water recovery

InactiveCN104197362AHigh implementabilityCost-effective recyclingIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionCold airThermodynamics

The invention provides a fume-dried closed pulverization coal-fired boiler unit with a function of exhaust water recovery. The fume-dried closed pulverization coal-fired boiler unit is characterized in that a weighing coal feeder weighs coal fed into a boiler and performs adjustment control, an air-locking powder feeder is provided, a drier mixing chamber is connected with a fume suction opening and a gas outlet of a pulverized coal collector and allows a first part extracted from exhaust and a part of fume extracted from the fume suction opening to be mixed into drier which is fed to a raw coal pre-drying device, an exhaust water recovery device cools high-humidity exhaust discharged by a pulverization subsystem so as to obtain a great deal of condensate and discharge cold exhaust, an air exhaust preheater heats a part of ambient cold air into hot air and heats the cold exhaust into hot exhaust, a part of the hot air, the other part of the ambient cold air and the hot exhaust are mixed into primary air, an air-powder mixer mixes the primary air and pulverized coal into air-powder mixture, and the other part of the hot air is used as secondary air directly supplied to a pulverized coal burner.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +2

Combustion system and combustion method

InactiveCN105202537ASimple systemSimple methodCombustion using catalytic materialNon-combustible gases/liquids supplyCombustion systemHydrogen

The invention relates to a combustion system, which comprises a hydrogen reaction tank, a mixed burner, a methanol tank, a working boiler, a steam header and a start-up boiler, wherein the hydrogen reaction tank is connected with the mixed burner through a hydrogen-contained steam pipe, the methanol tank is connected with the mixed burner through a methanol intake pipe, the mixed burner is mounted in match with the working boiler, the working boiler is connected with the steam header through a steam freeing pipe, the steam header is connected with the hydrogen reaction tank through a steam circulating pipe, the steam circulating pipe is provided with a three-way valve, and the three-way valve is connected with the start-up boiler through the steam intake pipe. The combustion system adopts two types of combustible mediums for mixed combustion, and is safe, energy-saving and environment-friendly; the defects that the calorific value of methanol is low, the combustion is insufficient, the energy utilization is not high and the like are favorably solved by fully atomizing the methanol through high-temperature hydrogen-contained steam, meanwhile, hydrogen is not needed to be stored and transported, and is used as soon as hydrogen is produced, so safety and reliability are realized; the combustion system has enormous value for industrial production and use and popularization.

Owner:耿烽

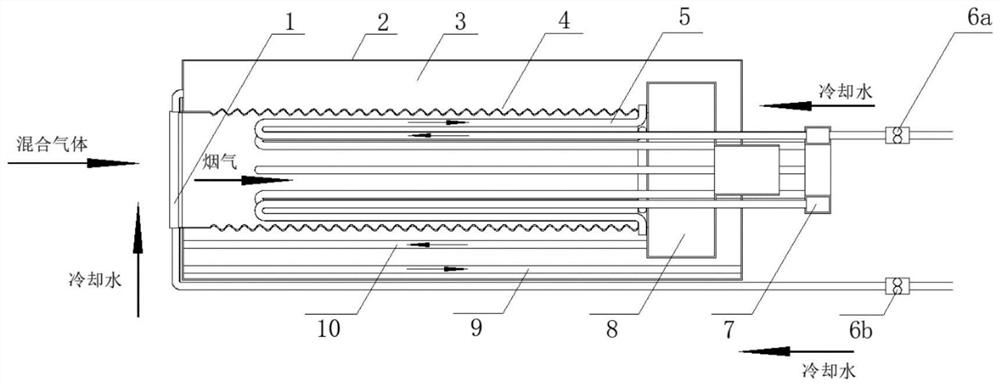

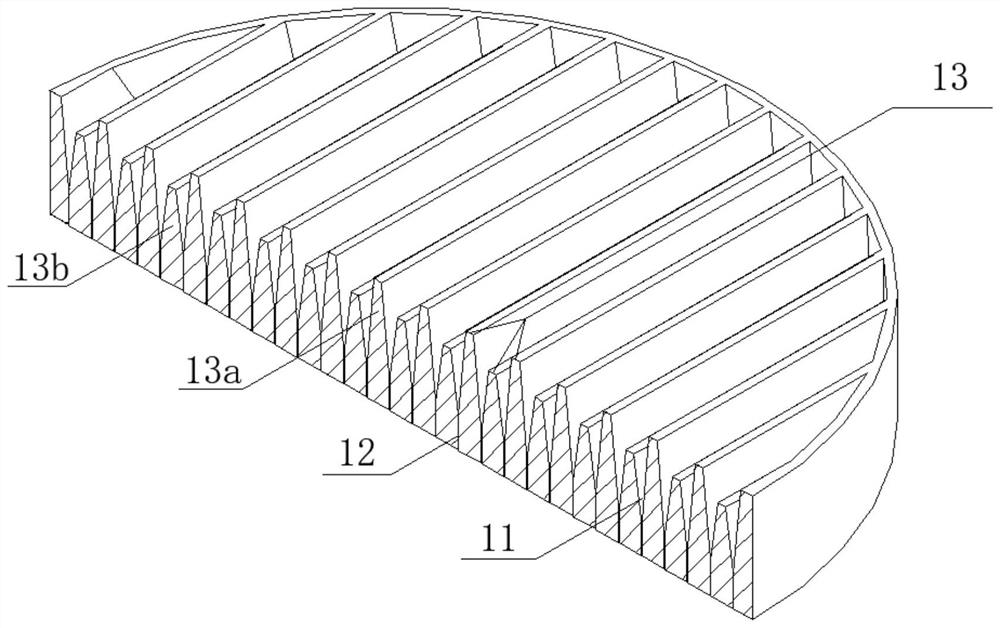

Regeneration type radiant tube gas combustor for medium-low-heat-value fuel gas

PendingCN108397770AIncrease the effective heat transfer areaEquilibrium heat equivalentIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorFlue gas

The invention provides a regeneration type radiant tube gas combustor for medium-low-heat-value fuel gas. According to the regeneration type radiant tube gas combustor, fuel gas inlets and air inletscommunicate with fuel gas channels, the fuel gas channels extend into a radiant tube, central ignition rods are arranged in the fuel gas channels, one ends of the central ignition rods are connected to sparking plugs arranged on combustion devices, the other ends of the central ignition rods are connected to ignition electrodes arranged in the fuel gas channels, disc-shaped nozzles and combustioncylinders are arranged in the radiant tube, the disc-shaped nozzles are arranged at outlets of the fuel gas channels, flue gas cavities are formed between the fuel gas inlets and the end part of the radiant tube, tubular heat exchangers are further arranged between the fuel gas inlets and the end part of the radiant tube, dividing wall type regenerators are arranged on the outer sides, extending into the radiant tube, of the fuel gas channels, and regenerator bodies fill between the dividing wall type regenerators and the inner side of the radiant tube. The regeneration type radiant tube gas combustor has the advantages that the fuel gas channels adopt tubular heat exchanger+dividing wall type regenerator structures, so that the effective heat exchange area can be increased, double preheating of air and the fuel gas can be achieved, the thermal equivalent is balanced, especially for medium-low-heat-value fuel gas, and the preheating effect can be better.

Owner:赵升智 +1

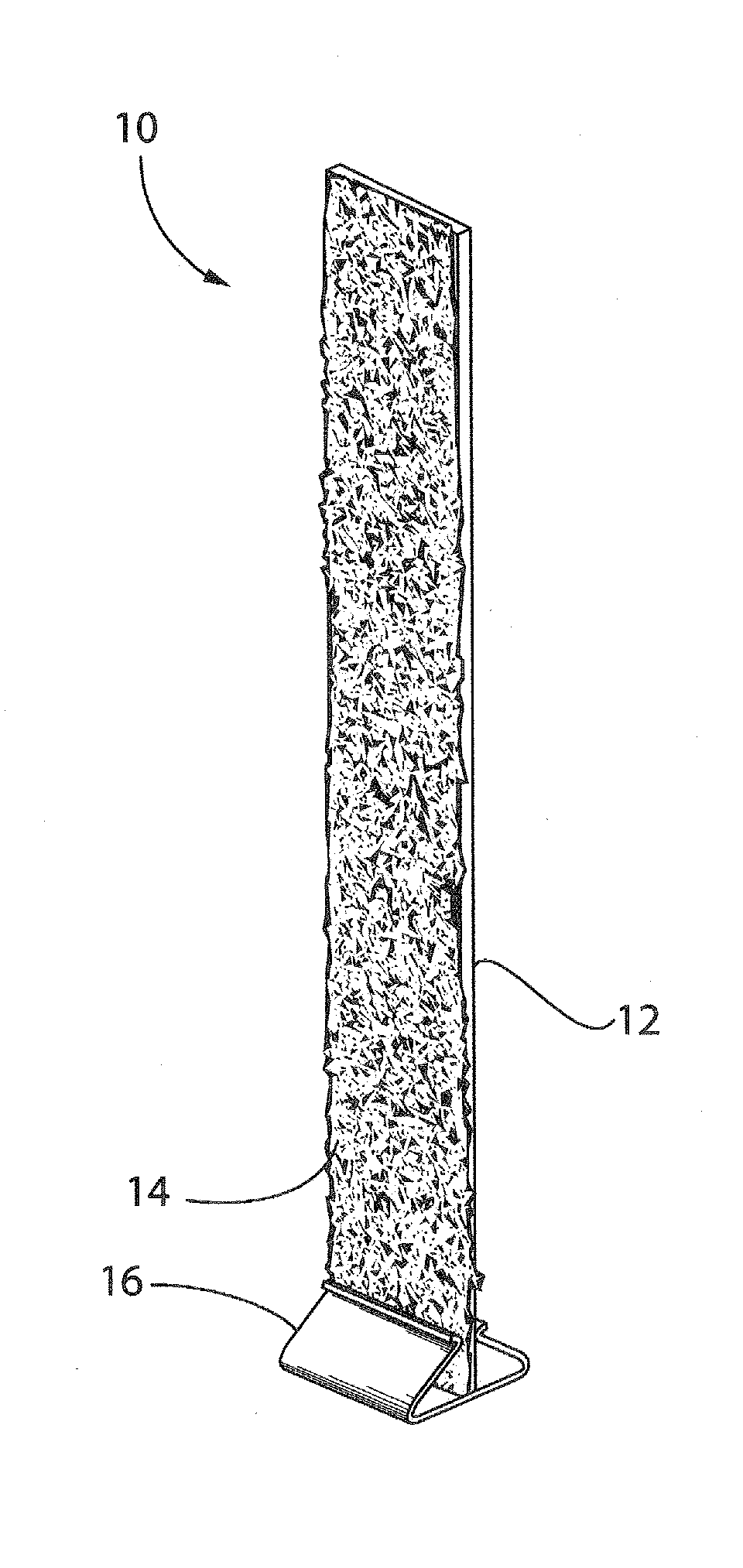

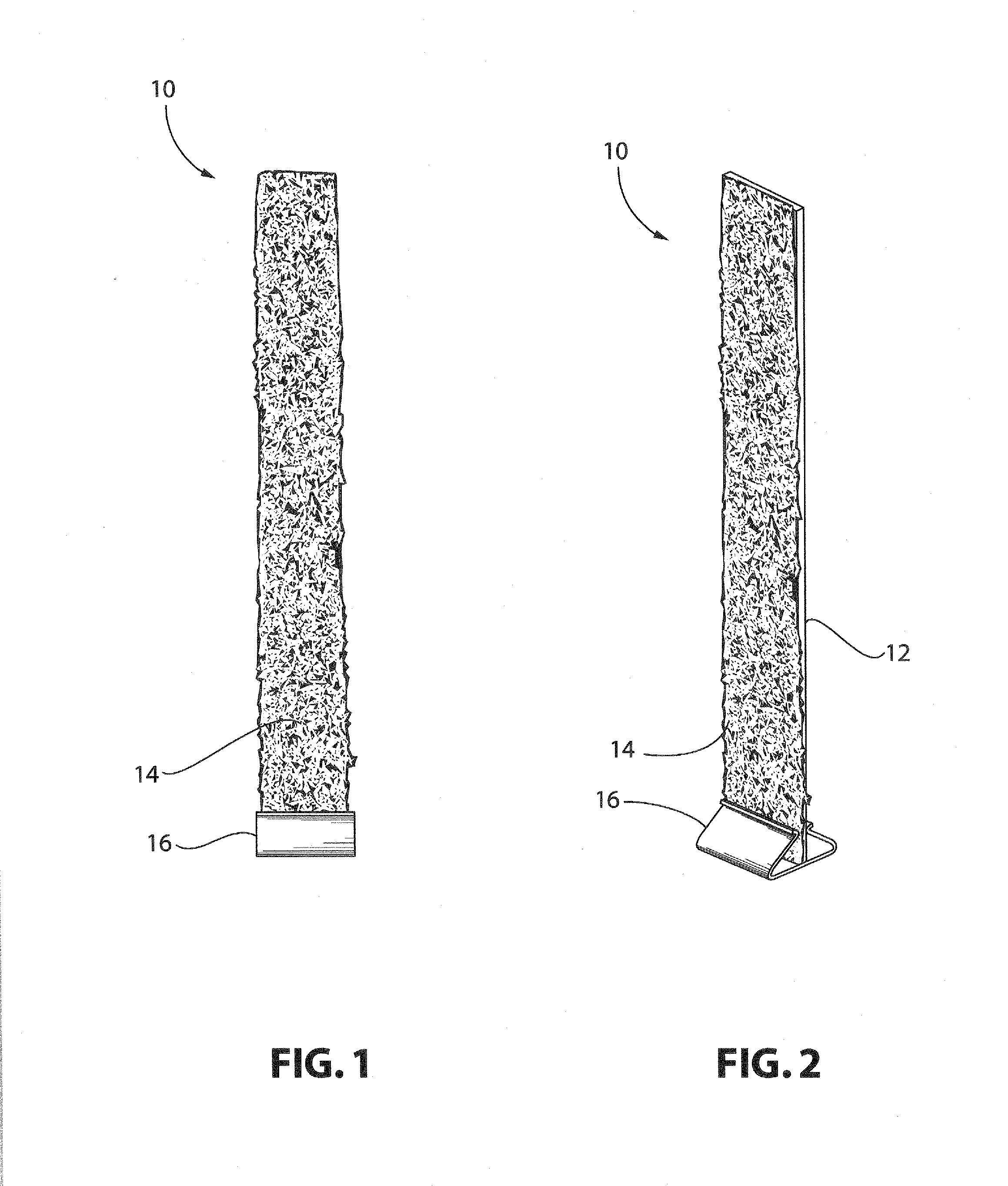

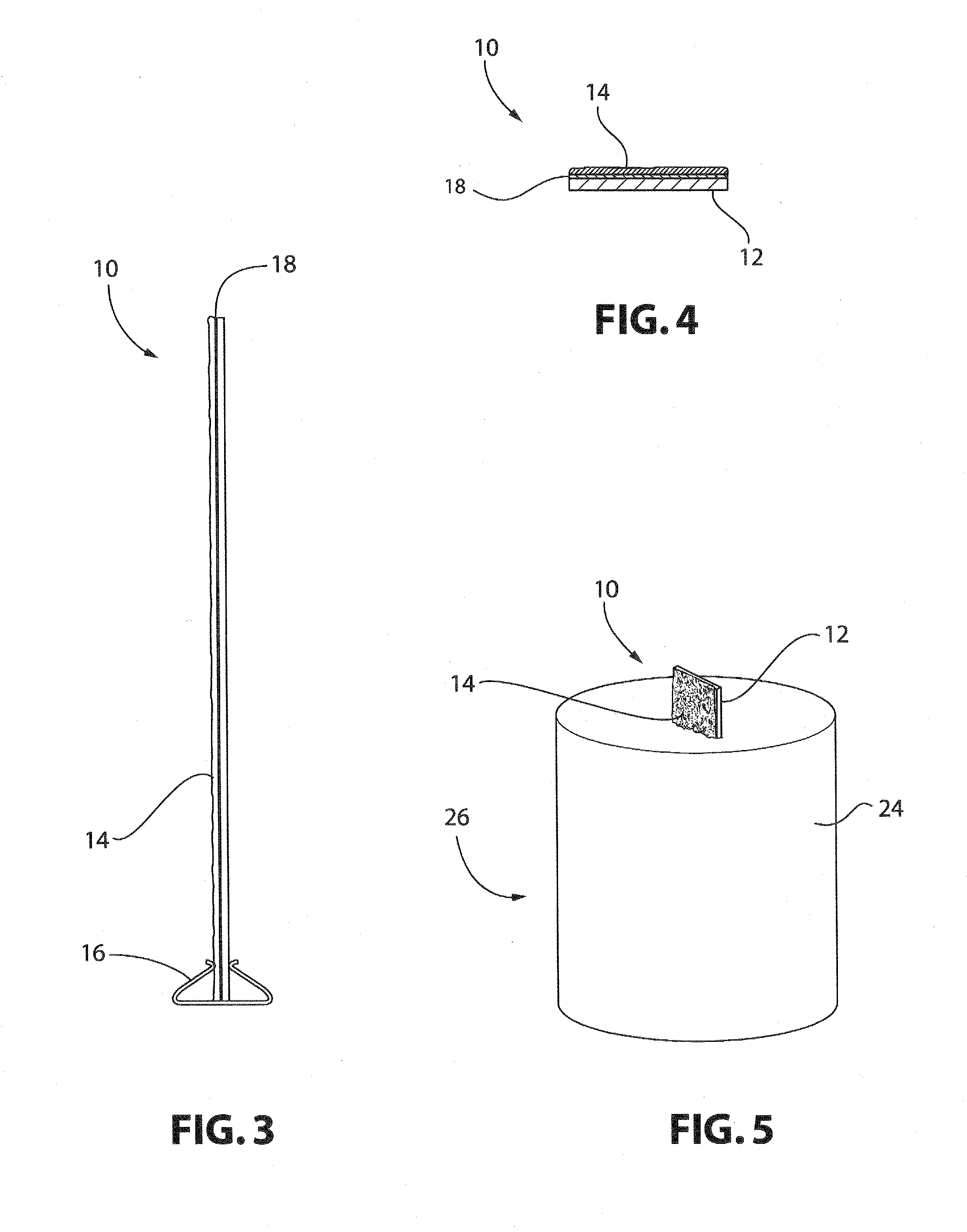

"Wood Wick Coated With Shavings"

ActiveUS20160272922A1Safely meltBurning safetyPretreated surfacesCapillary burnersCandle wickMedicine

Wood coated planar candle wick is disclosed. The wood wick comprises a planar body, and a shaving adhered to at least one side of the planar body.

Owner:DEL COTTO MELYNDA S

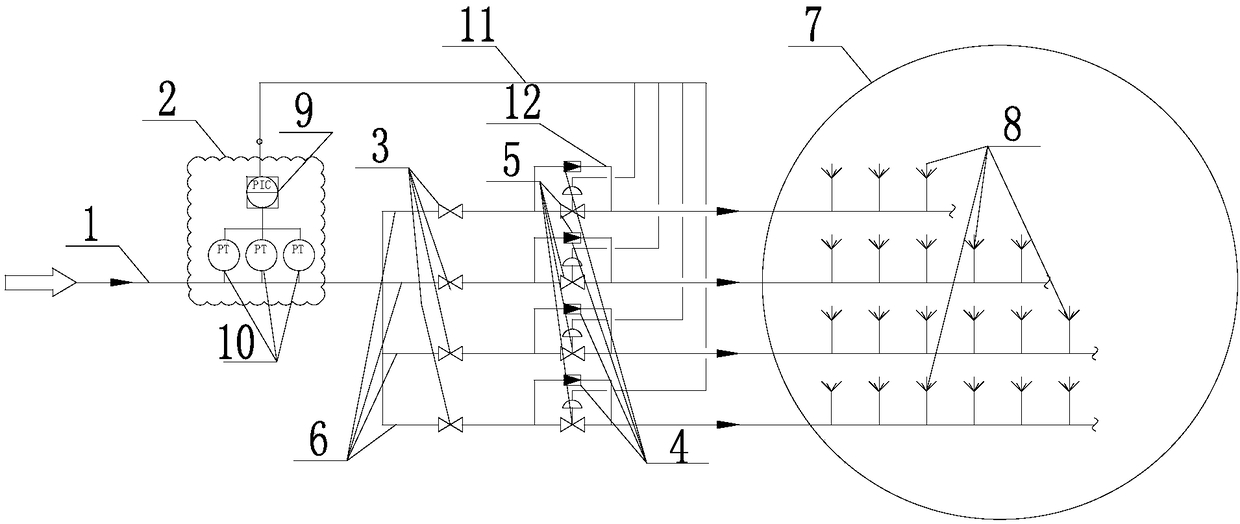

Ground torch grading emission control device and method

The invention discloses a ground torch grading emission control device and method. The ground torch grading emission control device comprises an empty main pipe, a grading emission system, a grading control system, a burner and a ground torch combustion furnace, wherein one end of the grading emission system communicates with a main pipeline, the other end of the grading emission system communicates with the burner, the grading control system communicates with the grading emission system and the main pipeline, and the burner is arranged in the ground torch combustion furnace. According to theground torch grading emission control device, the mutual effect of all levels of emission systems can be avoided, smokeless combustion can be realized under the pressure, automatic switching can be realized when any level fails, and the safety is high.

Owner:SINOPEC GUANGZHOU ENG +1

Surge device for air drilling

A surge device providing a vent for bleeding pressure off an air drilled well and providing connectors for surge lines in the blooie line. The surge device has a hollow, abrasion resistant, tapered chamber into which two surge lines and the blow down line enter the surge device. The device is provided with a flange at each end of the chamber for attaching the device into a blooie line with the narrow end of the tapered chamber attached to the downstream end of the blooie line and an enlarged end of the tapered chamber attached to the upsteam end of the blooie line. An abrasion resistant shield pipe penetrating the enlarged end of the tapered chamber and extending into the tapered chamber a sufficient distance to serve as a shield for the terminal ends of the surge lines and the blow down line.

Owner:FINCHUM RAY A

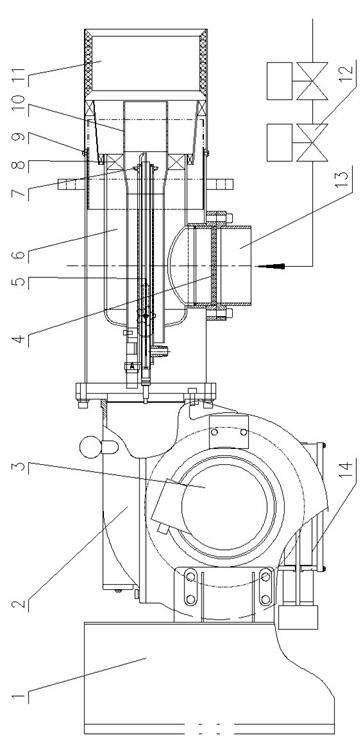

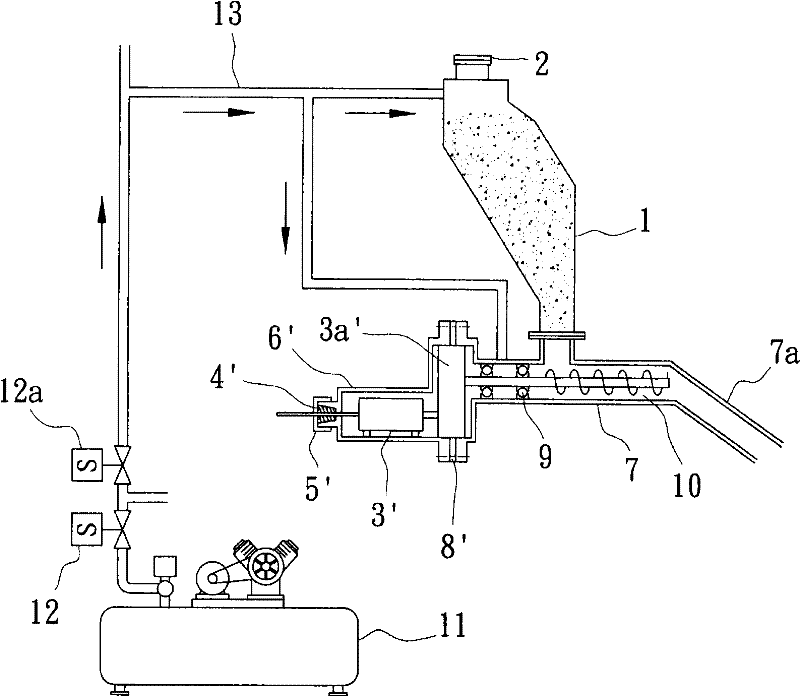

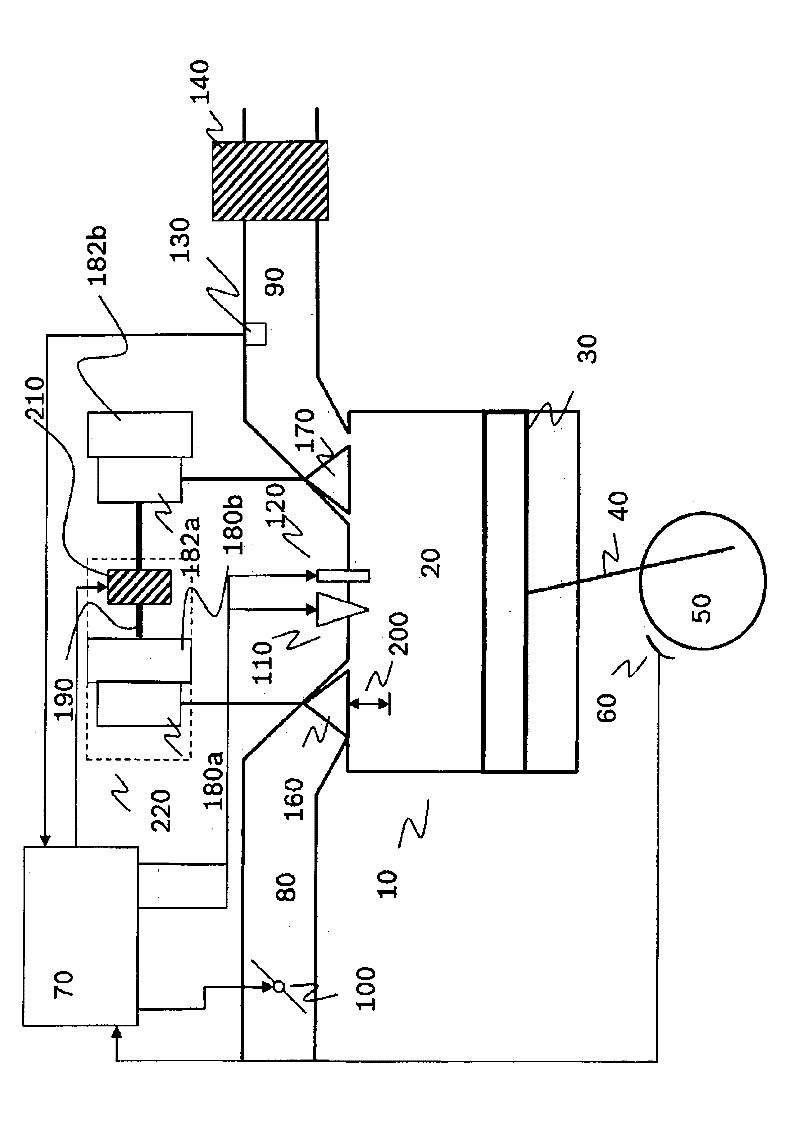

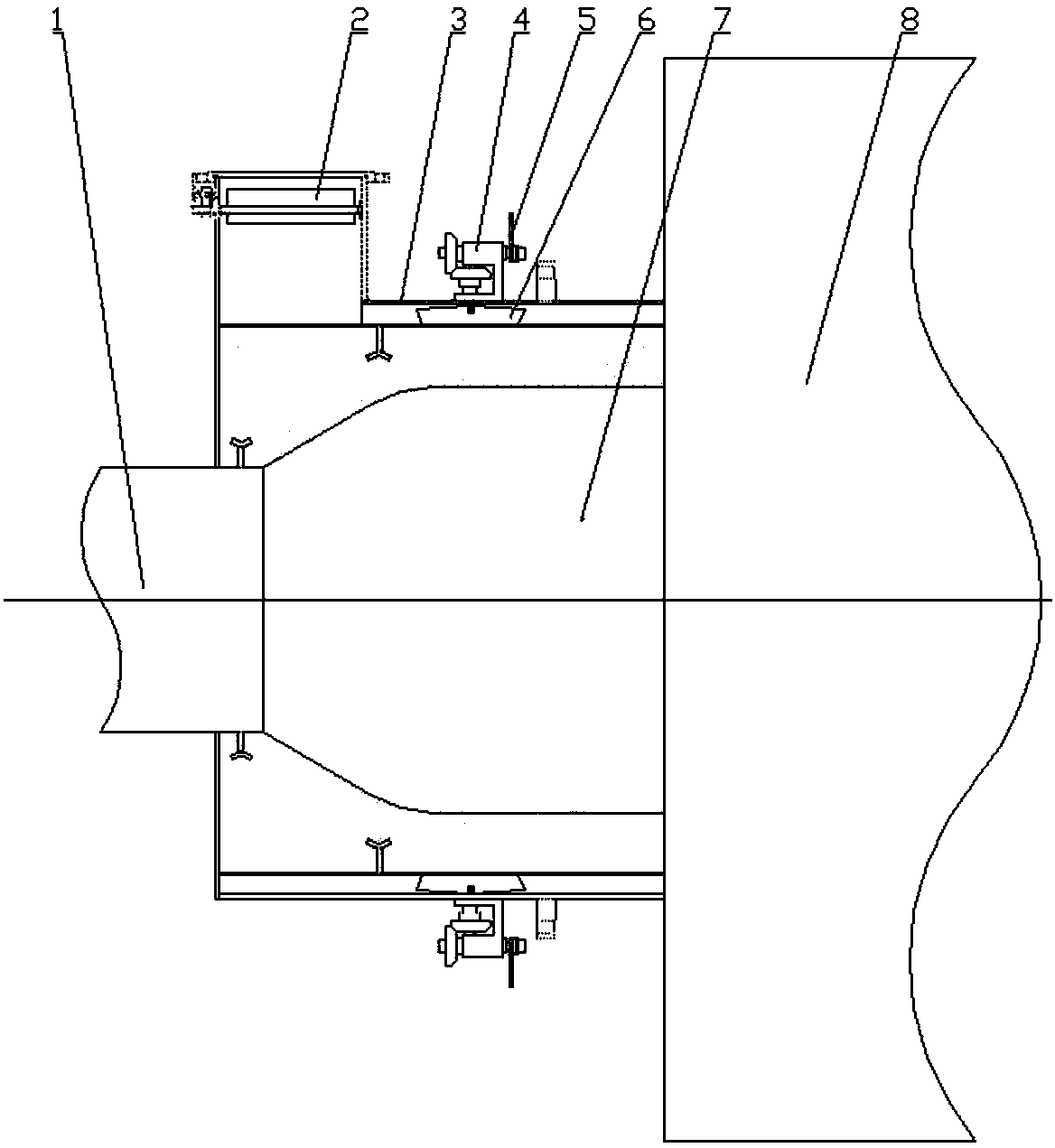

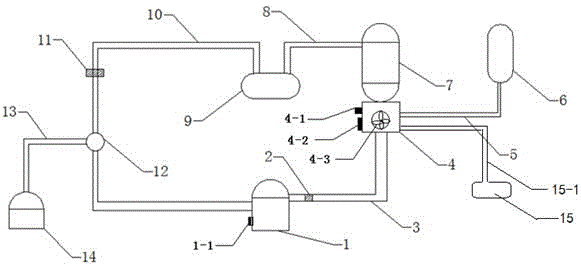

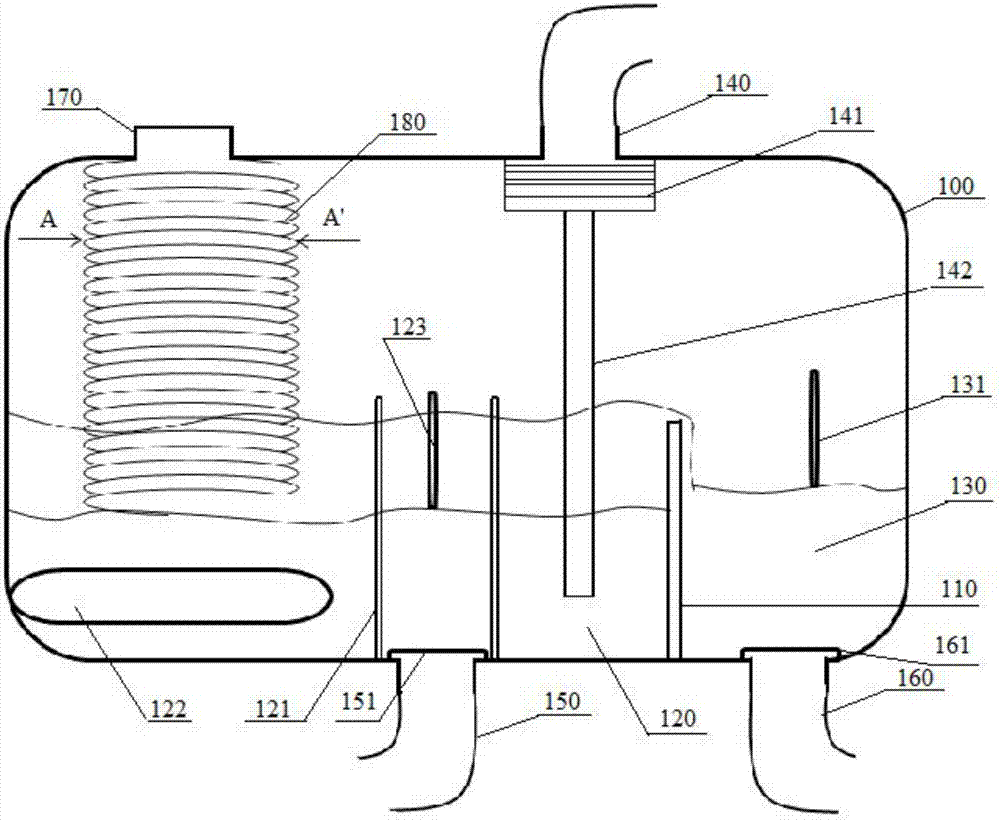

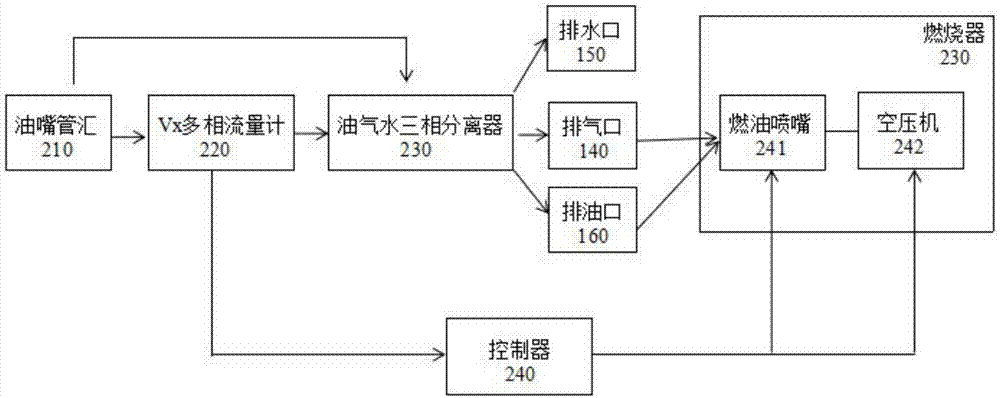

Three-phase separator, oil and gas well testing and measuring system and combustion control method of oil and gas well testing and measuring system

ActiveCN107355208ASimple structureReduce volumeFuel supply regulationSurveySpray nozzleEnvironmental geology

The invention discloses a three-phase separator. The three-phase separator comprises a shell body, an overflowing baffle, a gas outlet, liquid outlets, a gas-liquid inlet and a classification rotating blade, wherein a separating cavity is defined by the shell body, the overflowing baffle is arranged in the separating cavity and divides the separating cavity into a first cavity body and a second cavity body, and the height of the overflowing baffle can be adjusted; the gas outlet is formed in the top of the shell body, the liquid outlets comprise a water outlet and an oil outlet which are formed in the bottoms of the first cavity body and the second cavity body correspondingly, and the gas-liquid inlet is formed in the upper portion of the shell body; and the classification rotating blade is arranged below the gas-liquid inlet, communicates with the gas-liquid inlet and goes deep into the inner portion of the first cavity body. According to the three-phase separator, the structure is simple, operation is convenient, and the separating efficiency is high. The invention further provides an oil and gas well testing and measuring system and a combustion control method thereof. A Vx multiphase flowmeter is adopted, the surface flow rate of underground sample liquid is simply and rapidly measured, by using the three-phase separator, the underground sample liquid is separated efficiently, finally, the size of a fuel nozzle of a PID control combustor and the pressure of air compressed by an air compressor are blurred, and combustion treatment is more sufficient and safer.

Owner:CHINA FRANCE BOHAI GEOSERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com