Method for treating waste triethyl aluminum

A technology of triethylaluminum and mixed liquid, which is applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of hidden safety hazards, high processing costs, and unsatisfactory processing methods, and achieve the safety of the combustion process and the prevention of reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

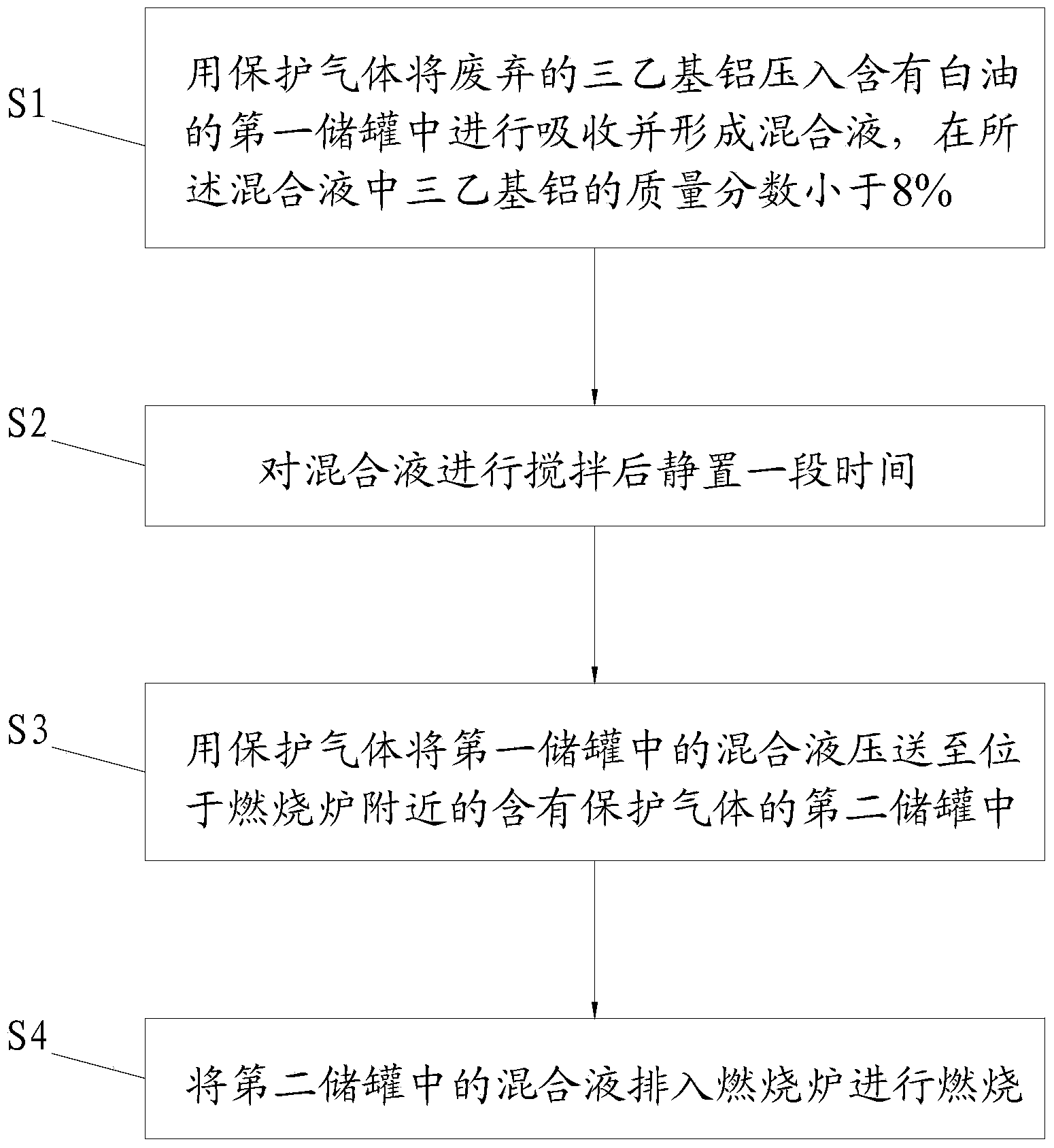

[0014] see figure 1 , figure 1 Shown is the first implementation method of the present invention, comprising steps:

[0015] S1. Use a protective gas to press the discarded triethylaluminum into the first storage tank containing white oil for absorption and form a mixed solution, in which the mass fraction of triethylaluminum is less than 8%;

[0016] S2, after stirring the mixed solution, let it stand for a period of time;

[0017] S3, using the protective gas to hydraulically send the mixture in the first storage tank to the second storage tank containing the protective gas located near the combustion furnace;

[0018] S4. Discharging the mixed liquid in the second storage tank into the combustion furnace for combustion.

[0019] Considering that when the mass fraction of triethylaluminum absorbed in the white oil exceeds 15%, the mixture of the two has a certain flash point, and the higher the concentration of triethylaluminum, the lower the flash point of the mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com