Combustion system and combustion method

A combustion system and burner technology, applied in the combustion method, combustion type, combustion equipment and other directions, can solve the problems of low calorific value of methanol, insufficient combustion, low energy utilization, etc., and achieve low energy consumption, easy atomization and low energy consumption. The effect of fully, improving the utilization rate and combustion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

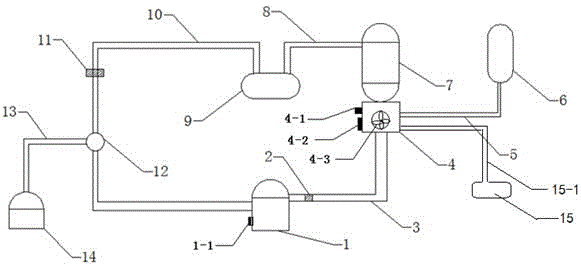

[0037] Turn on the boiler. When the steam pressure reaches 3kg and the temperature reaches 100°C, the steam passes through the steam inlet pipe, and through the three-way valve to the steam circulation pipe, and is introduced into the hydrogen reactor; high-temperature steam reacts with the catalyst in the hydrogen reactor to produce For high-temperature hydrogen-containing steam, when the pressure in the hydrogen reaction tank is higher than 8kg, the safety relief valve set on the hydrogen reaction tank will automatically exhaust and decompress to keep the pressure in the hydrogen reaction tank less than 5kg; the mixing burner is started, and the fan is turned on to blow air 10s, the methanol in the methanol tank enters the hybrid burner through the methanol intake pipe, and is ignited and burned; the hybrid burner is delayed by 5s through the delay switch, and the high-temperature hydrogen-containing steam processed by the steam-water separator is introduced into the hybrid bur...

Embodiment 2

[0039] Turn on the boiler. When the steam pressure reaches 4kg and the temperature reaches 120°C, the steam passes through the steam inlet pipe, and through the three-way valve to the steam circulation pipe, and is introduced into the hydrogen reactor; the high-temperature steam reacts with the catalyst in the hydrogen reactor to produce For high-temperature hydrogen-containing steam, when the pressure in the hydrogen reaction tank is higher than 8kg, the safety relief valve set on the hydrogen reaction tank will automatically exhaust and decompress to keep the pressure in the hydrogen reaction tank less than 5kg; the mixing burner is started, and the fan is turned on to blow air 13s, the methanol in the methanol tank enters the hybrid burner through the methanol intake pipe and is ignited and burned; the hybrid burner delays 8s through the delay switch, and the high-temperature hydrogen-containing steam processed by the steam-water separator is introduced into the hybrid burner ...

Embodiment 3

[0041] Turn on the boiler. When the steam pressure reaches 5kg and the temperature reaches 130°C, the steam passes through the steam inlet pipe and through the three-way valve to the steam circulation pipe, and is introduced into the hydrogen reactor; the high-temperature steam reacts with the catalyst in the hydrogen reactor to produce For high-temperature hydrogen-containing steam, when the pressure in the hydrogen reaction tank is higher than 8kg, the safety relief valve set on the hydrogen reaction tank will automatically exhaust and decompress to keep the pressure in the hydrogen reaction tank less than 5kg; the mixing burner is started, and the fan is turned on to blow air 15s, the methanol in the methanol tank enters the hybrid combustor through the methanol intake pipe and is ignited and burned; the hybrid combustor is delayed by 10s through the delay switch, and the high-temperature hydrogen-containing steam processed by the steam-water separator is introduced into the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com