Device for measuring nozzle angles and tangent circles of quadrangular tangential injection burning boiler

A four-corner tangent, measuring device technology, applied to measuring devices, using optical devices, instruments, etc., can solve problems such as thermal deviation, large measuring errors, coking of boiler water walls, etc., to reduce measuring errors, reasonable design, and fast installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

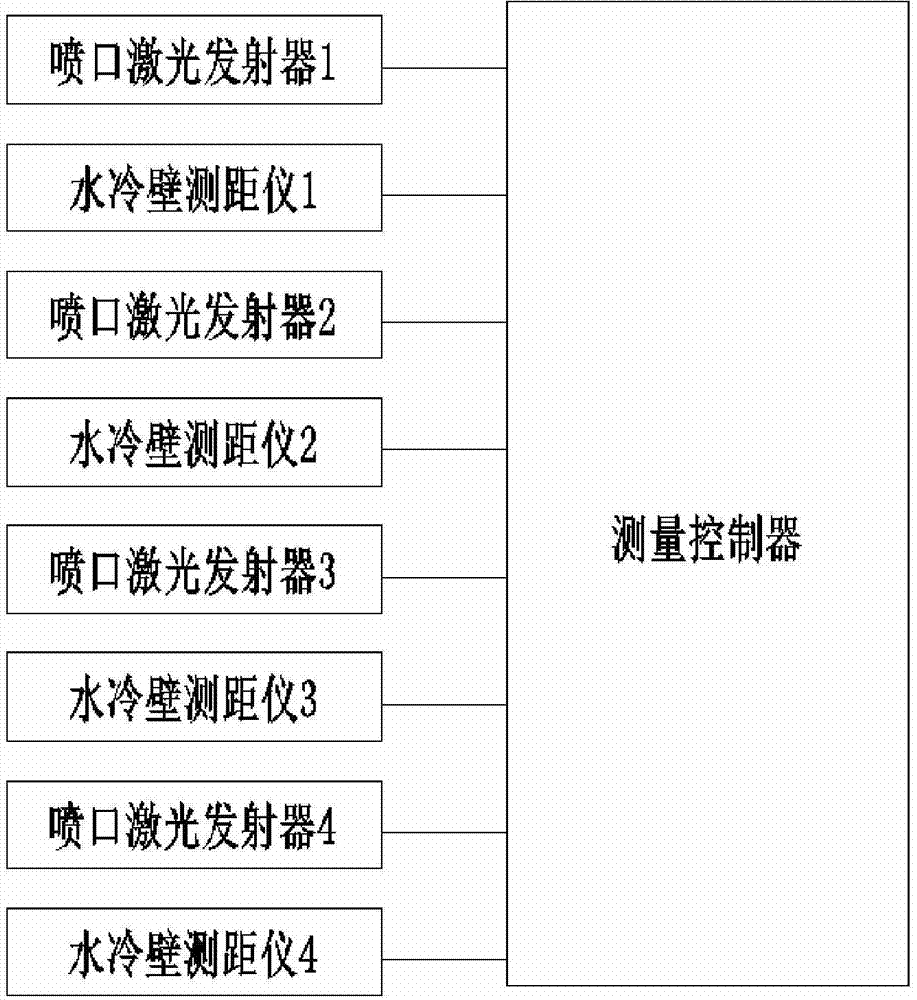

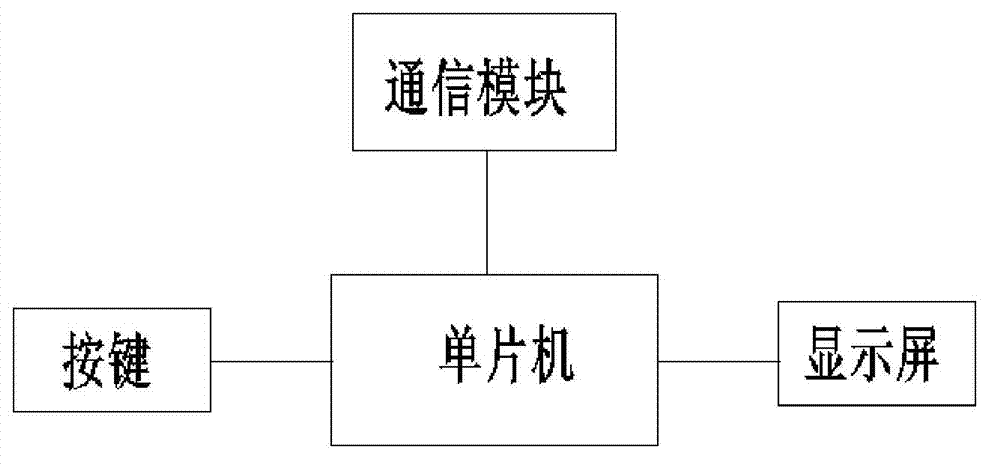

[0016] A four-corner tangential circular spray-fired boiler nozzle angle and tangential measuring device, such as figure 1 As shown, it includes the measurement controller, four nozzle laser transmitters and four water wall range finders, and the four identical nozzle laser transmitters and four identical water wall range finders communicate with each other wirelessly or wiredly. The measurement controllers are connected, and the four nozzle laser emitters and the four water-cooled wall distance meters communicate with the measurement controller to realize the measurement function. The wireless mode can adopt bluetooth communication mode or other wireless communication modes, and the wired mode can adopt RS232 communication mode, RS485 communication mode or other communication modes.

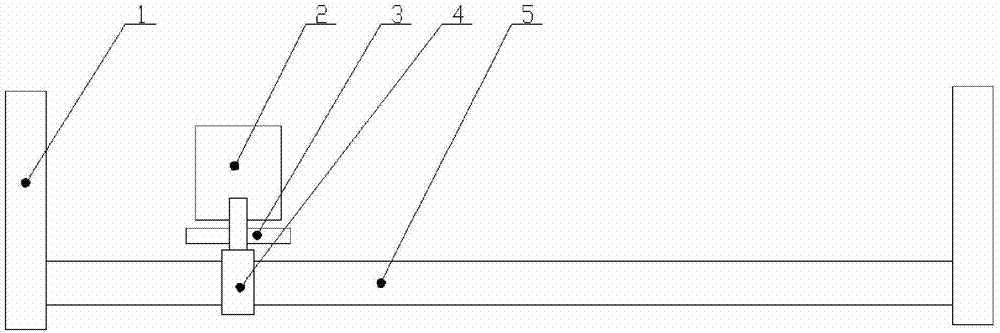

[0017] The nozzle laser emitter is installed on the nozzle of the injector to be measured, and the angle of the nozzle laser emitter is adjusted through a level gauge, so that the visible laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com