Ground torch grading emission control device and method

A technology for ground flare and emission control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

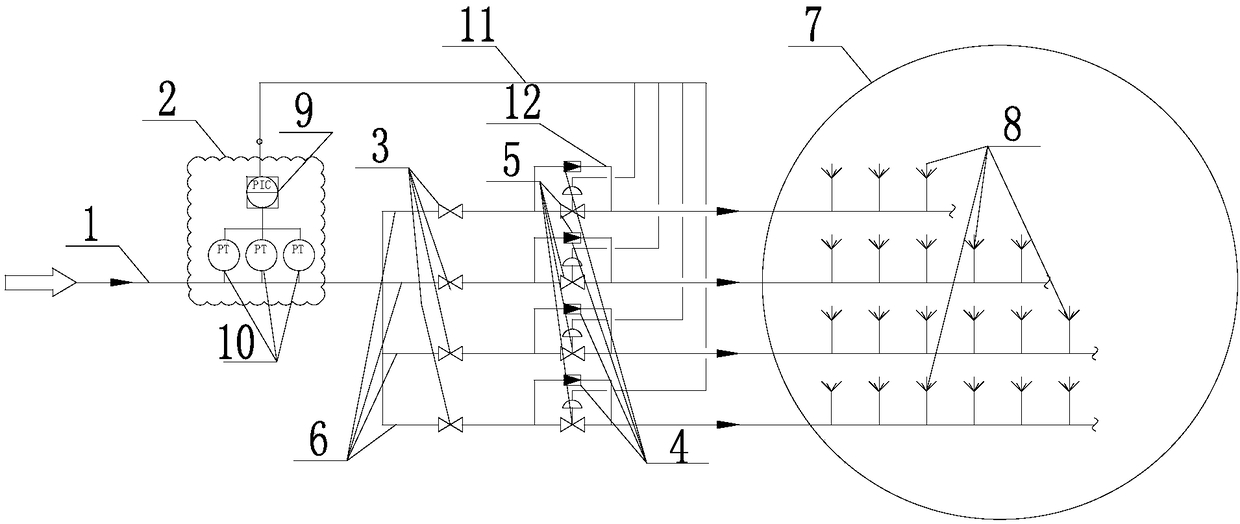

[0025] A ground torch staged emission control device, comprising a venting main pipe, a staged discharge system, a staged control system, a burner and a ground torch combustion furnace, one end of the staged discharge system communicates with the main pipeline, and the other end communicates with the burner, and the staged control system communicates with the burner The graded discharge system is connected with the main pipeline, and the burner is installed in the ground torch combustion furnace. The graded discharge system includes the main pipeline, sub-pipes, pressure control valves, and shut-off valves. The main pipeline is connected with the sub-pipes, and the sub-pipes are equipped with pressure control valves and Shut-off valve, the shut-off valve is located at the front end of the pressure control valve, and the hierarchical control system includes pressure control valves, pressure detection and pressure transmitters and signal lines, the pressure detection and pressure ...

Embodiment 2

[0027] A ground torch staged emission control device, comprising a venting main pipe, a staged discharge system, a staged control system, a burner and a ground torch combustion furnace, one end of the staged discharge system communicates with the main pipeline, and the other end communicates with the burner, and the staged control system communicates with the burner The graded discharge system is connected with the main pipeline, and the burner is installed in the ground torch combustion furnace. The graded discharge system includes the main pipeline, sub-pipes, pressure control valves, and shut-off valves. The main pipeline is connected with the sub-pipes, and the sub-pipes are equipped with pressure control valves and Shut-off valve, the shut-off valve is located at the front end of the pressure control valve, and the hierarchical control system includes pressure control valves, pressure detection and pressure transmitters and signal lines, the pressure detection and pressure ...

Embodiment 3

[0029] A ground flare discharge control method, characterized in that: 5 pressure signal gauges on the main pipeline, when the 4 or 5 pressure signal values on the main pipeline reach the opening and closing control values of the regulating valves on the sub-pipelines, the control valves on the sub-pipelines On and off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com