Method for coal slime combustion of circulating fluidized bed boiler

A circulating fluidized bed and boiler combustion technology, which is applied to fluidized bed combustion equipment, combustion methods, fuels burned in a molten state, etc., can solve problems such as improper control of material layer thickness, damage to the heating surface at the tail, and distance from the heating surface of the screen, etc. problems, to achieve the effect of easy burning through, heating and uniform combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

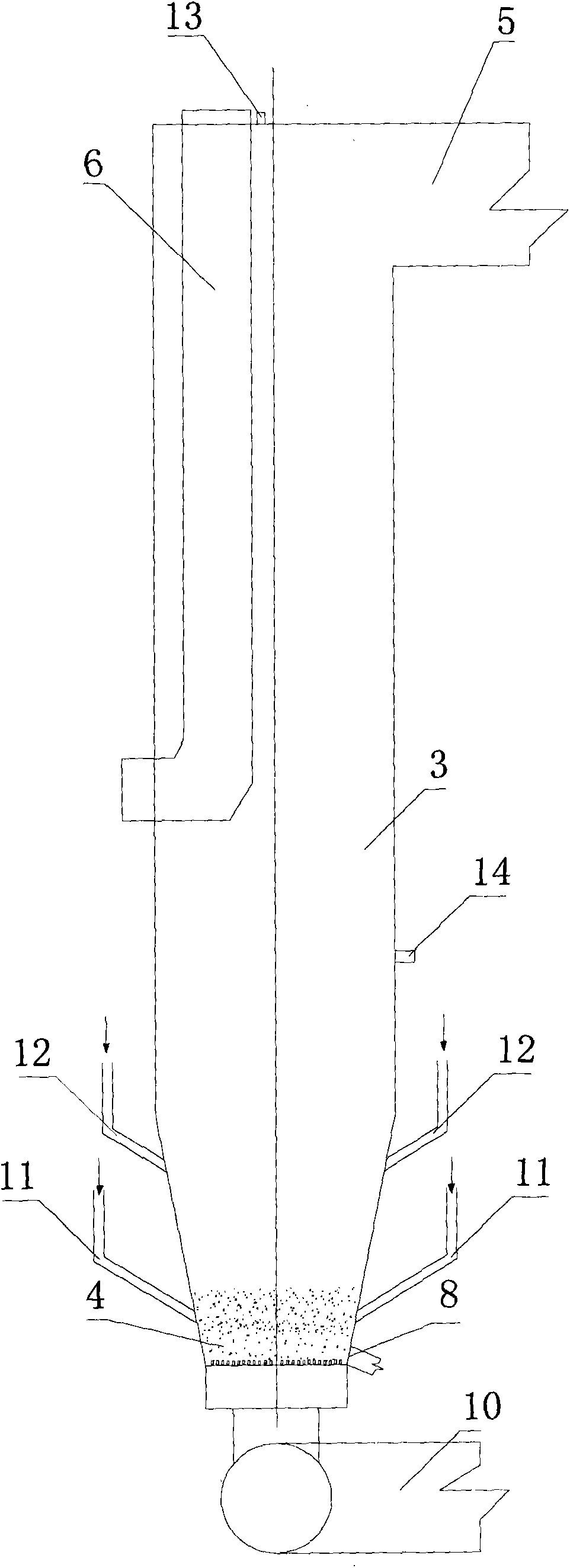

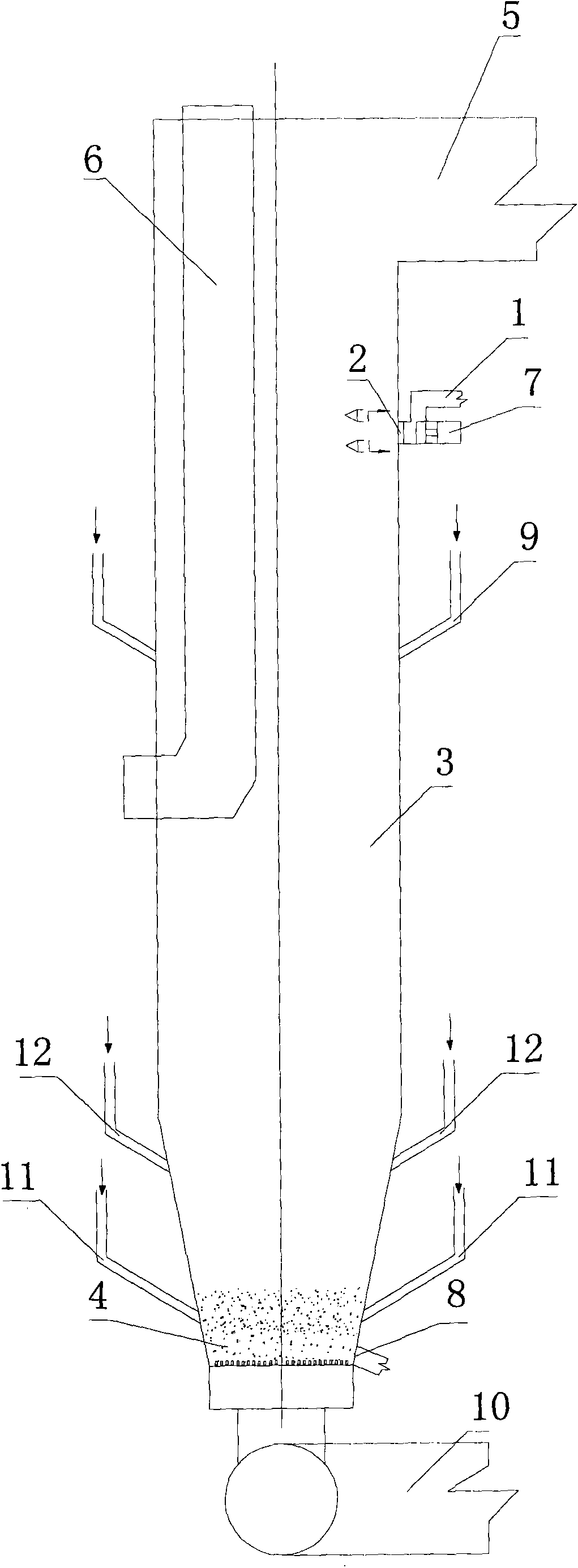

[0035] like figure 1 , figure 2 , image 3 Shown, a kind of circulating fluidized bed boiler combustion slime method of the present invention, it comprises the following steps:

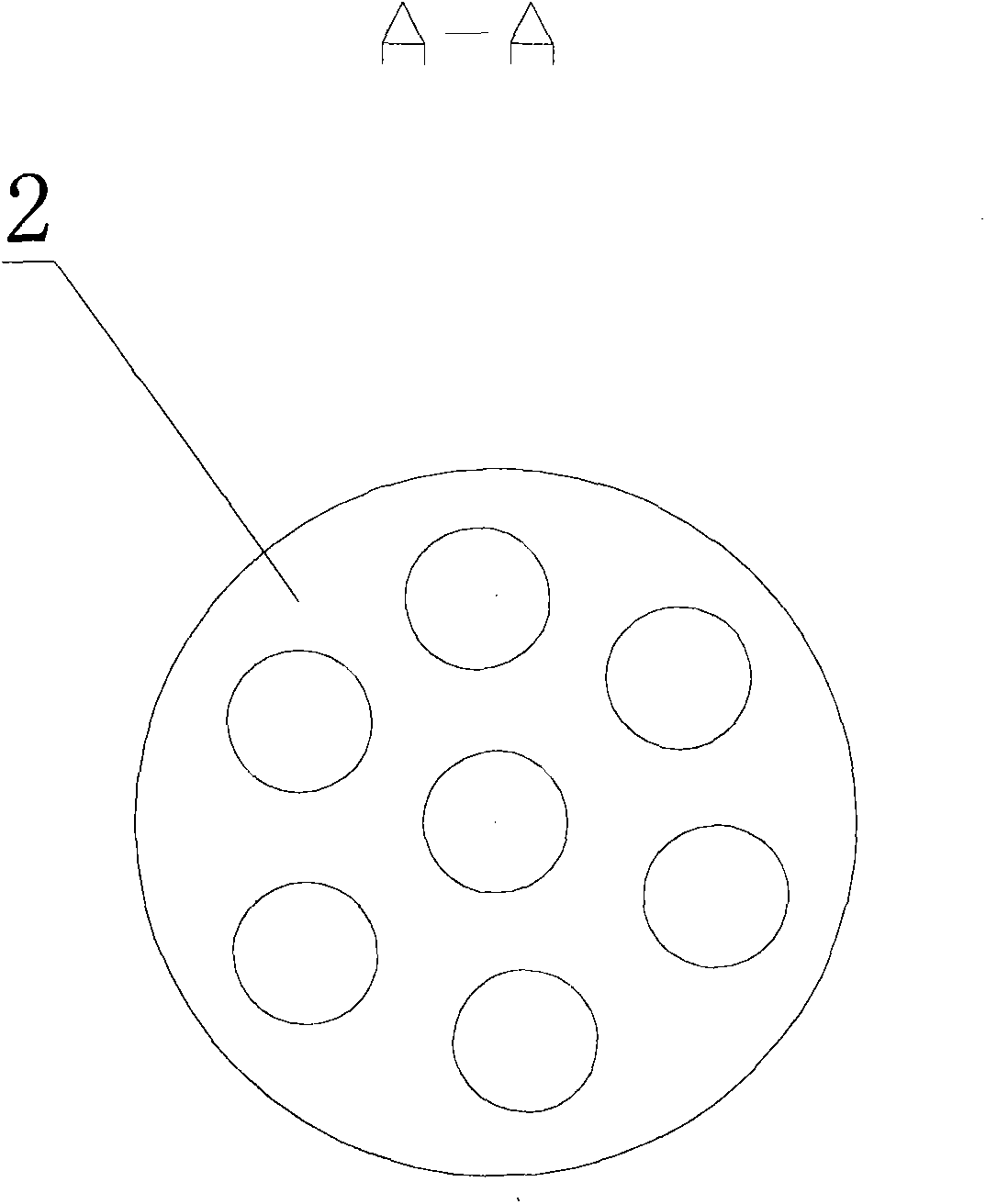

[0036] 1. The coal slime from the high-pressure coal slime conveying pipeline 1 enters the furnace 3 through the honeycomb slime inlet 2, so that the slime flow changes from one stream to multiple streams, and it is easy to disperse into rod-shaped slime balls during the falling process, which is heated and combustion evenly, easy to burn through; avoiding the deposition of large coal slime granules that have not burned through in the bed material layer 4 and blocking the slag discharge port 8 resulting in poor slag discharge.

[0037] 2. The honeycomb slime inlet 2 is arranged below the furnace outlet 5, so that the honeycomb slime inlet 2 is far away from the furnace outlet 5, and the honeycomb slime inlet 2 is also far away from the screen heating surface 6. The location of the honeycomb slime i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com