Methanol steam hydrogen production technology by using catalytic combustion flue gas as heat source

A catalytic combustion, catalytic burner technology, applied in the direction of hydrogen, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of reducing energy consumption costs, resource waste, etc., and achieve the effects of reducing energy consumption, complete combustion, and reducing H2 concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

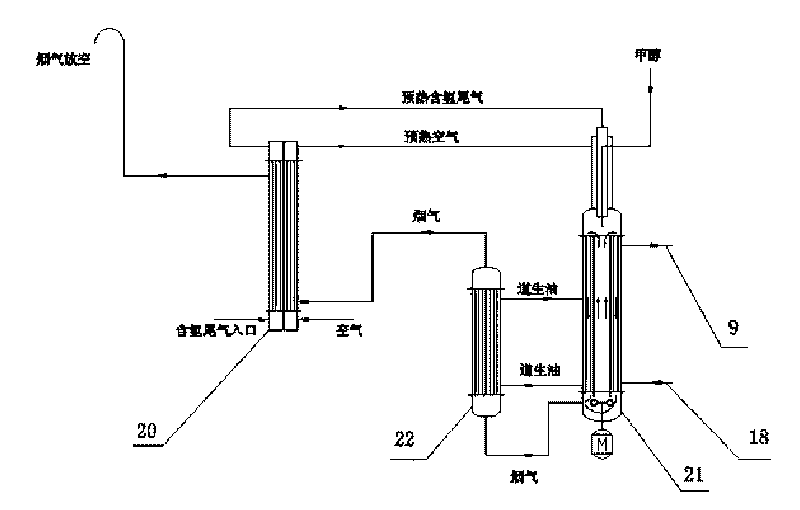

[0025] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

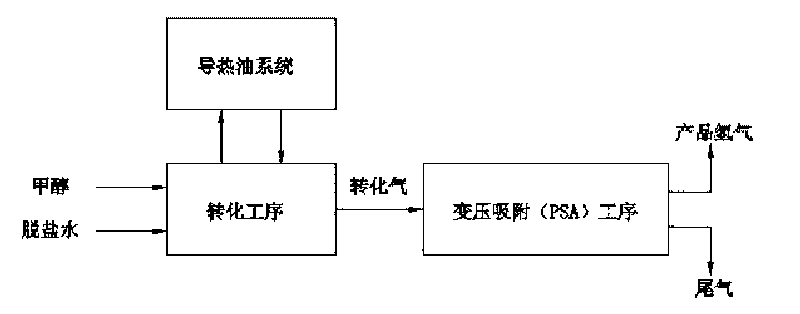

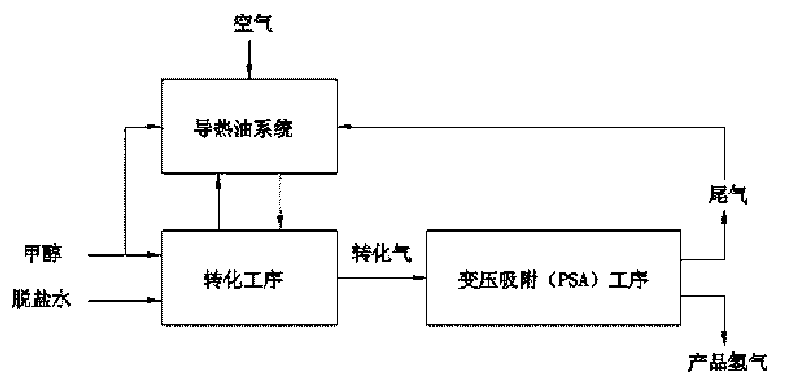

[0026] The methanol steam hydrogen production process of the present invention is as figure 2 As shown, methanol and desalinated water are used as raw materials, followed by preheating, gasification, superheating, and conversion processes to obtain reformed gas. The reformed gas is then subjected to pressure swing adsorption to obtain product hydrogen and exhaust tail gas. The conversion process is performed by the heat transfer oil system To provide heat, the tail gas enters the heat transfer oil system, and carries out a catalytic combustion reaction with the air under the action of a catalyst for catalytic combustion reaction, using this as a heat source to heat the heat transfer oil as a heat carrier, and part of the gasified methanol also participates in the catalytic combustion reaction to supplement Insufficient heat released by catalytic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com