Patents

Literature

34results about How to "Achieve complete oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

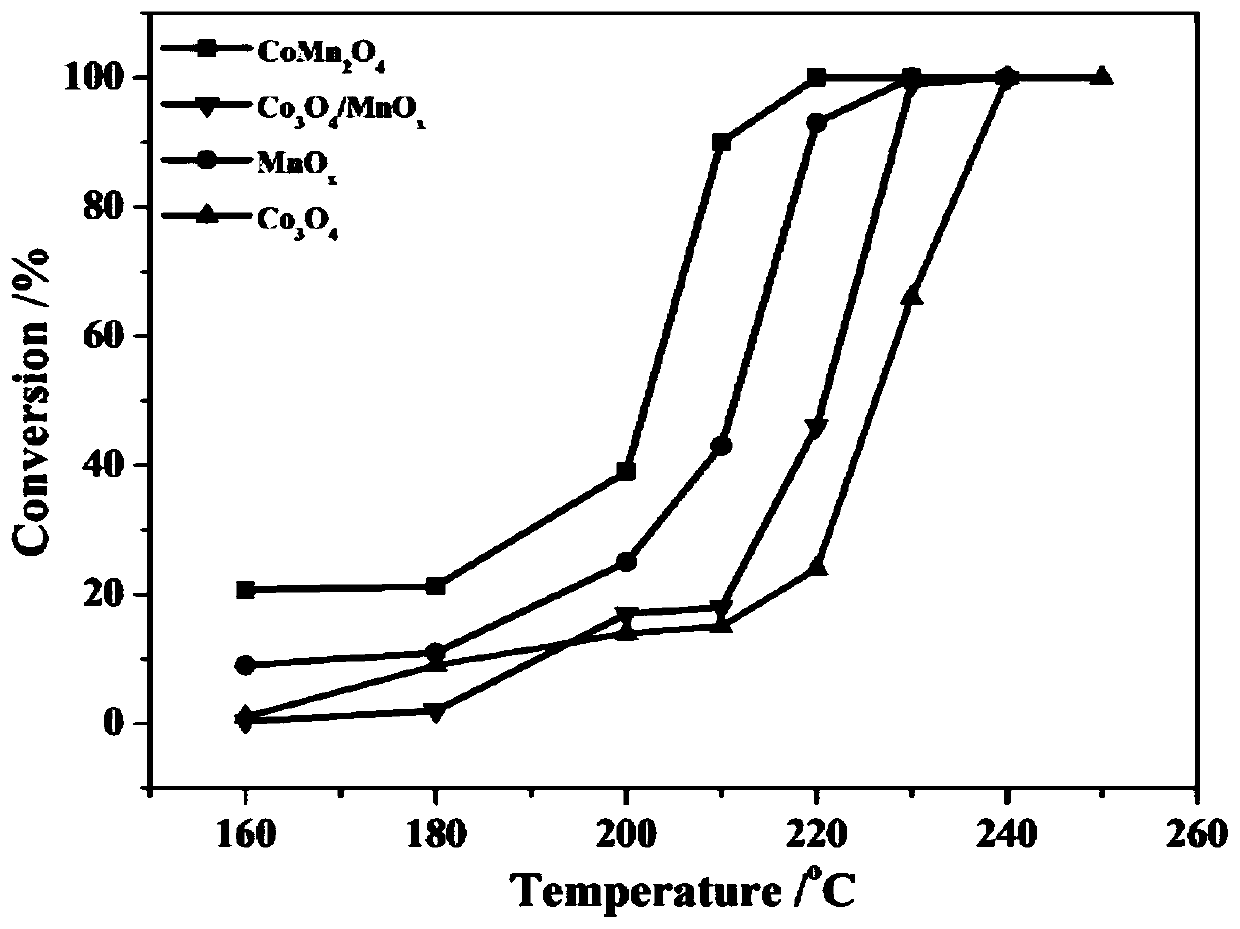

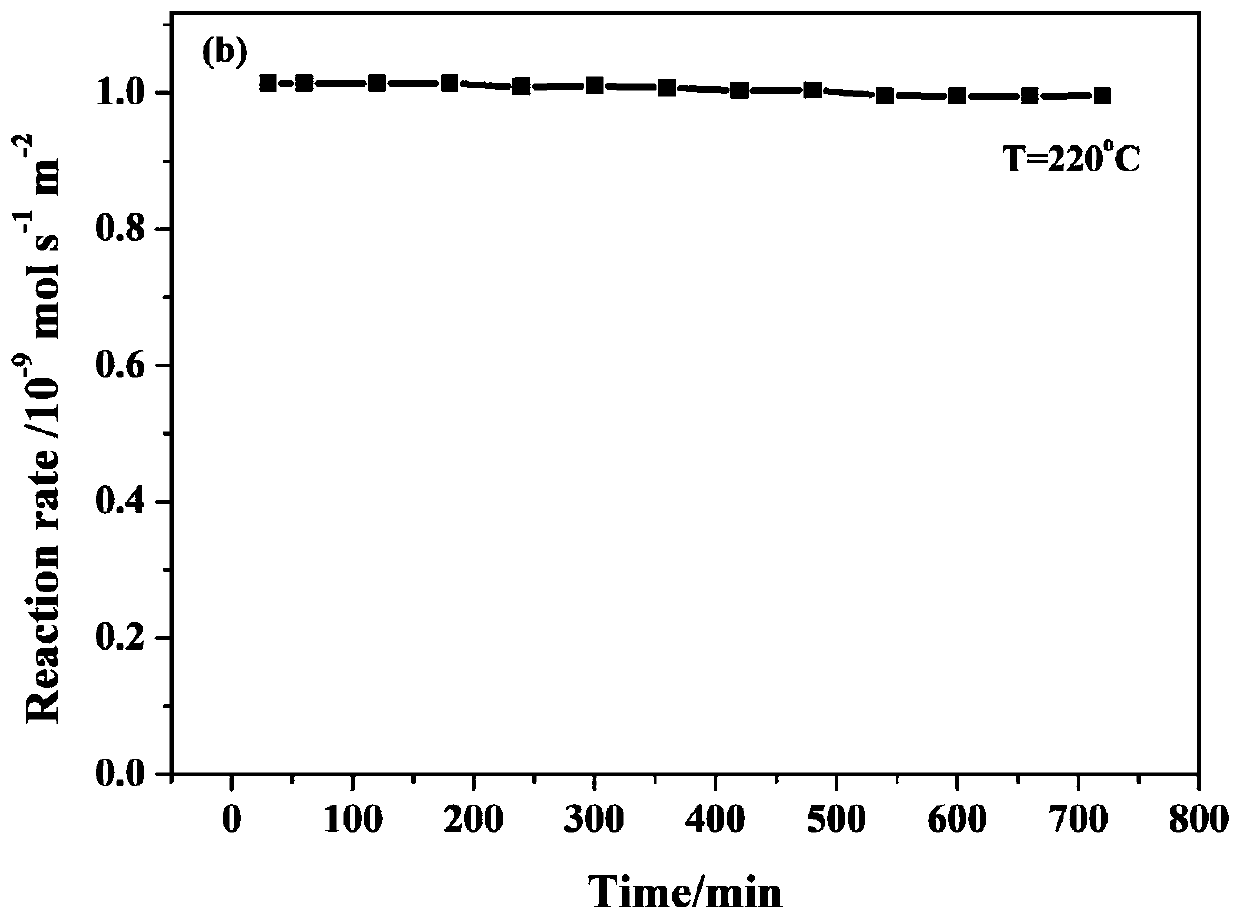

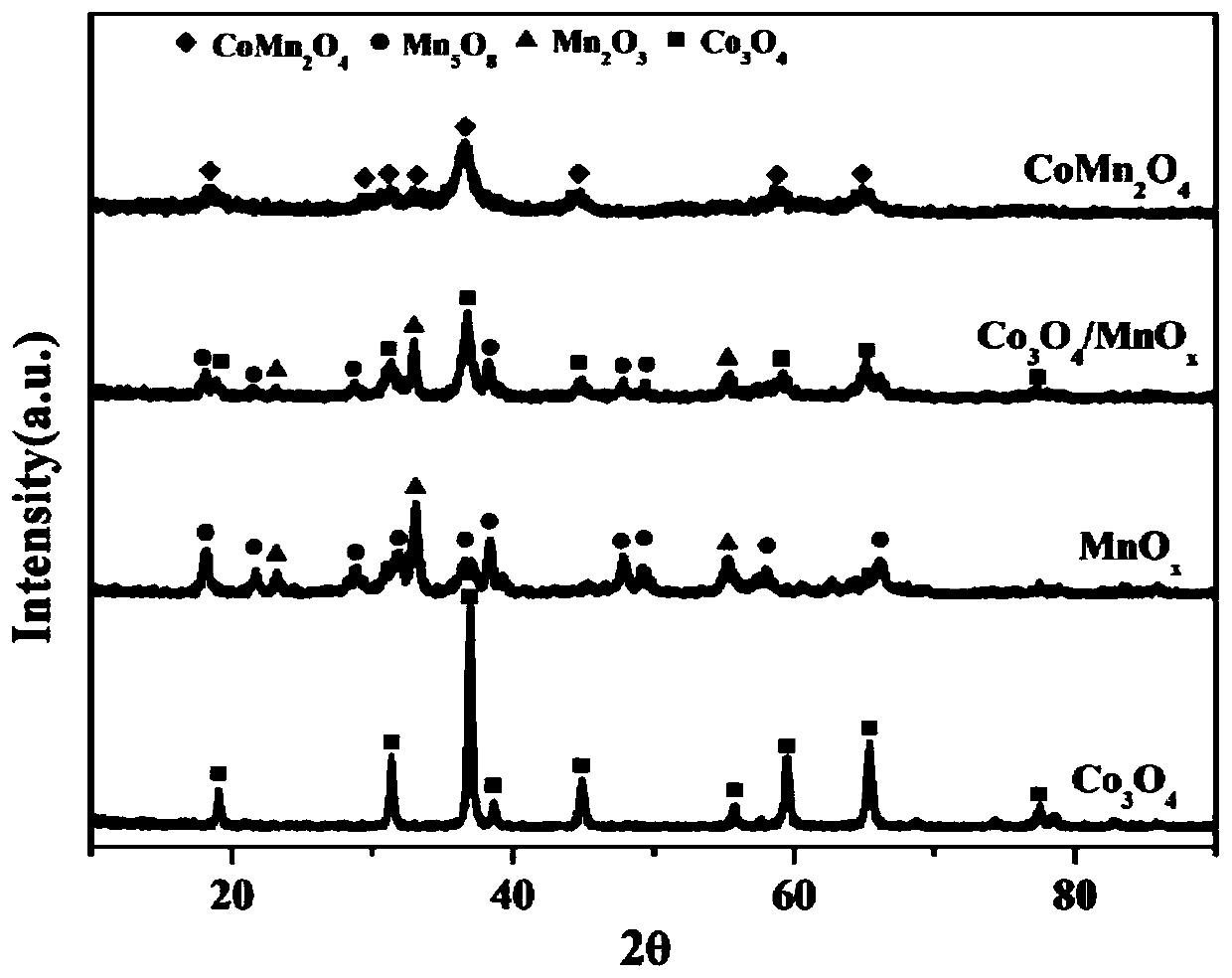

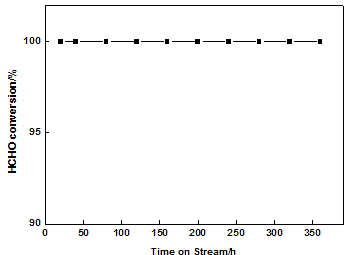

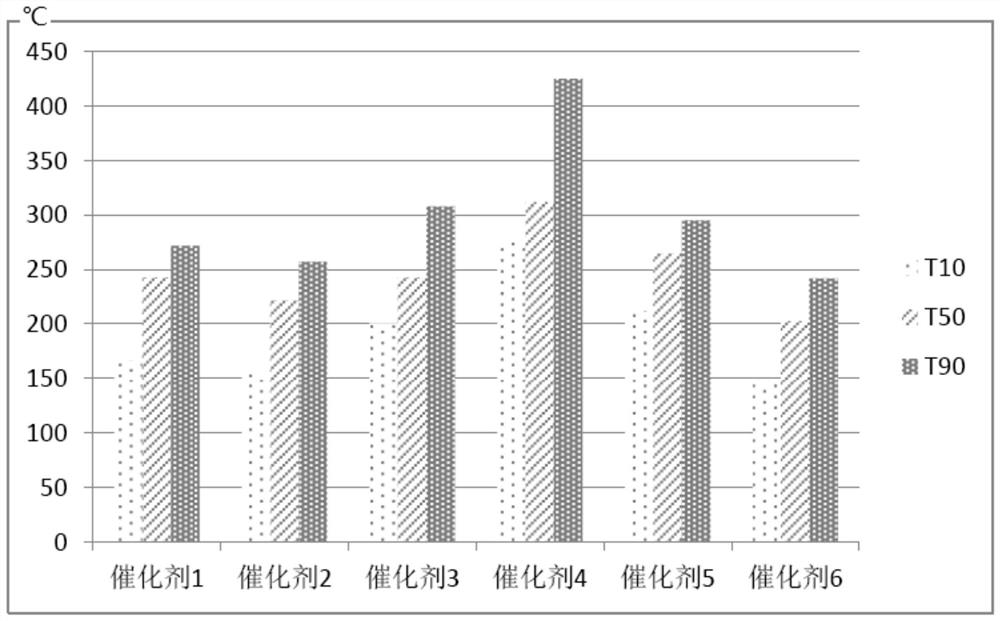

Nanoflower spinel CoMn2O4 catalyst for catalytic oxidation of VOCs (Volatile Organic Compounds), preparation method and application

ActiveCN108295866AHigh activityAchieve complete oxidationGas treatmentDispersed particle separationCatalytic oxidationSpinel

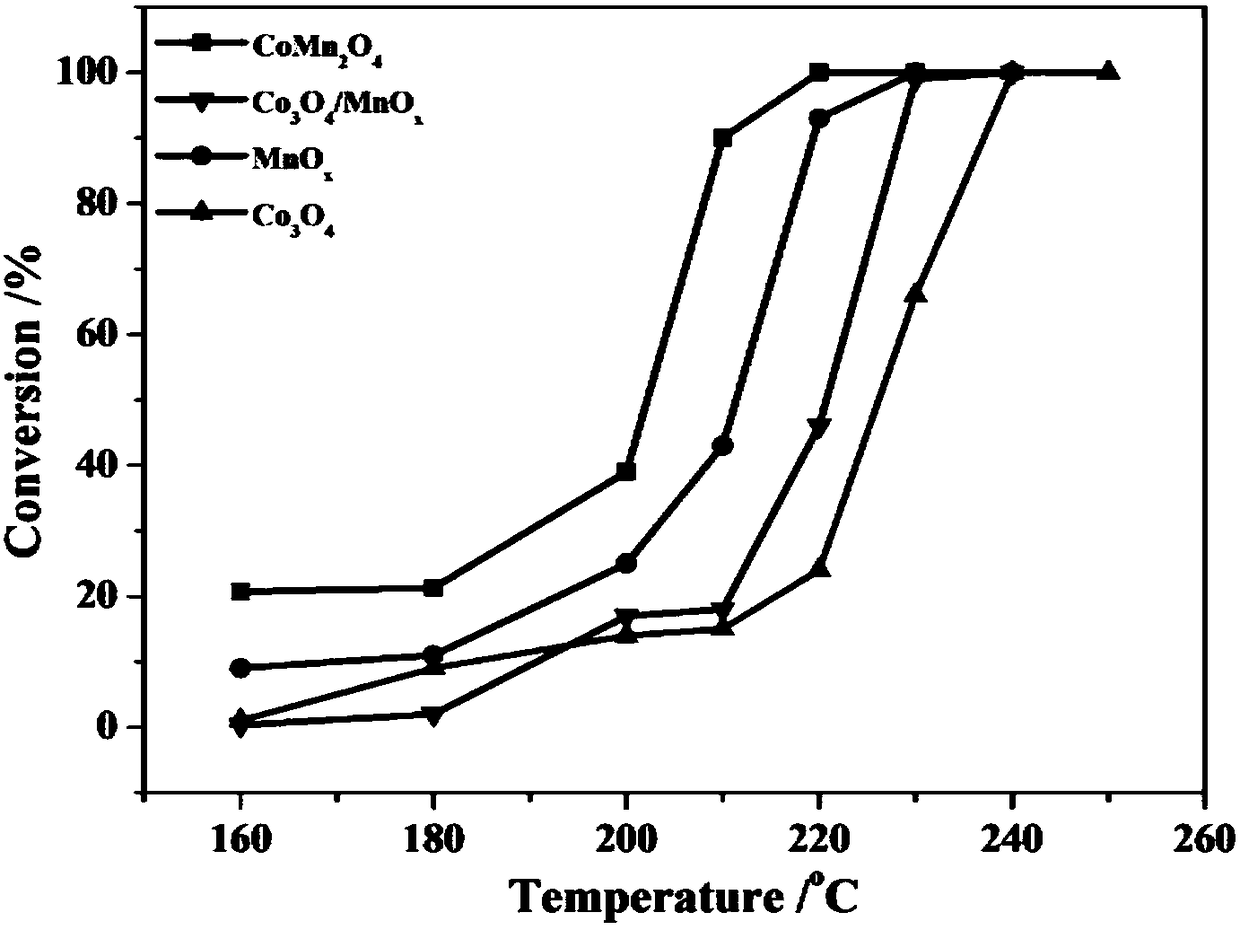

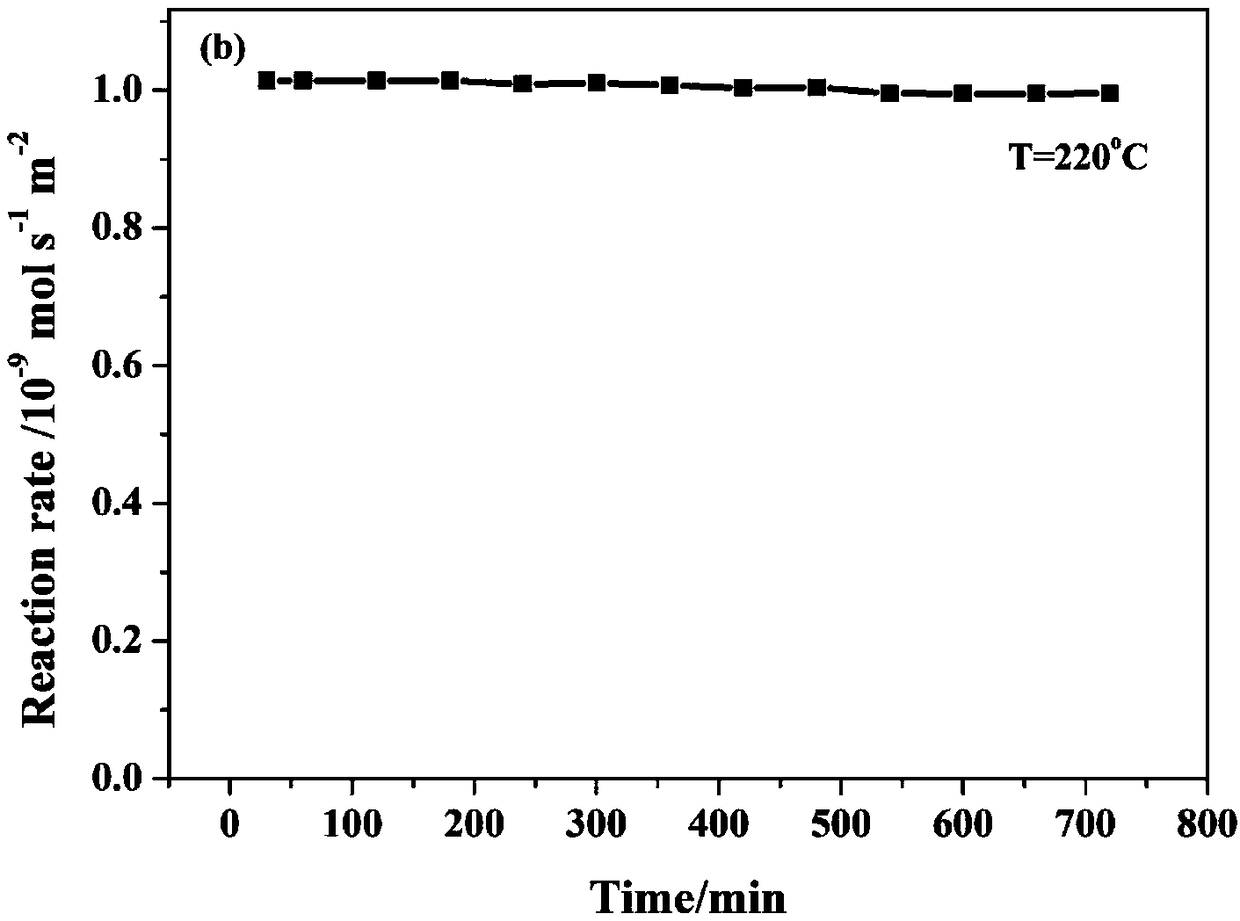

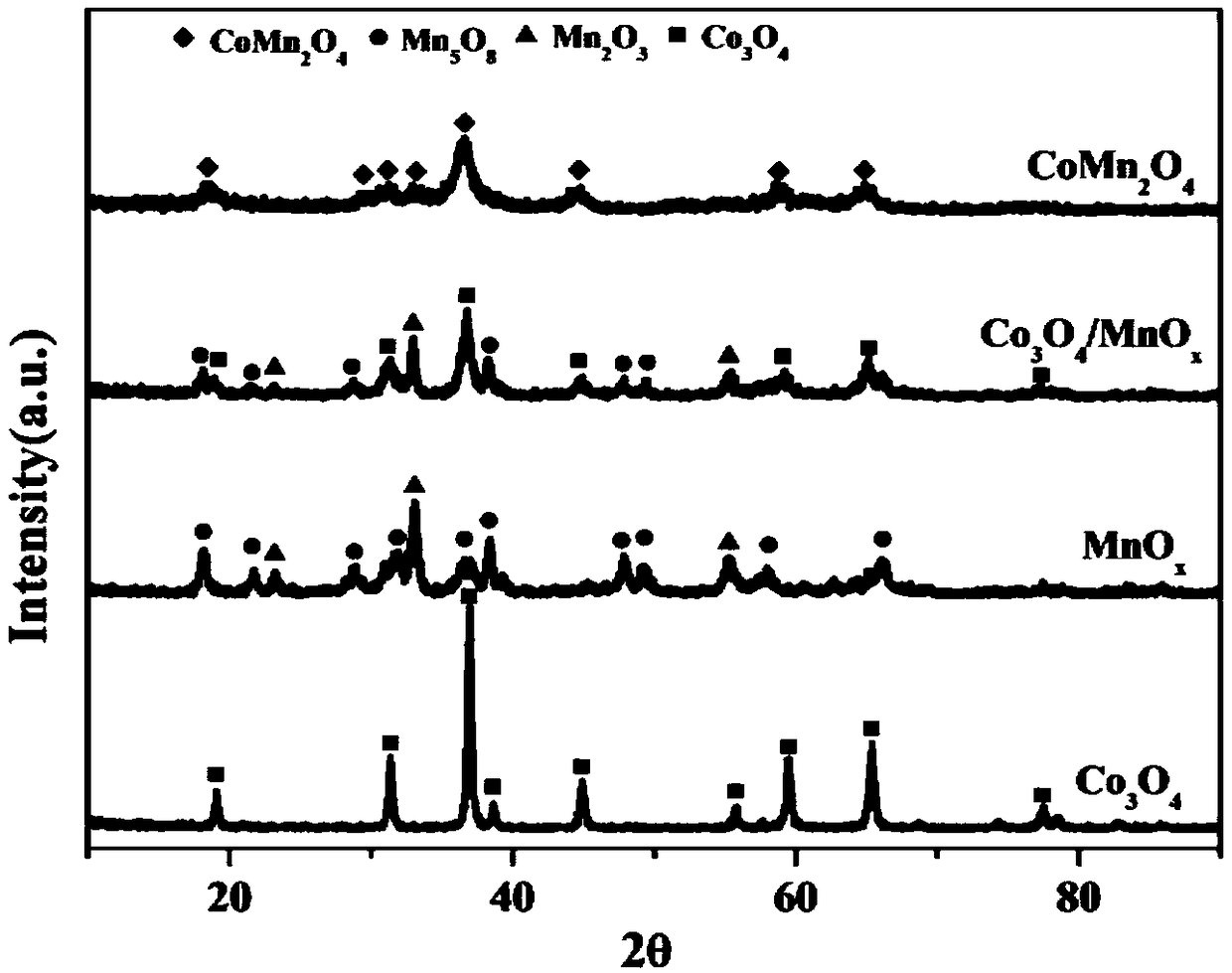

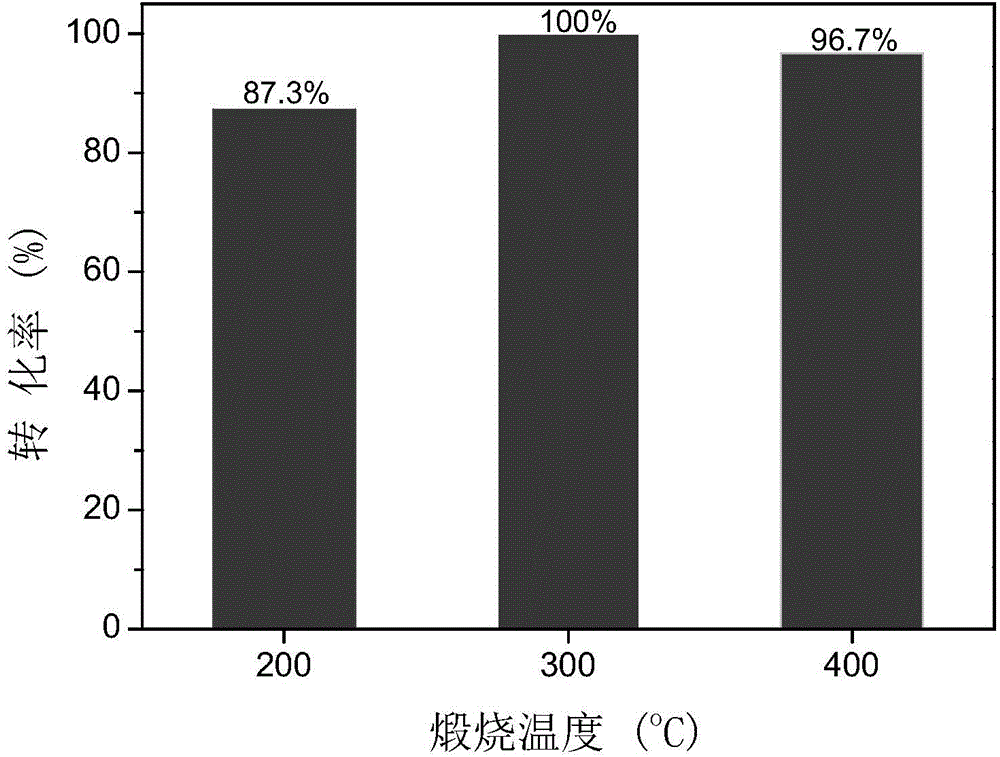

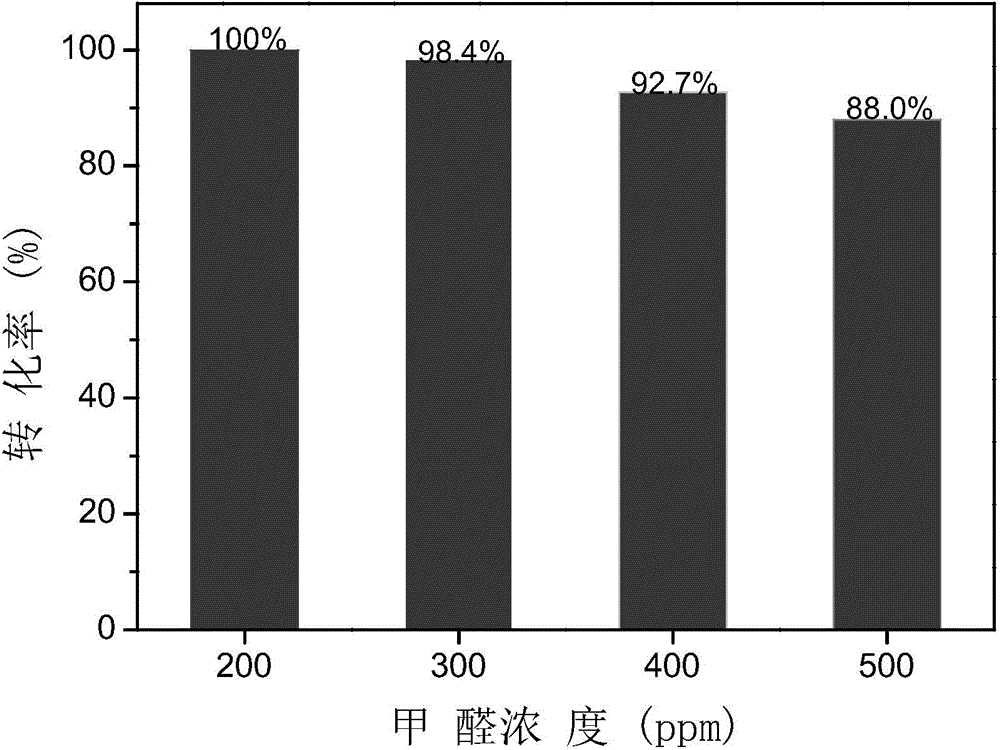

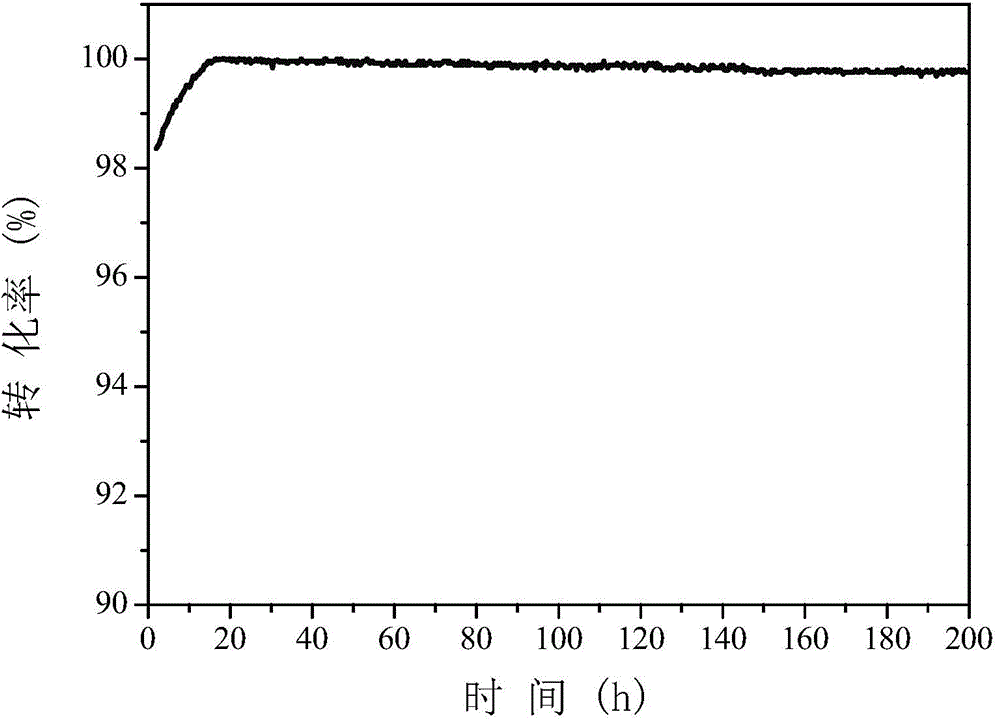

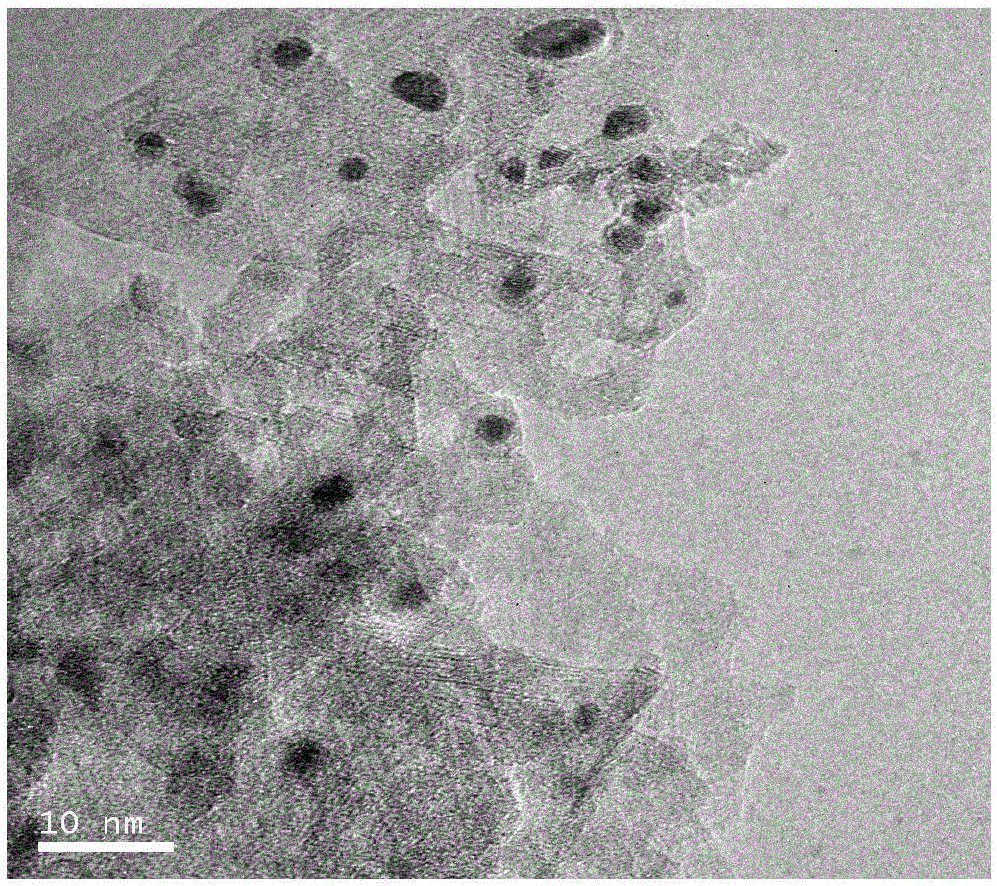

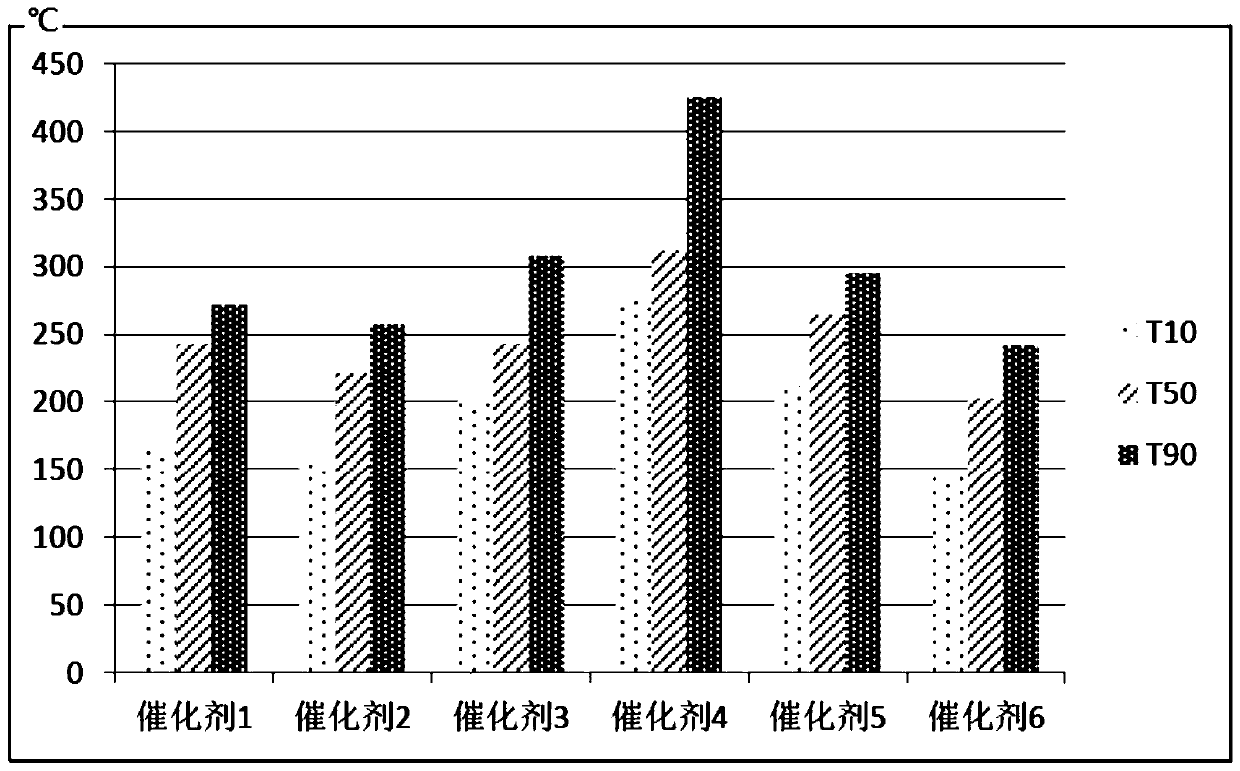

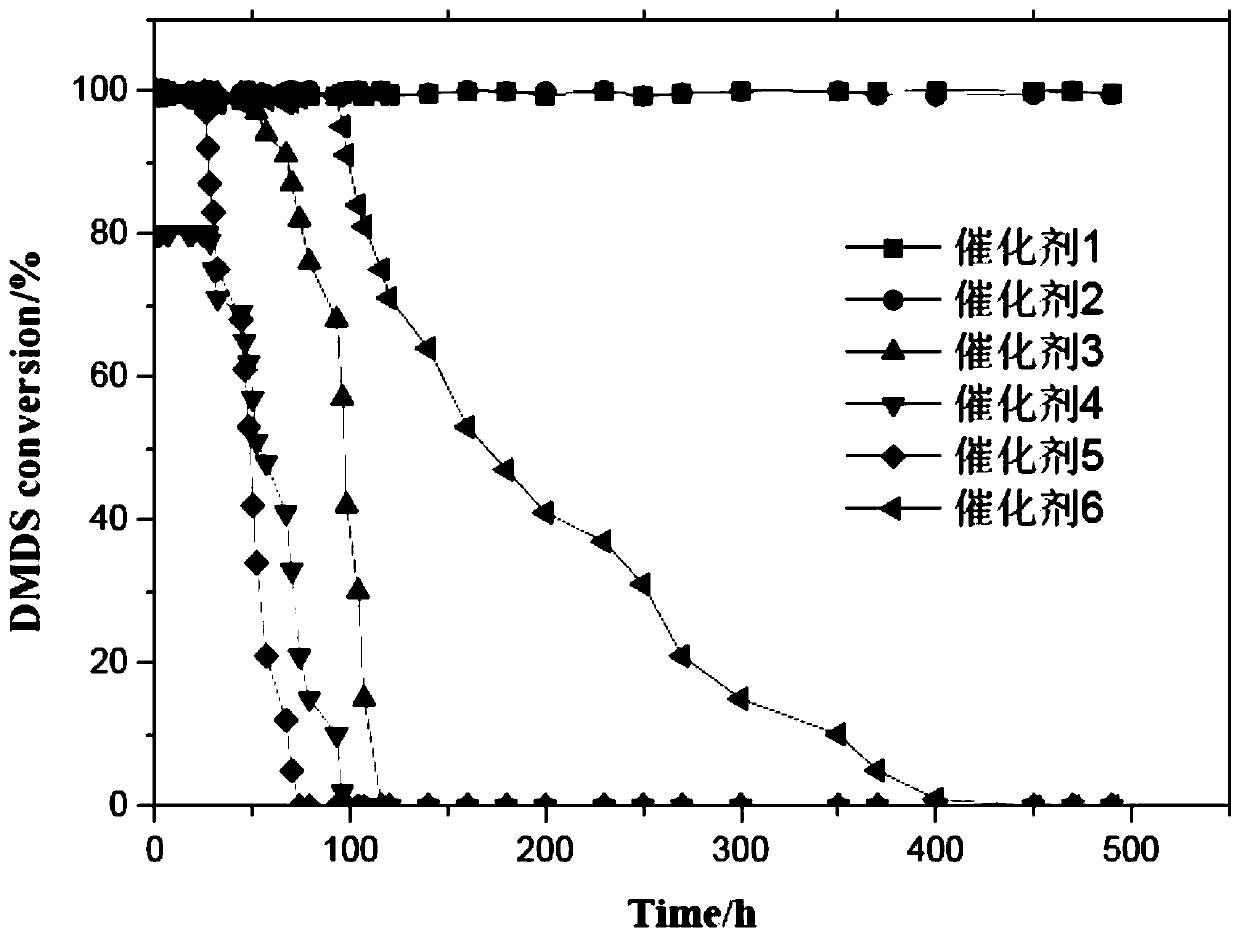

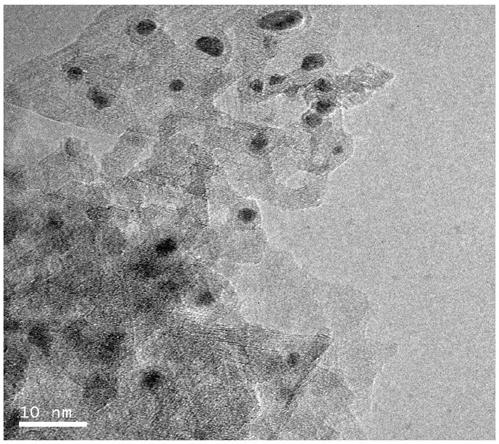

The invention belongs to the technical field of the catalytic purification of environments, and provides a nanoflower spinel CoMn2O4 catalyst for the catalytic oxidation of VOCs (Volatile Organic Compounds), a preparation method and application thereof. Oxalic acid is used as a precipitator; the pinel CoMn2O4 catalyst is obtained by washing, drying and calcination. The CoMn2O4 catalyst prepared bythe preparation method exhibits that nanosheets form a nanoflower-shaped structure through self-assembly. Compared with oxides Co3O4 and MnOx, a mixed phase Co3O4 / MnOx and a spinel CoMn2O4 catalyst reported by current literature, the spinel CoMn2O4 catalyst prepared by the preparation method shows better activity and stability in removal of the VOCs, can reach 99 percent of the toluene removal rate at 220 DEG C, is used for realizing 100 percent conversion of formaldehyde at 90 DEG C, meanwhile, can have the acetone removal rate reaching 100 percent at 170 DEG C, and has a better industrial application prospect.

Owner:DALIAN UNIV OF TECH

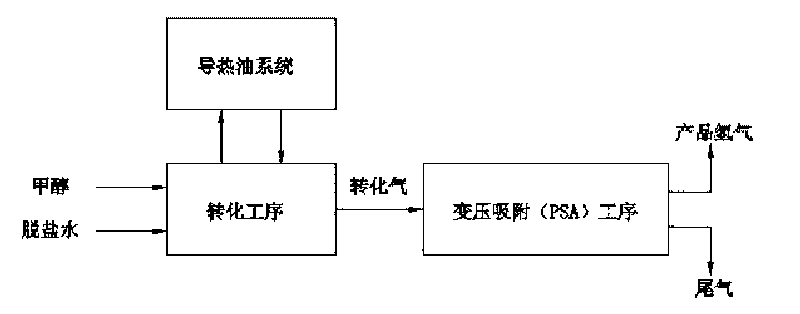

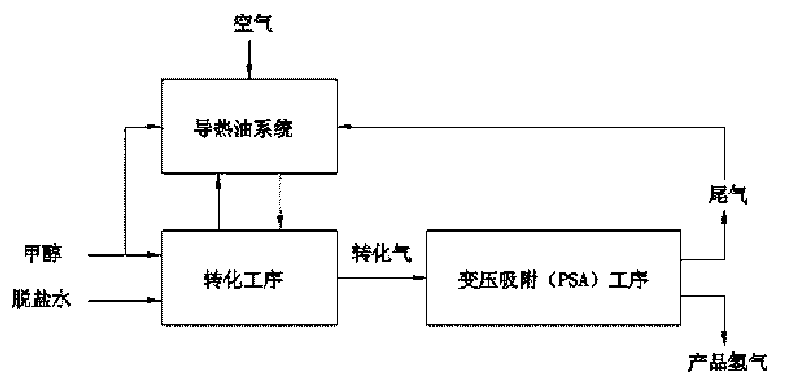

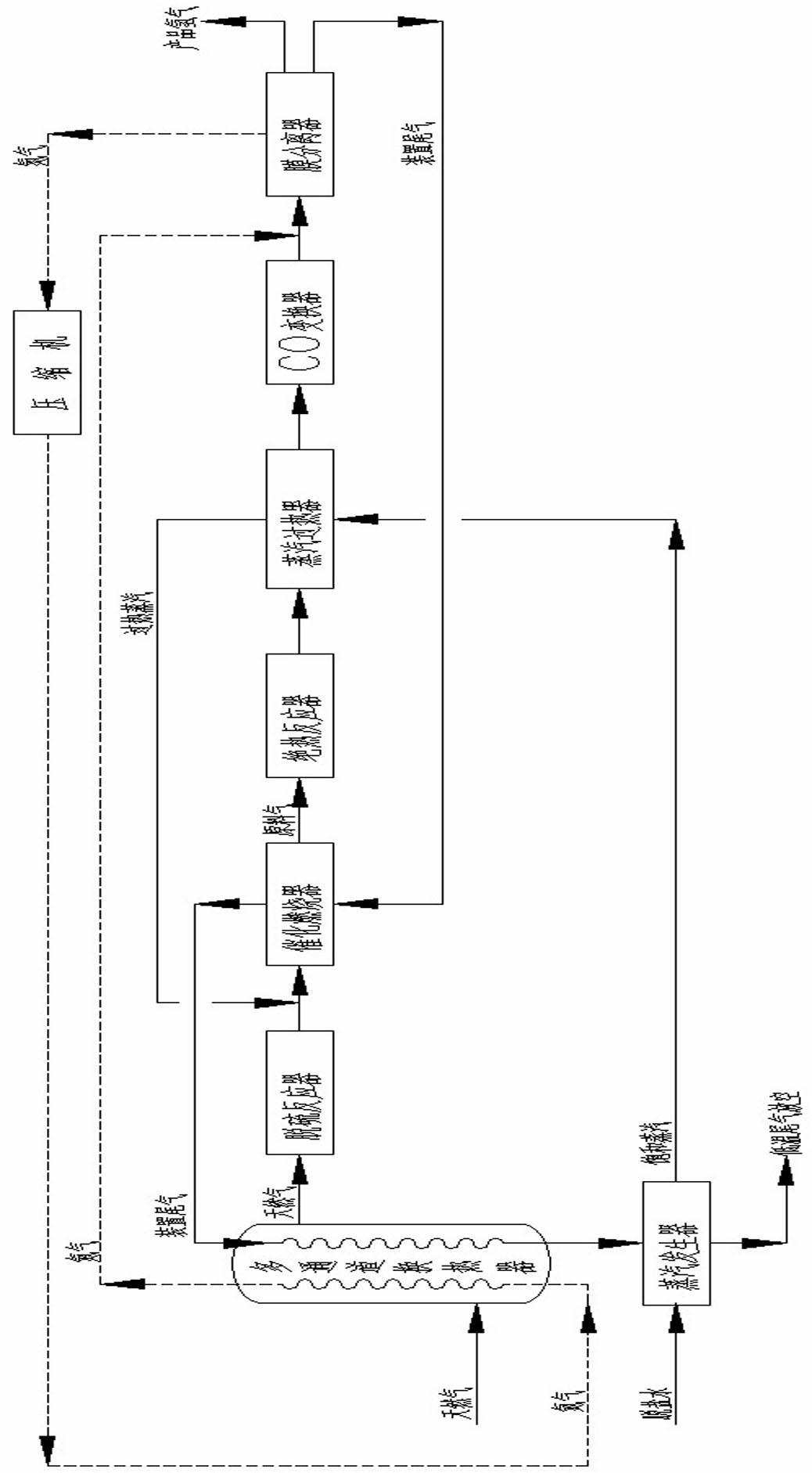

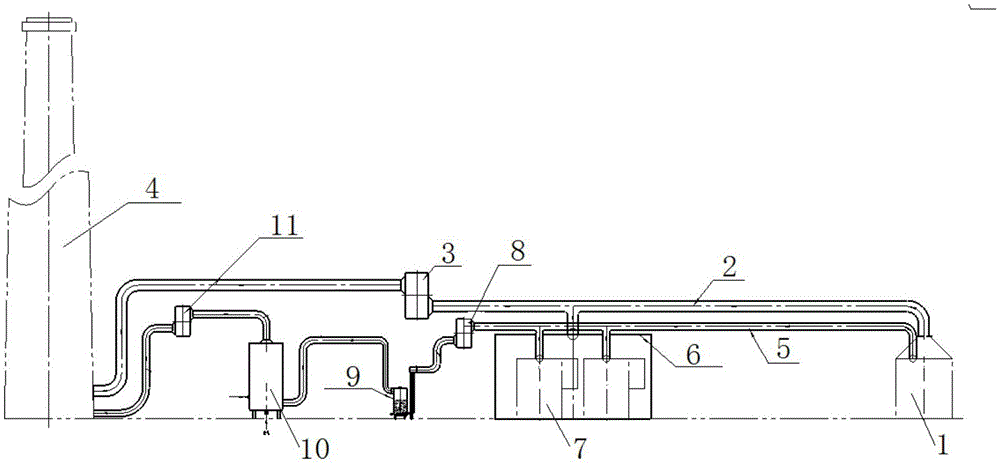

Methanol steam hydrogen production technology by using catalytic combustion flue gas as heat source

The invention discloses a methanol steam hydrogen production technology by using catalytic combustion flue gas as a heat source, relating to a hydrogen production technology, and aiming to solve the problem that tail gas is discharged but is not utilized to result in resource waste in the traditional methanol steam hydrogen production technology. Methanol and desalted water as raw materials are orderly preheated, gasified, overheated and converted to obtain converted gas; then the converted gas is adsorbed at variable pressure, the product hydrogen is obtained, and tail gas is discharged, wherein the heat quantity is supplied by heat conducting oil in the converting procedure, the tail gas generates the heat quantity through catalytic combustion and conducts the heat quantity to the heat conducting oil in a heat conducting system.

Owner:四川亚联氢能科技股份有限公司

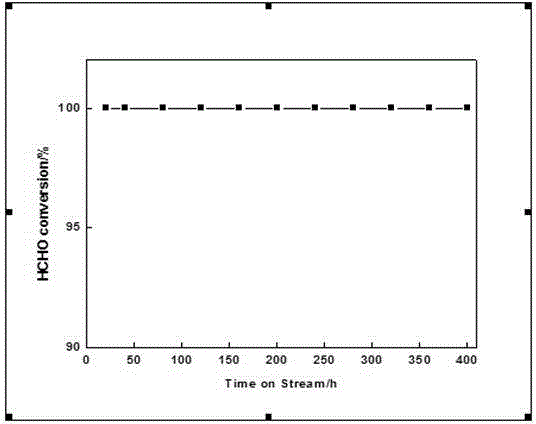

Pt/Al2O3 catalyst and application thereof in room-temperature catalytic oxidation of formaldehyde

InactiveCN103599774AWon't happenEasy to expand industrial productionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHydrogen atmosphereRoom temperature

The invention discloses a Pt / Al2O3 catalyst and an application thereof in room-temperature catalytic oxidation of formaldehyde. The Pt / Al2O3 catalyst is prepared by a method comprising the following steps: adding Pt2(dba)3 into propylene carbonate to obtain a mixture, stirring the mixture at the hydrogen atmosphere of 1-3MPa at room temperature for reaction, stop stirring after 1-2 hours and taking out the solution to obtain a solution containing Pt nano particles; and mixing the obtained solution containing Pt nano particles with an Al2O3 carrier, magnetically stirring so that the Pt nano particles are completely adsorbed on the Al2O3 carrier, filtering and roasting to obtain the Pt / Al2O3 catalyst. By virtue of the Pt / Al2O3 catalyst, formaldehyde can be completely eliminated at room temperature and the stability of the catalyst can be fully improved without adding alkali additives. The Pt / Al2O3 catalyst has good low-temperature catalytic activity and relatively high practical value.

Owner:ZHEJIANG UNIV OF TECH

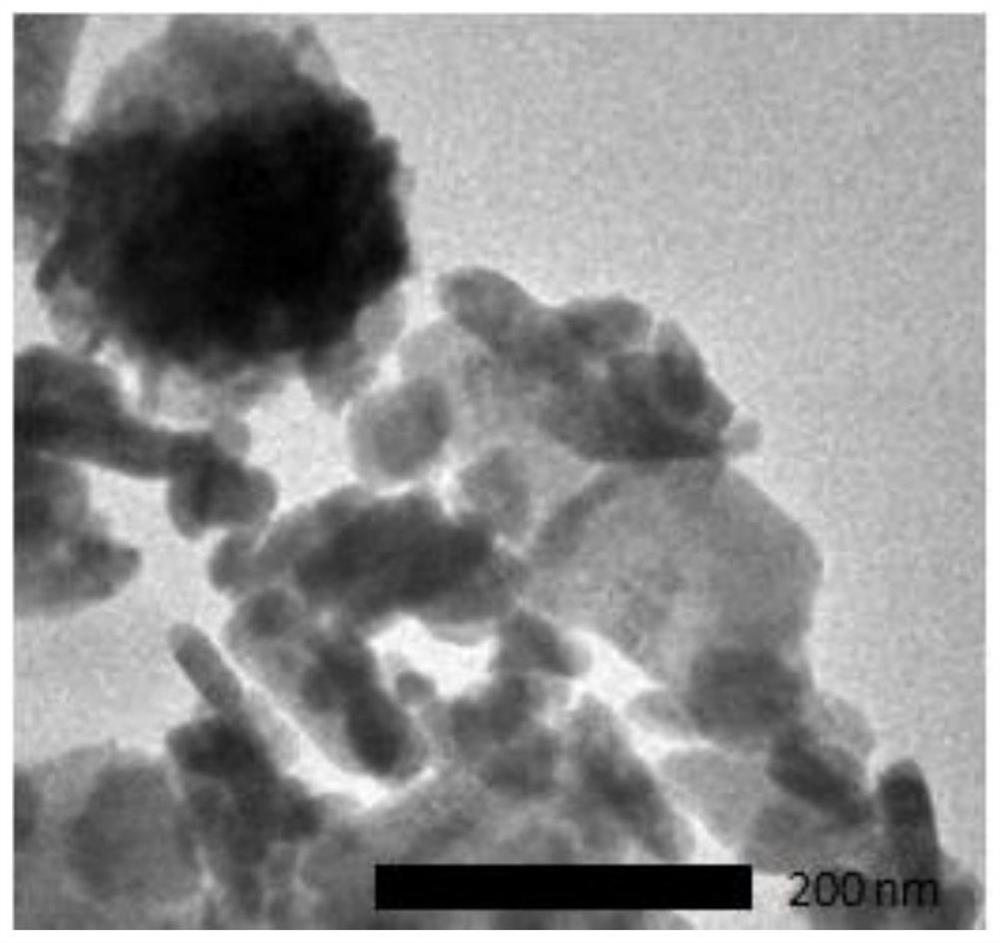

Low-load palladium-platinum core-shell structure catalyst and preparation method and application thereof

The invention provides a low-load palladium-platinum core-shell structure catalyst. The catalyst is prepared through the following method that a Pd precursor and propylene carbonate are mixed, stirring for reacting is carried out for 1 h to 5 h in the hydrogen atmosphere of 1 MPa to 4 MPa under the room temperature condition, and a solution containing Pd nano particles is obtained; a Pt precursor is added into the obtained solution containing the Pd nano particles, stirring for reacting is carried out for 1 h to 5 h in the hydrogen atmosphere of 1 MPa to 4 MPa under the room temperature condition, and a solution containing core-shell structure active components is obtained; the obtained solution containing the core-shell structure active components and a carrier Al2O3 are mixed, stirring is carried out for 4 h to 48 h, suction filtration is carried out, a filter cake is subjected to vacuum drying, and a finished product is obtained. According to the synthesis method of the catalyst, raw materials are easy to obtain and can be reused, waste gas and waste water are not generated, the environmental cost is low, scaling up can be easily carried out for industrial production, the activity of the prepared catalyst is higher than that of a catalyst obtained according to an existing method, stability is good, and the catalyst can be applied to a methylbenzene catalytic oxidation reaction.

Owner:ZHEJIANG UNIV OF TECH

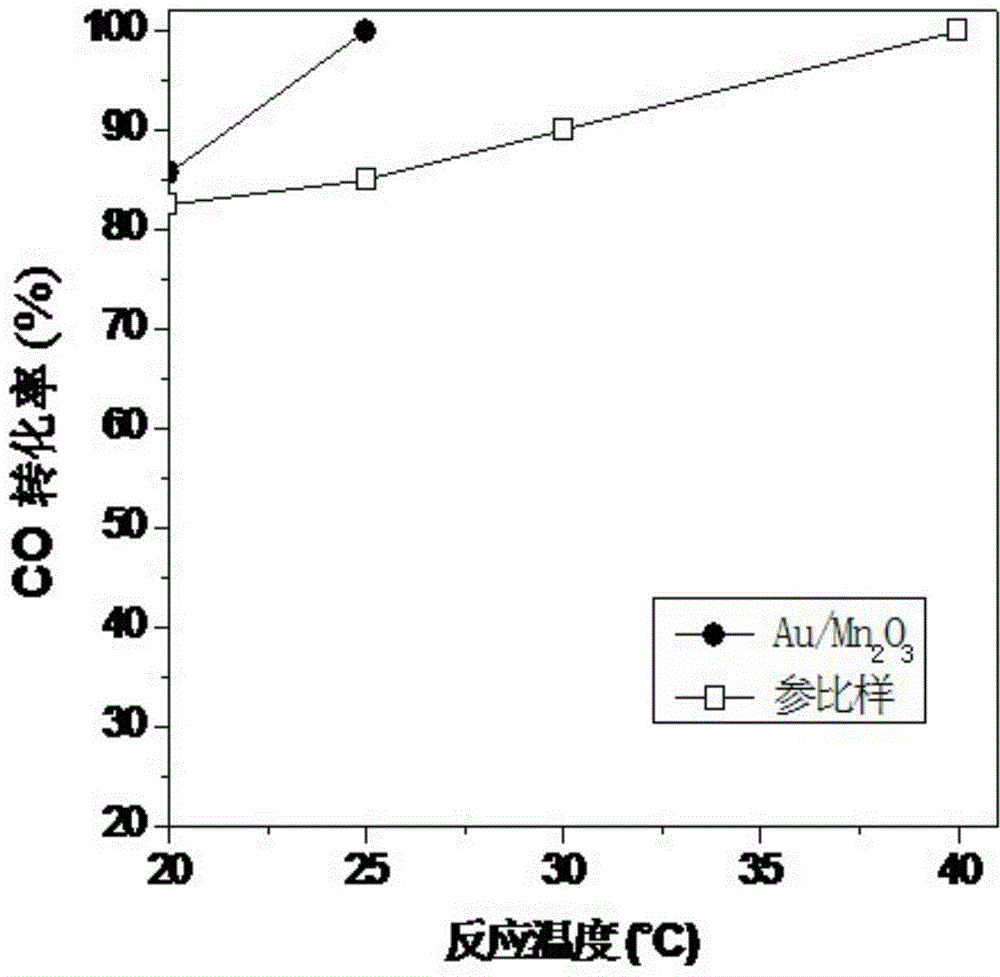

CO low-temperature catalytic oxidation catalyst, and preparation method and application thereof

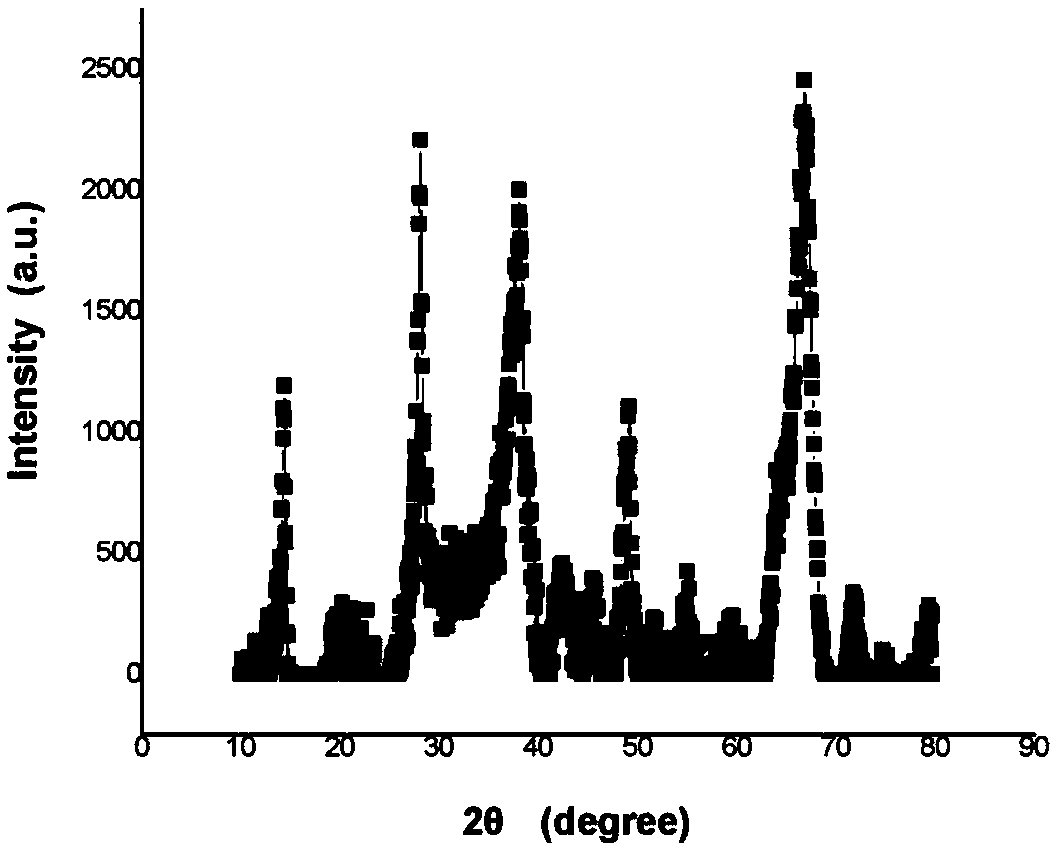

ActiveCN104128192AEasy to prepareSimple post-processingDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentNanoparticle

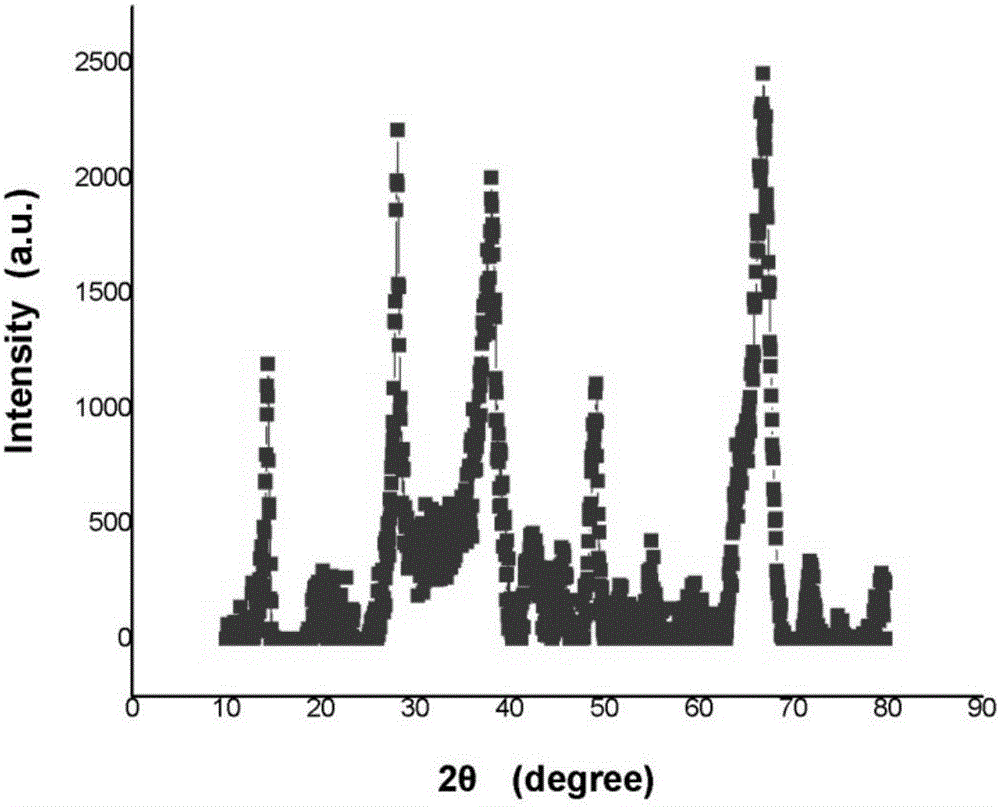

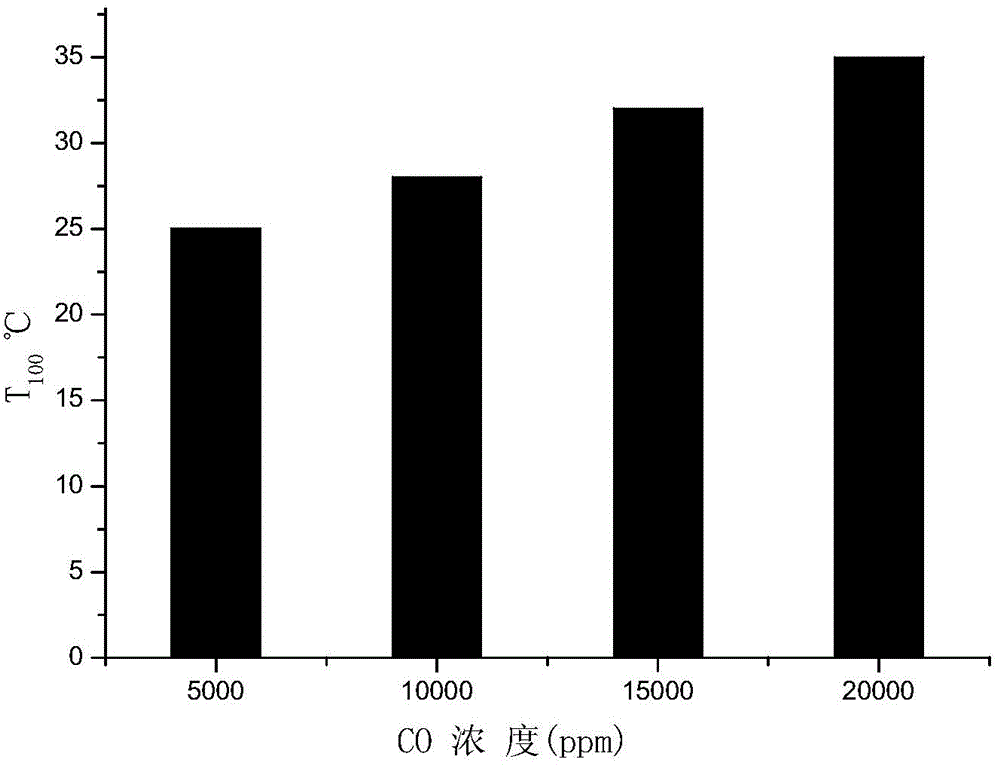

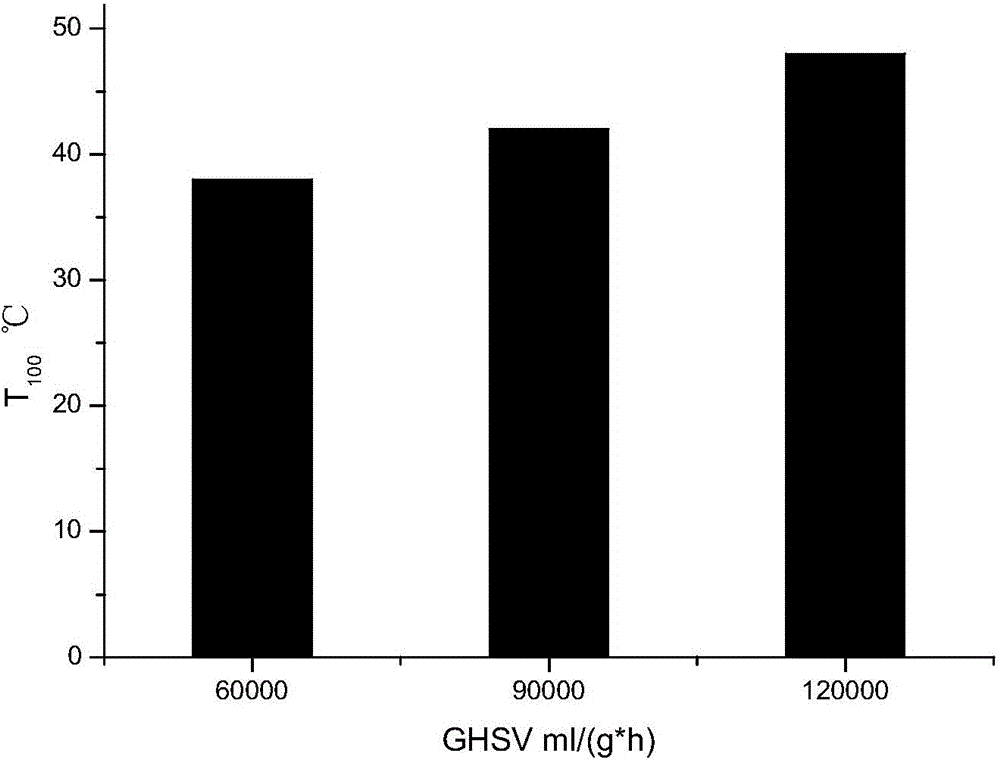

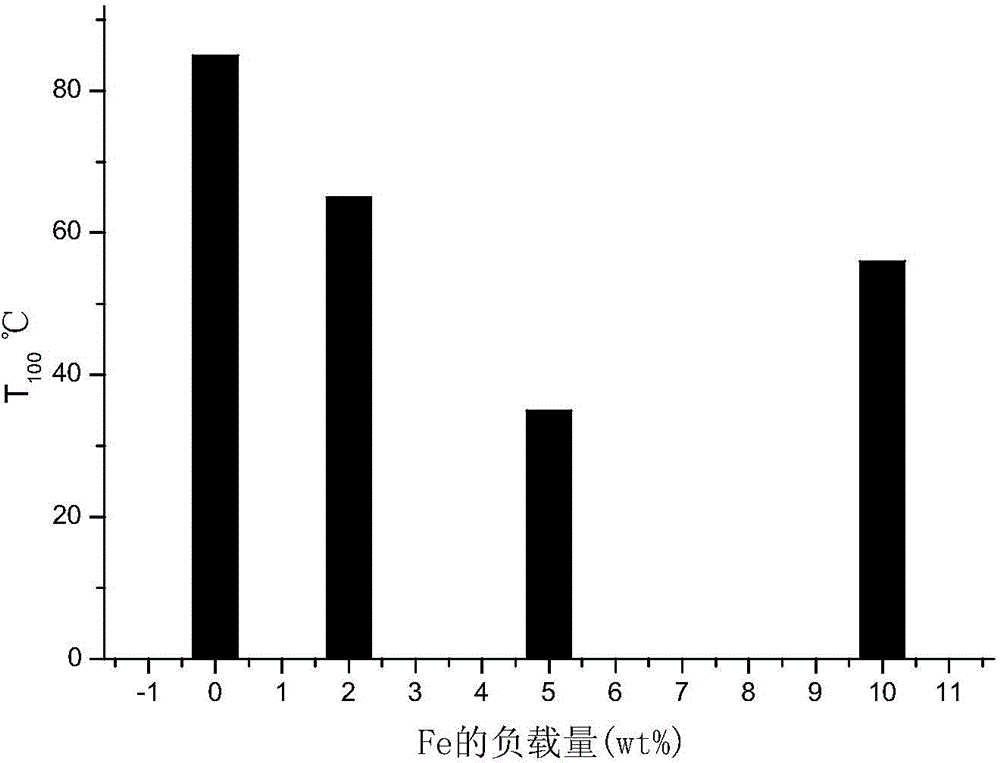

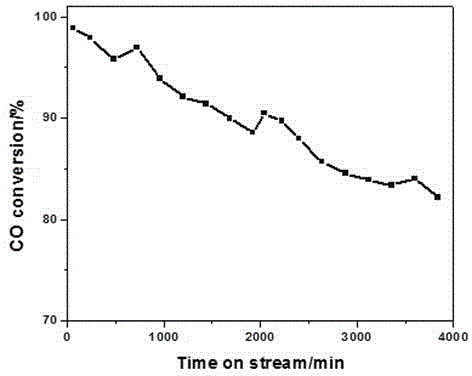

The invention discloses a CO low-temperature catalytic oxidation catalyst, and a preparation method and an application thereof. The catalyst is composed of a carrier TiO2 and an active component Pt-Fe3O4 composite type nano-particles. In the catalyst, a Pt load is 0.1-5wt%, and a Fe3O4 load is 2-20wt%. The Pt-Fe3O4 composite type nano-particles are obtained with the following method: under room temperature, chloroplatinic acid is added to a TEG solution of Fe3O4; the mixture is stirred, and H2 is delivered for reduction, such that the Pt-Fe3O4 composite type nano-particles are obtained. The preparation method of the catalyst provided by the invention is simple, and is suitable for expanded-scale industrialized production. With the addition of the magnetic Fe3O4 nano-particles, catalytic oxidation performance of the catalyst upon CO is greatly improved, and low-temperature CO complete oxidation can be realized. The catalyst has good stability.

Owner:ZHEJIANG UNIV OF TECH

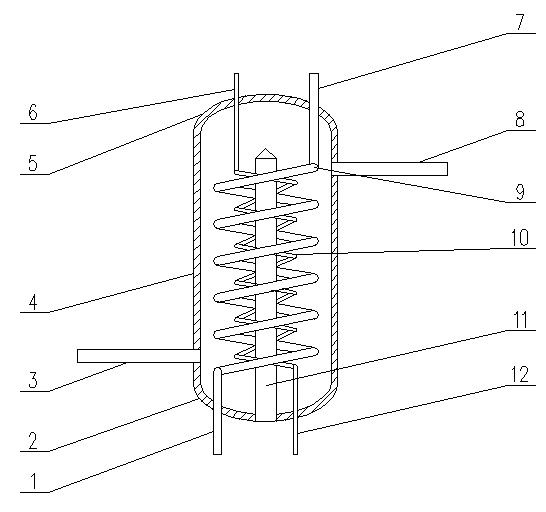

Method for preparing hydrogen with natural gas as raw material

The invention discloses a method for preparing hydrogen with natural gas as a raw material, comprising the following steps: the natural gas enters a desulphurization reactor to be desulfurized after passing through a multichannel heat exchanger; the desulfurized natural gas is mixed with overheated water vapour and then heated by a catalyzing burner before being sent into an adiabatic reactor in which the mixture of the natural gas and the overheated water vapour reacts with the air under the action of catalyst; the gas from the reaction is sent into a CO convertor for CO transformation reaction after undergoing heat transfer in a steam superheater; the gas from the reaction is sent into a membrane separator to be separated to obtain hydrogen and tail gas; the tail gas is sent into the catalyzing burner and goes through catalytic combustion reaction with air in the presence of the catalyst; the high-temperature flue gas generated in the reaction is sent into the multichannel heat exchanger for heat transfer and then heated in a steam generator for desalting water to obtain saturated vapour to be sent into the steam superheater. The invention has the advantages of simple technology, reduced production cost, low energy consumption and no pollution to the environment.

Owner:ALLY HI TECH CO LTD

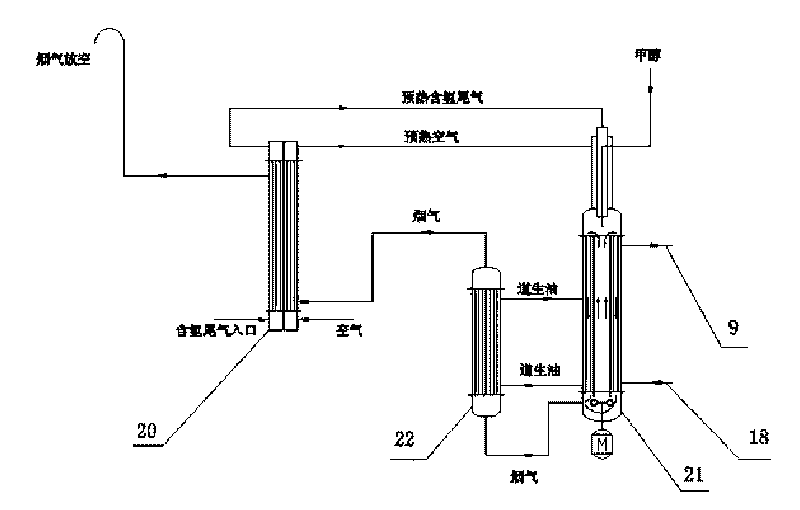

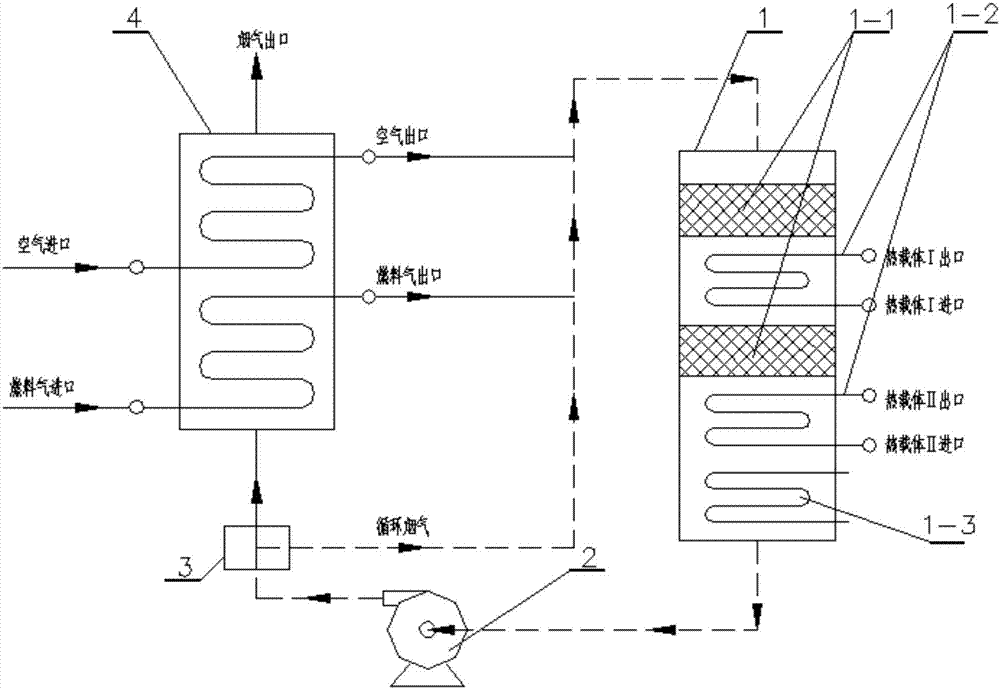

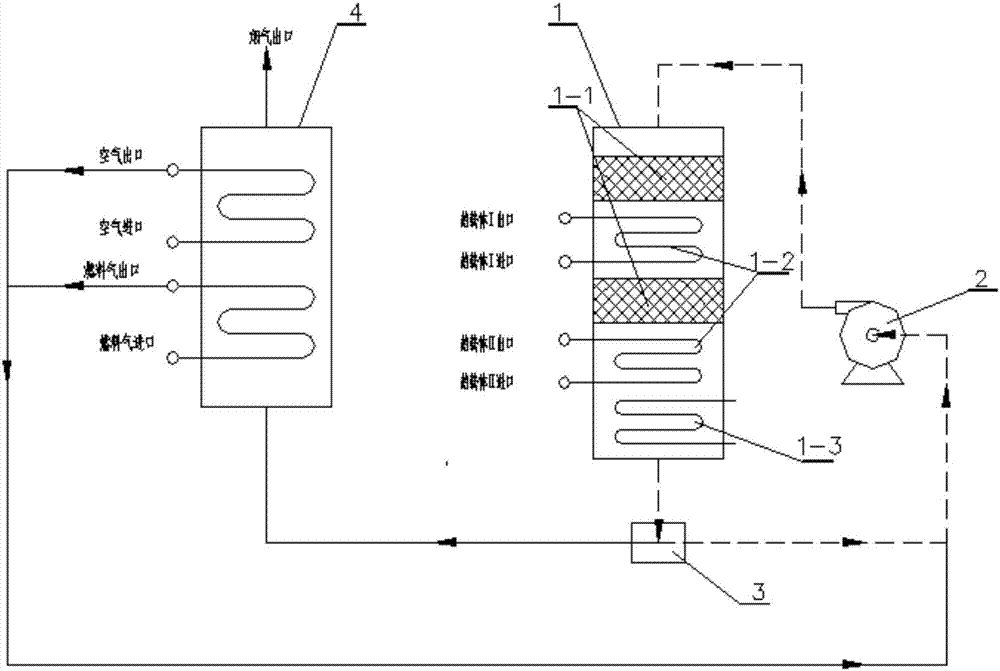

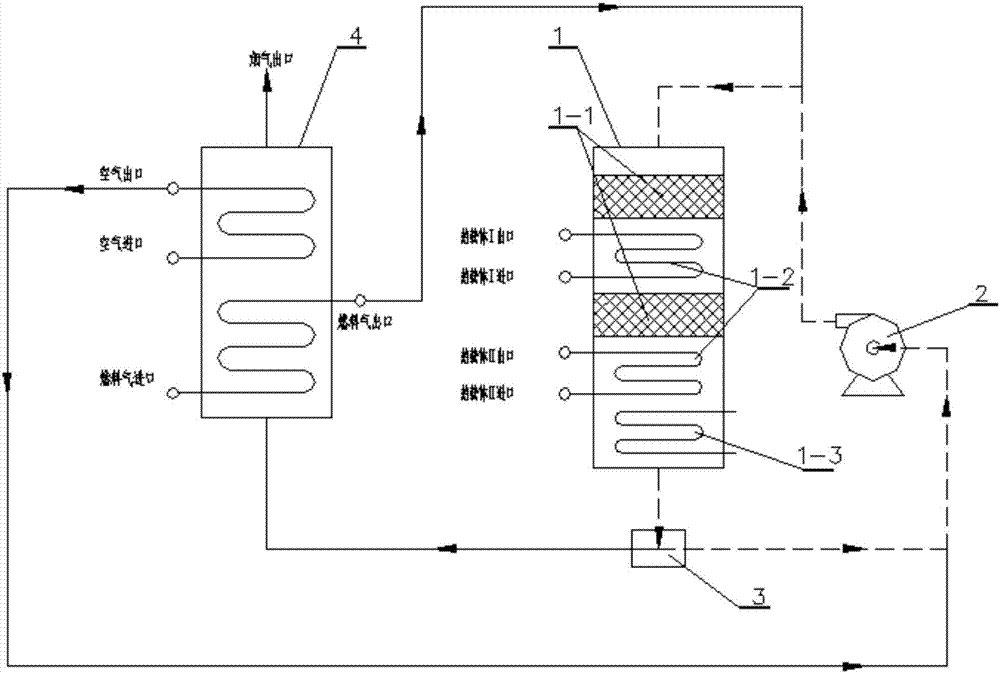

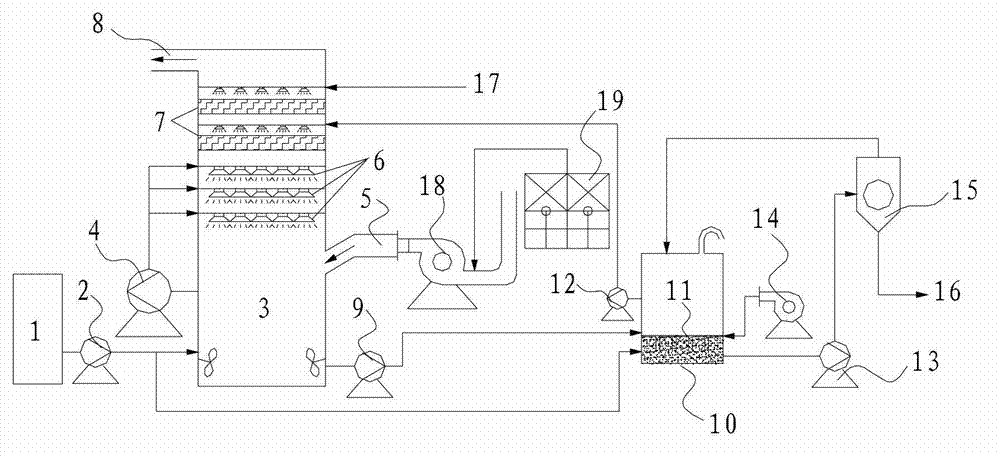

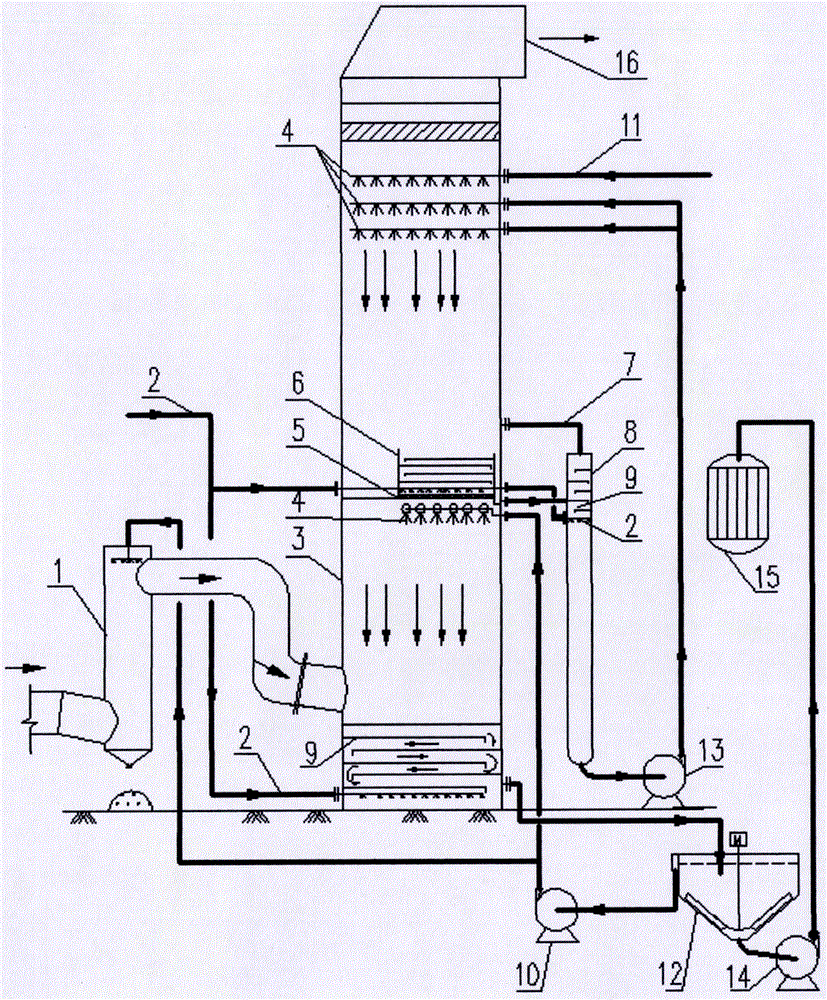

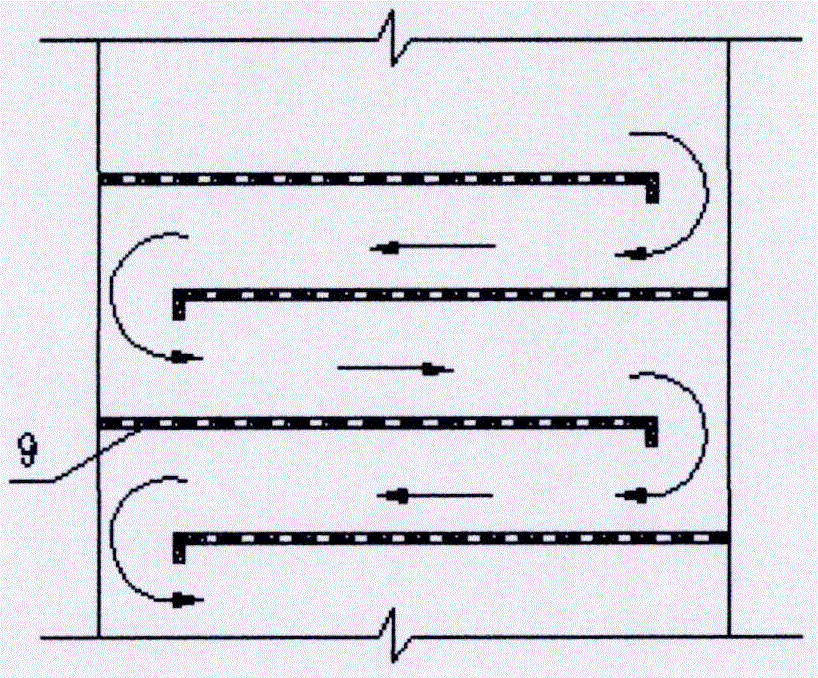

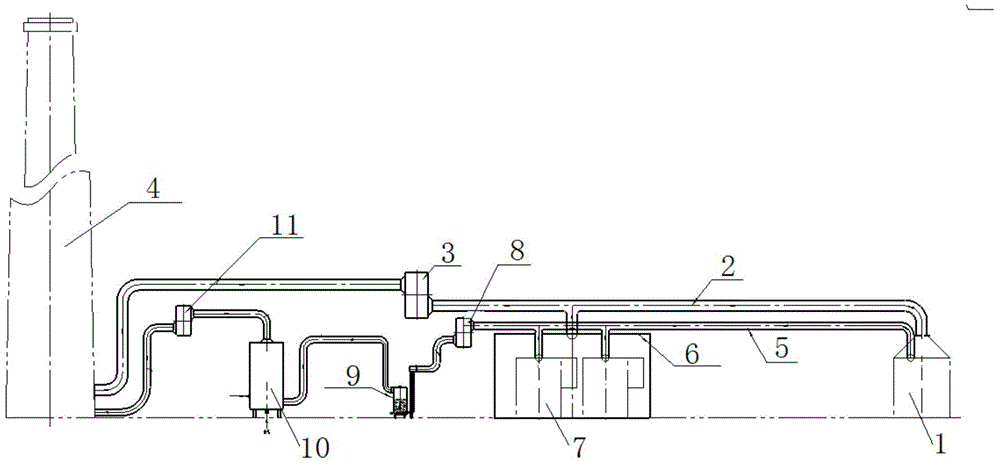

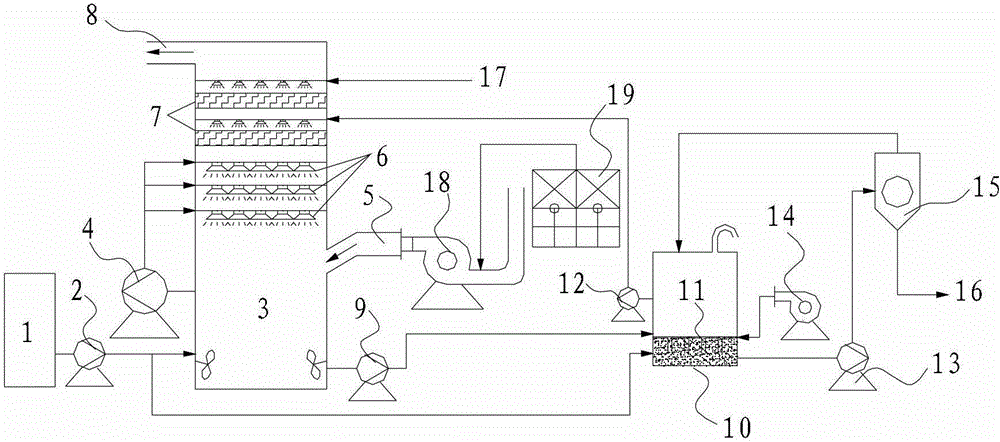

Catalytic combustion heating system and heating technology

InactiveCN107327856AAchieve re-useIncrease profitIncinerator apparatusAir quality improvementThermal energyHeat carrier

The invention discloses a catalytic combustion heating system and belongs to the technical field of catalytic combustion heating and environmental protection. With the system, a heat carrier is heated by heat released by a catalytic combustion reaction. The system comprises a catalytic combustion reaction heating zone, a flow control unit and a flue gas circulating device which is connected with the catalytic combustion reaction heating zone and the flow control unit in a communicating manner; and the catalytic combustion reaction heating zone is connected with the flow control unit in a communicating manner. The invention further relates to a technology for heating with the system. With the system and the technology, industrial waste gas is used as a heat source to provide heat for feed gas and the heat carrier which are required to be preheated, so that the heat utilization rate can be increased, the energy consumption can be reduced, the industrial waste gas is reused, the production cost is reduced, and environmental pollution is reduced. The catalytic combustion temperature is low, the complete reaction is realized, the energy consumption is low, the operation is simple and safe, and the purification efficiency is high. With the system, the land occupied by equipment can be effectively reduced, the cost can be reduced, and resource waste can be reduced.

Owner:ALLY HI TECH CO LTD

Amino wet combined desulfurization and denitration device and process

InactiveCN102824824AImprove desulfurization efficiency and ammonium sulfate crystal qualityEasy to separateDispersed particle separationAmmonium sulfatesNitric oxideNitrogen dioxide

The invention discloses amino wet combined desulfurization and denitration device and a process. The device comprises a desulfurization tower with an inlet flue, a liquid ammonia storage tank, an ozone generator, and a booster fan on the inlet flue; and a defogging layer, a spraying layer and a tower kettle are orderly arranged inside the desulfurization tower from top to bottom. The device also comprises an oxidization slot communicated with the tower kettle, and an oxidization fan connected to the oxidization slot; the liquid ammonia storage tank is communicated to the tower kettle through one path of pipeline, and is communicated to the bottom part of the oxidization slot through another pipeline; the ozone generator is communicated to an air inlet of the booster fan through the pipeline; ozone is sprayed into smoke from the air inlet of the booster fan; nitric oxide in the smoke is oxidized into nitrogen dioxide; the smoke oxidized by ozone is conveyed to the desulfurization tower; liquid ammonia is sprayed to desulfurize and denitrate; the smoke is discharged after being defogged and dried; and circulating liquid by which sulfur dioxide and nitrogen dioxide are absorbed is oxidized outside the tower, and the liquid ammonia is conveyed to the oxidization slot to adjust the pH (Potential Of Hydrogen) value in the oxidization slot during the oxidization process.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

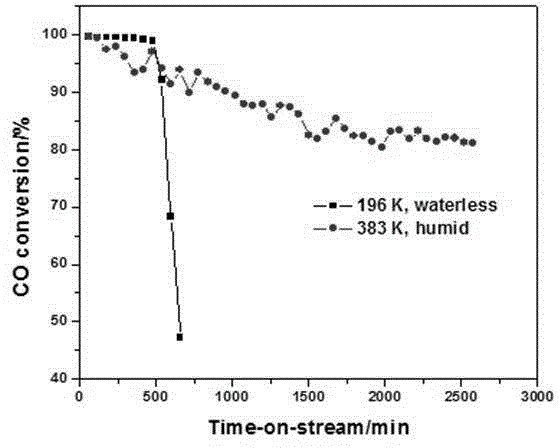

Preparation and catalytic application of PtMnO2/Co3O4/CeO2

InactiveCN105148934AAchieve complete oxidationPromotes rapid oxidationDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureComposite oxide

Disclosed are preparation of a catalyst of PtMnO2 / Co3O4 / CeO2 and a catalytic application of the catalyst to low-temperature oxidation of carbon monoxide and formaldehyde. The atomic ratio of Co to Mn to Ce in a composite oxide of MnO2 / Co3O4 / CeO2 is 38 / 1 / 1. The catalyst of PtMnO2 / Co3O4 / CeO2 related in the invention has preferable catalytic activity and has a conversion rate of CO oxidation of 99% at a relatively low temperature of 196K, wherein the conversion rate can continuously maintain for more than 480 min. Complete oxidation of formaldehyde can be realized at a room temperature.

Owner:邵建军

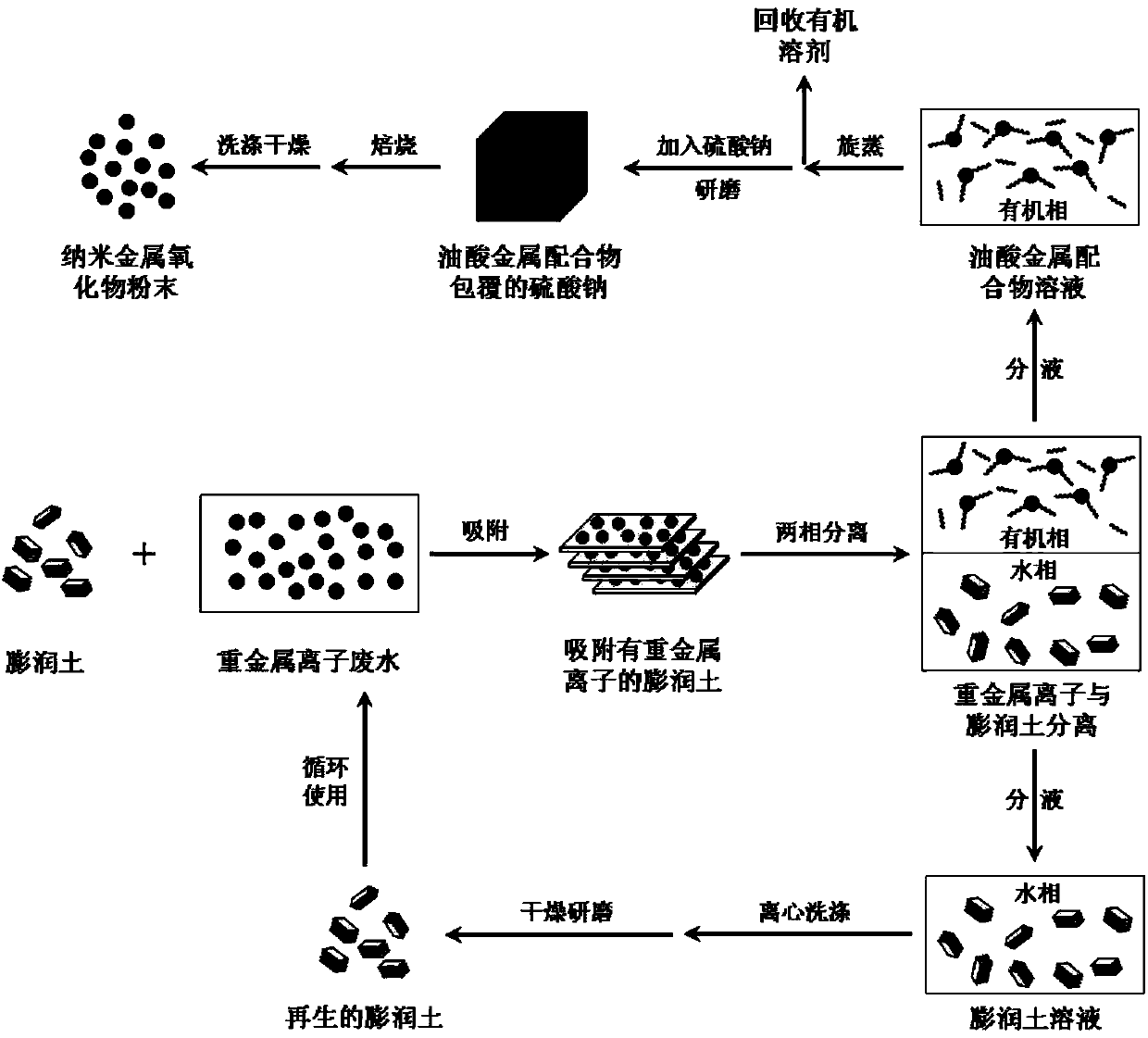

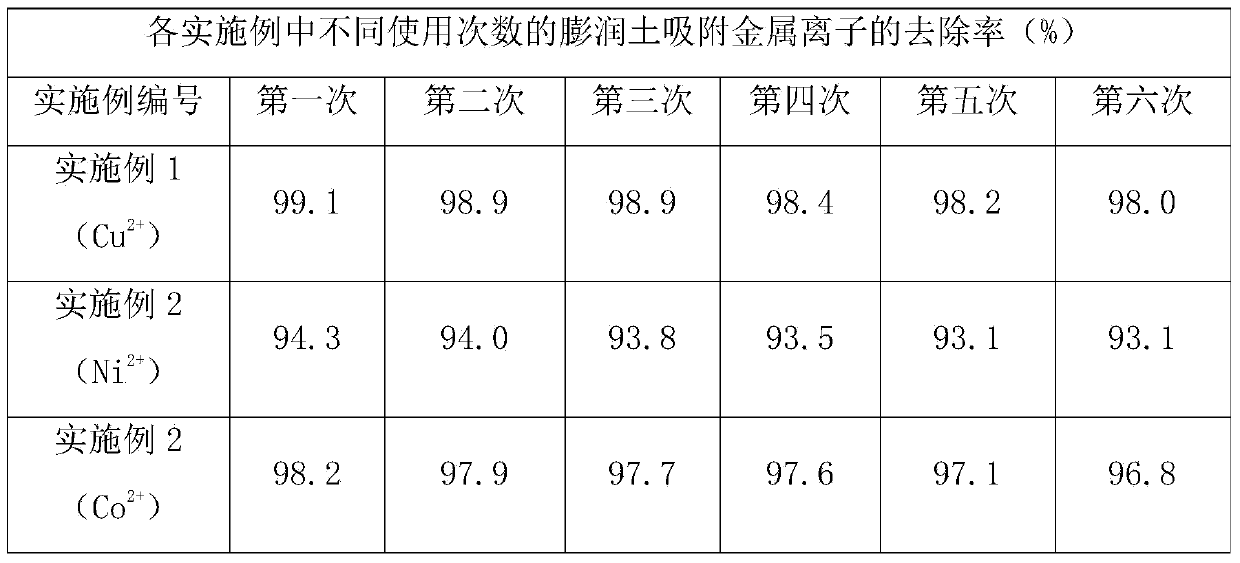

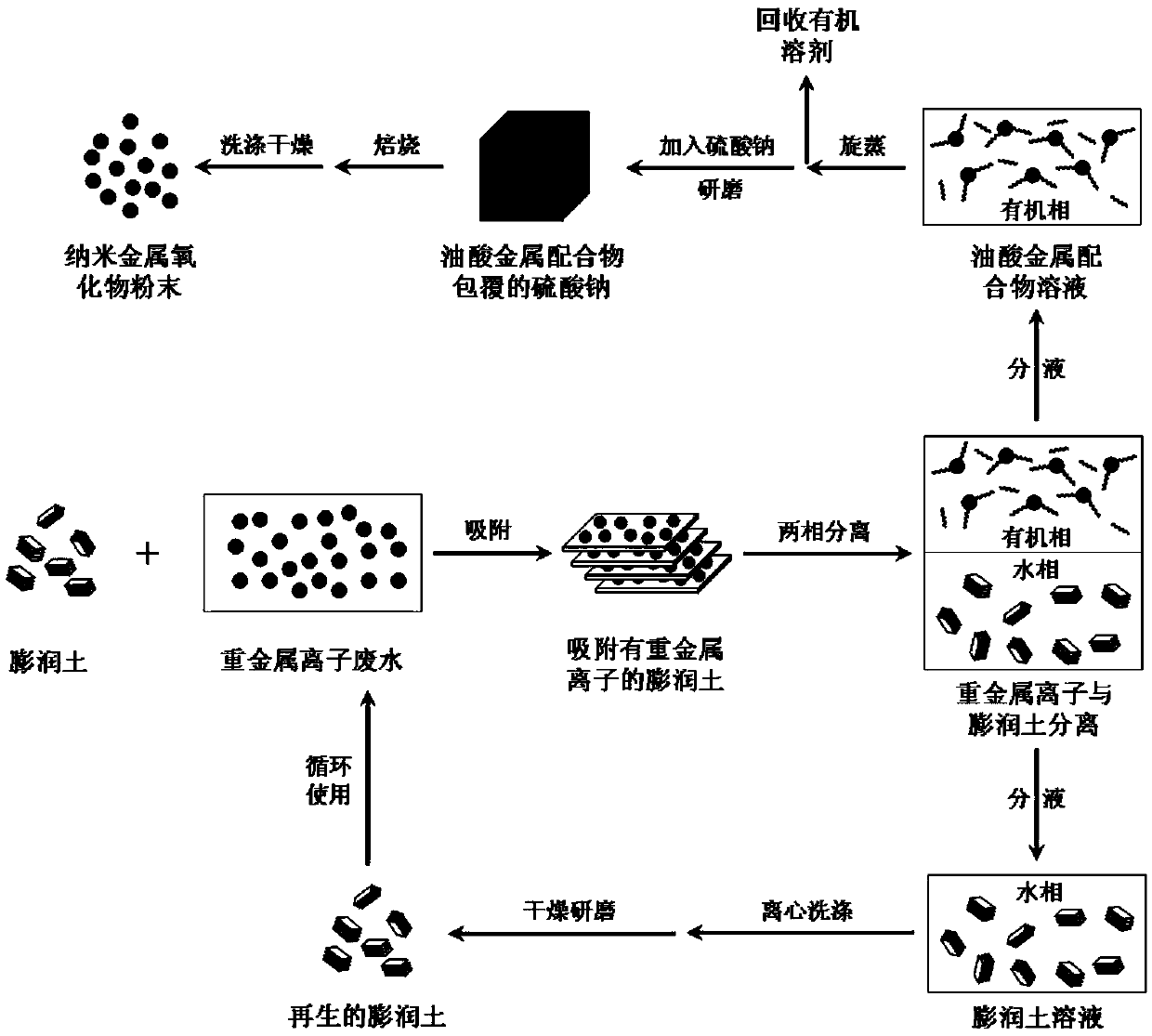

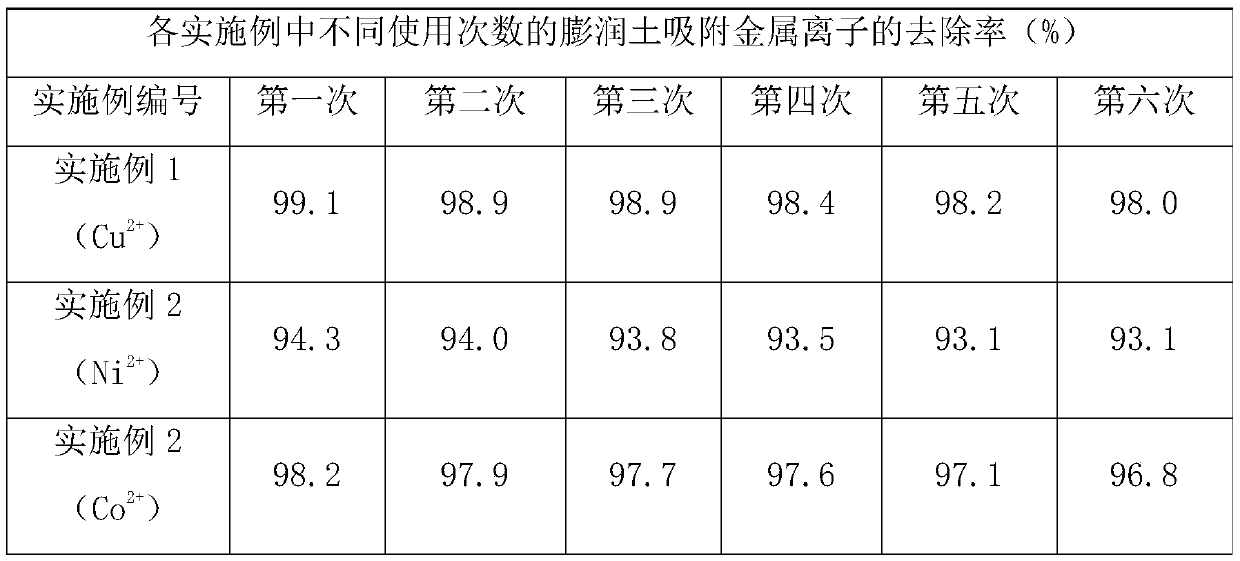

Metal ions adsorbed by bentonite and regenerating method thereof

ActiveCN104001472AAchieve recyclingRealize resource utilizationOther chemical processesCombustible gas purificationSorbentResource utilization

The invention relates to metal ions adsorbed by bentonite and a regenerating method of the metal ions adsorbed by the bentonite. According to the regenerating method, a good effect is achieved by treating Cu2+, Ni2+ and Co 2+ waste water through the bentonite serving as an adsorbent, after the collected metal ions are subjected to complexation and separation in a two-phase system, the metal ions adsorbed by the bentonite and oleic acid radical ions are subjected to complexation and transferred to an organic phase, the bentonite in a water phase can continue to be used for adsorbing metal ions after being washed centrifugally, the oleic acid-metal coordination compound in the oleic phase is respectively calcinated in the argon environment and the air environment to form nano metal oxide powder with high added-value, and resource utilization of the metal ions is achieved.

Owner:新疆德安环保科技股份有限公司

Ammonia process desulfurization device capable of saving energy by more than 50%

PendingCN106799126ARelieve pressureLower the altitudeGas treatmentUsing liquid separation agentEnergy recoveryElectric potential energy

The invention discloses an ammonia process desulfurization device capable of saving energy by more than 50%. One part of liquid conveyed out of a low circulating pump is conveyed to a cooling and dry powder discharging integrated pipe, is instantaneously evaporated into dried ammonium sulfate with hot flue gas and can be directly used for farmland fertilizers, so that lots of heat energy of a subsequent drying system is saved, the flue gas can be cooled, and a temperature-resistant range of an anticorrosive layer of a desulfurizing tower is reached; oxidation air upwards penetrates through small pores of a porous flanged gas-liquid plate, and liquid flows back and forth transversely and is repeatedly in contact with the oxidation air, so that the oxidation efficiency is improved; the liquid and air flows through respective channels without conflicting with each other, so that the operation is smooth, and the operating flexibility is greatly improved; due to an energy recovery pipe, high potential energy can be totally utilized, and the impact failure effect on equipment is relieved; the problem that the existing equipment is high in investment, high in power consumption, poor in absorption liquid oxidation effect and difficult to control is wholly solved, the capital of the desulfurizing tower can be theoretically saved by 33% or higher, and the energy and capital of a primary circulating pump of the maximum power consumption equipment can be saved by more than 50%.

Owner:刘荣甫

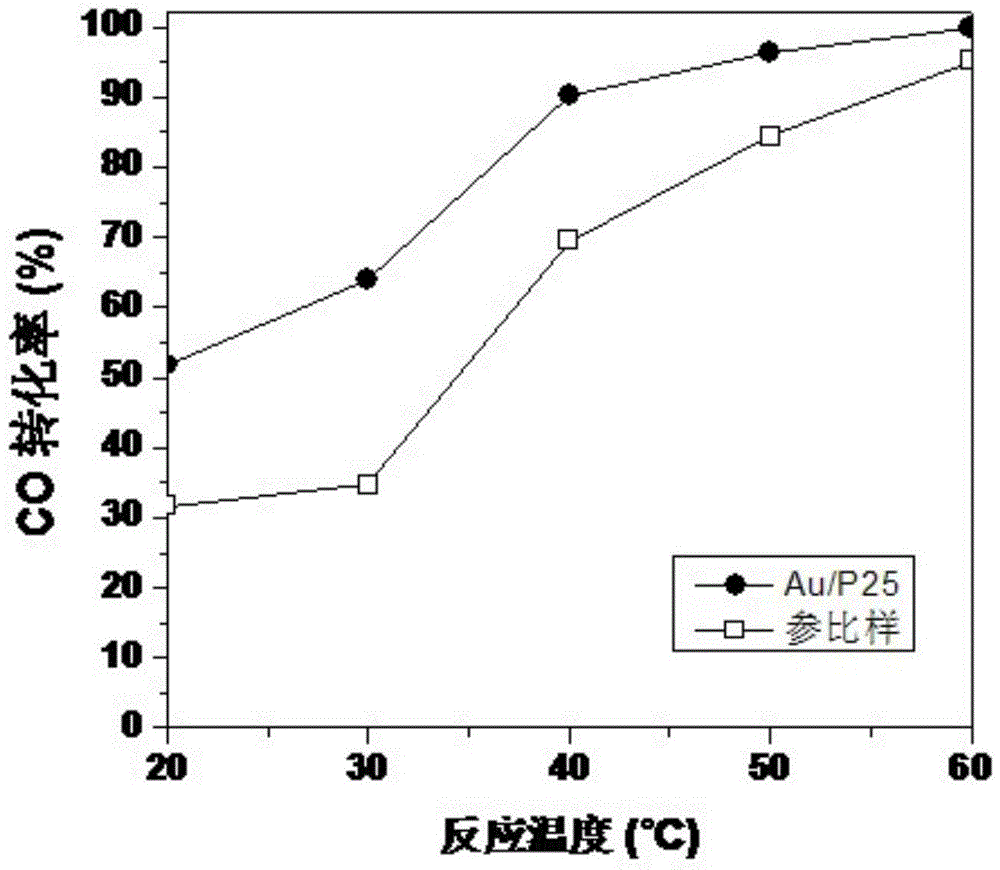

Gold-base catalyst for room-temperature carbon monoxide removal and preparation method thereof

ActiveCN103599777AImprove utilization efficiencyThe process is simpleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCoprecipitationUtilization rate

The invention discloses a gold-base catalyst for room-temperature carbon monoxide removal and a preparation method thereof. According to the invention, a traditional deposition-coprecipitation method for preparation of the gold-base catalyst is improved; a gold precursor is activated by adopting a light-heat combination mode to prepare a gold catalyst for performing catalytic oxidation on carbon monoxide at room temperature; and the gold utilization rate is improved. The method is simple in process flow, convenient to operate and high in repeatability, the preparation parameters are easily controlled, and the large-scale synthesis can be realized.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

A nanoflower spinel COMN for catalytic oxidation of VOCs 2 o 4 Catalyst, preparation method and application

ActiveCN108295866BHigh activityAchieve complete oxidationGas treatmentDispersed particle separationOXALIC ACID DIHYDRATEPtru catalyst

The invention belongs to the technical field of environmental catalytic purification and provides a nanoflower spinel CoMn used for catalytic oxidation of VOCs. 2 O 4 Catalysts, preparation methods and applications. Oxalic acid is used as a precipitant, washed, dried and calcined to obtain spinel CoMn 2 O 4 catalyst. CoMn prepared by the present invention 2 O 4 The catalyst exhibits self-assembly of nanosheets to form nanoflower-like structures. Compared to oxide Co 3 O 4 ,MnO x and mixed phase Co 3 O 4 / MnO x and the spinel CoMn currently reported in the literature. 2 O 4 Catalyst, spinel CoMn prepared by the present invention 2 O 4 The catalyst shows good activity and stability in VOCs removal. It can reach 99% toluene removal rate at 220°C, 100% conversion of formaldehyde at 90°C, and 100% acetone removal rate at 170°C. , has good industrial application prospects.

Owner:DALIAN UNIV OF TECH

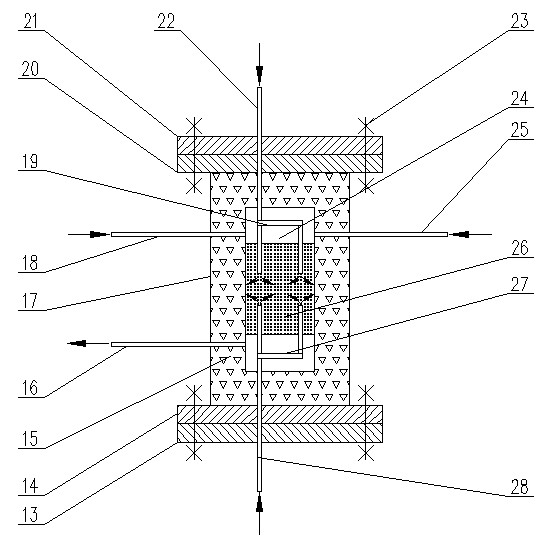

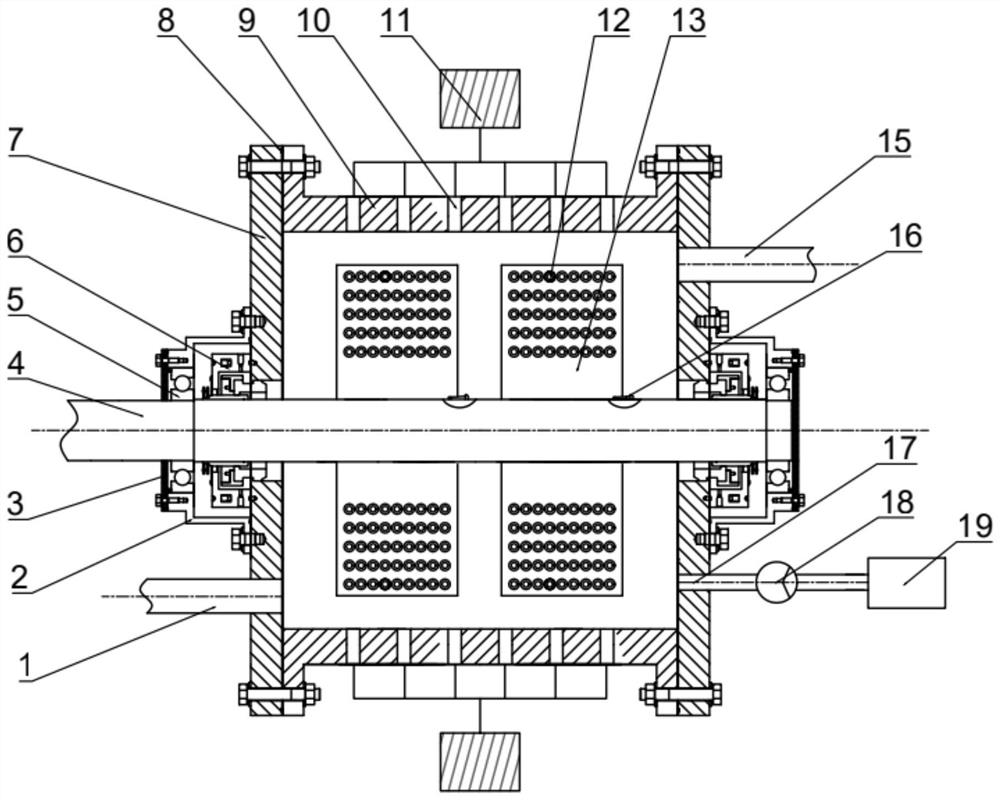

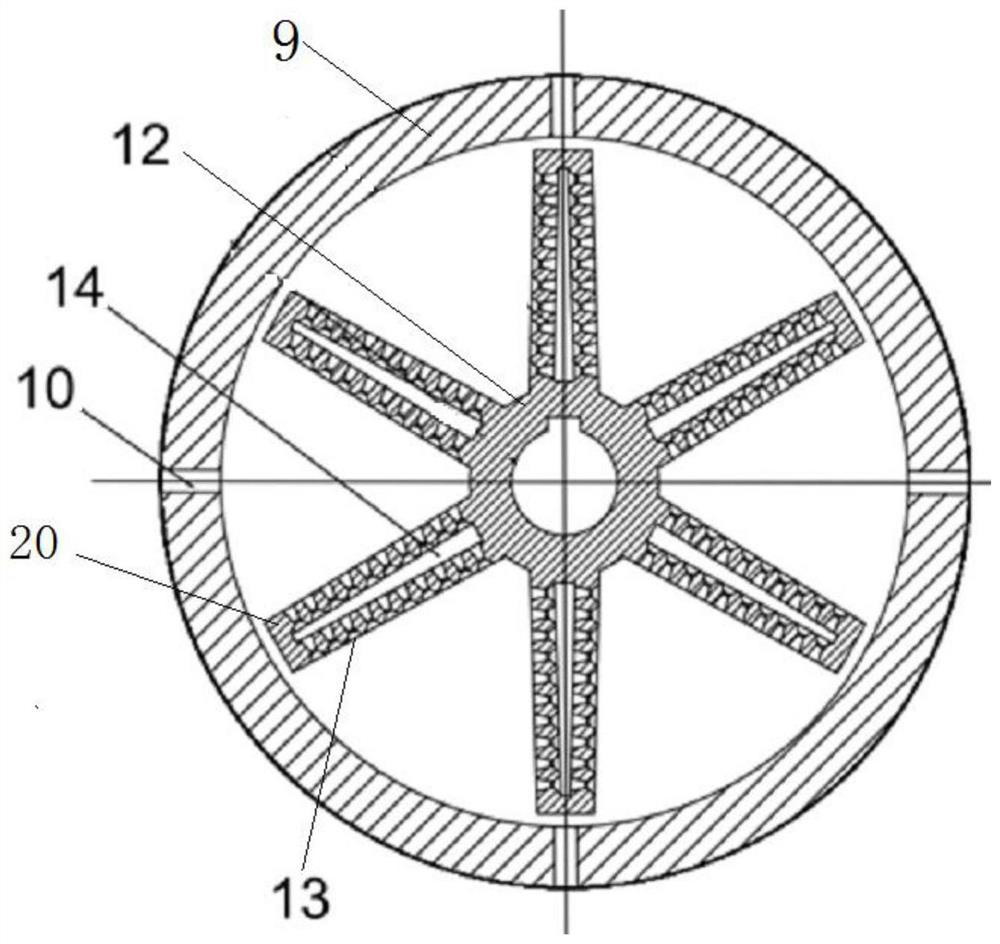

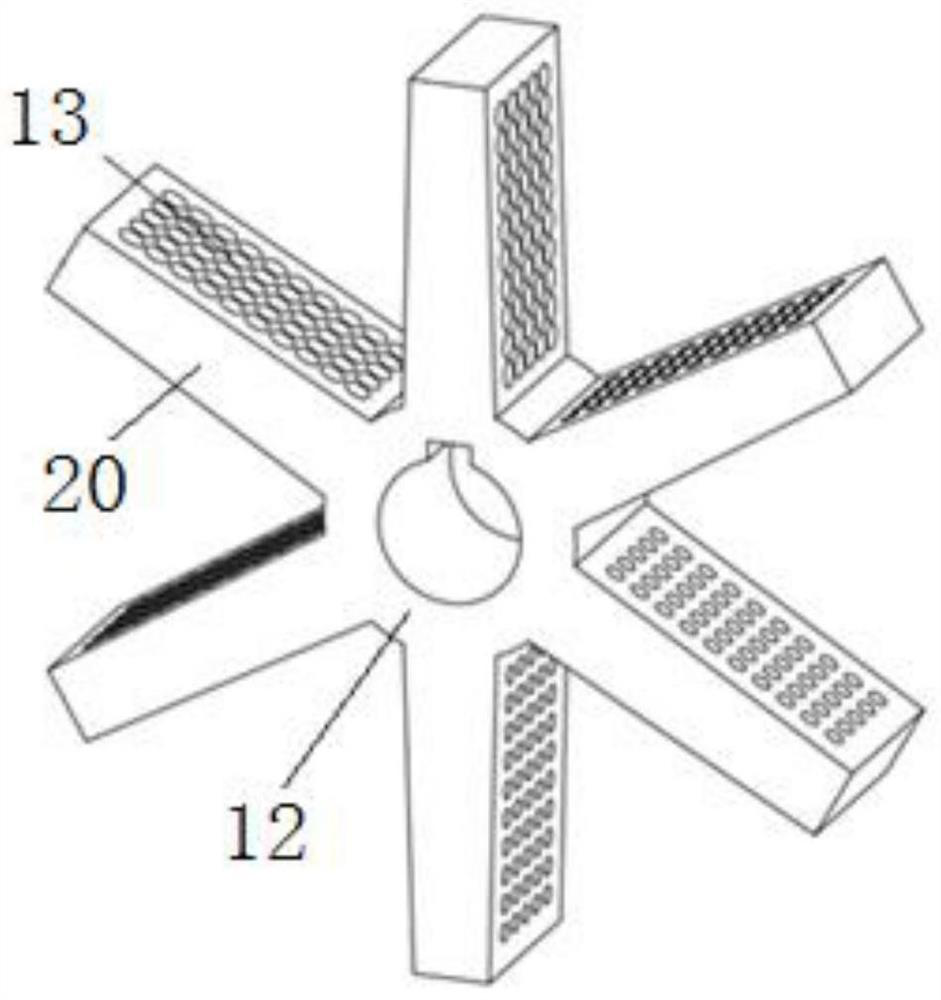

Hydrodynamic ultrasonic cavitation and advanced oxidation coupled degradation device for sulfide wastewater

InactiveCN112723519AAchieve complete oxidationThe degradation process is efficient and environmentally friendlyWater treatment compoundsWater/sewage treatment with mechanical oscillationsUltrasonic cavitationPhysical chemistry

The invention discloses a hydrodynamic ultrasonic cavitation and advanced oxidation coupled degradation device for sulfide wastewater. The device comprises a stator, a rotor, a rotating shaft and an ultrasonic transducer, the stator is a sealed cylinder, the ultrasonic transducer is installed on the inner wall of the stator, a liquid inlet and a liquid outlet are formed in the two sides of the stator respectively, an oxidizing agent injection device is arranged on one side of the liquid inlet, the rotating shaft is installed in the stator, one end of the rotating shaft extends out, the rotor is located in the stator and fixedly installed on the rotating shaft, blades are distributed on the circumference of the rotor, cavities are formed in the blades, and through holes are distributed in the two sides of each cavity. Sulfide wastewater is conveyed into the stator after being precipitated, an oxidizing agent is conveyed into the stator through the oxidizing agent conveying pipe and mixed with the wastewater, treatment is conducted through the cavitation technology, and degradation of organic matter is achieved. According to the device, hydrodynamic cavitation, ultrasonic cavitation and an advanced oxidation technology are combined to synergistically degrade the sulfide wastewater, the treatment efficiency is high, the treatment effect is good, and continuous operation can be realized.

Owner:SHANDONG UNIV

Preparation for Au-PtMnO2Co3O4CeO2 catalyst and catalytic application

InactiveCN105214681AAchieve complete oxidationPromotes rapid oxidationDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureMoisture

The invention relates to preparation for an Au-PtMnO2Co3O4CeO2 catalyst and catalytic application. The catalyst is characterized in that the mass percentages of Au and Pt in the catalyst are 2% and 1% of MnO2Co3O4CeO2, respectively, and the atomic ratio of Co, Mn and Ce in the MnO2Co3O4CeO2 composite oxide is 19 / 1 / 1. The moisture resisting property of the Au-PtMnO2Co3O4CeO2 catalyst is improved, the carbon monoxide oxidative activity of the catalyst in a normal temperature moisture environment can be further improved, and the catalyst can be used for completely oxidizing formaldehyde under a room temperature condition.

Owner:邵建军

Preparation method of waste gas purifying catalyst

ActiveCN110935470AImprove redox abilityGood dispersionCatalyst activation/preparationIncinerator apparatusPtru catalystExhaust fumes

A waste gas purifying catalyst. The invention belongs to the technical field of waste gas treatment. A preparation method of the catalyst includes: performing wet-impregnation with a water and dimethyl sulfoxide mixed solution as a solvent to prepare the double-metal supported catalyst Cu-Pt / CeO2-Al2O3. Compared with the prior art, the catalyst shows high catalytic activity under a normal workingcondition and can effectively suppress performance reduction of a catalyst active component due to sulfur in the waste gas. The process is suitable for mass production, has the possibility of industrial production and has extensive application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Brake shoe workshop curing furnace waste gas treating system and method

ActiveCN104482773AAchieve complete oxidationObvious effect of deodorizing and deodorizingIncinerator apparatusWaste heat treatmentCombustion chamberProduct gas

The invention discloses a brake shoe workshop curing furnace waste gas treating system and a brake shoe workshop curing furnace waste gas treating method. The system comprises a diffused smoke treating system and a waste gas treating system, wherein the diffused smoke treating system comprises a first gas flue which is respectively connected with diffused smoke outlets of a first curing furnace door smoke hood and a second curing furnace sealing chamber; the first gas flue is sequentially connected with a first centrifugal fan and an outer chimney; the waste gas treating system comprises a second gas flue which is respectively connected with waste gas outlets of a first curing furnace and a second curing furnace; the second gas flue is sequentially connected with a second centrifugal fan, a combustion chamber, a third centrifugal fan and the outer chimney. The system and the method have the beneficial effects that combustible pollutants, suspended carbon granules and smog-shaped organics in curing furnace waste gas can be burnt off, and odor gas can be completely oxidized; the system and the method have the advantages of obvious peculiar smell removing effect, high deodorization efficiency, convenient technique operation, stable operation performance and the like; a work field environment and the surrounding environment are greatly improved; the requirement of national environment protection is met.

Owner:CHINA RAILWAY LONGCHANG MATERIALS

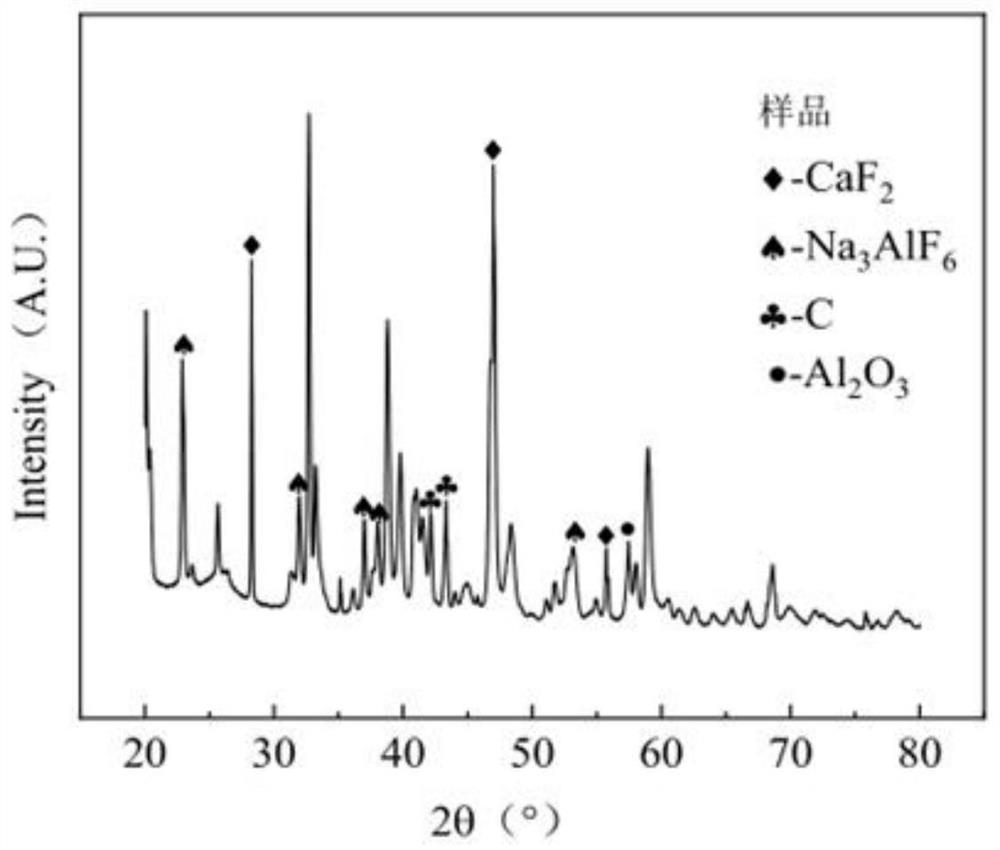

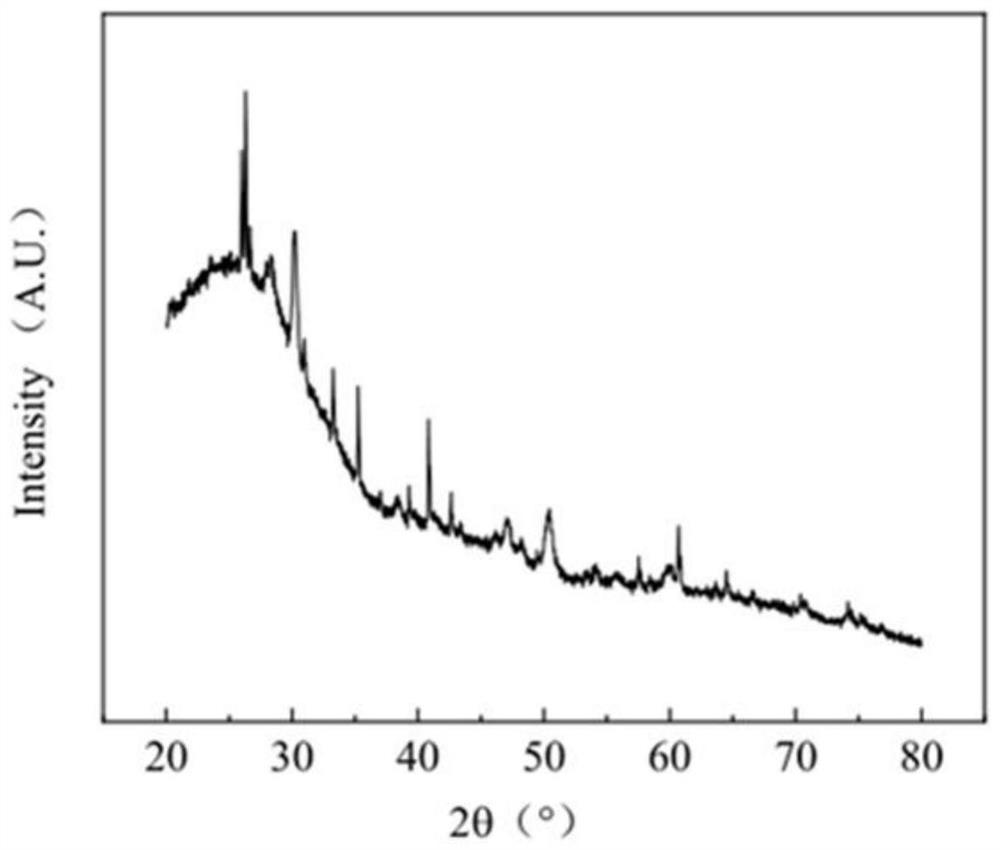

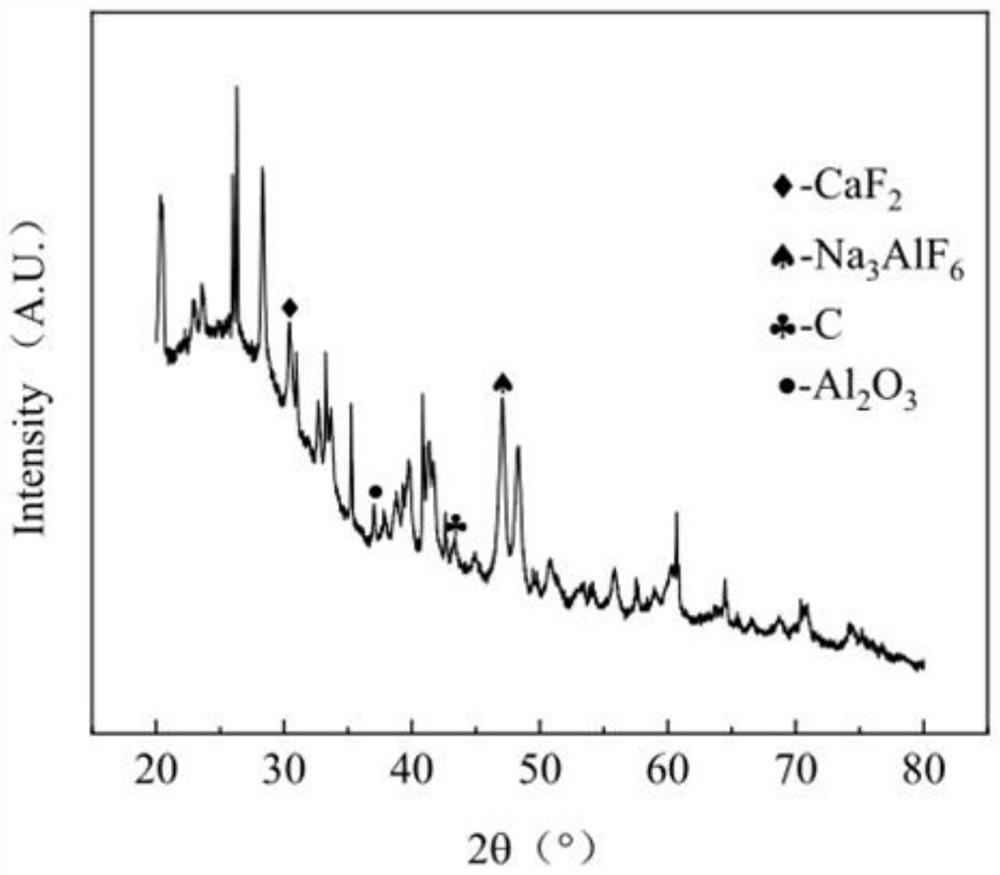

Process for treating electrolytic aluminum carbon residues through supercritical water oxidation

PendingCN114635163AWill not introduceOxidizingPressure vessels for chemical processSupercritical condition processesPhysical chemistrySupercritical water oxidation

The invention relates to the technical field of electrolytic aluminum, in particular to a process for treating electrolytic aluminum carbon residues through supercritical water oxidation and recycling electrolyte.The process comprises the steps that smashed carbon residues, water and an oxidizing agent are added into a reaction kettle, the temperature is increased to 374-380 DEG C, meanwhile, after the pressure in the reaction kettle is increased to 20-23 Mpa, heat preservation and pressure maintaining are conducted for 1-2 h, after the reaction is finished, a pressure relief valve is opened, and after the reaction is finished, the pressure relief valve is opened; and starting a cooling water cooling reaction system, carrying out gas-liquid separation, and then separating a solid-liquid mixture in the kettle. Compared with a traditional high-temperature roasting method for carbon removal, the supercritical treatment temperature is low, the supercritical treatment is carried out in a closed system of a reaction kettle, fluorine in the electrolytic aluminum carbon residues is not prone to volatilization, in other words, electrolyte cannot be denatured, and pollution caused by volatilization of the electrolyte cannot be caused; and secondly, oxygen dissolved in the supercritical water can completely oxidize carbon in the carbon residues in a short time, so that the treatment time of the electrolytic aluminum carbon residues is greatly shortened.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Anti-propylene mask and preparation method thereof

ActiveCN111716841AProtection against propylene poisoningPrevent accidents caused by static electricityFibre typesSynthetic resin layered productsWoven fabricCarboxylic group

The invention discloses an anti-propylene mask and a preparation method thereof. The anti-propylene mask is formed by sewing a fiber cloth contact layer, an anti-static non-woven fabric layer and a fullerene / nano titanium dioxide spunbond layer which are sequentially arranged, wherein the fullerene / nano titanium dioxide spunbond layer is prepared by spinning a modified resin material into a fiberweb by adopting a spunbond method; the modified resin material is prepared from the following raw materials: matrix resin, a carboxylated fullerene derivative, nano titanium dioxide, a lubricating agent and a coupling agent, the modified resin material is prepared by the following method: mixing and reacting a carboxylated fullerene derivative with nano titanium dioxide to prepare nano titanium dioxide modified by the carboxylated fullerene derivative, and then blending and extruding the nano titanium dioxide modified by the carboxylated fullerene derivative with the rest components in the rawmaterials to prepare the modified resin material. The mask is convenient to use and carry, can prevent propylene from entering a human body from respiratory organs of the human body, is good in anti-propylene effect, has an anti-static function, and is particularly suitable for being used in a propylene production workshop.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Low loading palladium platinum core-shell structure catalyst and its preparation method and application

ActiveCN106362736BAchieve complete oxidationThe result is obviousCarbon compoundsWaterHydrogen atmosphereSynthesis methods

The invention provides a low-loading palladium-platinum core-shell structure catalyst, which is prepared as follows: mix Pd precursor and propylene carbonate, stir and react for 1 to 5 hours in a hydrogen atmosphere of 1 to 4 MPa and room temperature, Obtain a solution containing Pd nanoparticles; add the Pt precursor to the obtained solution containing Pd nanoparticles, stir and react for 1 to 5 hours in a hydrogen atmosphere of 1 to 4 MPa at room temperature, and obtain a solution containing active components with a core-shell structure. ; The obtained solution containing core-shell structure active components and the carrier Al 2 O 3 Mix, stir for 4 to 48 hours, suction filtrate, and vacuum dry the filter cake to obtain the finished product; the raw materials of the synthesis method of the catalyst of the present invention are easy to obtain and can be reused, will not produce waste gas and waste water, have low environmental costs, and are easy to expand the scale for industrial production, so The prepared catalyst has higher activity than the catalyst obtained by the existing method, has good stability, and can be used in the catalytic oxidation reaction of toluene.

Owner:ZHEJIANG UNIV OF TECH

Catalyst for removing formaldehyde in wastewater, preparation method of catalyst and method for removing formaldehyde in wastewater

ActiveCN111744469AEfficient removalAvoid invalid decompositionMaterial nanotechnologyMolecular sieve catalystsPtru catalystNanoparticle

The invention relates to a catalyst for removing formaldehyde in wastewater, a preparation method of the catalyst and a method for removing formaldehyde in wastewater, and belongs to the technical field of wastewater treatment. The catalyst is formed by coating nanoparticles with the particle size of below 100 nm with graphene oxide. Nanoparticles with the particle size of below 100 nm in the catalyst can effectively improve the dispersity of graphene oxide in wastewater to guarantee that graphene oxide can be evenly dispersed in a reaction system without sedimentation, so that graphene oxidecan make full contact with formaldehyde and hydrogen peroxide in wastewater, and formaldehyde is efficiently removed. And graphene oxide in the catalyst can improve the oxidation capacity of hydrogenperoxide and can also avoid invalid decomposition of hydrogen peroxide. A hydrogen peroxide solution and the catalyst are sequentially added into formaldehyde-containing wastewater, and a stirring reaction is performed for 2-24 hours at a temperature of 25-75 DEG C. By adopting the method, formaldehyde in the wastewater can be effectively removed, the environmental problem caused by taking inorganic acid or alkali as the catalyst in the prior art is solved, and the method is environment-friendly, safe and non-toxic.

Owner:TAIYUAN INST OF TECH

Amino wet combined desulfurization and denitration device and process

InactiveCN102824824BLarge crystal sizeImprove qualityDispersed particle separationAmmonium sulfatesNitric oxideOzone generators

The invention discloses amino wet combined desulfurization and denitration device and a process. The device comprises a desulfurization tower with an inlet flue, a liquid ammonia storage tank, an ozone generator, and a booster fan on the inlet flue; and a defogging layer, a spraying layer and a tower kettle are orderly arranged inside the desulfurization tower from top to bottom. The device also comprises an oxidization slot communicated with the tower kettle, and an oxidization fan connected to the oxidization slot; the liquid ammonia storage tank is communicated to the tower kettle through one path of pipeline, and is communicated to the bottom part of the oxidization slot through another pipeline; the ozone generator is communicated to an air inlet of the booster fan through the pipeline; ozone is sprayed into smoke from the air inlet of the booster fan; nitric oxide in the smoke is oxidized into nitrogen dioxide; the smoke oxidized by ozone is conveyed to the desulfurization tower; liquid ammonia is sprayed to desulfurize and denitrate; the smoke is discharged after being defogged and dried; and circulating liquid by which sulfur dioxide and nitrogen dioxide are absorbed is oxidized outside the tower, and the liquid ammonia is conveyed to the oxidization slot to adjust the pH (Potential Of Hydrogen) value in the oxidization slot during the oxidization process.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Method for removing formaldehyde in wastewater by catalytic oxidation

PendingCN113683178AGood prospects for industrial applicationAvoid easy failureWater treatment parameter controlWater treatment compoundsEnvironmental chemistryHydrogen peroxide

The invention relates to a method for removing formaldehyde in wastewater by catalytic oxidation, and belongs to the technical field of wastewater treatment. Formaldehyde as a raw material, a transition metal oxide as a catalyst and a hydrogen peroxide solution as an oxidizing reagent are stirred and reacted for 15-60 minutes at 25-45 DEG C, and formaldehyde is catalytically oxidized into carbon dioxide and water, wherein the transition metal oxide is selected from any one of Fe2O3, Co2O3, NiO, CuO and ZnO. According to the method, formaldehyde in the wastewater can be effectively removed, the catalyst is easy to recover and can be repeatedly used, excessive hydrogen peroxide can be decomposed into water and oxygen, and the method is environmentally friendly, safe and non-toxic.

Owner:TAIYUAN INST OF TECH

A kind of bentonite adsorption metal ion and its regeneration method

ActiveCN104001472BAchieve recyclingRealize resource utilizationOther chemical processesCombustible gas purificationSodium BentoniteResource utilization

The invention relates to metal ions adsorbed by bentonite and a regenerating method of the metal ions adsorbed by the bentonite. According to the regenerating method, a good effect is achieved by treating Cu2+, Ni2+ and Co 2+ waste water through the bentonite serving as an adsorbent, after the collected metal ions are subjected to complexation and separation in a two-phase system, the metal ions adsorbed by the bentonite and oleic acid radical ions are subjected to complexation and transferred to an organic phase, the bentonite in a water phase can continue to be used for adsorbing metal ions after being washed centrifugally, the oleic acid-metal coordination compound in the oleic phase is respectively calcinated in the argon environment and the air environment to form nano metal oxide powder with high added-value, and resource utilization of the metal ions is achieved.

Owner:新疆德安环保科技股份有限公司

A kind of preparation method of exhaust gas purification catalyst

ActiveCN110935470BImprove redox abilityGood dispersionCatalyst activation/preparationIncinerator apparatusPtru catalystExhaust fumes

An exhaust gas purification catalyst belongs to the technical field of exhaust gas treatment. The preparation method of the catalyst uses a mixed solution of water and dimethyl sulfoxide as a solvent to prepare a bimetallic supported catalyst Cu-Pt / CeO by a wet impregnation method 2 ‑Al 2 o 3 . Compared with the prior art, the catalyst prepared by the present invention can show high catalytic activity under normal use conditions, can effectively inhibit the performance degradation of the catalyst active component caused by the (S) component in the exhaust gas, and is suitable for mass production , has the possibility of industrialized production, and has broad application prospects.

Owner:BEIJING UNIV OF CHEM TECH

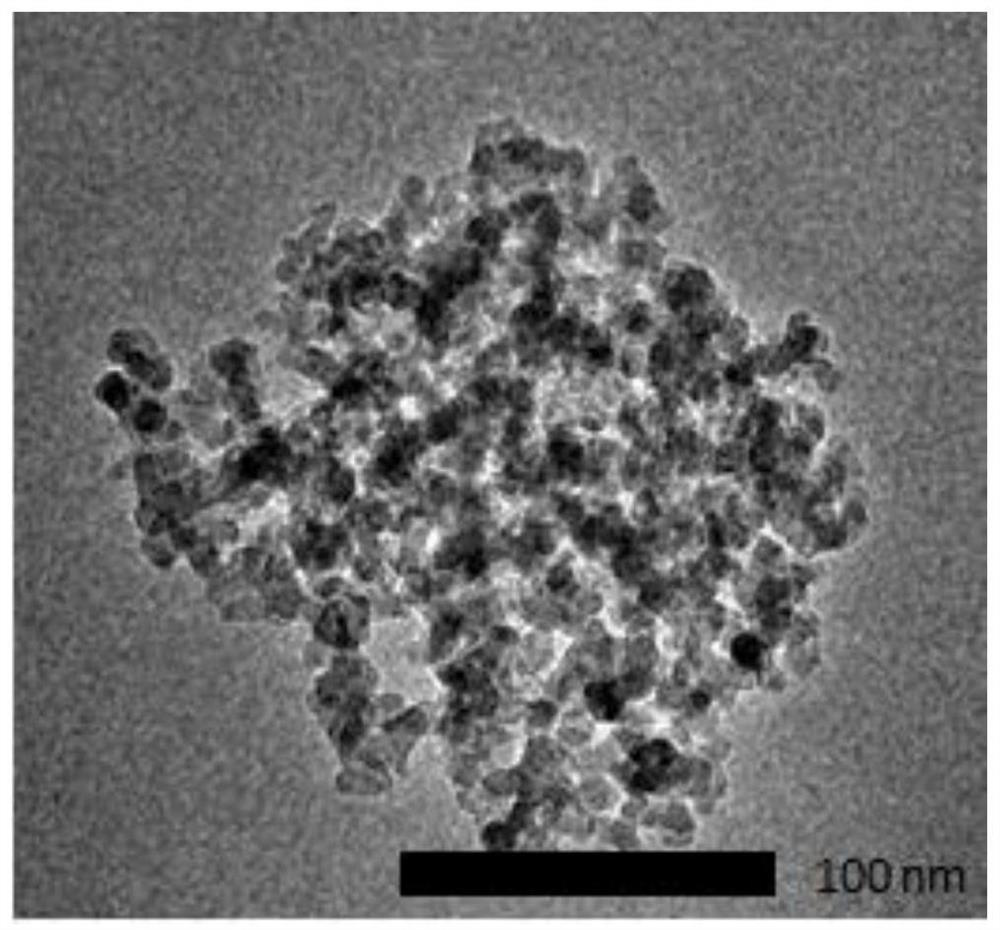

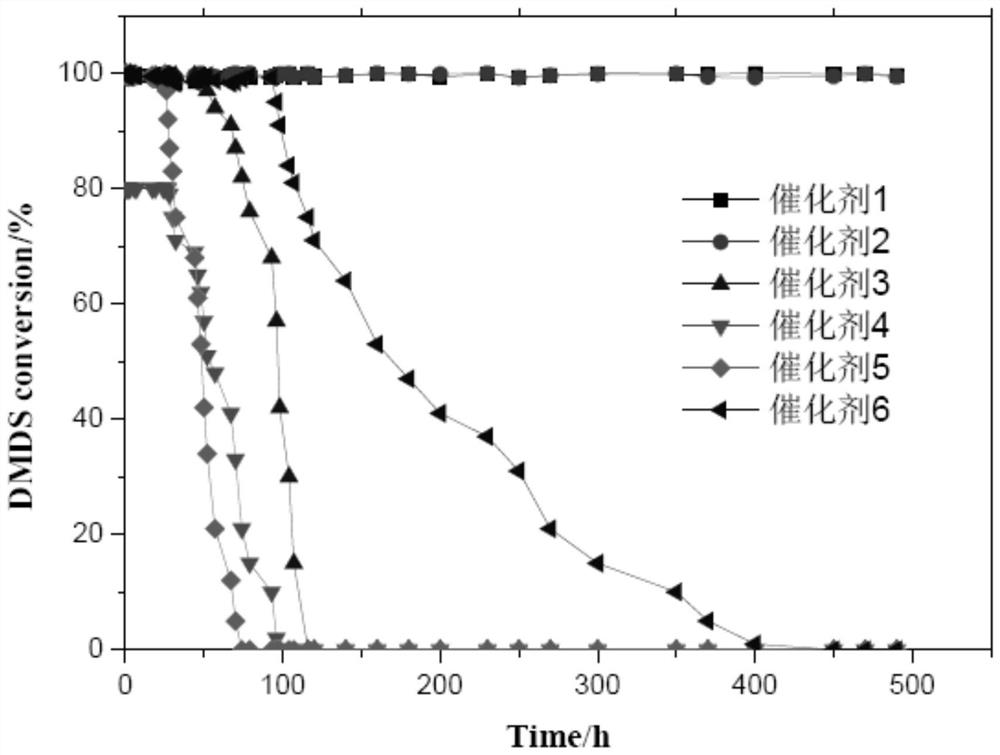

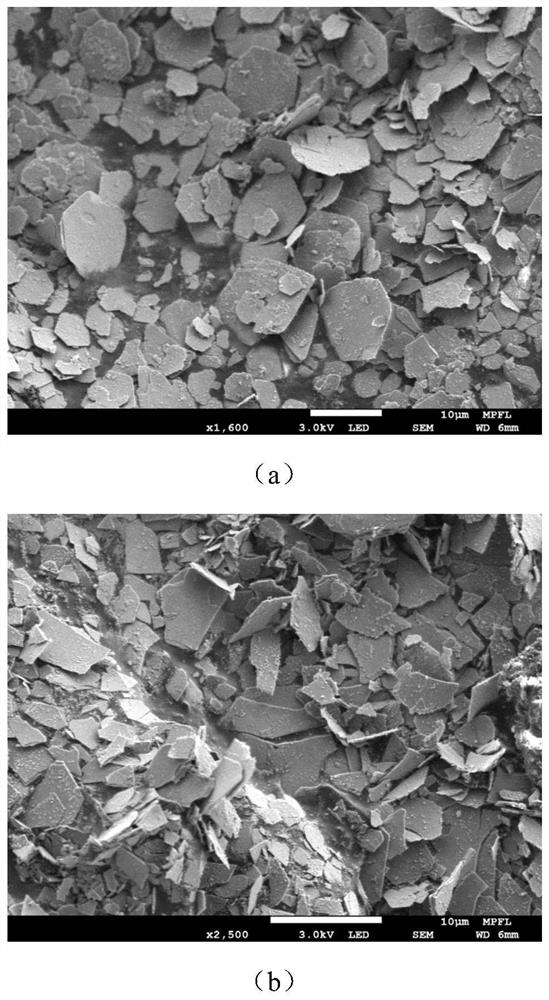

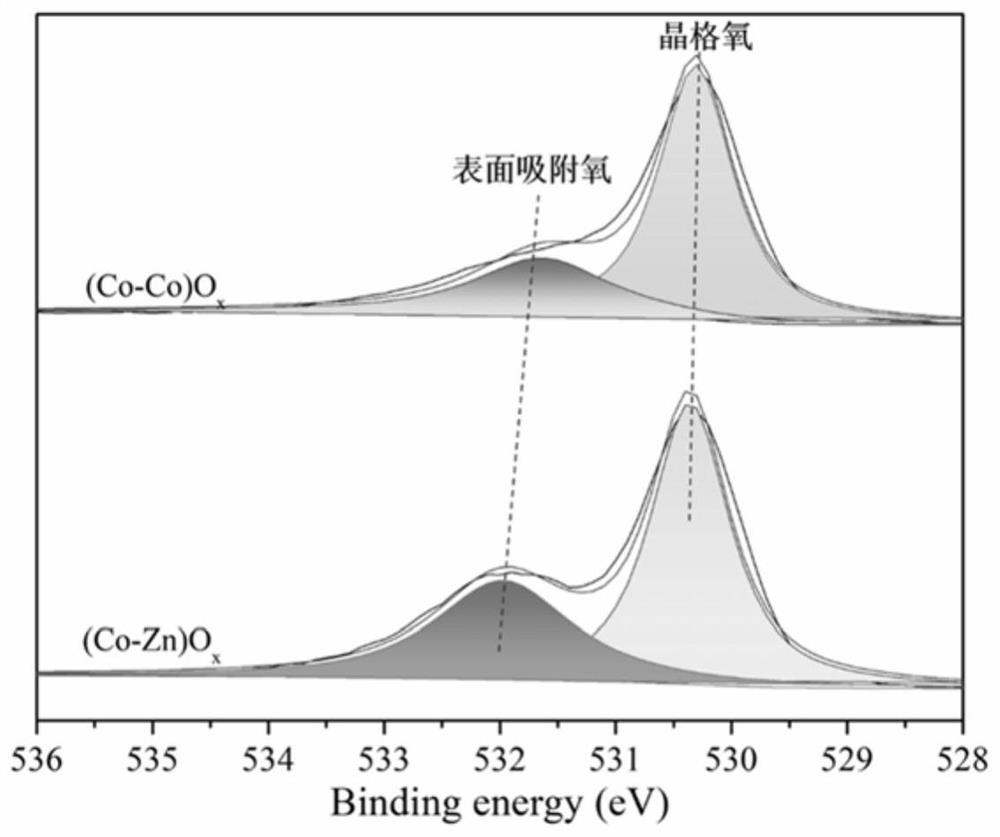

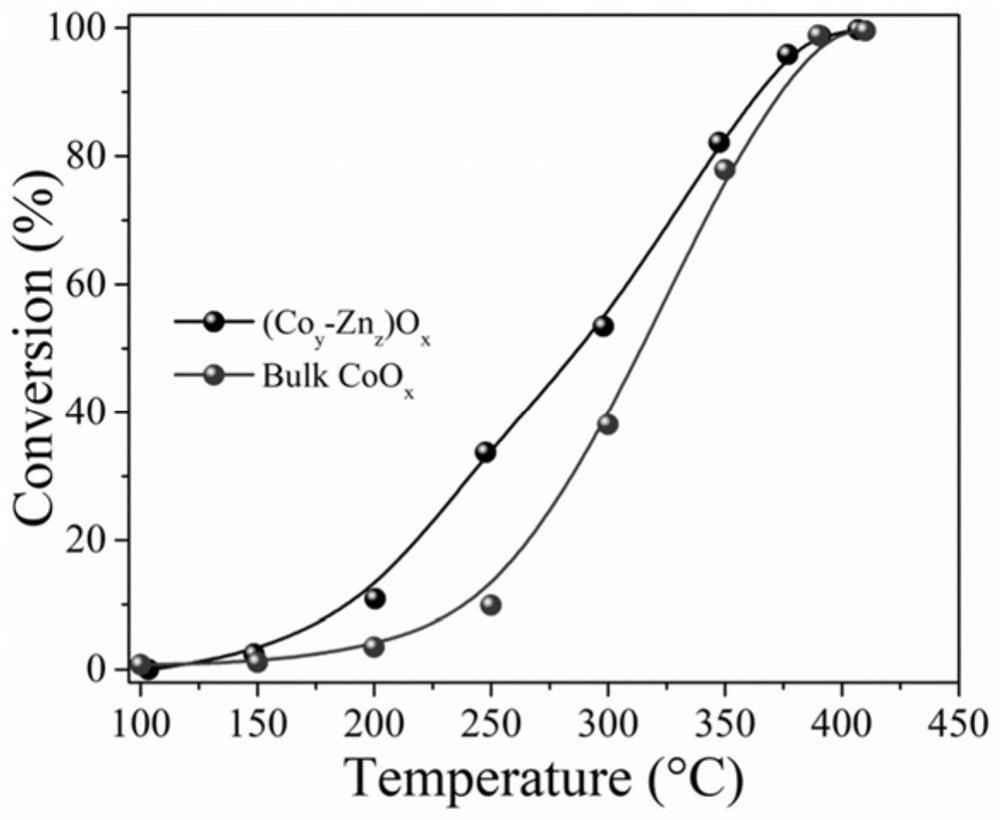

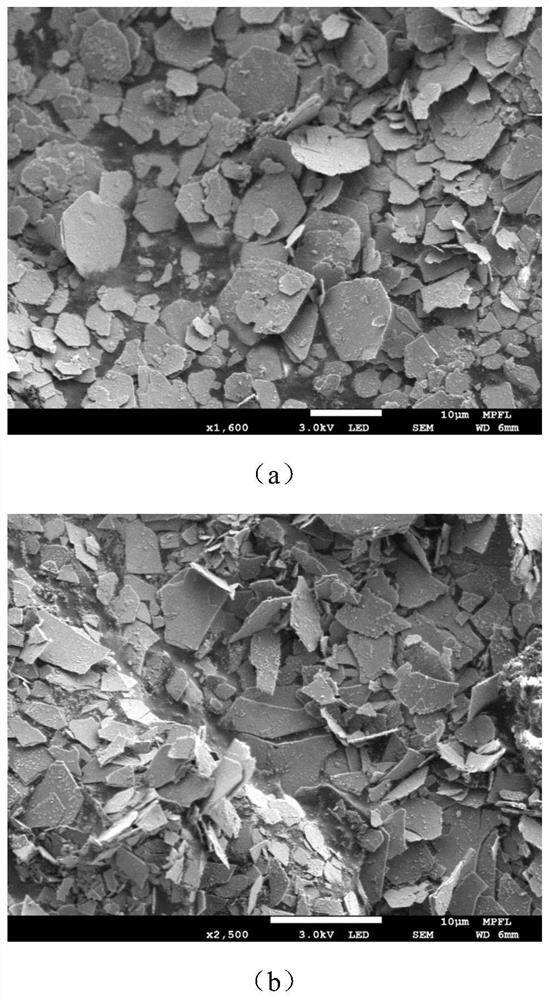

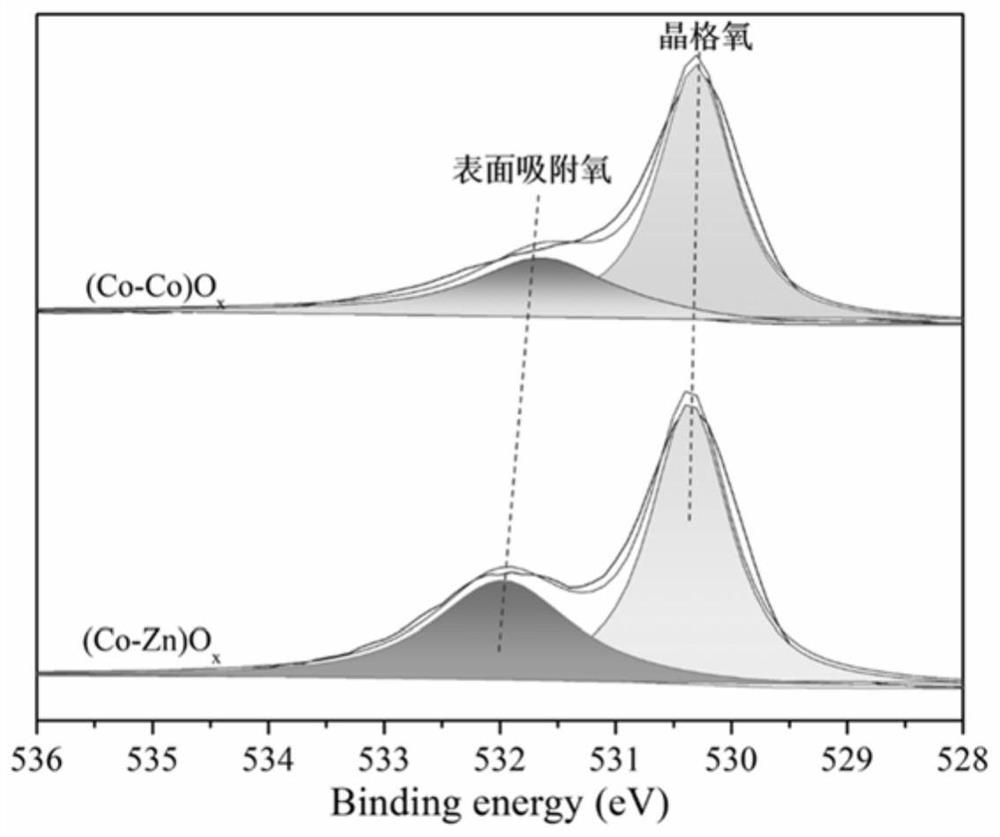

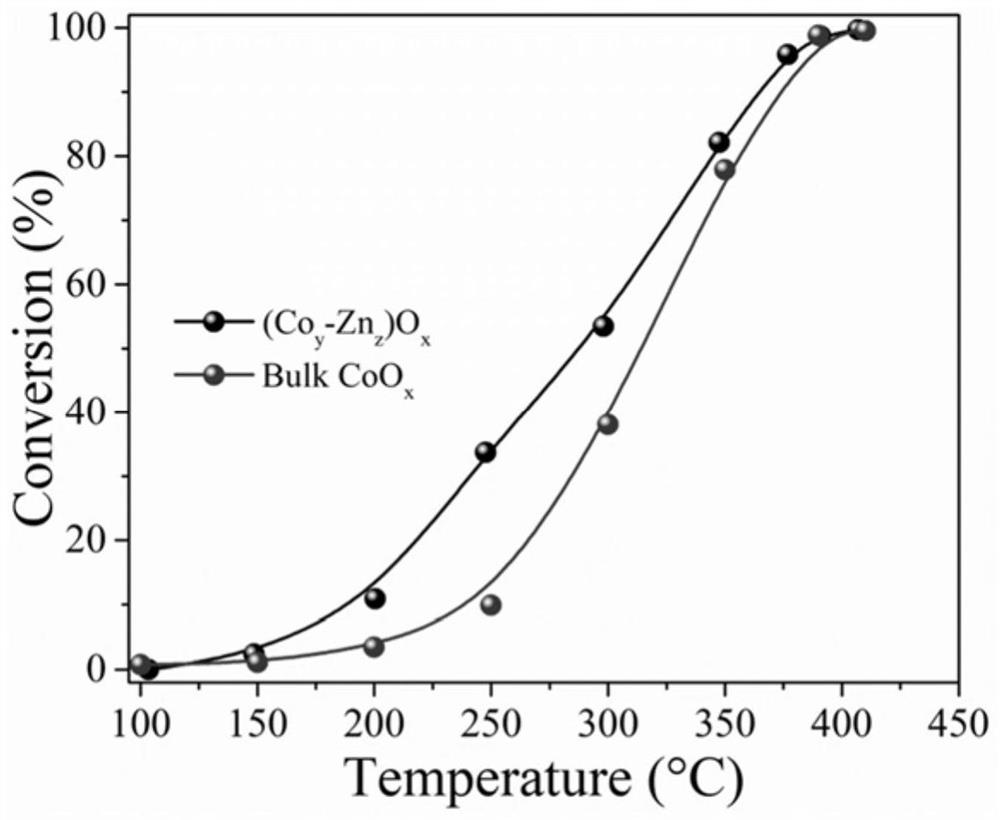

Preparation method of two-dimensional flaky porous composite oxide and application of two-dimensional flaky porous composite oxide in control of chlorine-containing volatile organic pollutants

ActiveCN112642433ARich pore structureImprove oxidation effectGas treatmentDispersed particle separationComposite oxideOrganopónicos

The invention discloses a preparation method of a two-dimensional flaky porous composite oxide and application of the two-dimensional flaky porous composite oxide in control of chlorine-containing volatile organic pollutants. The method comprises the following steps: adding a zinc nitrate hexahydrate water solution into a methanol solution of dimethylimidazole, stirring until the solution is white, and performing filtering, and drying to obtain white powder; adding a cobalt nitrate hexahydrate aqueous solution into a white powder aqueous solution, adding ammonia water, stirring, carrying out hydrothermal crystallization at 120-160 DEG C for 8-12 hours, then, performing drying and roasting to obtain the two-dimensional flaky porous composite oxide. The two-dimensional flaky catalytic material prepared by the invention has a very rich pore structure and high-dispersion active sites, and can effectively improve the mass transfer and transmission capacity of target pollutants, thereby showing excellent chlorine-containing volatile hydrocarbon oxidation performance. The preparation method is low in raw material price, simple in synthesis method, simple in synthesis condition and low in equipment requirement, and has a good industrial application prospect.

Owner:XI AN JIAOTONG UNIV +1

A kind of anti-acrylic mask and preparation method thereof

ActiveCN111716841BPrevent and/or prevent access toEffective protection against poisoningFilament forming substance formingBreathing filtersPolymer scienceNonwoven fabric

The invention discloses an anti-acrylic mask and a preparation method thereof. The anti-acrylic mask comprises a fiber cloth contact layer, an antistatic non-woven layer and a fullerene / nano-titanium dioxide spunbond layer which are sequentially arranged by stitching; wherein, the rich The spunbond layer of leene / nano-titanium dioxide is made by spinning the modified resin material into a fiber web by the spunbond method. The raw materials of the modified resin material include matrix resin, carboxylated fullerene derivatives, nano-titanium dioxide, lubricant and The coupling agent and the modified resin material are prepared by the following method: the carboxylated fullerene derivative is mixed with the nano-titanium dioxide to make the carboxylated fullerene derivative-modified nano-titanium dioxide, and then mixed with the remaining The components are blended and extruded to make it; the mask of the present invention is not only easy to use and carry, but also can prevent propylene from entering the human body from the human respiratory organs, has a good anti-propylene effect, and also has an anti-static function, and is especially suitable for use in propylene production workshops .

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Preparation method of a two-dimensional sheet-like porous composite oxide and its application in the control of chlorine-containing volatile organic pollutants

ActiveCN112642433BRich pore structureImprove oxidation effectGas treatmentDispersed particle separationHydration reactionComposite oxide

The invention discloses a preparation method of a two-dimensional flaky porous composite oxide and its application in the control of chlorine-containing volatile organic pollutants. The aqueous solution of zinc nitrate hexahydrate is added to the methanol solution of dimethylimidazole, and stirred until white, filtered, and dried to obtain a white powder; add an aqueous cobalt nitrate hexahydrate solution to the white powder aqueous solution, then add ammonia water, stir, and then hydrothermally crystallize at 120-160°C for 8-12h, then dry and roast to obtain Two-dimensional sheet-like porous composite oxides. The two-dimensional sheet-like catalytic material prepared by the invention has a very rich pore structure and highly dispersed active sites, which can effectively improve the mass transfer capacity of target pollutants, thereby exhibiting excellent oxidation performance of chlorinated volatile hydrocarbons. The invention has the advantages of low raw material price, simple synthesis method, simple synthesis conditions, low requirements on equipment, and good industrial application prospect.

Owner:XI AN JIAOTONG UNIV +1

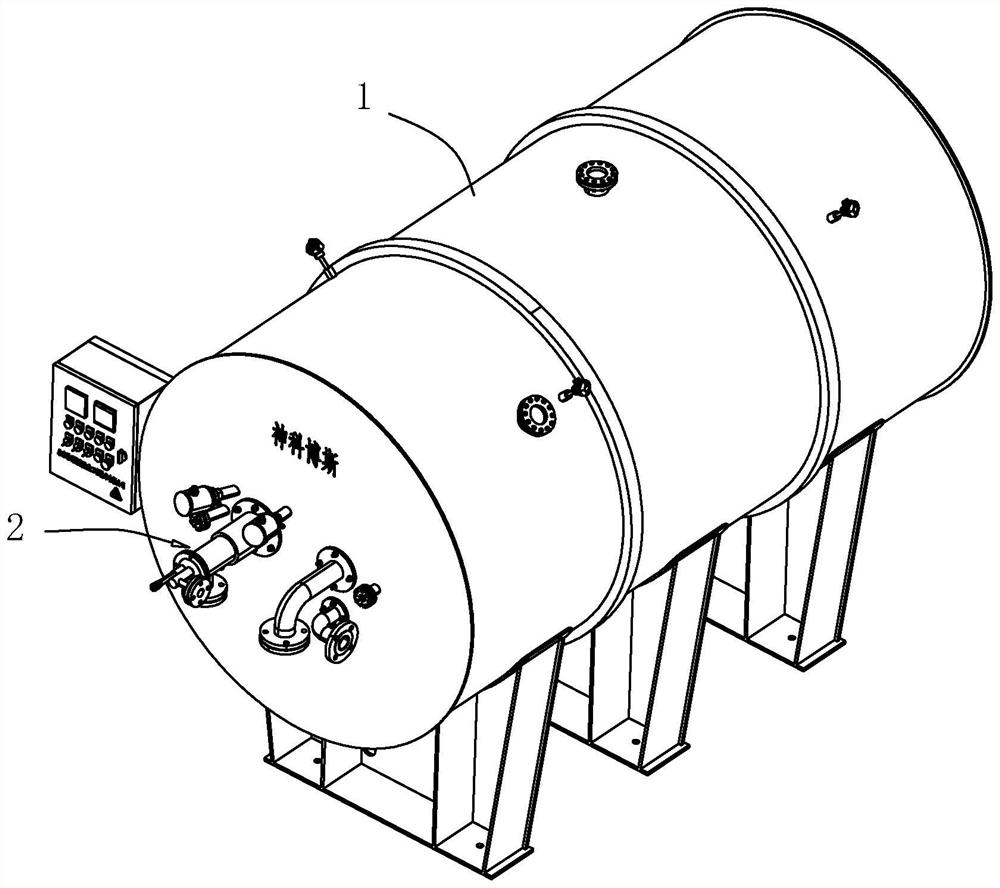

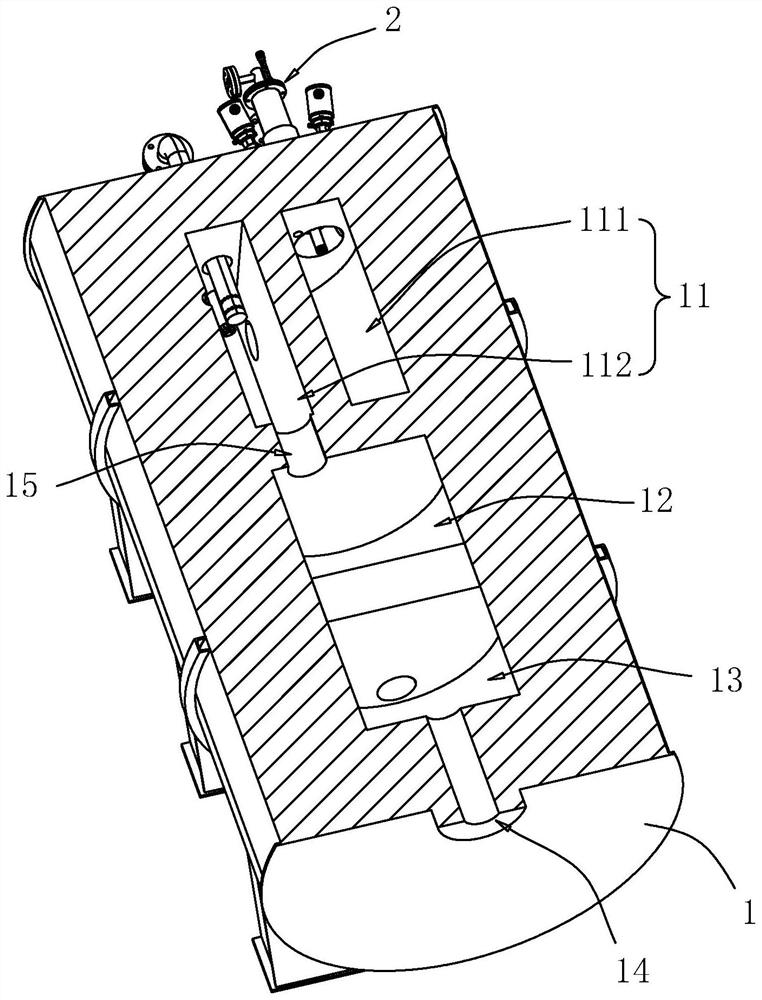

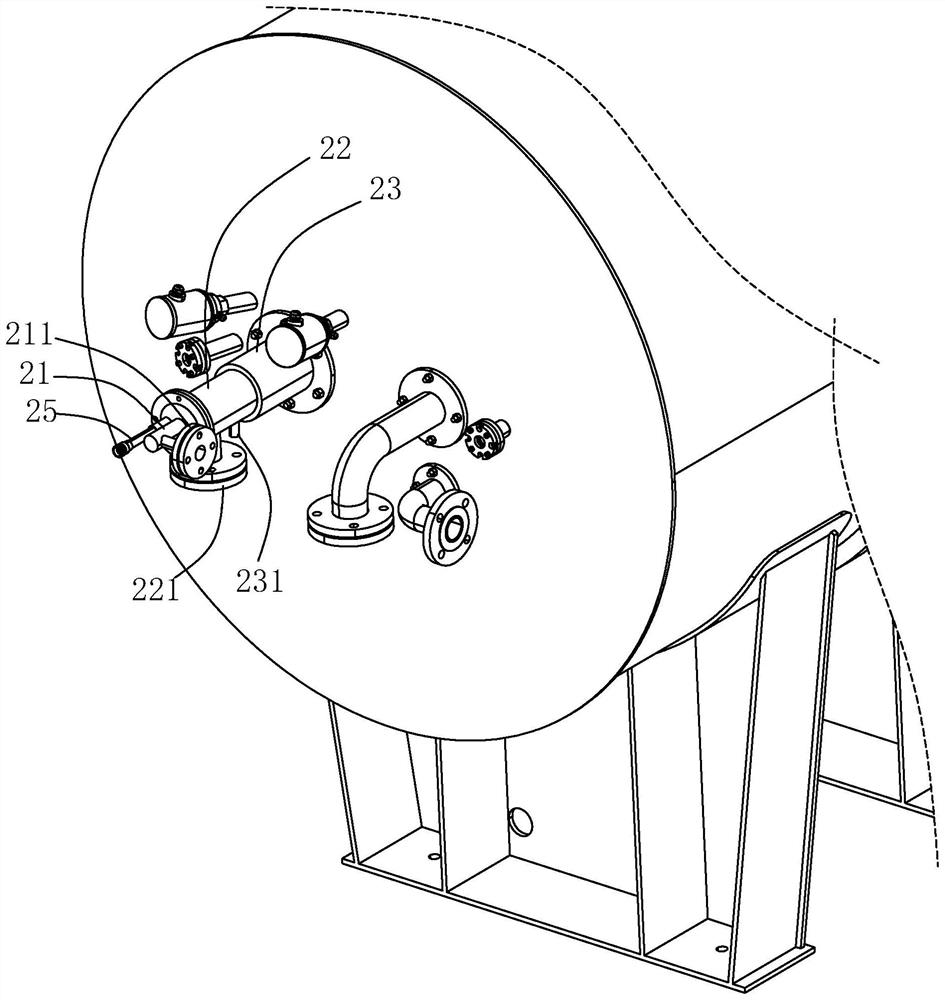

Nuclear waste gas all-oxidation combustion treatment device

PendingCN114413270AAchieve complete oxidationFully oxidizedIncinerator apparatusGaseous fuel burnerCombustion chamberExhaust fumes

The invention relates to the field of nuclear waste gas treatment equipment, in particular to a nuclear waste gas full-oxidation combustion treatment device which comprises an incinerator, a front-section combustion chamber, a middle-section combustion chamber and a tail-section combustion chamber which are used for prolonging the flowing time of waste gas in the incinerator are arranged in the incinerator, and the front-section combustion chamber, the middle-section combustion chamber and the tail-section combustion chamber are sequentially communicated; the incinerator is further provided with an ultra-low-nitrogen strong-rotational-flow high-speed burner communicated with the front-section combustion chamber. The ultra-low nitrogen strong rotational flow high-speed burner comprises a waste gas pipe for introducing nuclear waste gas and water vapor at the same time; the exhaust gas pipe is sleeved with the air pipe, and the air pipe is used for introducing combustion-supporting air which cools the exhaust gas pipe and assists the ultra-low nitrogen strong rotational flow high-speed burner in supporting combustion; the fuel gas pipe is arranged outside the waste gas pipe in a sleeving manner and used for introducing fuel gas mixed with the combustion-supporting air, and the igniter is used for igniting a mixture of the combustion-supporting air and the fuel gas. Harmless incineration treatment of the nuclear waste gas is achieved.

Owner:BEIJING SHENKEBOSI THERMAL ENERGY ENG TECH CO LTD

Exhaust gas treatment system and method for curing furnace in brake shoe workshop

ActiveCN104482773BAchieve complete oxidationObvious effect of deodorizing and deodorizingIncinerator apparatusWaste heat treatmentEnvironmental resistanceCombustion chamber

Owner:CHINA RAILWAY LONGCHANG MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com