Catalyst for removing formaldehyde in wastewater, preparation method of catalyst and method for removing formaldehyde in wastewater

A catalyst and waste water technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low removal efficiency, large oxidant, and harsh conditions, so as to improve oxidation ability, improve dispersion, avoid The effect of environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

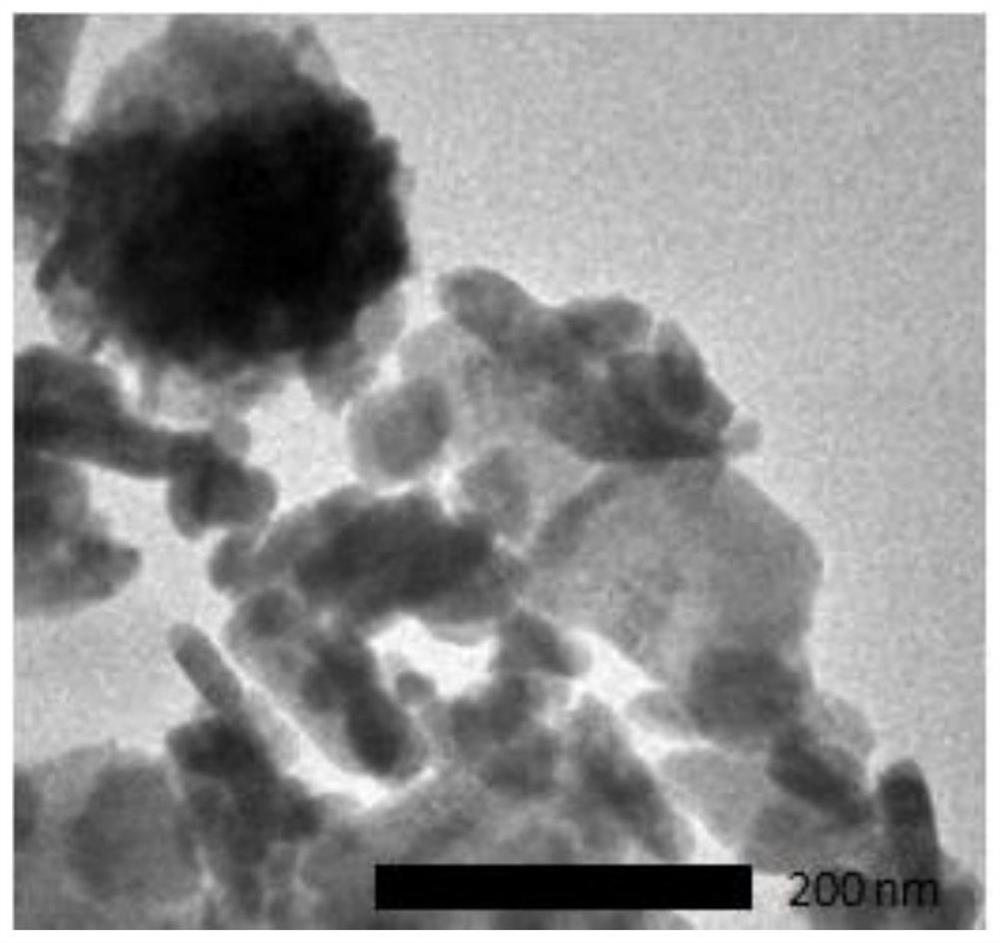

[0021] (1) According to the mass ratio of nano-tungsten oxide to graphene oxide 7:3, add nano-tungsten oxide with a particle size below 100nm into the graphene oxide solution under stirring, and vacuumize until there is no liquid to prepare a catalyst. The mass fraction of graphene oxide is 30%, and its TEM image is as follows figure 1 shown by figure 1 It can be seen that graphene oxide is basically wrapped on nano-tungsten oxide;

[0022] (2) Adding formaldehyde concentration in the 100mL there-necked flask is the waste water of 500mg / L, then add the catalyzer prepared in the hydrogen peroxide solution and the step (1) that mass fraction is 30% successively, to the hydrogen peroxide final concentration in the above-mentioned waste water The concentration of graphene oxide was 0.4wt%, and the final concentration of graphene oxide was 0.3wt%. Stirring and reacting at 75°C for 2h, and then performing liquid chromatography analysis, the measured formaldehyde conversion rate was...

Embodiment 2

[0024] (1) According to the mass ratio of nano-alumina and graphene oxide of 9:1, add nano-alumina with a particle size below 100nm into the graphene oxide solution under stirring, and vacuumize until there is no liquid to prepare a catalyst. The mass fraction of graphene oxide is 10%;

[0025] (2) Adding formaldehyde concentration in the 100mL there-necked flask is the waste water of 500mg / L, then add the catalyzer prepared in the hydrogen peroxide solution and step (1) that mass fraction is 40% successively, to the hydrogen peroxide final concentration in the above-mentioned waste water The final concentration of graphene oxide was 0.5 wt%, and the reaction was stirred and reacted at 25°C for 24 hours, and then analyzed by liquid chromatography, and the conversion rate of formaldehyde was measured to be 90%.

Embodiment 3

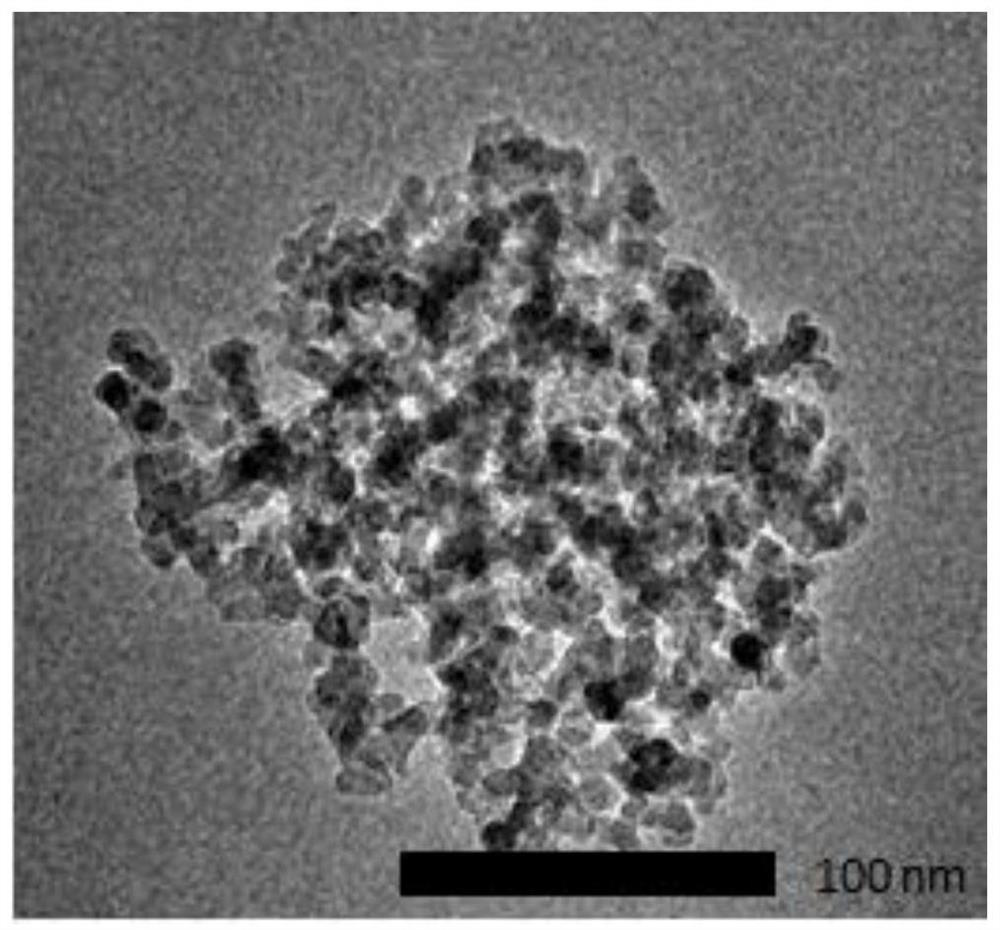

[0027] (1) According to the mass ratio of nano-silica and graphene oxide 19:1, under stirring, nano-silica with a particle size below 100nm is added in the graphene oxide solution, and vacuumized to no liquid to prepare the catalyst. The mass fraction of the catalyst graphene oxide is 5%, and its TEM figure is as follows figure 2 shown by figure 2 It can be seen that graphene oxide is basically wrapped on nano-silica.

[0028] (2) Adding formaldehyde concentration in the 100mL there-necked flask is the waste water of 500mg / L, then add the catalyzer prepared in the hydrogen peroxide solution and the step (1) that mass fraction is 50% successively, to the hydrogen peroxide final concentration in the above-mentioned waste water The final concentration of graphene oxide was 0.05wt%, and the final concentration of graphene oxide was 1wt%. Stirring and reacting at 50°C for 12h, and then performing liquid chromatography analysis, the measured formaldehyde conversion rate was 100%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com