Nanoflower spinel CoMn2O4 catalyst for catalytic oxidation of VOCs (Volatile Organic Compounds), preparation method and application

A catalytic oxidation and nanoflower technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. control, increase the cost of catalyst preparation, etc., to achieve good industrial application prospects, good low-temperature activity and stability, and good low-temperature reduction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

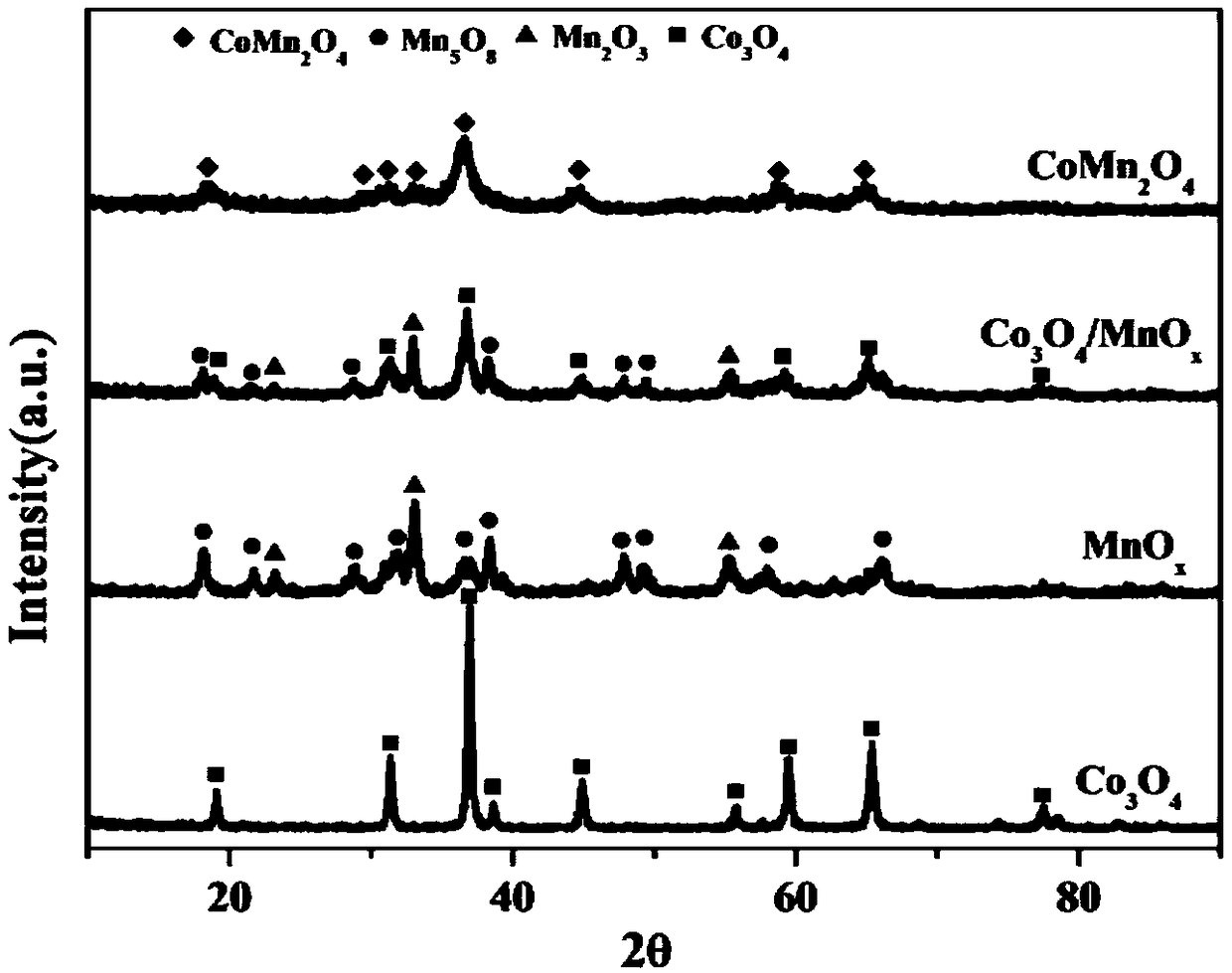

[0020] Spinel CoMn 2 o 4 Preparation of:

[0021] 0.04mol of manganese acetate and 0.02mol of cobalt nitrate were dissolved and dispersed in 10mL of ethanol solution, and placed in a collector-type constant temperature magnetic stirrer at 80°C for vigorous stirring. Then quickly add 0.24mol / L oxalic acid solution, control the ratio of metal to oxalic acid to 1:1.2, and continue to stir for 30min in a collector-type constant temperature magnetic stirrer at 80°C. The obtained material was centrifugally washed, dried in an oven at 60-100°C for 12-24h, and finally calcined in a muffle furnace at 400°C for 3h with a heating rate of 1°C / min to obtain spinel CoMn 2 o 4 catalyst.

Embodiment 2

[0027] The toluene oxidation performance test of the four catalysts prepared in Example 1 and Comparative Example 1 was carried out continuously on a self-built micro-response device, with argon as the balance gas, and a gas chromatograph GC2014 equipped with TCD and FID detectors for online detection After the reaction, the gaseous substance toluene molecules and the product CO 2 molecular.

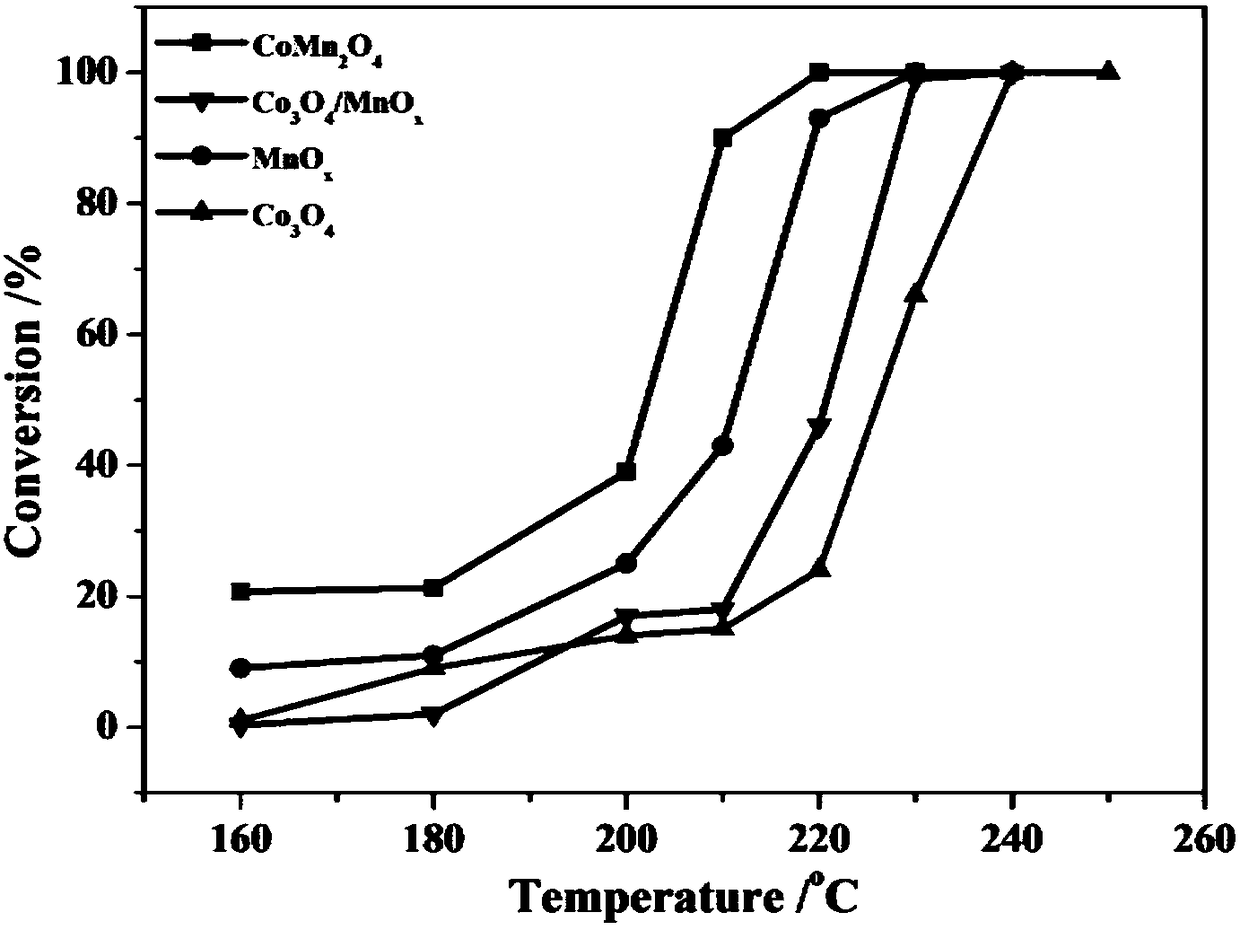

[0028] The specific reaction conditions are as follows: the concentration of toluene is 500 ppm, the flow rate of the mixed gas is 75 mL / min, and the reaction space velocity is 22500 mL / g h. The formula for calculating the oxidation conversion rate of toluene: conversion rate of toluene %=[(initial concentration of toluene-concentration after reaction of toluene) / initial concentration of toluene]*100. reactivity as figure 1 shown, where the spinel CoMn 2 o 4 The catalyst activity is the best, reaching 90% conversion of toluene at 210°C.

Embodiment 3

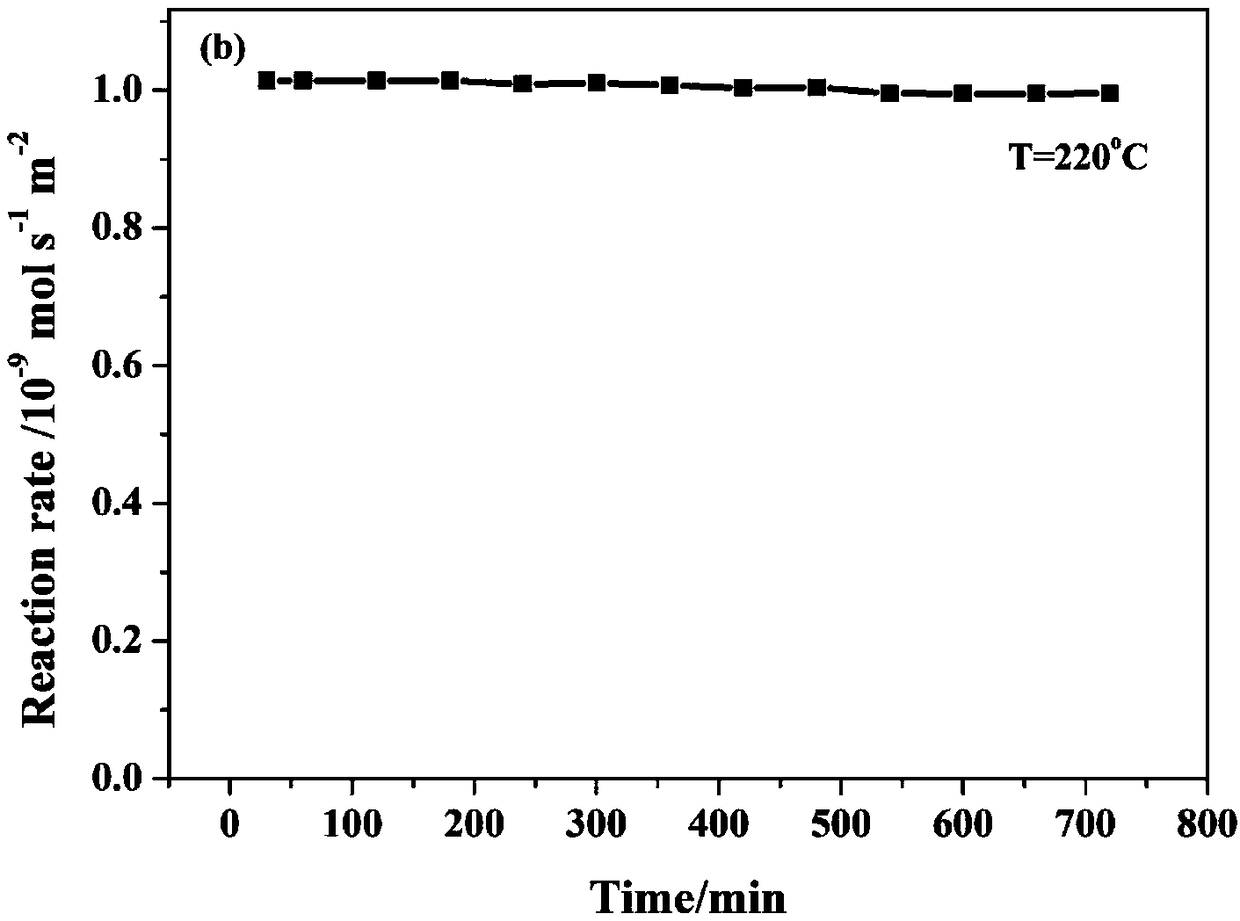

[0030] To the spinel CoMn that embodiment 1 prepares 2 o 4 Catalyst is under keeping embodiment 2 reaction conditions in 220 ℃ of continuous operation tests the stability performance of catalyst, and stability performance is as follows figure 2 As shown, the conversion rate remained above 98% within 700 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com