Preparation and catalytic application of PtMnO2/Co3O4/CeO2

A catalyst and a technology of catalytic activity, applied in the field of PtMnO2/Co3O4/CeO2 preparation and catalytic application, can solve the problem of low conversion rate and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] MnO with an atomic ratio of cobalt to manganese and cerium of 19:1:1 2 / Co 3 o 4 / CeO 2 Preparation of composite oxides. Preparation of MnO with an atomic ratio of cobalt, manganese and cerium of 38 to 1 to 1 by precipitation oxidation 2 / Co 3 o 4 / CeO 2 composite oxide catalyst. Under 333K and stirring conditions, 1mol / L Co(NO 3 ) 2 6H 2 O, 1mol / L Mn(NO 3 ) 2 6H 2 O and 1mol / L Ce(NO 3 ) 3 6H 2 O aqueous solution was slowly dropped into 0.2 mol / L sodium carbonate aqueous solution in proportion, the pH value was adjusted to 10.0 with 0.2 mol / L NaOH, and after aging at this temperature for 4 h, it was filtered and washed with deionized water. Then, the obtained precipitate was mixed again with deionized water and stirred, and an appropriate amount of H 2 o 2 (30%). After aging for 1 hour, filter and wash again with deionized water, dry at 383K for 12 hours, and bake at 538K for 4 hours.

Embodiment 2

[0013] PtMnO 2 / Co 3 o 4 / CeO 2 Catalyst preparation. The MnO prepared by the above method 2 / Co 3 o 4 / CeO 2 The powder is suspended in an aqueous solution, and dinitrosodiammine platinum is added under stirring, then evaporated to dryness at 323K, dried at 383K for 12 hours, and calcined at 533 for 4 hours to obtain PtMnO 2 / Co 3 o 4 / CeO 2 catalyst.

Embodiment 3

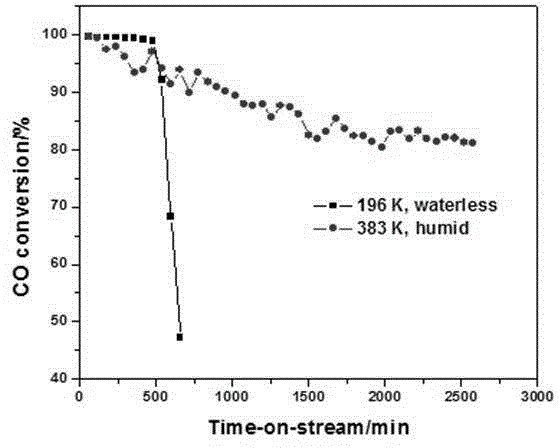

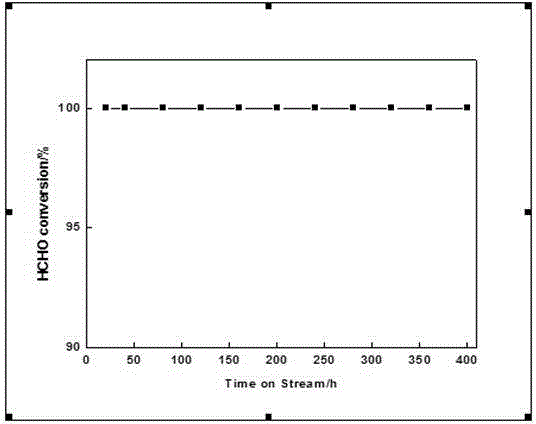

[0015] The test of the performance of the catalyst for the catalytic oxidation reaction of carbon monoxide. The activity test of the catalyst was carried out in a miniature fixed-bed quartz tube reactor at atmospheric pressure. The composite oxide powder is pressed into tablets, crushed and sieved to 40-60 mesh, and 200 mg is packed in a Ф=6mm quartz reaction tube. The low temperature reaction is to immerse the U-shaped reactor in the liquid nitrogen container, and control the reaction temperature by adjusting the distance between the catalyst and the liquid nitrogen surface. The humidity condition is achieved by bubbling the reaction gas through a 298K constant temperature water bath (moisture content is 3.1vol%). Before the reaction, the catalyst was pretreated in air at 538K for 1 h. The gas at the outlet of the reactor was analyzed on-line by a HP-6890 gas chromatograph, and a nickel converter was installed in front of the FID detector, and CO and CO were separated in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com